VistaPure 3000 Installation Manual & Owner's Manual

Ultra Pure Water System

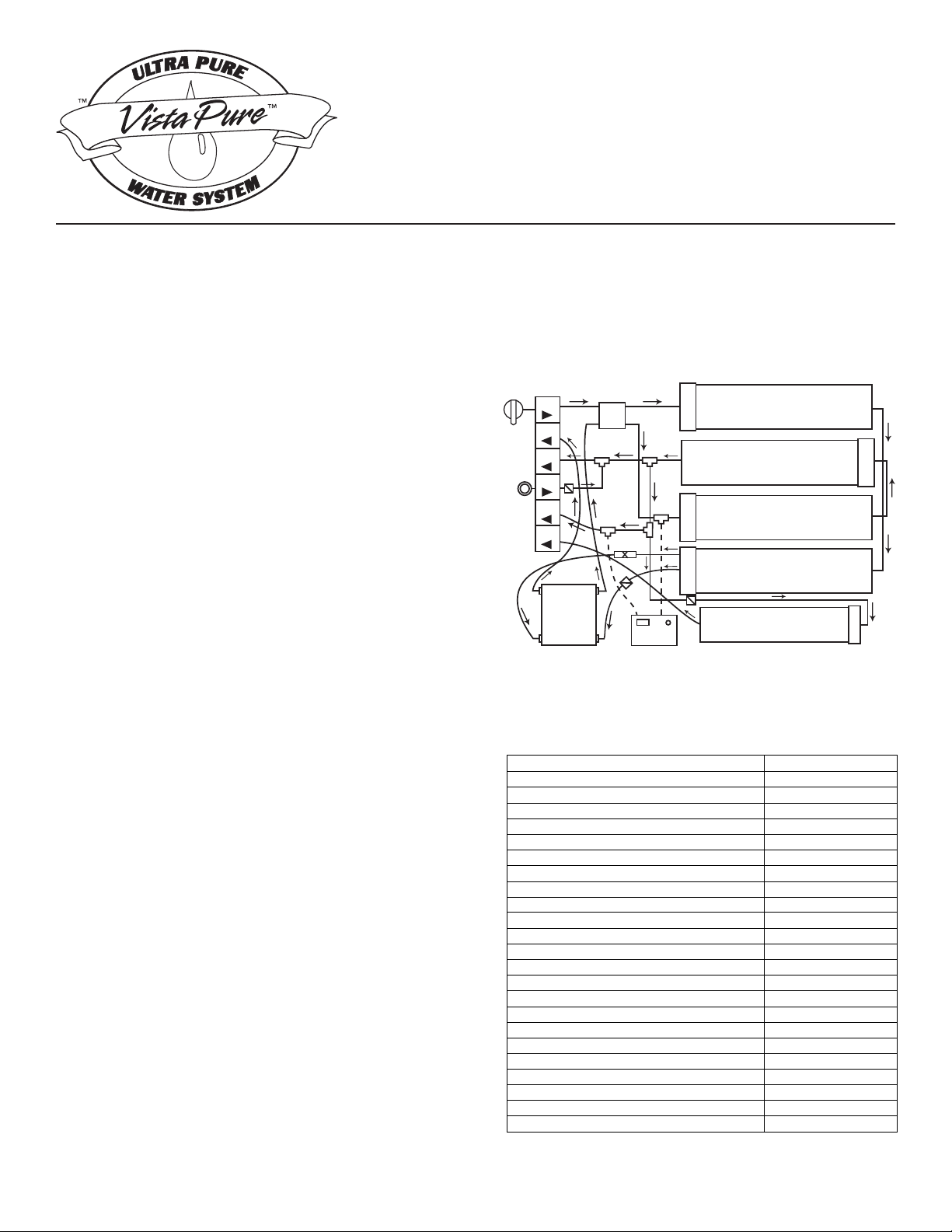

Prefilter

D/I #2

D/I #1

Hyperfiltration

Polishing

1

3

2

5

C

H

B

101

102

103

104

105

106

A

K

I

4

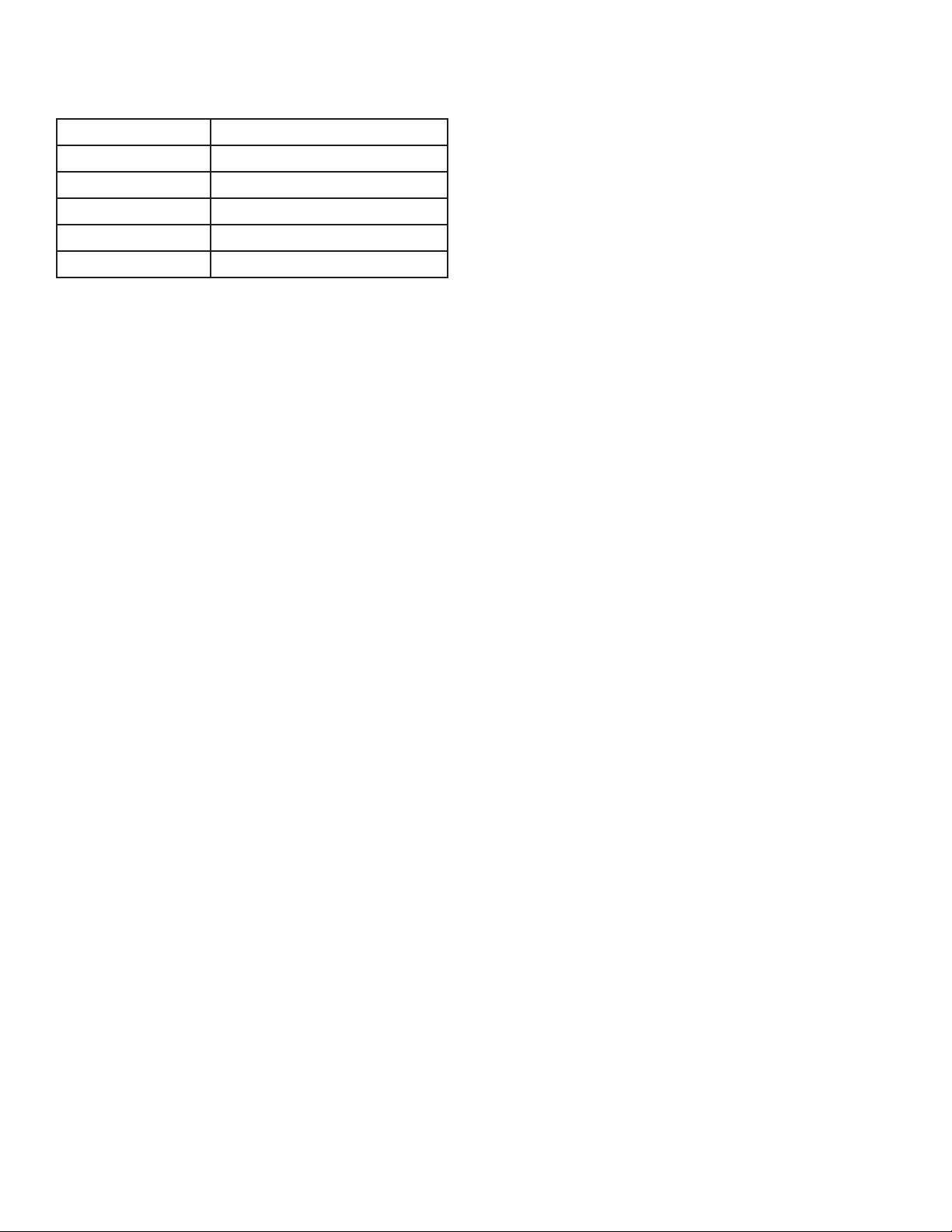

Maximum Operating Temperature

100° F

Minimum Operating Temperature

45° F

isp 001erusserP gnitarepO mumixaM

tseb isp +04 – isp 03erusserP muminiM

5.8 – 5.6egnaR Hp lamitpO

Maximum Total Dissolved Solids (TDS) 500

5.9 – 5.5egnaR Hp mumixaM

mpp 171/rg 01ssendraH tneulfnI mumixaM

mpp 50.0esenagnaM tneulfnI mumixaM

mpp 1.0norI tneulfnI mumixaM

Maximum Influent Hydrogen Sulfide none

Maximum Influent Chlorine/Chloramine 2 ppm

Maximum Daily Output (12 hours) 25 gal (94 L)

