Page 1

CL-80

Outdoor/Indoor Access Control Keypad

1. INTRODUCTION

The CL-80 is a versatile, weather-resistant digital

keypad, designed for outdoor and indoor use. Possible

applications include access control, electrical switching,

and security system arming and disarming.

User access codes ensure that all functions controlled

by the CL-80 are restricted to authorized persons only,

and each code can be assigned its own privilege level.

To improve access management, the CL-80 responds to

56 different access codes - each allocated to a single user

or a group of users.

2. SPECIFICATIONS

Code composition: Any combination, 1 to 8 digits

Keypad type: 12 keys in 3 X 4 matrix, tactile operation

Operating voltage: 9 -16 or 22 - 26 V AC/DC - selectable

Current drain: 15 ma standby, 55 ma with relay and AUX. Output

active

Power failure immunity: EEPROM retains all programmed

information even during total power loss

Relay contact rating: 10 A/28 VAC or DC

Relay pull-in: Programmable 1 – 98 seconds, or toggle mode (latch /

unlatch)

Current sinking capability of AUX. and PANIC outputs:

Up to 100 ma (protected by an 18 ohm series resistor)

Installation Instructions

Each of the 56 different access codes may be programmed to energize

either the built-in relay, or the auxiliary output, or both.

Programming is easily carried out via the keypad, and access codes can

be individually added, deleted, or the levels of control revised at any time.

Only the MASTER CODE holder has the privilege to program the unit.

In addition to a 10 A on-board relay, an auxiliary open-collector output with

7 operating modes can be programmed to control additional devices.

A simultaneous dual keystroke action activates the PANIC output, which

can be used to trigger a silent alarm in emergency situations.

LEDs: Green indicates keypad status

Red and yellow are available for optional indication (as required) and

have 1 k ohm series resistors connected.

Operating temperature:

-20°C to 65°C (-4°F to 149°F)

Index of Protection: Meets IEC529:1989 requirements for IP54

(protection against dust and sprinkled water)

Dimensions: (W X H X D): 8.2 X 12.2 X 3.1 cm

( 3-1/2 x 4-13/16 x 1-1/4 in)

Weight: 200 g (7.14 oz) including rubber gasket

Tamper switch: The dual function tamper switch is designed to

detect attempts to open the unit, or remove it from wall.

