Page 1

DE1220 1

HUNTER

HUNTERHUNTER

HUNTER

Anti-Masking, Self-Testing PIR Motion Detector

Installation Instructions

1111. INTRODUCTION

. INTRODUCTION. INTRODUCTION

. INTRODUCTION

The HUNTER is a sophisticated PIR that utilizes an advanced

motion analysis algorithm, the latest anti-masking technology and

motion simulation self-test routines.

The advanced motion analysis algorithm - True Motion

Recognition™ - provides improved distinction between true

motion of a human body and any other disturbance that would

cause other detectors to produce false alarms.

Masking and/or internal circuit malfunction cause trouble

indications to appear: the green LED flashes and the TRB

(trouble) relay drops out. At power up, a unique software routine

adapts the detector to its immediate surroundings. Despite this, if

an object is too close to the lens or the field of view is too narrow,

the detector will respond as it does upon masking.

The HUNTER includes temperature compensation circuits - for

maximum catch performance and optimum protection from false

alarms. A built-in motion event verification counter can be

programmed to trigger an alarm as a result of 1 or 2 consecutive

motion events, depending on the detection sensitivity required.

A “TEST” (T) input permits switching the detector to the walk-test

mode and back without removing the front cover. The test input

polarity can be selected with a DIP switch (see Para. 3.6).

Long-term stability and high reliability are assured by a special

self-adapting algorithm, that continuously compensates for

environmental changes. The entire electronic circuitry is enclosed

in a protective sealed module, with the sensor element practically

isolated from gusts of wind and insects.

2222.

. .

. SPECIFICATIONS

GENERAL

Sensor Type: Low-noise dual-element pyroelectric unit.

Alarm Relay: N.C. contacts with 18-ohm resistor in series;

contacts rated at 0.1 A resistive / 30 VDC

Alarm Period: 2-3 seconds minimum

Tamper Switch: N.C. contacts, 50 mA resistive / 30 VDC

TRB Relay: N.C. contacts with 18-ohm resistor in series;

