Vital Systems ArcPro Mach4 User Manual

ArcPro Mach4 Plasma Screen

User Guide

Document Revision 1.10

(Updated June 13, 2017)

© 2017 Vital Systems Inc.

Phoenix, AZ USA

For more information please visit the product web page:

http://www.vitalsystem.com/arcpro

Contents

License Agreement ........................................................................................................................................ 3

Introduction .................................................................................................................................................. 4

Wiring Diagrams ............................................................................................................................................ 5

THC150 and HiCON Integra ....................................................................................................................... 5

Plasma Electrical Noise Filter for Digitize Sensor ...................................................................................... 7

Mach4 Profile ................................................................................................................................................ 8

Mach4 I/O Configuration .............................................................................................................................. 9

ArcPro Mach4 Plasma Screen ..................................................................................................................... 10

THC Settings ............................................................................................................................................ 11

Probe Limit .......................................................................................................................................... 11

Probe Speed ........................................................................................................................................ 11

THC Max .............................................................................................................................................. 11

THC Min ............................................................................................................................................... 11

Ignition Height ..................................................................................................................................... 11

Pierce Height ....................................................................................................................................... 11

Pierce Delay ......................................................................................................................................... 11

THC Delay ............................................................................................................................................ 12

Anti-Dive .............................................................................................................................................. 12

THC Control ............................................................................................................................................. 12

THC Mode ............................................................................................................................................ 12

Probe Once .......................................................................................................................................... 12

Set/Clear Ref ....................................................................................................................................... 13

Torch ON ............................................................................................................................................. 13

Speed ................................................................................................................................................... 13

Plasma Cut Sequence .................................................................................................................................. 14

How to Launch GCode File for Plasma Cut: ......................................................................................... 15

How to Launch Start and Stop THC Motion via MDI ........................................................................... 15

Enable THC Motion through Scripts .................................................................................................... 15

Testing With Emulated THC Signals ............................................................................................................ 16

Testing with Jogging .................................................................................................................................... 17

Testing with Proma THC150 Test Mode ...................................................................................................... 18

© 2017 Vital Systems, Inc. 1 www.vitalsystem.com

Loading and Starting a Job with a GCode File ............................................................................................. 19

Troubleshooting .......................................................................................................................................... 21

The system disarms on the “TorchON” (or M3) command .................................................................... 21

The system hangs up during the “TorchON” (or M3) sequence ............................................................. 22

The Torch does not move toward the designated probe limit position ................................................. 22

The Torch completes the Torch ON setup sequence, but does not move up or down afterwards ....... 22

The Torch only moves in one direction, or the wrong direction while cutting....................................... 23

The Z axis moves too fast while cutting .................................................................................................. 23

Additional References ................................................................................................................................. 24

© 2017 Vital Systems, Inc. 2 www.vitalsystem.com

License Agreement

WARNING: Machines in motion can be extremely

Before using the “ArcPro Plasma Control” package and accompanying software tools, please take a

moment to go thru this License agreement. Any use of this hardware and software indicate your

acceptance to this agreement.

It is the nature of all machine tools that they are dangerous devices. In order to be permitted to use the

“ArcPro Plasma Control” package on any machine you must agree to the following license:

I agree that no-one other than the owner of this machine, will, under any circumstances be responsible,

for the operation, safety, and use of this machine. I agree there is no situation under which I would

consider Vital Systems, or any of its distributors to be responsible for any losses, damages, or other

misfortunes suffered through the use of the “ArcPro Plasma Control” package and any accompanying

software. I understand that the “ArcPro Plasma Control” package is very complex, and though the

engineers make every effort to achieve a bug free environment, that I will hold no-one other than myself

responsible for mistakes, errors, material loss, personal damages, secondary damages, faults or errors of

any kind, caused by any circumstance, any bugs, or any undesired response by the board and its software

while running my machine or device.

I fully accept all responsibility for the operation of this machine while under the control of the “ArcPro

Plasma Control” package, and for its operation by others who may use the machine. It is my responsibility

to warn any others who may operate any device under the control of the “ArcPro Plasma Control” package

of the limitations so imposed.

I fully accept the above statements, and I will comply at all times with standard operating procedures and

safety requirements pertinent to my area or country, and will endeavor to ensure the safety of all

operators, as well as anyone near or in the area of my machine.

dangerous! It is the responsibility of the user to design

effective error handling and safety protection as part of

the system. VITAL System Inc. shall not be liable or

responsible for any incidental or consequential damages.

