Page 1

IOX-4

AXS-100 I/O Expander

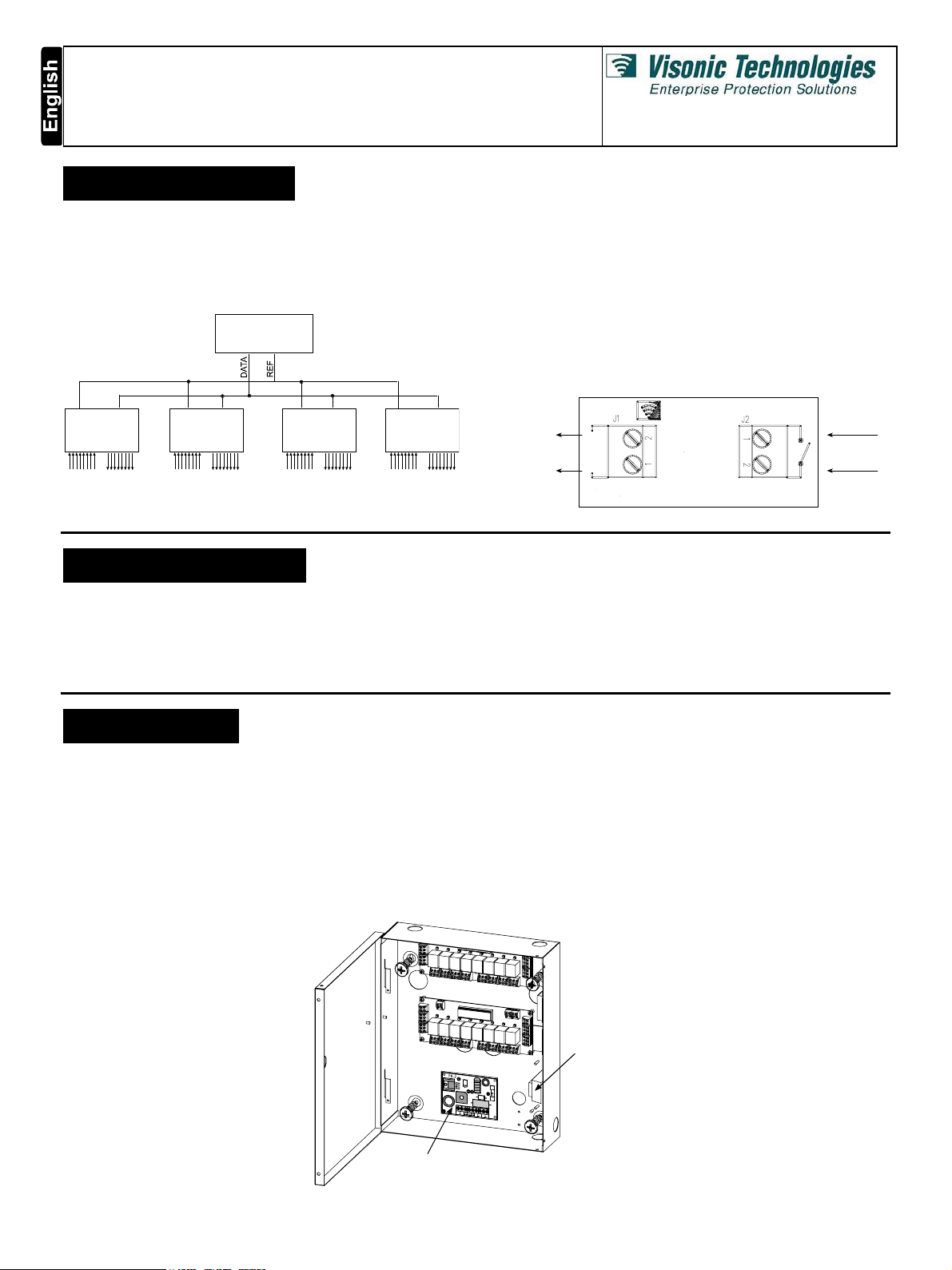

1. INTRODUCTION

The IOX-4 is an input / output expander for the AXS-100 access

control panel. It contains eight analog inputs and eight dry contact

relays output.

