Page 1

DE1851 1

,5,5

Indoor Photo-Electric Infrared Beam Barrier

Installation Instructions

,1752'8&7,21

IR-50 and IR-150 are pulse-modulated photoelectric infrared

beam barrier designed for indoor residential, commercial and

industrial applications. The system consists of a transmitter

producing a wide angle (IR-50) or concentrated (IR-150) invisible

infrared beam towards a narrow-angle receiver. Visible Beam

Locator light in the receiver (IR-50) or in the transmitter and the

receiver (IR-150), provide quick and easy alignment without

special tools or test equipment.

The transmitted beam is generated by 2 powerful infrared LEDs.

The 40° wide angle beam of IR-50 allows multiple receiver

installations using a single transmitter. The 6° receiver field of

view provides a large safety margin to prevent false alarms. Yet it

is narrow enough to eliminate reception of reflected beam. Internal

built-in optical filter prevents unwanted light penetration, other

than the infrared wavelength.

The system is immune to

fluorescent radiation, flickering

lights and indirect sunlight.

State-of-the-art electronic

circuitry provides protection

against RF interference and

supply voltage transients.

The transmitter emits an invisible

beam, to the receiver. When an

intruder crosses this beam

barrier, the receiver’s internal

alarm relay deenergizes.

IR-50 Transmitter & Receiver

Note: External view of IR-150

transmitter & receiver is similar.

The receiver’s walk test LED lights at the same time (when LED

selector is in Walk position, see par. 3.4). After crossing, the relay

again energizes and the LED extinguishes.

63(&,),&$7,216

FEATURE IR-50 IR-150

OPTICAL

Range (**)

Up to 50m (150 ft) Up to 150m (500 ft)

Transmitter beam width

40° (*) 6° (*)

Receiver field of view

6°(*)

Adjustment

Vertical +10° to 20°. Horizontal 30°.

Beam Locators Visible Beam Locator built into receiver and transmitter

ELECTRICAL

Voltage 9 - 16VDC (protected against reverse polarity)

Transmitter current 20mA 15mA

Receiver current 15mA

Relay output Normally closed (fail-safe) contacts. 18 ohm resistor in

series with contacts. Rating - 0.5A resistive/24 VDC.

Alarm period 2 - 3 seconds

Tamper contacts Normally closed. Rating - 0.5A resistive/24 VDC.

LED Three selectable operation modes

FEATURE IR-50 IR-150

Infrared source Long-life Gallium Arsenide LED

Infrared sensor PIN photodiode

Transmitter Frequency 1 kHz, 10 microsecond pulse width

IR wavelength 950 nm

Receiver type (Qty.) IRR-50 (one or multiple) IRR-150 (one)

ENVIRONMENTAL

Operating temperature

-10°C to 50°C (14°F to 122°F)

Storage temperature

-20°C to 60°C (-4°F to 140°F)

PHYSICAL

Dimensions 120 x 70 x 48 mm (4.7 x 2.7 x 1.9 in)

Weight 220 g (0.48 lb)

Colors Dark beige standard

cream/ white also available

Dark beige or standard

white

*

Typical, horizontal and vertical.

