Page 1

Instructions for Use

Page 2

Instructions for Use

2

This Manual Copyright © 2018 ITL

All rights reserved. No part of this manual may be reproduced, stored in a

retrieval system, or transmitted, by any means or in any form, without the

prior permission of Integrated Technologies Limited (ITL).

The information contained in this manual is subject to change without notice.

ITL assumes no responsibility for any errors that may appear in this or

related documentation.

Document: V501007

Revision: 3-1810

Vitl is the brand name for Integrated Technologies’ own range of laboratory

products. For further information, please visit the Vitl web site:

www.vitlproducts.com

All sales and technical enquiries should be addressed to:

UK

Vitl Customer Services

Integrated Technologies Limited

Viking House, Ellingham Way, Ashford, Kent, TN23 6NF

United Kingdom

+44 (0)1233 638383

sales@vitlproducts.com

USA

ITL Virginia Inc.

305 Ashcake Road, Suite L, Ashland, Virginia 23005

USA

+1 804-381-0905

sales@vitlproducts.com

CHINA

Integrated Electronic Systems (Shanghai) Co Ltd

T3-11 Unit 201, No. 5001 Hua Dong Road, Pudong,

Shanghai 201201, China

+86 (0)21 585 854 63

sales@vitlproducts.com

Page 3

Instructions for Use

3

Contents

1 Symbols Used in this Instruction Manual ..................................................... 6

2 Safety Precautions and Limitations of Use .................................................. 7

3 Regulatory Limitations of Use ................................................................... 11

4 Lu-mini Unit Description ............................................................................ 12

4.1 Acceptable Sample Vessel Types and Fill Volumes ................................. 15

5 Lu-mini Unit Installation ............................................................................. 16

6 Basic Unit Operation .................................................................................. 17

6.1 User Display and Controls ......................................................................... 17

6.2 Powering-up the Lu-mini Unit .................................................................... 20

6.3 Selecting the Active User .......................................................................... 22

6.4 Selecting a Protocol and Performing a Reading ....................................... 24

6.4.1 Selecting a Protocol .................................................................................. 24

6.4.2 Editing the Sample ID ................................................................................ 25

6.4.3 Sample Vessel Insertion and Removal ..................................................... 27

6.4.4 Performing a Reading ............................................................................... 29

6.4.5 Results Status Tagging and Adding a Comment Note .............................. 31

6.5 Viewing the Test Results Database .......................................................... 33

6.5.1 Deleting Test Results from the Lu-mini Database ..................................... 34

6.6 Using the Timer Function .......................................................................... 35

6.6.1 Using an Independent Timer ..................................................................... 36

6.6.2 Using Linked Cascading Timers................................................................ 38

6.6.2.1 Linking Timers into a Single Cascading Group ....................................... 38

6.6.2.2 Linking Timers into Multiple Cascading Groups ...................................... 40

6.6.3 Using the Timers whilst Sample Testing ................................................... 40

6.7 Unit Set-up Options ................................................................................... 41

6.7.1 Setting the Clock and Date/Time Formats ................................................ 43

6.7.2 Beeper and Button Click Volume .............................................................. 43

6.7.3 Remembering the Last Active User ID ...................................................... 44

6.7.4 Define Automatic Sample ID Text Format ................................................. 44

6.7.5 Reader Test Mode ..................................................................................... 45

6.8 Standby Mode and Unit Shutdown Procedure .......................................... 46

7 Lu-mini Windows App and Advanced Unit Configuration .......................... 48

7.1 Installing the Lu-mini Windows App and USB Driver ................................ 48

7.2 Lu-mini App Basic Functionality ................................................................ 50

7.2.1 Page Selection Buttons ............................................................................. 51

7.2.2 Toolbar Options ......................................................................................... 52

7.2.3 Help Menu Options .................................................................................... 52

7.2.4 Data Table Field Editing and Context Menu .............................................. 53

7.3 Data Synchronisation ................................................................................ 56

7.4 Test Results Database Page..................................................................... 57

7.4.1 Uploading Results Data ............................................................................. 58

7.4.2 Exporting Test Results Data ...................................................................... 58

7.4.3 Deleting Results Data ................................................................................ 59

7.5 User IDs Page ........................................................................................... 59

7.6 Global Unit Settings Page ......................................................................... 60

Page 4

Instructions for Use

4

7.6.1 Adding a New Unit .................................................................................... 61

7.7 Sample Measurement Protocols Page ...................................................... 61

7.7.1 Protocol Name and Reagent Assay .......................................................... 63

7.7.2 Sample Method Types .............................................................................. 63

7.7.2.1 Single Tube Measurements .................................................................... 64

7.7.2.2 Multiple Tube Measurements .................................................................. 64

7.7.2.3 Continuing a Multi-Tube Test from the Worklist ...................................... 66

7.7.3 Measurement Types ................................................................................. 67

7.7.4 Test Result Options and Banding ............................................................. 69

7.7.4.1 Single Sample Result Banding .................................................................... 71

7.7.4.2 Multiple Sample Comparison Bands............................................................ 72

7.8 Reagent Assays Page ............................................................................... 73

8 Troubleshooting ........................................................................................ 75

9 Maintenance and Servicing ....................................................................... 77

9.1 Routine Cleaning and Inspection .............................................................. 77

9.2 Decontamination Procedure ...................................................................... 79

9.3 Transportation and Storage ...................................................................... 80

9.4 Product Disposal ....................................................................................... 80

10 Warranty and Returns ............................................................................... 81

11 Technical Specification ............................................................................. 82

12 Glossary of Terms and Abbreviations ....................................................... 84

WARNING

Please ensure that you have read and fully understood the Safety

Precautions and Limitations of Use in Section 2 of this manual before

attempting to install or operate this product.

Failure to do so could result in severe injury or may damage the unit and

invalidate the product warranty.

Page 5

Instructions for Use

5

Tables

Table 1: Advisory Symbol Meanings.......................................................................... 6

Table 2: Unit Features ............................................................................................. 13

Table 3: Unit Accessories ........................................................................................ 14

Table 4: Acceptable Sample Vessel Types ............................................................. 15

Table 5: Main Menu Button Functions ..................................................................... 17

Table 6: Navigation Button Functions ...................................................................... 18

Table 7: Status and Prompt Symbols ...................................................................... 19

Table 8: Result Status Tag Symbols ....................................................................... 31

Table 9: Timer Function Buttons and Status Symbols ............................................. 35

Table 10: User Preferences and Options ................................................................ 42

Table 11: Automatic Sample ID Buttons .................................................................. 44

Table 12: Lu-mini App Page Select Buttons ............................................................ 51

Table 13: Lu-mini App Toolbar Options ................................................................... 52

Table 14: Lu-mini App Help Menu Options .............................................................. 52

Table 15: Data Cell Context Menu Options ............................................................. 55

Table 16: Test Results Database Data Fields ......................................................... 57

Table 17: User IDs Data Fields ................................................................................ 59

Table 18: Unit Settings Data Fields ......................................................................... 60

Table 19: Time and Date Synchronisation Options ................................................. 60

Table 20: Protocols Table Data Fields ..................................................................... 62

Table 21: Sample Method Options .......................................................................... 64

Table 22: Sample Measurement Types ................................................................... 68

Table 23: Reagent Assay Data Fields ..................................................................... 73

Table 24: Troubleshooting Suggestions .................................................................. 75

Table 25: Lu-mini Unit Error Codes ......................................................................... 76

Page 6

Instructions for Use

6

1 Symbols Used in this Instruction Manual

The following advisory symbols are used in this manual.

Table 1: Advisory Symbol Meanings

DANGER

Indicates a Risk of Electric Shock which could, if not avoided,

result in severe injury or death.

DANGER

Indicates a Risk of Explosion which could, if not avoided,

result in severe injury or death.

WARNING

Indicates a hazardous situation which could, if not avoided,

result in severe injury or death; or severely damage the unit.

CAUTION

Indicates a hazardous situation which could, if not avoided,

result in minor or moderate injury; or degrade or impair the

functionality of the unit.

CAUTION

Indicates an Electrostatic-Sensitive Device for which care

should be taken not to touch the exposed electrical contacts

as this could degrade or impair the functionality of the unit.

CAUTION

Indicates a possible crush hazard due to moving parts which

could, if not avoided, result in minor or moderate injury.

Advisory or other useful information.

Refer to Lu-mini App advanced features.

NN

Refer to “Section NN” for more details.