Up to four IOX-4 boards may be connected to each AXS-100

control panel, for a maximum of 32 inputs and 32 outputs for

each controller. All functionality programming is done from the

control panel.

AXS-100

Installation Instructions

The IOX-4 may be used for various purposes:

• Elevator control – up to 32 floors

• Event reporting to an alarm system –event types are separated

into eight groups of which seven control relays on IOX-4 #4.

• Energy management

• Counting inputs up/down

• Emergency operation of doors

Connection of an input device to an IOX-4 input should be done

via an input adapter (8 input adapters are supplied) as shown in

Figure 2. The input adapter includes an EOL termination resistor.

IOX-4

No. 1

(*) (**) (*) (**) (*) (**) (*) (**)

(*) 8 analog inputs

(**) 8 outputs (relays)

Figure 1 - Simplified Interconnection Block Diagram

IOX-4

No. 2

IOX-4

No. 3

IOX-4

No. 4

2. SPECIFICATIONS

ELECTRICAL:

Number of analog inputs: 8

Number of outputs (relays): 8 (N.C. & N.O.), 30VDC, 2A max.

Maximum IOX-4 units for each controller: 4 (for 32 inputs and

32 outputs)

IOX-4 Power Input, from PS-1 DC P.S.: 12 VDC, 0.5A

3. MOUNTING

It is recommended to install the IOX-4 in a Visonic Networks

EXT-100 lockable metal box, Cat. No. 3-6278-0 (not supplied with

the IOX-4.). It is possible to use another box but in this case the

Visonic Networks warranty, will not be valid.

EXT-100 Power Input, from AC Transformer: 14-16.5 VAC, 0.5A

EXT-100 (with two IOX-4 units) Power Input, from AC

Transformer: 14-16.5 VAC, 1A

Place the EXT-100 metal box on the wall, mark 4 screw

locations, drill and fasten the box to the mounting surface

by using 4 screws. Then fasten each IOX-4 board to the

metal box by using 4 screws.

IOX-4 IN

IOX-4 GND

Figure 2 - IOX-4 Input Adapter (End Of Line Termination P.C.B.)

ENVIRONMENTAL:

Operating Temperature: -20°C to 50°C (-4°F to 122°F)

Storage Temperature: -20°C to 50°C (-4°F to 122°F)

PHYSICAL

Dimensions

Weight: 222 g (8 oz)

An example of mounting the IOX-4 in the EXT-100 box (up to two

units) is shown in figure 3.

The EXT-100 box is supplied with a 50VA transformer and a

12 VDC, 1A power supply module.

(L x W x D): 180 x 85 x 22 mm (7-1/16x3-3/8x13/16in)

