Page 1

MC-302E PG2

PowerG Wireless, Door/Window Contact

with Wired Input

1. INTRODUCTION

The MC-302E PG2 is a two-way wireless PowerG magnetic contact device. The device includes a

built-in reed switch (that opens upon removal of a magnet placed near it) and an auxiliary hard-wired

input, programmable as either N.O., N.C. or E.O.L., for use with additional sensors – pushbuttons

detectors, door contacts, etc.

The MC-302E PG2 can be configured through the PowerMaster control panel to allow the installer to

disable the magnet-operated reed switch if only the auxiliary input is needed. The reed switch and the

auxiliary input behave as separate transmitters, although they trigger the same RF transmitter. The

MC-302E PG2 sends the parameters of the specific alarm to the control panel using PowerG two-way

communications protocol.

The MC-302E PG2 tamper switch is activated when the cover is removed.

A periodic supervision message is transmitted automatically. The control panel is thus informed, at

regular intervals, of the unit’s active participation in the system.

An LED lights whenever alarm or tamper events are reported. The LED does not light while a

supervision message is being transmitted.

Operating power is obtained from an on-board 3 V Lithium battery. When the battery voltage is low, a

“low battery” message is sent to the receiver.

2. INSTALLATION

Installation Instructions

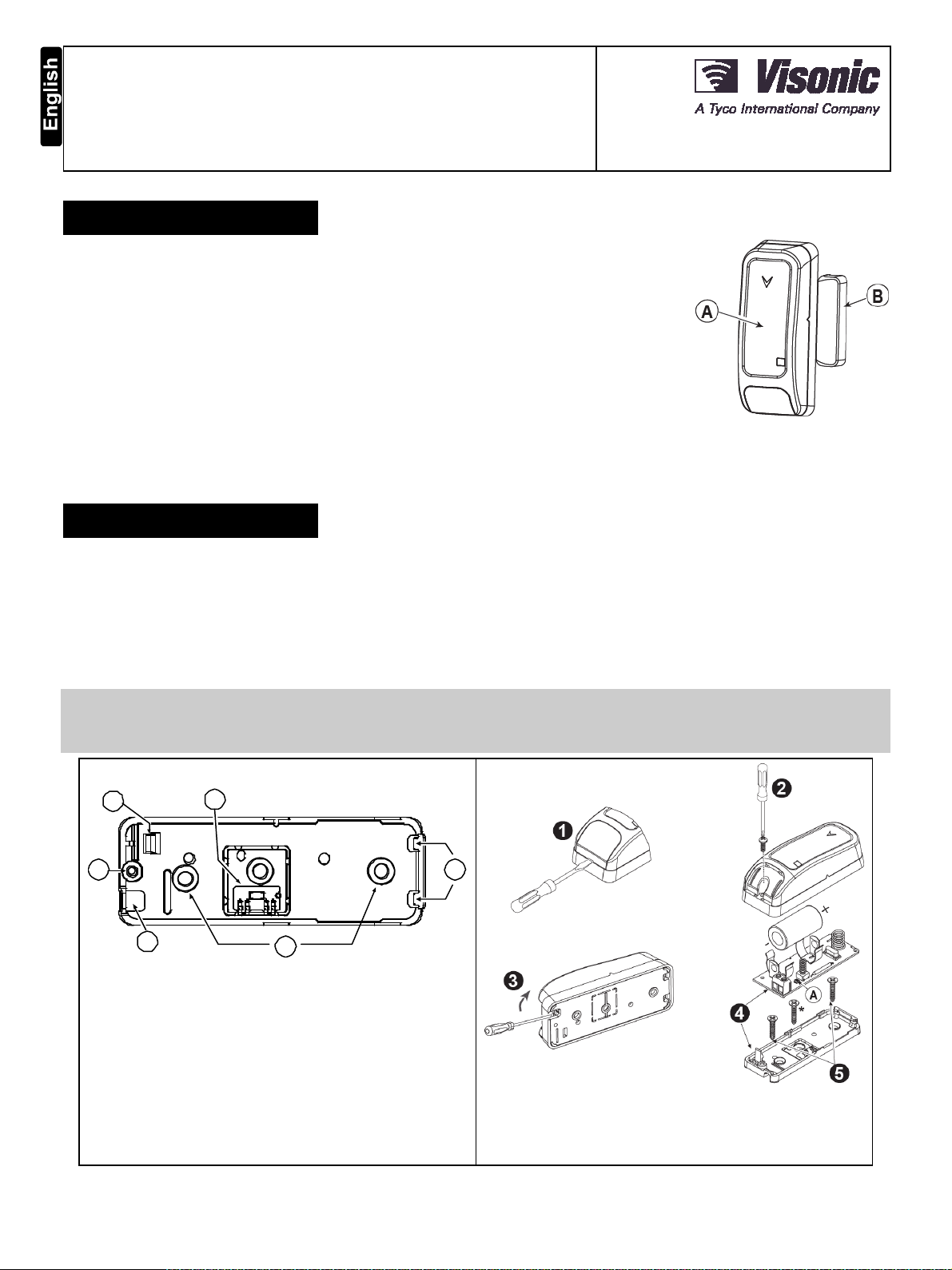

A. Transmission LED

B. Magnet

Figure 1: External View

2.1 Mounting (Fig. 3a and 3b)

It is highly recommended to attach the transmitter to the top of the door/window on the fixed frame and the magnet to the movable part

(door or window). Make sure that the magnet is located not more than 6 mm (0.25 in.) from the transmitter’s marked side.

Note: Once the cover is removed, a tamper message is transmitted to the receiver. Subsequent removal of the battery prevents

