Visonic DUO 200 User Manual

'82

Dual-Technology Microwave/PIR Intrusion Detector

,1752'8&7,21

DUO 200 is a state-of-the-art microcomputer controlled dualtechnology intrusion detector. Its operation is based on two

physical phenomena - the infr ared (IR) radiation emitted by the

human body and the Doppler frequency s hift caused by a pers on

moving in a microwave (MW) field. The IR and MW t echnologi es,

when combined in a single det ector, complement each ot her to

assure the most r eliable detection and immuni ty to false alarms.

The superiority of the DUO 200 over other dual detectors has

been achieved by the advent of the Tr ue Motion Recognition™

algorithm (patents applied for). This advanced motion analysis

method provides the DUO 200 with the ability to distinguish

between the true motion of a human body and any other

disturbances which invariably cause false alarms.

Another unique feature of the DUO 200 is the MW Motion

Simulator circ uit (patent s applied f or), whi ch si mulates t he effect

created by a human body moving in the MW fiel d. The si mulation

routine is car ried out periodically for the purpose of self -testing,

supervision and assurance that the MW detector operates

properly.

63(&,),&$7,216

Input Voltage: 9 to 16 VDC

Current Drain: About 23 mA @ 12 VDC

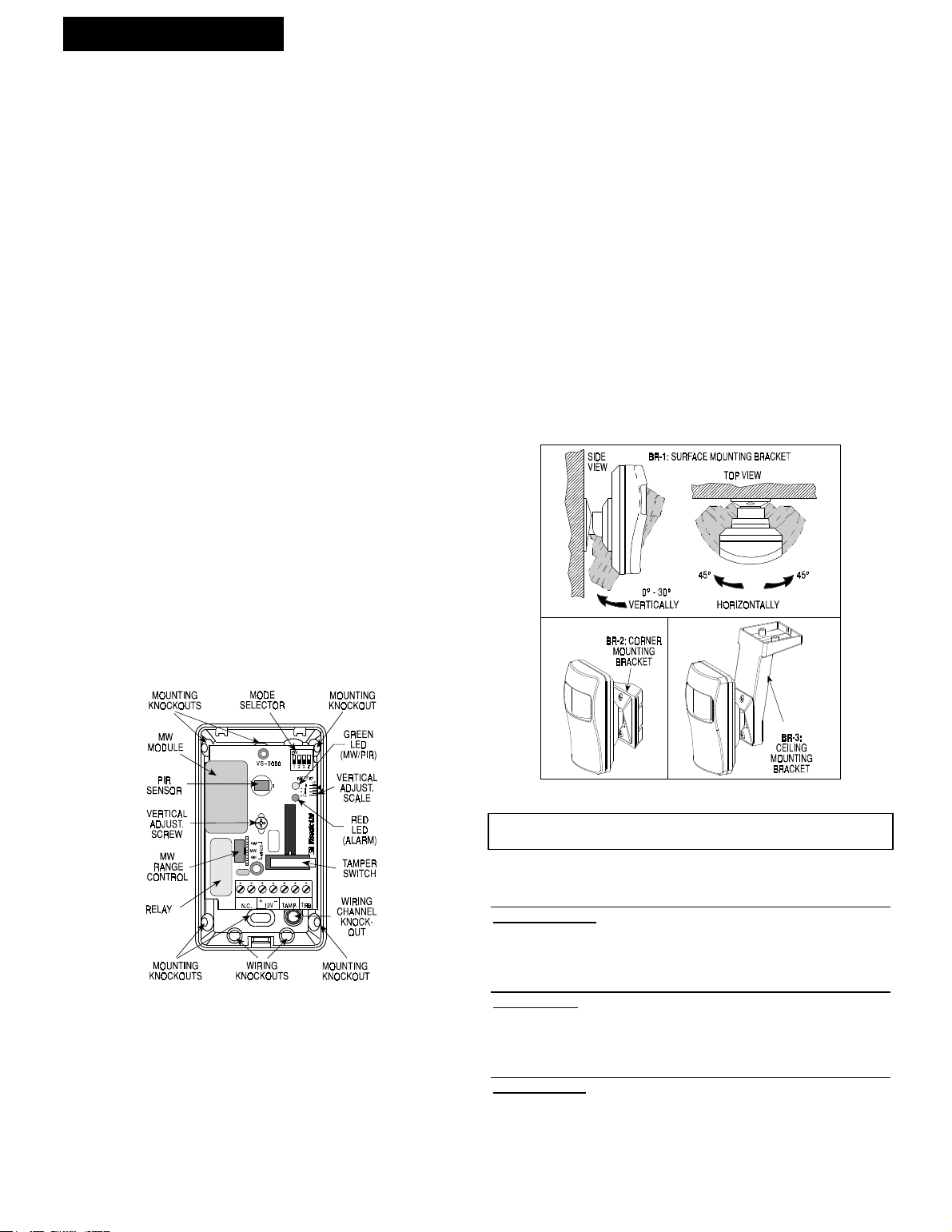

PIR SECTION (see Figure 2)

Detector: Low noise dual- element pyroelectric sensor

Trip Indication: Green LED flashes for up to 5 seconds

True Motion Event Verification Counter: Selectable, 1 or 2

motion events

Lens Data

No. of Beams: 34

Field of View: 90°

Max. Coverage: 12 x 12 m (40 x 40 ft)

Vertical Adjustment: +2° to –12°, by sliding the cir cuit board

along a calibrated s cale.