FROM INPUT

DEVICE

TRANSFORMER

PS-1 POWER SUPPLY

MODULE

Figure 3 - Mounting Two IOX-4 PCBs in EXT-100 Box

DE6314 1

Page 2

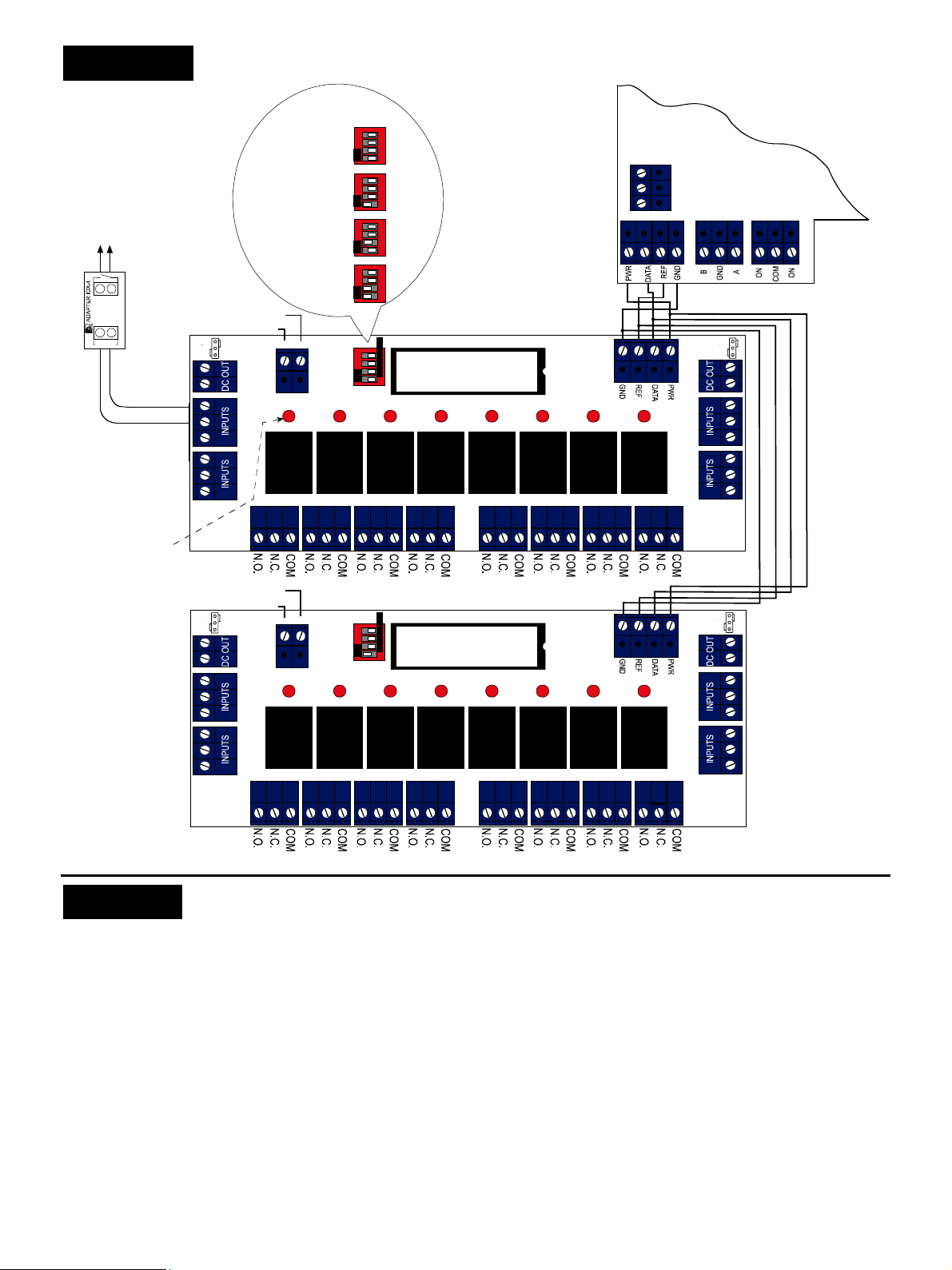

4. WIRING

TO N.O.

INPUT DEVICE

E.O.L. PCB

(INPUT ADAPTER)

IOX-4

12V

5V

12VDC INPUT

(SEE NOTE)

IOX-4 address settings

IOX-4 #1

IOX-4 #2

IOX-4 #3

IOX-4 #4

-

+

NOTE: UP TO 2 IOX-4

BOARDS CAN BE

POWERED FROM

THE AXS-100 (PWR

& GND TERMINALS).

CONNECTING 3 OR

4 BOARDS REQUIRES

USING AN EXTERNAL

POWER SUPPLY 12 VDC

FROM EXT-100 PS-1

MODULE

IOX-4

control panel

TB3

(SEE NOTE)

AXS-100

12V

5V

Every relay has

an LED above it

that lights

whenever the

relay is energized .