transmission of "TAMPER RESTORE", leaving the receiver in permanent alert. To avoid this, press the tamper switch while you remove

the battery.

Caution!

Risk of explosion if battery is replaced by an incorrect type. Dispose of used battery according to manufacturer's instructions.

Attention! The unit has a back tamper switch (optional) under the PCB. As long as the PCB is seated firmly within the base, the switch

lever will be pressed against a special break-away base segment that is loosely connected to the base (Figures 2 and 3a). Be sure to

fasten the break-away segment to the wall. If the detector unit is forcibly removed from the wall, this segment will break away from the

base, causing the tamper switch to open.

A

F

E

A. Flexible Retainer

B. Break-away base segment (for Back Tamper)

C. P.C. board edge supports

D. Mounting holes

E. Wiring inlet

F. Plastic standoff for case closure screw

Figure 2. Base with P.C. Board Removed

B

C

D

Figure 3a. Mounting

Note: 868 MHz device is illustrated in the above example. The

same mounting procedure should be performed for 433 MHz and

915 MHz devices.

* This screw is used for back tamper only.

D-303384 MC-302E PG2 Installation Instructions 1

Page 2

WARNING! To comply with FCC and IC RF exposure

R

A

D

Z

Z

Z

Z

-

X

Z

E

-

X

E

M

A

0

compliance requirements, the magnet contact device should be

located in a distance of at least 20 cm from all persons during

normal operation. The antennas used for this product must not

be co-located or operated in conjunction with any other antenna

or transmitter.

1. Insert a flat-edged screwdriver into

the slot and push upward to

remove cover.

2. Remove screw

3. Separate base from cover.

4. Flex catch and remove P.C. board

5. Mark & drill 2 holes in mounting

surface.

Fasten base with 2 countersunk

screws.

