Page 1

CLIP SMA

Wireless Curtain-Type Infrared Detector

1. INTRODUCTION

The CLIP SMA is the smallest and most elegant wireless curtainpattern PIR detector for indoor use and designed for easy

installation. Its function is based on new and sophisticated,

patented FM data acquisition and digital signal processing.

Modern technology is used to include 3 different detectors in a

single case, each programmable for optimized performance at

the specific mounting location. This results in better catch

performance and virtually no false alarms.

The superiority in performance of this detector is achieved by

applying an improved version of the patented True Motion

Recognition™ (TMR) algorithm. This advanced motion analysis

method allows the CLIP SMA to distinguish between the true

motion of the human body and any other disturbances that cause

false alarms.

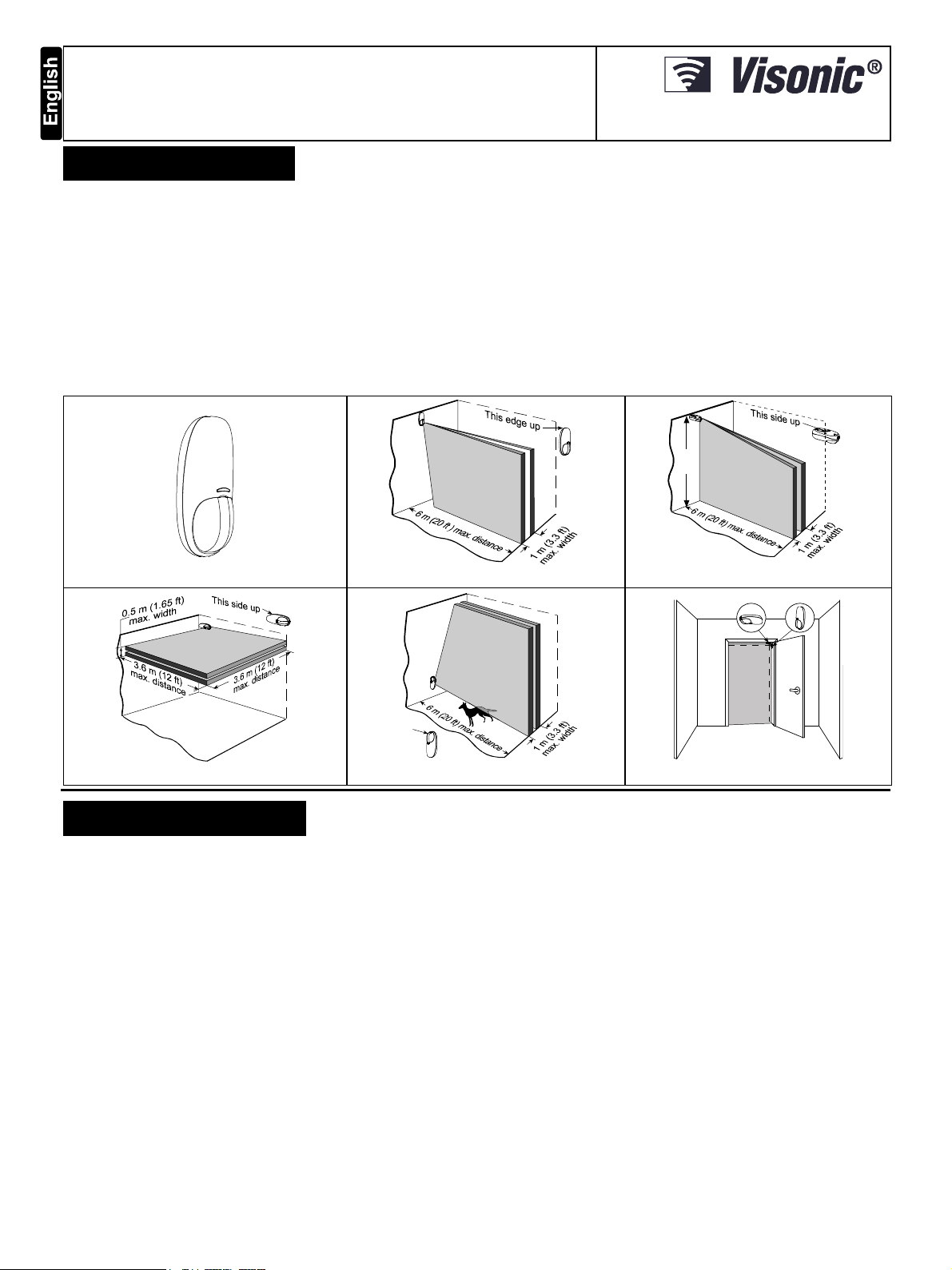

Figure 1. CLIP SMA General View

Figure 2. Wall-Mount Curtain

Installation Instructions

After detection, the detector disarms itself to save battery power.

It rearms (reverts to the ready state) if there is no subsequent

detection throughout the following 2-minute period.

The CLIP SMA includes the following features:

Very low current consumption

Microprocessor-controlled temperature compensation

Sealed chamber protects the optical system

Front cover tamper switch

White light protection

Elegantly styled, sturdy case

Detailed coverage patterns and mounting alternatives are

illustrated in Figures 2 through 6.

2.4m

Figure 3. Ceiling-Mount Curtain

OPTION A

OPTION B

DETECTION

CURTAIN

This

side

Figure 4. Overhead Curtain

up

Figure 5. Curtain / Pet Alley

Figure 6. CLIP SMA on Internal Doorframe

2. SPECIFICATIONS

OPTICAL

Detector Type: Dual-element low noise pyroelectric sensor.

Number of Curtain Beams: 2

Mounting Positions: See Figures 2 through 6.

Range Settings: Long (6 m/18 ft), Medium (4 m/12 ft) and Short (1.2 -

2m/6 ft) (Jumper-selected).

ELECTRICAL

Internal Battery: 3V Lithium battery, type CR123A. For UL installations,

use Panasonic, GP or Sanyo only.

Nominal Battery Capacity: 1450 mAh.

Battery Life: 3 years (for typical use).

Note: Inability to connect with wireless network, or wireless link quality no

higher than 20% may significantly reduce the expected battery life.

Battery Power Test: Performed immediately upon battery insertion

and periodically every several hours.

Microprocessor: 8-bit, low power CMOS.

FUNCTIONAL

Visual Indications (red LED):

LED lights for about 3 seconds upon transmission of alarm & tamper

messages and upon motion detection in the walk test mode.

LED flashes during the power-up stabilization period (approx. 2

min), or after restoring the cover (by pressing the tamper switch).

LED does not light upon transmission of supervision messages.

Alarm Period: Approx. 3 seconds.

D-303360 CLIP SMA Installer's Guide 1

Rearm Timer: Rearms the detector 2 minutes after the last alarm.

WIRELESS

Frequency: 2.4 Ghz as per IEEE 802.15.4

Tamper Alert: Reported when a tamper event occurs and in any

subsequent message, until the tamper switch is restored.

Supervision Message: Signaling at 24-minute intervals.

MOUNTING

Height: 1.8 - 2.4 m (6 - 8 ft). See Figures 2 – 6.

Installation Options: See Figures 2 – 6.

ENVIRONMENTAL

Operating Temperature: -10°C to 50°C (14°F to 122°F).

Storage Temperature: -20°C to 60°C (-4°F to 140°F).

RFI Protection: > 20 V/m to 1000 MHz.

Compliance with standards:

USA: CFR 47 part 15, Canada: RSS 210

ANSI/UL 639, ULC – S306

PHYSICAL

Dimensions (H x W x D): 105 x 35 x 30 mm (4-1/8 x 1-3/8 x

1-3/16 in.).

Weight (with battery): 60 g (2.1 oz).

Color: White.

PATENTS U.S. Patent 5,693,943 (other patents pending)

.

Page 2

J

R

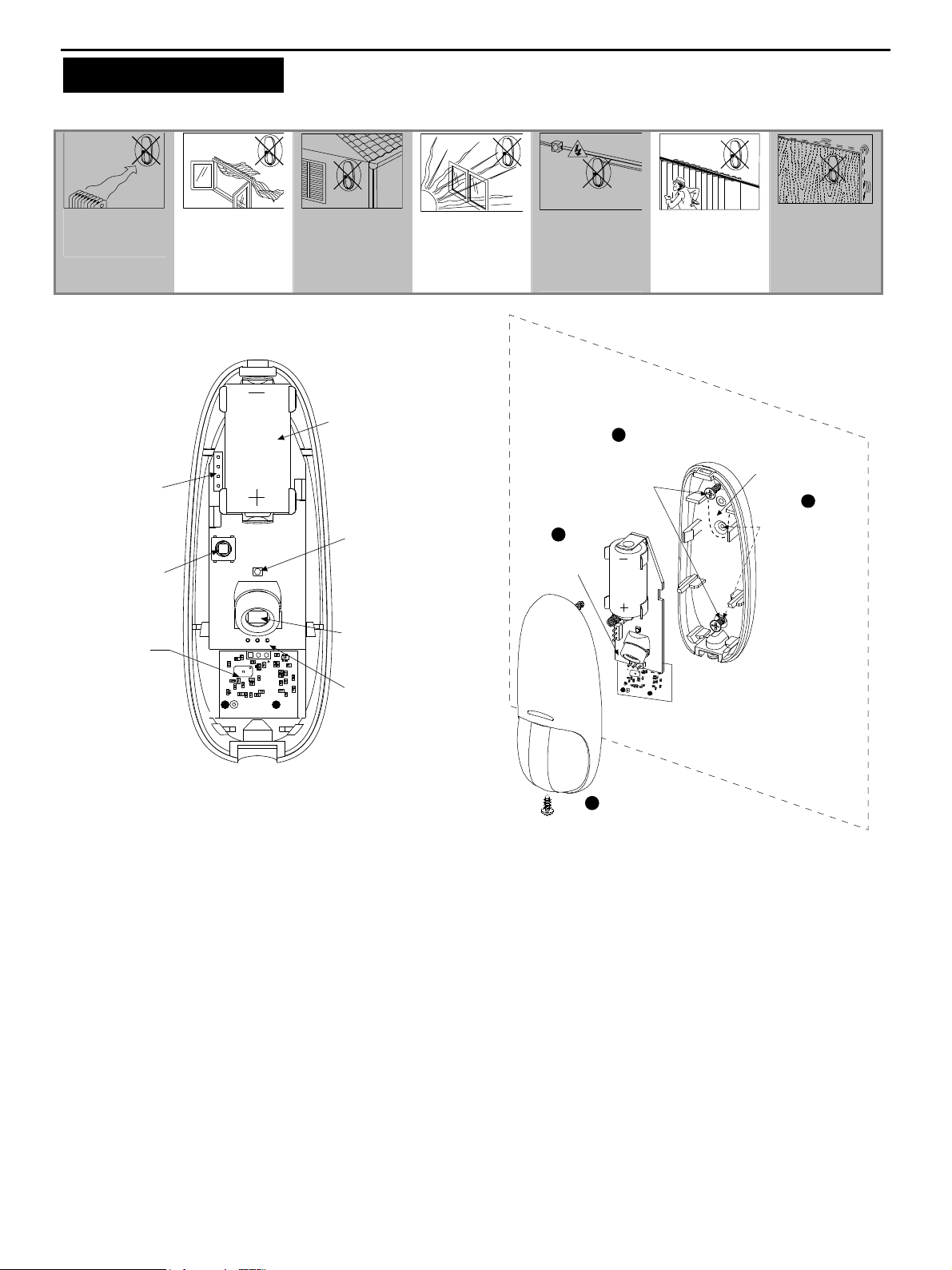

3. INSTALLATION

3.1 General Guidelines

Do not install

near sources of

heating/cooling.