Stage 1 Prefiltration Element Service Life 1 year max

Stage 1 Prefiltration Replacement Order # R5633

Stage 2 Hyperfiltration Element Service Life 3-5 years

Stage 2 Hyperfiltration Replacement Order # R3080

Stage 3 Deionization Element Service Life 4-18 mo – See pg 7

Stage 3 Deionization Replacement Order # R5662

Stage 4 Polishing Filter Element Service Life 1 year max

Stage 4 Polishing Replacement Order # R2551

System Dimensions (W x H x D) 22”x16”x 5”

”61 x ”5.9)H x aiD( snoisnemiD knaT

Approximate Shipping Weight (Dry-2 Cartons) 33 lbs

Model 3000

Installation Guide

& Owner’s Manual

The VistaPure Ultra Pure Water System is designed

to produce two grades of high-purity water – 1) distilledquality for use in your autoclaves and 2) non-corrosive water

for use in bottle systems and for other uses. It is critical that

water used in autoclaves be virtually free of dissolved solids

and contaminants in order to protect the heating chamber

and to prevent build-up of contaminants that can create hard

deposits and more frequent cleanings. If poor quality water

is used, the autoclave will generally need to be re-built or

replaced at substantial cost. Water used in self-contained

dental bottle systems should be of high quality but not the

same grade as used in autoclaves since distilled-grade water

is corrosive to metals used in the construction of dental

units. The VistaPure system is designed to be built-in to

sterilization centers, cabinetry or can be simply installed in

an equipment room. In addition to use with your autoclaves,

the high purity water produced by your new VistaPure can

be used for making coffee, tea and other beverages, for

laboratory use and more.

The system provides 2.7 gallons of treated water in the

pressurized storage tank and automatically produces a new

supply as water is drawn from storage. The system does

not require electricity – it only needs a potable supply of

cold water and a drain. It is highly recommended that water

supplied to the system be free of sediment. Further, if the

source water is hard, the system ltration elements will last

longer if the water supply is softened.

Please return the Warranty / Registration form

immediately upon installation.

Always follow local plumbing codes.

Note the following specications before proceeding:

Figure 1. Front view of the VistaPure system.

VistaPure Model 3000 Specications

Although actual installation of VistaPure is quite simple, it

is recommended that a professional technician familiar with

dental operatory systems perform the installation due to the

wide variety of possible options, running of water and air

lines, drain lines, etc. He/she should be familiar with the

local plumbing codes and techniques for successful dental

equipment installations.

Please read this entire manual before proceeding with

Please make certain that anyone responsible for future

operation and maintenance of the system is familiar with

all details contained in the installation and maintenance

installation and operation.

manuals.

Please keep the maintenance manual handy for

future reference.

UNPACKING – Carefully unpack the contents of

the product carton. It should include the system,

Installation Guide & Owner’s Manual, Warranty

Registration sheet, an accessory pack and a supply

of colored tubing. Check to make certain there was

no damage during shipment. If damage is evident,

contact the shipping company or your distributor

immediately.

Installation Procedure

( Please refer to drawings that follow )

1. If the system is not already mounted in another

product (sterilization center, etc.) mount as desired

near a cold water source and 1-1/2” drain.

DATA – Locate the serial tag on the system and record

it on the blue Warranty Registration sheet. Provide

all of the information requested on the Warranty

Registration sheet and mail it immediately to Vista

Research Group, LLC upon installation. Write the

date of installation and the installer’s name on the tag

using a ne tip, permanent marker (e.g. a Sharpie®)

or some other writing instrument that will not smear.

