Vista 10SE, N7227V5 User Manual

9,,

9

6

6

7

7

$

$

6

6

(

(

6HFXULW\6\VWHP

,QVWDOODWLRQDQG6HWXS*XLGH

*

AWAY

NO AC

STAY

CHIME

INSTANT

BAT

ALARM

BYPASS

CHECK

FIRE

NOT READY

OFF AWAY STAY

2

1

MAX TEST BYPASS

INSTANT CODE CHIME

897

READY

0

*

PANIC

ARMED

READY

3

654

#

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

®

N7227V5 10/00

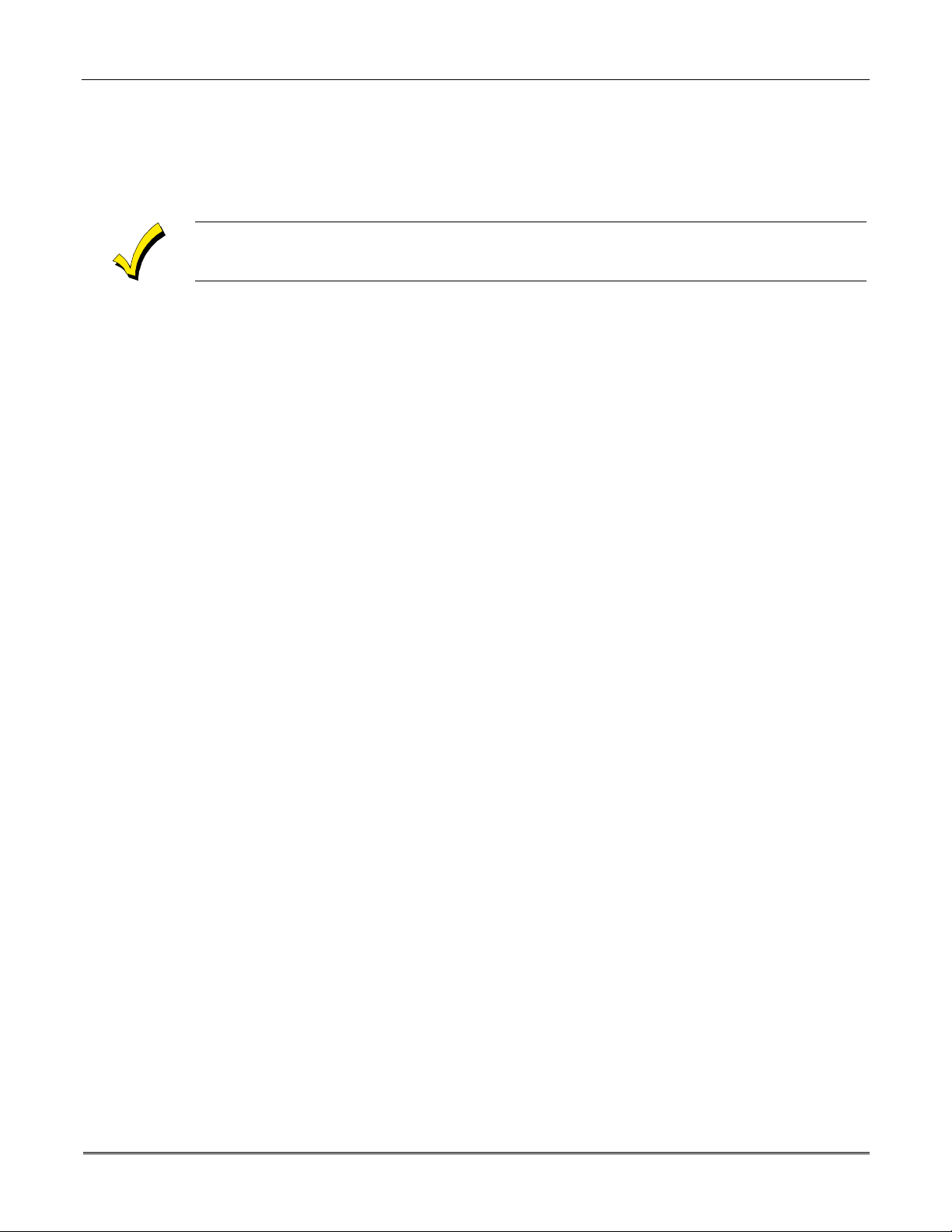

RECOMMENDATIONS FOR PROPER PROTECTION

DINING

KITCHEN

BEDROOM

BEDROOM

BEDROOM

BEDROOM

LIVING ROOM

✪

✪

✪

✪

✪

▲

▲

BEDROOM

BDRM

BDRM

DINING

LIVING ROOM

TV ROOM

KITCHEN

■

■

■

✪

✪

✪

✪✪

✪

▲

✪

✪

✪

BEDROOM

BEDROOM

TO

BR

■

■

■

■

■

LVNG RM

BASEMENT

KTCHN

▲

▲

.

CLOSED

DOOR

GARAGE

▲

Smoke Detectors for Minimum Protection

Smoke Detectors for Additional Protection

Heat-Activated Detectors

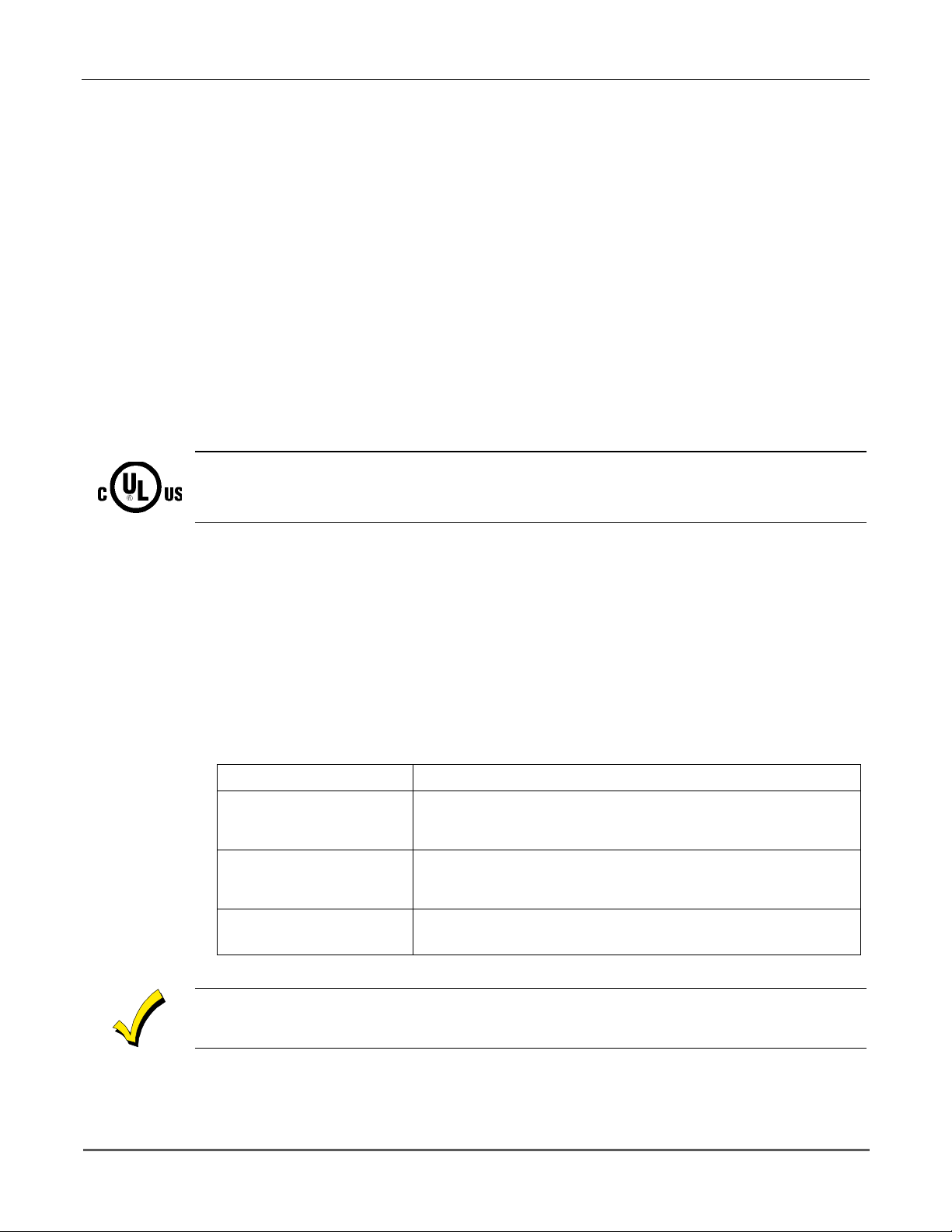

The following recommendations for the location of fire and burglary detection devices help provide

proper coverage for the protected premises.

Recommendations for Smoke and Heat Detectors

With regard to the number and placement of smoke/heat detectors, we subscribe to the

recommendations contained in the National Fire Protection Association's (NFPA) Standard #72

noted below.

Early-warning fire dete ctio n is be st achie ve d by th e in stallatio n o f f ire de te ction equ ipm en t in all

rooms and areas of the household as follows: For minimum protection, a smoke detector should

be installed outside of each separate sleeping area, and on each additional floor of a multi-floor

family living unit, includin g basements. The installation of sm oke detectors in kitc hens, attics

(finished or unfinished), or in garages is not normally recommended.

For maximum protection, the NFPA recommends that you install heat or smoke detector s in

the living room, dining room, bedroom(s), kitchen, hallway(s), attic, furnace room, utility and

storage rooms, basements and attached garages.

In addition, we recommend the following:

• Install a smoke detector inside every bedroom where a smoker sleeps.

• Install a smoke detector inside every bedroom where someone sleeps with the door partly or

completely closed. Smoke could be blocked by the closed door. Also, an alarm in the hallway

outside may not wake up the sleeper if the door is closed.

• Install a smoke detector inside bedrooms where electrical appliances (such as portable

heaters, air conditioners, or humidifiers) are used.

• Install a smoke detector at bo th ends of a hallway if the hallway is more than 40 feet (12

meters) long.

• Install smoke detectors in any room where an alarm control is located, or in any room where

alarm control connections to an AC source or phone lines are made. If detectors are not so

located, a fire within the room could prevent the control from reporting a fire or an

intrusion.

THIS CONTROL COMPLIES WITH NFPA REQUIREMENTS FOR

TEMPORAL PULSE SOUNDING FOR FIRE NOTIFICATION APPLIANCES.

Recommendations for Proper Intrusion Protection

For proper intrusion coverage, sensors should be located at every possible point of entry to a home or

commercial premises. This would include any skylights that may be present, and the upper windows

in a multi-level building.

In addition, we recommend th at radio backup be u sed in a security system so that alarm sig nals can

still be sent to the alarm monitorin g station in the event that the teleph one lines are out of order

(alarm signals are normally sent over the phone lines, if connected to an alarm monitoring station).

ii

Table of Contents

••••••••••••••••••••••••••••••••••••••••••••••••••

SECTION 1. Introduction............................................................................................................................1–1

Description........................................................................................................................................................1-1

Features.............................................................................................................................................................1-1

SECTION 2. Installing the Control...........................................................................................................2–1

Mounting the Cabinet ......................................................................................................................................2-1

Installing the Lock (if used) .............................................................................................................................2-1

Mounting the Control's Circuit Board Alone in the Cabinet.........................................................................2-2

Mounting the Control and RF Receiver Circuit Boards Together.................................................................2-2

Standard Phone Line Connections ..................................................................................................................2-3

SECTION 3. Installing Remote Keypads .................................................................................................3–1

Keypads That May Be Used.............................................................................................................................3-1

Wiring to the Keypads......................................................................................................................................3-1

Mounting the Keypads .....................................................................................................................................3-2

Supplementary Power for Additional Keypads ..............................................................................................3-2

Preliminary Checkout Procedure ....................................................................................................................3-3

SECTION 4. Basic Hardwired Zones 1–6 .................................................................................................4–1

Installing the Hardwired Zones.......................................................................................................................4-1

Programming Hardwired Zones ......................................................................................................................4-2

SECTION 5. Wireless Expansion (5800 System) ....................................................................................5–1

About Wireless Expansion ...............................................................................................................................5-1

Installing the 5881/5882 Receiver ...................................................................................................................5-2

Installing the 5800TM Module ........................................................................................................................5-3

About Jam Detection and Reporting ...............................................................................................................5-3

5800 Series Transmitters.................................................................................................................................5-3

Installing 5800 Series Transmitters................................................................................................................5-6

SECTION 6. Relay Output Devices...........................................................................................................6–1

Relay Device Basics..........................................................................................................................................6-1

4204 Relay Modules..........................................................................................................................................6-1

Programming Options ......................................................................................................................................6-2

SECTION 7. 4285 and 4286 VIP Module...................................................................................................7–1

Installing the (Voice Interactive Phone) Module............................................................................................7-1

Programming the Control for Phone Access...................................................................................................7-4

Checking the Operation of the VIP Module....................................................................................................7-4

SECTION 8. External Sounders.................................................................................................................8–1

Compatible Sounders.......................................................................................................................................8–1

Sounder Connections and Power ....................................................................................................................8–2

SECTION 9. Long-Range Radio.................................................................................................................9–1

About Long-Range Radio..................................................................................................................................9-1

Programming for Long-Range Radio...............................................................................................................9-1

Dynamic Signaling Feature .............................................................................................................................9-2

SECTION 10. Audio Alarm Verification (AAV) Unit.............................................................................10–1

About Audio Alarm Verification ....................................................................................................................10-1

iii

SECTION 11. Final Power-Up ....................................................................................................................11–1

Earth Ground Connections ............................................................................................................................11-1

Wiring the AC Transformer...........................................................................................................................11-1

AC Power-Up ..................................................................................................................................................11-2

Calculating the Battery Size Needed ............................................................................................................11-2

Connecting the Backup Battery.....................................................................................................................11-3

SECTION 12. Mechanics of Programming..............................................................................................12–1

About Programming .......................................................................................................................................12-1

Entering the Program Mode ..........................................................................................................................12-1

SECTION 13. Zone Response Type Definitions .....................................................................................13–1

Zone Type Definitions.....................................................................................................................................13-1

SECTION 14. Data Field Descriptions ......................................................................................................14-1

Descriptions of System Data Fields...............................................................................................................14-1

SECTION 15. Zone Programming..............................................................................................................15–1

About Zone Programming .............................................................................................................................15–1

SECTION 16. Output Device Programming............................................................................................16–1

Programming Options Defined .....................................................................................................................16–1

Programming Output Relays........................................................................................................................16–3

SECTION 17. Zone Lists .............................................................................................................................17–1

SECTION 18. Alpha Descriptor Programming ......................................................................................18–1

About Alpha Descriptor Programming..........................................................................................................18-1

Zone Descriptors.............................................................................................................................................18-1

SECTION 19. Remote Programming and Control (Downloading)....................................................1 9–1

SECTION 20. System Communication .....................................................................................................20–1

Panel Communication with Central Station.................................................................................................20-1

Report Code Formats......................................................................................................................................20-1

Table of Contact ID Event Codes...................................................................................................................20-2

SECTION 21. System Operation ................................................................................................................21–1

Security Codes ................................................................................................................................................21-1

Keypad Functions...........................................................................................................................................21-2

Trouble Conditions .........................................................................................................................................21-4

SECTION 22. Testing the System ...............................................................................................................22-1

Test Procedure ................................................................................................................................................22-1

SECTION 23. Specifications & Accessories ............................................................................................23–1

Specifications ..................................................................................................................................................23-1

Accessories (Compatible Devices)..................................................................................................................23-2

APPENDIX A REGULATORY AGENCY STATEMENTS .........................................................................A-1

APPENDIX B Limitations and Warranties................................................................................................B-1

Programming Form .....................................................................................................................................Insert

iv

SECTION 1

Introduction

••••••••••••••••••••••••••••••••••••••••••••••••••

In This Section

Description

♦

••••••••••••••••••••••••••••••••••••••••••••••••••

Features

♦

Description

The VISTA–10SE is a control that supports up to 22 hardwired and wireless zones, plus

remote keypads.