Do not aim at

windows.

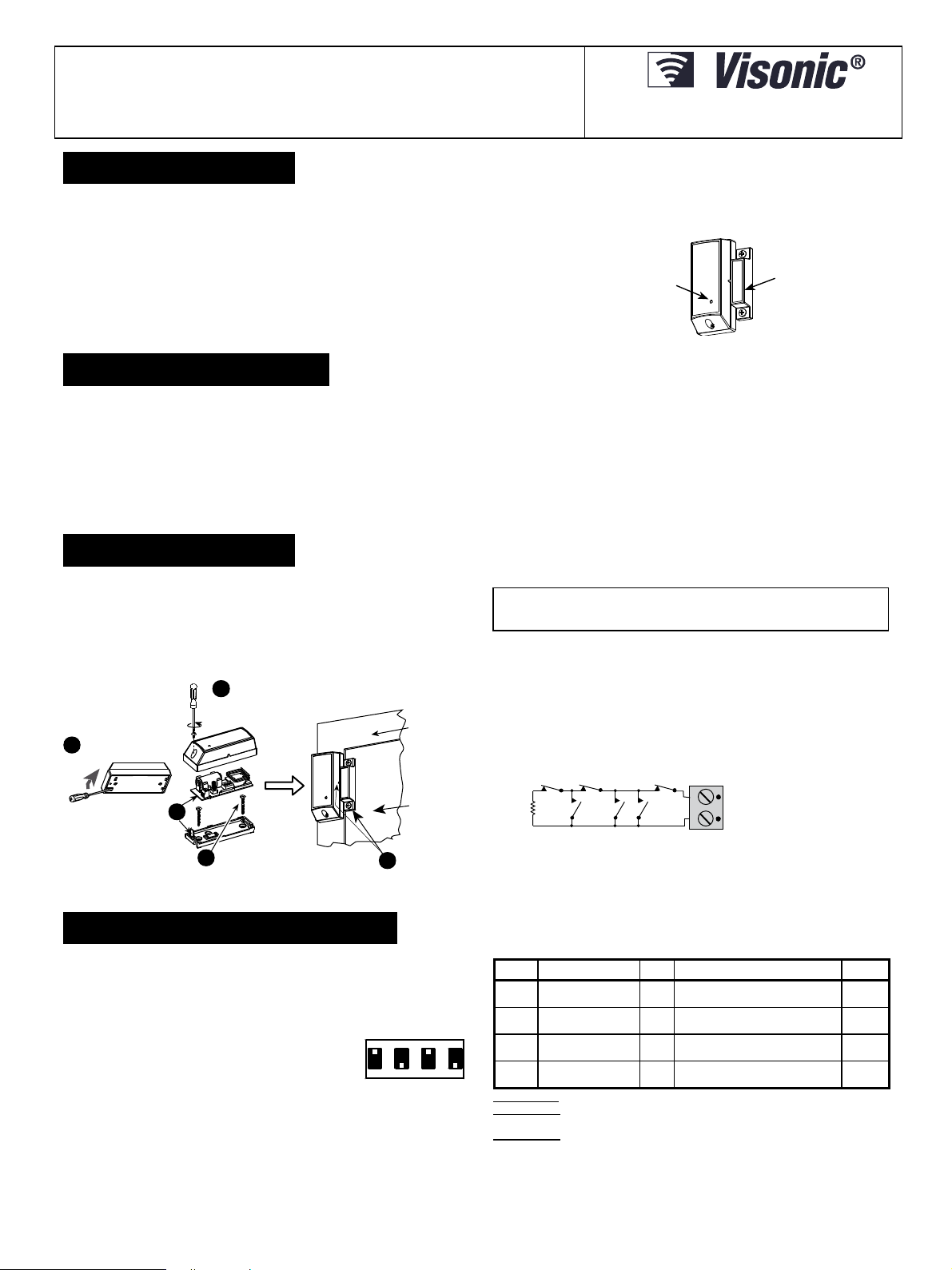

3.2 Regular Mounting

RANGE

SELECT

UMPE

FRONT

TAMPER

SWITCH

RF

MODULE

Do not install

outdoors.

3 VOLT

LITHIUM

BATTERY

BACK

TAMPER

SWITCH

(OPTIONAL)

SENSOR

LEDS

Do not install

where direct

sunlight can

strike the unit.

Do not install

near high-

voltage electrical

lines.

DRILL TWO HOLES

IN THE MOUNTING

SURFACE AND

SECURE BASE

WITH TWO

SCREWS

3

POSITION THE

PCB IN ITS

PLACE IN THE

BASE

M

Do not install

behind any

obstruction.

O

U

N

T

I

N

G

S

U

1

R

F

A

C

E

BREAK-AWAY

SEGMENT

FOR BACK TAMPER

(OPTIONAL), DRIL L

TWO HOLES

AND SECURE

WITH TWO SCREW

ATTENTION: The back tamper

switch becomes functional

only when the break-away

segment is secured to the

wall with a scre w .

Do not mount

on unstable

surfaces.

2

Figure 7. Internal View

INSERT SCREW TO

SECURE COVER

4

WITH BASE

Figure 8. Surface Mounting

Notes:

1) After mounting, be sure that no gaps remain in the detector

housing, for example, in the area around the screw holes.

2) Remove the battery using your fingers, and not with a screwdriver.

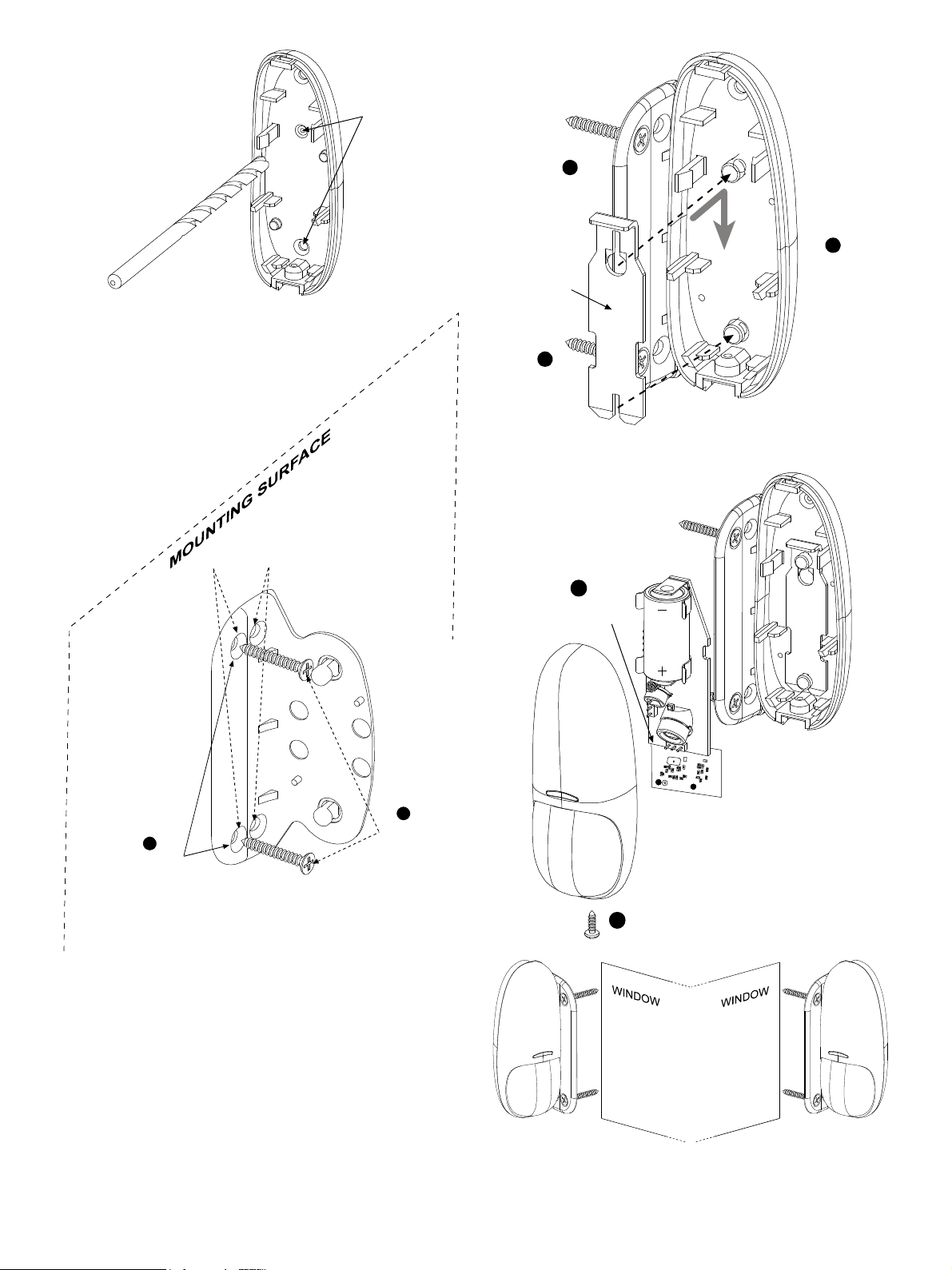

3.3 Bracket Mounting

Note: When mounting using the bracket, the back tamper is not

functional.

2 D-303360 CLIP SMA Installer's Guide

Page 3

THE BRACKET PROVIDES TWO MOUNTING OPTIONS

Figure 9. Drilling Holes

NOTE:

FOR OPTIMUM ANGLE COVERAGE .

