Visonik MCT-501 User Manual

MCT

SMARTHOME.COM™ 1-800-SMART-HOME 949-221-9200 http://www.smarthome.com

Order#73951

SMARTHOME™ #73951

MCT-501

MCTMCT

-501

-501-501

Advanced Acoustic Sensor / PowerCode Transmitter

1111. INTRODUCTION

. INTRODUCTION

. INTRODUCTION. INTRODUCTION

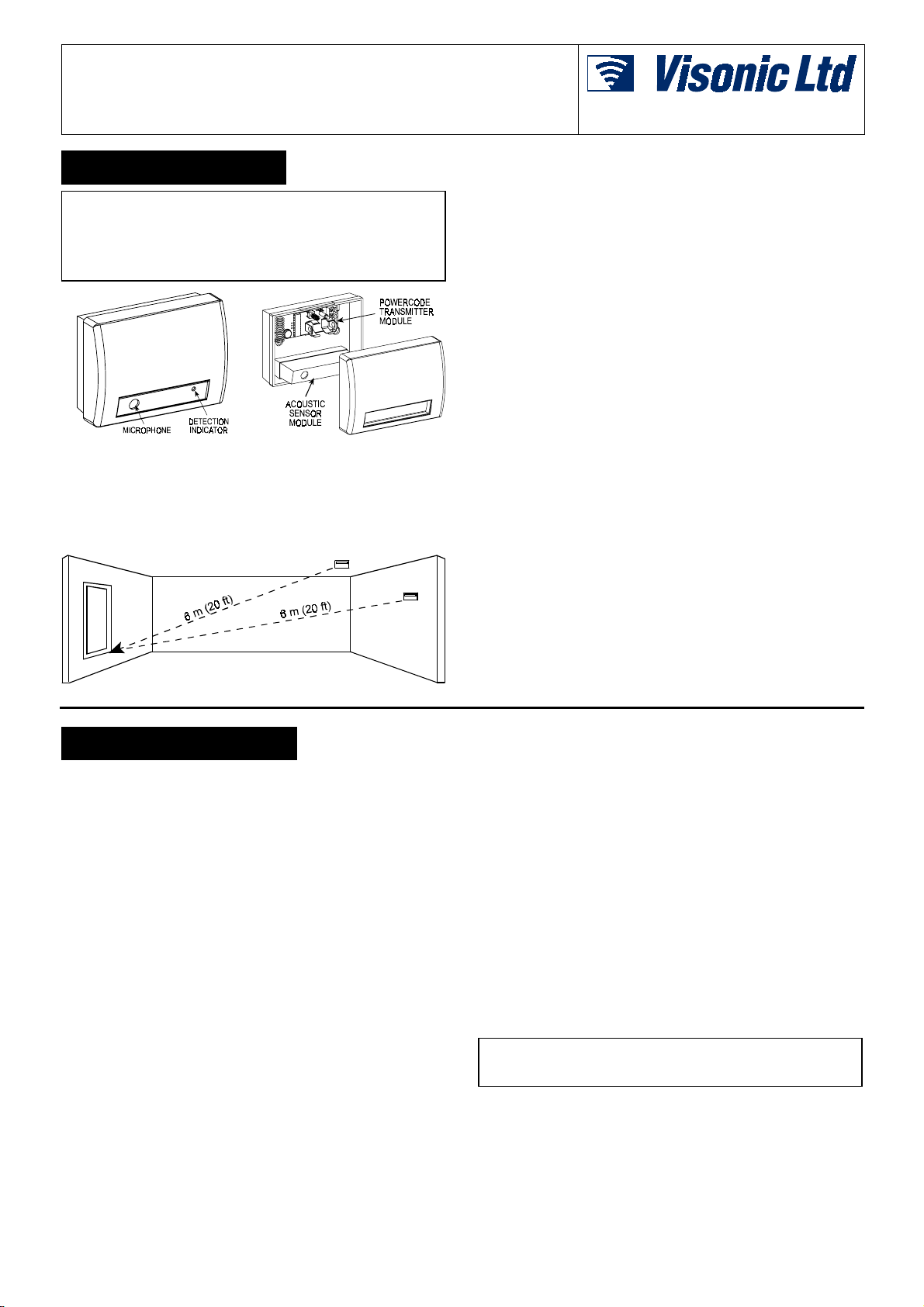

The MCT-501 combines two modules:

•••• The Sentrol Inc. ShatterPro™ acoustic sensor with Pattern

Recognition Technology™ (Protected under U.S. Patent

5,192,931)

•••• The Visonic Ltd. MCT-302 PowerCode™ transmitter

Figure 1. General View Figure 2. Module Identification

1.1 Acoustic Sensor

The acoustic sensor module of the MCT-501 is omni-directional,

providing 360° coverage. Coverage is measured from the sensor

to the point on the glass farthest from the sensor (see Fig. 3). The

sensor can be mounted as close as 1 m (3.3 ft) from the glass.