The relay

energizing

periods are

predefined during

the programming

process.

Note

12V

5V

in1

gnd

in2

in3

relay relay relay relay relay relay relay relay

gnd

in4

RL1 RL2 RL3 RL4 RL5 RL6 RL7 RL8

12VDC INPUT

(SEE NOTE)

-

+

IOX-4

in1

gnd

in2

in3

relay relay relay relay relay relay relayrelay

gnd

in4

RL1 RL2 RL3 RL4 RL5 RL6 RL7 RL8

Figure 4 - IOX-4 Connection Diagram

in5

gnd

in6

in7

gnd

in8

OUTPUTSOUTPUTSOUTPUTSOUTPUTSOUTPUTSOUTPUTSOUTPUT SOUTPUTS

12V

NOTE: IT IS

5V

RECOMMENDED TO

USE TWISTED PAIR

CABLES

in5

gnd

in6

in7

gnd

in8

OUTPUTSOUTPUTSOUTPUTSOUTPUTSOUTPUTSOUTPUTSOUTPUT SOUTPUTS

5. SETUP

5.1 Setting Up the IOX-4 Board

The IOX-4 is connected to the AXS-100 via two or four wires. If

one or two IOX-4 boards are connected to the AXS-100, power

for operating the boards may be drawn from the AXS-100.

Connecting three or four boards requires using an external power

supply.

The IOX-4 has a four-position DIP-switch for setting the board

address.

Each input device has to have an EOL PCB input adapter connected

next to it (see figure 4). The IOX-4 is supplied with 8 modulars.

Inputs and outputs #1 through #8 are on IOX-4 #1.

Inputs and outputs #9 through #16 on IOX-4 #2.

Inputs and outputs #17 through #24 on IOX-4 #3.

Inputs and outputs #25 through #32 on IOX-4 #4.

2 DE6314

Steps:

1. Connect DAT and REF terminals between AXS-100 TB3 and

IOX-4. If less than 3 IOX-4 boards connected, you may also

connect power from AXS TB3.

2. If more than one IOX-4 is to be connected, you will need to

connect the wires in parallel between IOX-4 #1 to#2, etc.

3. Connect input devices to input terminal blocks as shown in

Figure 4.

4. Connect dry contact outputs to relay terminal blocks as shown

in Figure 4.

5. Program input functionality in controller setup (SETUP / INPUT

SETUP).

The AXS-100 controller does not poll IOX-4 boards unless instructed

to. SETUP FLAGS 5 in LOCAL SETUP contains 4 flags (see AXS100 User's Guide, Para. 5.2.5). Flags 1 to 4 represent the IOX #. For

example: If flag #1 is set to ON, the AXS-100 controller will enable

IOX board 1. If flag #3 is set to ON, the AXS-100 controller will

enable IOX board 3, etc.

Page 3

5.2. Programming Input Functionality

M

M

M

M

The AXS-100 allows programming input functionality through the

INPUT SETUP selection in the SETUP menu.

Each input can be programmed to operate in one of the modes of

the IOX-4:

Disabled Input is disabled

Timer Output 1 is controlled by timer

Allow Entry Allow entry through door 1 or 2 of controller

Open All Open all doors in loop while input active

Control

Reader

Counter Up/down count events

Output Output to relay

Each input can be in one of four states:

Idle The sensing device is present and in idle mode.

Active The sensing device is in active mode (triggered).

Short There is a short on the line.

Cut There is a cut on the line – no device detected.

All enabled inputs will cause a trouble event to be generated if a

short or a cut is detected on their line, and a trouble restored

event when the short or cut goes away. A transition from normal

to active or from active to normal will be reported for OUTPUT

mode. In case of OUTPUT mode, generating an event is

dependent on programming.