Features

Basic Hardwired Zones

Provides 6 basic hardwired zones having the following characteristics:

•

Zones 1-6 response time is 300–500 milliseconds.

•

Zone 3 programmable fast response time is 10–15 milliseconds.

•

EOLR supervision supporting N.O. or N.C. sensors

•

Zone 5 supports as many 4-wire smoke or heat detectors as can be powered from the

control).

•

Zones 7, 95, and 96 are keypad Panics.

•

Zone 8 is Duress.

•

Zone 9 is Tamper.

Optional Expansion Zones

Wireless Expansion:

•

Supports up to 16 wireless zones.

•

Requires the use of a 5881 (5882 in Canada) type RF receiver (with 5800 Series wireless

transmitters), as shown below.

Receiver Model No. of Zones

5881L (5882L*) Up to 8 5800

5881M (5881M*) Up to 16 5800

5881H (5882H*) Up to 16 5800

*

Used in Canada.

Remote Keypads

Up to 4 of any of the following keypads may be used:

Fixed-Word Keypads:

*

This keypad cannot be used if a 4285/4286 VIP Module is being used.

6127*, 6128, and 6137.

Transmitter Type

Alpha Keypads

When programming from a keypad, a 6139 2-line alpha keypad must be connec ted (but need

not stay in the system).

6139 (2-line alphanumeric display).

6138 (1-line alphanumeric display).

1–1

VISTA-10SE Installation and Setup Guide

Security Codes

• One Master code for entire system (User 2). Installer code is User 1.

• 4 secondary user codes (Users 3–6).

• One duress code (User 8).

Duress Code:

An emergency code that, when used to disarm or arm the system, will send a

silent duress message to the central station

Keypad Panic Keys

•

Up to 3 programmable panic key functions are provided.

•

Designated as Zones 7, 95, 96.

•

Activated by wired and wireless keypads.

•

Reported separately.

Paging Feature

If the paging feature has been programmed for your system, your pager will respond to

certain conditions as they occur in your system, and display code numbers indicating the type

of condition that has occurred.

Quick Arm Feature

“Quick Arm” may be programmed, allowing use of the [#] key in place of the security code for

arming (Quick Arm will not work unless the Master code has been programmed into the

system).

Optional Bell Supervision

This is a hardware-enabled option, achieved by cutting a red jumper on the PC board. If the

“Alarm Output” loop connected to an external sounder is then opened or shorted, a “bell

trouble” message will be displayed at the touchpads, accompanied by a trouble sound. A

trouble report will also be sent to the central station.

.

1-2

Optional RF Jam Detection for 5800 Wireless Systems

If RF jam detection is programmed for a 5800 RF system, the RF receiver will detect a

condition that may impede proper RF reception (i.e., jamming or other RF interference). Such

a condition will produce a message display, and a report will be sent to the central

monitoring station (if trouble reporting is enabled).

Optional Output Relays

•

Up to 4 relays using one 4204 Relay Module.

•

Actions programmable to respond to zone activity or manual keypad ent ries.

Optional VIP Module

•

Supports the ADEMCO 4285/4286 VIP Module.

•

Provides access to t he system via on-premises or off-premises phones for arming,

disarming, etc., plus control of relay outputs.

Optional Long-Range Radio

Allows all messages that have been programmed to go to the primary telephone number to be

reported additionally to a 7720 PLUS or 7820 radio.

Alarm Output

•

Provides a 12VDC, 2 AMP output that can drive the compatible sounders listed in the

EXTERNAL SOUNDERS section (assumes a fully charged battery is connected).

•

Steady output for burglary/panic, or temporal pulse sounding output for fire notification,

as required by UL.

•

Uses current-limiting circuitry for protection.

Auxiliary Power Output

•

Provides 12VDC, 500mA maximum. Uses current limiting circuitry for protection.

•

This output interrupts for smoke detector reset if 4-wire smoke detectors are used.

Programming

•

Programmed options are stored in electrically erasable, nonvolatile EEPROM memory

(information can be reprogrammed at any time and will not be lost in the event of a power

loss).

•

The system can be uploaded, downloaded, or controlled via an IBM-compatible computer,

using ADEMCO's Compass Windows downloading software, and a modem specified by

ADEMCO.

Keypad programming consists of:

•

Data field programming.

•

Interactive (menu) mode programming.

Section 1 - Introduction

For programming from a keypad, a 6139 2-line alpha key pad must be c onnected (but need not

stay in the system).

Communication Formats Supported

•

ADEMCO Low Speed (Standard or Expanded)

•

Sescoa/Radionics (Standard or Expanded)

•

ADEMCO Express

•

ADEMCO Contact ID

Zone Descriptors

You can assign alpha descriptors to all zones (useful only when using alpha keypads and/or

the 4285/4286 VIP Module).

AC Power Supply

Uses No. 1321, 120VAC plug-in transformer with 16.5VAC 25VA output (1321CN in

Canada).

Backup Battery

Rechargeable (Sealed Lead Acid) 12VDC, 4AH minimum.

1-3

VISTA-10SE Installation and Setup Guide

1-4

SECTION 2

Installing the Control

••••••••••••••••••••••••••••••••••••••••••••••••••

In This Section

Mounting the Control and RF Receiver Circuit

Mounting the Cabinet

♦

Installing the Lock

♦

Mounting the Control's Circuit Board Alone in

♦

the Cabinet

••••••••••••••••••••••••••••••••••••••••••••••••••

Mounting the Cabinet

Mount the control cabinet to a sturdy wall using fasteners or anchors (not supplied), in a

clean, dry area that is not readily accessible to the general public. Four mounting holes are

provided at the back of the cabinet for this purpose.

If an RF receiver is being used and you intend to mount its PC board within the cabinet, note

the following:

•

Do not mount the cabinet on or near metal objects. This will decrease RF range and/or

block RF transmissions from wireless transmitters.

♦

Board in the Cabinet

Standard Phone Line Connections

♦

•

Do not locate the cabinet in an area of high RF interference (revealed by frequent or pro-

longed lighting of the LED in the receiver after it is operational). Random flicker is OK.

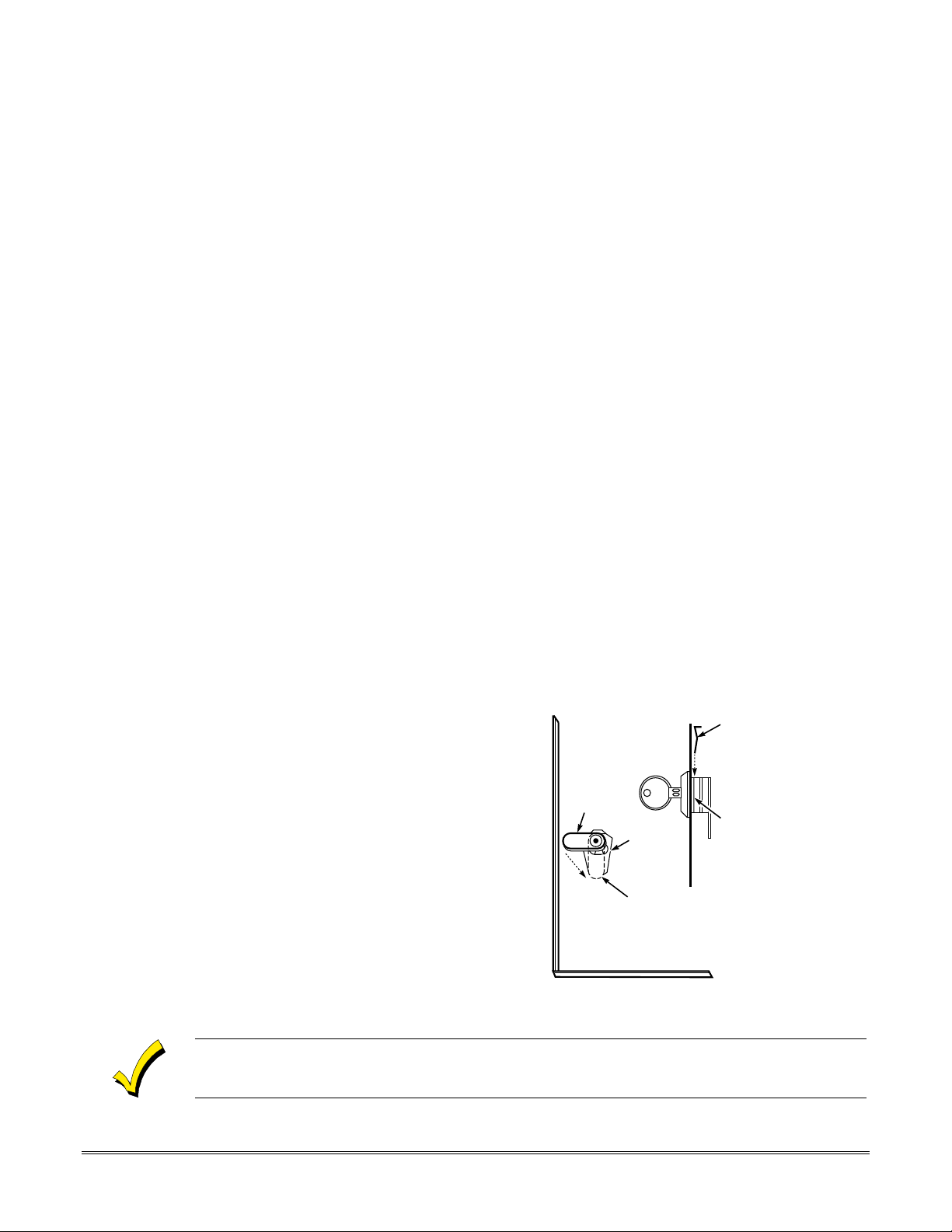

Installing the Lock

Use an ADEMCO No. N6277 Cam Lock and No. N6277–1 Push-On Clip (Retainer Clip).

NOTE:The cabinet can be closed and secured

1. Remove the cabinet door.

removable for servicing and is easily

re-installed.

2. Remove the lock knockout from the

control cabinet door. Insert the key

into the lock. Position the loc k in the

hole, making certain that the latch

will make contact with the latch

bracket when the door is closed.

3. Hold the lo ck steady, and insert the

retainer clip into the retainer slots.

Position the clip as illustrated in

order to permit easy removal.

edge.

It is easily

without

a lock by using 2 screws in the cover's

LOCKED

RETAINER

CLIP

UNLOCKED

CABINET DOOR BOTTOM

Figure 1. Installing the Lock

RETAINER CLIP

(NOTE POSITION)

RETAINER

SLOTS

V10SE-002-V0

Before installing the cabinet's contents, remove the metal c abinet knockouts required for wiring

entry. Do not attempt to remove the knockouts after the circuit board has been installed.

2–1

VISTA-10SE Installation and Setup Guide

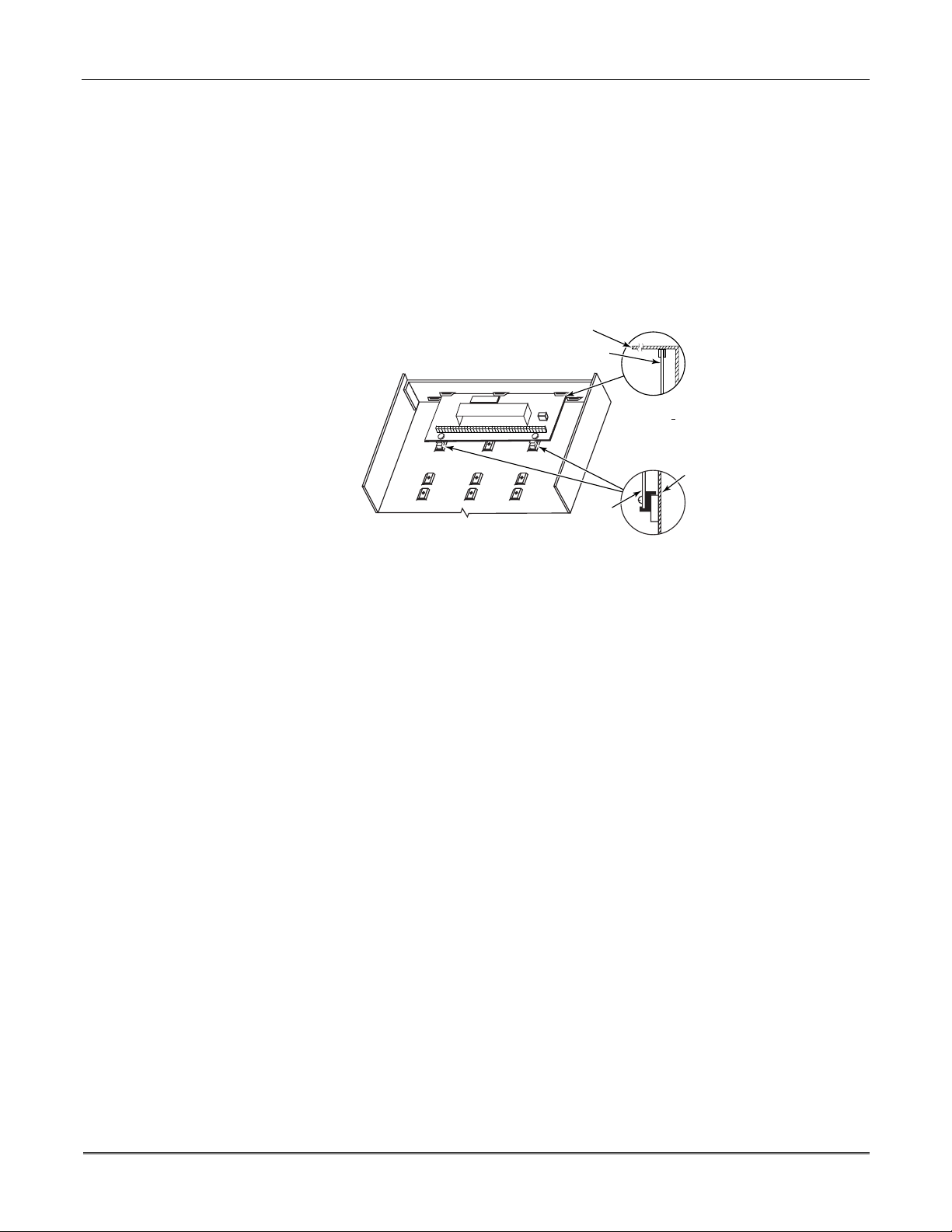

Mounting the Control's Circuit Board Alone in the Cabinet

To mount the circuit board alone in the cabinet, follow these steps:

1. Hang two mounting clips* (provided ) on the raised cabinet tabs (see Detail B in Figure 2

below).

