Vital CNC Control

(DSPMC pn7762)

CNC Control for

Milling, Lathe, Plasma

Machines

User Guide

Document Revision 1.1

(Updated July 26, 2014)

© 2014 Vital Systems Inc

Phoenix, AZ USA

For more information please visit the product web page:

http://www.vitalsystem.com/cnc

Vital CNC Control User Guide

Table of Contents

License Agreement........................................................................................................................................ 2

I. Introduction ............................................................................................................................................... 3

Package Contents ...................................................................................................................................... 3

II. Setup ......................................................................................................................................................... 4

Setting up the Vital CNC Control ............................................................................................................... 4

Integrating the Vital CNC Control with your machine .............................................................................. 6

Internal Layout ...................................................................................................................................... 6

Digital I/O Signals .................................................................................................................................. 7

Drive Connection with Maxsine AC Servo Drives and 7736 Board ....................................................... 8

Drive Connection Without Using the 7736 Board ................................................................................ 9

Mach3 and Software Setup ..................................................................................................................... 11

Configuring the Default Profile ........................................................................................................... 11

Creating your own Mach3 profile ....................................................................................................... 16

III. Operation ............................................................................................................................................... 19

Front Panel Controls ............................................................................................................................... 19

MPG Handwheel Controls ....................................................................................................................... 21

TroubleShooting .......................................................................................................................................... 22

© 2014 Vital Systems, Inc. 1 www.vitalsystem.com

Vital CNC Control User Guide

WARNING: Machines in motion can be extremely dangerous!

It is the responsibility of the user to design effective error

handling and safety protection as part of the system. VITAL

Systems shall not be liable or responsible for any incidental or

consequential damages. By using the Vital CNC Control, you

agree to the license agreement.

License Agreement

Before using the Vital CNC Control and any accompanying software tools, please take a moment to

review this License agreement. Any use of this hardware and software indicate your acceptance to this

agreement.

It is the nature of all machine tools that they are dangerous devices. In order to be permitted to use the

Vital CNC Control on any machine you must agree to the following license:

I agree that no-one other than the owner of this machine, will, under any circumstances be responsible,

for the operation, safety, and use of this machine. I agree there is no situation under which I would

consider Vital Systems, or any of its distributors to be responsible for any losses, damages, or other

misfortunes suffered through the use of the Vital CNC Control and its software. I understand that the

Vital CNC Control is very complex, and though the engineers make every effort to achieve a bug free

environment, that I will hold no-one other than myself responsible for mistakes, errors, material loss,

personal damages, secondary damages, faults or errors of any kind, caused by any circumstance, any

bugs, or any undesired response by the board and its software while running my machine or device.

I fully accept all responsibility for the operation of this machine while under the control of the Vital CNC

Control, and for its operation by others who may use the machine. It is my responsibility to warn any

others who may operate any device under the control of the Vital CNC Control of the limitations so

imposed.

I fully accept the above statements, and I will comply at all times with standard operating procedures

and safety requirements pertinent to my area or country, and will endeavor to ensure the safety of all

operators, as well as anyone near or in the area of my machine.