Page 7

Instructions for Use

7

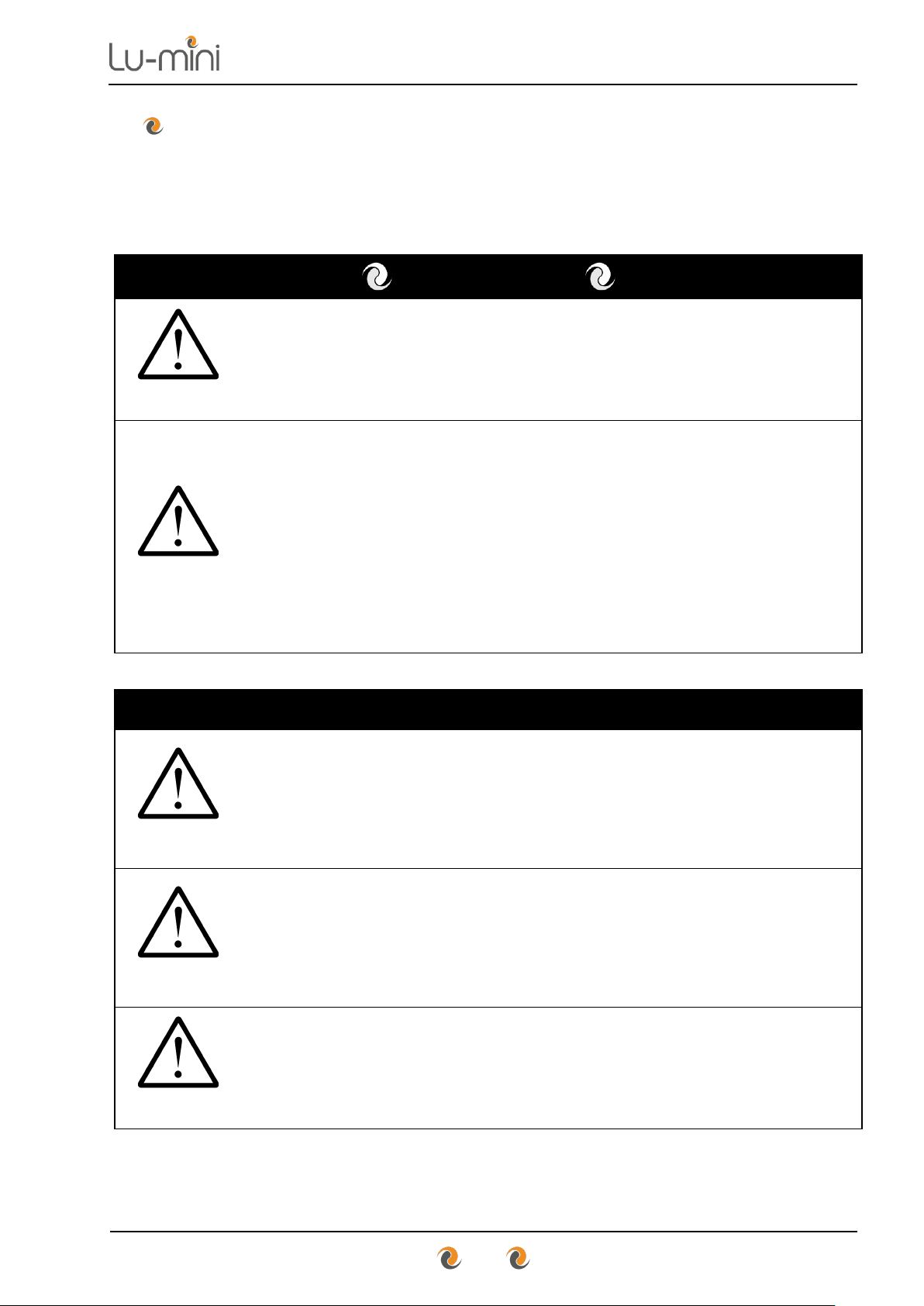

2 Safety Precautions and Limitations of Use

It is essential that all users of this equipment have fully read and understood

the following safety precautions and limitations of use before installing or

operating the Lu-mini unit.

IMPORTANT

WARNING

The protection provided by this equipment may be impaired if

it is not used in a manner described in this manual.

WARNING

It is essential that the user of this equipment is aware of the

potential hazards associated with the unit and its accessories.

All operators should be familiar with the safety precautions

and warnings given in these instructions before attempting to

operate the unit.

Improper use of this unit or its accessories may impair their

functionality and invalidate the manufacturer’s warranty.

Unit Handling Precautions

CAUTION

Care should be taken not to drop the unit or subject it to rough

physical handling, both during normal use and during

installation, transportation and storage.

Do not use the unit if it shows any signs of damage or wear.

WARNING

The unit should be held and supported in both hands when

lifting or moving. Do not lift the unit by the lid.

Care should be taken to avoid trapping fingers under the unit

when placing it down on a solid surface.

CAUTION

Care should be taken not to knock the LCD display.

Do not use excessive force when pressing the touchscreen

buttons or when cleaning it.

Page 8

Instructions for Use

8

Unit Installation and Operating Environment

DANGER

WARNING

The Lu-mini unit is designed for indoor laboratory use only.

The acceptable operating temperature range is 18ºC to 38ºC,

with a relative humidity of 20% to 85% non-condensing, at a

maximum altitude of 2000m above sea level.

If the unit is stored in conditions outside of these ranges, it

must be left to stand unpowered until it has acclimatised to

within these environmental limits before being powered.

DANGER

Use the USB power adaptor provided with the unit.

Care should be taken when powering the unit from a computer

USB port or alternative USB power source.

WARNING

Always ensure that the USB power cord is securely inserted

into the rear of the unit.

Ensure that any excess power cord does not pose a potential

trip or pull hazard.

DANGER

Do not operate the unit in any area which is, or has been, or is

thought to have been exposed to explosive or flammable

gases, vapours or liquids.

WARNING

The unit must be installed and operated on a solid, stable,

vibration-free and level working surface.

CAUTION

For best results, the unit should be installed and operated in a

stable thermal environment, out of direct sunlight and away

from sources of heat or draught.

Page 9

Instructions for Use

9

General Operating Precautions

DANGER

Ensure that the power is switched off at the mains outlet

before inserting or removing the USB power cord.

If a spillage occurs in or over the unit, switch the power off and

unplug the USB cord at the power adaptor before attempting

to deal with the spill.

DANGER

The unit is intended for use with aqueous solutions only.

Never use the unit with any explosive, volatile or highly

reactive substances or chemicals.

WARNING

To avoid liquid spills and possible cross-contamination of

samples, use sealed or capped tubes of the type specified in

Section 4.1.

Always follow prescribed laboratory procedures and use

appropriate personal protective equipment (PPE - such as

gloves, clothing, goggles, etc.) when handling samples.

CAUTION

The unit lid poses a possible finger crush hazard.

Take care when opening and closing the lid to ensure hands,

fingers and protective gloves do not get trapped.

Do not insert your finger into the reader sample chamber.

CAUTION

The unit lid catch contains a small magnet. Avoid direct

contact with any magnetic-sensitive devices or assays.

CAUTION

Avoid touching the contacts of the USB port on the rear of the

unit as an Electrostatic Discharge (ESD) could degrade or

impair the functionality of the unit.

Page 10

Instructions for Use

10

Unit Maintenance and Serviceability

WARNING

There are no user or operator serviceable parts inside the

unit.

Do not remove the unit casework. Removal of the unit's

casework will void the manufacturer’s warranty.

DANGER

Always disconnect the USB power cord from the unit before

performing any cleaning or decontamination procedure.

If liquid is spilt into or over the unit, switch off and disconnect

the USB from the source before attempting to deal with the

spillage.

CAUTION

The use of harsh chemicals and cleaning agents may damage

the unit and degrade its performance.

Always follow the cleaning and decontamination procedures

specified in Sections 9.1 and 9.2 of this instruction manual.

Page 11

Instructions for Use

11

3 Regulatory Limitations of Use

Declaration of Conformity

Integrated Technologies Limited (ITL) affirm that this product

fulfils the essential requirements of the Low Voltage Directive

2014/35/EU and the EMC Directive 2014/30/EU, when

installed and operated in accordance with the instructions in

this manual.

Safety Standards

• EN 61010-1:2010,

• EN 61010-2-010:2003

• UL 61010-1:2001 3nd Edition (CAN C22.2 CSA 61010-1)

• MET Labs NRTL Electrical Safety – Listing No E113628

EMC Standards

• EN 61326:2013, Class A

• FCC CFR 47 Parts 15.107 and 15.109, Class A

RoHS and WEEE Directive Compliance

This product complies with the requirements of the RoHS2

Directive 2011/65/EU for Electrical and Electronic Equipment

and in accordance with BSEN 50581:2012.

Where applicable, the Lu-mini unit should be disposed of in

accordance with the European Union WEEE Directive

2002/96/EC on Waste Electrical and Electronic Equipment.

Do not dispose of this product into unsorted municipal waste

or public landfill. Please refer to Section 9.4 for details of how

to correctly dispose of this product.