2. Insert the top of the circuit board between the rows of slots at the top of the cabinet as

shown in Detail A.

3. Position the base of the board onto the mounting clips and secure both to the cabinet with

the supplied screws (see Detail B).

*

These mounting clips are also used for mounting the same end of the circuit board when an RF

receiver is mounted above it, as in Figure 3.

CABINET

CIRCUIT BOARD

+

+

CIRCUIT

BOARD

DETAIL A

SIDE VIEW

OF BOARD

SUPPORTING

SLOTS

CABINET

DETAIL B

SIDE VIEW

OF MOUNTING

CLIPS

Figure 2. Mounting the Control's Circuit Board Alone in the Cabinet

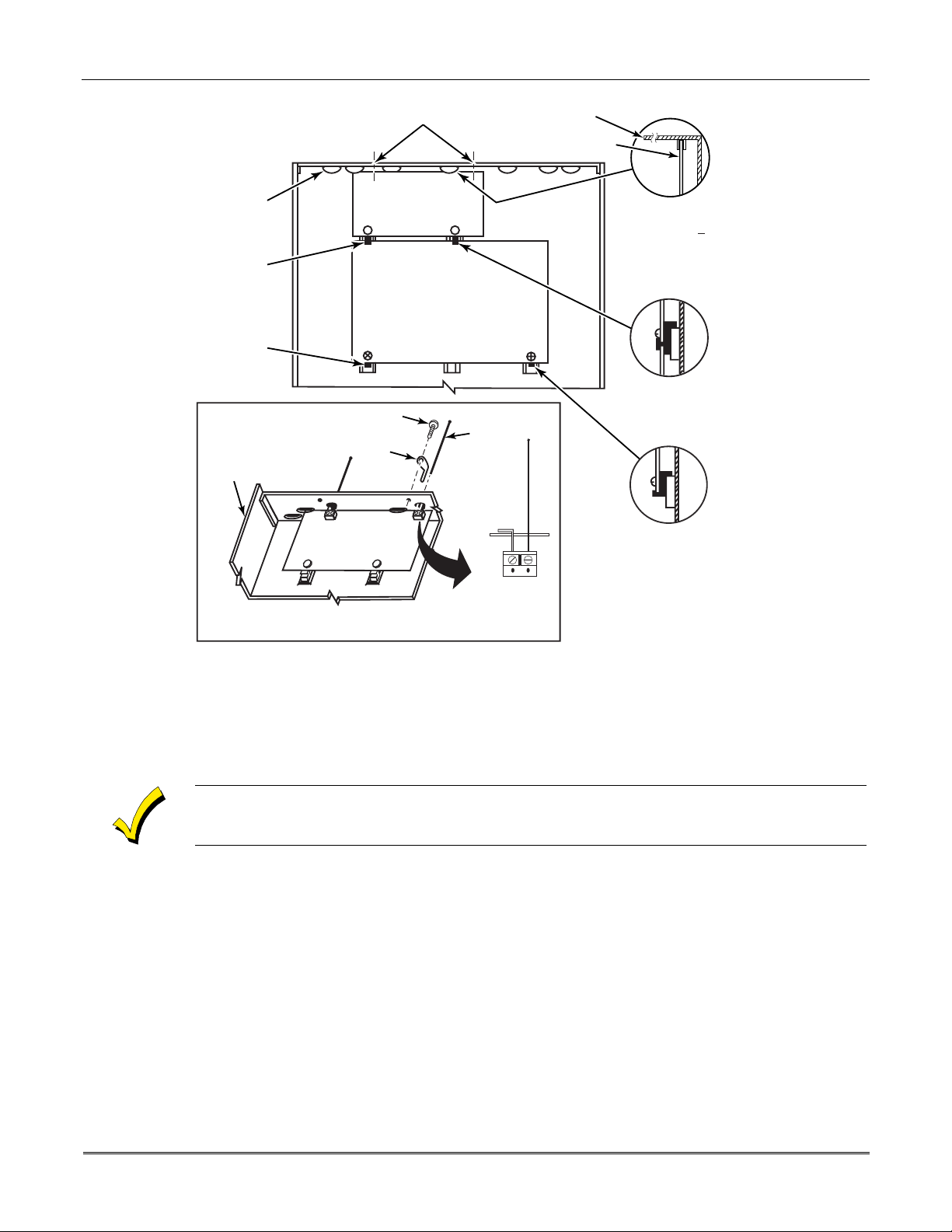

Mounting the Control and RF Receiver Circuit Board in the Cabinet

To mount the control and RF receiver boards together in the cabinet, do the following:

1. Hang two mountin g clips (p rovid ed with receiv er) o n the raise d cabine t tabs, as shown in

Detail B in Figure 3.

2. Insert the top of the receiver board (removed from its own case as described in its

instructions) between the rows of slots at the top of the cabinet, as shown i n Detail A.

3. Position the base of the receiver board onto the mounting clips and secure both to the

cabinet with the supplied screws (see Detail B).

4. Hang two mounting clips (supplied with the contro l board), on the raise d cabinet tabs as

shown in Detail C in Figure 3.

5. Insert the top of the control board into the slots of the mounting clips secured in step 3

above.

6. Position the lower end of the control board into place on the mounting clips and secure

both to the cabinet with the two supplied screws.

7. Insert both grounding lugs (supplied with the receiver) through the top of the cabinet

into the left-hand terminals of the antenna blocks (located at the upper edge of the

receiver board), and secure them to the cabinet with the screws provided, as shown in

Detail D.

8. Insert the receiv er's antennas thr ough the top of the cabinet, into the bloc ks' right-hand

terminals, and tighten the screws.

Refer to setup and wiring instructions for the receiver in the WIRELESS EXPANSION (5800

RF SYSTEMS) section.

V10SE-003-V0

2-2

Section 2 - Installing the Control

BOARD

SUPPORTING

SLOTS

MOUNTING

CLIP

MOUNTING

CLIP

CABINET

HOLES FOR ANTENNAS

AND GROUNDING LUGS

RECEIVER CIRCUIT BOARD

(See Detail D)

++

CONTROL

CIRCUIT

BOARD

SCREW

(2)

GROUNDING

LUG

(2)

RCVR BRD

++

ANTENNA AND GROUNDING LUG INSTALLATION

DETAIL D

ANTENNA

(2)

CIRCUIT BOARD

ANTENNA

MOUNT

(2 PLACES)

CABINET

DETAIL A

SIDE VIEW

OF BOARD

SUPPORTING SLOTS

DETAIL B

SIDE VIEW

OF MOUNTING

CLIP

DETAIL C

SIDE VIEW

OF MOUNTING

CLIP

V10SE-004-V0

Figure 3. Mounting the PC Board and RF Receiver Together in the Cabinet

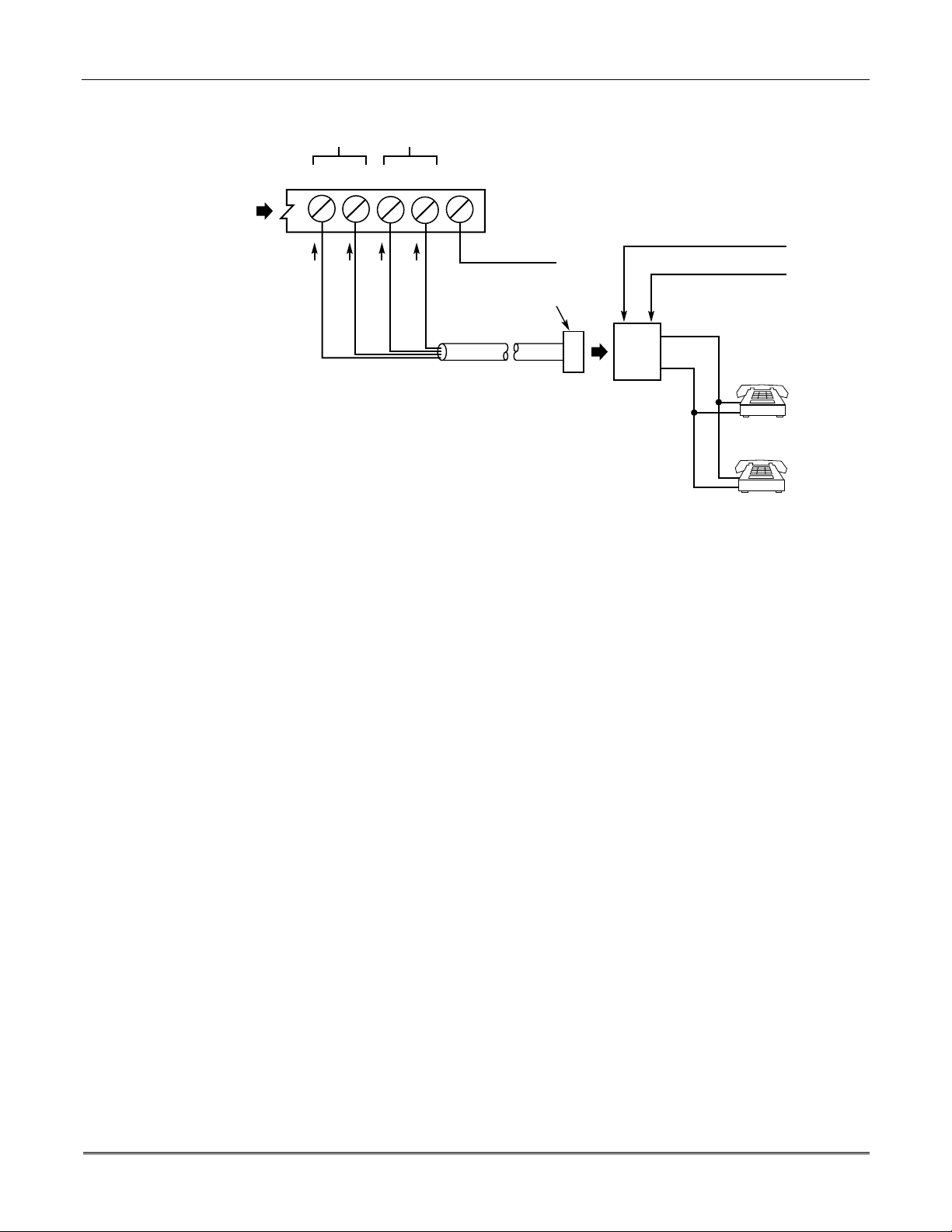

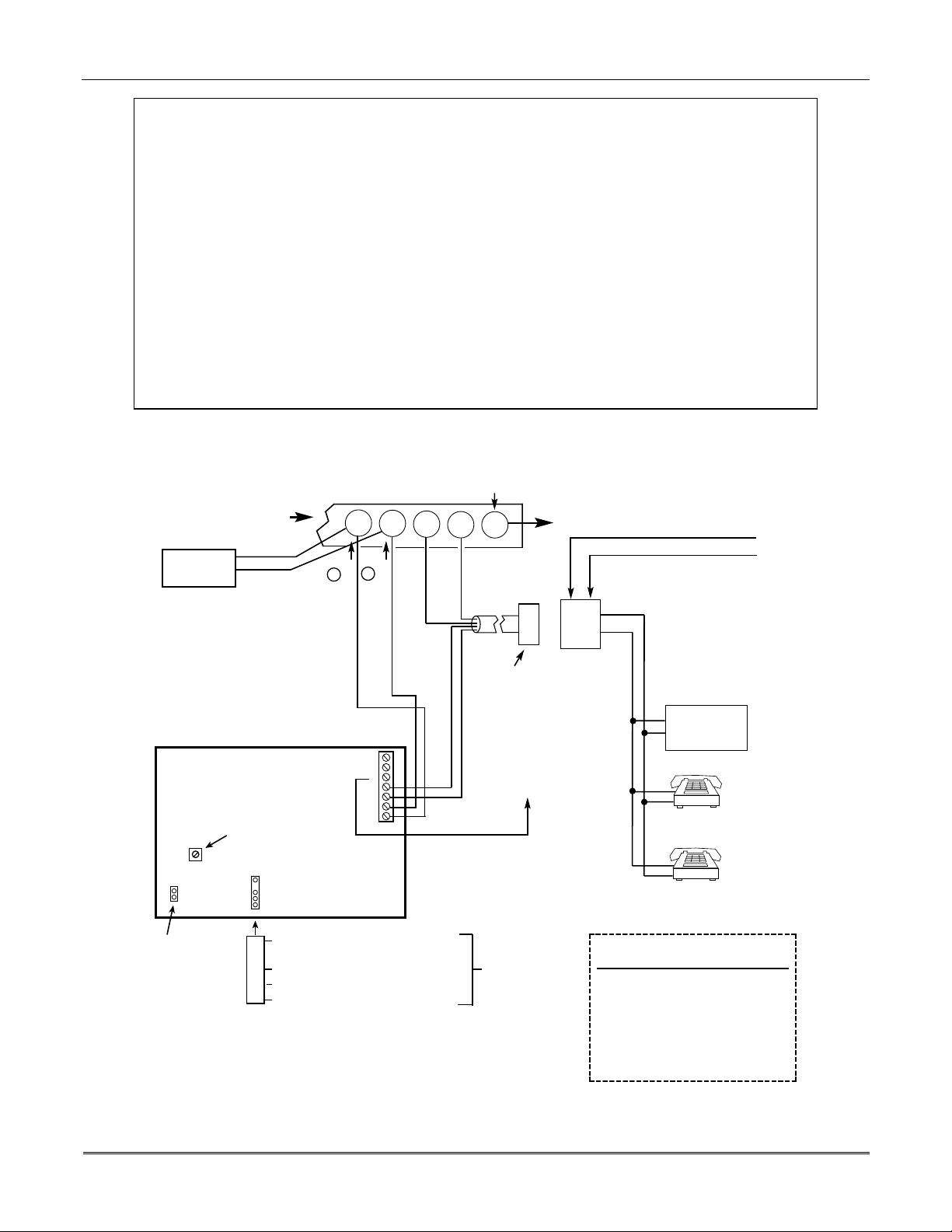

Standard Phone Line Connections

The wiring connections shown here are not applicable if a 4285/4286 VIP Module is used. Refer

to the

4285/4286 VIP MODULE

are different than those shown here.

Connect incoming phone line and handset wiring to the main terminal block via an RJ31X

jack (CA38A jack in Canada) as follows and as shown in Figure 4.

Term. 17: Local Handset (TIP – Brown*).