© 2014 Vital Systems, Inc. 2 www.vitalsystem.com

Vital CNC Control User Guide

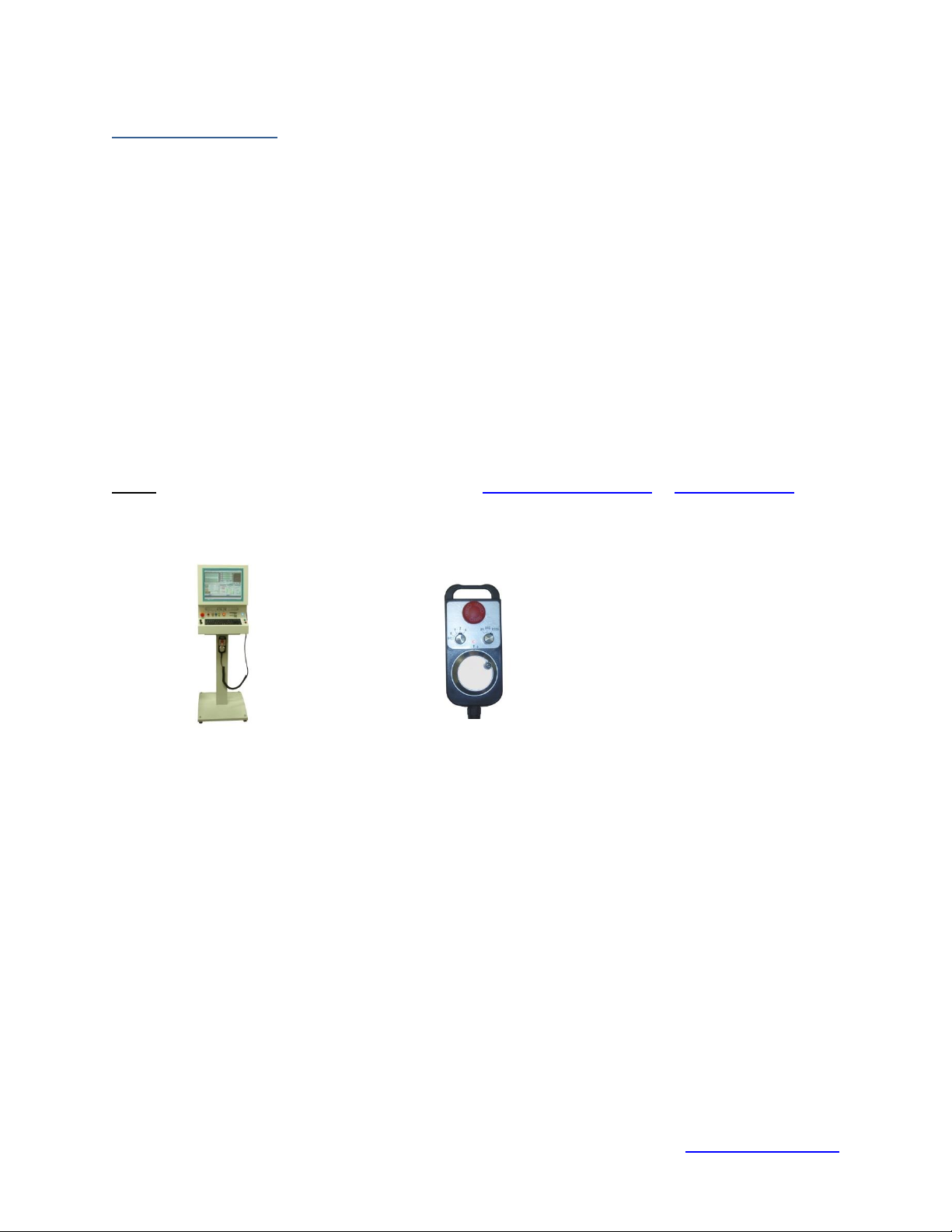

Vital CNC Control

with optional stand

MPG Handwheel

(Optional)

I. Introduction

Package Contents

Before proceeding to setup your Vital CNC Control, please take a moment to verify that all necessary

components are present within the delivery.

The Vital CNC Control Package should contain the following items:

- Vital CNC Control

- Vital CNC Control Stand (optional)

- MPG handwheel (optional)

- Operator’s Keys

- Backup Software disc (Windows 7)

NOTE: The Vital CNC Control may contain either the HiCON Integra (pn7766) or DSPMC (pn7762)

motion controller depending on the purchase.

© 2014 Vital Systems, Inc. 3 www.vitalsystem.com

Vital CNC Control User Guide

IMPORTANT: Before powering up the unit, make sure that all

packing material is properly removed from the inside of the

Vital CNC Control unit.

II. Setup

Setting up the Vital CNC Control

NOTE: It is recommended to mount your Vital CNC Control or assemble the optional stand before

proceeding with the setup phase.

