Visonik V1065S4, V1265S4, V1565S4, V106S4, V126S4 Instruction Manual

Dear Customer,

Congratulations on your purchase of the world’s finest brand of car audio

amplifiers. At Visonik we are committed to producing musical reproduction at

its best, and we are pleased you chose our product. Through years of critical

testing procedures and hand craftsmanship, we have created a wide range of

products that reproduce music with all the clarity and richness you deserve.

For maximum performance we recommend you have your new

Visonik product installed by an Authorized Visonik Dealer. Please read

your warranty and retain your receipt and original carton for possible

future use.

To learn more about Visonik, current world records held by Visonik and other

information, please visit us on the world wide web at:

www.VisonikCarAudio.com

!! Attention !!

Continuous, excessive exposure to sound pressure levels in excess of 85 dB

can cause a loss in hearing. While Visonik sound systems are capable of

producing sound pressure levels greater than 85dB,they are also designed for

enjoyment at reasonable levels. Please observe all local sound ordinances

while listening to your Visonik sound system

Table of Contents

FEATURES & SPECIFICATIONS 1

CALCULATING ENCLOSURE VOLUME 2

SUBWOOFER PARAMETERS 3

ENCLOSURE CONSTRUCTION 4

SUBWOOFER WIRING DIAGRAMS 5

TROUBLESHOOTING 6

WARRANTY 8

NOTES 9

WARNING 10

- 1 -

FEATURES

§ Single 4 Ohm Impedance

§ Non-Pressed Paper Cone

§ Vented Magnet

§ Single 2” Voice Coil

§ Die Cast Aluminum Basket

§ Rubber Sealant Gasket

§ Chrome Post Terminals

SPECIFICATIONS

Die Cast Basket

The S4 Series Woofers uses a die cast basket for better voice coil alignment.

The basket is aluminum and non-magnetic for better efficiency. In Addition,

the aluminum dissipates heat far better than steel which allows more power

handling. The Q of the speaker will be much higher than with a stamped steel

frame, thus giving a lower resonate frequency.

Non-Pressed Paper Cone

The cone is a spruce pulp paper that has been treated with a water resistant

Poly Vinyl Acetate (PVA) emulsion. This provides cone rigidity and lowers

distortion. Additionally the combination of weight and strength allows for high

output levels without cone break up.

Single 4 Ohm Aluminum Voice Coil

For High efficient thermal transfer the voice coil is constructed with a black

voice coil formed from anodized aluminum. This makes the voice coil highly

efficient in dissipating heat thus improving the power handing capability.

Dual Laminated Dupont Spider

Provides strong suspension for the subwoofer, which results in higher

excursion capabilities.

Hyper-Extended Pole Piece

Better low frequency response is obtained by having a better linear

magnetic field for the operation of the woofer.

Foam Surround

Double Treated Foam for the front suspension is proven to add mechanical

strength and reliability.

- 2 -

CALCULATING ENCLOSURE VOLUME

Do you want to take up all the available space inside your Vehicle? Or are

you looking for something that is compact enough to be removed easily when

necessary? These are important questions you must answer before beginning

your project.

First, measure out the area you’re interested in placing the subwoofer

enclosure. Use a good-quality measuring tape to determine the MAXIMUM

height, width, and depth of your area. Height is the measurement up-anddown, width is the measurement from side-to-side, and depth is the

measurement back-to-front.

It is extremely important to know the internal volume necessary for the

Subwoofer you’re using (also known as “box size”). Since not all subwoofers

require the same amount of airspace, different lines of the same brand of

woofer can have completely different enclosure size requirements. As general

rule of thumb, making the enclosure too small will result in a lack of low-end

bass response, and if it’s too large, you won’t have as much output as you

could and the woofer’s power handling will suffer.

Calculating the correct box size is easy if you just remember a few simple

formulas and calculations. The key to calculating internal box dimensions is a

basic understanding of volume: Cubic volume is derived by multiplying each

of an object’s dimensions (height, width, depth) by each other.