3. INSTALLATION

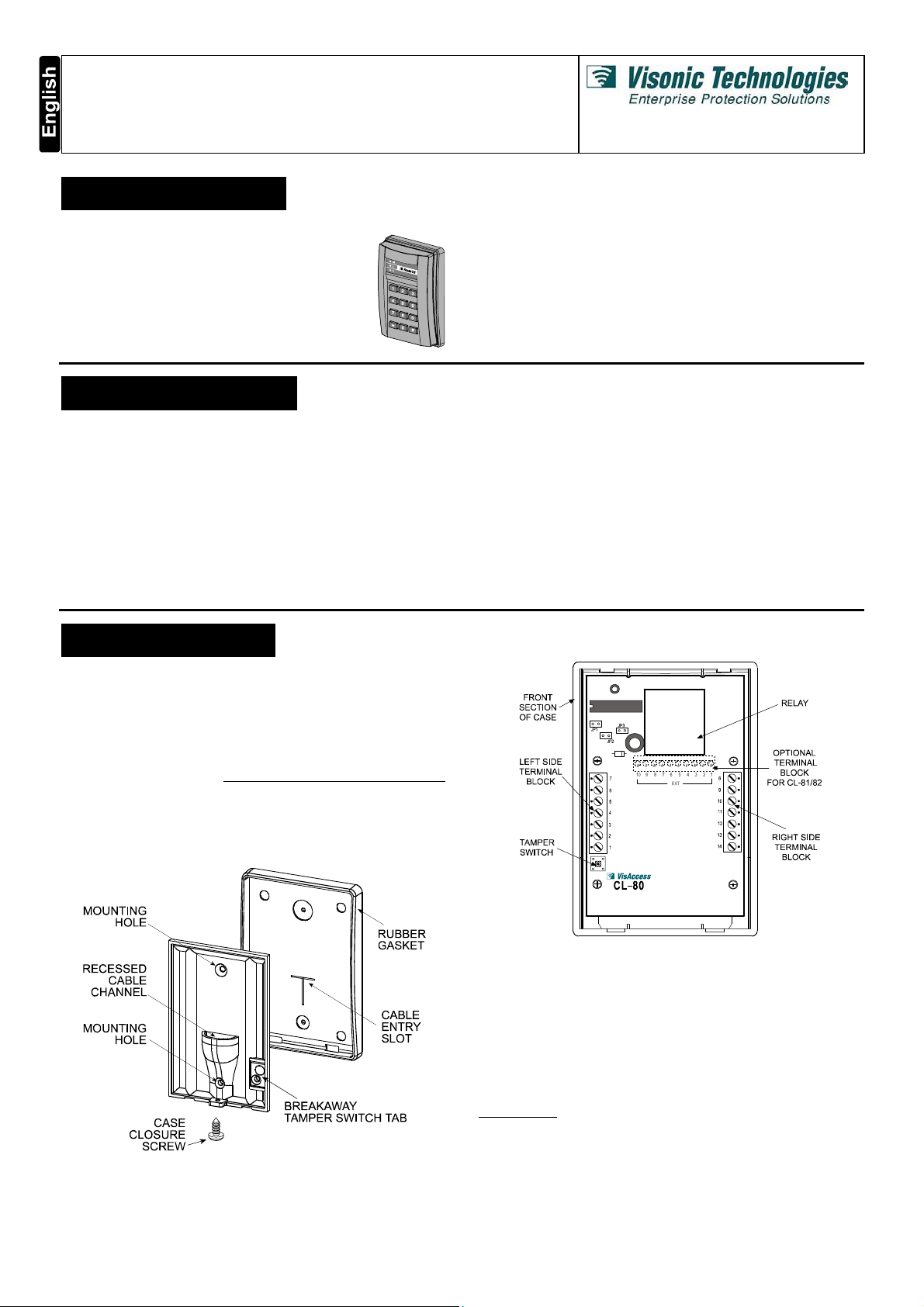

3.1 Mounting

Select a suitable mounting location with a stable flat surface. Remove

the case closure screw from the bottom edge of the keypad, and

remove the keypad assembly from the base. Hold the base in position

and mark the 3 screw locations for drilling.

Note: The Tamper switch will be activated if the front part of the

keypad is removed and also if the base is forced away from the wall.

This is achieved by incorporating a breakaway tab at the bottom right

corner of the base (see Figure 1). It is therefore especially important

to firmly attach this tab to the wall with a long screw.

Fit the base into the rubber gasket and use the 3 mounting screws to

attach the base and gasket to the selected surface.

Figure 1. Base and Rear Sealing

Gasket

Figure 2. Front Casing and Circuit Board

3.2 Wire Gauges and Routing

Use # 20 AWG or larger for connections between relay and door

strike, control panel or other switching devices. All other connections

are to be made with # 22 AWG or larger. Route the wires through the

slot in the rubber sealing gasket and the recessed entry channel in

the keypads base. Avoid contact between uninsulated wires and the

printed circuit board.

3.3 Connections

IMPORTANT! Before wiring, set jumper JP3 in the position

that corresponds with the power source you are using:

Voltage Selection:

9 - 16 V AC/DC - mount the jumper across the two pins of JP3

22 - 26 V AC/DC - remove the jumper or mount it on a single pin of JP3

DE6217 1

Page 2

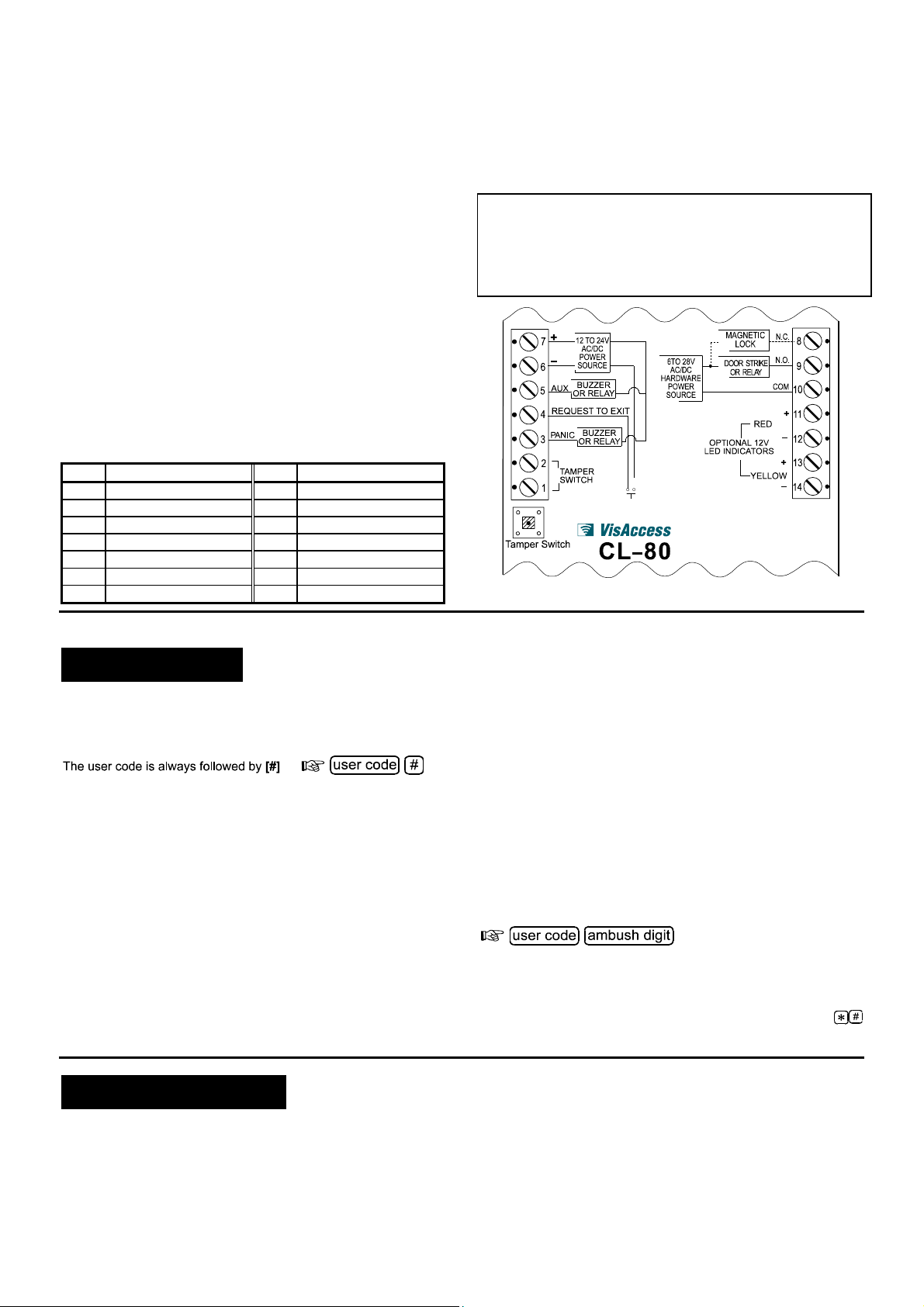

The connections to the terminal block are shown in Figure 3, with

each terminal duly identified. Proceed as follows:

A. Connect one lead of the door strike to one of the hardware

(door strike) power supply terminals. Connect the other lead

from the door strike to terminal No. 9 (N.O.) of the CL-80.

Note: If you are using a magnetic door lock, connect one of

the leads to one of the hardware power supply terminals.

Connect the other lead to terminal No. 8 (N.C.) of the CL-80.

B. Connect the other terminal of the door strike or magnetic lock

power supply to terminal 10 (COM).

C. Connect the panic buzzer or relay between terminals 3 (PANIC)

and 7. Observe polarity when using a DC power source.

D. Connect the auxiliary buzzer or relay between terminals 5 (AUX)

and 7. Observe polarity when using a DC power source.