contacts rated at 0.1 A resistive / 30 VDC

True Motion Event Verification Counter: 1 or 2 events

Masking Detection Delay: 30 seconds

POWER SUPPLY

Input Voltage: 9 - 16 VDC

Standby Current Drain: 17 mA @ 12 VDC

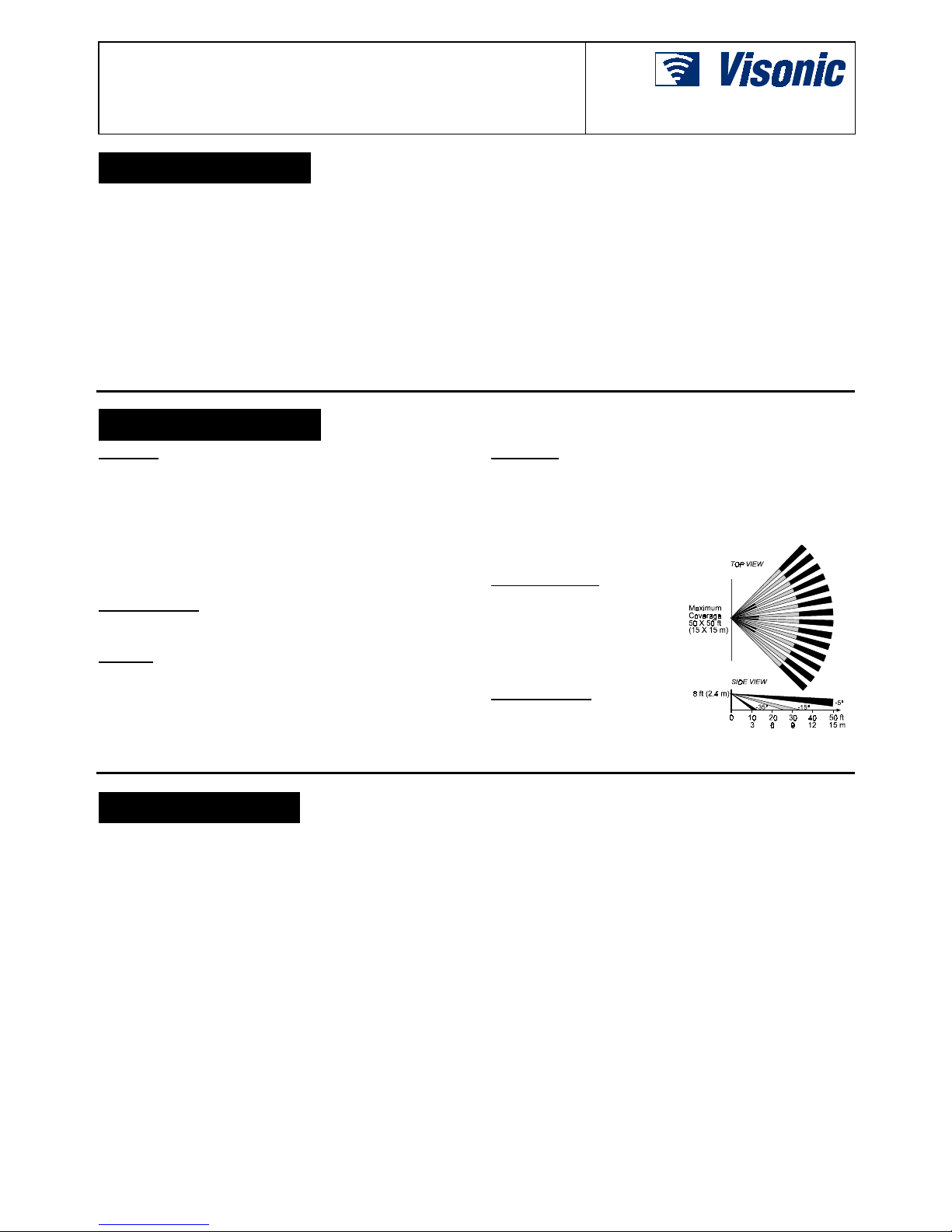

OPTICAL

Lens Type: 90° (wide angle), 34 beams in 3 detection layers.

Coverage Area: 15 x 15 m (50 x 50 ft).

Adjustment:

Vertical: 0° to - 12° with built-in calibrated scale.

Horizontal: ±7.5° by shifting the lens left or right in the front

window (greater shift is possible with optional swivel brackets).

MOUNTING

Configurations: Surface or corner (without swivel brackets)

Height: Up to 3.6 m (12 ft)

Optional Accessories: BR-1: Swivel bracket for surface

mounting, adjustable 30° downward and 45° left, 45° right.

BR-2: BR-1 with corner mounting adapter.

BR-3: BR-1 with ceiling

mounting adapter.

ENVIRONMENTAL

Operating Temperatures:

-10° to 50°C (14° to 122°F)

Storage Temperatures:

-20° to 60°C (-4° to 140°F)

RFI protection: Greater than

20 V/m up to 1000 MHz.

PHYSICAL DATA

Dimensions (H x W x D):

116 x 60 x 45 mm

(4-9/16 x 2-3/8 x 1-3/4 in.)

Weight: 112 g (4 oz)