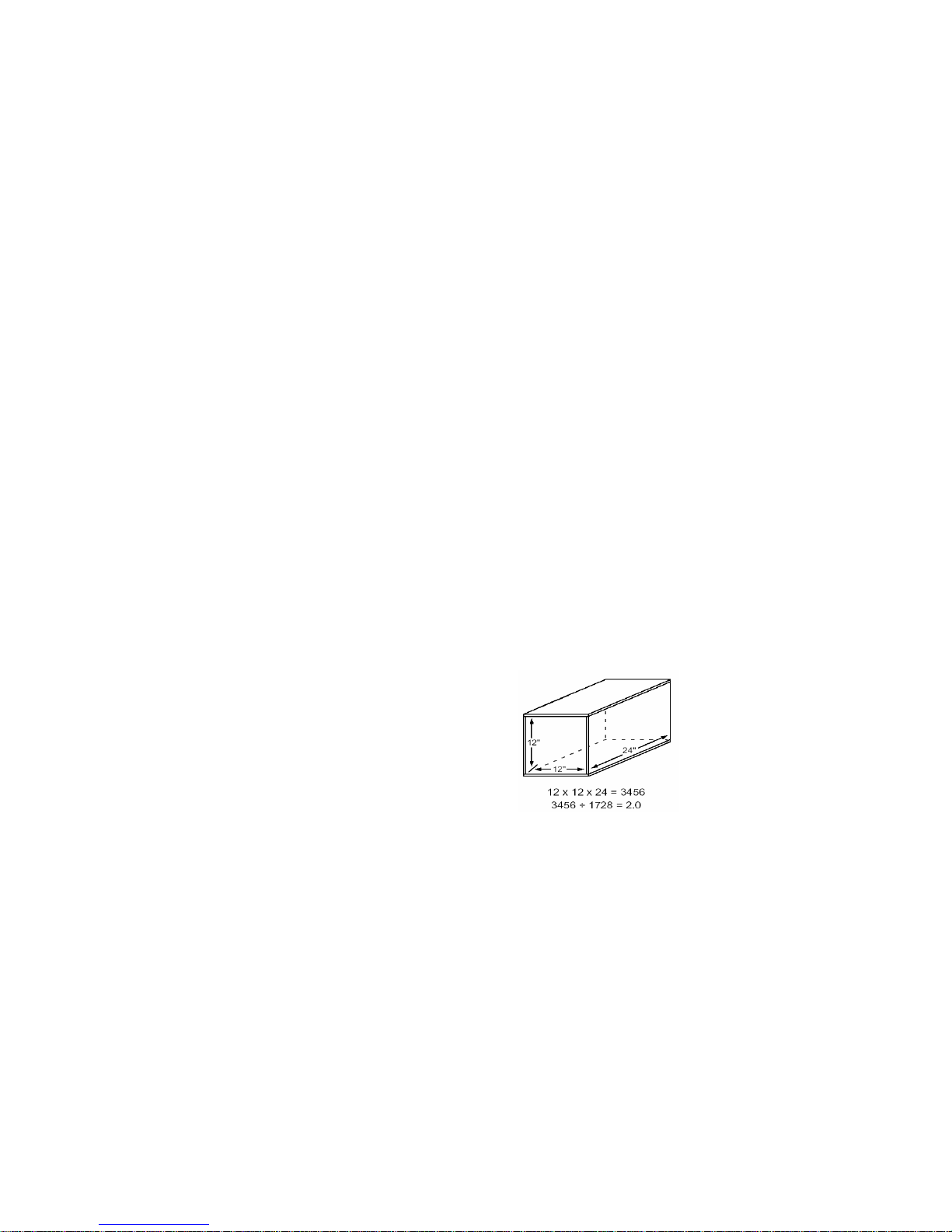

For example: If you measure the

internal dimensions of a rectangular object

(like a subwoofer box) and its internal

height is 12", its width is 24", its depth is

12", and then multiply those dimensions

together (12" X 24" X 12"), then you come

up with a volume of 3,456 cubic inches.

Divide this number by 1728 (1 cubic foot)

and the total is the internal cubic volume of

the box, which in this case is 2.0 cubic feet.