The Lu-mini unit is designed and manufactured under ISO 9001 by:

Integrated Technologies Limited

Viking House, Ellingham Way, Ashford, Kent, TN23 6NF

United Kingdom

Page 12

Instructions for Use

12

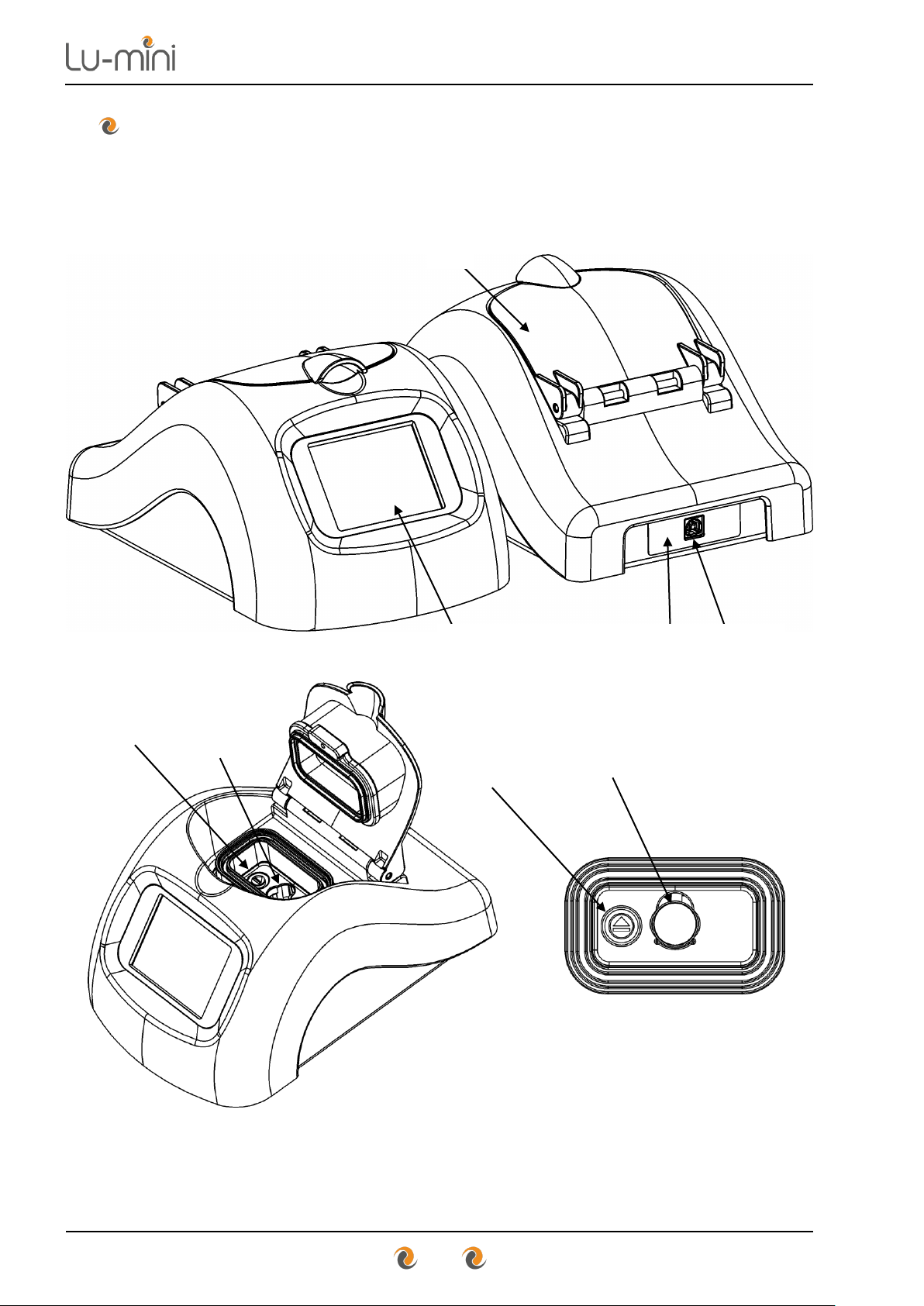

4 Lu-mini Unit Description

The Lu-mini unit is a benchtop Luminometer and has the following external

features:

Page 13

Instructions for Use

13

Table 2: Unit Features

LCD Touchscreen User Interface

6.1

Unit Lid

6.4

Reader Sample Chamber

4.1

Sample Vessel Eject Button

6.4.3

Power Rating

11

USB Power Inlet

0

Unit Label and Serial Number

0

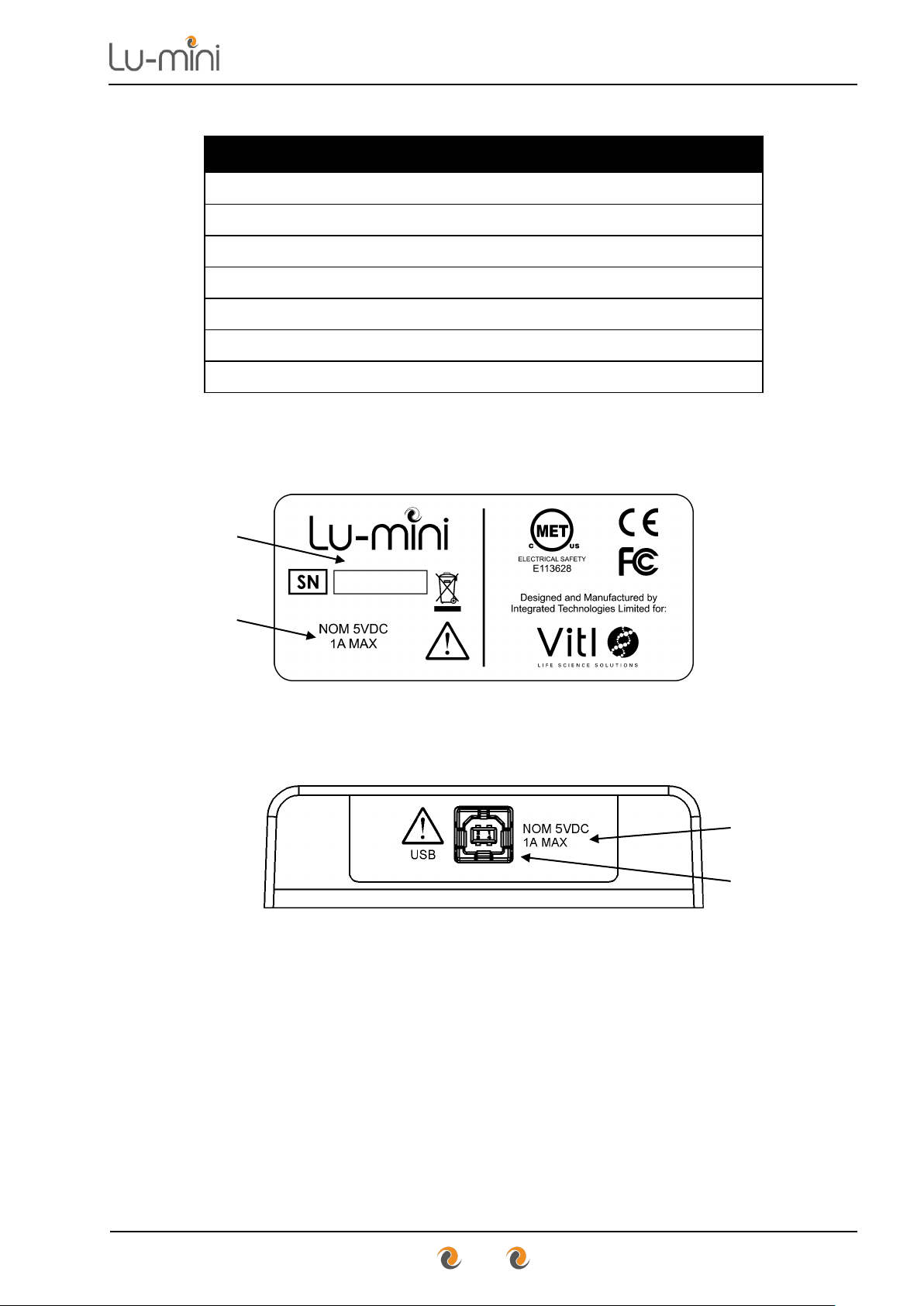

The unit label is located on the underside of the unit and provides the unit

serial number, voltage and power ratings:

There is also a label surrounding the USB Power Inlet at the rear of the unit

which provides the voltage and power ratings:

Page 14

Instructions for Use

14

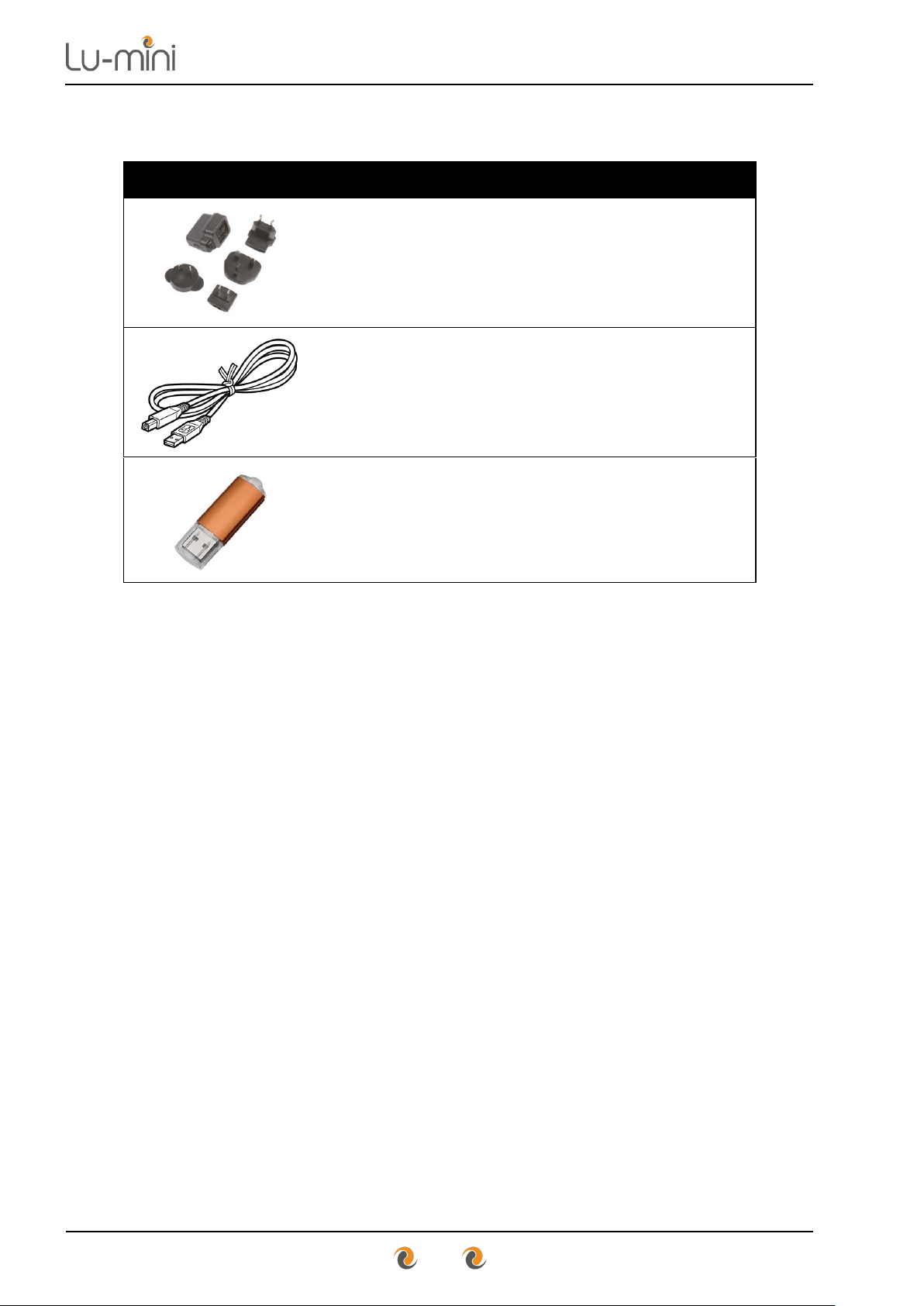

The unit is supplied with the following accessories:

Table 3: Unit Accessories

AC/DC USB Power Adaptor

6.2

USB Power Cable

6.2

11

Lu-mini App Install Flash Drive

7

Page 15

Instructions for Use

15

4.1 Acceptable Sample Vessel Types and Fill Volumes

The Lu-mini unit is designed to accept the following sample vessel types.

Table 4: Acceptable Sample Vessel Types

Vessel Type

Vessels Sizes

Sample Volumes

Tube

Round round-bottomed

10mm to 12mm diameter

47mm# to 75mm* tall

* Including cap

10mm | 12mm

Recommended:

500uL | 800uL

Minimum:

200uL | 300uL

Vial

Round flat-bottomed

15mm diameter

48mm# tall

15mm

Recommended: 1500uL

Minimum: 600uL

Cuvette

Square flat-bottomed

12.5mm square

48mm# tall

10mm path length

12.5mm

Recommended: 1000uL

Minimum: 500uL

The recommended tube type is the 12mm x 75mm (5mL) round-bottomed

polypropylene test tube with a screw cap. Such as:

• Universal Medical Inc - GS-6148R or GS-6148W

• Corning Life Sciences - Falcon 352003 or 352058

CAUTION

To avoid liquid spills and possible cross-contamination of

samples, use sealed or capped tubes whenever possible.

#

Note: Refer to Section 6.4.3 for specific details on how to insert and remove

the sample vessels from the Reader Sample Chamber – particularly for

sample vessels with a height of less than 50mm.

Page 16

Instructions for Use

16

5 Lu-mini Unit Installation

Before installing the Lu-mini unit, please check that the delivery is complete

(see Table 3) and that the unit and all accessory parts are intact and free

from any signs of transportation damage. Also ensure that all external and

internal packaging has been removed from the unit before installation.

Please retain all packaging for future transportation and storage of

the unit and its accessories.

The Lu-mini unit should be installed in a location which meets the following

requirements:

• Safe and suitable operating environment (see Section 2)

• Solid, stable, vibration-free and level working surface

• At least 10cm clearance around the unit to adjacent objects and walls

• Out of direct sunlight and away from sources of heat or draught

WARNING

Please also observe and abide by the Unit Installation and

Operating Environment safety precautions and preconditions

listed in Section 2 of this manual.

When the unit is initially installed, the real-time clock will need to set to your

local time and date. Please read Section 6 first, and then refer to Section

6.7.1 for details.

NOTE

When the unit is initially powered, or if the unit has been in storage

or left unpowered for several months, the internal real-time clock

battery will need recharging.

The unit may report an E85 warning (see Section 8).

Please leave the unit powered for at least 2 hours (preferably 8

hours) to recharge the battery.

Please refer to Section 7.1 for details on installing the associated

Lu-mini Windows App.

Page 17

Instructions for Use

17

6 Basic Unit Operation

WARNING

Please ensure that you have read and fully understood all of

the Safety Precautions and Limitations of Use listed in

Section 2 before attempting to operate the Lu-mini unit.

6.1 User Display and Controls

The unit’s user interface consists of a colour LCD touch screen display. The

menu structure is divided into two main sections as shown below.

Control and Status

Function and Option buttons

The above screen shows the Main Menu buttons, which provide the following

functionality.

Table 5: Main Menu Button Functions

Select active User ID (Any User / Specific User)

6.3

Select Protocol and perform Reading

6.4

View the Test Results Database

6.5

Enter Timer function

6.6

Enter unit Set-up options menu

6.7

Unit Standby and Wakeup modes

6.8

Page 18

Instructions for Use

18

Below is a list of other menu and data list navigation buttons and their

functions.

Table 6: Navigation Button Functions

Accept or Cancel option

6.7

Return to Main Menu

6.1

Return to Previous menu

6.4

Edit Sample ID

6.4

Expand database result

6.5

Test result Status tag

6.4.5

Test result Comment

6.4.5

Jump to Top or Bottom of data list

6.5

Move Up and Down data list

or Increase and Decrease value

6.5

Move to Next value

6.7

Other function-specific button icons are explained in Sections 6.3 to 6.8.

Page 19

Instructions for Use

19

There are also various status and prompt symbols that may appear in the

main screen area, as detailed in Table 7 below.

Table 7: Status and Prompt Symbols

Prompt: Open Lid

6.4.3

Prompt: Insert Sample vessel

6.4.3

Prompt: Use specified Tube Number

6.4.3

Status: Sample Inserted correctly

6.4.3

Prompt: Close Lid

6.4.3

Prompt: Remove Sample vessel

6.4.3

When the lid is open, the unit also periodically beeps to prompt the user to

close the lid as soon as possible.

For optimum reader performance, the lid should always be kept

closed when not inserting or removing a sample vessel.

Please refer to Section 7 for additional buttons and symbols which

relate to specific Lu-mini App features.

Page 20

Instructions for Use

20

6.2 Powering-up the Lu-mini Unit

The Lu-mini unit is powered via a standard USB cable, from the supplied

AC/DC USB Power Adaptor. However, it can also be powered from a USB

port on a desktop or laptop computer, a USB battery pack or a 12V to USB

Car Charger.

AC/DC USB

Adaptor (Supplied)

Computer USB Port

or Powered Hub

USB Battery

Pack

12V to USB

Car Charger

Plug the supplied USB Cable into the Lu-mini Unit and then into the power

source, and (if necessary) switch on the power source.

The Lu-mini unit LCD will light-up and display the power-up progress screen

whilst the internal data memory is checked and the reader initialised.

Power-up Screen

→

Page 21

Instructions for Use

21

Following this the Main Menu screen is displayed.

User ID Screen

Power-Up

Screen

→

Set-up

Standby

The current time and date are displayed on the Main Menu screen as a

visual check that there are correctly set. This is important as the time and

date are required for the Reading and Timer options to function correctly.

Note: If the unit clock is not set, the time and date are displayed in Red and

the Reading and Timer options are disabled until the clock is set.

To set the clock, press the Set-up options button followed by the Date/Time

button. See Section 6.7.1 for more details.

→

→

Date

→ →

Time

→

Page 22

Instructions for Use

22

6.3 Selecting the Active User

The User ID function allows the current active user of the unit to log all the

test results they perform against their own personal User ID. To change the

User ID, press the User ID button from the Main Menu.

User ID Screen

Main

Menu

Screen

→ →

Cancel

Jump to

Top

Move

Up

Move

Down

Accept

By default, the User ID is set to Any User and there are no other User IDs

available to choose from, therefore the Up and Down arrow buttons are

disabled. To return to the main menu press the Accept or Cancel button.

Additional User IDs can only be added and edited via the Lu-mini

Windows Application. See Section 7.5 for details.

When additional User IDs have been downloaded to the unit, the Up and

Down buttons will be enabled to allow the desired User ID to be selected

from the list.

Page 23

Instructions for Use

23

User ID Screen

Main

Menu

Screen

→

→

Cancel

Jump to

Top

Move

Up

Move

Down

Accept

The Padlock symbol ( ) on the right indicates that the User ID is password

protected (see Section 7.5). When selected, the QWERTY keyboard is

displayed to allow the password to be entered.

→

→ → →

→ → →

Main

Menu

Screen

→

→

Enter

password

→ →

The User ID and User Name are displayed on the Main Menu screen, and

the User ID button changes to a solid figure indicating a specific User ID is

active.

By default, the unit remembers the most recently selected User ID and

automatically selects this user when the unit is next powered up. To change

this behaviour, refer to Section 6.7.3.

Page 24

Instructions for Use

24

6.4 Selecting a Protocol and Performing a Reading

Once the User ID has been checked and set, the sample measurement

Protocol can be selected so that a sample test can be performed.

6.4.1 Selecting a Protocol

The Protocol function allows the user to select the appropriate measurement

protocol for the test about to be performed. To select the measurement

Protocol, press the Protocol button from the Main Menu.