By using any product purchased from VITAL System

Inc., you agree to the license agreement.

© 2017 Vital Systems, Inc. 3 www.vitalsystem.com

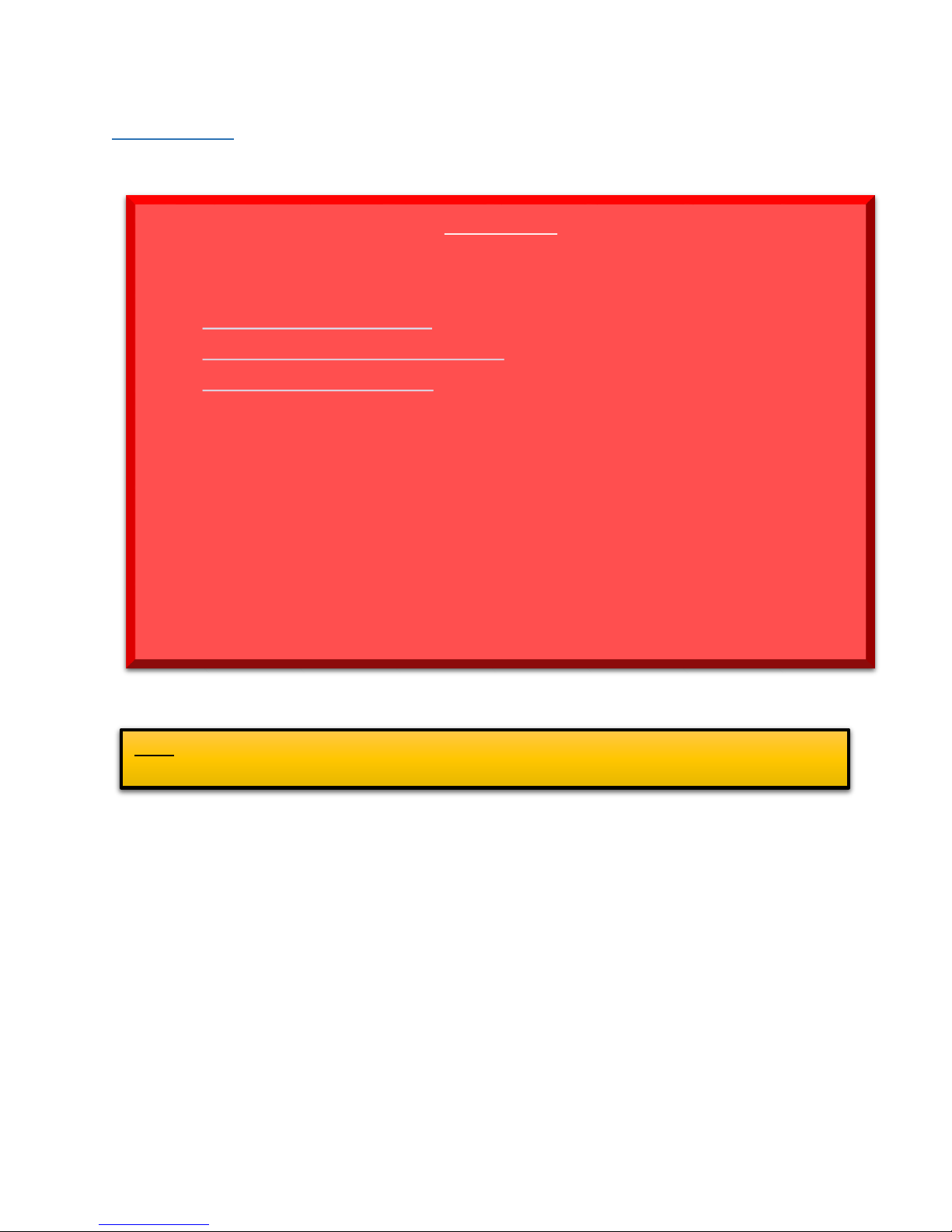

Introduction

IMPORTANT

This document makes the assumption that the reader has thoroughly reviewed

the necessary documentation:

Has completed the proper hardware setup, and possesses basic knowledge and

understanding of Mach4 CNC Software.

This document DOES NOT serve as a primer or tutorial for the use of Mach4. As

such, readers without basic understanding of Mach4, and other software

components not associated with Vital System Inc. are advised to consult the

appropriate user manual and/or software vendor.