Term. 18: Local Handset (RING – Gray*).

Term. 19: Incoming Phone Line (TIP – Green*).

Term. 20: Incoming Phone Line (RING – Red*).

*

Colors of wires in Direct Connect Cord.

section for information regarding phone line connec tions , whic h

2-3

VISTA-10SE Installation and Setup Guide

HANDSET

17 18 19 20 21

TERMINALS

ON CONTROL

INCOMING

TELECOM

LINE

GROUND

BROWN (TIP)

GREY (RING)

GREEN (TIP)

RED (RING)

EARTH GROUND

PLUG

DIRECT

CONNECT

CORD

INCOMING TELECOM LINE

TIP

RING

RJ31X

JACK

Figure 4. Standard Telephone Line Connections

TIP

RING

PREMISES

PHONES

V10SE-024-V0

2-4

SECTION 3

Remote Keypads

••••••••••••••••••••••••••••••••••••••••••••••••••

In This Section

Keypads That May Be Used

♦

Wiring to the Keypads

♦

Mounting the Keypads

♦

••••••••••••••••••••••••••••••••••••••••••••••••••

This section lists the wired keyp ads that may be used and provides instruction s for wiring

and mounting the keypads.

A preliminary checkout procedure is also provided to ensure that the connected keypads are

functioning properly in the syst em.

Supplementary Power for Additional Keypads

♦

Preliminary Checkout Procedure

♦

Keypads That May Be Used

• Fixed-Word Display: 6127, 6128, 6137

• Alpha Display: 6138, 6139

• Up to 4 keypads, independe nt of auxiliary power con siderations (yo u may need to use an

auxiliary power supply if the 500mA aux. output is exceeded)

If you are going to use a 4285/4286 VIP Module, you MUST use addressable key pads (6128,

6137, 6138, 6139) in the system, but set to the non-addressable mode (address 31).

Wiring to the Keypads

1. Determine wire gauge by referring to the wiring length/gauge chart below.

For devices (keypads, RF receivers, etc.) connected to a single 4-wire run, determine the

current drawn by all units connected to the single wire run, then refer to the Wiring Run

chart to determine the maximum wire length that can be safely used for each wire size.

Current draw for all devices can be found in the

section.

NOTE: Refer to “Auxiliary Dev ice Current Draw Wo rksheet” in the

section for current draw for all keypads.

Maximum wire lengths for any device that is homerun to the c ontrol can also be determined

from the chart, based on the current draw of that device

SPECIFICATIONS & ACCESSORIES

FINAL POWER-UP

alone

.

3–1

VISTA-10SE Installation and Setup Guide

5

6

7

4

CONTROL

TERMINALS

BLACK

RED

GREEN

YELLOW

V10SE-026-V0

KEYPADS

KEYPAD CONNECTOR CABLE

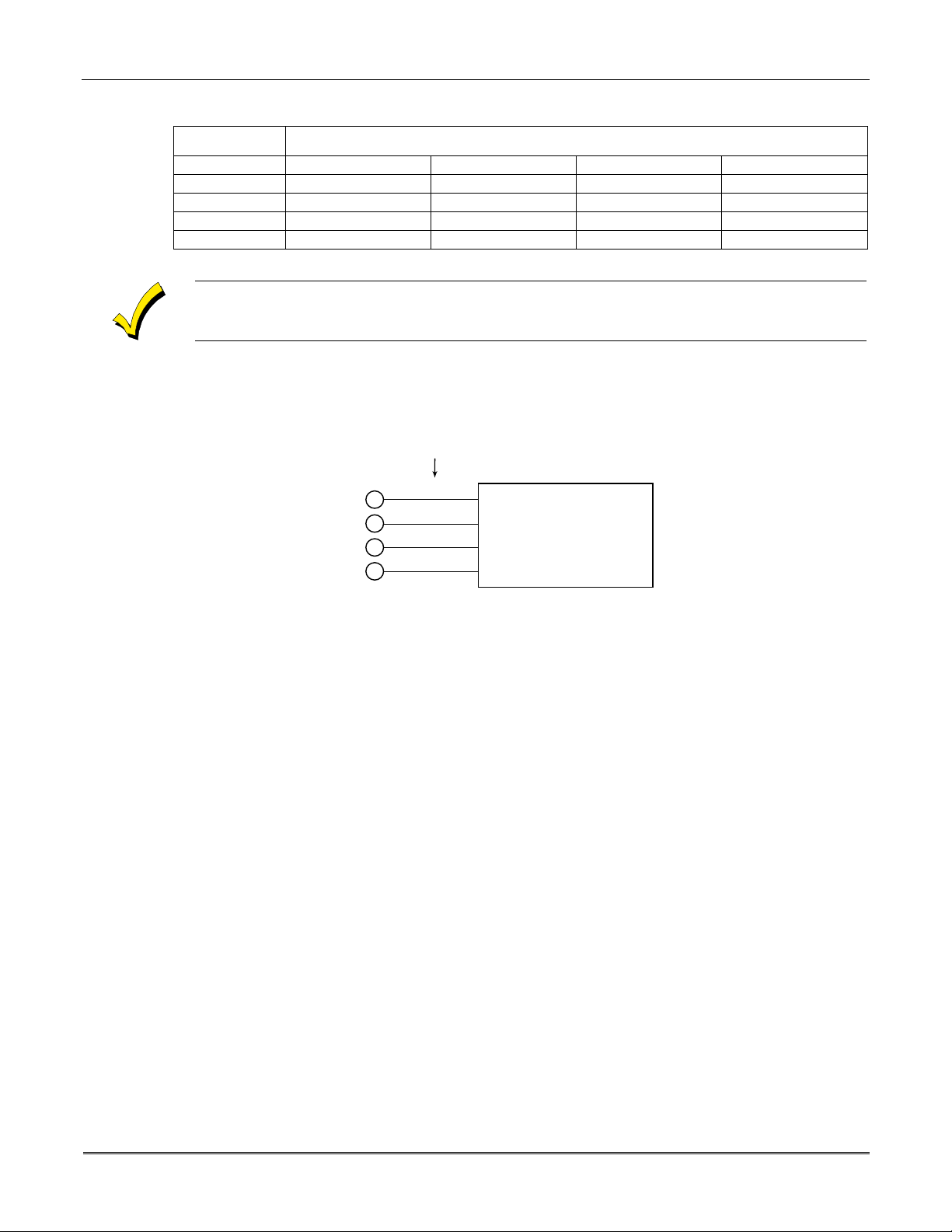

Wiring Run Chart for Devices* Drawing Aux Power From the Control (12V+ & 12V–)

TOTAL CURRENT DRAWN BY ALL DEVICES CONNECTED TO A SINGLE WIRE RUN

Wire Size 50mA or less 100mA 300mA 500mA

#22 500 ft (152m) 250 ft (76m) 80 ft (24m) 50 ft (15m)

#20 750 ft (228.6m) 380 ft (116m) 130 ft (39.6m) 80 ft (24m)

#18 1300 ft (396m) 650 ft (198m) 220 ft (67m) 130 ft (39.6m)

#16 1500 ft (457m) 1000 ft (305m) 330 ft (100.5m) 200 ft (70m)

*

Includes keypads, RF receivers, relay units, and 4285/4286 VIP Modules.

The length of all wire runs must not exceed 1500 feet ( 457m) when unshielded quad c onductor

cable is used (750 feet if shielded cable is used) . This restric tion is due to the capacitive effect

on the data lines

when quad cable is used.

2. Run field wiring from the control to the keypads (using standard 4-conductor twisted

wire cable using the wire gauge determined in step 1).

3. Connect remote keypads to terminals 4, 5, 6, and 7 on the control board, as shown in

Figure 5.

Figure 5. Keypad Connections to the Control Board

Mounting the Keypads

1.

Make sure addressable-type keypads

addressable mode (address 31), which is the factory default setting. Refer to the

instructions provided with the keypad for address setting procedure.

2.

Mount the keypads

at a height that is convenient for the user. Refer to the instructions

provided with the keypad for mounting procedure.

You can either surface mount or flush mount keypads (using an appropriate Trim Ring

Kit: 6139TRK). Refer to the mounting instructions and template included with the

keypad and/or trim ring kit for specific information.

Supplementary Power for Additional Keypads

The control provides 500mA for powering keypads (up to a maximum of 4) and o ther devices

from the auxiliary po wer output. The backup battery w ill supply power to th ese keypads in

the event that AC power is lost.

When the control’s auxiliary power load for all devices exceeds 500mA, you can power

additional keypads from a regulated, 12VDC power supply (e.g., 487-12 supplies 12V, 250mA;

488-12 supplies 12V, 500mA). Use a UL Listed, battery-backed supply for UL installations.

The 487-12/488-12 power supplies have a backup battery that can power these keypads in the

event of AC power loss.

(6128, 6137, 6138, and 6139) are set to non-

3-2

Section 3 - Installing Remote Keypads

Keypads powered from supplies that do not have a bac kup battery

will not function

when AC

power is lost. Therefore, be sure to power at least one keypad from the Control's auxiliary

power output.

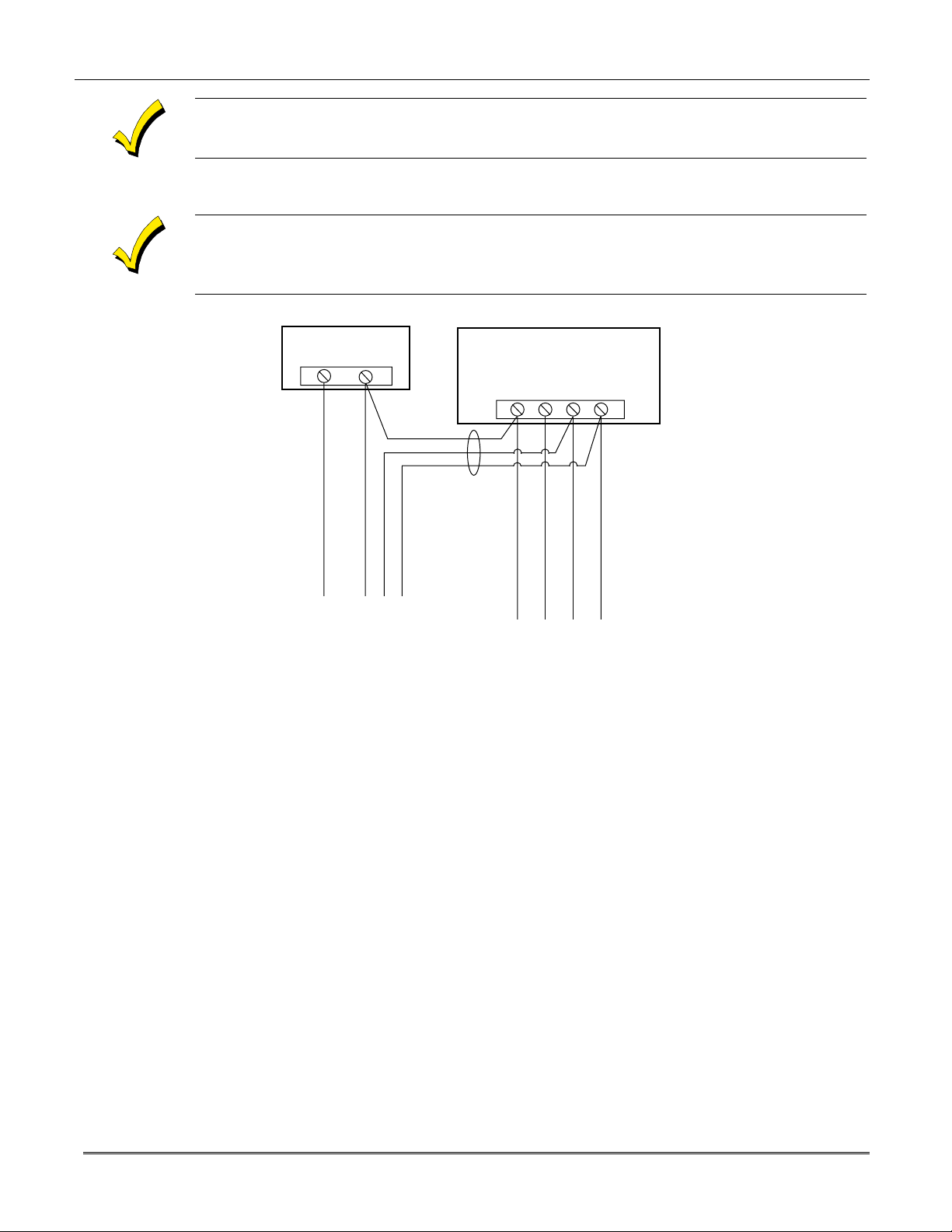

Connect the additional keypads as shown in Figure 6, using the keypad wire colors shown. Be

sure to observe the current ratings for the power supply used.

Make connections directly to the sc rew terminals as shown in

Figure 6

. Make no connection to

the keypad blue wire (if present).

Be sure to connect the negative (–) terminal on the Power Supply unit to ter minal 4 (AUX – ) on

the control.

SUPPLEMENTARY

POWER SUPPLY

+

–

TO KEYPAD RED WIRE

TO KEYPAD BLK WIRE

TO KEYPAD GRN WIRE

IMPORTANT:

MAKE THESE

CONNECTIONS

DIRECTLY TO

SCREW

TERMINALS AS

SHOWN.

TO KEYPAD YEL WIRE

CONTROL TERMINAL STRIP

AUX. DATA

AUX.

+

–

456 7

TO KEYPAD BLK WIRE

DATA

IN

OUT

TO KEYPAD RED WIRE

TO KEYPAD GRN WIRE

TO KEYPAD YEL WIRE

V10SE-008-V0

Figure 6. Using a Supplementary Power Supply for Keypads

Preliminary Checkout Procedure

If you want to check that the system is working before connecting field wiring from zones and

devices, do the following:

1. Temporarily connect a 1000 ohm end-of-line resistor across each of the basic hardwire

zones 1–6, as shown in the Summary of Connections diagram.

Without actual zone wiring or EOL resistors connected, the key pads in the system will not

display the “Ready” message.

2. Power-up the system temporar ily by plugging the AC transformer (previously wired to the

control) into a 120VAC outlet.

–

3. Busy

After approximately 1 minute*, the green READY LED (or POWER LED on some types of

keypads) should light, and the word "

"

DISARMED...READY TO ARM"

is functioning properly.

* To bypass the 1-minute delay, press # + 0.

Standby (on alpha keypads) or

dI

(on fixed-word keypads) will be displayed.

READY"

(on fixed-word keypads) or the words

(on alpha keypads) sh o uld be di splay e d, ind ica ting the sy ste m

3-3

VISTA-10SE Installation and Setup Guide

If the “Ready” message is not displayed on any of the keypads in the system, or a “Not

Ready” message is displayed, check the keypad wiring connections, and make sure each of

the 6 basic hardwired zones has a 1000 ohm resistor connected across its terminals.

Do not remove the EOL resistors until you are ready to make connections to the hardwired

zones, to allow for testing later in the manual.