USE THESE TWO HOLES TO INCREASE

THE COVERAGE RANGE BY 5

USE THESE TWO HOLES TO INCREASE THE

COVERAGE RANGE BY 10

DRILL TWO

7 mm (1/4“)

HOLES

AT THE

MARKED

SPOTS

2

PLACE THE

LOCKING PLATE

OVER THE TWO

PINS

1

PLACE THE

LOCKING

PLATE

BASE SLOTS

OVER THE

TWO

BRACKET

PINS

3

SECURE THE

LOCKING

PLATE BY

PRESSING

DOWNWARD

Figure 11. Securing Locking Plate to Base

**

1

DRILL TWO

HOLES IN THE

MOUNTING

SURFACE

*

Figure 10. Mounting Bracket to Surface

2

SECURE

BRACKET

WITH TWO

SCREWS

1

POSITIONTHE

PCB CORRECTLY

IN THE BASE

INSERT SCREWTO

SECURE COVER

2

WITH BASE

Figure 12. Mounting Cover to Base

Note: The CLIP SMA can be mounted on either side of a window.

Figure 13. Mounting on Both Sides of a Window

D-303360 CLIP SMA Installer's Guide 3

Page 4

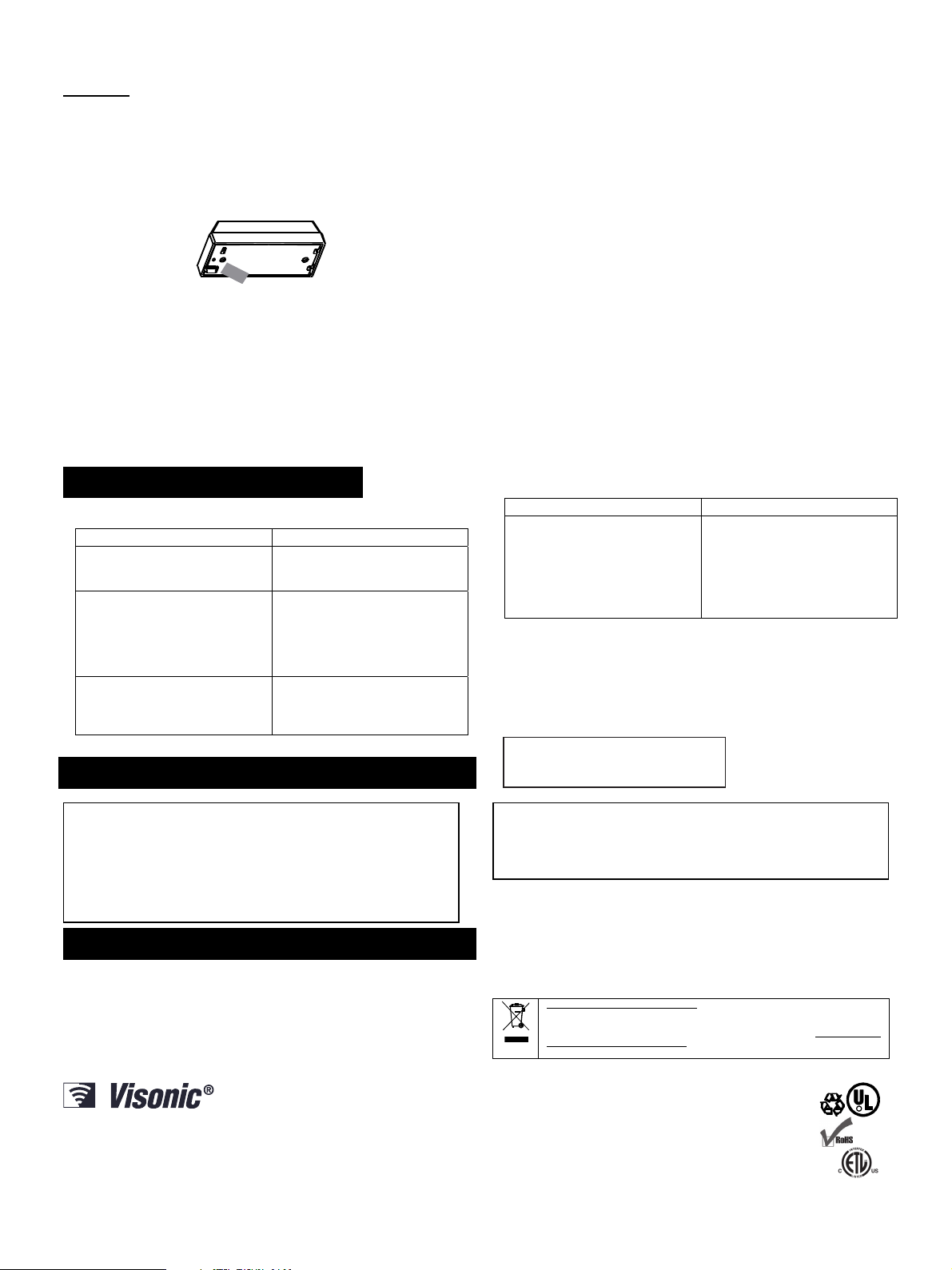

3.4 Setting the Coverage Range

y

y

A 4-pin jumper is used to select 3 ranges, according to the type of

installation, for the curtain beams (see Figures 2-6 and 15).

Short range -

approx.

2 m (6 ft)

Figure 14. Range Jumper Settings

Short Range Medium Range

Figure 15. Range Setting Diagram

The purpose of the range setting is to ensure optimal signal

processing and high immunity against false alarms.

Mount the range jumper in the desired position and make sure

that the protected area is within the selected coverage range (see

figure 15). Carry out a walk test (see Para. 3.7) to verify proper

performance.

Medium range -

approx.

4 m (12 ft)

Long range -

approx.

6 m (18 ft)

Long Range

3.6 Pairing/Defaulting the Detector

To pair the detector to the control panel, you must set it to pairing

mode.

A. Press and hold down the detector’s tamper switch.

B. Insert the battery into the detector. Wait for the RF

module’s green LED to light.

C. Release the tamper switch and press it again within 4

seconds. When the detector is in pairing mode, the

green LED starts to blink.

D. Complete the pairing procedure on the control panel

(see the pairing instructions in the control panel’s

installation guide).

3.7 Walk Testing

A. Mount the cover and tighten the screw. Wait for the detector

to stabilize (the LED stops flashing approx. two minutes after

the cover is closed).

B. Walk slowly across the far end of the curtain pattern (in

opposite directions). The LED indicator lights for approx. 3

seconds whenever you enter or exit a curtain beam.

Important: Perform walk test at least once a week to assure

proper function of the detector.

Note: After closing the cover the detector enters a 15 minute

walk-test mode. In this mode the LED will flash each time a

detection occurs, regardless of LED jumper settings, and the

detector will transmit on the occurrence of each detection event.

3.5 Activating the Detector

To activate, pull the strip that protrudes from the battery

compartment.

Figure 16. Activation Strip

4. TROUBLESHOOTING

If you encounter one of the following problems with the CLIP

SMA, perform the suggested remedy:

Problem Remed

Attempt to pair the sensor is

unsuccessful.

The sensor and the panel do

not communicate.

The sensor sends a Low

Battery indication.

Make sure that the sensor has

been defaulted and is set to

pairing mode (see section 3.6).

Perform the signal strength

testing procedure described in

the control panel installation

manual. Make sure that the

signal is sufficient. If

necessary, replace the

sensor’s battery.

To ensure continuous proper

operation, replace the battery

within two weeks of the first

Low Battery indication.

Problem Remed

Panel does not arm because of

an unrecognized sensor

malfunction

Consult with your installer or

system provider before you

disable a zone.

Disable the sensor zone (see

the control panel user manual).

Note that disabling a sensor

zone lowers the overall security

level of your system.

4 D-303360 CLIP SMA Installer's Guide

Page 5

5. SPECIAL COMMENTS

5.1 Product Limitations

Visonic Ltd. wireless systems are very reliable and are tested to

high standards. However, due to their low transmitting power and

limited range (required by FCC and other regulatory authorities),

there are some limitations to be considered:

A. Receivers may be blocked by radio signals on or near their

operating frequencies, regardless of the code selected.

B. A receiver can only respond to one signal at a time.

C. Wireless equipment should be tested regularly to determine

whether there are sources of interference and to protect

against faults.

5.2 Compliance with Standards

FCC

This device complies with Part 15 of the FCC Rules and RSS-210 of

Industry and Science Canada. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that

may cause undesired operation.

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of

the device.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas

produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le brouillage est susceptible

d'en compromettre le fonctionnement.

WARNING! Changes or modifications to this unit not expressly

approved by the party responsible for compliance could void

the user's authority to operate the equipment.

D. Even the most sophisticated detectors can sometimes be

defeated or may fail to warn due to: DC power failure /

improper connection, malicious masking of the lens,

tampering with the optical system, decreased sensitivity in

ambient temperatures near that of the human body and

unexpected failure of a component part.

The above list includes the most common reasons for failure

to detect intrusion, but is by no means comprehensive. It is

therefore recommended that the detector and the entire alarm

system be checked weekly, to ensure proper performance.

E. An alarm system should not be regarded as a substitute for

insurance. Home and property owners or renters should be

prudent enough to continue insuring their lives and property,

even though they are protected by an alarm system.

The digital circuit of this device has been submitted for testing in

order to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in

residential installations. This equipment generates uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference

to radio and television reception. However, there is no guarantee

that interference will not occur in a particular installation. If this

device does cause such interference, which can be verified by

turning the device off and on, the user is encouraged to eliminate

the interference by one or more of the following measures:

– Re-orient or re-locate the receiving antenna.

– Increase the distance between the device and the receiver.

– Connect the device to an outlet on a circuit different from the

one which supplies power to the receiver.

– Consult the dealer or an experienced radio/TV technician.

Visonic Ltd, M/N: E203826

FCC ID: WP3ZBT

IC: 1467C-ZBT

ANSI/UL

Complies with ANSI/UL 639, ULC – S306

D-303360 CLIP SMA Installer's Guide 5

Page 6

WARRANTY

Visonic Limited (the “Manufacturer") warrants this product only (the "Product") to the original purchaser only

(the “Purchaser”) against defective workmanship and materials under normal use of the Product for a

period of twelve (12) months from the date of shipm ent by the Manufacturer.

This Warranty is absolutely conditional upon the Product having been properly installed, maintained and

operated under conditions of normal use in accordance with the Manufacturers recomm ended installation

and operation instructions. Products which have become defective f or any other reason, according to the

Manufacturers discretion, such as im proper installation, failure to follow recommended installation and

operational instructions, neglect, willful damage, misuse or vandalism, accidental damage, alteration or

tampering, or repair by anyone other than the manufacturer, are not covered by this Warranty.

The Manufacturer does not represent that this Product may not be compromised and/or circumvented or

that the Product will prevent any death and/or personal injury and/or damage to property resulting from

burglary, robbery, fire or otherwise, or that the Product will in all cases provide adequate warning or

protection. The Product, properly installed and maintained, only reduces the risk of such events without

warning and it is not a guarantee or insurance that such events will not occur.