Figure 3. Typical Range Measurement

When mounted on opposite wall or adjoining walls, the range is

6 m (20 ft) for plate, tempered, laminated and wired glass.

When mounted on the ceiling, the maximum range is 6 m (20 ft)

for plate, tempered, laminated and wired glass

For armor-coated glass, mount the sensor no more than 3.65 m

(12 ft) from the glass.

1.2 PowerCode Transmitter

The acoustic sensor shares its housing with a miniature

transmitter which has a unique 24-bit PowerCode ID, selected in

the factory from over 16 million possible code combinations.

Upon alarm (glass break detection), a digital message is

transmitted, composed of the PowerCode ID followed by various

status and message-type markers. Alarm and other data are thus

forwarded to the wireless alarm control panel.

Since transmitted messages might collide with transmissions

from other PowerCode transmitters used in the system, a smart

anti-collision transmission sequence is used.

The MCT-501 is protected by a tamper switch that is activated

when the cover is removed. In a tamper situation, a message is

transmitted with the “tamper alert” marker ON.

A periodic supervision message, distinguished by a specific

marker, is transmitted automatically once in 60 minutes. The

wireless control panel is thus informed, at regular intervals, of the

sensor’s active participation in the system.

A red LED mounted on the transmitter PCB (visible only when the

cover is off) lights whenever alarm or tamper events are reported.

The LED does not light while a supervision message is being

transmitted.

Operating power is obtained from an on-board 3.6 V Lithium

Thionyl Chloride battery. A weak battery will cause a “low battery”

marker to be added to any message transmitted.

Installation Instructions

2222. SPECIFICATIONS

. SPECIFICATIONS

. SPECIFICATIONS. SPECIFICATIONS

ACOUSTIC SENSOR SECTION

Microphone: Omni-directional electret

Alarm Duration: 4 seconds

RF immunity: 20 V/m, 1 MHz to 1000 MHz

Temperature range: -10° to 50°C (14° to 120°F)

Recommended Glass Size:

Minimum: 0.3 x 0.6 m (1 x 2') or larger glass thickness

Plate: 2.4 to 6.4 mm (3/32 to 1/4")

Tempered: 3.2 to 6.4 mm (1/8 to 1/4")

Wired: 6.4 mm (1/4")

Laminated: 3.2 to 6.4 mm (1/8" to 1/4")

POWERCODE TRANSMITTER SECTION

Frequency (MHz): 315, 404, 418, 433.92 or other frequencies

according to local requirements.

Transmitter's ID Code: 24-bit digital word, over 16 million

combinations, pulse width modulation.

Overall Message Length: 36 bits

Message Repetition: One-shot transmission (default) or once

every 3 minutes.

Supervision: Signaling at 60-minute intervals (U.S. version) or

15 minute interval (UK version)

Response to Tamper Event: Tamper report every 3 minutes

(until the tamper switch is restored).

POWER SUPPLY

Power Source: 3.6 V Lithium Thionyl Chloride (LiSOCl2) battery,

size 1/2 AA, Tadiran TL-5902 or equivalent.

Nominal Battery Capacity: 1.2 Ah

Current Drain: 24 µA standby, 13 mA on alarm (including LED)

Battery Life (with LED on):

@ 10 transmissions per day:

@ 50 transmissions per day:

Battery Supervision:

as part of any status report.

PHYSICAL

Operating Temperature:

Dimensions:

Weight (less battery) :

Housing Material and Color: Flame retardant ABS, white

Standards:

The 418 & 433.92 MHz models of this device comply with the

European Council Directive EMC 89/336/EEC & 92/31/EEC, and

bear the CE mark and certification.

