Visonic TOWER 20 AM INSTALLATION

TOWER 20 AM

Outdoor Octa-Quad™ Mirror Detector with Anti-Mask

[Grade 3]

1. INTRODUCTION

Detector's Features

• Patented 8 independent quad PIR detectors (Octa-QUAD™) operating in

true Quad configuration with true motion recognition (TMR) processing

for each of the 8 PIR detectors and central motion processing - can

distinguish between a moving intruder and moving trees and bushes.

• Advance Obsidian Black Mirror

• High protection against snow, rain, dust, wind and direct sunlight.

• Tamper protection against opening and removal from wall.

• Alarm LED is visible in sunlight.

TM

optics (patent pending).

• Low voltage detection

• Self test

• Day & night or night only setting.

•

Robust housing with recessed window.

•

Smart anti masking can distinguish

between masking spray and rain.

•

Immunity to pets weighing up to 18 Kg

(40lb), not pet alley.

• Built in swivel bracket.

2. SPECIFICATIONS

OPTICAL

Black Mirror Max. Coverage: At

least 12 meters (40 ft)/90º.

Detector Technology: 8

independent quad PIR detectors

operating in true Quad

configuration.

Pet- immune: Up to 18Kg (40lb.)

ELECTRICAL

Input Power: 8-16VDC

Standby Current:

15mA@12VDC.

Supply Current: 70 mA max.

(red and yellow LEDs light

steadily)

Low Voltage Detection: If

input voltage is below 7.5 VDC

Outputs:

Alarm output: Solid State

Relay. NC, 100 mA / 30 V, 35

ohm maximum internal

resistance. (see Table 4).

Trouble output: Solid State Relay. NC, 100 mA / 30 VDC, 35 ohm

maximum internal resistance.