THIS WARRANTY IS EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES, WHETHER WRITTEN, ORAL, EXPRESS OR IMPLIED, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR

OTHERWISE. IN NO CASE SHALL THE MANUFACTURER BE LIABLE TO ANYONE FOR ANY

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF THIS WARRANTY OR ANY OTHER

WARRANTIES WHATSOEVER, AS AFORESAID.

THE MANUFACTURER SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES OR FOR LOSS, DAMAGE, OR EXPENSE,

INCLUDING LOSS OF USE, PROFITS, REVENUE, OR GOODWILL, DIRECTLY OR INDIRECTLY

ARISING FROM PURCHASER’S USE OR INABILITY TO USE THE PRODUCT, OR FOR LOSS OR

DESTRUCTION OF OTHER PROPERTY OR FROM ANY OTHER CAUSE, EVEN IF MANUFACTURER

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

THE MANUFACTURER SHALL HAVE NO LIABILITY FOR ANY DEATH, PERSONAL AND/OR BODILY

INJURY AND/OR DAMAGE TO PROPERTY OR OTHER LOSS WHETHER DIRECT, INDIRECT,

INCIDENTAL, CONSEQUENTIAL OR OTHERWISE, BASED ON A CLAIM THAT THE PRODUCT

FAILED TO FUNCTION.

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from which you orignially purchased it. If you are discarding this product and not

returning it for repair then you must ensure that it is returned as identified by your supplier. This product is not to be thrown away with everyday waste.

Directive 2002/96/EC Waste Electrical and Electronic Equipment.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or damage arising

under this limited warranty, THE MANUFACTURER'S MAXIMUM LIABILITY (IF ANY) SHALL NOT IN

ANY CASE EXCEED THE PURCHASE PRICE OF THE PRODUCT, which shall be fixed as liquidated

damages and not as a penalty, and shall be the complete and exclusive remedy against the Manufacturer.

When accepting the delivery of the Product, the Purchaser agrees to the said c onditions of sale and

warranty and he recognizes having been informed of.

Some jurisdictions do not allow the exclusion or limitation of incidental or c onsequential damages, so these

limitations may not apply under certain circumstances.

The Manufacturer shall be under no liability whatsoever arising out of the corruption and/or malfunctioning

of any telecommunication or electronic equipment or any programs.

The Manufacturers obligations under this W arranty are limited solely to repair and/or replace at the

Manufacturer’s discretion any Product or part thereof that may prove defective. Any repair and/or

replacement shall not extend the original Warranty period. The Manufacturer shall not be responsible for

dismantling and/or reinstallation costs. To exercise this Warranty the Product must be returned to the

Manufacturer freight pre-paid and insured. All freight and insurance costs are the responsibility of the

Purchaser and are not included in this Warranty.

This warranty shall not be modified, varied or extended, and the Manufacturer does not authorize any

person to act on its behalf in the modification, variation or extens ion of this warranty. This warranty shall

apply to the Product only. All products, accessories or attachments of others used in conjunction with the

Product, including batteries, shall be covered solely by their own warranty, if any. The Manufacturer shall

not be liable for any damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or attachments of

others, including batteries, used in conjunction with the Products. This W arranty is exclusive to the original

Purchaser and is not assignable.

This Warranty is in addition to and does not affect your legal rights. Any provision in this warranty which is

contrary to the Law in the state or country were the Product is supplied shall not apply.

Warning: The user must follow the Manufacturer’s installation and operational instructions including testing

the Product and its whole system at least once a week and to take all necessary precautions for his/her

safety and the protection of his/her property.

1/08

VISONIC LTD (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.):

VISONIC LTD. (UK): FRASER ROAD, PRIORY BUSINESS PARK, BEDFORD MK44 3WH. TEL.: +44(0)845 0755800 FAX: +44(0)845 0755801

PRODUCT SUPPORT: +44(0)845 755802

INTERNET: www.visonic.com

VISONIC LTD. 2011 CLIP SMA D-303360 - (Rev. 3, 10/11).

65 WEST DUDLEY TOWN ROAD

, BLOOMFIELD CT. 06002-1376. PHONE: (860) 243-0833, (800) 223-0020 FAX: (860) 242-8094

6 D-303360 CLIP SMA Installer's Guide

Page 7

MCT-302 SMA

Magnetic Contact Wireless Sensor

1. INTRODUCTION

The MCT-302 SMA is a fully supervised, wireless magnetic contact sensor. The sensor

includes a built-in reed switch (that opens upon removal of a magnet placed near it) and

an auxiliary hard-wired input, programmable as either N.C. or E.O.L., for use with

additional sensors - pushbuttons, detectors, door contacts etc.

An on-board DIP switch allows the installer to disable the magnet- operated reed

switch if only the auxiliary input is needed.

The reed switch and the auxiliary input behave as separate transmitters, although they

trigger the same RF transmitter. Each input has a unique ID.

The MCT-302 SMA tamper switch is activated when the cover is removed.

A periodic supervision message is transmitted automatically. The target receiver is thus

informed, at regular intervals, of the unit’s active participation in the system.

2. SPECIFICATIONS

Frequency: 2.4 Ghz as per IEEE 802.15.4

Alarm Inputs: 2, one internal and one external, with a separate sensor ID each.

Auxiliary Input Circuit Type: N.C. / E.O.L., selected with DIP switch

E.O.L. Resistor Required: 47 k

Message Repetition: Repetitive transmission (once every 3 minutes) or one-shot, as

selected with on-board DIP switch.

Supervision: Signaling at 24-min. intervals.

Response to Tamper Event: Tamper report every 3 minutes (until the tamper switch

is restored).

Power Source: 3 V Lithium CR-2 type battery, Panasonic, Sanyo or GP only.

3. INSTALLATION

3.1 Mounting (Fig. 2)

It is highly recommended to attach the sensor to the top of the door/window on the fixed

frame and the magnet to the movable part (door or window). Make sure that the magnet is

located not more than 6 mm (0.25 in.) from the sensor’s marked side.

Note: Once the cover is removed, a tamper message is transmitted to the receiver.

Subsequent removal of the battery prevents transmission of "TAMPER RESTORE",

leaving the receiver in permanent alert. To avoid this, during the enrolling process,

press the tamper switch while you remove the battery.

1

REMOVE SCREW

SEPARATE BASE

2

FROM COVER

P.C. BO AR D

BASE WITH

FLEX CATCH AND

REMOVE BOARD

3

4

MARK & DRILL 2 HOLES IN MOUNTING SURFACE.

FASTEN BASE WITH 2 COUNTERSUNK SCREWS.

Figure 2 – Mounting the Sensor

MOUNTTHE MAGNET NEAR ITS

LOCATION MARK WITH 2 SCREWS.

FIXED FRAME

MOVING PART

5

Installation Instructions

An LED lights whenever alarm or tamper events are reported. The LED does not light

while a supervision message is being transmitted.

Operating power is obtained from an on-board 3V Lithium battery. When the battery

low, a “low battery” message is sent to the receiver.

voltage is

MAGNET

TRANSMISSION LED

Fig. 1 - MCT-302 SMA

Battery Life Expectancy: 3 years (for typical use)

Note: Inability to connect with wireless network, or wireless link quality no higher than

20% may significantly reduce the expected battery life.

Battery Supervision: Automatic transmission of battery condition data as part of any

status report.

Operating Temperature: 0C to 49C (32F to 120F).

Dimensions: 81 x 32 x 25 mm (3-3/16 x 1-1/4 x 1 in.)

Weight: 53g (1.9 oz)

Standards: USA: CFR 47 part 15, Canada: RSS 210.

ANSI/UL 639, ULC – S306

.

3.2 Auxiliary Input Wiring (Fig. 3)

Remember! If your application does not require the auxiliary input, be sure to set

DIP switch SW2 to OFF and to short the input terminals together with a piece of

jumper wire.

A. Connect the auxiliary sensor contacts across the MCT-302 SMA auxiliary input

terminals.

B. If the auxiliary input of the MCT-302 SMA is defined as a Normally Closed (N.C.)

type (SW2 set to OFF), series connected N.C. sensor contacts must be used

exclusively. An E.O.L. resistor will not be required.

C. For E.O.L. supervision, set SW2 to ON.

Normally Closed (N.C.) as well as Normally Open (N.O.) sensor contacts can be

used, as show in figure 3. A 47k E.O.L. resistor must be wired at the far end of

the zone loop.

Note: For UL installations, the device connected to the initiating circuit must be

located in the same room as the sensor.

47

k

Figure 3 - E.O.L Wiring Example

NOTE - An alarm message is transmitted once the loop is opened or short circuited.

N.O. AND N.C. ALARM CI RCUI T

WITH E.O . L RESIS TO R

4. PREPARATION FOR USE

4.1 The Function Switches

A. Switch Tasks

The MCT-302 SMA has a 4-position DIP switch function selector. Each switch lever

allows you to select one of two options.

B. Setting the Switches

Set the function switches as desired prior to applying

power. Use a ball point pen or another pointed object to

shift the switch levers. The ON position is indicated by

the arrow on the switch body.

D-303365 MCT-302 SMA Installation Instructions 1

ON

1234

Function Selector

Table 1. Getting acquainted with the function selector

Sw- Function Pos. Selected Option Default

SW1 Reed switch input

enable/disable

SW2 Aux. input type

selector

SW3 Restore reports

enable/disable

SW4 Transmit mode

SWITCH SW1: Determines whether the reed switch input will be active or inactive.

SWITCH SW2: Determines whether the auxiliary input will behave as an end-of-line

(E.O.L.) input or as a normally closed (N.C.) input.

SWITCH SW3: Determines whether the sensor will report a restore event when an

input restores from an alarm condition.

selector

ON

Reed switch input is enabled

OFF

Reed switch input is disabled

ON

Aux. input is E.O.L. (47 k)

OFF

Aux. input is N.C.

ON

Restore events reported

OFF

Restore events not reported

ON

Alarms reported every 3 min.

OFF

Alarms reported only once

ON

OFF

ON

OFF

Page 8

Note: Selecting the ON position enables you to find out whether the door or window

under surveillance are open or closed.

Note: For UL installations, SW3 must be set to On position.

SWITCH SW4: In non-supervised systems, it is sometimes required to report an alarm

repeatedly at short intervals, until the disturbed input reverts to its normal

(undisturbed) state. SW4 is used to select between repetitive and one-shot

transmission.

Note: Transmissions initiated by “tamper” events will be repeated once every 3

minutes, regardless of SW4 setting.

When done, install the battery as directed in Para. 4.4.

4.2 Activating the Sensor

To activate, pull the strip that protrudes from the back of the sensor.

Fig. 4 – Activation Strip

4.3 Pairing/Defaulting the Sensor

To pair the sensor to the control panel, you must set it to pairing mode.