If an OC or OPEN CIRCUIT display is present on the keypad, data from the control is not

reaching the keypad. Check the wiring.

3-4

SECTION 4

Basic Hardwired Zones 1–6

••••••••••••••••••••••••••••••••••••••••••••••••••

In This Section

Installing the Hardwired Zones

♦

Programming Hardwired Zones

♦

••••••••••••••••••••••••••••••••••••••••••••••••••

Installing the Hardwired Zones

Common Characteristics for Zones 1–6

•

Response time from 300 - 500 milliseconds (400 milliseconds nominal).

•

Zone 3 can be programmed (in field

(10mSec max) to an open (suitable for vibration type contacts). Default response is

400mSec nominal, which should be used for most standard contacts.

•

EOLR supervised zones support both open-circuit and closed-circuit devices.

•

As many 4-wire smoke detectors as can be powered from Aux Power on the control (on

zone 5).

52) for normally-closed sensor fast response

✱

U

L

Wiring Burglary and Panic Devices to Zones 1–6

Wiring 4-Wire Smoke/Combustion Detectors on Zone 5

4-Wire Smoke/Combustion detectors are

To wire burglary and panic devices to zones 1-6, perform the following steps, referring to

Figure 17. VISTA-10SE Summary of Connections

1. Connect sensors/contacts to the hardwired zone terminals (8 through 16). See the

Summary of Connections diagram.

2. Connect closed circuit devices in series i n the high (+) side of the loop. The EOL resistor

must be connected in series with the devices, following the last device. See the Summary

of Connections diagram.

3. Connect open circuit devices in parallel across the loop. The 1000 ohm EOLR must be

connected across the loop wires

If the EOLR is not at the end of the loop, the zone will not be properly supervised, and the

system may not respond to an open circuit on the zone.

The system will support as man y 4-wire detectors as can be pow ered from Auxiliary Po wer

on the control on zone 5. Refer to the detector’s instructions for complete d etails re g arding its

proper installation a nd operation.

1. Co nnect 12-volt power for th e detectors from Auxiliary Power terminals 4 and 5 (which

will interrupt power for fire alarm reset). Observe proper polarity when connecting

detectors. See

2. Connect detectors (including heat detectors, if used) across terminals of zone 5. All

detectors must be wired in parallel.

Figure 7

.

not

at the last device.

permitted in UL installations.

on the inside back cover of this manual.

Remove 1000 ohm EOL resistor if connected across the zone terminals. You mus t connect the

EOL resistor across the loop wires at the last detector.

4–1

VISTA-10SE Installation and Setup Guide

3. To meet NFPA 72 requirements, you must use a supervisory module to supervise power

(e.g., System Sensor No. A77-716B Relay module).

5

AUX PWR

OUTPUT

TERMINALS

+

_

4

+

TO HI SIDE OF

ZONE 5

TO LO SIDE

+

HEAT

DETECTOR

_

Figure 7. 4-wire Smoke Detector Connections (Zone 5)

4-WIRE SMOKE

OR COMBUSTION

DETECTORS

_

DETECTOR

HEAT

BLK

+

_

_

VIOLET

1000

OHMS

EOLR

+

RED

EOL

POWER

SUPERVISION

RELAY MODULE

A77-716B

V10SE-010-V0

Compatible System Sensor 4-Wire Smoke/Combustion Detectors

1412

2412

2412TH

A77–716B

2112/24T

4-wire ionization products of combustion detector

4-wire photoelectric smoke detector

4-wire photoelectric smoke detector w/135°F (57°C) heat detector

EOL relay module (supervisory module for wired 4-wire fire zone)

Low-profile 4-wire photoelectric smoke detector w/135°F (57°C) heat

detector

Programming Hardwired Zones

Each zone must be programmed into the system using the ✱56 Zone Programming Mode or

✱

58 Expert Programming Mode, which assigns characteristics that define the way the system

responds to faults on that zone. Refer to the ZONE RESPONSE TYPE DEFINITIONS and

ZONE PROGRAMMING sections for specific instructions on programming hardwired zones.

4-2

SECTION 5

Wireless Expansion

••••••••••••••••••••••••••••••••••••••••••••••••••

(5800 System)

In This Section

About Wireless Expansion

♦

Installing the 5881/5882 Receiver

♦

Installing the 5800TM Module

♦

••••••••••••••••••••••••••••••••••••••••••••••••••

About Jam Detection and Reporting

♦

5800 Series Transmitters

♦

Installing 5800 Series Transmitters

♦

About Wireless Expansion

The VISTA-10SE supports up to 16 wireless zones that may be used exclusively or in

addition to hardwired zones 1 through 6.

The receiver detects signals from

The following 5881 Receivers may be used with this system (5882 in Canada), and each

supports the number of zones shown:

RF Receiver No. of Zones

5881L/5882L up to 8

5881M/5882M up to 16

5881H/5882H up to 16

wireless transmitters

within a nominal range of 200 feet.

U

L

Receiver Supervision

House Identification

Wireless may not be used in UL Commercial Burglary installations.

In Canada

Series of receivers applies as well to the 5882 Series. 5881 and 5882 Series receivers can

support the same 5800 type transmitters.

Any zone

with the number of zones that can be used, which is shown in table above).

The receiver is supervised. The following conditions cause a Trouble report to be generated

and CHECK and ZONE 09 messages to be displayed:

•

Communication between the panel and the receiver is interrupted.

or

No

•

If you are using a 5804BD, 5827, or 5827BD Wireless Keypad with the system, you must

program a House ID Code (01-31) in field

must be set to the same ID.

12 hours.

valid

, 5800 systems must use 5882 Series receivers. Information relative to the 5881

number

from 10–25 can be used as a 5800 Series wireless zone (do not confuse this

RF signals from at least one supervised wireless transmitter are received within

✱

24 to establis h proper communication. The keypad

House ID 00 disables all wireless keypads.

5–1

VISTA-10SE Installation and Setup Guide

Installing the 5881/5882 Receiver

RF System Installation Advisories

Follow the guidelines below when installing the RF receiver. (Disregard if the receiver is

mounted in the control cabinet.)

Installation and Setup of the 5881/5882 Receiver

ON OFF

5

4

3

2

1

Place the

•

Do not locate the receiver or transmitters on or near metal objects. This decreases range

•

RF receiver

in a high, centrally located area for best reception.

and/or block transmissions.

Do not locate the receiver in an area of high

•

interference (revealed by frequent or

RF

prolonged lighting of the LED in the receiver; random flicker is OK).

The RF receiver must be at least 10 feet from any remote keypads to avoid interference

•

from the microprocessors in those units.

To install the recei ver, take the following steps (refer to

1. Set the receiver's

< <

switches shown at l eft are in the OFF posit ion).

DIP switch

for device address 0, as described in its instructions (all

Figure 8

below):

2. Mount the receiver. The RF receiver can detect signals from transmitters within a

nominal range of 200

feet

. Take this into consideration when determining mounting

location.

3. Connect the

receiver's

wire harness to the control's keypad terminals (4, 5, 6, and 7). Plug

the connector at the other end of the harness into the receiver.

4. Refer to the

installation

instructions provided with the receiver for further installati on

procedures regarding antenna mounting, etc.

MOUNTING

HOLES

CIRCUIT

BOARD

ANTENNAS

INSERT IN

RIGHT-HAND

TERMINALS

DIP SWITCH

DIP SWITCH #5 (PRESET ONLY ON 5881EH)

ON: SETS 5881EH FOR USE IN COMMERCIAL

FIRE APPLICATIONS (SEE THE RECEIVER'S

INSTRUCTIONS)*.

OFF: USE IN NON-COMMERCIAL FIRE

INSTALLATIONS.

* FOR COMMERCIAL FIRE APPLICATIONS

THE 5881EH PC BOARD MUST BE MOUNTED

IN A SEPARATE CABINET (SEE RECEIVER'S

INSTRUCTIONS FOR DETAILS).

INTERFERENCE

INDICATOR LED

PLUG & SOCKET

YELLOW

RED

BLACK

GREEN

WIRING

OPENING

TO CONTROL'S REMOTE KEYPAD

CONNECTION POINTS. EACH RECEIVER

MUST BE ON INDIVIDUAL HOME RUN.

USE MAX. of 220 ft. [67m of #22 (0.64mm)

WIRE or 550 ft. (168m) of #18 (1mm) WIRE

FOR EACH RUN]. OBSERVE 20 ft. MAX.

FOR COMMERCIAL FIRE INSTALLATIONS.

(SEE RECEIVER'S INSTRUCTIONS.)

DIP SWITCH WHITE AREAS = SWITCH

HANDLES. POSITIONS 2-4 DETERMINE

RECEIVER'S ADDRESS. CONSULT

CONTROL'S INSTRUCTIONS FOR

ADDRESS TO USE. DIP SWITCH BELOW

SHOWN SET FOR ADDRESS "0."

SWITCH

POSITION

Figure 8. 5881/5882 RF Receiver (cover removed)

RECEIVER ADDRESS SETTINGS

(" - " MEANS OFF)

0 1 2 3 4 5 6 7

PRESENT ONLY ON 5881EH (SEE TEXT AT LEFT)

5

4

3

2

1

ON ON ON

ON

ONON

FOR FUTURE USE

ONON

ONON ONON

5-2

Installing the 5800TM Module

Installation of this module is necessary only if you are using one or more 5827BD Wireless

Bi-directional keypads, 5804 or 5804BD Transmitters (wireless keys).

Mounting the 5800TM Module

The 5800TM must be located next to the RF receiver (between one and two feet from the

receiver’s antennas). The 5800TM must not be installed within the control cabinet. Mount

the unit using its accompanying mounting bracket.

Wiring the 5800TM Module

Connect the 5800TM to the control panel’s keypad connection terminals, using the supplied

connector with flying leads, as follows:

Wire Terminal on Control

BLACK (Ground) Terminal 4

RED (+12VDC) Terminal 5

GREEN (Data to Control) Terminal 6

YELLOW (Data from Control) Terminal 7

BLUE Not Used

Do not cut any of the jumpers on the 5800TM when using it with the VISTA-10SE.

For additional information, refer to the 5800TM’s instructions.

Section 5 - Wireless Expansion

About Jam Detection and Reporting

When field ✱22, option 4 (RF SYSTEM) is selected, a 5800 Series receiver detecting a jam

condition sends an E344 (RF Receiver Jam Detect) Contact ID report to the central station.

At the same time, a Rcvr Jam (on alpha keypads) or CHECK 90 (on fixed-word keypads)

message alternates with the present system message on the keypad. When the jam condition

is cleared, a Restore message is sent to the CS. Entering a code and OFF restores the

keypad display.

The default for this option is 0 (disabled).

Normal use of a 5827 wireless keypad may cause a false RF jam message to be displayed in

systems that have been programmed for RF Jam Detection.

5800 Series Transmitters

Programming Wireless Zones

5800 Series transmitters have built-in serial numbers that must be enrolled” into the system

✱

using the

the control via the downloader. 5800 Series transmitters (except 5827, described separately)

do not have DIP switches.

Program each transmitter's zone number into the system using

Zone Programming section). Some transmitters, such as the 5816 and 5817, can support

more than one “zone” (referred to as loops or inputs). On the 5816, for example, the wire

connection terminal block is loop 1, the reed contact is loop 2. Each loop must be assigned a

different zone number.

56 or ✱58 programming modes in the ZONE PROGRAMMING section, or input to

✱

56 or ✱58 mode (refer to the

U

L

The 5816 and 5817 transmitters do not have EOL supervision of their loop wiring. Therefore, for

UL Household Burglary installations, the loop wiring may not exceed 3 feet.

5-3

VISTA-10SE Installation and Setup Guide

For button transmitters (RF keys), such as the 5801, 5804, and 5804BD, you must assign a

unique zone number to each individual button used on the transmitter. Each button on the

transmitter also has a pre-designated loop or input number, which is automatically displayed

on the keypad.

Programming an RF House ID

Programming an RF House ID (01–31) in field

5827BD Wireless Keypads or 5804BD Transmitters. An RF House ID is not necessary for

other 5800 Series Transmitters, and the entry should be left at 00 (default) in those cases.

The 5827 reports low-battery status as zone 00.

Transmitter Supervision

Except for some transmitters that may be carried off-premises (5802, 5802CP, 5803, 5804,

5804BD, 5827, and 5827BD), each transmitter is supervised by a check-in signal that is sent

to the receiver at 70-90 minute intervals. If at least one check-in is not received from each

supervised transmitter within a 12-hour period, the “missing” transmitter number(s) and the

message CHECK is displayed.

In accordance with ULC standards, the RF supervision period for the VISTA-10SE is three hours

for fire zones (Zone Type 9) and 12 hours for all other zone types.

✱

24 is necessary only if you are using 5827 or

The supervision for a particular transmitter in the system that may also be carried off the

premises (5801, 5802MN) may be turned off by enrolling it as a “UR” (unsupervised RF) type,

as described later.

5800 Series transmitters have built-in tamper protection and annunciate as a Check

condition if covers are removed.