**

distance between transmitter to receiver

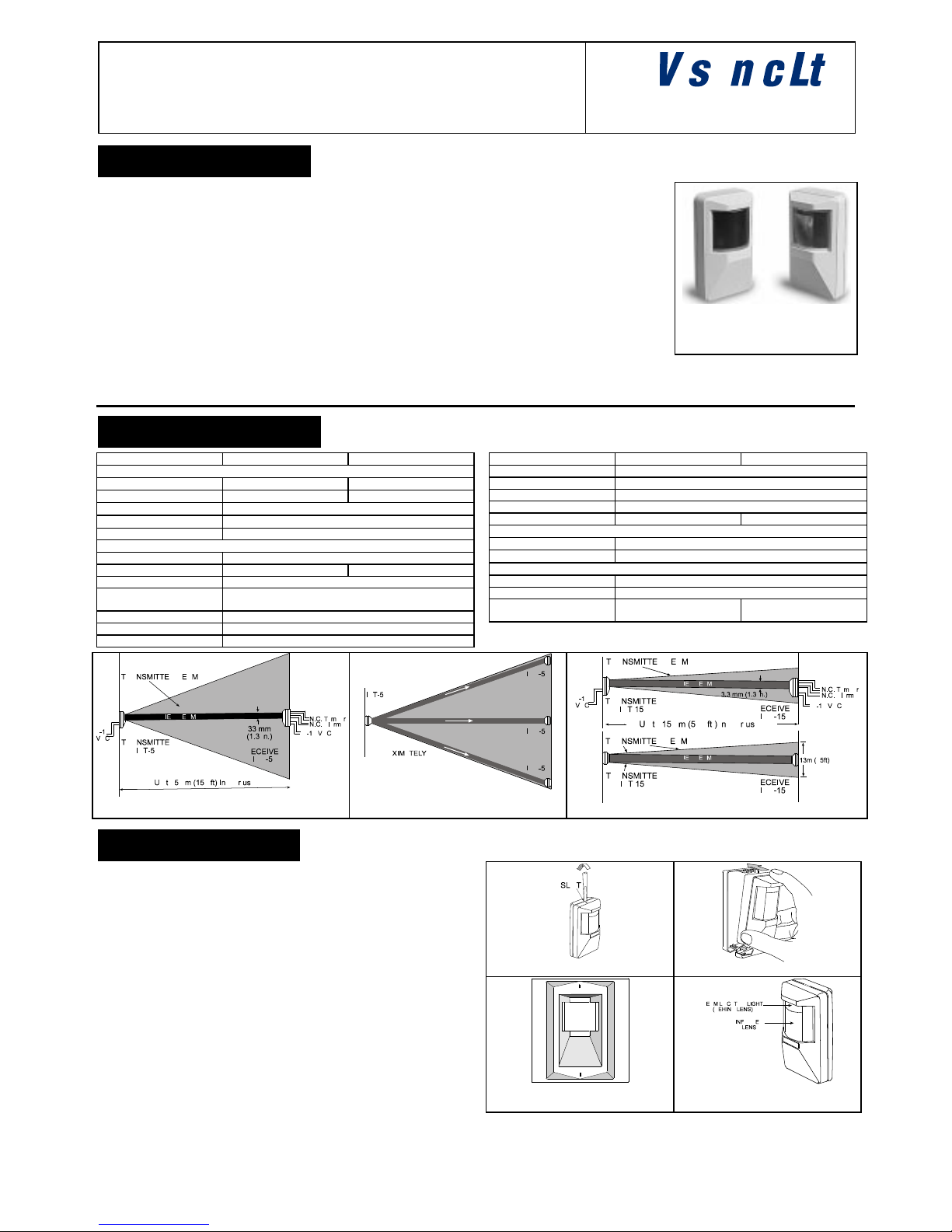

Figure 1A.

IR-50 Side View Beam Pattern

Figure 1B.

IR-50 Top View - Multiple

Receivers

Figure 2.

IR-150 View Beam Pattern

,167$//$7,21

6HOHFWLQJ0RXQWLQJ/RFDWLRQ

A. Select mounting locations / height for the transmitter and

receiver(s) so that an intruder will cross the beam(s). The

receiver and transmitter should be mounted facing each other,

and their angular back housing allow installation directly onto a

wall (surface mount), or in a corner. They may also be

flush-mounted using optional bracket SRF-201. (Fig. 5).

B . Prevent receiver’s lens exposure to direct sun light, to prevent

false alarm.

C . For maximum reliability, locate the receiver as far as possible

from fluorescent light or flickering lights.

NOTE: The transmitter unit is not sensitive to any of the above

disturbance sources and may be placed wherever desired.

0RXQWLQJ

A. Insert a small screw driver into the slot on top of the unit, press

lightly down and remove the cover.

Figure 3. Cover Removal

Figure 4. Cover Replacement

Figure 5. Flush Mounting

Bracket SRF-201

Figure 6. Beam Locator Light

Side View

Top View

Page 2

2 DE1854

B. Mount the base (with the P.C. board) in the selected location

and height for optimum coverage. For surface mounting use

the 2 base rear knockout holes. For corner mounting use the

angled sides knockouts. The unit(s) must be fastened tightly to

the mounting surface to avoid vibrations.

C . To close the front cover (after wiring), insert the legs, located

on the bottom of cover, into their respective slots in the bottom

of the base and close by exerting slight downward.

:LULQJ

A. To route wires into the housing, use either the wiring

knockouts or one of the lower circular mounting knockouts.

B. Wiring the receiver

1) Connect Tamper N.C. terminals

to control panel normally

closed 24h protection zone.

Tamper contact opens when

cover is removed.

Figure 7 - Terminal Block

Wiring - Receiver

2) Connect Relay N.C. terminals to control panel normally

closed burglar protection zone. Relay contacts opens when

an intruder is detected or during power loss.

3) Connect the 12VDC (+) and (-) terminals to 9-16VDC

power source and verify correct polarity. Multiple receivers

(IR-50 only) should be connected in parallel.

C. Wiring the transmitter

The transmitter requires only the connection of the supply

voltage (9 -16 VDC) to the 12VDC (+) and (-) terminals.

Note: It is advisable to use power supply with battery back-up.

$OLJQPHQW

Receiver and transmitter alignment is accomplished with Visible

Beam Locator lights that operate through the upper section of the

receiver’s lens (for IR-150: receiver and the transmitter) (Fig. 6).

The receiver should be aligned horizontally and vertically so that

the LED light is fully visible through the Beam Locator section of

the lens when viewed from the transmitter. The transmitter is then

similarly aligned, using the transmitter Beam Locator light.