An enabled input can be responsive all the time or controlled by

one or two devices, both physical and logical. Table #1 lists all

control devices and their numbers. An input device controlled by

another device will cause an action to be taken only if controlling

devices are active.

Each input device has an optional secondary output relay, which is

controlled in one of two modes with disregard to control devices’

status. To select a secondary output relay, set its number in

OUTPUT 2 screen. The secondary relay can be triggered for

amount of time defined in OUT TIME 2 screen if MODE is set to 1.

If mode is set to 2, the relay will be operated in toggle mode.

0 No control device

1 .. 36 Physical input device (1..8 on IOX-4 #1, 25..32 on

Enable/disable reader 1 or 2 or both readers of

controller

It can be normally open or normally closed.

Table #1: Control I/O device addresses

The next two screens allow you to select controlling devices for

this input (see table #1 above for device numbers). If you do not

want to select a device, simply enter zero as its number.

CONTR OL L E D B Y

0

Press Enter to continue.

Enter output number (may be lock number or reader number as

defined in the modes below).

OUTPU T

1

Press Enter to continue.

Set output time for relay output.

OUT T I

E

10

Press Enter to continue.

If you would like to set the independent auxiliary output, enter its

number.

OUTPU T 2

20

Press Enter to continue.

If auxiliary output number is not zero, the following screens will

appear.

The mode for the auxiliary output can be 1 for pulse or 2 for toggle.

ODE

1

Press Enter to continue.

Set output time for auxiliary relay output.

OUT T I

E

10

Press Enter to continue.

Note: To reset all IOX-4 outputs, enter the INPUT SETUP mode,

and when asked by the controller for the input number, press the

UP arrow key (see Figure 5). Then, press Enter continuously until

you return to INPUT SETUP.

ENTER PASSWORD

XXXX

EnterEnter

rEnte

#4, 33..36 on-board)

40 .. 99 Key up/down counter

224 .. 255 Output relay condition. These outputs are used

only for activating alarm relays and to receive

The d isplay w ill be:

SET UP

EDIT KEY S

events. To activate an alarm relay or to receive an

event, add 128 to the output number found in the

register.

225 .. 255 These outputs are used only to receive events and

to activate the controller alarm relay

LOCK SETUP

INPUT SETUP

Enter

SELECT

INPUT #

Note: If you want to receive an event and to activate the alarm

relay, add 128 to the output number.

The programming for each mode varies slightly.

The following screens show the programming of the input device.

Enter Enter Ent er

Enter Enter

First select which input device you would like to program.

S

E L E C T

I N P U T 1

Type input number followed by Enter.

Select input mode by pressing the up and down arrow keys

followed by Enter.

I N P U T

OD E

INPUT SETUP

PASSWORDS

Esc Esc

Figure 5 - INPUT SETUP Mode

OU T P U T

Select input polarity (normally open or normally closed).

P OL A R I T Y

N O

Press 1 for normally closed and 0 for normally open. Press Enter

to continue.

DE6314 3

Page 4

Using Flag Set#2, Flag 5, to Activate to IOX-4 Relays

In Setup→Local Setup menu, it is possible to activate IOX-4 relay

numbers 25 to 32 depending on event type, as follows:

Relay 26 - Valid key indication.

Relay 27 - Unknown key indication.

Relay 28 - Alarm conditions.

Relay 29 - Trouble conditions.

Relay 30 - Long read indication.

Relay 31 - Arm/disarm alarm system.

Relay 32 - Valid key failed to open

5.3 Elevator Control

The Elevator Control function enables authorized people to use

an elevator, up and down, to the desired predefined floors.

AXS-100,

of up to 32 floor buttons in an elevator, for every authorized user.

For this purpose, connect up to 8 floor buttons to the relay

outputs 1 through 8 of each IOX-4 expander. In this way, four

IOX-4 expanders provide control of up to 32 floor buttons.