Enclosure volumes are never listed in cubic inches, so it is necessary to

convert from cubic inches to cubic feet. (A cubic foot is no more than

12" X 12" X 12" or 1,728 cubic inches.) So, to convert from cubic

inches to cubic feet, simply divide the volume in cubic inches by 1,728.

- 3 -

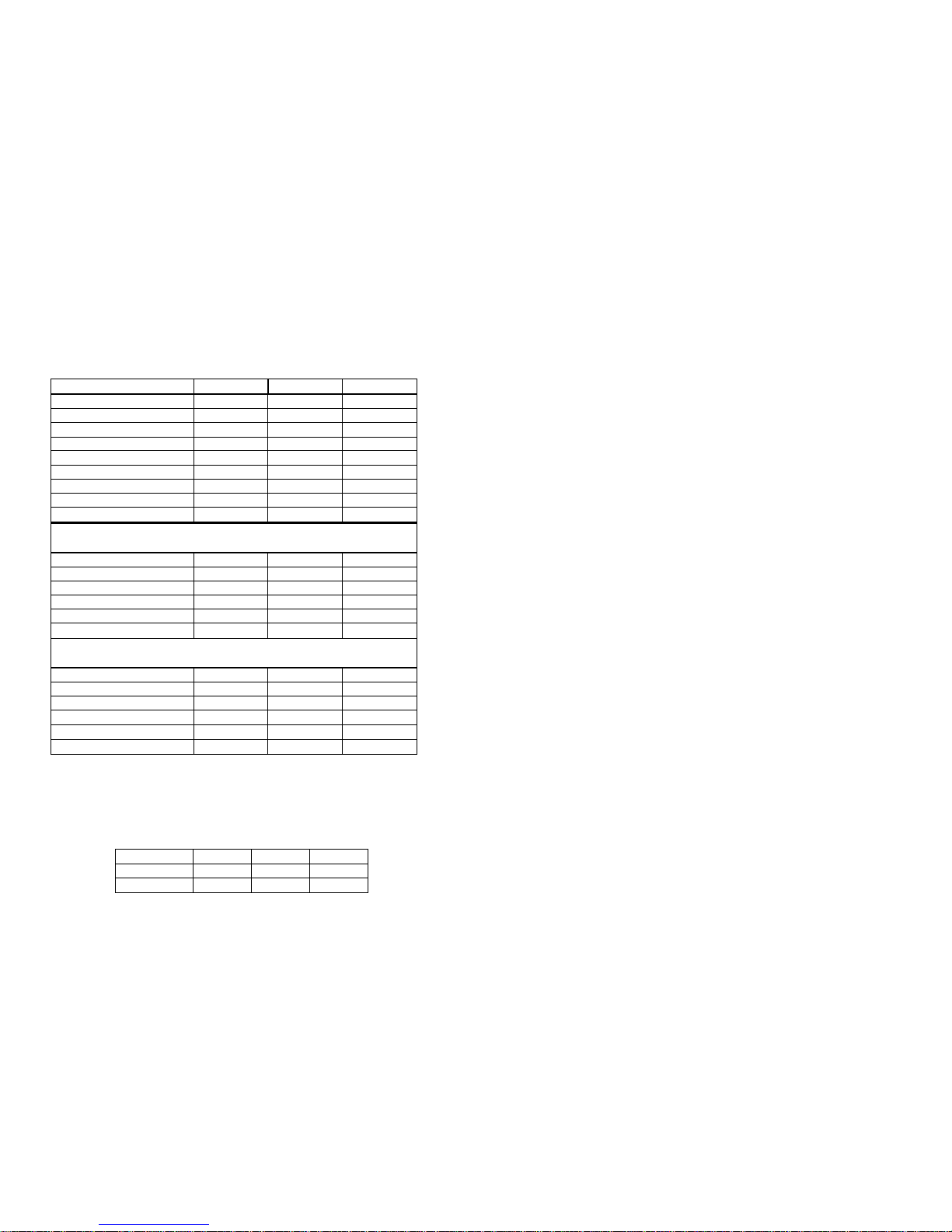

SUBWOOFER PARAMETERS

The Following Parameters are for Optimal Subwoofer Performance.