1. Press and hold down the sensor’s tamper switch.

2. Insert the battery into the sensor. Wait for the RF module’s green LED to light.

3. Release the tamper switch and press it again within 4 seconds. When the sensor

is in pairing mode, the green LED starts to blink.

4. Complete the pairing procedure on the control panel (see the pairing instructions

in the control panel’s installation guide).

5. TROUBLESHOOTING

If you encounter one of the following problems with the MCT-302 SMA, perform

the suggested remedy:

Problem Remedy

Attempt to pair the sensor is

unsuccessful.

The sensor and the panel do not

communicate.

The sensor sends a Low Battery

indication.

Make sure that the sensor has been

defaulted and is set to pairing mode

(see para 4.3).

Perform the signal strength testing

procedure described in the control

panel installation manual. Make sure

that the signal is sufficient. If

necessary, replace the sensor’s

battery.

To ensure continuous proper

operation, replace the battery within

two weeks of the first Low Battery

indication.

6. COMPLIANCE WITH STANDARDS

FCC

This device complies with Part 15 of the FCC Rules and RSS-210 of Industry and

Science Canada. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause undesired

operation of the device.

4.4 Testing the Unit

Before testing, set DIP switches SW1 through SW4 as required for the particular

application (Para. 4.1).

A. Insert the battery between the battery clips, at the correct polarity. For proper

operation, only Lithium battery (Panasonic, Sanyo, or GP type CR2) should be

used.

Caution: Risk of explosion if battery is replaced by an incorrect type. Dispose used

battery according to manufacturer's instructions.

B. Press the tamper switch once and release it.

Note: Since the cover is removed and power is applied, a tamper situation exists.

Verify that the MCT-302 SMA transmits (the LED lights briefly) once every 3

minutes.

C. When you are satisfied that tamper signals are transmitted properly, put the cover

on to return the tamper switch to its normal (undisturbed) position. Wait slightly

over 3 minutes to verify that tamper transmissions cease. If operation is normal,

secure the front cover to the base with the case closure screw.

D. Momentarily open the door or window and verify that the sensor LED lights,

indicating that transmission is in progress.

If SW4 is ON, wait 3 minutes to verify that the transmission is repeated at 3minute intervals.

E. Close the door or window, thus restoring it to the undisturbed state and watch the

LED. If SW3 is set to ON, a “restore” transmission will now take place.

F. If the auxiliary input is used, momentarily activate the detector connected to it and

check for a response similar to that described in D above. Then restore the input

loop to its undisturbed state. The response should be as in E above.

Note Regarding Tamper Message Transmission:

- If the reed switch input is enabled (SW1 is ON), the tamper message will be sent

with the reed switch’s ID.

- If the reed switch input is disabled (SW1 is OFF), the tamper message will be

sent with the auxiliary input’s ID.

Problem Remedy

Panel does not arm because of an

unrecognized sensor malfunction

Visonic Ltd, M/N: E203826

FCC ID: WP3ZBT

IC: 1467C-ZBT

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

ANSI/UL

Complies with ANSI/UL 639, ULC – S306

Consult with your installer or

system provider before you disable

a zone.

Disable the sensor zone (see the

control panel user manual). Note that

disabling a sensor zone lowers the

overall security level of your system.

7. MISCELLANEOUS COMMENTS

Visonic Ltd. wireless systems are very reliable and are tested to high standards.

However, due to low transmitting power and limited range (required by FCC and other

regulatory authorities), there are some limitations to be considered:

A. Receivers may be blocked by radio signals occurring on or near their operating

frequencies, regardless of the digital code used.

B. A receiver responds only to one transmitted signal at a time.

C. Wireless devices should be tested regularly to determine whether there are

sources of interference and to protect against faults.

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 65 WEST DUDLEY TOWN ROAD, BLOOMFIELD CT. 06002-1376. PHONE: (860) 243-0833, (800) 223-0020. FAX: (860) 242-8094

VISONIC LTD. (UK): UNIT 6 MADINGLEY COURT CHIPPENHAM DRIVE KINGSTON MILTON KEYNES MK10 0BZ. TEL.: +44(0)845 0755800 FAX: +44(0)845 0755801

PRODUCT SUPPORT: +44(0)845 755802

VISONIC GmbH (D-A-CH): KIRCHFELDSTR. 118, D-40215 DÜSSELDORF, TEL.: +49 (0)211 600696-0, FAX: +49 (0)211 600696-19

VISONIC IBERICA: ISLA DE PALMA, 32 NAVE 7, POLÍGONO INDUSTRIAL NORTE, 28700 SAN SEBASTIÁN DE LOS REYES, (MADRID), ESPAÑA. TEL (34) 91659-3120,

FAX (34) 91663-8468. www.visonic-iberica.es

INTERNET: www.visonic.com

VISONIC LTD. 2011

D-303365 MCT-302 SMA (Rev 3, 10/11)

2 D-303365 MCT-302 SMA Installation Instructions

The user is cautioned that changes or modifications to the unit, not expressly

approved by Visonic Ltd., could void the user’s FCC or other authority to

operate the equipment.

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from

which you orignially purchased it. If you are discarding this product and not returning it for

repair then you must ensure that it is returned as identified by your supplier. This product is not

to be thrown away with everyday waste.

European Directive 2002/96/EC Waste Electrical and Electronic Equipment.

R

Page 9

MCT-427 SMA

Supervised Wireless Smoke / Heat Detector

1. DESCRIPTION AND APPLICATIONS

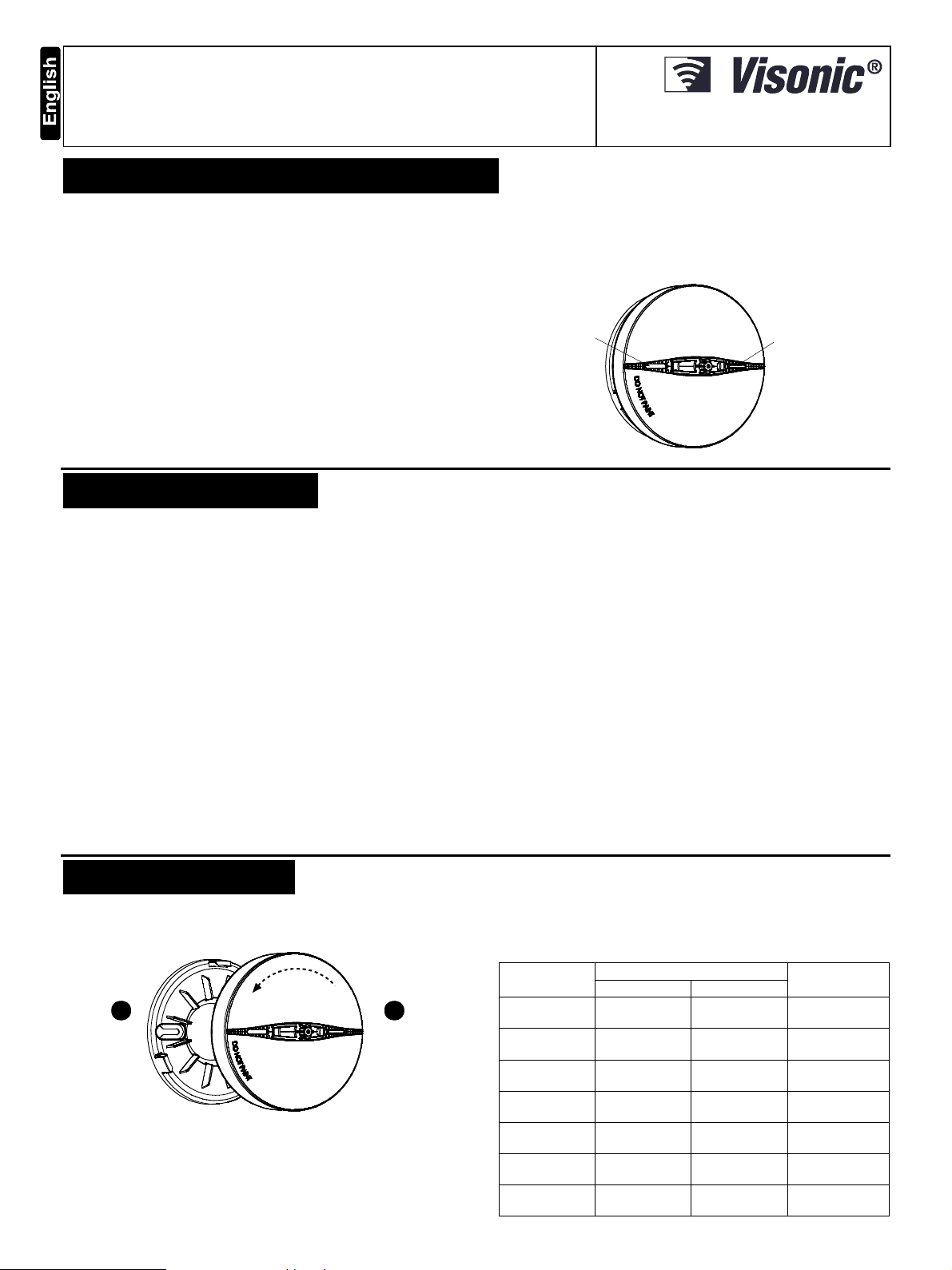

MCT-427 SMA (heat and smoke detector) are automatic fire detectors

with integral audible signal for open area protection, designed to

sense heat or smoke (not flame) and fitted with an iControl compliant

wireless transceiver.

MCT-427 SMA provides early warning of developing fire by sounding

an alarm with its built-in alarm horn, and by transmitting a coded

alarm signal to an iControl compliant control panel.

MCT-427 SMA will activate a fire alarm upon either smoke or heat

(temperature rate-of-rise) condition. With two fire sensors (heat and

smoke), the MCT-427 SMA detector may shorten the time to fire

alarm activation.

It must be borne in mind, though that effective prewarning of fire

accidents is only possible if the detector is located, installed and

maintained as described here.

In alarm condition, the buzzer sound can be stopped for 12 minutes by

pressing the TEST/MUTE switch. It will not restore the alarm condition,

but will temporarily silence the buzzer while you correct the condition.

After 12 minutes, the detector restarts the alarm buzzer sound.

2. SPECIFICATIONS

Alarm Sound Level: 85 dB at 3 m (10 feet)

TRANSMITTER AND CODING

Operating Frequency:

Supervision: Automatic signaling at 24-minute intervals.

Tamper Alerts: Tamper event (removal of the unit from its bracket) is

reported once. Tamper restore is reported when the tamper switch is

restored.

Transmission Indicator: Yellow LED lights upon transmission

(visible only when LED function is pre-defined, see par. 3.7).

ALARM REPORT:

Every 20 seconds for the first 3 minutes. Then, every 3 minutes until

30 minutes have elapsed.