HOW THE SYSTEM WORKS – The system is a

unique design that combines several technologies

using multiple stages to produce the highest purity

product – water with a total dissolved solids (TDS)

reading as low as zero (000).

The rst stage is a Prelter that removes sediment,

chlorine and other contaminants by physical ltration,

absorption and adsorption. Next is the Hyperltration

stage where pressure from the water source and the

non-electric permeate pump forces the water through

a semi-permeable membrane removing contaminants

at the molecular level. Contaminants are rinsed away

from the membrane and down the drain. The water

is then sent to two cartridges in series that contains

both cationic and anionic resins for removing any

remaining contaminants by a Deionization process.

The nished water is sent to a 2.7 gallon storage tank

where it is delivered on demand to the autoclave ller

wand or the bottle faucet as needed. Water running

to the secondary faucet (for lling bottles, etc.) runs

through the Polishing lter after leaving the tank

where a small amount of dissolved solids is added

back to the water to prevent corrosion.

LOCATION: The VistaPure system can be installed

nearly anywhere in the typical dental, medical, lab or

hospital setting, typically near a faucet and sink. The

system and tank are designed to t under a countertop

and connect directly to the cold water supply line and

drain. It may also be installed in any area where there

is a quality cold water supply and drain connection.

INSTALLATION: Although actual installation of

VistaPure is quite simple, you may wish to enlist the

services of a professional technician since your system

is going to be directly connected to the plumbing

system. He/she is familiar with the wide variety of

possible installation options, running of water and

drain lines, local plumbing codes and techniques for

successful equipment installations.

2. Position storage tank as near VistaPure system

board as possible.

3. Locate the white elbow tank valve in accessory

pack and attach valve to the side of the tank. Handtighten only!! Never use tools on system valves and

ttings!

4. Provide for a 1/4” connection to the cold water

supply. This is usually done using a piercing saddle

valve or compression tting.

5. Provide a 1-1/2” vertical drain riser with trap as

shown in Figure 3 or Figure 4. The Air Gap drain

tting and 1/4” push-type tting is included in the

accessory pack. The Air Gap drain tting should be

glued to the drain riser as shown. See page 6 for drain

congurations.

6. Mount the faucet on the sink or countertop deck.

The faucet & push-type faucet connector tting are

included in the accessory kit.

7. Attach colored tubing to the proper segments on the

system manifold and the appliance/device as shown

in Figure 2. When attaching tubing to the push-type

ttings, make certain all tubing cuts are straight and

free from burrs. Tubing must be rmly inserted into

the tting (11/16” plunge) to avoid leaks.

IMPORTANT NOTE: If the system is mounted

inside a cabinet, under a sink or on a sliding device,

be careful that tubes are not crushed or crimped. If

the system is on a sliding device for easy access,

make certain to create a coil with the tubes that will

allow the system to move in and out without causing

damage or restriction. See Figure 7 for the proper

coil layout.

IMPORTANT NOTE: If the VistaPure system is

to be installed remote to the autoclave(s) and/or in a

cabinet, sh the solid blue tubing behind cabinetry

to the autoclave center. The solid blue tubing and

the coiled blue tubing are to be joined with the white

1/4” x 3/8” push-type union that is already attached

to one end of the coiled tubing. Please see Figure 2.

Make certain to provide a restraint at the straight

end of the coiled tubing near the union so that when

pulling out on the autoclave wand and coiled tubing

the union connection is not stressed.

2

Extra lengths of tubing are included with each system.

Below is the tubing color code chart. Please refer to

Figure 2 for detail.