1. Plug in the power cable to the Vital CNC Control and connect the other end to an outlet. If you

intend setup any wiring, such as inputs, it is recommended that you keep the power switch at

“0”.

© 2014 Vital Systems, Inc. 4 www.vitalsystem.com

Vital CNC Control User Guide

Unit is ON

2. Your Vital CNC Control should now be operational and can be turned on with the ON/OFF

Button. The next steps will cover integrating the Vital CNC Control with your machine. During

this phase, the unit must be turned off and unpowered.

© 2014 Vital Systems, Inc. 5 www.vitalsystem.com

Vital CNC Control User Guide

Integrating the Vital CNC Control with your machine

For these next steps, you will need to open your Vital CNC Control to inspect the internal components.

Internal Layout

Below is an image of the contents of the Vital CNC Control. Please use this image as reference while

continuing with the next setup procedures.

NOTE: Some Vital CNC Controls may contain different parts as requested by the user before shipping.

© 2014 Vital Systems, Inc. 6 www.vitalsystem.com

Vital CNC Control User Guide

PNP Digital I/O Wiring

NPN Digital I/O Wiring

Digital I/O Signals

NOTE: Please verify the model of your 7535 Digital I/O Breakout Board before continuing as they can

be provided in PNP (7535P) and NPN (7535N) versions.

Wire the required Digital I/O signals of your machine to the provided Digital I/O Breakout Board. This

breakout board allows the use of 16 Inputs and 8 Outputs, as well as the use of 24V for said Digital I/O.

Detailed Wiring instructions for PNP and NPN versions can be found in their respective sections

See “Internal Layout” section for location of the I/O Breakout Board.

NOTE: You must also wire your 3phase contactor supplying power to

your Servo Drives to the Estop button

contact located inside the Vital CNC

Control to achieve a true hardware EStop.

The Red Disarm Button located on your MPG

Handwheel (if you have purchased it) only

disarms the motion controller.

© 2014 Vital Systems, Inc. 7 www.vitalsystem.com

Vital CNC Control User Guide

Connection on 7736 Differential Encoder and StepGen

Board

NOTE: You may also view a video tutorial for this

connection method.

link: http://www.youtube.com/watch?v=xDHRH0ZVeow

Connection on Maxsine AC Servo Drives

WARNING: NEVER interchange the Blue Drive cables with the

Green Encoder cables. Doing so may damage your drives and the

Vital CNC Control.

Drive Connection with Maxsine AC Servo Drives and 7736 Board

AC Servo Motor and Drive Packages purchased from the Vital Systems website come with additional

components, for a simple and quick plug-and-play wiring setup.

Said components are:

- 1x Drive Interface Board (EPx-DIB) plugs on the servo drive

- 1x Blue RJ45 Drive cable

- 1x Green RJ45 Encoder cable

- 7736 Differential Encoder and StepGen Board

NOTE: the 7736 board works with both DSPMC and HiCON Integra motion controllers. However, this is

only used for the Step/Dir Outputs with the DSPMC.

Setting up the drive connection is simply a matter of plugging the colored cables to the corresponding

colored and labeled RJ45 Ports on the 7736 board and the Drive Interface Board.

The Blue RJ45 cables connect to the drive ports while the green cables connect to the encoder ports.

© 2014 Vital Systems, Inc. 8 www.vitalsystem.com

Vital CNC Control User Guide

Pin#

Function

Pin#

Function

1

+12V, 100mA max

20

Analog Input 0

14

+5V, 500mA max

8

Analog Input 1

2

-12V, 50mA max

21

Analog Input 2

15

Analog Output 0

9

Analog Input 3

3

Analog Output 1

22

Ground (return)

16

Analog Output 2

10

Analog Input 4

4

Analog Output 3

23

Analog Input 5

17

Ground (return)

11

Analog Input 6

5

Analog Output 4

24

Analog Input 7

18

Analog Output 5

12

Ground (return)

6

Analog Output 6

25

Ground (return)

19

Analog Output 7

13

+5V, 500mA max

7

Ground (return)

Drive Connection Without Using the 7736 Board

This method is used in case the 7736 Board is not installed or interfacing with non-Maxsine AC Servo

Drives.