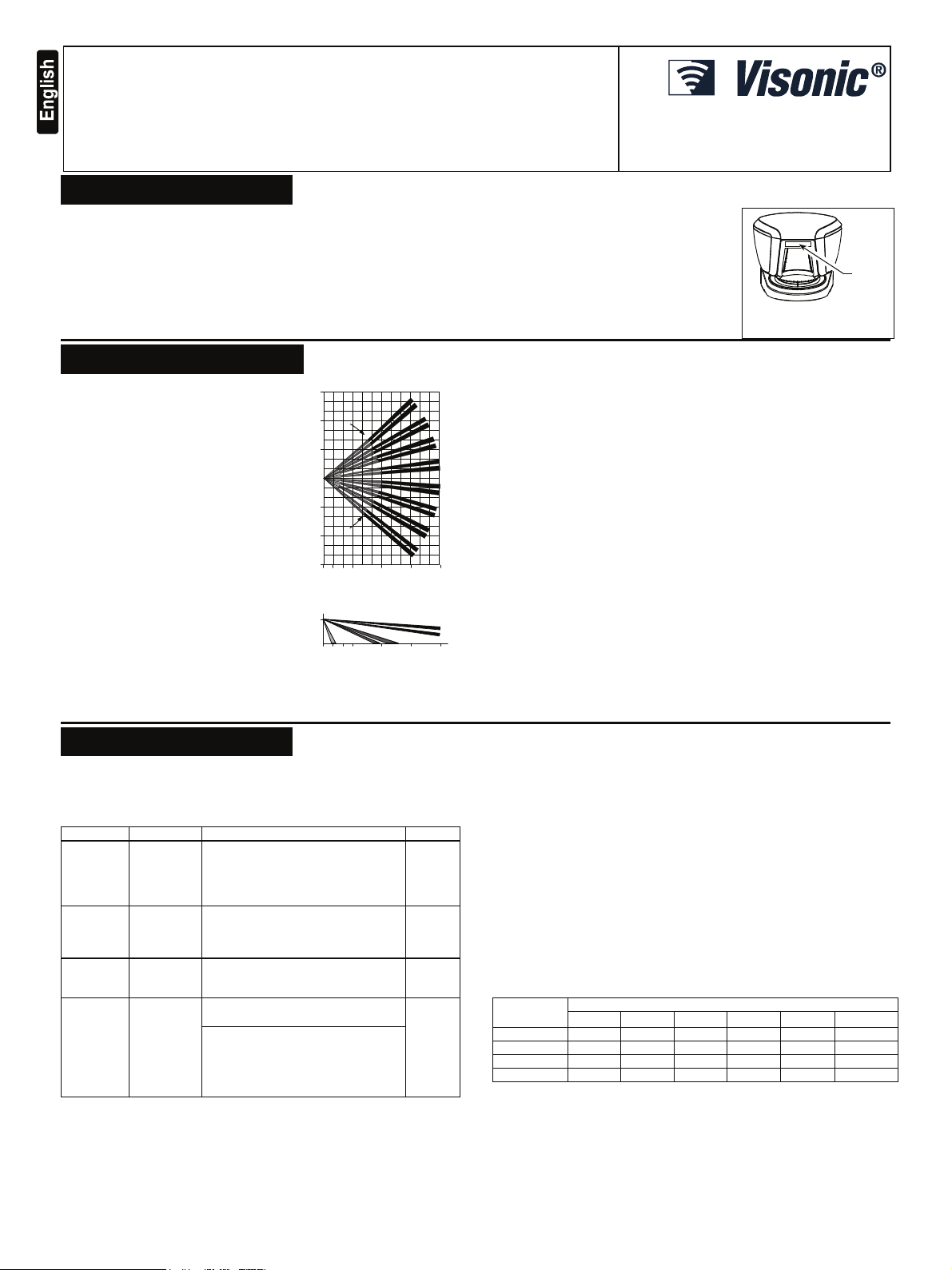

9m (30ft)

6m (20ft)

3m (10ft)

3m (10ft)

6m (20ft)

9m (30ft)

2.4 m

(8 ft)

Fig. 2 - Coverage pattern

(see Table 4).

TOP VIEW

90°

0

36912 m0

10 20 30 40 ft

SIDE VIEW OF

EACH DETECTOR

36912 m0

10 20 30 40 ft

Tamper output: NC switch, 50mA / 30 VDC. "Open" by opening

detector’s cover or removing it from mounting surface.

Masking detection delay: 120 sec.

Remote LED enable input (TST): High impedance input. Affects

LEDs operation only if internal LEDs selector is set to OFF.

MOUNTING

Mounting type: Wall mounting

Mounting height: 1.5 - 3.0 meters (5 – 10 ft)

Vertical adjustment: 0º to -10º, in 2.5º steps.

Horizontal adjustment: -45º to +45º, in 5º steps.

ENVIRONMENTAL

Operating Temperature: -35°C to 60°C (-31°F to 140°F)

Storage Temperature: -35°C to 60°C (-31°F to 140°F)

Humidity: 95% max.

White light immunity: Above 25000 lux

PHYSICAL

Dimensions (height x length x width: 157x147x124mm (6-3/16 x 5-13/16

x 4-7/8").

Weight: 600g (21 oz)

Color: White or gray

STANDARDS COMPLIANCE

(FCC) CFR 47 Part 15, EN 50130-4, EN 60950, EN 50130-5

Environmental class IV. IP 55.

US Patents: 7250605, 6818881, 5693943. Other patents pending.