Protocol Selection Screen

User ID

Protocol Count

Main

Menu

Screen

→ →

Main

Menu

Worklist

Move

Up

Move

Down

Accept

By default, the Protocol selection list consists of just the Standard RLU

Measurement with no other protocols to choose from, therefore the Up and

Down buttons at the bottom of the screen are greyed-out.

The Worklist button is also greyed-out at this point (see Section 7.7.2.3).

There is a small User ID icon at the top of the protocol screen to indicate the

currently active User ID.

Additional Protocols and Worklists can only be added and edited

via the Lu-mini Windows Application. See Section 7.7 for details.

Page 25

Instructions for Use

25

Once the required Protocol has been selected, press the Accept button to

start the testing procedure.

→ →

Sample

Test

Screen

6.4.2 Editing the Sample ID

The top left corner of the Test screen shows the Sample ID which is a unique

ID assigned to the reading result. The figure in the top right corner of the

screen shows how full the results Database is.

In the middle of the screen the selected protocol is displayed along with the

time and date; and visual prompts to instruct the user on how to perform a

reading.

Sample Test Screen

Sample ID

Database Usage

Protocol

Screen

→ →

Previous

Edit

ID

Select

Location

Tube

Select

Accept

The default Sample ID allocation is a sequential numerical ID - however other

Sample ID options can be selected from the unit Set-up options menu (see

Section 6.7.4 for details).

Page 26

Instructions for Use

26

If desired, the sample ID can be edited at this point by pressing the Edit

button. If this is not required, skip forward to Section 6.4.3.

Edit Sample ID Screen

Test

Screen

→ →

Cancel

Accept

Using the keyboard, the Sample ID can be entered or edited. Once the

desired ID has been entered, press the Accept button to continue or the

Cancel button to undo and return to the Test screen.

Edit

Sample ID

Screen

→

Edit Sample ID

→ →

Sample

Test

Screen

→

No edit required

→ →

If the unit has been set-up to have no automatic Sample ID (see

Section 6.7.4) the QWERTY keyboard will automatically appear as

soon as the test begins.

At the bottom of the sample Test screen, the Location and Tube Select

buttons are greyed-out as these features are only available when using the

Lu-mini Windows Application. See Section 7 for details.

Page 27

Instructions for Use

27

6.4.3 Sample Vessel Insertion and Removal

Once the Sample ID has been set (see Section 6.4.2), insert the test sample

vessel into the reader sample chamber using the following procedure.

→

Open Lid

Insert Sample Vessel

Ensure that the sample vessel is fully pushed down into sample chamber

until the bottom of the vessel is touching the bottom of the chamber.

→

Ensure Vessel Fully Inserted

Close Lid

Once inserted, vessels that are less than 50mm tall are almost completely

enveloped by the sample chamber and cannot be easily retrieved by hand.

→ →

75mm Tube Fully Inserted

48mm Vial Fully Inserted

Page 28

Instructions for Use

28

The Lu-mini features a push button to allow for easy removal of short sample

vessels. The vessel Eject button is located next to the Reader Sample

Chamber inside the unit (see Section 4).

To remove a sample vessel from the reader sample chamber, use the

following procedure:

1) Open the unit lid when instructed.

→

2) If the vessel is easily accessible then it can be simply removed by

hand. If the vessel is difficult to access then the Eject button can be

used.

3) Use a finger to push down on the eject button. As the button is

depressed the vessel will be pushed up out of the sample chamber

slightly.

4) Release the eject button.

5) There should now be enough of the vessel protruding from the

chamber to allow easy removal by hand.

→

→

48mm Vial Fully Inserted

Press Eject to raise Vial

Remove Vial by Hand

Eject Button

Page 29

Instructions for Use

29

6.4.4 Performing a Reading

Once the sample vessel has been inserted into the unit and the lid closed

(see Section 6.4.3 above), press the Accept button start the reading.

→ →

→ →

Open Lid

Insert

Sample

Sample

Inserted

Close Lid

Sample

Ready

Accept

The measurement countdown begins.

At the end of the countdown period the reading result is displayed on the

Test Results screen.

Test Result Screen

Sample ID

Readings Count

Remove

Tube

Status

Tag

Move

Up

Move

Down

Results

Database

Page 30

Instructions for Use

30

At this point the user can choose to either:

1) View the Test Results Database (Section 6.5)

2) Tag the result (Section 6.4.5)

3) Perform another sample test (continue)

4) Return to the Main Menu (continue)

To perform another sample test or return to the Main Menu, open the unit lid

and remove the sample tube just tested. See Section 6.4.3 for sample vessel

removal.

→

Open Lid

Remove Sample

The sample Test screen will then appear. To perform another test, follow the

visual prompts in the middle of the screen as detailed in Sections 6.4.2 thru

6.4.4 above.

Otherwise, to return to the Main Menu press the Previous Menu button and

follow the visual prompts. This will then navigate the user back to the protocol

screen where the Main Menu button can be pressed to return to the main

menu.

→ →

Protocol

Screen

→ →

Main

Menu

Return to

Previous Menu

Close

Lid

Main

Menu

Page 31

Instructions for Use

31

6.4.5 Results Status Tagging and Adding a Comment Note

Each test result can be tagged with a Status icon to signify its overall result

status – as listed in Table 8 below.

Table 8: Result Status Tag Symbols

None: Status unspecified

Good: Good protocol test result

Uncertain: Unclear protocol test result

Bad: Bad protocol test result

Flagged: Result flagged as interesting

Invalid: Invalid/out-of-range test result

The Status tag can be added to the result immediately after the test has

been completed (and before the tube is removed) or when reviewing test

results via the results Database screen (see Section 6.5).

Press the Status tag button to access the status options.

Result Status Screen

Result

Screen

→ →

Cancel

Comment

Accept

Page 32

Instructions for Use

32

For user-defined Protocols (see Section 7.7), the unit’s user can

be prevented from changing the pre-assigned status value, in

which case the status option buttons are greyed-out.

The Comment button can be used to add a short note to the test result. This

is particularly useful when the Flagged status option is selected. This text will

appear in the Notes field of the Lu-mini App Test Results Database table.

→

Enter

comment

→

To change the result status, press the required Status button in the middle of

the screen. The display will jump back to the Result screen with the new

status value shown at the bottom of the screen.

Result Screen

Result

Status

Screen

→ →

Good

Result

The Status tag and Comment can be changed at any time by pressing the

Status button from the Result screen and selecting a different status option.

Page 33

Instructions for Use

33

6.5 Viewing the Test Results Database

The test results Database is where all the test results are stored and can be

accessed either from the Main Menu or test Results screen. To view the

database from the Main Menu, press the Database button.

Results Database Screen

Main

Menu

Screen

→ →

Main

Menu

Jump to

End

Move

Up

Move

Down

Expand

Result

The Database screen displays a list of all the test results that have been

completed. Results are listed in date/time order with the most recent result at

the top of the list.

The Up and Down buttons can be used to scroll up and down the list one

test at a time or alternatively use the jump to Top or Bottom buttons to

quickly jump to the top or bottom of a long list of results.

When a result is highlighted the Expand button can be used to view the fullsize Result screen for that specific result.

Database Screen

→ →

Result Screen

(for highlighted result)

Press the Database button to return to the Database screen.

Results

Screen

→ →

Database

Screen

Page 34

Instructions for Use

34

Likewise, the test results Database can also be accessed directly after a

reading has been taken by pressing the Database button.

Test

Result

Screen

→ →

6.5.1 Deleting Test Results from the Lu-mini Database

Test results cannot be directly deleted from the Lu-mini’s Results Database.

When the database is full, the oldest result is automatically overwritten.

However, they can be tagged as Invalid using the result status tag (see

Section 6.4.5 for details).

Results can only be deleted from the unit via the Lu-mini Windows

Application. See Section 7.4.1 for details.

Page 35

Instructions for Use

35

6.6 Using the Timer Function

The Timer Function provides up to 8 timers that can be individually set from

5 seconds up to 95 minutes. The timers can be operated independently of

each other or grouped together so that when one timer finishes the next one

automatically starts.

Table 9: Timer Function Buttons and Status Symbols

Select Timer (1 of 8)

6.6

Start Timer

6.6.1

Stop Timer

6.6.1

Silence Timer Alarm

6.6.1

Unlinked Independent Timer

6.6.2

Linked Cascading Timer

6.6.2

Status: Timer Inactive (stopped)

6.6.1

Status: Timer Running (started)

6.6.1

Status: Timer Alarming (beeping)

6.6.1

Page 36

Instructions for Use

36

From the Main Menu press the Timer Function button to view the Timer

Summary screen.

Timer Summary Screen

Main

Menu

Screen

→ →

Main

Menu

Start

Timer 1

The Timer Summary screen displays all 8 timers, labelled 1 to 8, with each

being assigned a default time between 0:30 seconds to 60:00 minutes.

6.6.1 Using an Independent Timer

To use a single independent timer, select a Timer from the Timer Summary

screen (e.g. Timer 1 with a default time of 0:30 seconds) to pull up the Timer

Details screen for that timer.

Timer Details Screen

Timer

Summary

Screen

→ →

Previous

Screen

Timer

Unlinked

Increase

Time

Decrease

Time

Start

Timer

Page 37

Instructions for Use

37

The timer duration can be set between 0:05 seconds and 95:00 minutes by

using the Increase and Decrease buttons.