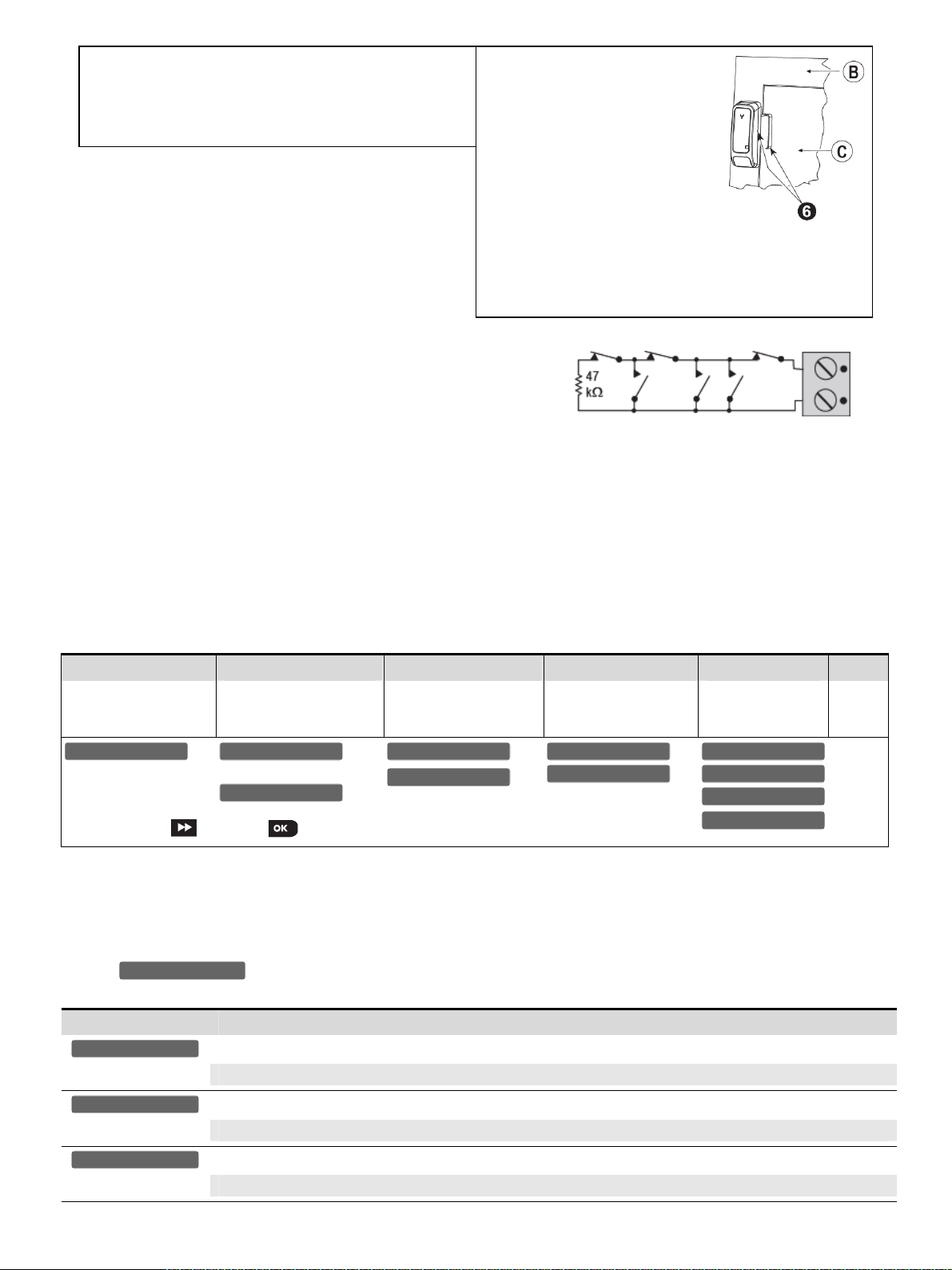

6. Mount the magnet near its location

mark with 2 screws

Figure 3b. Mounting

A. Enroll button

B. Fixed frame

C. Moving part

2.2 Auxiliary Input Wiring (Fig. 4)

A. Connect the auxiliary sensor contacts across the MCT-302E auxiliary

input terminals.

B. If the auxiliary input of the MCT-302E PG2 is defined as a Normally

Closed (N.C.) type, series connected N.C. sensor contacts must be

used exclusively. An E.O.L. resistor will not be required.

Figure 4. E.O.L. Wiring Example

C. If the auxiliary input of the MCT-302E PG2 is defined as a Normally Open (N.O.) type, parallel connected N.O. sensor contacts must

be used exclusively. An E.O.L. resistor will not be required.

D. For E.O.L. supervision:

Normally Closed (N.C.) sensor contacts can be used, as shown in Figure 4. A 47k E.O.L. resistor must be wired at the far end of the

zone loop.

Note: For UL installations, the device connected to the initiating circuit must be located in the same room as the transmitter.

The drawing below illustrates a N.O. and N.C. alarm circuit with E.O.L. resistor.

Note: An alarm message is transmitted once the loop is opened or short circuited.

2.2. Enrollment

Refer to the PowerMaster panel's Installer Guide and follow the procedure under the "02:ZONES/DEVICES" option of the Installer Menu.

A general description of the procedure is provided in the following flow chart.