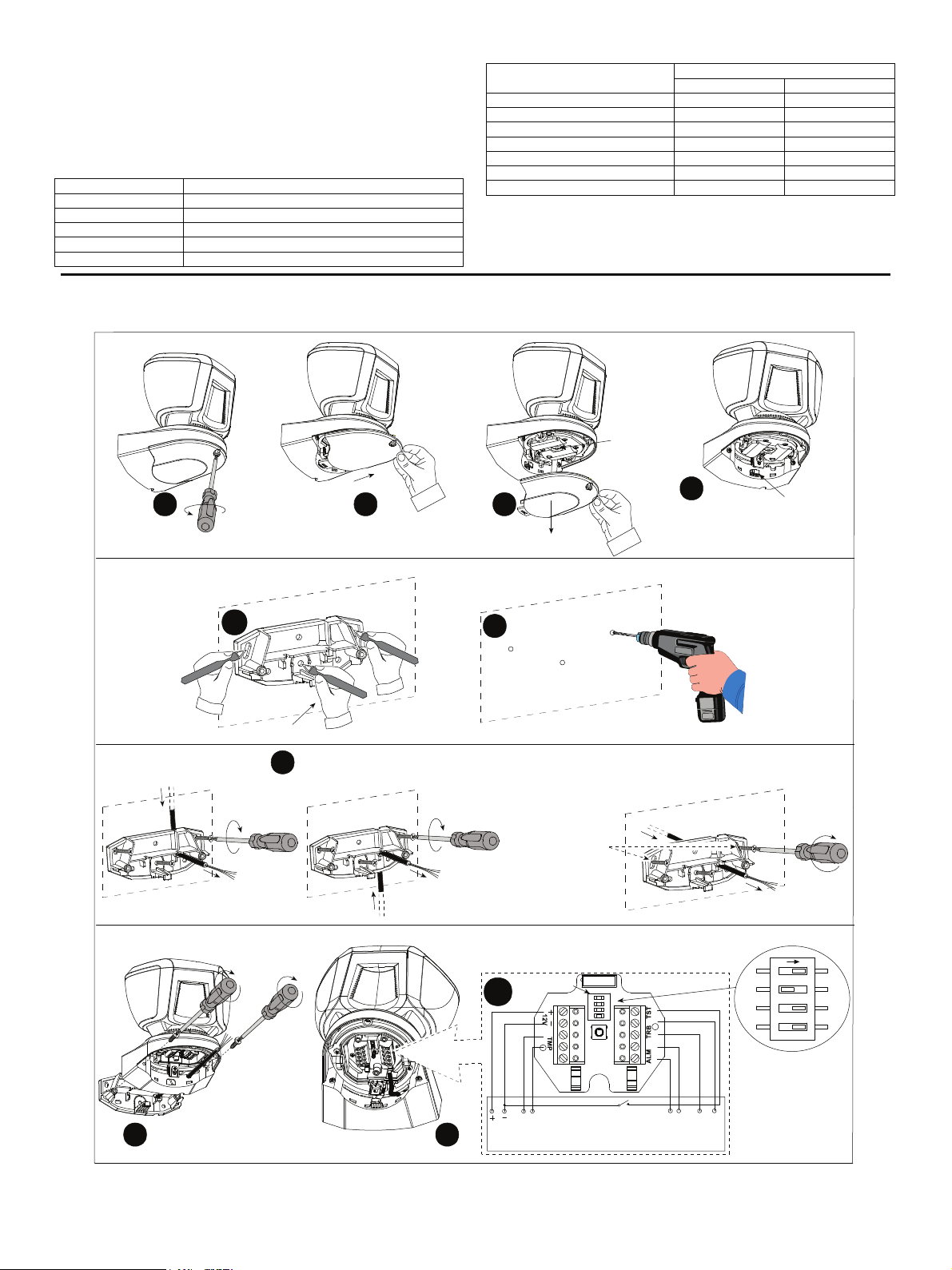

3. INSTALLATION

3.1 DIP Switches Setup

Remove the 2 detector's bottom covers (see Figure 3, steps 4-8) to gain

access to the DIP switches. Set the DIP switches, according to Table 1:

DIP SW # Function Description Default

LEDs

1

OFF/ON

24H / night

2

only

AM ON /

3

OFF

Masking

event opens

4

Alarm relay

(EN

standard)

* Switching from OFF to ON resets the detector for a stabilization

period of 60 sec. and causes the detector to re-adapt to its

current surroundings. Remain at a distance of at least 0.5 m (1.5

ft.) from the detector to prevent disruption of this process.

** Use ON for EN approved control panels / installations. However,

many installers prefer not to have the ALARM relay opened on a

masking event.

Table 1 – DIP Switch Setup

OFF: Motion and masking alarm LEDs

is disabled (OFF). Can be enabled by

TST input (Active "low")

ON: Motion and masking alarm LEDs

is enabled (ON).

OFF: Motion alarms are always

enabled (24 hours).

ON: Motion alarms are enabled only

at dark (night).