Alarm stops reporting after 30 min., or if the detector goes into "alarm

restore".

After 30 minutes, an alarm bit will be sent as part of the supervision

message.

ELECTRICAL DATA

Power Source: 3 Volt CR123A / CR17450 lithium.

Panasonic/GP/Sanyo recommended

Operation Voltage: From 2.7 V to 3 V.

Current Drain: 18 µA standby, 70 mA max. in operation

Smoke Density: 1.44%/ft to 2.74%/ft

Cover Range: 50 – 100 cubic meters (1770 – 3530 cubic ft.)

2.4 GHz as per IEEE 802.15.4

3. INSTALLATION

Installation Instructions

Note: The TEST/MUTE switch functions as TEST switch (in normal

operation) or as MUTE switch (in alarm condition).

The tamper switch actuator (Fig. 3a/3b) is pressed against the bracket

when the unit is attached to the bracket. Removal of the unit from the

bracket causes the switch contacts to open, creating a tamper event,

which is reported by the transmitter to the alarm system control panel.

BUZZER

HOLE

Figure 1. General View (MCT-427)

Battery Supervision: Automatic transmission of battery status data as

part of any transmitted message.

Battery Life Expectancy: Battery life exceeds the minimum life required by

UL 268. Visonic warrantees the life of the battery for 5 years for typical use.

Note: Inability to connect with wireless network, or wireless link

quality no higher than 20% may significantly reduce the expected

battery life.

Audible and Visual Low Battery Warning: Built-in horn beeps every

30 seconds simultaneously with red LED flashing (for up to 30 days

when the battery voltage drops).

Audible and Visual Degraded Chamber Sensitivity Warning: Builtin horn beeps every 30 seconds in the middle of red LED flashing

intervals – indicates that the detector must be replaced.

Clean Warning Transmission: A clean (maintenance) signal is

transmitted when the detector's chamber becomes stained, causing the

detector to operate at high sensitivity.

PHYSICAL DATA

Operating Temperature: -10C to 50C (14F to 122F).

Relative Humidity: 10% to 85%

Dimensions: 120 mm (4.7") x 63 mm (2.5")

Weight (including battery): 165 g (5.8 oz)

Compliance with Standards:

USA: CFR 47 part 15, Canada: RSS 210.

ANSI/UL 639, ULC – S306

TEST / MUTE

BUTTON

&

LEDS

3.1 Disassembly

Separate the unit from its mounting bracket as shown in Figure 2.

1

Hold the

bracket with

one hand

Figure 2. Separating the Detector from Its Bracket

BRACKET DETECTOR

2

Rotate the

detector

anticlockwise

and pull it from

the bracket

3.2 Audible and Visual Indications

The dual color LED and buzzer are used to signal various alarm and

trouble messages as shown in Table 1 below:

Condition

Smoke alarm Flash every

Heat alarm(***) Flash every

Tamper

alarm(*)

Standby Flash every 30

Low battery Flash every 30

Smoke sensor

trouble

Low sensitivity

alarm

Table 1. Visual and Audible Indications

Visual Indication (LEDs) Audio

Red Yellow

500ms

500ms

- - Long beep every

sec.

sec.

Flash every 60

sec.

Flash every 30

sec.(**)

3 Flashes every

60 sec.

Indication

- 3 long beeps every

- Long beep every

- -

- Short beep every

- Short beep every

4 sec.

2 sec.

2 sec.

30 sec.

Short beep every

60 sec.

30 sec.

D-303364 MCT-427 SMA Installation Guide 1

Page 10

Condition

Heat sensor

trouble

Need to clean 2 flashes every

Visual Indication (LEDs) Audio

Red Yellow

Flash every 60

sec.

5 Flashes every

60 sec.

Short beep every

60 sec.

- 2 short beeps

30 sec.

every 30 sec.

Indication

Test See par. 3.6

* The tamper alarm will mute for 3 minutes at first power on, and

will revert to normal mode when the tamper switch condition is

changed.

** Delay of 15 sec. between buzzer beep and LED operation

3.3 Battery Connection and Initial Test

Caution! Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the manufacturer's instructions.

Attention: The detector battery cover is fitted with a red button that

prevents the detector from locking onto bracket if there is no battery

inside.

The smoke detector is supplied with a 3V CR123A / CR17450 battery.

Battery connection for both types of batteries is illustrated in Figure 3a

and 3b below.

3 volts CR123A

Battery cover

Open battery cover and

connect the battery to its

terminals (without

insulator). Verify proper

polarity.

Transmission

LED ON/OFF

button

3 volts CR17450

Transmission

LED ON/OFF

button

Battery cover

Tamper

switch

Open battery cover and connect the battery to its terminals.

Figure 3b. Battery Connection for CR17450

Figure 3a. Battery Connection for CR123A

Tam pe r

switch

Note: When the battery first makes contact, the alarm horn may

sound for one second. This indicates that the battery is connected

properly.

Close the cover, then press the test button (see fig. 1) for about 5

seconds, (for further details see par. 3.6)

.

3.4 Pairing/Defaulting the Detector

3.5 Mounting

Note: It is much easier to carry out this operation while holding the

MCT-427 in your hand, close to the control panel.

To pair the detector to the control panel, you must set it to pairing

mode.

A. Press and hold down the detector’s tamper switch.

B. Insert the battery into the detector. Wait for the RF

module’s green LED to light.

C. Release the tamper switch within 4 seconds and press it

again. When the detector is in pairing mode, the green

(1 of 3)

BRACKET DETECTOR

tab

LED starts to blink.

D. Complete the pairing procedure on the control panel (see

the pairing instructions in the control panel’s installation

guide).

Notes

1. A battery must be inserted into the detector

before the detector can be mounted onto the

bracket.

2. Unauthorized removal of the unit from the bracket

will initiate a tamper alert!

mounting surface with 2 screws.

1

Mark and drill 2 holes in

the mounting surface.

Fasten the bracket to the

2

Align bracket tabs with the

detector slots and rotate the detector

as shown. Pull the detector outward to

verify that it is securely attached.

Figure 4. Mounting the Detector

2 D-303364 MCT-427 SMA Installation Guide

Page 11

3.6 Test

Enter the test mode by pressing the test button. In this mode, the

detector will test smoke, heat and battery functions. If all functions are

good, the red LED lights 0.5s, off 0.5s, the yellow LED lights 0.5s, off

0.5s followed by a loud 3-beep alarm and the red LED flashes

simultaneously. Otherwise, the detector produces the warning signals

as detailed in Table 1.

3.7 LED Transmission Procedure

The yellow LED can be set to ON or OFF by pressing the

Transmission LED (yellow) ON/OFF button (see Figure 3a), as

indicated in Table 2 below.

Table 2. Interpreting the Transmission ON/OFF Button

Transmission LED ON/OFF

button (yellow) press

Press and release, flashes once ON

Press and release, flashes twice OFF

4. SMOKE DETECTOR INSTALLATION OVERVIEW

LED (yellow) Status during

transmission

4.1 Where to Install Smoke Detectors

Smoke detectors should be installed in accordance with the NFPA

Standard 74 (National Fire Protection Association, Batterymarch

Park, Quincy, MA 02169). For complete coverage in residential units,

smoke detectors should be installed in all rooms, halls, storage

areas, basements and attics in each family living unit. Minimum

coverage is one detector on each floor and one in each sleeping area

and attics in each family living unit. For maximum protection, a

smoke detector should be located outside primary sleeping areas or

on each level of your home. Here are a few useful tips for you:

Install a smoke detector in the hallway outside every separate

bedroom area, as in Figure 5. Two detectors are required in homes

with two bedroom areas, as in Figure 6.

Install a smoke detector on every floor of a multi-floor home or

apartment, as shown in Figure 7.

Install a minimum of two detectors in any household.

Install a smoke detector inside every bedroom.

Install smoke detectors at both ends of a bedroom hallway if the

hallway is more than 12 meters (40 feet) long.

Figure 5. Locations for Placing Smoke Detectors in a Single

Residence with only One Sleeping Area

Install a smoke detector inside every room where one sleeps with

the door partly or completely closed, since smoke could be blocked

by the closed door and a hallway alarm may not wake up the

sleeper if the door is closed.

Install basement detectors at the bottom of the basement stairwell.

Install second-floor detectors at the top of the first-to-second floor

stairwell.

Be sure no door or other obstruction blocks the path of smoke to

the detector.

Install additional detectors in your living room, dining room, family

room, attic, utility and storage rooms.

Install smoke detectors as close to the center of the ceiling as

possible. If this is not practical, put the detector on the ceiling, at

least 10 cm (4 inches) away from any wall or corner, as shown in

Figure 8.

If ceiling mounting is not possible and wall mounting is permitted by

your local and state codes, locate the detectors between 10 - 15

cm (4 - 6 inches) from the ceiling, also see Figure 8.

If some of your rooms have sloped, peaked, or gabled ceilings, try

to mount detectors 0.9 meter (3 feet) measured horizontally from

the highest point of the ceiling as shown in Figure 9.

Figure 9. Recommended

Figure 8. Recommended Best

and Acceptable Locations to

Mount Smoke Detectors

CAUTION (As required by the California State Fire

Marshall)

"Early warning fire detection is best achieved by the

installation of fire detection equipment in all rooms and

areas of the household as follows:

(1) A smoke detector installed in each separate sleeping area (in the

vicinity, but outside the bedrooms), and (2) Heat or smoke detectors

in the living rooms, dining rooms, bedrooms, kitchens, hallways,

attics, furnace rooms, closets, utility and storage rooms, basements

and attached garages."

Location to Mount Smoke

Detectors in Rooms with

Sloped, Gabled or Peaked

Ceiling

4.2 Where Not to Install Smoke Detectors

False alarms occur when smoke detectors are installed where they

will not work properly. To avoid false alarms, do not install smoke

detectors in the following situations:

Combustion particles are by-products of something burning. Do not

install smoke detectors in or near areas where combustion particles

Figure 6. Locations for Placing Smoke Detectors in Single-Floor

Residence with More than One Sleeping Area.

Figure 7. Placing Smoke Detectors in a Multi-Floor Residence

D-303364 MCT-427 SMA Installation Guide 3

are present, such as kitchens with few windows or poor ventilation,

garages where there may be vehicle exhaust, near furnaces, hot

water heaters and space heaters.

Do not install smoke detectors less than 6 meters (20 feet) away

from places where combustion particles are normally present, like

kitchens. If a 20-foot distance is not possible, try to install the

detector as far away from the combustion particles as possible,

preferably on the wall. To prevent false alarms, provide good

ventilation in such places.

IMPORTANT: Never try to avoid false alarms by disabling the

detector.