Three mode LED selector

The receiver’s LED selector consists of a 4-pin connector and a

jumper which can be inserted to link two pins, enabling three

operational modes:

A. WALK/ALARM (Jumper links pins 1-2) - This mode is used for

walk testing. The LED lights up for 2-3 seconds whenever the

beam is interrupted.

B. ALIGN (Jumper links pins 2-3) - This mode is used for

aligning. The LED lights continuously to enable convenient

observation of the red light in the beam locator lenses (Fig. 6.)

C. OFF (Jumper links pins 3-4) - This mode can be used to

disable the LED after final test is completed, to prevent

unauthorized persons from tracing the direction of the beam.

Note: The LED mode selection does not interfere with alarm relay

operation, which will signal whenever the beam is interrupted.

For IR-150: The LED selector in the transmitter lRT-150 enables

only two operational modes: ALIGN and OFF.

For aligning, move the jumper of the LED selector in both units to

ALIGN. The LEDs should light continuously.

Horizontal Alignment

The field of view of each unit can be adjusted horizontally

approximately 30°, by rotating the lens to the left or right. To

adjust, remove the lens-locking devices, located on both sides of

the lens, by pushing them from the inside of the cover. Rotate the

lens carefully to the desired position. Holding firmly in place, insert

locking devices from outside (ridges pointed outward) and firmly

push into place until a click is heard. The transmitter is aligned

similarly, using its Beam Locator light.

For IR-50: To align, look towards the receiver from the transmitter

location. Move to the left and to the right of the transmitter, to

determine the area in which the Beam Locator light on the

receiver is fully visible. Align the receiver's lens, so that the center

of the area in which the Beam Locator light is fully visible will be

approximately at the place where the transmitter is located.

Vertical Adjustment

The P.C. board vertical adjusting scale (IR-150: in both units) and

the plastic pointer on the base indicate the approximate vertical

angle in degrees between the receiver's (for IR-150: receiver’s or

transmitter's) line of sight and the horizontal line of the unit.

To change the vertical adjustment, loosen the screw which

fastens the printed circuit board to the base. Slide the P.C. board

up or down to the desired angle and tighten the screw firmly.

To align the receiver, look toward the receiver from the transmitter

location. Align the receiver (vertically) so that the Beam Locator

light will be fully visible from the floor level below the transmitter

and up to the same distance above the transmitter (provided the

distance between the transmitter and receiver is at least 20 times

larger than their height from the floor). The transmitter is aligned

similarly, using the Beam Locator light on the transmitter.

)LQDO7HVW

The system should be checked at least once a week as follows:

A . Move the LED selector jumper to 'WALK' position. Replace

the receiver front cover [IR-50: receiver(s)]. The LED should

go off, indicating correct alignment of the receiver.

B. Walk-test by crossing the path between the transmitter and

receiver [IR-50: receiver(s)]. The receiver LED should light for

2-3 seconds indicating alarm condition caused by interruption

of infrared beam barrier. This test should be performed with all

fluorescent lights at the protected area turned on.

C . Determine the signal margin by slowly covering the receiver

lens from the bottom upward (using a piece of cardboard) until

the LED lights up. The ratio between the size of the covered

lens area and the total lens area (excluding the Beam Locator

area) indicates the signal margin of the system. If alignment is

correct, the signal margin should be more than 35 percent.

D . Move the jumpers (IR-150: in both units) from 'WALK' to 'OFF'

position to disable the LED and prevent unauthorized persons

from ascertaining the path(s) of the infrared beam barrier(s).

The user should be instructed to cross the infrared barrier to

assure an alarm output prior to each system arming.

Figure 8. Printed Circuit Board

$YRLGLQJ5HIOHFWHG%HDP3DWKV

Eliminate reflected beams as follows:

A. For IR-50 only: Apply piece of black insulation tape on inner

side of transmitter window, to narrow the transmitter beam and

allow emission of infrared energy only in the receiver direction.

B. Change the receiver alignment (for IR-150: of receiver and

transmitter), adjusting them away from the reflecting surface.

C. Reduce receiver’s sensitivity by lens partial covering (from

inside). When the reflected beam barrier is eliminated recheck

system signal margin (para. 3.5c.).

VISONIC LTD (ISRAEL):

P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.):

10 NORTHWOOD DRIVE, BLOOMFIELD CT. 06002-1911. PHONE: (860) 243-0833, (800) 223-0020 FAX: (860) 242-8094

VISONIC LTD. (UK):

UNIT 1, STRATTON PARK, DUNTON LANE BIGGLESWADE, BEDS. SG18 8QS. PHONE: (01767) 600857 FAX: (01767) 601098

VISONIC LTD. 1998 IR-50 / IR-150 D-1851-0 NEW: DE1851- (REV. 1, 7/98). WARRANTY STATEMENT IS AVAILABLE UPON REQUEST.

Loading...

Loading...