Step 1 Step 2 Step 3 Step 4 Step 5 Step 6

Enter the Installer menu

and select

“02:ZONES/DEVICES”

2.ZONES/DEVICES

Select "ADD NEW

DEVICE" Option

See Note [1]

DD NEW DEVICES

ODIFY DEVICES

means scroll and select

Notes:

[1] If the magnetic contact device is already enrolled you can configure the magnetic contact device parameters via the “Modify Devices” option

– see Step 2.

[2] Select the "Device Settings" option and refer to section 2.3 to configure the magnetic contact device parameters.

Enroll the device or Enter

the device ID

NROLL NOW or

NTR ID:XXX

XXX

Select the desired Zone

Number

06:Contact Sens

ID No. 101

XXX

Configure Location,

Zone Type &

Chime Parameters

06.LOCATION

06.ZONE TYPE

06.SET CHIME

06.DEV SETTINGS

Configure

the

Magnet

See Note

[2]

2.3. Configuring the Magnetic Contact Device Parameters

Enter the menu and follow the configuration instructions for the MC-302E PG2 magnetic contact device as described in the

following table.

larm LED

eed Switch #1

Input #1

2 D-303384 MC-302E PG2 Installation Instructions

EVICE SETTINGS

Option Configuration Instructions

Determine whether or not the alarm LED indication will be activated.

Optional settings: LED Enabled or LED Disabled (default).

Determine whether to enable or disable the internal reed switch.

Optional settings: Enabled or Disabled (default).

Define the external input according to the installer's requirements.

Optional settings: Disabled, EOL-End Of Line (default), Normally Open or Normally Closed.

Page 3

3. LOCAL DIAGNOSTICS TEST

Before testing, separate the base from the cover (see Fig. 3a).

A. Press the tamper switch once and release it.

B. Put back the cover to return the tamper switch to its normal (undisturbed) position, and then secure the front cover to the base with

the case closure screw.

C. Momentarily open the door or window and verify the red LED blinks, indicating detection.

D. After 2 seconds the LED blinks 3 times.

The following table indicates received signal strength indication.

LED response Reception

Green LED blinks Strong

Orange LED blinks Good

Red LED blinks Poor

No blinks No communication

IMPORTANT! Reliable reception must be assured. Therefore, "poor" signal strength is not acceptable. If you receive a "poor" signal from

the device, re-locate it and re-test until a "good" or "strong" signal strength is received.

Note: For detailed Diagnostics Test instructions refer to the control panel Installer Guide.

4. MISCELLANEOUS COMMENTS

Visonic Ltd. wireless systems are very reliable and are tested to high standards. However, due to low transmitting power and limited

range (required by FCC and other regulatory authorities), there are some limitations to be considered:

A. Receivers may be blocked by radio signals occurring on or near their operating frequencies, regardless of the digital code used.

B. A receiver responds only to one transmitted signal at a time.

C. Wireless devices should be tested regularly to determine whether there are sources of interference and to protect against faults.

5. COMPLIANCE WITH STANDARDS

Compliance with Standards

EN 50131-1 Security Grade

EN 50131-1 Environmental Class

FCC Compliance Statement

The digital circuitry of this device has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in residential installations. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio and television reception. However, there is no guarantee that interference will not occur in a

particular installation. If this device does cause such interference, which can be verified by turning the device off and on, the user is

encouraged to eliminate the interference by one or more of the following measures:

– Re-orient or re-locate the receiving antenna.

– Increase the distance between the device and the receiver.

– Connect the device to an outlet on a circuit different from the one which supplies power to the receiver.

– Consult the dealer or an experienced radio/TV technician

D-303384 MC-302E PG2 Installation Instructions 3

Europe: EN 301 489-3, EN 50130-4:( 95) & A1 : (98) & A2: (03), EN 300 220-2, EN 60950-1,

EN 50130-5, EN 50131-1, EN 50131-6, , EN 50131-2-6: 2008.

The MC-302E PG2 is compatible with the RTTE requirements - Directive 1999/5/EC of the European

Parliament and of the Council of 9 March 1999 and EN50131-1 Grade 2 Class II.

Certified by the Dutch testing and certification body Telefication BV.

USA: CFR 47 part 15 (FCC)

Canada: RSS 210

This device complies with Part 15 of the FCC Rules and with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

This device complies with the essential requirements and provisions of Directive 1999/5/EC of the

European Parliament and of the Council of 9 March 1999 on radio and telecommunications

terminal equipment.