The Volume Parameters are calculated to include the displacement by the

subwoofer Magnet and Basket.

PARAMETERS V1065S4 V1265S4 V1565S4

Fo (Hz) 26.98 29.1 30.3

QMS 5.72 5.13 6.7

QES 0.39 0.38 0.69

QTS 0.36 0.35 0.63

VAS (Liters) 40.59 71.01 139.25

REVC (Ohms) 3.3 3.4 3.2

SPL @ 1 watt / 1 meter (dB) 84.9 88.4 89.31

X-max Linear peak-peak (mm) 24 24 24

LEVC at 1k Hz (mH) 3.53 4.11 3.52

ENCLOSURE VOLUME'S

SEALED

Minimum sealed (Cubic Feet) 0.5 0.85 1.75

Fill Required (%) No No No

3dB down point (-3dB Hz) 54 57 43

Maximum sealed (Cubic Feet) 1.0 1.25 2.75

Fill Required (%) No No No

3dB down point (-3dB Hz) 55 58 38

ENCLOSURE VOLUME'S

PORTED

Vented (Cubic Feet) 2.25 3.0 4.0

Vented to (Hz) 35 33 35

3dB down point (-3dB Hz) 29 27 33

Port Diameter (") 3 4 4

Port Length (") 12 19 20

Number of Ports 2 2 3

For more advanced competition information and enclosures,

please visit the Visonik Technical Support page at:

www.VisonikCarAudio.com

Power Handling Capabilities

Model V1065S4 V1265S4 V1565S4

RMS Power 400W 450W 500W

MAX Power 800W 900W 1000W

- 4 -

ENCLOSURE CONSTRUCTION

Once the chosen the type of application for your subwoofer(s) and the

dimensions of the box are calculated, the materials need to be selected. The

following is a list of common enclosure construction materials:

Particle Board: Very inexpensive, however this board tends to come

apart under the high stress of subwoofers, and is very susceptible to water

damage! Not suitable for very large enclosures unless a great deal of internal

bracing is added for extra rigidity.

Medium Density Fiber Board (MDF): The best overall material for

speaker enclosures, fiberboard is extremely rigid, and will not come apart at

even the highest pressure levels.

Plywood (all types): A poor choice for car stereo subwoofer

enclosures, as plywood tends to de-laminate under heat and weather ranges

found in cars. It can also buzz at low frequencies when played at high volume.

The thickness of material for the enclosure is governed by the overall size

of the enclosure. The smallest of enclosures (1.0 cu ft or less) can use 5/8" or

1/2" material. Average size enclosures (1.0 cu ft to 4.0 cu ft) should use 3/4".

Very large enclosures (over 4.0 cu ft) should use 1" material with braces to

prevent enclosure flex.

Adding damping material, such as fiberglass, or Dacron polyester (pillow

stuffing like Poly-Fill) to your subwoofer enclosure helps cancel any standing

waves or resonances that form in the enclosure because of its particular

dimensions. We recommend adding stuffing only to sealed enclosures. It will

not make up for a poorly-constructed enclosure or an enclosure that is built too

small, but it can help make the enclosure play low frequencies with added

emphasis. It is possible to make your speaker think that it is in a larger box

than it actually is by adding extra damping material, up to 75% of the entire

enclosure volume. The general rule here is to add 1 pound of fill material (R19 fiberglass, Dacron, or lamb's wool) per cubic foot of enclosure volume.

Always follow the above general rule of thumb when selecting the amount

of Fill. Fill should only be used for sealed enclosures only. This fill

recommendation can be found on the Parameters and Specifications Page.

Don’t compress the material, just loosely add fill to the enclosure. This works

because the fibers of the material cause the sound waves to bend around them,

slowing the waves down and taking longer to reach the enclosure’s sides. As

much as a 15% change in box volume/response can be achieved by this

method

Loading...

Loading...