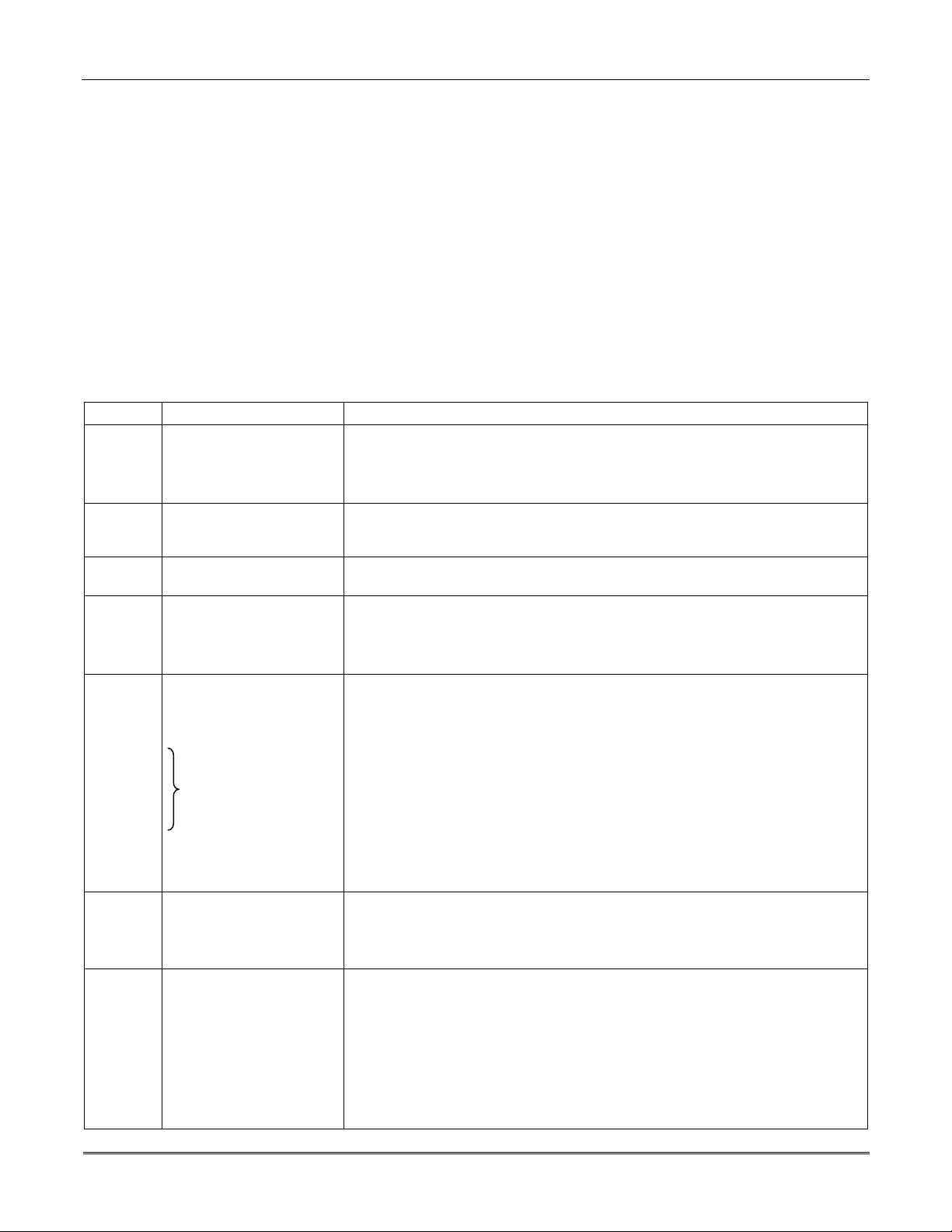

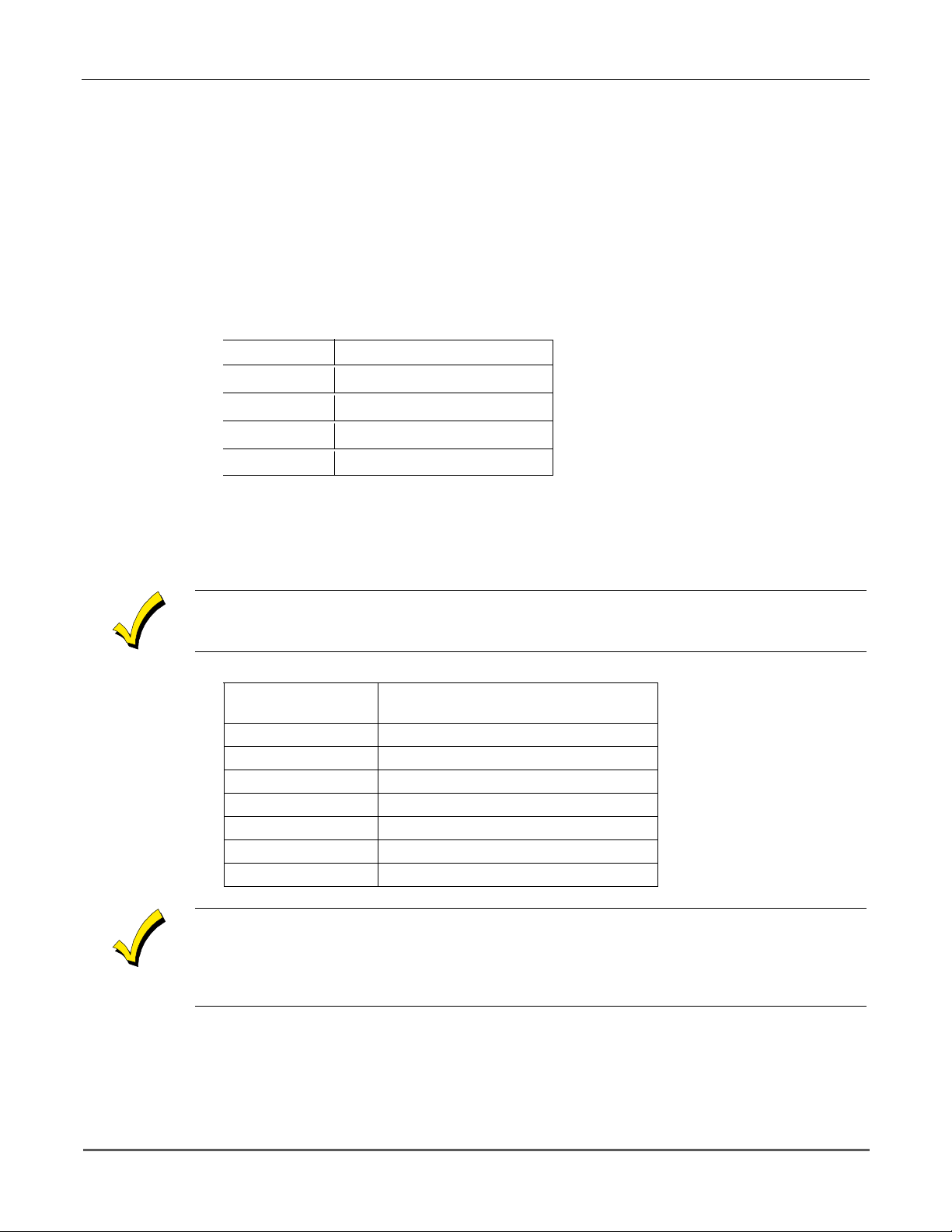

Transmitter Input Types

All of the transmitters described have one or more unique, factory-a ssigned input (loop) ID

codes. Each of the inputs requires its own programming zone (for example: a 5804's four

inputs require four programming zones). Refer to the ZONE PROGRAMMING section.

Transmitters can be enrolled as one of the following types:

Type Description

RF

(Supervised RF)

UR

(Unsupervised RF)

BR

(Unsupervised Button RF)

Transmitter Battery Life

Sends periodic check-in signals, as well as fault, restore, and lowbattery signals. The transmitter must remain within the receiver's

range.

Sends all the signals that the “RF” type does, but the control does

not supervise the check-in signals. The transmitter may therefore be

carried off-premises.

Sends only fault signals. It will not send a low-battery signal until it is

activated. The transmitter may be carried off-premises.

5-4

Do not install batteries in wireless transmitters until you are ready to enroll the transmitters

during system programming. After enrolling, batteries need not be removed.

Batteries in the wireless transmitters may last from 4 to 7 years, depending on the

environment, usage, and the specific wireless device being used. Factors such as humidity,

extreme temperatures, as well as large temperature variations may all reduce the actual

battery life in a given installation.

The wireless system can identify a true low-battery situation, thus allowing the dealer or

user of the system time to arrange a change of battery and maintain protection for that point

within the system.

Some transmitters (e.g., 5802, 5802CP, and 5804) contain long-life but nonreplaceable

batteries, and no ba ttery installati on is required. At the end of their life, the complete unit

must be replaced (and a new serial number enrolled by the control).

Button-type transmitters (such as 5801, 5802, 5802MN/MN2, 5802CP, and 5804) should be

periodically tested for battery life.

The 5802MN and 5804 Button Transmitters have replaceable batteries.

Using the Transmitter Sniffer Mode

The Transmitter Sniffer mode is a procedure that verifies that all transmitters have been

properly programmed. To verify programming, refer to the TESTING THE SYSTEM section.

5800 Series Transmitters Table

Model Description Input Type and Special Notes

5801 Wireless Panic

Transmitter

5802

5802CP

5802MN

5802MN

5804

5804BD

5806

5807

5808

5807L

5807LT

5807LST

5808LST

5809

5816

5816MN

5816

5817 Multi-Point Universal

Pendant Belt Clip

(Personal Emergency)

Transmitters

Miniature Personal

Emergency Trans.

2

Wireless Key

Transmitter

Wireless Photoelectric

Smoke Detectors

Low-profile version

of the Wireless

Photoelectric Smoke

Detectors

HeatSensor, 135

Detector/Transmitter

Door/Window

Transmitter

TEMP

Low Temp Sensor

Transmitter

º

Enroll as “3” for RF (supervised), or “4” for UR (unsupervised).

Unit has 4 pushbuttons, each with a unique input (loop) code.

Each pushbutton must be assigned to a zone.

Input loop (button) No. 4 must always be used.

NOTE:

Enroll as “5” for BR (button-type transmitter).

Enroll as “3” for RF (supervised), or “4” for UR (unsupervised).

Single pushbutton-type transmitter.

Enroll as “5” for BR (button-type transmitter).

Has 4 pushbuttons, each with a unique input (loop) code.

Each pushbutton must be assigned to a zone.

All buttons must be assigned the same input type.

NOTE:

Enroll as “3” for RF (supervised).

At the “INPUT S/N” prompt, fault the detector as follows:

On many detectors, you must press a special test switch (not test button) to

1.

fault the

NOTE:

detector. Disengage the detector’s cover and swing it open. These contacts

are on the PC board near a blue jumper (see detector’s instructions).

Momentarily short these contacts with a small screwdriver.

Two keypad beeps occur when the detector is faulted the first time.

Wait 6 to 8 seconds, then press and release the test switch (or momentarily

2.

short the contacts) again. If the control has accepted the input code, 3 beeps

sound and the enrolled input (loop) number is displayed.

Enroll as “3” for RF (supervised).

Has two unique input (loop) zones: one for a wired closed-circuit contact loop,

and the other for a built-in reed switch (used in conjunction with a magnet).

Either or both may be used.

Enroll as “3” for RF (supervised).

Has three unique input (loop) codes: one for a DIP switch-set “Primary” contact

loop, and the others for two “Auxiliary” closed-circuit contact loops.

The “Primary” loop may be set for:

•

•

•

3-Minute or no Transmission Inhibit

detector

With some detectors, you must short two contacts to fault the

Repeating or Single Transmission

Normally Open or Normally Closed circuit

Slow or Fast Response

(see detector’s instructions).

Section 5 - Wireless Expansion

5-5

VISTA-10SE Installation and Setup Guide

5800 Series Transmitters Table (

Model Description Input Type and Special Notes

5817

(cont'd.)

Multi-Point Universal

Transmitter

(cont'd.)

5818 Recessed Magnetic

Contact Transmitter

5819

5819

5819

5849

5850

Shock Processor

Transmitter

BRS

WHS

Glassbreak

Detector/Transmitter

5852

5890

5890P1

PIR Detector/

Transmitter

DIP Switches:

All loops must be assigned the same input type.

NOTE:

Enroll as “3” for RF (supervised).

Enroll as “3” for RF (supervised).

Has three unique input (loop) zones: one for a wired closed-circuit contact loop,

one for use with inertia-type shock detectors (mounted externally), and one for a

built-in reed switch (used in conjunction with a magnet).

Enroll as “3” for RF (supervised).

Enroll as “3” for RF (supervised).

The cover must be on the unit when enrolling the serial number.

Set all DIP switches to the OFF position when enrolling the

serial number.

When “enrolling” a transmitter’s ID code(s), any PIR in the vicinity that is not being enrolled

should be covered with a cloth, tissue, etc. to prevent activation.

Installing 5800 Series Transmitters

To be sure reception of the transmitter's signal at the proposed mounting location is

adequate, perform a Go/No Go Test in the TESTING the SYSTEM section.

continued)

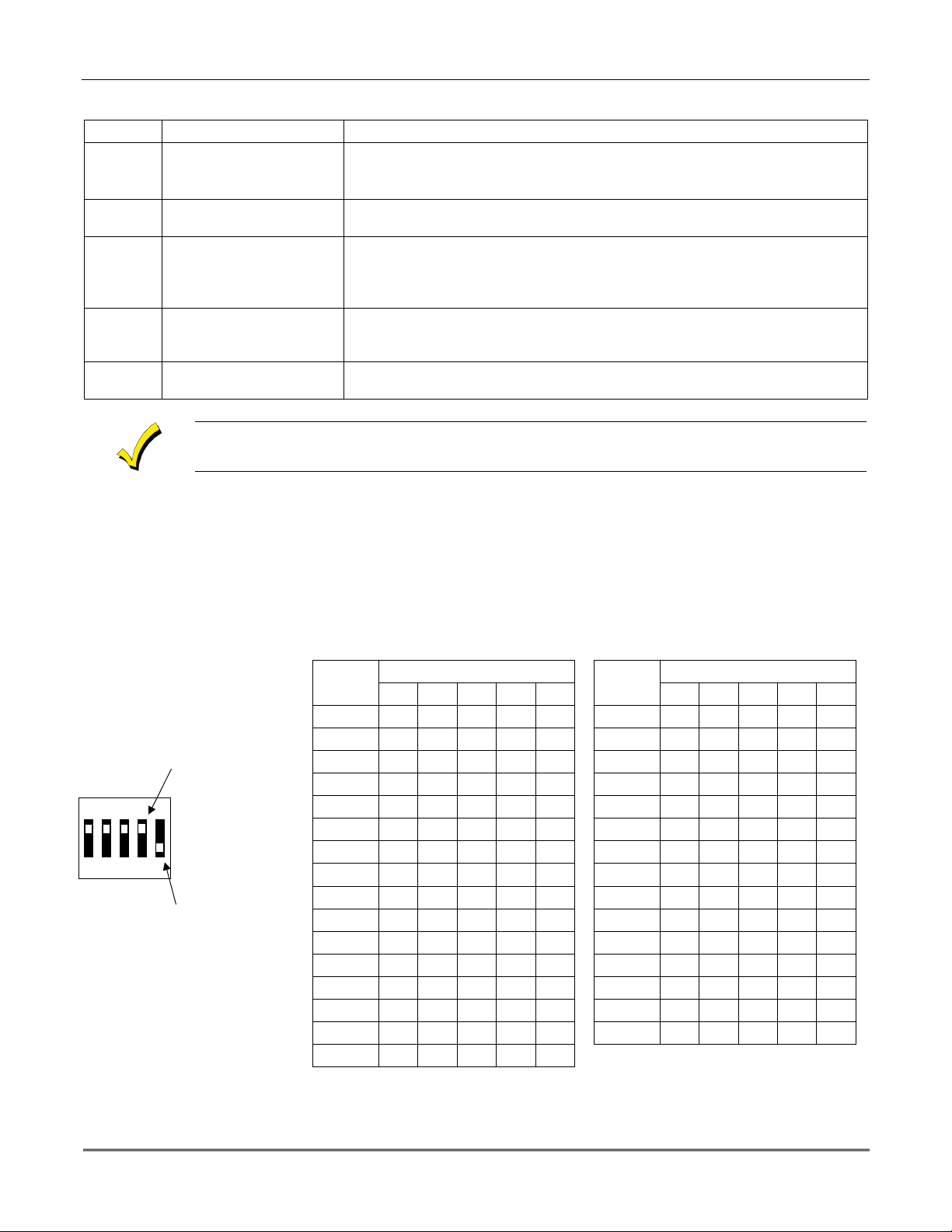

Setting DIP Switches on the 5827 Transmitter(s)

You must set a 5827 Transmitter to the programmed House ID, using its DIP switches.