ON: AM on

OFF: AM off

*

OFF: masking event reported to panel

as TROUBLE (Trouble relay opens).

ON: masking event reported to panel

as TROUBLE and ALARM (EN

standard). Trouble and Alarm relay

opens at the same time.

**

ON

OFF

ON

OFF

3.2 Installation

Bracket installation (see figure 3) – firmly fix the bracket on a stable

wall or pillar. The orientation of the fixed bracket should be as parallel

as possible to the surveyed ground surface.

3.3 Wiring

Perform wiring (see figure 3, step 8 - 10)

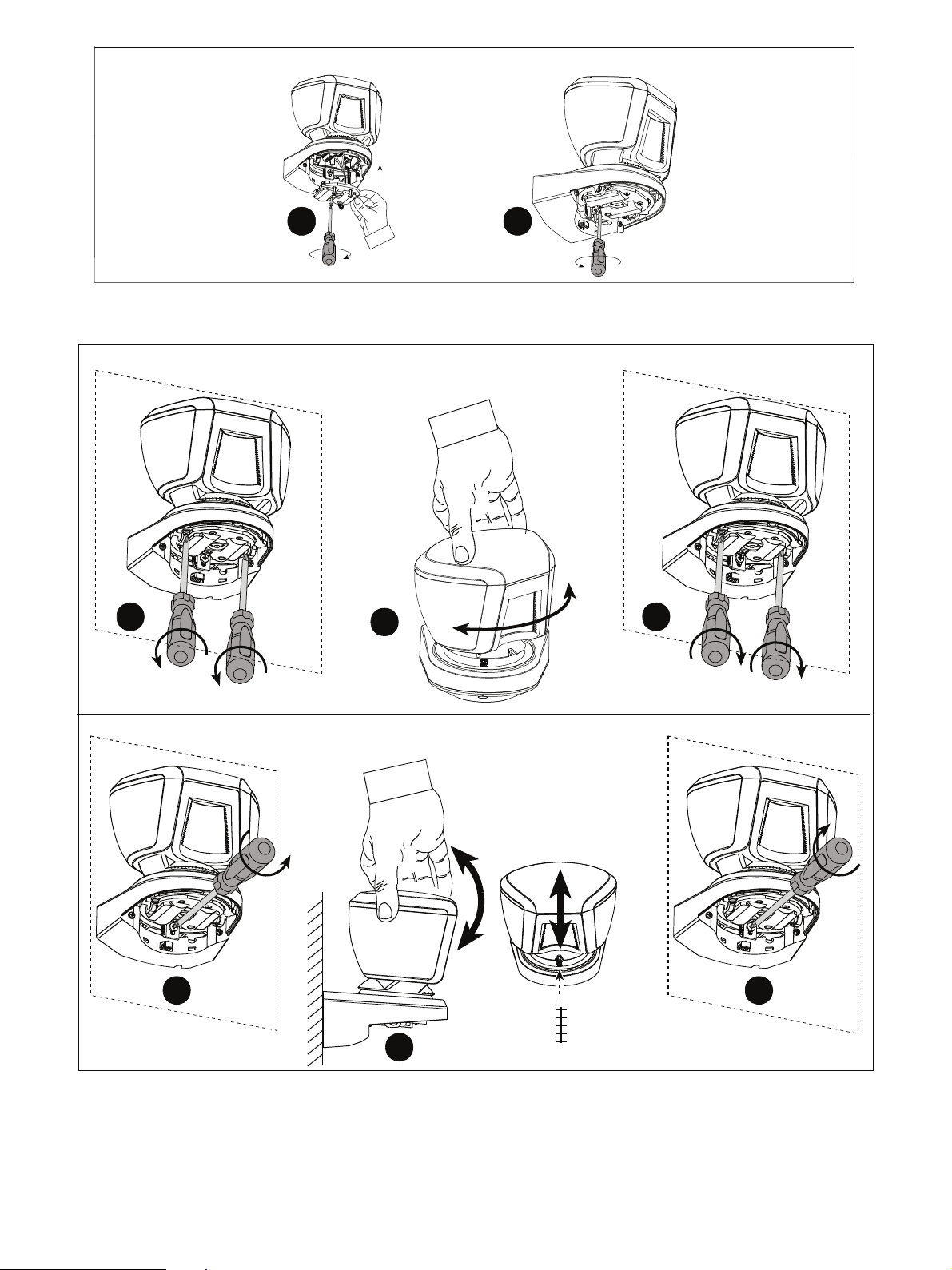

3.4 Adjustments

Adjust detector's horizontal and vertical angles (see Fig. 4, steps 1 - 6),

according to the surveyed ground surface and close the detector, as

shown in Fig. 3, steps 7 - 12.