3. INSTALLATION

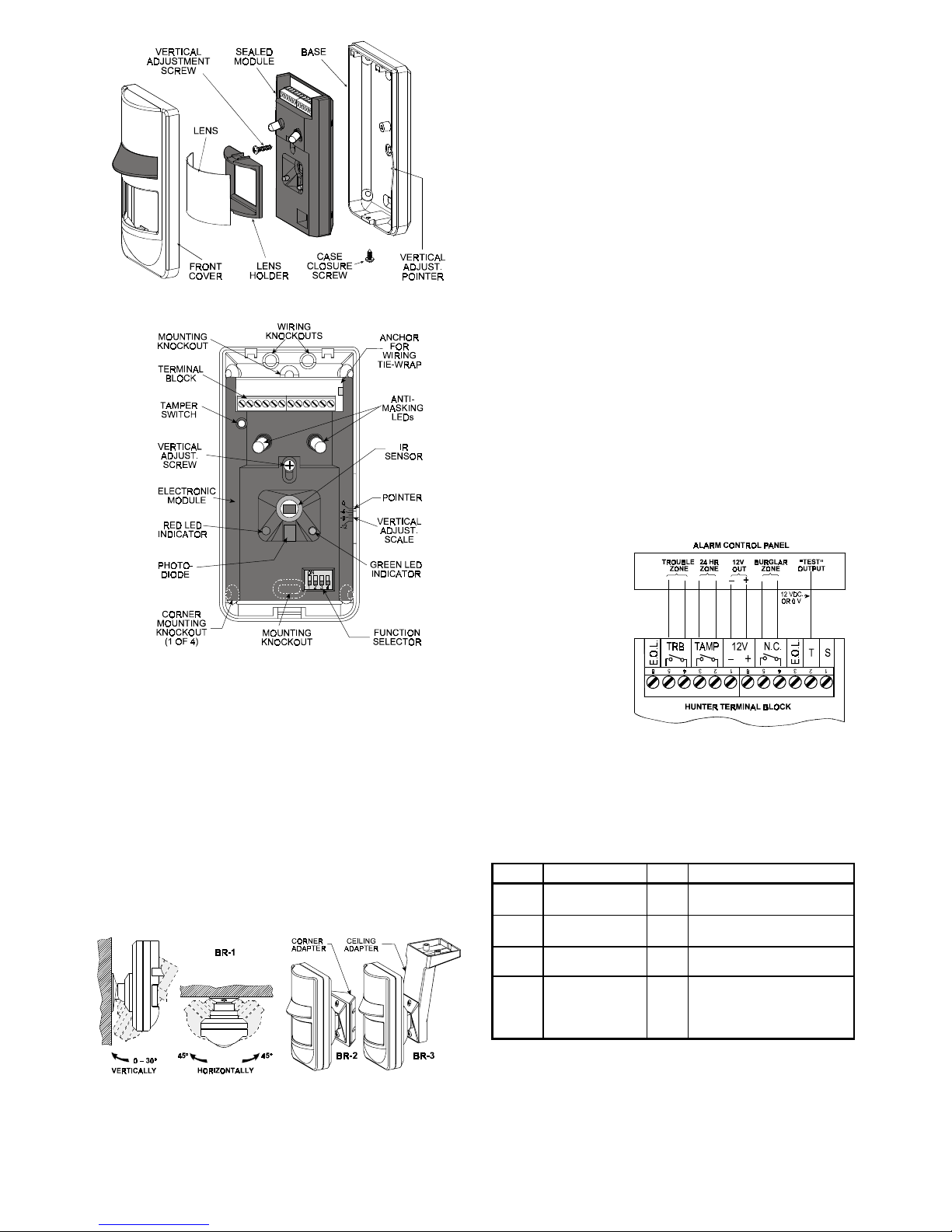

3.1 Construction Details

The electronic circuitry is enclosed in a sealed module, attached

to the base with a single screw (see Figure 2).

The electronic module may be shifted up or down along the base

for vertical adjustment of the detection beam angle.

The front cover accommodates the Fresnel lens, that can be

unfastened for horizontal adjustment or for replacement. The LEDs,

which are positioned behind the lens, are visible when illuminated.

3.2 Selecting the Mounting Location

Always mount the detector unit on a firm and stable surface.

A. Select the mounting location so that the expected motion of an

intruder would cross the beams of the coverage pattern.

B. Avoid aiming the detector at heaters, sources of bright light

and windows that are subject to direct sunlight. Also avoid

running the wiring close to high-power electrical cables.

C. Make sure not to install the unit where obstacles are present

0.5 meter (1.5 ft) away from the lens or closer.

3.3 Mounting

A . Remove the screw located at the bottom and then take the

front cover off (see Figure 2).

B . Remove the vertical adjustment screw and detach the module

from the base.