Inside the elevator, the user presents his tag/card to the proximity

reader. If the tag/card is recognized as a valid one, certain

predefined elevator floor buttons will be active for a predefined

period (see AXS-100 user guide, par. 5.2.6). During this period,

the user should press the desired floor button. If the user presses

a floor button after this period, the button is not active.

To allocate authorized floors (doors) for any user, perform "Add

Key" / “Modify Key” programming, as detailed in the AXS-100 user

guide, par. 3.3.1 and 3.3.5. For example, to allocate floors 2, 8, 16,

20, 25 and 30 to a specific user (key), define doors 2, 8 and G in

“Valid Doors 1” and define doors 4, 9 and E in “Valid Doors 2”.

When the controller operates in toggle mode or time zone

function and soft valid tag is defined and the trigger is set to ON,

all the doors will open and when the trigger is set to OFF all the

doors will close.

Note: In Elevator Control mode, flag set #2, flag 5 must be in

OFF position.

with four IOX-4 expanders, enables / disables the function

5.4 Input Operation Modes

The following sections describe the input modes.

A. Input Disabled

This input is disabled and will cause no action to be taken.

B. Allow Entry

The input will cause left side or right side lock of the controller to

be unlocked for the predefined amount of time. The OUTPUT

number should be 1 or 2 respectively.

Note: Do not operate the input when unlock time operates in

toggle mode (0 seconds).

C. Open All

When the controller operates in toggle mode, or when time zone

function is defined as function 2 (first valid Tag) and the door is in

open state. If trigger is set to ON, all the doors are open; and if

trigger is set to OFF, all the doors are closed.

When the input is in this mode and it goes active, it will make ALL

door locks in this loop to open until the input goes back to normal.

This should be used for fire emergencies.

The OUTPUT number is not important.

Note: It is recommended, in this mode, not to use more than one

input for each loop.

D. Control Reader

The input will cause left side or right side or both readers of the

controller to be enabled or disabled according to its state. The

OUTPUT number should be 1, 2 or 3 respectively. Data Register

3 has to be set to 65535 to enable this feature (see “EDIT

REGISTERS” in AXS-100 programming manual).

Note: When completing the task in Control Reader mode,

change the value of the register #3 to 0.

E. Counter

The AXS-100 can use an input for counting events expressed as

pulses on any of the inputs. The counting is done in data registers

40 to 99. The OUTPUT number should reflect which data register is

to be used. More than one input can affect a counting data register.

Each input setup can be configured to count up and/or down. This

facilitates the ability to count up using one input and count down

using another input. The OUT TIME number should be 1 for upcount, 2 for down-count and 3 for both up and down count (when

pressed counting is upward; when released counting is downward).

Note: If the value of the up/down counter (40 to 99) =0, the

controller will not count downwards.

F. Output

An input may be used to control an output relay on the IOX-4

boards. The OUTPUT number defines which output relay is to be

controlled (1 through 32). Adding 64 to relay number will cause

input to operate the relay in toggle mode. Adding 128 to relay

number will cause the input triggering and restoring to generate

an event message. Set the OUT TIME number to amount of time

in seconds to operate the relay (1 through 2000 seconds).

G. Timer

1. OUTPUT 1 is controlled by the timer. OUT TIME 1 is the period

of time that the counter counts from 1 second to 2000 seconds.

2. To operate OUTPUT 1, press down on the INPUT at every

counting period. After counting is completed, the OUTPUT is

functional.

3. To receive an event, add the number 128 to the OUTPUT

number. The received event is the INPUT TRIGGER.

5.5 Using Relay Outputs Without Inputs

The IOX-4 relay outputs can be used with no input functionality.

The following functions can be enabled by setting flags in LOCAL

SETUP:

Event group type output Set flag 5 in SETUP FLAGS 2.