Red From Cold Water Supply

Black To Drain

Natural To and From Tank

Blue Smooth To Autoclave Area

Blue Coiled To Autoclave Filler Wand

White To Faucet

8. Cleansing the system (after all tubing connections

have been made). Find the 35 ml syringe that’s

included in the accessory kit. Place about 20-30 ml

of clean water into a small paper cup and add about

two (2) drops of standard household bleach. Stir

gently with the syringe then pull the solution into the

syringe. Remove the safety cap from the injection

port at “K” on the manifold (see Figure 2). To remove

the cap simply hold the collet back against the cap

tting and pull it away from the check valve. Inject

the solution into the Injection Port. Draw 20-30 ml of

fresh water into the syringe and also inject it into the

Port in order to push all the bleach out of the check

valve. Replace the safety cap by pushing it rmly

onto the Injection Port tube. Immediately “Open”

the Water Supply Inlet Valve “I” on the manifold and

water will begin to ow into the system lling the

tank with treated water and the bleach.

9. Allow the system to run for twenty (20) minutes.

Waste water should be running to the drain Air Gap

“D” and a pulsing / clicking sound should be heard

coming from the Permeate Pump “C.” After twenty

minutes, “Close” the Water Supply Inlet Valve “I”

on the system manifold then discharge water from

both the Autoclave Wand “F” and Faucet “G” until

Tank “E” is empty and water ow stops. The system

is now cleansed.

10. “Open” Water Supply Inlet Valve “I” and allow

it ro run until the tank is full. This will take over an

hour for the tank to completely ll. However, water

can be used anytime after about thirty minutes since

the system produces and stores up to 2.7 gallons of

water and can deliver water to both the Wand and

the Faucet even while it’s making new water. The

system capacity is about 25 gallons of production per

12 hour work day.

Monitoring TDS

Total dissolved solids (TDS) is the quantitative

measure of virtually ALL constituents found in a

particular water supply counted as parts per million

(ppm) or milligrams per liter (mg/l). Water is simply

H2O – basically, everything else found in it would

contribute to the TDS. A typical city water supply will

have a TDS reading of from 150 – 350 TDS, although

it varies greatly. The federal standard for municipal

water systems is a maximum of 500 ppm TDS. Some

rural well waters are quite often found to range from

300 to over 1,000 ppm. Water for use in autoclaves

should be of distilled quality which is a TDS of 0 – 5

ppm (some more sensitive autoclaves require 0 – 3

ppm). Water with TDS readings higher than 5 ppm

will eventually cause staining, scale build-up, etc. and

require cleaning and/or repair. The worse the water,

the more costly the maintenance and repairs – to the

point that some autoclaves won’t even operate if the

TDS is high.

The VistaPure system comes equipped with a battery-

operated dual TDS meter. This allows you to check

the water quality throughout the system. For example,

slide the switch on the TDS meter (see Figure 5)

to “IN.” This reads the level of TDS in the water

emerging from the Hyperltration module. Slide the

switch to “OUT” and this will display the level of TDS

emerging from the Deionization modules on its way

to the Tank and/or Autoclave Wand. Water should be

running during test.

A separate handheld TDS meter is also included that

can be used to determine the level of TDS in the

Supply Water fed to the system. With these data one

can monitor the complete process as necessary. For

example, under normal operating conditions, typical

TDS levels might be as follows in this example:

City Water Feed 200 TDS X

After Hyperltration 010 TDS 5% of X

After Deionization 000 TDS After D/I

Remember, this is only an example. However, the

reading on the “IN” should generally be about 5% of

the inbound water TDS and the D/I modules remove

the balance remaining to achieve the 0-3 TDS level

desired.

Figure 7 shows the handheld TDS monitor provided

with your system. It can be used at any time to

determine the quality of the raw and treated water.

Simply remove it from the leather case, remove the

protective cap exposing the probe, push the power

button to activate, immerse the probe into the water.

The LCD display will show the TDS level. NEVER

immerse the monitor beyond the rst section

(marked as “A” on Figure 5). While immersed, the

“hold” button can be pushed to lock the display. After

use, shake the water out of the probe area and wipe the

outer portion dry – never push anything into the probe

area. Check the water quality frequently and change

lter elements as required (see the Specications on

cover for replacement frequency). Both TDS monitors

are operated by a simple button cell battery available

at most any store.

3

Loading...

Loading...