NOTE: The 7736 Board uses RJ45 ports for Encoders. For wiring differential quadrature encoders to the

7736 Differential Encoder and Step/Dir Board, please refer to the 7736 Wiring Guide.

NOTE: With this method, it is highly recommended to read the User Guide for the DSPMC Ethernet

Motion Controller. Encoders 8 through 15 are only accessible via the 7736 Differential encoder and

Step/Dir Board on internal ports J11 and J12.

J2 Pin Assignments (Analog Outputs and Inputs):

© 2014 Vital Systems, Inc. 9 www.vitalsystem.com

Vital CNC Control User Guide

Pin#

Function

Pin#

Function

1

Encoder Channel 0 A+

8

+5V 500mA

14

Encoder Channel 0 A-

21

Ground (Return)

2

Encoder Channel 0 B+

9

Encoder Channel 2 A+

15

Encoder Channel 0 B-

22

Encoder Channel 2 A-

3

Encoder Channel 0 Z+

10

Encoder Channel 2 B+

16

Encoder Channel 0 Z-

23

Encoder Channel 2 B-

4

+5V 500mA

11

Encoder Channel 2 Z+

17

Ground (Return)

24

Encoder Channel 2 Z-

5

Encoder Channel 1 A+

12

+5V 500mA

18

Encoder Channel 1 A-

25

Ground (Return)

6

Encoder Channel 1 B+

13

Reserved

19

Encoder Channel 1 B-

7

Encoder Channel 1 Z+

20

Encoder Channel 1 Z-

Pin#

Function

Pin#

Function

1

Encoder Channel 3 A+

8

+5V 500mA

14

Encoder Channel 3 A-

21

Ground (Return)

2

Encoder Channel 3 B+

9

Encoder Channel 5 A+

15

Encoder Channel 3 B-

22

Encoder Channel 5 A-

3

Encoder Channel 3 Z+

10

Encoder Channel 5 B+

16

Encoder Channel 3 Z-

23

Encoder Channel 5 B-

4

+5V 500mA

11

Encoder Channel 5 Z+

17

Ground (Return)

24

Encoder Channel 5 Z-

5

Encoder Channel 4 A+

12

+5V 500mA

18

Encoder Channel 4 A-

25

Ground (Return)

6

Encoder Channel 4 B+

13

Reserved

19

Encoder Channel 4 B-

7

Encoder Channel 4 Z+

20

Encoder Channel 4 Z-

J6 Pin Assignments (Encoder Channels 0 – 2):

J7 Pin Assignments: (Encoder Channels 3 – 5):

© 2014 Vital Systems, Inc. 10 www.vitalsystem.com

Vital CNC Control User Guide

Mach3 and Software Setup

Configuring the Default Profile

After the digital I/O and the drives have been properly wired, it is now time to switch ON your Vital CNC

Control.

NOTE: Your Vital CNC Control may be password protected on the windows log in. The default

password is “CNC”. It is recommended that the user change this to their own password.

NOTE: Although the purchase of a Vital CNC Control along with Maxsine Motors and Drives allows

Vital Systems to make several configurations within the factory, Digital I/O will have to be wired

manually and configured by the user to suit the target machine.

For a more detailed guide on using DSPMC with Mach3, please refer to the DSPMC User Guide.

Open Mach3 using the default profile provided. You should then see this window popup at the start of

Mach3. Select “M3dspMC” as shown in the picture.

A message like the one below should appear in the Mach3 Status Bar indicating that communication has

been established between Mach3 and the DSPMC.

© 2014 Vital Systems, Inc. 11 www.vitalsystem.com

Vital CNC Control User Guide

DSPMC Port

Mach3 Ports and Pins

J4

Port 1, pins 0 – 15

J5

Port 1, pins 16 – 31

J11

Port 1, pins 32 – 47

J12

Port 1, pins 48 – 63

DSPMC Port

Mach3 Ports and Pins

J4

Port 1, pins 0 – 7

J5

Port 1, pins 8 – 15

J11

Port 1, pins 16 – 23

J12

Port 1, pins 24 – 31

Digital I/O can be configured by going to the Ports and Pins Menu, then the “Input Signals” and Output

Signals tab.