The Timer can then be immediately started by pressing the Start button. The

button will change to a Stop button and the time will start counting down. The

Timer can be cancelled at any time before it reaches 0:00 by pressing the

Stop button.

0:30

→ →

0:30 0:29 0:28

→ →

0:30

If the Timer is left to reach 0:00, the timer Alarm starts sounding and the

Stop button changes to a Silence alarm button. Press the Silence button to

stop the Alarm and reset the Timer.

0:30

→ →

0:30

→

0:00

→ →

0:30

Press the Previous button to return to the Timer Summary screen.

Multiple timers can be started by pressing the Timer select button to go into

the individual Timer Details screen, pressing the Start button to start the

timer and then the Previous button to return to the Timer Summary screen;

and then selecting the next timer to be started; and so on.

→

0:30

→ →

0:30 0:29

→

→

→ →

1:00

→ →

1:00 0:59

→

→

→ →

20:00

→ →

20:00 19:59

→

etc…

The status of all 8 timers can then be monitored, Stopped and Silenced

from the main Timer Summary screen.

Page 38

Instructions for Use

38

6.6.2 Using Linked Cascading Timers

If required, some or all of the timers can be linked together so that when one

timer finishes the next one automatically starts. A timer is always linked to the

next sequential timer i.e. Timer 1 to 2, Timer 2 to 3, and so on.

All the timers can be linked together into a single group or multiple groups.

6.6.2.1 Linking Timers into a Single Cascading Group

Instructions on how to link timers are as follows:

1) Select a Timer from the timer summary screen e.g. Timer 1.

2) Edit the time if required.

3) Press the Unlinked button located at the bottom of the screen.

Timer Details Screen

Timer

Summary

Screen

→ →

Previous

Screen

Timer

Unlinked

Increase

Time

Decrease

Time

Start

Timer

Page 39

Instructions for Use

39

4) On the Link Edit screen press the Link Timer button, and then the

Accept button to save the new setting.

Cancel

Accept

5) The Timer Details screen now shows the Timer Linked button and that

Timer 1 is now linked to Timer 2.

Previous

Menu

Timer

Linked

Increase

Value

Decrease

Value

Start

Timer

6) Return to Previous menu. There is now a small arrow between Timer 1

and Timer 2 to indicate that they are linked together.

7) Select Timer 2 and edit the time as required before returning to the

Previous menu.

8) Press the Start button to start the Timer 1.

Page 40

Instructions for Use

40

9) Timer 1 will start counting down until it finishes, then Timer 2 will start

automatically.

More timers can be added into a linked group by activating the linked function

in each timer sequentially i.e. Timers 3, 4, 5, 6, 7 and 8.

6.6.2.2 Linking Timers into Multiple Cascading Groups

Multiple groups of linked Timers can also be set-up if required i.e. Timer 2

linked to 3 and then Timer 5 linked to 6. To create more than one linked

group the timer at the start of a new group must not already be linked to the

previous timer.

Multiple timer groups are started by pressing the Start button on the

individual Timer Details screen for the first timer in each group.

6.6.3 Using the Timers whilst Sample Testing

It is possible to use the unit as normal whilst the timers are running. Once a

timer has been started press the Main Menu button to return to the Main

Menu, and the unit can continue to be used as normal.

→

Start

Timer

Main

Menu

The active timer/s will not be visible on the unit display; however, when a

timer finishes the alarm will sound and this can be muted by pressing

anywhere on the display no matter what screen is displayed.

Page 41

Instructions for Use

41

6.7 Unit Set-up Options

The unit Set-up menu provides options for customising the unit’s behaviour

and shows the current state of the settings.

Press the Set-up button from the Main Menu screen to view the Set-up

Options menu.

Set-up Options Screen

Main

Menu

Screen

→ →

Main

Menu

Reader

Test

To change a setting, press the associated option button in the middle of the

screen, then select a new value (designated by the green bar) and press the

Accept button to save the new setting.

Cancel

Accept

Page 42

Instructions for Use

42

The available options are summarised in Table 10 and described in the more

detail in the following sub-sections.

Table 10: User Preferences and Options

Set clock and

Date/Time

formats

Year/Month/Day

Day/Month/Year

Month/Day/Year

6.7.1

AM/PM

24 Hour

Beeper volume

Muted

Normal

6.7.2

Touchscreen button

click volume

Silent

Click

6.7.2

Default User setting

Default

Most Recent

6.7.3

Sample ID

auto-text

Edit Prefix

6.7.4

None

Auto Number

Daily Number

Reader

test mode

Test Mode

6.7.5

Page 43

Instructions for Use

43

6.7.1 Setting the Clock and Date/Time Formats

The clock option allows you to change the unit date and time, as well as the

date and time formats (as listed in Table 10).

→

→

DATE

→ →

→

TIME

→

Set

Clock

Date

Format

Adjust

Date

Next

Time

Format

Adjust

Time

Accept

If using the Lu-mini Windows App, the date and time can be

automatically set and synchronised with the computer’s clock. This

will also set the date and time formats. See Section 7.6 for details.

6.7.2 Beeper and Button Click Volume

The unit beeper sounds at the end of each sample measurement and when a

timer has finished. This can be Muted if required.

→

Muted / Normal

Done

Likewise, the LCD touch screen button click can be independently set to

Silent if desired.

→

Silent / Click

Done

Page 44

Instructions for Use

44

6.7.3 Remembering the Last Active User ID

By default, the unit is set to remember the last active User ID each time the

unit is powered up. This option can be changed so that the User ID reverts

back to Any User on unit power-up.

→

Default / Remember

Done

6.7.4 Define Automatic Sample ID Text Format

The Sample ID text format can be edited as required using the sample ID

editor function. From the Set-up menu select the Sample ID Auto-text

button.

Sample ID Auto-text Screen

→

→

Previous

Prefix

Auto ID

By default, the sample ID is set to sequential numeric with no prefix. All the

options for ID editing available are detailed in Table 11.

Table 11: Automatic Sample ID Buttons

Edit Prefix Text (0 to 6 characters)

ABCDEF

No Automatic ID

Sequential Numeric ID (6 digits)

123456

Daily Sequential ID (10 digits)

YYMMDD-123

Page 45

Instructions for Use

45

The Sample ID can be a maximum of 16 characters long i.e. if set to a Daily

Sequential ID with a 6-character prefix. Press the appropriate button/s to set

the sample ID as required.

→

→

→

Set

Auto ID

Prefix

Text

Auto

Text

Done

Note: It is possible to have no automatic ID and no prefix set. In this case,

when a sample Test is performed, the unit automatically prompts to user to

manually enter the Sample ID by displaying the QWERTY keyboard. A

sample ID must be given to the sample before a test can be performed.

6.7.5 Reader Test Mode

The reader test mode allows background reading to be performed either with

or without a sample vessel present in the unit.

Press the Reader Test button on the set-up menu to display the reader test

mode screen.

Reader Test Mode Screen

Set-up

Screen

→ →

Cancel Accept

Page 46

Instructions for Use

46

Press the Accept button to perform a reading using the Standard RLU

Measurement protocol. When the test result is displayed, either press

Accept to perform another reading or press Previous to return to the Set-up

Menu.

Note: As these are only background test readings, they are not stored in the

unit’s results database.

6.8 Standby Mode and Unit Shutdown Procedure

After use, and before switching off the power to the unit, it is recommended

to put it in standby mode.

Firstly remove any sample tube that may be present in the unit, and close the

unit lid.

→

Remove Sample Tube

Close Lid

Then, on the Main Menu screen, press the Standby button to activate the

standby mode.

Standby Mode Screen

Main

Menu

→ →

Wake-up

Page 47

Instructions for Use

47

Once the unit is in standby mode then the power can be safely removed.

When the power to the unit is switched off or disconnected, the

LCD may remain illuminated for several second before going

blank.

To wake-up the unit from standby mode, press the Wake-up button on the

standby screen.

Page 48

Instructions for Use

48

7 Lu-mini Windows App and Advanced Unit Configuration

The Lu-mini Windows App activates the following advanced settings and

features on the Lu-mini Unit:

• Uploading of Test Results to a common results Database

• Export of Test Results to an Excel compatible CSV file

• Creation of User IDs with optional passwords

• Creation of custom Protocols and Assays

• Management of multiple Lu-mini units to ensure common settings

Multiple Lu-mini units can be connected to a single computer using several

USB ports and a powered USB hub.

7.1 Installing the Lu-mini Windows App and USB Driver

DISCLAIMER

THIS SOFTWARE IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND EITHER EXPRESSED

OR IMPLIED INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

INTEGRATED TECHNOLOGIES LTD SHALL NOT BE LIABLE FOR ANY LOSS OF PROFIT, LOSS OF

USE, LOSS OF SOFTWARE, LOSS OF DATA, INTERRUPTION TO BUSINESS, NOR FOR ANY DIRECT,

INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY OR CONSEQUENTIAL DAMAGES OF ANY KIND

ARISING FROM THE USE OF THIS SOFTWARE OR RELATED THIRD-PARTY SOFTWARE WHETHER

UNDER THIS AGREEMENT OR NOT.

BY INSTALLING OR USING THIS SOFTWARE YOU ARE AGREEING TO BE

BOUND BY THE CONDITIONS OF THIS AGREEMENT.

Page 49

Instructions for Use

49

To install the Lu-mini App, run the Install.msi file from the Installation Drive to

initiate the install procedure. Then follow the on-screen prompts.

The Lu-mini App is designed to run on 32-bit and 64-bit versions of

Windows 7, 8 and 10. To install the software you may require

additional Administrator rights from your IT Administrator.