E. Connect the CL-80 power supply leads across terminals 6(–)

and 7(+). Observe polarity

F. Connect the remote request-to-exit pushbutton or PIR

contacts across terminals 4 and 6

G. LED indicators. - to light the red LED, connect 12 VDC across

terminal 11 (+) and 12 (–). To light the yellow LED, connect

12 VDC between terminals 13 (+) and 14 (–).

H. Connect the tamper terminals 1 and 2 to a control panel’s

normally-closed, 24-hour protection zone, or any other system

used to monitor the tamper contacts.

Table 1. Terminal Assignments

Term. Description

1 Tamper Switch 8 Relay N/C

2 Tamper Switch 9 Relay N/O

3 Panic Output 10 Relay Common

4 Request to Exit 11 + Red LED

5 Aux. Output 12 – Red LED

6 -12 / 24 V (Common) 13 + Yellow LED

7 +12 / 24 Volt 14 – Yellow LED

Term. Description

Notes:

1. The red and yellow LEDs can be connected to the AUX and

PANIC output terminals regardless of the power supplied to

the unit (12 or 24 Volts, AC or DC).

2. The

3. If the CL-80 is powered from a 24 VDC supply, make sure

Caution! When operating the CL-80 from AC power, disregard

polarity, but note that external buzzers connected to the AUX or

PANIC outputs will require a separate DC power supply. For proper

operation, the buzzer circuit should be wired as follows:

DC Power supply [–] to CL-80 terminal 6

DC Power supply [+] to Buzzer [+]

Buzzer [–] to AUX or PANIC output (as required).

PANIC and AUXILIARY outputs each include an 18

ohm resistor in series with the terminal. The maximum

permissible current for each output is 100 mA.

that all external relays used are 24-Volt units.

Figure 3. Terminal Connections

4. OPERATION

The main function of the CL-80 is to recognize valid user codes and

respond according to pre-programmed instructions.

4.1 Keying Format

4.2 Keypad Response

When a valid access code is keyed, the keypad responds by

activating the on-board relay (usually allocated to unlocking the door),

and/or activating the auxiliary circuit. Each of the 56 different access

codes may be programmed to operate the on-board relay, the

auxiliary output or both. The green LED illuminates for as long as the

internal relay remains energized.

4.3 Latching the Relay

For special applications, the relay may be toggled, so that keying the

code once causes the relay to latch, and keying the code again

unlatches the relay.

4.4 Request to Exit

The REQUEST TO EXIT input activates the access control relay to

open the door from inside without keying a code, thereby facilitating

quick and simple exit from the protected area.

4.5 Automatic Reset

When keying user codes, the intervals between digits must not exceed 5

seconds. Should the user exceed this time, or enter a wrong code, an

automatic reset results, requiring the user to wait a few seconds and then

to repeat entry of the security code again.

4.6 Lockout

A penalty lockout is provided to defeat "code-crackers". Three wrong

entries result in a 10 minute lockout, during which an auxiliary output is

activated, but can be reset after 30 seconds by entering a valid user code.

4.7 Access under Duress

If you are forced to access under threat, press the programmed

AMBUSH digit after the last digit of your code. This activates the

PANIC

output without arousing suspicion.

Enter the user code followed by the ambush digit

4.8 Operating Tips

A. Do not wait more than 5 seconds between successive

keystrokes, or else the keypad will reset.

B. To initiate an alarm without opening the door, press

simultaneously. This activates the PANIC circuit which is

usually connected to a silent alarm.

5. PROGRAMMING

Programming should be carried out as soon as installation is

completed. This provides a set of “instructions” which determines

how the keypad will react to various code inputs.

2 DE6217

Programming changes can be made as many times as

necessary, but for security reasons, this operation is restricted to

the "master code" holder (the master user).

Page 3

5.1 Accessing the Programming Menu

The programming menu is accessible only by the master

user

As soon as code programming takes place, this default code is

automatically replaced by the first newly allocated code - No. 01.

Because user code No. 01 will become the new master code, it

should be assigned to the person in charge of security.

All code allocations should be recorded, and a User Code

Programming Chart - Appendix A, is supplied for this purpose.

Remember! To prevent unauthorized programming it is

important to assign a new master code which should be used

for programming only.

To access the programming menu

The green LED will start flashing slowly, indicating that the

programming menu is active.