Digital I/O Signals on the DSPMC can be mapped by using setting the Port as 1, and pins 0 – 63. Below is

a table showing the physical pin layout and its corresponding Mach3 pin layout.

Inputs

Outputs

The image below shows an example for X Home and Limit switches connected to J4 and the Y homing

and limit switches connected on J5. Both must be wired using the 7535 I/O Board.

© 2014 Vital Systems, Inc. 12 www.vitalsystem.com

Vital CNC Control User Guide

© 2014 Vital Systems, Inc. 13 www.vitalsystem.com

Vital CNC Control User Guide

You can monitor the current I/O states and other status information via the “Status Window”.

© 2014 Vital Systems, Inc. 14 www.vitalsystem.com

Vital CNC Control User Guide

The I/O mapping can also be checked from the Mach3 Diagnostic Tab.

If the Mach3 signals do not correctly activate in response to the state of the Digital Input, then you may

need to check the “Status Window” to see if the Digital I/O state works (or is wired) correctly. If the

signal polarity is incorrect, the active low setting can be changed in the Ports and Pins Config.

© 2014 Vital Systems, Inc. 15 www.vitalsystem.com

Vital CNC Control User Guide

1. Click on Create Profile

2. Type a new profile name. You can either

start with default profile values or clone an

existing profile.

3. Your new profile should now be useable.

4. You may also create a shortcut to your

new profile by creating a shortcut of the

“Mach3.exe” file then right-click to

“Properties”

Creating your own Mach3 profile

Should you want to create your own Mach3 profile, you would need to perform these steps to get your

profile working correctly with the Vital CNC Control.

NOTE: This method requires a better understanding of Mach3, as well as experience with the HiCON or

DSPMC plugin config. It is always recommended to use one of the default profiles.

Open the Mach3 application which can be found in C:\Mach3\Mach3.exe. The profile selection screen

will show up when you open Mach3.

© 2014 Vital Systems, Inc. 16 www.vitalsystem.com

Vital CNC Control User Guide

After creating your own profile, you must perform these additional steps.

1. Copy the macropump.m1s file from the macros folder of any default profile

(Mach3\macros\<profile>\macropump.m1s) and paste it into the macros folder of your new

profile(Mach3\macros\<yourNewProfile>\macropump.m1s).

2. After Mach3 is opened. Go to the general config to enable the macropump.

© 2014 Vital Systems, Inc. 17 www.vitalsystem.com

Vital CNC Control User Guide

3. Enable the “Vital CNC Control” brain and the “MPG Buttons

Selector” brain (if using MPG). To do this, go to “Brain

Control” from the “Operator” menu in Mach3.

© 2014 Vital Systems, Inc. 18 www.vitalsystem.com

Vital CNC Control User Guide

Control

Function

Wiring Location

1. Operator Key

Slot

Enables the use of motion control or system enable.

DSPMC:

[J5, Input 6]

2. CPU LED

Indicates the current status of the internal motion controller.

NOTE: If the HiCON motion controller is used, a heartbeat blink

pattern indicates that the motion controller is operational. This LED

will turn off during firmware upgrade by the user.

If using the DSPMC motion controller, the CPU LED will blink slowly

to indicate operational status.

DSPMC:

[J5, Output 0]

3. Estop Button

Disarms the current system and stops all motion. The button can be

twisted clockwise after being pressed to remove the system from

the Estop state.

DSPMC:

[J5, Input 7]

4. Error LED

Turns on when the internal motion controller incurs an error.

DSPMC:

[J5, Output 2]

5. User

Programmable

Function

Buttons

These buttons are wired to specific inputs on the HiCON or DSPMC

and can be mapped to execute custom commands or macros in

Mach3.