SWITCH UP FOR "ON"

SWITCH DOWN FOR "OFF"

SHOWN SET FOR

HOUSE ID # 30

DIP SWITCH POSITION

12345

1 ----UP

2 ---UP3 - - - UP UP

4--UP-5--UP-UP

6--UPUP7 - - UPUPUP

8 -UP--9 - UP - - UP

10 - UP - UP 11 - UP - UP UP

12 - UP UP - 13 - UP UP - UP

14 - UPUPUP 15 - UPUPUPUP

16UP----

DIP SWITCH POSITIONHOUSE

ID

17 UP - - - UP

18 UP - - UP 19 UP - - UP UP

20 UP - UP - 21 UP - UP - UP

22 UP - UP UP 23 UP - UPUPUP

24 UP UP - - 25 UP UP - - UP

26 UP UP - UP 27 UP UP - UP UP

28 UP UP UP - 29 UP UP UP - UP

30 UP UP UP UP 31 UP UP UP UP UP

12345

5-6

SECTION 6

Relay Output Devices

••••••••••••••••••••••••••••••••••••••••••••••••••

In This Section

Relay Device Basics

♦

4204 Relay Modules

♦

Programming Options

♦

••••••••••••••••••••••••••••••••••••••••••••••••••

Relay Device Basics

Relays are programmable switches that can be used to perform many different functions.

They can be used to turn lights on and off, control sounders, or for status indications. In this

system, each relay must be programmed as to how to act (ACTION), when to activate

(START), and when to deactiva te (STOP). Each of these is described below.

The control supports a total of 4 output relays.

The 4204 Relay modules provide Form C (normally open and normally closed) contacts.

In ✱80 and ✱81 interactive modes, a series of keypad prompts will request entries for

programming of the Relay outputs used in the system. Refer also to “OUTPUT RELAY

✱

DEVICE WORKSHEET FOR

80 AND ✱81 INTERACTIVE MODES” in the blank

programming form provided in the separate Programming Form manual.

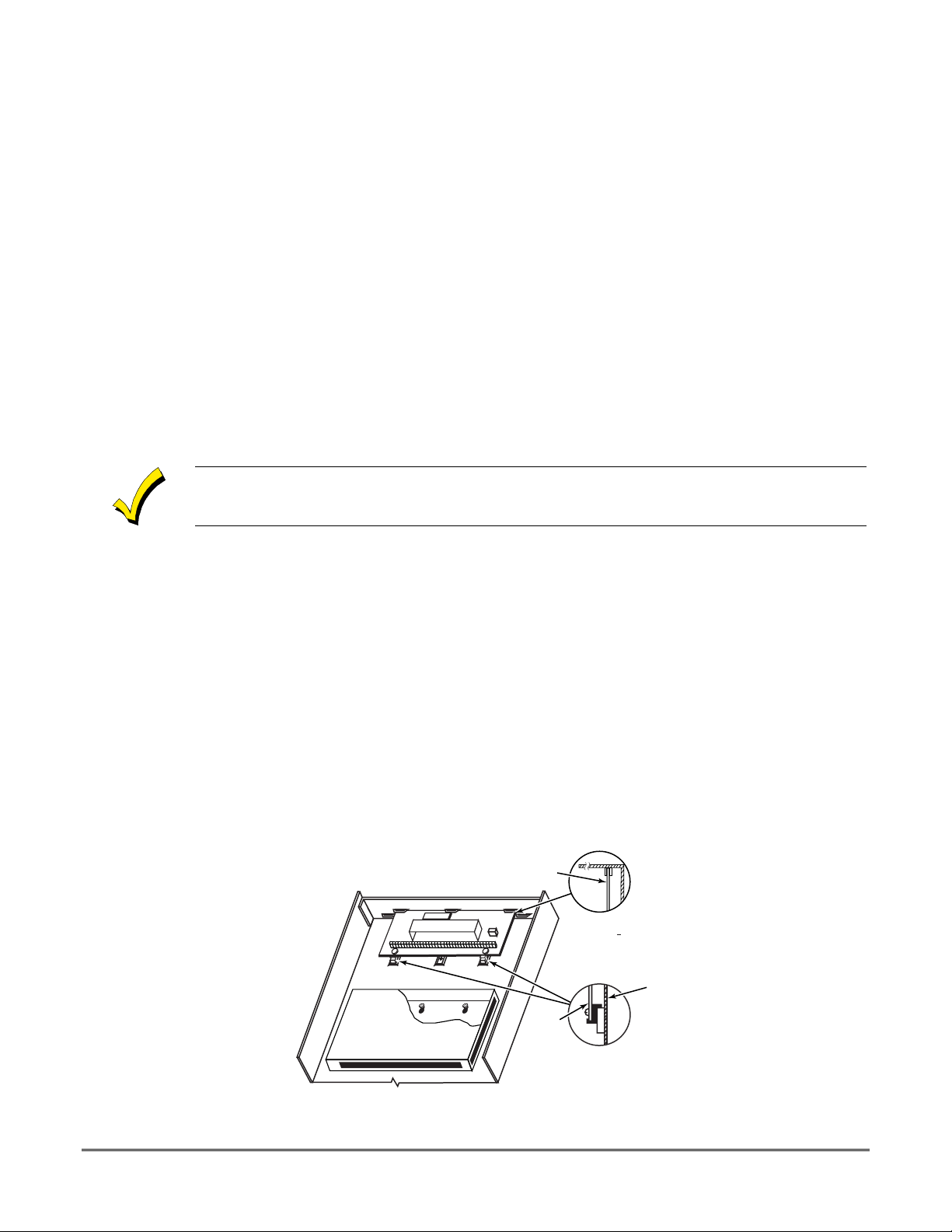

4204 Relay Modules

4204 Relay Unit (if installed in cabinet)

1. Insert self-tap pin g screw s (prov ide d ) in two adj ace nt raise d cabin e t tabs. Leav e the he ads

projecting 1/8".

2. Hang the unit on the screw heads via two of the slotted holes at the rear of its housing, as

shown in

Figure 9

below.

3. The 4204's co ver can be left o ff if the u nit's DIP switch is set with its p osition 1 "ON" (to

the right) as shown in its instructions. The tamper-protected cover is necessary for

installations outside of the control's ca binet.

+

Figure 9. Mounting the PC Board in the Cabinet with a 4204 Relay Unit

CIRCUIT BOARD

+

CIRCUIT

BOARD

DETAIL A

SIDE VIEW

OF BOARD

SUPPORTING

SLOTS

DETAIL B

SIDE VIEW

OF MOUNTING

CLIPS

CABINET

V10SE-003-V0

6–1

1 2 3 4 5

OFF ON

ON

@@@@@@@@e?

@@@@@@@@e?

@@h?

@@h?

@@h?

@@h?

@@h?

@@h?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

?@@

?@@

?@@

?@@

?@@

?@@

?@@@@@@@@

?@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@

@@g

@@g

@@g

@@g

@@g

@@g

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

VISTA-10SE Installation and Setup Guide

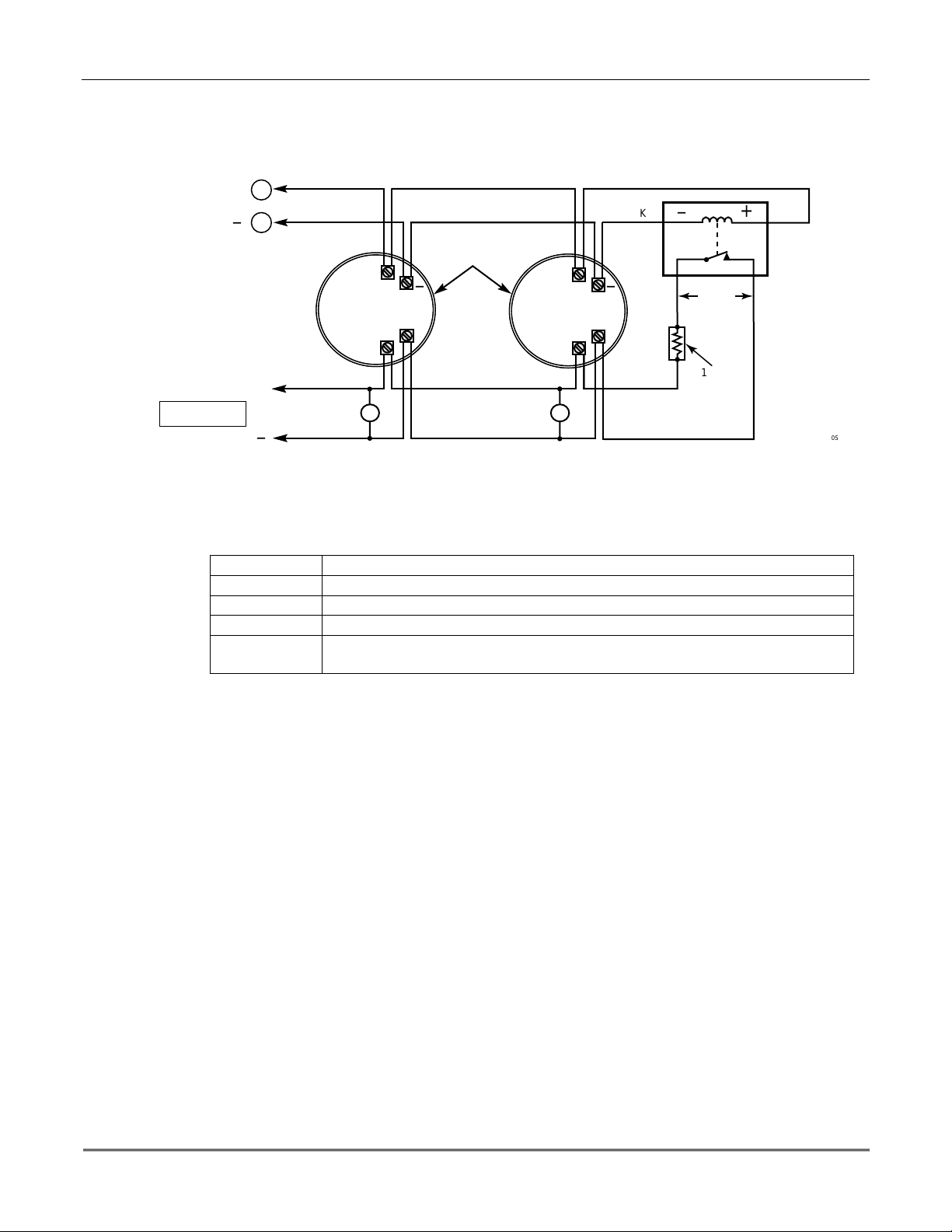

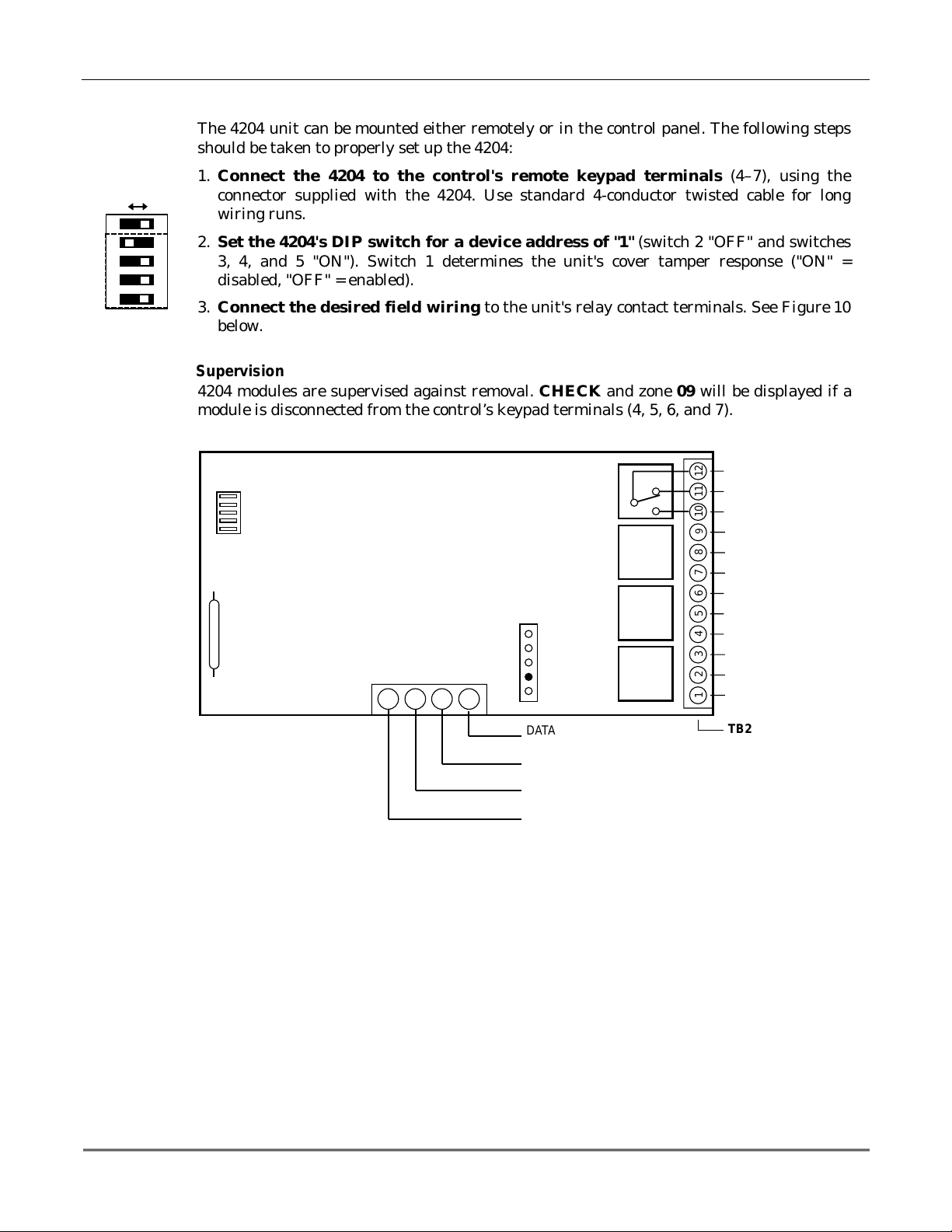

4204 Setup

The 4204 unit can be mounted e ither remote ly or in the control p anel. The follo wing ste ps

should be taken to properly set up the 4204:

1. Connect the 4204 to the control's remote keypad terminals (4–7), using the

connector supplied with the 4204. Use standard 4-conductor twisted cable for long

wiring runs.

2. Set the 4204's DIP switch for a device address of "1" (switch 2 "OFF" and switches

3, 4, and 5 "ON"). Switch 1 determines the unit's cover tamper response ("ON" =

disabled, "OFF" = enabled).

3. Con nect the des ired fie ld wiri ng to th e unit's r elay c ontact te rmin als. See Figure 10

below.

Supervision

4204 modules are supervised against removal. CHECK and zon e 09 will be displayed if a

module is disconnected from the control’s keypad terminals (4, 5, 6, and 7).