While the programming menu is active (green LED flashes slowly),

you can select various programming functions by pressing a number

from 1 to 5 (see Table 2).

Table 2. Programming Menu

Func. Activity Value to enter Description

1

Programming

user codes

2

Setting the

relay timing

Latching the

relay

3

Selecting an

AUXI LI ARY

output mode

4

Deleting a

single user

code

Deleting all

user codes

5

Ambush digit

Delete

ambush digit

Notes:

1: If the CL-80 detects an error during programming, the green LED

goes out for 3 seconds after the [#] is pressed and then reverts to

slow flashing. This indicates that the data has not been accepted and

the entire programming sequence should be repeated.

Any combination

of 1 to 8 digits

01 to 98

99

1 to 7

User number,

02 - 56

+ [master code]

[master code]

0 to 9

2: If you make an error while programming, press [] for instant

return to the programming menu.

# +

Assigns access codes to an

individual or group of users

(see Programming)

Sets relay closure duration

between 1 and 98 seconds

Converts relay to toggle mode

(latch/unlatch)

The number entered

determines the operating

mode (see Table 3)

User code corresponding to

the user number entered is

deleted

All user codes are deleted in a

single operation, except for

master code 01

The programmed digit will be

valid until deleted or replaced

The ambush digit is canceled

5.2 Deleting all User Codes

IMPORTANT! Besides the default master code (code No.1), a specific test

code is programmed in the factory as code No. 2. It is therefore important,

before initial programming, to delete all user codes that may remain in the

memory!

The response will be as follows:

After entering the first [4] – The green LED starts to flash rapidly

After entering

steadily for 2 seconds, and resumes rapid

After entering the [master code] followed by

remains lit for 2 seconds and then reverts to slow

[ ]

followed by

[#]

– The green LED lights

flashing.

[#] – the LED

flashing.

5.3 Programming New User Codes

and Their Extent of Control

then repeat

.

to verify

The user number is the number assigned to this user in the user list,

not the code.

• The green LED lights steadily for two seconds and starts to

flash rapidly

B.

• The green LED lights steadily for 2 seconds and resumes rapid

flashing

C. Select a trip code from the list below. This determines

which outputs will be tripped by the new master code.

1 to trip the relay only

2 to trip the auxiliary output only

3 to trip both the relay and the auxiliary output

• The green LED lights steadily for 2 seconds and then

flashes slowly

, indicating that the new code has been

programmed successfully and that the keypad has

returned to the programming menu. To continue

programming user codes, follow the sequence A through D

above, or quit by

Caution! Code No. 01 will now become the master code, and will

provide the only access to future programming.

Prepare a list of user codes you want to program and record them in

your Programming Chart (see Appendix A).

5.4 Deleting Selected User Codes

The response will be as follows:

After entering the first [ 4 ] – the green LED starts to flash rapidly

After entering

steadily for 2 seconds, then resumes rapid

Entering the [master code] followed by

remains lit for 2 seconds and then begins flashing slowly

[user number]

followed by

[ # ]

– the green LED lights

flashing.

[ # ] – the LED

.

5.5 Setting the Relay Timer

[ TT ] is the relay contact closure time

Set duration from 1 to 98 seconds, enter a number from 01 to 98

Convert the relay to toggle mode (latch/unlatch), enter 99

5.6 Selecting the AUX Output Mode

[M] is expressed by a number selected from the mode column in

Table 3. User codes must be authorized to activate the AUX

output.

Mode Description

1 Output is pulsed for 1 second.

2 Output is toggled (latch/unlatch).

3 Output operates concurrently with the relay timer, but stays enabled

for 5 seconds longer than the relay. If toggle mode has been

selected for the relay, the auxiliary output will be enabled for 5 sec.

each time the relay is toggled. This mode does not work for user

codes that are not programmed to operate the relay.

4 Output latches by user codes authorized to trip the auxiliary output,

unlatches by pressing .

5 Output enabled for ten seconds by pressing any key.

6 Output oscillates at the rate of 1 Hz after 3 consecutive code errors.

This condition will persist for 10 minutes, and may be reset only by

entering a valid user code (resetting is possible only after the first

30 seconds).

7 Output turned on by pressing the 1 and 3 keys -simultaneously.

Remains on until both keys are released.