Page 12

Do not mount smoke detectors in the path of fresh air intake. The

flow of fresh air in and out can drive smoke away from the smoke

detector; thus reducing its efficiency. Figure 10 indicates the correct

and incorrect locations concerning this problem.

Near pain thinner fumes.

In close proximity to an automobile exhaust pipe; this will damage

the detector.

In damp or very humid areas or near bathrooms with showers.

Moisture in humid air can enter the sensing chamber, then turns

into droplets upon cooling, which can cause false alarms. Install

smoke detectors at least 3 meters (10 feet) away from bathrooms.

In very cold or very hot areas, including unheated buildings or

outdoor rooms. If the temperature goes above or below the

operating range of smoke detector, it will not work properly. Verify

that the temperature range of the detector falls within the Operating

Temperature, (see chapter 2. Specifications).

In very dusty or dirty areas, dirt and dust can build up on the

detector's sensing chamber, to make it overly sensitive.

Additionally, dust or dirt can block openings to the sensing

chamber and keep the detector from sensing smoke.

Near fresh air vents or very drafty areas like air conditioners,

heaters or fans. Fresh air vents and drafts can drive smoke away

from smoke detectors.

Dead air spaces are often at the top of a peaked roof, or in the

corners between ceilings and walls. Dead air may prevent smoke

from reaching a detector. See Figures 8 and 9 for recommended

mounting locations.

In insect-infested areas. If insects enter a detector's sensing

chamber, they may cause a false alarm. Where bugs are a

problem, get rid of them before putting up a detector.

Near fluorescent lights, electrical "noise" from fluorescent lights

may cause false alarms. Install smoke detectors at least 1.5 meters

(5 feet) from such lights.

Smoke detection depends on the smoke density present in a

room. Smoke density is greater in small rooms, for the same

amount of smoke, than in large rooms.

In small rooms less than 25 cubic meters (883 cubic ft.) in size,

a small amount of smoke may activate a smoke alert. For

example, smoking or bathroom steam may activate a smoke

alert.

Figure 10. Recommended Smoke Detector Locations to Avoid Air

WARNING: Never remove batteries to stop a false alarm. Open a

window or fan the air around the detector to get rid of the smoke. The

alarm will turn itself off when the smoke is gone. If false alarms persist,

attempt to clean the detector as described in this manual.

WARNING: Do not stand close to the detector when the alarm is

sounding. The alarm is loud in order to wake you in an emergency.

Too much exposure to the horn at close range may be harmful to your

hearing.

Streams with Combustion Particles

4.3 Smoke Detector Limitations

A. This smoke detector is designed for use in a single residential unit

or offices, which means that it should be used inside a single

family home or apartment or office.

B. Please refer to NFPA 101, the Life Safety Code, NFPA72 for smoke

detector requirements for fire protection in buildings not defined as

"households".

C. The smoke detector will not sense a fire if the smoke does not

reach the sensor. In order for a smoke detector to sense smoke, it

must be installed in the immediate vicinity of the fire.

In addition, smoke from fires in chimneys, in walls, on roofs, in remote

parts of the building, or on another level from where the smoke detector

is located, may not reach the smoke detector quickly enough for

occupants to escape unharmed. For this reason, installer shall install

smoke detectors on every level, in every sleeping area and in every

bedroom of the household.

D. Smoke detector may not be heard. The alarm horn in this smoke

detector meets or exceeds current Underwriter’s Laboratories

standards. However, if the smoke detector is not located in the same

room as the occupant or if it is blocked by a closed door or normal

noise, the alarm horn may not be heard. In addition, sound sleepers,

or persons who are under the influence of drugs or alcohol may not

hear the alarm or be able to react to it. Therefore, locate this

smoke detector, which has a sounder rated at 85 dB at 10 feet,

on every level, in every sleeping area and in every bedroom of

the household.

E. This detector, if used as a stand-alone unit, will not alert people

who are hard of hearing.

F. In general, detectors may not always warn you about fires

caused by carelessness and safety hazards like smoking in bed,

violent explosions, escaping gas, improper storage of flammable

materials, overloaded electrical circuits, children playing with

matches or arson.

G Smoke detectors are not fool-proof. Like all electronic devices,

smoke detectors have limitations. No type of smoke detector

can sense every kind of fire every time. In addition, smoke

from slow, smoldering fires rises slowly and may not reach

the smoke detector until actual flame breaks out. This type of

smoke may not reach the smoke detector in time for

occupants to escape unharmed.

H. Smoke detectors are not a substitute for life or property

insurance. Though smoke detectors have been responsible for

saving many lives, they are not warranted or implied to protect

lives or property in the event of fire.

I. These wireless systems are very reliable and are tested to high

standards. However, due to their low transmitting power and

limited range (required by the regulatory authorities), there are

some limitations to be considered:

i) Receivers may be blocked by radio signals on or near their

operating frequencies, regardless of the code selected.

ii) A receiver can only respond to one transmitted signal at a time.

iii) Wireless equipment should be tested regularly to determine

whether there are sources of interference and to protect

against faults

.

5. TAKING CARE OF THE MCT-427 SMA

5.1 Battery Replacement

The MCT-427 SMA was designed to be as maintenance-free as

possible. To keep the smoke detector in good working order, you must

test it weekly, as instructed in Para. 6.1 below.

Make it a rule to replace the detector’s battery (lithium) once every

8 years even if there is no indication that the battery is weak. Also

be sure to replace it immediately upon reception of a low battery

message via your control panel.

If you disregard this message, an audible reminder in the form of

4 D-303364 MCT-427 SMA Installation Guide

once-per-minute "beep" will sound after a few days. The lowbattery "beep" should last at least 30 days before the battery dies

out completely.

NOTE: For best performance, use only lithium batteries as

replacement batteries (see specifications). Carbon zinc batteries are

not acceptable.

Caution! Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the manufacturer's instructions.

Replace the battery as follows:

A. Separate the detector from its bracket (see figure 2).

Page 13

B. Replace battery (see Figure 3a or Figure 3b according to the

battery used).

5.2 Maintenance

It is necessary to maintain the detector frequently to ensure it working

properly. Follow these tips for taking care of your detector:

Use a vacuum cleaner to clean the air vents occasionally to keep

them free of dust. When a "Clean Warning" transmission is

received, the detector should be cleaned. When a trouble event is

received, the detector should be removed (see Table 1 for visual

6. ADDITIONAL ADVICE

and audible indications).

Perform detector functional test (see par. 3.6) weekly.

A clean (maintenance) signal is transmitted when the detector's

chamber sensitivity becomes degraded.

Note: This transmission applies to the PowerMax+ control panel

only.

Note: If false alarms keep occurring, check whether the detector's

location is adequate (see Para. 4.1 and 4.2). Relocate the unit if it is

not located properly. Clean as described above.

6.1 Routine Testing

The detector should be tested weekly and also whenever you suspect

that it does not go into alarm. Push the test button firmly with your finger

until the horn sounds (it may take up to 20 seconds, for further details

see par. 3.6). Also verify that the control panel responds to the

transmitted fire alarm. If the detector fails, have it repaired or replaced

immediately, to ensure that it works properly.

Every 3 months the smoke detector must be checked by using smoke

detectors test sprayer.

WARNING: Never use an open flame of any kind to test your

detector. You may set fire to damage the detector as well as your

home. The built-in test switch accurately tests all detector

functions, as required by Underwriters' Laboratories. This is the

only correct way to test the unit.

NOTE: If the alarm horn produces a loud continuous sound and the

red LED flashes when you are not testing the unit, this means the

detector has sensed smoke or combustion particles in the air. Verify

that the alarm is a result of a possible serious situation, which

requires your immediate attention.

The alarm could be caused by a false situation. Cooking smoke or

a dusty furnace, sometimes called "friendly fires" can cause the

alarm to sound. If this happens, open a window or fan the air away

to remove the smoke or dust. The alarm will turn off as soon as the

air is completely clear.

CAUTION: Do not disconnect the battery from the detector. This

will remove your protection from fires.

If there is any question as to the cause of an alarm, it should

be assumed that the alarm is due to an actual fire and the

residence should be evacuated immediately.

If the alarm horn begins to beep once every 30 sec (for further

details, see par. 3.2), this signal means that the detector's battery is

weak. Install a new battery immediately. Keep fresh batteries on

hand for this purpose.

6.2 Tips to Enhance Your Protection

From Fires

Putting up smoke detectors is only one step in protecting your family

from fires. You must also reduce the chances of fires starting in your

home. You must also increase your chances of escaping safely if one

does start. To have a good fire safety program you must apply the

following tips to enhance your family's protection from fires:

A. Install smoke detectors properly. Carefully follow all the

instructions in this manual. Keep your smoke detectors clean

and test them every week.

B. Remember that detectors that do not work will not alert you.

Replace your smoke detectors immediately if they are not

working properly.

C. Follow fire safety rules, and prevent hazardous situations:

Use smoking materials properly. Never smoke in bed.

Keep matches and cigarette lighters away from children.

Store flammable materials in proper containers. Never use them

near open flame or sparks.

Keep electrical appliances in good condition. Do not overload

electrical circuits.

Keep stoves, fireplaces, chimneys, and barbecue grills grease

free. Make sure they are properly installed and away from any

combustible materials.

Keep portable heaters and open flames such as candles away

from combustible materials.

Do not allow rubbish to accumulate.

Keep a supply of extra batteries on hand for your battery

powered smoke detectors.

D. Develop a family escape plan and practice it with your entire

family. Be sure to include small children in your practice.

Draw a floor plan of your home, and find two ways to exit from

each room. There should be one way to get out of each

bedroom without opening the door.

Explain to children what the smoke detector alarm signal means.

Teach them that they must be prepared to leave the home by

themselves if necessary. Show them how to check to see if doors

are hot before opening them. Show them how to stay close to the

floor and crawl if necessary. Show them how to use the alternate

exit if the door is hot and should not be opened.

Decide on a meeting place which has a safe distance from your

house. Make sure that all your children understand that they

should go and wait for you there if there is a fire.

Hold fire drills at least every 6 months, making sure that everyone,

even small children, knows what to do to escape safely.

Know where to go to call the Fire Department outside your home.

Provide emergency equipment, such as fire extinguishers, and

teach your family to use this equipment properly.

6.3 More Tips on How to Face a Fire at

Home

If you have made an escape plan and practiced it with your family,

their chances of escaping safely are increased. Go over the following

rules with your children when you have fire drills. This will help

everyone remember the rules in a real emergency.

A. Don't panic and stay calm. Your safe escape may depend on

thinking clearly and remembering what you have practiced.

B. Get out of the house as quickly as possible. Follow a planned escape

route. Do not stop to collect anything or to get dressed.

C. Feel the doors to see if they are hot. If they are not, open them

carefully. Do not open a door if it is hot. Use an alternate escape

route.