C . Mount the base (with the wiring entry knockouts up) in the

location and height selected for optimum coverage. For

surface mounting, use the two knockouts at the back of the

base. For corner mounting, use the knockouts on the angled

sides (see Figure 3).

Figure 1. Coverage Pattern

Page 2

2 DE1220

Figure 2. Exploded View of the HUNTER

Figure 3. HUNTER as Viewed with Cover Removed

D. Put the electronic module back in place and remount the

vertical adjustment screw (but do not tighten it fully yet).

E. Set the DIP switch function selector as required for the

particular application (see Paragraph 3.6 for details).

F. Carry out the necessary wiring operations as outlined in

Paragraph 3.5).

3.4 Optional Swivel Brackets

Three optional swivel brackets are available. They are intended to

enhance the flexibility of installation. Each bracket comes

complete with detailed installation instructions in its own packing

box.

BR-1 - a surface-mounted swivel bracket (see Fig. 4).

BR-2 - corner mounting swivel bracket (see Fig. 5).

BR-3 - ceiling mounting bracket (see Fig. 5).

Attention! With swivel brackets in use, the effective detection

range may differ from that indicated in Table 2.

Fig. 4. Hunter with BR-1 Fig. 5. Hunter with BR-2 / BR-3

3.5 Wiring

A. Terminal Assignments

N.C. relay output:

The normally closed alarm relay contacts open upon detection of

motion (alarm) or during a power failure.

TAMP (tamper output): The TAMP (tamper) contacts, which are

normally closed, open when the unit’s front cover is removed.

TRB (trouble) Relay: The normally closed trouble relay contacts

open when masking is sensed or when trouble is detected by the

unit’s self test circuitry.

T (TEST) input: Used to remotely switch the detector into the

walk-test mode and back to normal, by applying +12 VDC or 0

VDC to this terminal (see SW-4 in Para. 3.6).

E.O.L. terminals: The two “floating” E.O.L. terminals serve only

as connection points for E.O.L. (end-of-line) resistors.

B. Wiring Procedure

Refer to Figure 6 and use #22 AWG or larger conductors to wire

the detector as follows:

(1) Connect one N.C. output terminals of the detector to a burglar

zone terminals of the alarm control panel.

(2) Connect the detector’s TAMP terminals across the terminals

of a 24-hour zone of the alarm control panel.

Note: If the control panel is set for E.O.L. and you are wiring the

most distant detector in the loop, use the closest E.O.L. terminal

to connect the required E.O.L. resistor in series with the loop.

( 3 ) Connect the detector’s TRB relay terminals across the

terminals of a 24-hour trouble zone of the control panel.

( 4 ) Connect a single wire between the detector’s T terminal and

the walk-test control voltage source (see Para. 3.6 for TEST

input polarity).

( 5 ) Connect the 12 V

(+) and (–)

terminals to a 9 16 VDC power

source and check

for correct polarity.

The power supply

must have

at

least

4

hours of battery

backup.

The

standby current

consumption

of

each detector unit

is about 17 mA.

Figure 6. Terminal Block Wiring

3.6 The Function Switches

A. Switch Tasks

The HUNTER is equipped with a 4-position DIP switch function

selector (see Fig. 3).

Table 1. Setting the Function Selector

Switch Function Pos. Selected Option

SW-1

Motion event

Counter

ON

OFF

2 motion events to alarm

1 motion event to alarm

SW-2

LED control ON

OFF

Both LEDs are enabled

Both LEDs are disabled

SW-3

Reset after trouble - Resets the unit when switched

from OFF to ON or ON to OFF

SW-4

Selects the TEST

(“T”) input signal

polarity

ON

OFF

0 V disables walk test

+12 VDC enables walk test*

+12 VDC disables walk test*

0 V enables walk test*

* +12 VDC or open circuit.

Note: OFF is not effective in the walk test mode and during the

power-up adaptation period.

Page 3

DE1220 3

B. Setting the Switches

Set the function switches as desired prior to applying power. The

ON position is indicated on the switch body.

SWITCH SW-1:

If you set this switch to OFF (1 motion event),

the detector’s sensitivity will be increased, and if you set this

switch set to ON (2 motion events), you will get the highest

immunity against false alarms.