DSPMC:

FN1 – [J5, Input 0]

FN2 – [J5, Input 1]

FN3 – [J5, Input 2]

III. Operation

Front Panel Controls

© 2014 Vital Systems, Inc. 19 www.vitalsystem.com

Vital CNC Control User Guide

6. Enable Button

Enables/Arms the system. Motion can only be performed if the

system is armed. Glows orange to indicate that the system is armed

and ready for motion.

DSPMC: [J5, Input 3]

7. Feedrate

Override

Overrides the current feedrate to speed up or slow down the

execution of a gCode file in Mach. Range varies from 0% (left) to

250% (right).

DSPMC:

Analog Input 0

8. ON/OFF Button

Turns ON the Vital CNC Control if pressed. Turns OFF the Vital CNC

Control if held while the unit is currently ON. The power sign glows

blue to indicate that the Vital CNC Control is turned on.

9. Spindle RPM

Override

Overrides the current Spindle RPM. Range varies from 0% (left) to

250% (right) depending on the current spindle speed.

DSPMC:

Analog Input 1

10. USB and Audio

Jack Slots

General purpose and easy-access USB slots and Audio Slots.

11. Cycle Start

Button

Initiates the execution of the current GCode File in Mach.

DSPMC:

[J5, Input 5]

12. Cycle Stop

Button

Stops the execution of the Current GCode File in Mach.

DSPMC:

[J5, Input 4]

© 2014 Vital Systems, Inc. 20 www.vitalsystem.com

Vital CNC Control User Guide

Control

Function

Wiring Location

1. Axis Control

Knob

Changes which axis to jog with the MPG

DSPMC:

X - [J5, Input 11]

Y - [J5, Input 10]

Z - [J5, Input 9]

A - [J5, Input 8]

2. Estop Button

Disarms the current system and stops all motion. The button can be

twisted clockwise after being pressed to remove the system from

the Estop state.

DSPMC:

[J5, Input 7]

3. Jog Increment

Knob

Changes the current jog increment.

DSPMC:

[J5, Input 7]

MPG Handwheel Controls

© 2014 Vital Systems, Inc. 21 www.vitalsystem.com

Vital CNC Control User Guide

TroubleShooting

My unit is powered up and the CPU LED is blinking, but the Digital I/O do not physically turn

ON/OFF correctly.

- Check the 24V Power Supply and see if the red LED is

turned on. If not, check the fuse close to it. If it is blown,

then the 24V are not supplied to the Motion Controller

(DSPMC or Integra). 24V are required for Digital Inputs and

Outputs.

I can’t enable/arm my Vital CNC Control.

- Make sure that the operator keys are inserted into the key slot on the front panel and turned

clockwise. Check the error LED on the front panel if it is lit up. This could mean that one of the

Estop Buttons is currently triggered. Estop buttons are sticky switches and will need to be

rotated clockwise to deactivate.

I have wired my drives, but I can’t get any motion.

- Make sure that the axes are properly configured within the plugin config.

o Set the Output Type to “Stepper” (Step/Dir), or ”DAC” (+/-10V).

o Set the Output Index to the correct channel.

o Set the Control Input Source to “Machxx”.

- Ensure the “Drive Enable Signal” (Enable1) is mapped to the correct output in the Ports and Pins

Config.

- Check that the Axes are enabled in the Ports and Pins config (“Motor Outputs” tab).

- Directions on the setup process and other information can be found in the DSPMC User Guide.

I have wired my drives, but I keep getting “Following Error” messages during motion.

- Make sure that the axis feedback is properly configured in the plugin config.

- If using Encoders:

o Set the Feedback Source to “Encoder”.

o Set the Feedback Index to the correct encoder channel.

o Use Feedback gain if the “counts per unit” of the encoder is different from that of the

motor’s (i.e. using linear encoders on the milling table). Otherwise, it is set to ‘1’.

For more information, visit vitalsystem.com or email us at support@vitalsystem.com.

© 2014 Vital Systems, Inc. 22 www.vitalsystem.com

Loading...

Loading...