D. Stay close to the floor. Smoke and hot gases rise.

E. Cover your nose and mouth with a wet or damp cloth. Take short,

shallow breaths.

F. Keep doors and windows closed. Open them only if you have to in

order to escape.

G. Meet at your planned meeting place after leaving the house.

H. Call the Fire Department as soon as possible from outside your

house. Give the address and your name.

I. Never go back inside a burning building. Contact your local Fire

Department. They will give you more ideas about how to make your

home safer from fires and how to plan your family's escape.

D-302151 5

Page 14

y

)

7. TROUBLESHOOTING

If you encounter one of the following problems with the MCT-427

SMA, perform the suggested remedy:

Problem Remed

Attempt to pair the sensor is

unsuccessful.

Make sure that the sensor has

been defaulted and is set to

pairing mode (see section 3.4).

The sensor and the panel do

not communicate.

Perform the signal strength

testing procedure described in

the control panel installation

manual. Make sure that the

signal is sufficient. If

necessary, replace the

sensor’s battery.

8. STATEMENTS OF COMPLIANCE

FCC

This device complies with Part 15 of the FCC Rules and RSS-210 of

Industry and Science Canada. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that

may cause undesired operation.

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of

the device.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas

produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le brouillage est susceptible

d'en compromettre le fonctionnement.

WARNING! Changes or modifications to this unit not expressly

approved by the party responsible for compliance could void the

user's authority to operate the equipment

WARRANTY

Visonic Limited (the “Manufacturer") warrants this product only (the "Product") to the original purchaser only (the

“Purchaser”) against defective workmanship and materials under normal use of the Product for a period of twelve

(12) months from the date of shipment by the Manufacturer.

This Warranty is absolutely conditional upon the Product having been properly installed, maintained and operated

under conditions of normal use in accordance with the Manufacturers recommended installation and operation

instructions. Products which have become defective for any other reason, according to the Manufacturers

discretion, such as improper installation, failure to follow recom mended installation and operational instructions,

neglect, willful damage, misuse or vandalism, acc idental damage, alteration or tampering, or repair by anyone

other than the manufacturer, are not covered by this Warranty.

The Manufacturer does not represent that this Product may not be compromised and/or circumvented or that the

Product will prevent any death and/or personal injury and/or damage to property resulting from burglary, robbery,

fire or otherwise, or that the Product will in all cases provide adequate warning or protection. The Product,

properly installed and maintained, only reduces the risk of such events without warning and it is not a guarantee

or insurance that such events will not occur.

THIS WARRANTY IS EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, OBLIGATIONS

OR LIABILITIES, WHETHER WRITTEN, ORAL, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR OTHERWISE. IN NO CASE SHALL

THE MANUFACTURER BE LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES

FOR BREACH OF THIS WARRANTY OR ANY OTHER WARRANTIES WHATSOEVER, AS AFORESAID.

THE MANUFACTURER SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES OR FOR LOSS, DAMAGE, OR EXPENSE, INCLUDING LOSS

OF USE, PROFITS, REVENUE, OR GOODWILL, DIRECTLY OR INDIRECTLY ARISING FROM

PURCHASER’S USE OR INABILITY TO USE THE PRODUCT, OR FOR LOSS OR DESTRUCTION OF

OTHER PROPERTY OR FROM ANY OTHER CAUSE, EVEN IF MANUFACTURER HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE.

THE MANUFACTURER SHALL HAVE NO LIABILITY FOR ANY DEATH, PERSONAL AND/OR BODILY

INJURY AND/OR DAMAGE TO PROPERTY OR OTHER LOSS WHETHER DIRECT, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR OTHERWISE, BASED ON A CLAIM THAT THE PRODUCT FAILED TO FUNCTION.

The technical documentation as required by the European Conformity Assessment procedure is kept at:

UNIT 6 MADINGLEY COURT CHIPPENHAM DRIVE KINGSTON MILTON KEYNES MK10 0BZ. Telephone number: 0870 7300800, Fax number: 0870 7300801

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from which you orignially purchased it. If you are discarding this product and not

returning it for repair then you must ensure that it is returned as identified by your supplier. This product is not to be thrown away with everyday waste.

Directive 2002/96/EC Waste Electrical and Electronic Equipment.

The sensor sends a Low

Battery indication.

To ensure continuous proper

operation, replace the battery

within two weeks of the first

Low Battery indication.

Panel does not arm because of

an unrecognized sensor

malfunction

Consult with your installer or

system provider before you

disable a zone.

Disable the sensor zone (see

the control panel user manual).

Note that disabling a sensor

zone lowers the overall

security level of your system.

Visonic Ltd, M/N: E203826

FCC ID: WP3ZBT

IC: 1467C-ZBT

The digital circuit of this device has been tested and found to comply

with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in residential installations. This

equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio and television reception.

However, there is no guarantee that interference will not occur in a

particular installation. If this device does cause such interference,

which can be verified by turning the device off and on, the user is

encouraged to eliminate the interference by one or more of the

following measures:

– Re-orient or re-locate the receiving antenna.

– Increase the distance between the device and the receiver.

– Connect the device to an outlet on a circuit different from the one

which supplies power to the receiver.

– Consult the dealer or an experienced radio/TV technician.

ANSI/UL

Complies with ANSI/UL 639, ULC – S306

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or damage arising under this

limited warranty, THE MANUFACTURER'S MAXIMUM LIABILITY (IF ANY) SHALL NOT IN ANY CASE

EXCEED THE PURCHASE PRICE OF THE PRODUCT, which shall be fixed as liquidated damages and not as a

penalty, and shall be the complete and exclusive remedy against the Manufacturer.

When accepting the delivery of the Product, the Purchaser agrees to the said conditions of sale and warranty and

he recognizes having been informed of.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so these

limitations may not apply under certain circumstances.

The Manufacturer shall be under no liability whatsoever arising out of the corruption and/or m alfunctioning of any

telecommunication or electronic equipment or any programs.

The Manufacturers obligations under this W arranty are limited solely to repair and/or replace at the

Manufacturer’s discretion any Product or part ther eof that may prove defective. Any repair and/or replacement

shall not extend the original Warranty period. The Manufacturer shall not be responsible for dismantling and/or

reinstallation costs. To exercise this Warranty the Product must be returned to the Manufacturer freight pre-paid

and insured. All freight and insurance costs are the responsibility of the Purchaser and are not included in this

Warranty.

This warranty shall not be modified, varied or extended, and the Manufacturer does not authorize any person to

act on its behalf in the modification, variation or extension of this warranty. This warranty shall apply to the

Product only. All products, accessories or attachments of others used in conjunction with the Product, including

batteries, shall be covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or otherwise, caused by the

malfunction of the Product due to products, ac cessories, or attachments of others, including batteries, used in

conjunction with the Products. This Warranty is exclusive to the original Purchaser and is not assignable.

This Warranty is in addition to and does not af fect your legal rights. Any provision in this warranty which is

contrary to the Law in the state or country were the Product is supplied shall not apply.

Warning:The user must follow the Manufacturer’s installation and operational instructions including testing the

Product and its whole system at least once a week and to take all necessary precautions for his/her s afety and

the protection of his/her property.

1/08

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 65 WEST DUDLEY TOWN ROAD, BLOOMFIELD CT. 06002-1376. PHONE: (860) 243-0833, (800) 223-0020. FAX: (860) 242-8094

VISONIC LTD. (UK): UNIT 6 MADINGLEY COURT CHIPPENHAM DRIVE KINGSTON MILTON KEYNES MK10 0BZ. TEL.: +44(0)845 0755800 FAX: +44(0)845 0755801

PRODUCT SUPPORT: +44(0)845 755802

VISONIC GmbH (D-A-CH): KIRCHFELDSTR. 118, D-40215 DÜSSELDORF, TEL.: +49 (0)211 600696-0, FAX: +49 (0)211 600696-19

VISONIC IBERICA: ISLA DE PALMA, 32 NAVE 7, POLÍGONO INDUSTRIAL NORTE, 28700 SAN SEBASTIÁN DE LOS REYES, (MADRID), ESPAÑA. TEL (34) 91659-3120,

FAX (34) 91663-8468. www.visonic-iberica.es

INTERNET: www.visonic.com

VISONIC LTD. 2011

MCT-427 SMA D-303364 Rev 3 (10/11

TCC 2

BOSEC

9213

6 D-303364 MCT-427 SMA Installation Instructions

Page 15

MCT-442 SMA

V

Supervised Indoor Wireless CO Gas Detector

1. INTRODUCTION

The carbon monoxide (CO) detector is designed to monitor the

CO gas level in residential dwellings and give early warning

before potentially dangerous levels exist. The CO alarm is

transmitted to the iControl control panel.

The CO gas is considered to be a highly dangerous poisonous

gas because it is colorless, odorless, tasteless and very toxic.

Presence of CO gas inhibits the blood's capacity to transport

oxygen throughout the body, which can eventually lead to brain

damage. CO gas is produced by incomplete combustion of fuels

(such as natural gas, propane, heating oil, kerosene, coal,

charcoal, gasoline or wood) that can occur in any device that

depends on burning for energy and heat (such as furnaces,

boilers, room heaters, hot water heaters, stoves, grills and in any

gasoline powered vehicle or engine).

Before CO harmful level is reached, the detector's internal buzzer

beeps sound periodically and the detector's red LED flashes. In

this condition, the buzzer sound can be stopped for 6 minutes by

pressing the TEST/MUTE switch. It will not correct the CO gas

problem, but will temporarily silence the buzzer while you correct

the problem. After 6 minutes, the detector restarts alarm if the CO

level remains high.

The detector provides

low battery and detector

end-of-life indications.

Caution: The detector

expiry date is stamped

on the detector. After

the expiry date, the

detector should not be

used - do not wait for

end-of-life indication!!

The detector is continuously self-tested and has a TEST button

that enables the user to test the detector anytime.

Note: The TEST/MUTE switch functions as TEST switch (in

normal operation) or as MUTE switch (in alarm condition).

The tamper switch actuator (fig. 3), is pressed against the bracket

when the unit is attached to the bracket. Removal of the unit from

the bracket causes the switch contacts to open, creating a tamper

event, which is reported by the transmitter to the alarm system

control panel.

2. SPECIFICATIONS

CO DETECTION

Detection principle: Electrochemical cell

Detector Active Life: 5 years

Selectable Sensitivity:

DIP switch in EN Mode

No warning at 30 ppm for 120 minutes, 50 ppm for 60 minutes,

100 ppm for 10 minutes.

Warning at 50 ppm between 60-90 minutes, 100 ppm for 10-40

minutes, 150 ppm within 3 minutes.

DIP switch in UL Mode

No warning at 30 ppm for 30 days, 70 ppm for 60 minutes, 150

ppm for 10 minutes, 400 ppm for 4 minutes.