SWITCH SW-2: You may enable or disable the LED walk-test

indicators. However, even if disabled, they will be automatically

enabled when the detector is switched to the test mode.

SWITCH SW-3

Resetting after trouble - it makes no difference whether the lever

is switched from OFF to ON or vice versa.

SWITCH SW-4: Set this switch in accordance with the control

panel’s TEST output. If there is no such output, simply wire the

control panel’s 0 VDC (ground) to the detector’s “T” terminal

through a TEST switch installed at a convenient location.

Set SW-4 to OFF if you do not intend to use the T input.

3.7 Vertical Pattern Adjustment

To adjust the vertical pattern, loosen the vertical adjustment

screw slightly and slide the electronic module up or down to the

desired angle. Adjust the scale according to Table 2 for the

desired mounting height and coverage range. Once the module is

aligned correctly, tighten the screw firmly.

Table 2. Vertical Adjustment Chart

3.8 Horizontal Pattern Adjustment

The coverage pattern may be

adjusted ±7.5° by shifting the lens

off its centered position:

A . Remove the lens holder as

shown in Figure 7.

B . Shift the lens in the desired

direction (right or left).

C . Hold the lens in position and

re-insert the lens holder bottom end first. Next, push

the top end against the front

cover until the lens holder

snaps into place.

Figure 7. Releasing the Lens

4. OPERATION AND TESTING

4.1 Output Circuit Behavior

A. Alarm Relay

When an alarm occurs, the alarm relay contacts open for 2-3

seconds.

B. TRB Relay

The TRB relay drops out (its contacts open) whenever masking is

detected, or upon detection of an internal malfunction by

automatic self test routine. The relay pulls in as soon as the

cause for trouble is removed.

4.2 LED Display

Two LEDs, red and green, convey status information by various

signaling combi- nations, as detailed in Table 3 below. However,

the following rules must be taken into account:

A. The LED indicators may be enabled by setting DIP switch

SW-2 to ON or applying “test enable” voltage to the “T”

terminal. While being enabled by one, the LEDs can not be

disabled by the other.

B. Even if the LEDs are disabled, they will still function

throughout the 2-minute power-up adaptation period and as

trouble indicators.

Table 3. LED Displays

State of

RED LED

State of

GREEN LED

Interpretation

Flashing Flashing Adaptation period (about 2 minutes)

upon power up.

OFF OFF Ready to detect. There are presently

no alarm/trouble events.

ON (2-3 s) N/A Motion is being detected.

N/A Flashing Masking or internal failure state.

4.3 Resetting after Trouble

Flashing of the green LED indicates that masking or internal

circuit trouble are being sensed. While the green LED flashes,

the TRB relay contacts are open.

To determine the cause for trouble, check for masking:

• Foreign material may be glued to the lens or sprayed on it.

• An object may have been placed less than 0.5 m (1.5 ft) away

from the detector.

• An object situated in the detector’s field of view less than 0.5 m

(1.5 ft) from the detector has been re-located (the detector

“considers” this change in its surroundings as a masking event).

Note: Erratic behavior of the detector may result from partial

masking - check the lens very carefully.

Remove masking if found. Then remove the cover, change the

position of DIP switch SW-3 (from OFF to ON or vice versa),

mount the cover quickly in place and get away from the detector.

IMPORTANT! Changing the position of SW-3 resets the

detector and causes it to re-adapt to its current surroundings for

2-minutes. Stay at least 0.5 m (1.5 ft) away from the detector,

so as not to disrupt this process. The green and red LED will

flash alternately until the 2 minute period is up. If they continue

to flash, check again for masking.

Reset is also possible without removing the cover - apply the “test

enable” voltage to the “T” terminal (see Para. 3.6) and conduct a

short walk test, causing the detector to alarm at least 3 times.

After reset, the detector should function normally - the green LED

should not flash and the TRB relay contacts should close. If this

is not so, and masking has been ruled out, the trouble indication

is probably due to internal circuit trouble. The only remedy for this

is replacing the detector unit with a new one.