Table 3. Auxiliary Output Operating Modes

DE6217 3

Page 4

5.7 Deleting the Ambush Digit

If you do not intend to use an ambush digit, it is imperative that

you delete the ambush digit code – to ensure that no previously

programmed digit remains in memory.

5.8 Selecting an Ambush Digit

IMPORTANT: If you have programmed an ambush digit, you must

restrict user codes to seven digits each (or less) and you must

avoid choosing user codes ending with that same digit as the

ambush one.

5.9 How to Quit Programming

while the green LED is flashing slowly

The LED will extinguish.

[ A ] is the desired ambush digit, chosen from 0 to 9.

6. RESETTING THE DEFAULT MASTER CODE

If you forgot or lost the master code (code No.01) and it becomes

necessary to reprogram the keypad, you will have to reset the master

code to the factory default (1234) as follows:

A. Open the keypad's case, uncovering the printed circuit board.

B. Install the jumper across the two pins labeled JP2 (see Fig. 2).

C. Momentarily short circuit the pins labeled JP1 using a screw-

driver or jumper wire.

D. Wait ten seconds, remove the jumper from JP2, and immediately

press 1234#. The green LED will light steadily for two seconds

and will then start flashing slowly, indicating that the programming

menu is active.

Important Note: The master code has temporarily

reverted to 1234. Remember, however, that all other data

programmed previously remains intact!

E. Program a new master code (user code No. 01) immediately, and

record it in a secret, safe place.

If you choose to quit programming at this stage, press # while the

green LED is flashing slowly.

Appendix A. User Code Programming Chart

Date

26/6 John K 1 01 # 43182307 # 43182307 # 3 #

26/6 Mark D 1 02 # 1283046 # 1283046 # 1 #

1 01 # # # # 1 30 # # # #

1 02 # # # # 1 31 # # # #

1 03 # # # # 1 32 # # # #

1 04 # # # # 1 33 # # # #

User

Name

1 05 # # # # 1 34 # # # #

1 06 # # # # 1 35 # # # #

1 07 # # # # 1 36 # # # #

1 08 # # # # 1 37 # # # #

1 09 # # # # 1 38 # # # #

1 10 # # # # 1 39 # # # #

1 11 # # # # 1 40 # # # #

1 12 # # # # 1 41 # # # #

1 13 # # # # 1 42 # # # #

1 14 # # # # 1 43 # # # #

1 15 # # # # 1 44 # # # #

1 16 # # # # 1 45 # # # #

1 17 # # # # 1 46 # # # #

1 18 # # # # 1 47 # # # #

1 19 # # # # 1 48 # # # #

1 20 # # # # 1 49 # # # #

1 21 # # # # 1 50 # # # #

1 22 # # # # 1 51 # # # #

1 23 # # # # 1 52 # # # #

1 24 # # # # 1 53 # # # #

1 25 # # # # 1 54 # # # #

1 26 # # # # 1 55 # # # #

1 27 # # # # 1 56 # # # #

1

User

No. #

New code

1-8 digits #

Repeat

Code #

Trip

Code # Date

User

Name

1 User

No. #

New code

1-8 digits #

Repeat

Code #

Trip

Code #

1 28 # # # #

1 29 # # # #

VISONIC TECHNOLOGIES. (ISRAEL): 30 Habarzel St. Tel Aviv 69710 ISRAEL Tel 972-3-7681400 Fax: 972-3-7681415 E-MAIL: support@visonictech.com

VTA (VISONIC TECHNOLOGIES AMERICAS): 65 West Dudley Town Road, Bloomfield CT. 06002-1911 USA. TEL.: (860) 243 0833, (800) 223 0020

FAX: (860) 242-8094.

E-MAIL: usa_support@visonic.com

VT UK (VISONIC TECHNOLOGIES UK): Fraser Road, Priory Business Park, Bedford MK44 3WH ENGLAND. TEL.: 44-870-730-0840; FAX: 44-870-730-0839

INTERNET: www.visonictech.com

VISONIC TECHNOLOGIES LTD. 2004 DE6217- (REV. 4, 10/04) Refer to separate warranty statement)

4 DE6217

Loading...

Loading...