NOTE: Several notes such as this can be found throughout this document which list key points and

comments worth remembering.

HiCON Integra User Guide

Mach4 HiCON Integration Manual

Compact THC 150 Manual

© 2017 Vital Systems, Inc. 4 www.vitalsystem.com

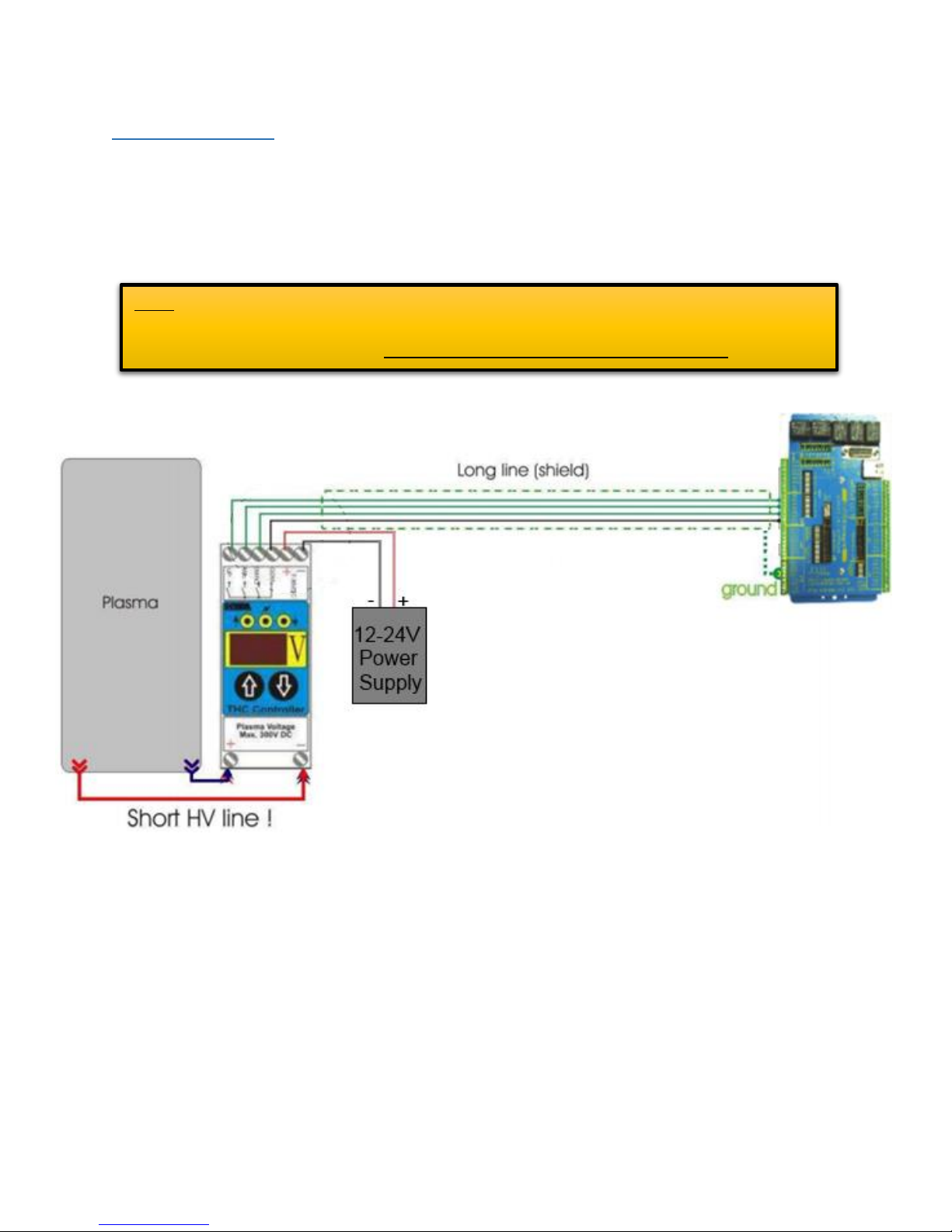

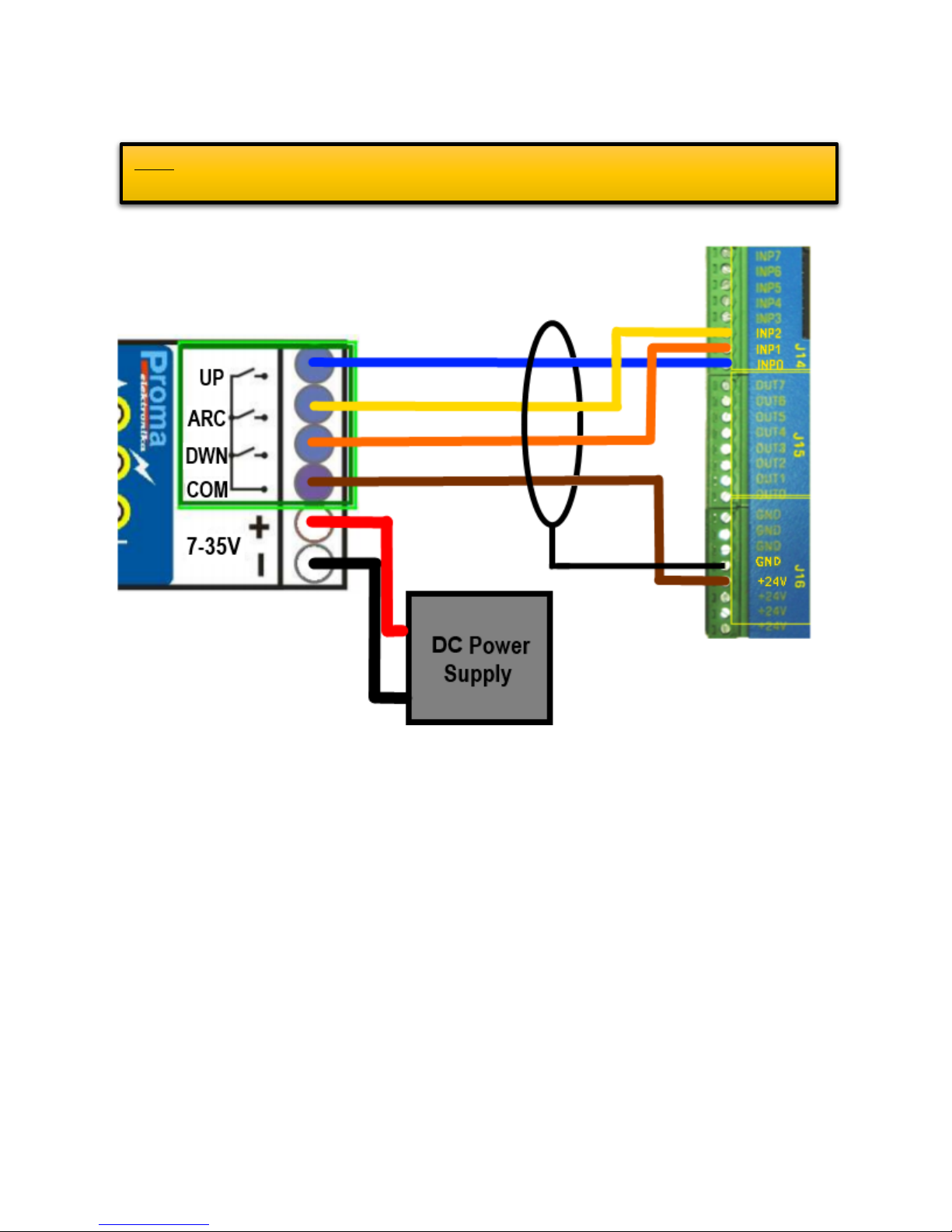

Wiring Diagrams

NOTE: To reduce the possibility of the electrical interference entering into the Motion Controller, the

connection should be made with a shielded cable - the shielding must be connected to ground

terminals on the Motion Controller. Do not connect the shielding to the THC unit side.

THC150 and HiCON Integra

© 2017 Vital Systems, Inc. 5 www.vitalsystem.com

NOTE: It is highly recommended to use a separate 12V or 24V (1Amp) Power Supply for the Compact

THC 150 to avoid high-voltage surges from feeding into the Motion Controller.