Meets FCC Part 15, ETS 300-220 and MPT1349

Automatic transmission of battery condition data

80 x 108 x 43 mm (3.13 x 4.24 x 1.70 in.).

130 g (4.6 oz)

Over 10 years

About 6 years

0°C to 49°C (32°F to 120°F).

DE3596 1

3333. INSTALLATION

SMARTHOME.COM™ 1-800-SMART-HOME 949-221-9200 http://www.smarthome.com

Order#73951

. INSTALLATION

. INSTALLATION. INSTALLATION

3.1 Optimizing Detection and Avoiding

False Alarms

For best detection, avoid installing in:

!

Rooms with lined, insulating, or sound deadening drapes.

!

Rooms with closed wooden window shutters inside.

For best false alarm immunity:

!

Avoid 24-hour loop applications (perimeter loop OK).

!

Don't use where white noise, such as air compressor noise, is

present (a blast of compressed air may cause a false alarm).

!

Avoid rooms smaller than 3 x 3 m (10 x 10 ft) and rooms with

multiple noise sources such as small kitchens, glass booths

noisy areas, garages, small bathrooms, etc.

Areas to avoid:

!

Glass airlocks and glass vestibule areas

!

Noisy kitchens

!

Residential car garages

!

Small utility rooms

!

Stairwells

!

Small bathrooms

!

Other small acoustically live rooms. For glass break protection

in such applications, use shock sensors on the windows or

window frames.

Do Not Install In Humid Rooms The Wireless MCT-501 is not

hermetically sealed. Excess moisture on the circuit board can

eventually cause a short and a false alarm.

Avoid 24-Hour Loop Applications The MCT-501 is

recommended for perimeter loops and is designed to function in

occupied area. In 24-hour loop applications, where the sensor is

armed all day and all night, the false alarm prevention technology

will be pushed to its limit. Some sounds can duplicate the glass

break pattern the acoustic sensor detects.

Install the MCT-501 on a perimeter loop which is armed

whenever the door and window contacts are armed.

Protecting Occupied Areas

The false alarm immunity is best in rooms with only moderate

noise. For 24-hour occupied area protection, use shock sensors.

Proper Testing

The MCT-501 is designed to detect the breaking of framed glass

mounted in an outside wall. Testing the sensor with unframed

glass, broken bottles, etc., may not trip the sensor. The sensor

typically does not trip to glass breaking in the middle of the room.

No burglar breaks glass in the middle of a room, so such “breaks”

are false alarms.

NOTE: MCT-501 may not consistently detect cracks in glass, or

bullets which break through the glass. Glass-break sensors

should always be backed up by interior protection.

For best false alarm immunity the sensor should be located at

least 1.2 m (4 ft) away from noise sources (televisions, speakers,

sinks, doors, etc.). The sensor must always be in direct line of

sight of all protected windows. It cannot consistently detect glass

breaking around corners, in other rooms, etc. Front or back, up or

down orientation is not necessary.