MW SECTION

Oscillator: Microstrip DRO-stabili zed type

Frequency: 10.525 GHz in USA, 10.687 and 2.45 GHz i n the UK

and Europe.

Detection Range: Adjustable from 25% to 100% (3 m to 12 m)

Trip Indication: Green LED illuminates for up to 5 seconds

ALARM & TAMPER DATA

Alarm Indication: Red LED illuminates for 1.3 to 5 seconds if

both detectors trip

Relay Contacts: Normally closed, 0.1 A resistive/24 VDC; 18

resistor in series with contacts

Alarm Duration: 1.3 to 5 seconds (red LED lights and output

relay contacts open)

Tamper Switch Contacts: Normally closed, 0.1A resistive

/24VDC

PHYSICAL CHARACTERISTICS

Dimensions (H x W x D): 104 x 60 x 32 mm (2.4 x 4.1 x 1.3 in.)

Weight: 80 gr (2.8 oz)

MOUNTING

Direct: Surfac e or corner without additional br acket, up to 2.5 m

(8 ft)

Ω

ACCESSORIES (see Figure 4)

BR-1: Surface mounted s wivel brack et, adjus table 30° down and

45° left/45° right.

BR-2: BR-1 with a corner adapter (kit)

BR-3: BR-1 with a ceil i ng adapter (kit)

ENVIRONMENTAL CONDITIONS

Operating Temperatur e: –10°C to 50°C (14°F to 122°F)

Storage Temperature: –20°C to 60°C (–4°F to 140°F)

RFI Protection: Gr eater than 30 V/m (20 MHz to 1000 MHz)

PATENTS

U.S. Patent 5,237,330; Des. 346,567 (other patents pending)