The Power G peripheral devices have two- way communication functionality, providing additional benefits as described in

the technical brochure. This functionality has not been tested to comply with the respective technical requirements and

should therefore be considered outside the scope of the product’s certification.

Opening Closing Direction Opening Closing

20mm+/-

5mm

14mm+/-

5mm

25mm+/-

5mm

Wood Support

14mm+/6mm

15mm+/5mm

24mm+/-

5mm

Grade 2

Class 2

s

X 15mm+/-

Y 15mm+/-

Z 25mm+/-

5mm

5mm

5mm

Soft Iron

14mm+/5mm

14mm+/5mm

24mm+/5mm

Page 4

IC statement:

g

y

y ty

y

)

y

g

)

y

g

)

This device complies with Part 15 of the FCC Rules and with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that

may cause undesired operation of the device.

Le present appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est

autorisee aux deux conditions suivantes :(1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioelectrique subi, meme si le brouillage est susceptible d'en compromettre le fonctionnement.

WARNING!

To comply with FCC and IC RF exposure compliance requirements, the device should be located at a distance of at least 20 cm from all

persons during normal operation. The antennas used for this product must not be co-located or operated in conjunction with any other

antenna or transmitter.

WARNING!

The user is cautioned that changes or modifications to the unit, not expressly approved by Visonic Ltd., could void the user’s FCC or

other authority to operate the equipment.

The technical documentation as required by the European Conformity Assessment procedure is kept at:

UNIT 6 MADINGLEY COURT CHIPPENHAM DRIVE KINGSTON MILTON KEYNES MK10 0BZ. TEL.: +44(0)845 0755800 FAX: +44(0)845 0755801

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from which you orignially purchased it. If you are discarding this product and not

returning it for repair then you must ensure that it is returned as identified by your supplier. This product is not to be thrown away with everyday waste.

Directive 2002/96/EC Waste Electrical and Electronic Equipment.

APPENDIX: SPECIFICATIONS

Frequency Band (MHz) Europe and rest of world: 433-434, 868-869 USA: 912-919

Communication Protocol PowerG

Alarm Input One internal

Supervision Si

Tamper Alert Reported when a tamper event occurs

Power Suppl

Batter

Type C

pe 3 V Lithium CR-123 type battery, Panasonic, Sanyo or GP only.

Battery Life Expectancy 8

Low Battery Threshold 2.2 V

Battery Supervision Automatic transmission of battery condition data as part of periodic status report and immediately upon

Operatin

Temperature 0C to 49C (32F to 120F

Humidity Average relative humidity of approximate 75% non-condensing. For 30 days per year relative

Dimensions (LxWxD) 81 x 34 x 25 mm (3-3/16 x 1-1/4 x 1 in.

Weight (including battery) 53g (1.9 oz)

WARRANTY

Visonic Limited (the “Manufacturer") warrants this product only (the "Product") to the original purchaser only (the

“Purchaser”) against defective workmanship and materials under normal use of the Product for a period of twelve

(12) months from the date of shipment by the Manufacturer.

This Warranty is absolutely conditional upon the Product having been properly installed, maintained and operated

under conditions of normal use in accordance with the Manufacturers recommended installation and operation

instructions. Products which have become defective for any other reason, according to the Manufacturers

discretion, such as improper installation, failure to follow recom mended installation and operational instructions,

neglect, willful damage, misuse or vandalism, acc idental damage, alteration or tampering, or repair by anyone

other than the manufacturer, are not covered by this Warranty.

The Manufacturer does not represent that this Product may not be compromised and/or circumvented or that the

Product will prevent any death and/or personal injury and/or damage to property resulting from burglary, robbery,

fire or otherwise, or that the Product will in all cases provide adequate warning or protection. The Product,

properly installed and maintained, only reduces the risk of such events without warning and it is not a guarantee

or insurance that such events will not occur.

THIS WARRANTY IS EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, OBLIGATIONS

OR LIABILITIES, WHETHER WRITTEN, ORAL, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR OTHERWISE. IN NO CASE SHALL

THE MANUFACTURER BE LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES

FOR BREACH OF THIS WARRANTY OR ANY OTHER WARRANTIES WHATSOEVER, AS AFORESAID.