Next the USB Driver must be installed. This is done by running the

appropriate driver install program from the CP210x_Driver sub-folder on the

Installation Drive and following the onscreen prompts:

• For 64-bit Windows: Run CP210xVCPInstaller_x64.exe

• For 32-bit Windows: Run CP210xVCPInstaller_x86.exe

Alternatively, this can also be done by selecting the Install USB Driver

option from the Help menu in the Lu-mini App (see Section 7.2.3 from

details).

To run the Lu-mini App, click on the Lu-mini App icon on the desktop, or in

the VITL Products section of the programs Start menu.

Desktop

→

Lu-mini App

or

→

Programs

→

VITL Products

Lu-mini App

Page 50

Instructions for Use

50

7.2 Lu-mini App Basic Functionality

The Lu-mini App enables data to be transferred to and from the Lu-mini unit

and a Windows computer, making it easy to add User IDs and customise the

unit with specific sample measurement Protocols.

The application display format consists of a spreadsheet-style layout, with

Page selection buttons down the left-hand side of the screen and a Toolbar

across the top.

Page 51

Instructions for Use

51

7.2.1 Page Selection Buttons

The Lu-mini App features numerous spreadsheet-style Tables, which are

selected by clicking the associated Page button down the left-hand side of

the application Window.

Table 12: Lu-mini App Page Select Buttons

Test Results Database

7.4

Future Feature: Test Results Database Filters

Future Feature: Scheduled Test Sample Work List

Future Feature: Sample Locations

Future Feature: Test Plans

User IDs

7.5

Sample Measurement Protocols

7.7

Reagent Assays

7.8

Unit Settings

7.6

Please refer to the subsequent Sections for more details.

Page 52

Instructions for Use

52

7.2.2 Toolbar Options

The toolbar provides the basic data functions as follows:

Table 13: Lu-mini App Toolbar Options

Sync

Sync Lu-mini Unit to the Lu-mini App

7.3

Save

Save table data changes to disk

7.2.4

Refresh

Refresh page table data

7.2.4

Export

Export data to Excel compatible CSV file

7.4.2

Add

Create new user, protocol, etc

7.2.4

Edit

Edit existing data within App

7.2.4

Delete

Delete existing data within App

7.2.4

Help

Help menu

7.2.3

Close

Close Lu-mini App

Please refer to the specific Sections for more details.

7.2.3 Help Menu Options

The Help Menu is accessed by clicking on the Help button in the toolbar,

and provides the following options:

Table 14: Lu-mini App Help Menu Options

Instructions for Use

Open Lu-mini User’s Manual

Install USB Driver

Install appropriate USB Driver

Check online for App Updates

Future Feature

Capture Unit Screenshot

Capture Lu-mini screen image

Reset Unit Software and Settings

Future Feature

About Lu-mini App

Lu-mini App software details

The Install USB Driver option can be used the install the Windows USB

Driver for the Lu-mini Unit. Using this method, the application automatically

detects the Windows version (32-bit or 64-bit) and loads the appropriate

driver.

Page 53

Instructions for Use

53

The Capture Unit Screenshot option can be useful for taking snapshots of

the current display on the Lu-mini Unit, so that they can be pasted into your

own standard operating procedure documents.

7.2.4 Data Table Field Editing and Context Menu

Each Page displays a specific spreadsheet Table, consisting of a matrix of

data Cells organised in Lines (running down the sheet in rows) of related

data Fields (arranged across the sheet in columns).

Fields ➔

Lines

➔

Lines or Cells which are greyed-out cannot be changed. All other cells in

the table can be edited in any of the following three ways:

(a) Double-clicking on the Cell text:

Cell

→

Edit cell

value

→

Enter

or

Tab

(b) Right-clicking on the Cell and selecting the Edit option from the

Context Menu:

Cell

→

Edit '…'

→

Edit cell

value

→

Enter

or

Tab

Cell

Page 54

Instructions for Use

54

(c) Selecting a table Line and then clicking the Edit button in the

Toolbar:

Line

→ →

Edit cell

value

→

Enter

or

Tab

After changing the Cell text, press the Enter key to accept the new value; or

press the Escape key to cancel editing; or press the Tab key to accept the

new value and automatically move on to edit the next field cell in the line.

WARNING: There is currently no Undo button; hence any changes

made to the table data cannot be easily reversed. The only way to

restore the table values is to Exit the application or to use the

Refresh button (see below for details).

When a data cell value has been changed, the line text colour changes to

Blue to signify that it has been modified but has not yet been saved to disk.

To save any changes to disk, simply click the Save button in the Toolbar.

The modified lines will then turn black again.

Modified

lines

→ →

Data

saved

If changes have been made to the data, but you have changed you mind,

there is no Undo option. However, the entire data table can be reloaded from

disk to the state it was when last saved by clicking the Refresh button.

Modified

lines

→ →

Data

reloaded

New data Lines can be added to the end of the table in two ways:

(a) Clicking the Add button in the Toolbar:

→

New line

added

→

Edit first

cell value

→

Enter

or

Tab

Page 55

Instructions for Use

55

(b) Right-clicking on a Line and then selecting the Duplicate Line

option from the Context Menu:

Line

→

Duplicate

Line

→

New line

added

One or more data Lines can also be deleted in two ways:

(a) Selecting the Lines to be deleted and then clicking the Delete

button in the Toolbar:

Select

lines

→ →

Yes

→

Lines

deleted

(b) Selecting the Lines to be deleted and then Right-clicking on a

Lines and then selecting the Delete Line option from the Context

Menu:

Select

lines

→ →

Delete

Line

→

Yes

→

Lines

deleted

The full list of right-click Context Menu options are as per Table 15 below.

Table 15: Data Cell Context Menu Options

Edit 'field'

Edit cell value

7.2.4

Copy 'field'

Copy cell value to paste clipboard

7.4.2

Copy Line(s)

Copy selected line(s) to clipboard

7.4.2

Copy Line(s) with Header

Copy Header and Selected line(s)

7.4.2

Select All

Select all lines

Select None

Select no lines

Duplicate Line

Duplicate entire line contents

7.2.4

Delete Line

Delete selected line(s)

7.2.4

Please refer to the associated Sections for more details.

Page 56

Instructions for Use

56

7.3 Data Synchronisation

The toolbar Sync button is used to transfer data between the Lu-mini App

and all attached Lu-mini Units, by performing the following tasks:

• Discover and add New Unit details

7.6.1

• Upload test results from Unit

7.4

• Delete test results from Unit’s database

7.4

• Check for Unit Software updates

• Update Unit’s time and date settings [Optional]

7.6

• Update Unit’s User IDs list

7.5

• Update Unit’s Protocols list

7.7

Click the Sync button on toolbar to initiate the data transfer. The Lu-mini Unit

will display the Download screen until the process is complete.

→ &

Sync

Unit Download Screen

App Synchronisation Progress Window

When synchronisation is completed, the Lu-mini Unit will restart. Click the OK

button to close the progress window.

Once restarted, the attached Units will have any new User and Protocol data

loaded on to them from the Lu-mini App, and the App will contain all the test

results data from the Units.

Page 57

Instructions for Use

57

NOTE: Uploading the test results removes them from the Lu-mini

Unit and permanently stores them in the Lu-mini App Test Results

Database table (see Section 7.4).

7.4 Test Results Database Page

The Test Results Database page stores all the test results that have ever

been uploaded from the Lu-mini Units.

The available Test Results Database table data fields are listed in Table 16

below.

Table 16: Test Results Database Data Fields

Results ID

Unit test result unique ID within the database

Unit ID

Unit serial number and name

7.6.1

User ID

User ID

7.5

Date/Time

Date and Time when sample test performed

Location

Sample location name

Patient ID

Optional: Patient ID from Worklist

Sample ID

Test Sample ID

6.4.2

Sample Type

Sample Type (S, C, 1, 2, 3, 4, 5 or 6)

7.7.2

Protocol

Protocol name

7.7.1

Measurement Type

Measurement type

7.7.3

Tube Reading

Sample tube reading

7.7.4

Reading Units

Reading Units-of-measurement

7.7.4

Test Result

Test Result

7.7.4

Results Units

Result Units-of-measurement

7.7.4

Status

Overall test result Status tag

6.4.5

Band

Banded result Name

7.7.4

Lower Limit

Banded result lower limit

7.7.4

Upper Limit

Banded result upper limit

7.7.4

Kinetic Data

Kinetic data points

7.7.3

Notes

Optional: Additional notes

7.2.4

None of these data field values can be modified except for the Notes field.

Page 58

Instructions for Use

58

7.4.1 Uploading Results Data

Each time the Lu-mini App synchronises with Lu-mini Unit any new test

results are uploaded and stored in the Test Results Database table.

→ →

Results

uploaded

Once the results have been uploaded and saved in the Lu-mini App they are

automatically deleted from the Lu-mini Unit.

7.4.2 Exporting Test Results Data

Test results data can be exported to an Excel compatible CSV file by clicking

the Export button on the toolbar.

This can either be the all the data in the table, or just the selected lines.

→ →

Save data

to CSV file

→

Open file

in Excel

Alternatively, the data can be Copied and Pasted into an existing Excel

sheet. This is achieved by selecting the Lines to be copied and then rightclicking on a Line and clicking the Copy Line(s) option in the Context Menu.