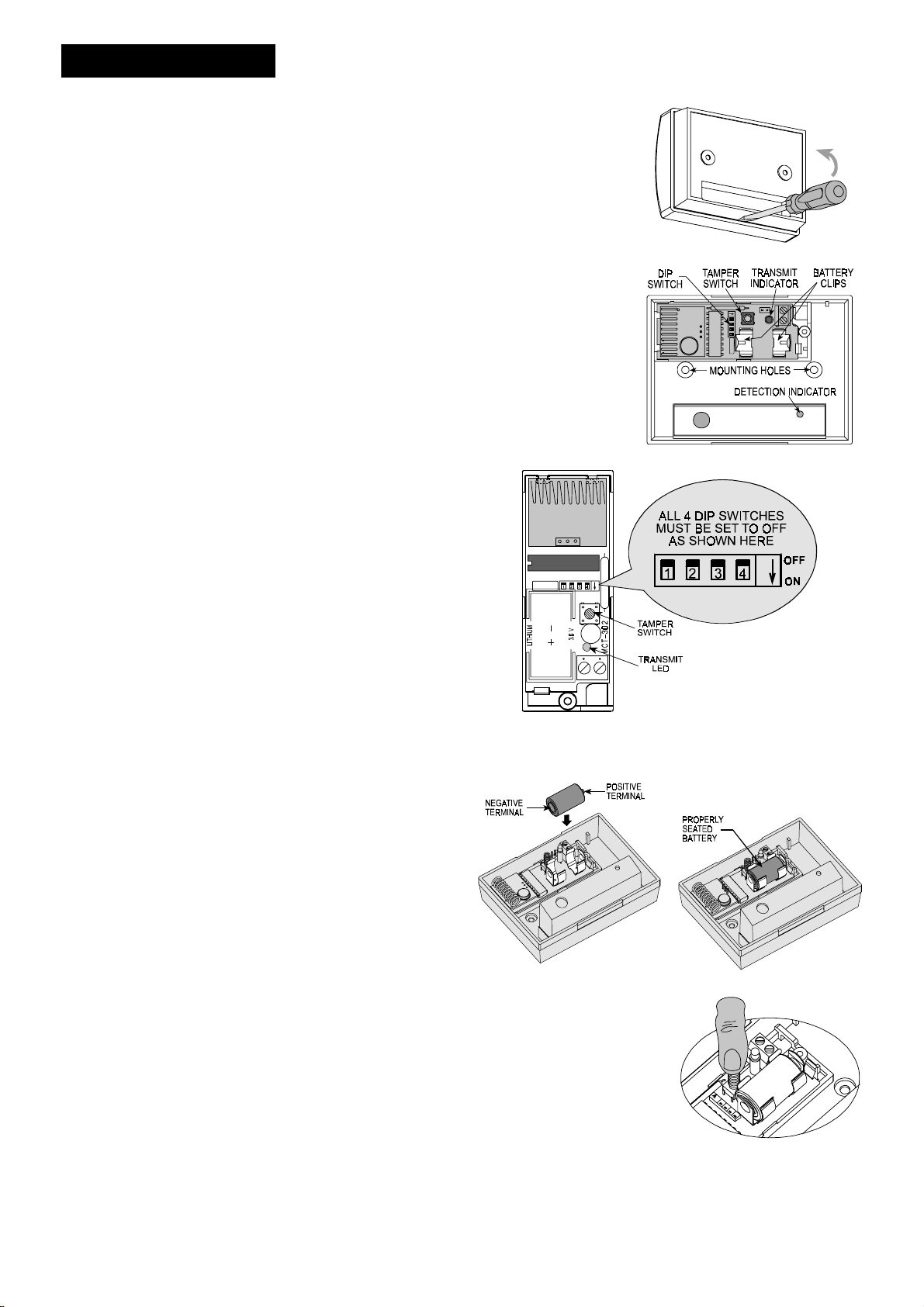

3.3 Preparing the Unit

A. Use a screwdriver to

separate the cover

from the base, as

shown in Figure 4.

You will find inside a

nylon bag with the

battery, two masonry

anchors (wall plugs)

and two mounting

screws.

B. Get to know the

items indicated in

Fig. 5 - they are all

relevant to the steps

you will have to take

in the course of

installation.

C. Verify that all 4 DIP

switch levers are set

to OFF as shown in

Figure 6 below. If not

- set them all OFF.

Figure 6. DIP Switches - Correct Position

D. Insert the battery into the battery clips, as shown in Figures 7

and 8. Observe Polarity!

Figure 4. Opening the Unit

Figure 5. Inside View

Use only Lithium Thionyl Chloride

battery (Tadiran TL-5902 or

equivalent)

.

3.2 Sound Travel Considerations

Since the sound of breaking glass travels directionally out from

the broken window, the best location for mounting the sensor is

on the opposite wall - assuming the glass to be protected is within

the sensor's range and line of sight. The ceiling and adjoining

(side) walls are also good sensor locations. A ceiling mounted

sensor will have better detection if positioned 2 - 3 m (6 - 10 ft)

away from the protected glass into the room.

As with all glass-break sensors, detection is reduced with

same-wall mounting, since such detection is partially dependent

on glass break sound reflecting off the opposite wall. Test the

range with Sentrol 5709C unit held flat against the glass. There

may be a reduction in range, depending on room acoustics.

Figure 7. Battery Insertion

E. Click the tamper switch

once and release it to reset

the transmitter at power up.

Note: Since the cover is

removed and power is

applied, a tamper situation

exists. Verify that the

MCT-501 transmits (the

transmit LED lights briefly)

once every 3 minutes.

Figure 8. Battery in Place

Figure 9. Resetting the Unit

2 DE3596

Loading...

Loading...