© 2017 Vital Systems, Inc. 6 www.vitalsystem.com

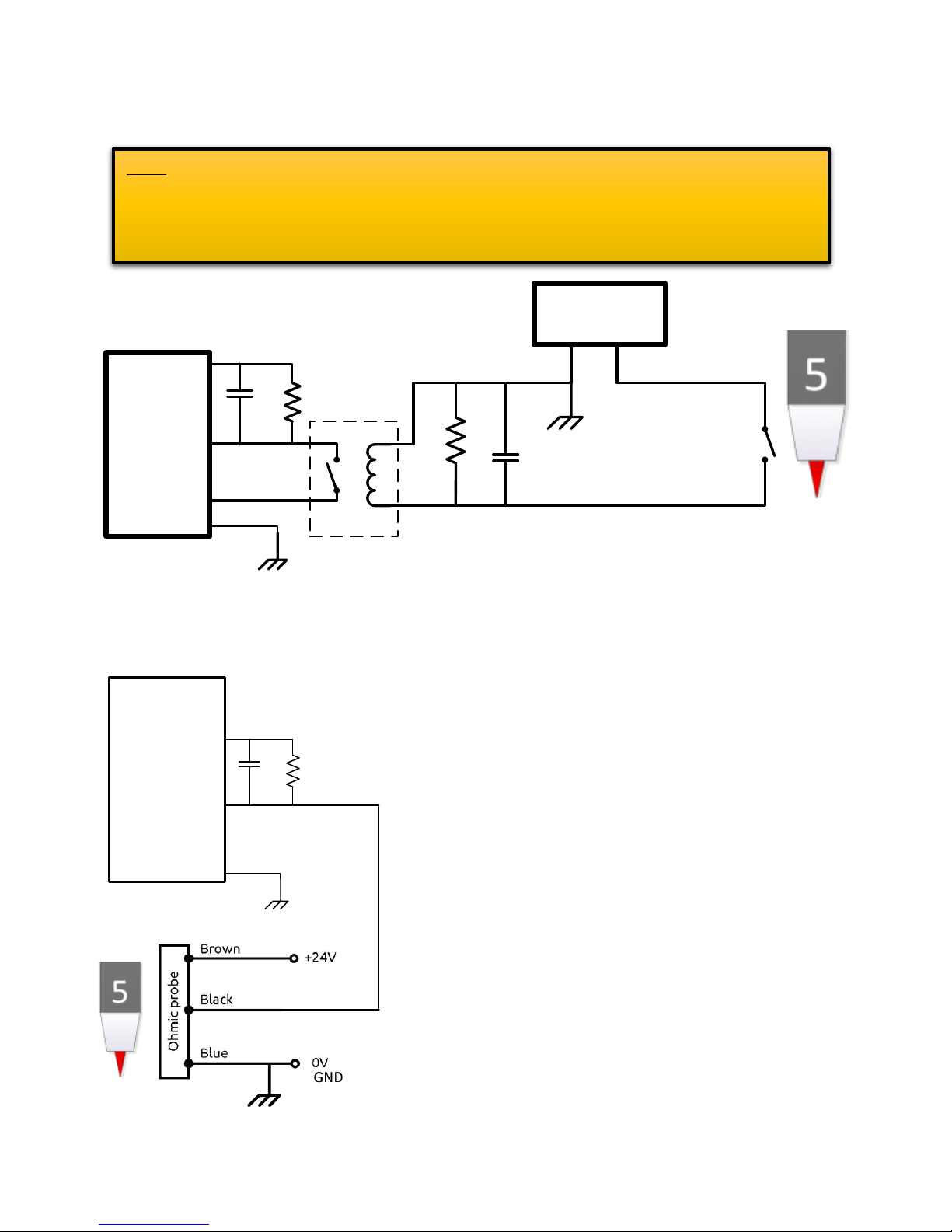

Plasma Electrical Noise Filter for Digitize Sensor

24v THC

Power Supply

Earth

Ground

3KΩ

1W

0.47uF

1kV

+

-

Digitize

Switch

-

+

24V Relay

N.O.

3KΩ

1W

GND

Earth

GND

Integra

Input 3

(Digitize)

Integra

J16 24V

0.47uF

1kV

-

+

HiCON Integra

3.9KΩ

1W

GND

Earth

GND

Integra

Input 3

(Digitize)

0.47uF

1kV

-

+

HiCON Integra

Earth

NOTE: It is highly recommended to follow the circuit diagram below when using a Digitize sensor on

the torch head. Because a Plasma Torch uses high-voltage for cutting, voltage spikes and electrical

noise must be properly filtered in order to safely connect the sensor to a digitize input on the HiCON

Integra.

Connecting PNP Digitize Sensor (Ohmic Probe)

© 2017 Vital Systems, Inc. 7 www.vitalsystem.com

Loading...

Loading...