THE MANUFACTURER SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES OR FOR LOSS, DAMAGE, OR EXPENSE, INCLUDING LOSS

OF USE, PROFITS, REVENUE, OR GOODWILL, DIRECTLY OR INDIRECTLY ARISING FROM

PURCHASER’S USE OR INABILITY TO USE THE PRODUCT, OR FOR LOSS OR DESTRUCTION OF

OTHER PROPERTY OR FROM ANY OTHER CAUSE, EVEN IF MANUFACTURER HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE.

THE MANUFACTURER SHALL HAVE NO LIABILITY FOR ANY DEATH, PERSONAL AND/OR BODILY

INJURY AND/OR DAMAGE TO PROPERTY OR OTHER LOSS WHETHER DIRECT, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR OTHERWISE, BASED ON A CLAIM THAT THE PRODUCT FAILED TO FUNCTION.

naling at 4-min. intervals

ears (for typical use

low batter

humidit

condition detection

may vary between 85 % and 95 % non-condensin

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or damage arising under this

limited warranty, THE MANUFACTURER'S MAXIMUM LIABILITY (IF ANY) SHALL NOT IN ANY CASE

EXCEED THE PURCHASE PRICE OF THE PRODUCT, which shall be fixed as liquidated damages and not as a

penalty, and shall be the complete and exclusive remedy against the Manufacturer.

When accepting the delivery of the Product, the Purchaser agrees to the said c onditions of sale and warranty and

he recognizes having been informed of.

Some jurisdictions do not allow the exclusion or limitation of incidental or c onsequential damages, so these

limitations may not apply under certain circumstances.

The Manufacturer shall be under no liability whatsoever arising out of the corruption and/or m alfunctioning of any

telecommunication or electronic equipment or any programs.

The Manufacturers obligations under this W arranty are limited solely to repair and/or replace at the

Manufacturer’s discretion any Product or part ther eof that may prove defective. Any repair and/or replacement

shall not extend the original Warranty period. The Manufacturer shall not be responsible for dismantling and/or

reinstallation costs. To exercise this Warranty the Product must be returned to the Manufacturer freight pre-paid

and insured. All freight and insurance costs are the responsibility of the Purchaser and are not included in this

Warranty.

This warranty shall not be modified, varied or extended, and the Manufacturer does not authorize any person to

act on its behalf in the modification, variation or extension of this warranty. This warranty shall apply to the

Product only. All products, accessories or attachments of others used in conjunction with the Product, including

batteries, shall be covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or otherwise, caused by the

malfunction of the Product due to products, ac cessories, or attachments of others, including batteries, used in

conjunction with the Products. This Warranty is exclusive to the original Purchaser and is not assignable.

This Warranty is in addition to and does not af fect your legal rights. Any provision in this warranty which is

contrary to the Law in the state or country were the Product is supplied shall not apply.

Warning: The user must follow the Manufacturer’s installation and operational instructions including testing the

Product and its whole system at least once a week and to take all necessary precautions for his/her s afety and

the protection of his/her property.

1/08

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 65 WEST DUDLEY TOWN ROAD, BLOOMFIELD CT. 06002-1376. PHONE: (860) 243-0833, (800) 223-0020.

FAX: (860) 242-8094

VISONIC LTD. (UK): UNIT 6 MADINGLEY COURT CHIPPENHAM DRIVE KINGSTON MILTON KEYNES MK10 0BZ. TEL.: +44(0)8450755800

FAX: +44(0)845 0755801 PRODUCT SUPPORT: +44(0)845 755802

VISONIC GmbH (D-A-CH): KIRCHFELDSTR. 118, D-40215 DÜSSELDORF, TEL.: +49 (0)211 600696-0, FAX: +49 (0)211 600696-19

VISONIC IBERICA: ISLA DE PALMA, 32 NAVE 7, POLÍGONO INDUSTRIAL NORTE, 28700 SAN SEBASTIÁN DE LOS REYES, (MADRID), ESPAÑA.

TEL (34) 91659-3120, FAX (34) 91663-8468. www.visonic-iberica.es

INTERNET: www.visonic.com

VISONIC LTD. 2012 D-303384 MC-302E PG2 (REV. 1,02/12)

4 D-303384 MC-302E PG2 Installation Instructions

Loading...

Loading...