Elevator control Set controller operating mode to 9 in

Note: In the IOX-4, relay 25 will be activated each time a tag is

presented to the reader when KEY FLAG 7 of the tag is set to

ON. This has no relevance to FLAG 5 in SETUP FLAGS 2, (see

AXS-100 User Guide Para. 3.3.2 Modify Key Flags).

LOCAL SETUP.

6. TESTING

After mounting and wiring, the IOX-4 should be tested. Activate

the unit inputs and verify proper operation according to the

application used.

WARNING! Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

4 DE6314

It is recommended to perform a periodical test once a week such as presenting a tag to the reader and verifying that the

relevant door is opened.

No maintenance is required for the IOX-4 unit.

Page 5

W

ARRANTY

Visonic Technologies Ltd. and/or its subsidiaries and its affiliates ("the Manufacturer")

warrants its products hereinafter referred to as "the Product" or "Products" to be in

conformance with its own plans and specifications and to be free of defects in materials and

workmanship under normal use and service for a period of twelve months from the date of

shipment by the Manufacturer. The Manufacturer's obligations shall be limited within the

warranty period, at its option, to repair or replace the product or any part thereof. The

Manufacturer shall not be responsible for dismantling and/or reinstallation charges. To

exercise the warranty the product must be returned to the Manufacturer freight prepaid and

insured.

This warranty does not apply in the following cases: improper installation, misuse,

failure to follow installation and operating instructions, alteration, abuse, accident or

tampering, and repair by anyone other than the Manufacturer.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or

liabilities, whether written, oral, express or implied, including any warranty of

merchantability or fitness for a particular purpose, or otherwise. In no case shall the

Manufacturer be liable to anyone for any consequential or incidental damages for breach

of this warranty or any other warranties whatsoever, as aforesaid.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in the modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products.

The Manufacturer does not represent that its Product may not be compromised and/or

circumvented, or that the Product will prevent any death, personal and/or bodily injury

and/or damage to property resulting from burglary, robbery, fire or otherwise, or that the

Product will in all cases provide adequate warning or protection. User understands that a

properly installed and maintained alarm may only reduce the risk of events such as

burglary, robbery, and fire without warning, but it is not insurance or a guarantee that

such will not occur or that there will be no death, personal damage and/or damage to

property as a result.

The Manufacturer shall have no liability for any death, personal and/or bodily injury

and/or damage to property or other loss whether direct, indirect, incidental,

consequential or otherwise, based on a claim that the Product failed to function.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or

damage arising under this limited warranty or otherwise, regardless of cause or origin, the

Manufacturer's maximum liability shall not in any case exceed the purchase price of the

Product, which shall be fixed as liquidated damages and not as a penalty, and shall be

the complete and exclusive remedy against the Manufacturer.

Warning: The user should follow the installation and operation instructions and among

other things test the Product and the whole system at least once a week. For various

reasons, including, but not limited to, changes in environmental conditions, electric or

electronic disruptions and tampering, the Product may not perform as expected. The user

is advised to take all necessary precautions for his /her safety and the protection of

his/her property.

6/91

VISONIC TECHNOLOGIES. (ISRAEL): 30 Habarzel St. Tel Aviv 69710 ISRAEL Tel 972-3-7681400 Fax: 972-3-7681415 E-MAIL: support@visonictech.com

VTA (VISONIC TECHNOLOGIES AMERICAS): 65 West Dudley Town Road, Bloomfield CT. 06002-1911 USA. TEL.: (860) 243 0833, (800) 223 0020

FAX: (860) 242-8094. E-MAIL: usa_support@visonic.com

VT UK (VISONIC TECHNOLOGIES UK): Fraser Road, Priory Business Park, Bedford MK44 3WH ENGLAND. TEL.: 44-870-730-0840; FAX: 44-870-730-0839

INTERNET: www.visonictech.com

VISONIC TECHNOLOGIES LTD. 2004 IOX-4 DE6314- (REV. 3, 08/03)

DE6314 5

Loading...

Loading...