Select

lines

→ →

Copy

→

Paste data into

Excel sheet

To export Kinetic Data (see Section 7.7.3 for protocol setting), select the

required results data lines then click the Export button and select the Export

Selected Kinetic Data option.

Select

lines

→

Export Selected

Kinetic Data

→

Save data

to CSV file

→

Open file

in Excel

Page 59

Instructions for Use

59

7.4.3 Deleting Results Data

Results are automatically deleted from the unit when they are uploaded to

the application during the synchronisation process. All results data from the

unit is stored on the application until it is deleted by the user.

To delete results data from the application’s Test Results Database, refer the

Section 7.2.4 for details.

7.5 User IDs Page

By default, the Lu-mini unit has only a single generic Any User user profile.

This page of the application allows for custom User IDs to be created for the

unit as required.

New users are created by adding a new line to the User IDs table (see

Section 7.2.4).

→ →

Edit new User

ID fields

The available User IDs table data field options are listed in Table 17 below.

Table 17: User IDs Data Fields

Active

Selects whether the User ID is downloaded to the unit

Below

User ID

Unique User ID

6.3

User Name

Name associated with the User ID

6.3

Password

Optional password

6.3

Notes

Optional: Additional notes

7.2.4

New User IDs will appear on the Lu-mini unit when the Sync button is next

clicked.

→

Save

Sync

New User IDs are created with the Active field set to Yes, meaning the User

ID will be loaded onto the Lu-mini unit when it is next synchronised with the

application.

There is no limit to the number of User IDs that can be created in the Lu-mini

App, however only 50 active Users IDs can be stored in the Lu-mini Unit.

Page 60

Instructions for Use

60

Hence, to limit the size of this list, the Active field must be changed from Yes

to No for some Users IDs.

7.6 Global Unit Settings Page

The Unit Settings table stores a list of all the Lu-mini units which have been

synchronised with the Lu-mini App.

The available Unit Settings table data fields are listed in Table 18 below.

Table 18: Unit Settings Data Fields

Unit Number

Fixed: Unique Lu-mini Unit serial number

Unit Name

Optional: Name that appears at the top of unit’s Main

Menu screen

7.6.1

Last Synced

Fixed: The date and time with unit was last

synchronised

Notes

Optional: Additional notes

7.2.4

Time and Date Synchronisation options are listed in Table 19 below.

Table 19: Time and Date Synchronisation Options

Time Format

AM/PM or 24H: Used on unit display and in the

Test Results Database table

7.4

Date Format

YYYY/MM/DD, DD/MM/YYYY or

MM/DD/YYYY: Used on unit display and Test

Results Database table

7.4

Automatically set

unit time and date

Selects whether unit’s time/date settings are

automatically updated when by Sync update

Page 61

Instructions for Use

61

7.6.1 Adding a New Unit

New Lu-mini units are automatically added to the Unit Settings table

whenever a Sync is performed.

The Unit Name field can then be set with a short description that appears on

the unit’s Main Menu screen next time the unit is synchronised.

7.7 Sample Measurement Protocols Page

By default, the Lu-mini Unit has only the Standard RLU Measurement

protocol. This page allows custom protocols to be created and developed as

required.

To create a new Protocol, click the toolbar Add button and then enter all the

appropriate data field values.

→ →

New Protocol created

(edit cells to define protocol)

→ →

Protocols

Page

Add

Save

Sync

Alternative a copy of an existing Protocol can be copied and modified by

right-clicking on the existing protocol Line and then selecting the Duplicate

Line option from the Context Menu and editing the required data field values.

Line

→

Duplicate

Line

→

New protocol

added

→

Edit protocol

fields

Page 62

Instructions for Use

62

The available Sample Measurement Protocols table data fields are listed in

Table 20 below.

Table 20: Protocols Table Data Fields

Active

Selects whether protocol is downloaded to unit

Below

Protocol Name

Unique name for this protocol

7.7.1

Description

Description of the protocol

7.7.1

Assay

Assay name from Reagent Assay Table

7.7.1

Scaling Factor

Assay reading scaling factor

7.7.1

Sample Method

Sample method (S, C, C+1S to C+6S)

7.7.2

Measurement

Type

Sample measurement type

7.7.3

Show Graph

Show data progress graph for long

measurement times

7.7.3

T1

Result analysis start time t1 in seconds

7.7.3

T2

Result analysis end time t2 in seconds

7.7.3

Window

Result analysis window size in seconds

7.7.3

Threshold

Percentage change threshold limit

7.7.3

Result DPs

Result display number of decimal-places

7.7.4

Result Units

Result Units-of-measurement

7.7.4

Lock Status

Prevent user from changing the result status

7.7.2

Result Banding

Result colour banding data

7.7.2

Limit Result

Limit result value to maximum/minimum bands

7.7.2

Comparison

Bands

Comparative result acceptance range data

7.7.2

Show Relative

Show comparative result as relative percent

7.7.2

Notes

Optional: Additional notes

7.2.4

The Active field can be used to specific which Protocols will be downloaded

to the Lu-mini Units. This is handy when developing new or experimental

Protocols to select only the active definitions.

Please refer to the relevant Sections for specific details on field usage.

Page 63

Instructions for Use

63

7.7.1 Protocol Name and Reagent Assay

The first group of Protocol definition fields define the protocol name and

associated Assay (see Section 7.8).

Protocol Name

Unique name for this protocol

Description

Description of the protocol

Assay

Assay name from Reagent Assay Table

Scaling Factor

Scale assay reading to allow for different units of

measurement (0.000001 to 1000000.0 but normally 1.0)

The Protocol Name and Description appear on the Lu-mini Unit in the

Protocol selection screen (along with the Result Units of measurement).

The Assay is the name of the Reagent Assay (see Section 7.8) being used

for this protocol. Usually multiple protocols will use the same Assay.

The assay Scaling Factor can be used to convert the Assay output reading

into different units of measurement (for instance) or to correct for calibration

rescaling. See Section 7.7.4 for additional details.

7.7.2 Sample Method Types

The Sample Method field (listed in Table 20) defines how many related tests

will be performed on a particular sample.

Page 64

Instructions for Use

64

Table 21: Sample Method Options

Single Sample

One standard test per sample volume

Control Only

One control test per sample (such as QC check)

Control + 1 Sample

One baseline control test plus one comparative standard

test per sample

Control + 2 Samples

One baseline control test plus up to two comparative

standard tests per sample

etc

etc

Control + 6 Samples

One baseline control test plus up to six comparative

standard tests per sample

This setting determines how the Lu-mini Unit processes the sample tube

readings and displays the result to the user.

7.7.2.1 Single Tube Measurements

For the Single Sample and Control Only options, the Unit measures a

single test tube and presents the result in the specified numerical format with

optional Banding (see Section 7.7.4).

7.7.2.2 Multiple Tube Measurements

For multiple sample tests (Control + 1 Sample thru Control + 6 Samples),

however, the additional Sample results are compared against the baseline

Control test result and displayed as a bar chart (see Section 7.7.4 for

details).

The first sample test is always on the Control sample, and is represented as

normal numeric value (as shown in Section 6.4.4).

When the Control tube is removed, the Tube Selection screen is displayed.

Page 65

Instructions for Use

65

This show that the Control tube has been measured and that Sample 1 to 6

are still to be tested. Press the appropriate tube number (i.e. 1, 2, 3, 4, 5 or

6) to select that tube to be measured next, or the Cancel button to return to

the Protocol selection screen.

The Test screen then prompts for the specific tube number for be inserted, or

press the Tube Select button the select a different tube number.

Test Screen

Tube

Selection

Screen

→ →

Cancel

Sample

ID

Location

Tube

Select

Accept

Once two or more tubes have been measured, the result is displayed as a

comparative bar chart.

Refer to Section 7.7.4 for details of how the define the Comparison Band

limits.

Page 66

Instructions for Use

66

7.7.2.3 Continuing a Multi-Tube Test from the Worklist

For a multi-tube test, it may be necessary to perform the Control reading and

then return some time later to perform the related Sample tube measurement

(for instance if the sample has been incubated).

This is achieved by pressing the Worklist button on the Protocol screen to

display and select any unfinished tests.

Worklist Screen

Protocol

Screen

→ →

Cancel

Jump to

End

Move

Up

Move

Down

Accept

Highlight the required sample test from the list and then press the Accept

button to continue with that test, or the Cancel button to return to the

Protocol selection screen.

Tube Selection Screen

→ →

Page 67

Instructions for Use

67

7.7.3 Measurement Types

The next group of Protocol definition fields relate to how the sample is

measured by the Lu-mini Unit to produce a test result value.

When the Lu-mini unit measures a test sample, it performs the following

steps, as defined by the selected Protocol:

Acquire measurement data

→ Optional: Pre-zero phase

Below

→ Open internal shutter

→ Initial 10-second reading

→ Optional: Additional 1 to 600-second data collection

Below

→ Close internal shutter

Translate reading data according to Assay curve

7.8

Process reading data (as per Protocol definition)

Below

Calculate final test result

7.7.4

Hence the measurement sequence is:

→

Luminescent

Signal Data

Acquisition

→

Assay

Standard

Curve

→

Process

Reading

Data

→

Calculate

Formatted

Result

→

Result

Sample

Read

Translate

Process

Calculate

Store

The measurement parameters are:

Measurement Type

Sample measurement type

Show Graph

Show data progress graph for long measurement times

T1

Result analysis start time t1 in seconds

T2

Result analysis end time t2 in seconds

Window

Result analysis window size in seconds

Threshold