The vertical angle indicator position for various installation height and

coverage distance combinations is detailed in Table 2 (the

information refers to a relatively flat surveyed area. however, in any

case the vertical adjustment should be verified by walk-test).

Mounting

Height

3.0m / 9,8 ft - 1 2 2 3 3

2.5m / 8,2 ft 1 1 2 3 4 4

2.0m / 6.7 ft 1 2 3 4 5 5

1.5m / 4.9 ft 2 3 4 5 - -

3.5 Test

A. Set the detector in Walk-Test mode, by setting DIP switch 1 (LEDs

ON/OFF) to ON position (see Fig. 3, steps 10 and 11), or activate

the remote TST input by connecting it to GND.

B. Walk into the detector's field of view at the expected far edge of the

coverage area. Verify that each time your motion is detected the red

LED lights for 2 seconds and the control panel receives the alarm. If

required, perform detector's horizontal / vertical readjustments.

Installation Instructions

Table 2 - Vertical Adjustment Reference

Coverage Distance

2m / 6.7ft 4m / 13ft 6m / 20ft 8m / 26ft 10m / 33 ft 12m / 39 ft

Figure 1 -

TOWER 20 AM

LEDS

D-301524 1

Important! Instruct the user to perform walk test at least once a

week, to verify proper operation of the detector.

C. Place a piece of cardboard on the detector’s front side, to

deliberately mask the optical window. After 2 minutes, the yellow

LED should light (see Table 3) and the alarm control panel should

receive the masking alarm.

D. Remove the masking from the detector’s front side. The LED

should extinguish (after about 30 seconds).

Table 3 – LED Operation

Event / status Indication

Low voltage Red flashing

Warm-up (60sec.) Yellow + Red flashing alternately

Self-test failure Yellow + Red flashing simultaneously

AM detection Yellow ON

ALARM Red ON for 2 sec.

3.6 Cover Closure (see Fig. 4, steps 7 - 10)

Table 4 – Relay Outputs

Event / status

Complete power failure Open Open

Standby Closed Closed

Low voltage Open Closed

Self-test failure Open Closed

AM detection DIP-SW4 = ON Open Open

AM detection DIP-SW4 = OFF Open Closed

Alarm Closed Open for 2 sec.

Tamper switch

Relay Output

Trouble Alarm

Mark

5

For wall Tamper switch

Bracket fastening (3 cable routing options)

7

31 2

6

Wiring

10

Drill

Note

The 2 screw holes

enable adjustment

of the bracket on

the wall, if needed

as a result of the

walk test.

DIP switches

4

Fasten

(3 long screws)

Press firmly

to release the

bracket

OFF ON

1

2

3

4

SPARE

(2 short

screws)

24-HOUR

TAMPE R

12

VDC

8

9

ZONE

ALARM CONTRO L PANEL

TEST

SWITCH

(OPTION)

BURGLAR

ZONE N.C.

24 HOUR

TROUBLE

ZONE N.C.

Figure 3 - Installation

2 D-301524

Mounting on bracket

A

11

B

Figure 3 – Installation (Continued)

HORIZONTAL ADJUSTMENT

(-45

1 3

2

to +45°)

°

12

3 screws

Adjust

Release locking

4

Release locking

VERTICAL ADJUSTMENT

to -10° in 2.5° clicks / steps)

(0

°

Adjust

Vertical

angle

5

Figure 4 – Adjustment and Cover Closure

steps

5

4

3

2

1

Lock

6

Lock

D-301524 3

Loading...

Loading...