Installation Instructions

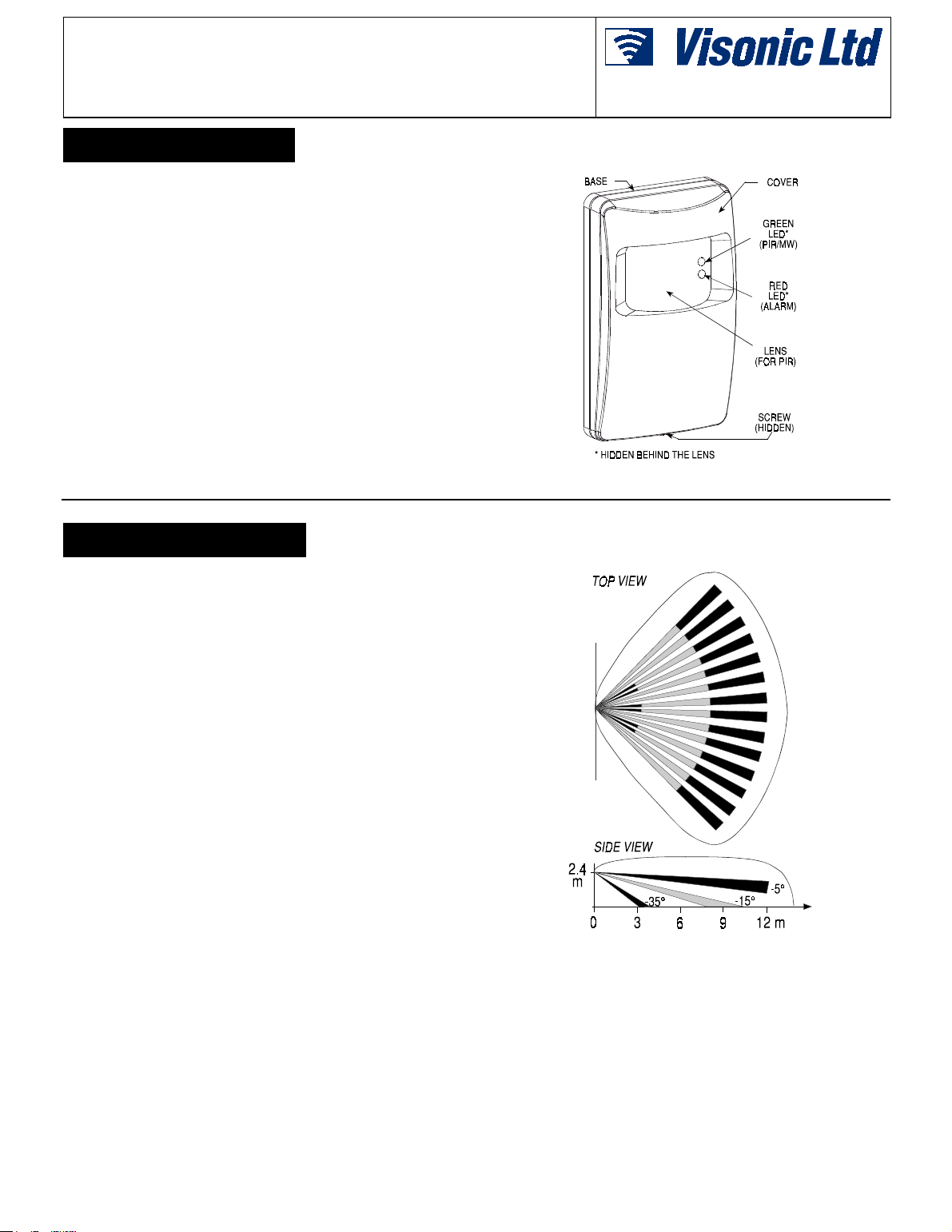

Figure 1. DUO 200 General View

Figure 2. PIR and MW Coverage Pat tern

DE1821 1

,167$//$7,21

*HQHUDO*XLGHOL QHV

A few important rules must be observed before selecting a

mounting location:

A. Microwave radiation passes through glass and non-metallic

walls. Be sure to adjust the MW range so that it does not

exceed the room limits, or else a rotating ceiling fan in the

next room, or moving traffic along the out er side of the wall

will cause the MW detector to alarm.

B. Large reflecting objects (especially metals) within the

coverage area can dist ort the microwave detector's coverage

pattern.

C. Although the DUO 200 is extremely immune to false alarms, it

is recommended to avoid installation in a room with very

strong air tur bulence or close t o high-power electrical cables.

D. If two DUO 200 units are installed in the same room or on

opposite sides of a shared wall, they should not face each

other and must be mounted at l east 2 meters apart .

E. For best performance at high ambient temperatures, it is

recommended to aim the unit towards the cooles t place i n the

protected area.

F. Always mount t he unit on a f ir m and st abl e s ur fac e at a hei ght

that renders optimum coverage of the protected area.

Increasing the vertic al angle at a certain height will increase

the coverage range.

G. Do not install the DUO 200 i n places where one of the t wo

detector circuits alarms constantly or intermittently, due to

environmental interference.

C. Selec t the mounting location in accordance with the guidelines

in Section 3.1.

D. Temporar ily remove the PC board from the base. Tak e care

not to lose the fas tening screw.

E. Use the base as a template for marking the drilling points.

F. Drill mounting holes and insert masonry anchor s if required.

G. Pass the wires through the punched-out wiring inlet(s) and

mount the base in place using two screws .

H. Seal all openings in the base wit h RTV to pr event i ns ec ts f rom

entering the unit.

I. Remount the PC board and secure it with its vertical

adjustment scr ew.

2SWLRQDO6ZLYHO %U DFNHWV

The BR-1 is a general purpos e swivel bracket used for vert ical

and horizontal positioning of the DUO 200. With the BR-1, the

unit can be tilted down from 0° to -30° and swivell ed 45° left or

right (see Fig. 4).

The BR-2 is a swivel bracket kit for room corner installations,

consisting of the BR-1 and a corner adapter. The BR-3 i s a swivel

bracket kit for ceiling instal lations. It consi sts of the BR-1 and a

ceiling mounting adapter.

'LUHFW0RXQWLQJ

The unit can be installed directly on the wal l or in a room corner

using the mounting knockouts. Optional swivel brackets permit

greater flexibility when adjusting the coverage area (Secti on 3.8).

A. Loosen and remove the screw at the bottom of the c ase (see

Figure 1) and then take t he cover off.

B. Punch out the appropriate mounting and wiring knockouts in

the base.

Figure 3. Printed Cir cuit Board Layout

Notes:

1. For wall surface mounting, use the two elongated

knockouts at the middle of the bas e. For c or ner mounting, us e

two diagonally opposite knoc kouts at the angled sides of the

base (see Figure 3).

2. To route the wiring t o a lower conduit, use the t wo wiring

knockouts at the bottom of the base (see Fi gure 3). To r oute

the wires under the base towards t he ceiling, use the wiring

channel and its associated knockout.

Figure 4. Optional Swivel Brackets

Caution! When a swivel brac ket is used, the effec tive detection

range may differ from that i ndicated in Table 3 (see Para. 3.8).

:LULQJ

Connect wires to the terminal block in the following or der:

Terminal: TAMP (tamper switc h)

Connect to: A normally closed 24-hour tamper zone of the

control panel.

Details: When the cover is r emoved, the t amper swit ch cont acts

open.

Terminal: NC (alarm relay)

Connect to: Normally closed burglar protection zones of the

control panel.

Details: Upon alarm or power failure, the out put relay's normally

closed contacts open.

Terminal: TRB (trouble output)

Connect to: 24-hour trouble zone, paral lel to an E.O.L. resist or

(see Figure 5).

Details: The TRB open collector output will be grounded upon

detector malfunc tion, causing disturbanc e in the trouble zone of

the associated alarm system.

2 DE1821

Loading...

Loading...