4.4 Testing procedure

A. Set SW-2 to ON, or leave it OFF but apply the “test enable”

voltage to the “T” terminal. Remount the detector’s cover.

B. Power up the system. The red and green LEDs will flash

alternately, indicating that the detector is adapting itself to its

present surroundings. Stay at least 0.5 m (1.5 ft) away from

the detector, until the 2-minute startup period ends (until

the LEDs stop flashing alternately).

Page 4

4 DE1220

C. Enter the detector’s field of view and walk test the entire

coverage area, while observing the red LED. The LED will

light for 2-3 seconds each time your motion is detected.

D. Tape a piece of cardboard to the detector’s front to

deliberately mask the lens. After 30 seconds, the green LED

should start flashing, and the trouble zone of the control panel

should go into alarm (the TRB relay drops out).

E. Remove the masking from the detector’s front. The green LED

should extinguish (after a few seconds).

F. Apply the desired voltage to the “T” terminal, or set SW-2 as

desired to enable/disable the LEDs. The detector is ready for

use.

WARRANTY

WARRANTYWARRANTY

WARRANTY

Visonic Ltd. and/or its subsidiaries and its affiliates ("the Manufacturer") warrants its

products hereinafter referred to as "the Product" or "Products" to be in conformance with

its own plans and specifications and to be free of defects in materials and workmanship

under normal use and service for a period of twelve months from the date of shipment by

the Manufacturer. The Manufacturer's obligations shall be limited within the warranty

period, at its option, to repair or replace the product or any part thereof. The Manufacturer

shall not be responsible for dismantling and/or reinstallation charges. To exercise the

warranty the product must be returned to the Manufacturer freight prepaid and insured.

This warranty does not apply in the following cases: improper installation, misuse,

failure to follow installation and operating instructions, alteration, abuse, accident or

tampering, and repair by anyone other than the Manufacturer.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or

liabilities, whether written, oral, express or implied, including any warranty of

merchantability or fitness for a particular purpose, or otherwise. In no case shall the

Manufacturer be liable to anyone for any consequential or incidental damages for breach

of this warranty or any other warranties whatsoever, as aforesaid.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in the modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products.

The Manufacturer does not represent that its Product may not be compromised and/or

circumvented, or that the Product will prevent any death, personal and/or bodily injury

and/or damage to property resulting from burglary, robbery, fire or otherwise, or that the

Product will in all cases provide adequate warning or protection. User understands that a

properly installed and maintained alarm may only reduce the risk of events such as

burglary, robbery, and fire without warning, but it is not insurance or a guarantee that such

will not occur or that there will be no death, personal damage and/or damage to property

as a result.

The Manufacturer shall have no liability for any death, personal and/or bodily injury

and/or damage to property or other loss whether direct, indirect, incidental,

consequential or otherwise, based on a claim that the Product failed to function.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or

damage arising under this limited warranty or otherwise, regardless of cause or origin, the

Manufacturer's maximum liability shall not in any case exceed the purchase price of the

Product, which shall be fixed as liquidated damages and not as a penalty, and shall be the

complete and exclusive remedy against the Manufacturer.

Warning: The user should follow the installation and operation instructions and among

other things test the Product and the whole system at least once a week. For various

reasons, including, but not limited to, changes in environmental conditions, electric or

electronic disruptions and tampering, the Product may not perform as expected. The user

is advised to take all necessary precautions for his/her safety and the protection of his/her

property.

6/91

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.): 10 NORTHWOOD DRIVE, BLOOMFIELD CT. 06002-1911. PHONE: (860) 243-0833, (800) 223-0020 FAX: (860) 242-8094

VISONIC LTD. (UK): FRASER ROAD, PRIORY BUSINESS PARK, BEDFO RD MK44 3WH. PHONE: ( 0870) 7300800 FAX: (0870) 7300801

INTERNET:

www.visonic.com

VISONIC LTD. 2002 HUNTER D-1220-0 NEW: DE1220- (REV. 5, 5/02)

Loading...

Loading...