4204

DIP SWITCH

FOR SETTING DEVICE ADDRESS

AND ENABLING/DISABLING TAMPER

COVER T AMPER (REED) SWITCH

Programming Options

RELAY

4

TYPICAL

(SHOWN "OFF")

4-PIN KEYPAD PLUG

EITHER OR BOTH

CAN BE USED

TB1

13 14 15 16

YEL

BLK

GRN

RED

Figure 10. 4204 Connections to Control

DATA I N

FROM CONTROL

(–) GROUND

DATA OUT

TO CONTROL

(+) 12V

RELAY

3

RELAY

2

RELAY

1

C

121110

NC

NO

9

C

87654321

NC

NO

C

NC

NC

NO

C

NC

NO

TB2

V10SE-016-V0

6-2

In the VISTA-10SE, each device must be programmed as to how to act (ACTION), when to

activate (START), a n d when to de-activate (STOP). Refer to t he programming procedures for

✱

80 and

✱

81 interactive modes that are provided in the MECHANICS of PROGRAMMING,

OUTPUT DEVICE PROGRAMMING, and ZONE LISTS sections for specific programming

details.

SECTION 7

4285 and 4286 VIP Module

••••••••••••••••••••••••••••••••••••••••••••••••••

In This Section

Installing the VIP Module

♦

Programming the 4285/4286 VIP Module

♦

••••••••••••••••••••••••••••••••••••••••••••••••••

Checking 4285/4286 VIP Module Operation

♦

Installing the (Voice Interactive Phone) Module

General Information

The 4285/4286 VIP Module is an add-on accessory for the VISTA–10SE that permits access to

the security system via a TouchTone phone (either on premises or by a call-in when away).

The VIP Module can announce many of the same words that would normally be displayed on

an alpha keypad under the same system conditions.

When using the VIP Module, addressable keypads must be used in the system, but set to the

non-addressable mode (address 31); i.e., do not use a 6127 keypad.

When properly connected, the VIP Module will enable the user to do the following via a

TouchTone telephone:

•

Receive synthesized voice messages over the phone regarding the status of the security

system.

•

Arm and disarm the security system and perform most other commands using the

telephone keypad, with voice annunciation provided over the phone as confirmation after

a command is entered.

The phone used f or p ho ne acce ss must h ave To uc hTo ne capability , tho u gh Tou ch Ton e se rv ice

is not necessary (if premises uses PULSE dialing, switchable phones must be set for

TouchTone temporarily before attempting phone access).

A Pho ne Access User's Guide for phone access to the security system is provided with the

VIP Module for the user of the system.

U

L

Mounting the VIP Module

The VIP Module is not Listed for UL installation use

The VIP Module may be mou nted in the control cabine t if space is available or, if th is is not

possible, on the side of the cabinet or adjacent to it.

When mounting the VIP Module outside the cabinet, use the screw holes at its rear. That will

permit it to be mounted horizontally or vertically (double-sided tape may be used, if

preferred). Wires can be bro ug ht o ut f ro m th e sid e or back (a ro un d bre ako ut is also available

on the back).

Affix the VIP Module’s connections label (supplied separately) to the inside of the VIP

Module's cover if the cover is used. If yo u have installed th e module within the cabinet, affix

the label to the ins ide of the control cabinet's door.

.

7–1

VISTA-10SE Installation and Setup Guide

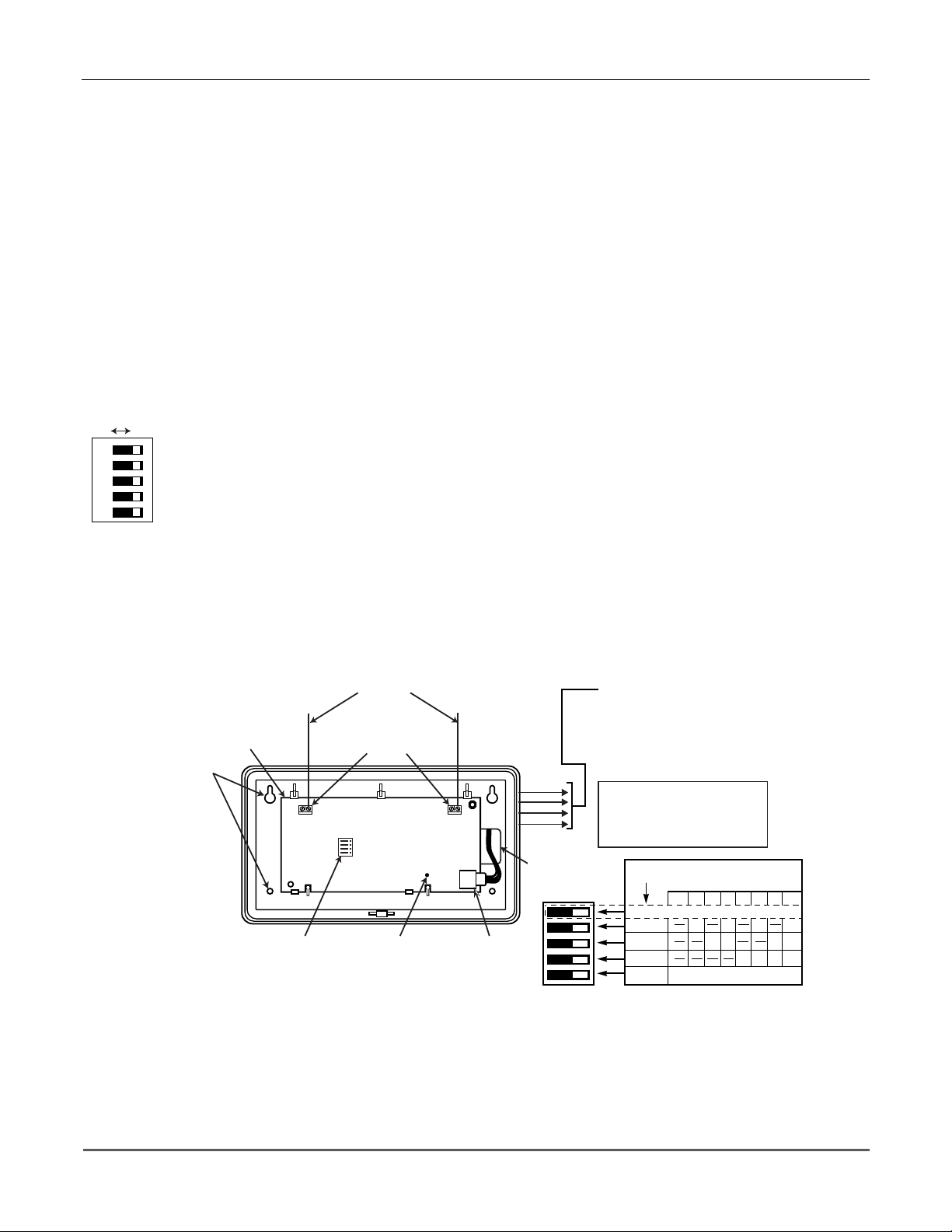

VIP Module Wiring

The VIP Module is wired between the control panel and the premises handset(s). It listens

for touch-tones on the phone line and reports them to the control panel. During on-premises

phone access, it powers the premises phones; during off-premises phone access, it seizes the

line from the premises phones and any answering machines.

NOTE: The phone lines must be in service for the VIP Module to function, even when

accessing the system from an on-premises phone.

1. Make 12V (+) an d (–) and data in and data out connections from the VIP Module to the

control, using the connector cable supplied with the VIP Modul e (see Figure 10).

Color Lead Terminal On Control

GREEN DATA IN (terminal 6)

BLACK AUX – (terminal 4)

RED AUX + (terminal 5)

YELLOW DATA OUT (terminal 7)

2. Insert the keyed connector at the other end of the connector cable into the mating header

on the VIP Module (see diagram on next page for location of the header).

*

*

These are the same connections

as those used for remote

keypads

.

3. Conne ct terminals 1 through 4 on the VIP Module as shown in the Wiring Table and in

the 4285/4286 wiring diagram that follows.

Use an RJ31X jack with a direct-connect cord and make all connections exactly as shown. If

the leads on the direct-connect cord are too short to reach their assigned terminals, splice

additional wires to them, as required.

4285/4286 WIRING TABLE

4285/4286/4286

Terminal

Phone In (Tip)

1.

Phone In (Ring)

2.

Phone Out (Tip)

3.

Phone Out (Ring)

4.

NOT USED

5.

Output High

6.

Output Rtn

7.

If no touch-tones are produced following access to the security system

Connects to:

Terminal (17) on control.

Terminal (18) on control.

BROWN lead from direct-connect cord.

GRAY lead from direct-connect cord.

——

Not used (4285). Spkr High on 4286.

Not used (4285). Spkr Return on 4286.

from on-premises

(this

problem may arise in rare cases), it may be necessary to reverse the wires connected to

terminals 3 and 4 on the VIP Module

control.

Figure 11

shows the wiring connections that will provide proper operation in most

and

the wires connected to terminals (17) and (18) on the

cases.

7-2

Caller ID Units

If the telephone system on the premises includes a Caller ID unit, connect the ID unit

directly to the “Handset” terminals (17 and 18) on the control, as shown in Figure 11.

Section 7 - 4285/4286 VIP Module

4285/4286 VIP Module WIRING NOTES:

1.

Wire the VIP Module exactly as shown, using a direct-connect cord and RJ31X jack.

2.

If you do no hear tones when pressing keys after accessing the security system via an on-premises

phone, try reversing the pair of wires connected to terminals 3 and 4 on the VIP Module

pair of wires connected to terminals 17 and 18 on the control.

3. If you hear an error signal (fast busy signal) when trying to access the system via the phone, check

for correct line se izure wiring, as described in note 4.

4. Connection to the incoming telco line via a RJ31X jack and direct-connect cord, as shown in this

diagram, is essential, even if the system is not connected to a central station.

The 4285 or 4286

will not function if this is not done.

The house phone lines (gray and brown wires) must be wired to the VIP Module

terminals, not to the control terminals. Otherwise, an error signal (fast busy signal) will

occur when you try to access the system from an on-premises phone.

5. If the telephone system on the premises includes a Caller ID unit, connect the unit

“Handset” terminals (17 and 18) on the control, as shown.

and

directly

the

to the

TERMINALS

ON CONTROL

CALLER ID

UNIT

IMPORTANT NOTE FOR

EXISTING INSTALLATIONS:

EXISTING WIRES

CONNECTED TO THE

"HANDSET" TERMINALS ON

CONTROL MUST BE MOVED

FROM THERE TO TERMINALS

3 AND 4 ON THE 4285.

4285/4286

VIP MODULE

SPEAKER VOLUME

ADJUSTABLE ON

4286 ONLY

KEYED

HEADER

UNUSED

CONNECTOR

WITH FLYING

LEADS

YELLOW: TO DATA OUT (term. 7)

NO CONNECTION

RED: TO AUX (+) (term. 5)

BLACK: TO AUX. GROUND (–) (term.4)

GREEN:

Handset

{

17

1

MUST CONNECT TO

ON 4285 (TIP)

TO DATA IN (term. 6)

Incoming

Teleco Line

{

19

18

2

GREEN (TIP)

ON 4285 (RING)

MUST CONNECT TO

12345 6 7

20

21

DIRECT

CONNECT

CORD

RED (RING)

PLUG

GREY (R)

BROWN (T)

CONNECTION

TO CONTROL

PANEL

TERMINALS

USED FOR

KEYPAD

CONNECTIONS

GROUND

NO

TO EARTH GROUND (COLD WATER PIPE, ETC.)

INCOMING TELCO LINE

TIP

RING

TIP

RJ31X

RING

JACK

CA38A

IN

CANADA

PREMISES ANSWERING

MACHINE AND PHONES

ANSWERING

MACHINE

*

*

*

NOTE: IF THE TELEPHONE HAS BUILT-IN CALLER ID,

THE CALLER ID FUNCTION MAY NOT WORK

TERMINAL ASSIGNMENTS

1 - TIP

2 - RING

3 - TIP

4 - RING

5 - NO CONNECTION

6 -

}

7 -

4285/4286

PHONE INPUT

}

PHONE OUTPUT

}

AUDIO OUT

4286 ONLY

V10SE-029-V0

.

Figure 11. 4285/4286 VIP Module Wiring Connections

7-3

VISTA-10SE Installation and Setup Guide

Programming the Control for Phone Access

To program the control for phone access using the 4285/4286 VIP Module, you must assign a

✱

VIP Module access code (

26) and ring detection count (✱95). Also, you may optionally select

words and/or form custom words that would be displayed on the keypad. Refer to THE DATA

FIELD DESCRIPTION and ALPHA DESCRIPTOR PROGRAMMING sections for specific

programming details.

Perform a preliminary check of the VIP Module, as indicated next.

Checking the Operation of the VIP Module

To Check VIP Module Operation From an On-Premises Phone

1. Pick up the phone and enter the programmed 2-digit VIP Module access code.

Annunciation of a system status report should automatically start. See the User Guide

accompanying the VIP Module for detailed information regarding the nature of the status

report, if necessary.

2. During any pause in the status report, or immediately following it, key the following via

the keypad on the phone:

4111 (Installer code) + 1 (OFF).

You should hear a beep on the phone and from a wired keypad. You should als o hear the

words, "Disarmed...Ready to Arm" or "Disarmed...Not Ready to Arm," indicating that

the command was entered successfully. (The voice message, "Disarmed...Not Ready to

Arm" indicates an open zone).

3. Hang up the phone.

To Check VIP Module Operation from an Off-Premises Phone:

1. Have someone dial the premises phone number, using a TouchTone phone.

•

If the phone system does not include an answ ering machine, the caller hears 2 long

tones, followed by a voice prompt "

HELLO, ENTER PHONE CODE NOW

must enter the programmed 2-digit phone code (entered in field

MODULE ACCESS CODE)

•

If the premises phone system includes an answering machine, the 2-digit phone

.

code must be entered during a pause at the beginning of, or during, the outgoing

answering machine message. Then the caller hears a voice prompt asking for entry of

the 4-digit system code ( "

ENTER SYSTEM CODE NOW

2. The caller sh ould then enter the Installer Code ( 4111). As a safety feature , there is a 3-

try limit in which to enter each code (phone code and system code), after which time the

call-in is aborted. Also, if no keys are pressed for a period of 20 seconds, the call-in is

aborted.

Annunciation of a system status report will start if both codes were entered correctly.

3. During an y pause in the statu s report, or imme diately follo wing it, the caller sh ould key

the following via the keypad on the phone:

Installer Code (4111), then 1 (OFF).

The caller should hear a beep from the phone and a wired keypad on the premises. The

caller should also hear the words "Disarmed...Ready to Arm" or "Disarmed...Not

Ready to Arm" on the phone, indicating that the command was entered successfully.

"Disarmed...Not Ready to Arm" would indicate an open zone.

4. At this point, the caller can hang up the phone.

5. Verify with the caller that there was successful access to the system and that the

appropriate voice announcements were hea rd over the phone.

").

" The caller

.

✱

28,

PHONE)

7-4

6. If the VIP Module functioned satisfactorily, unplug the AC transformer from the AC

outlet.

Loading...

Loading...