Instruction Manual

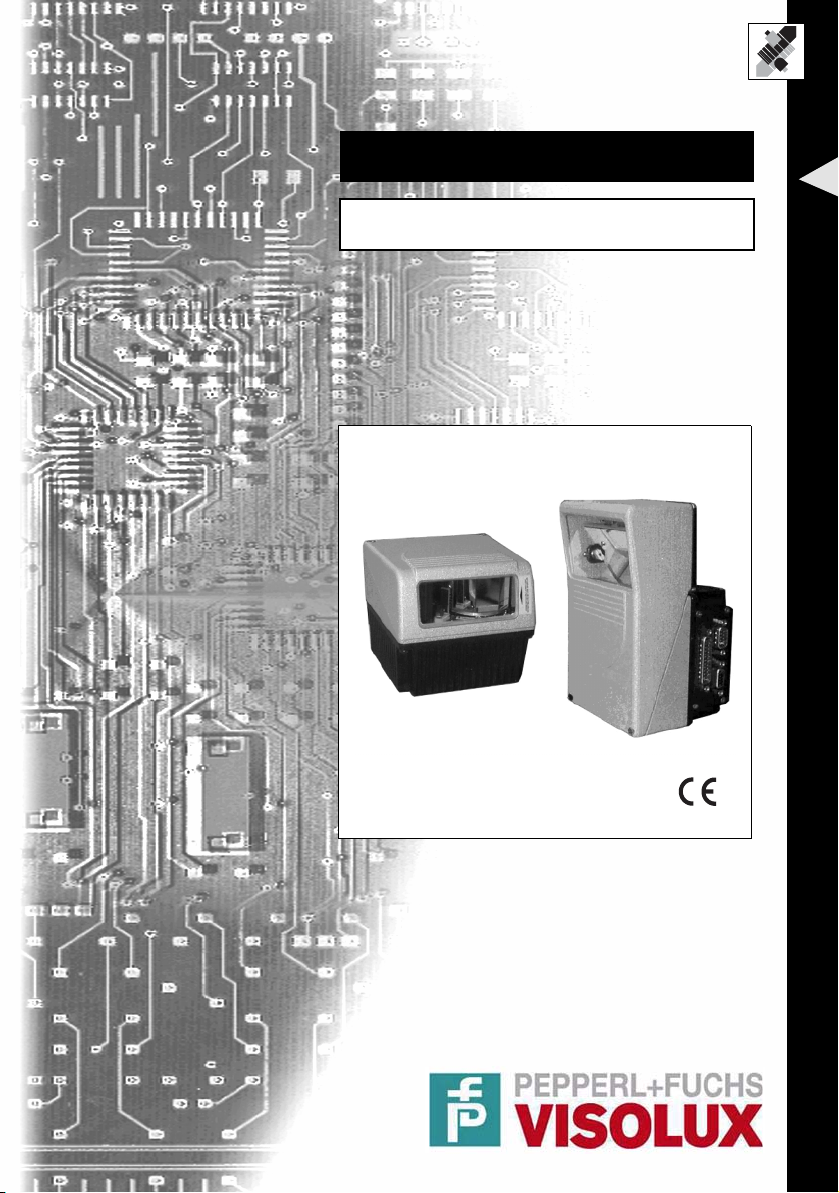

Barcode Reader VB34

FACTORY AUTOMATION

With regard to the supply of products, the current issue of the following document is applicable: The General

published by the Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindus-

in its most recent version as well as the supplementary clause: "Expanded reservation of proprietorship"

For this reason, this printed matter is produced on paper bleached without the use of chlorine.

Terms of Delivery for Products and Services of the Electrical Industry,

trie (ZVEI) e.V.)

We at Pepperl+Fuchs/VISOLUX recognize a duty to make a contribution to the future.

Barcode reader VB34

S

P

Table of contents and general information

1 REFERENCE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 ADDITIONAL DOCUMENTATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Maintenance, support and warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Maintenance and support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Laser safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Standard regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Device views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Installation overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Point-to-point installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Lonworks master/slave installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.1 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Available models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Oscillating mirror models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.1 Contents of the package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.1 Installation of the reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.2 Installation of the reader with accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.1 Primary/secondary interface and I/O connections . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.2 Lonworks connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.3 Ethernet connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.4 DeviceNet connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.5 Profibus connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.6 Voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4 Operator interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5 Adjusting the reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.6 Typical installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6.1 Standard installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6.2 Installation with an angle of rotation of 45°. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.7 Typical hardware configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7.1 Point-to-point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7.2 Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.7.3 RS232 master/slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.7.4 Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.7.5 Local Lonworks network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.6 Fieldbus network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.8 FLASH™ dynamic focusing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.8.1 Fixed adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Date of issue 06/13/2005

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

epperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

1

Barcode reader VB34

S

P

Table of contents and general information

6.8.2 Continuous adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.8.3 Trigger operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.8.4 D-Flash™ operating mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.9 Key field and display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.9.1 Internal Net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.9.2 Test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7 Software configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.1 Software installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2 Hints on quick configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.1 Assistant for quickly setting up the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.2 Network Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.3 Enhanced configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.4 Basic settings for parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8 Optical properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.1 ACR technology (ACR™ 3 reconstruction) . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.1.1 Tilt angle for the ACR reconstruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.2 PackTrack™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2.1 PackTrack™ calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3 Read diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.3.1 VB34 standard model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.3.2 VB34 model with reflex mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

9.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

11 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

12 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

13 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

General information

This symbol warns the user of possible danger. Failure to heed this

warning can lead to personal injury or death and/or damage to

equipment.

Warning

This symbol warns the user of the possibility of device failure. Failure to

observe this warning can lead to the complete failure of the device or

Attention

Note

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

2

epperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

any device connected to it.

This symbol advises the user of important tips.

Date of issue 06/13/2005

Barcode reader VB34

S

P

Table of contents and general information

Declaration of conformity

We, Pepperl+Fuchs GmbH, declare herewith at our sole responsibility that the

Barcode Scanner VB34

and all models of this product to which this declaration pertains, are compliant with

the following standards and other regulating documents

EN 55022, August 1994: RADIO INTERFERENCE OF INFORMATION

TECHNOLOGY EQUIPMENT (ITE), MEASURING

METHODS AND LIMITS

EN 50082-2, March 1995: ELECTROMAGNETIC COMPATIBILITY,

GENERIC IMMUNITY STANDARD PART 2:

INDUSTRIAL AREA

and the guidelines of the following directive(s):

89/336 CEE AND SUBSEQUENT CHANGES MADE,

92/31 CEE; 93/68 CEE

A corresponding declaration of conformity may be requested from the

manufacturer.

Note

Pepperl+Fuchs GmbH, in D-68301 Mannheim, has a certified quality assurance

program in accordance with ISO 9001.

ISO9001

Date of issue 06/13/2005

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

epperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

3

Barcode reader VB34

REFERENCE INFORMATION

1 REFERENCE INFORMATION

1.1 ADDITIONAL DOCUMENTATION

The following additional documentation on the VB34 system is available:

• C-BOX100 manual

• GFC-60 90° deflecting mirror

• GFC-600 90° near range deflecting mirror

• Documentation on Profibus communication

1.2 Maintenance, support and warranty

1.2.1 Maintenance and support

Pepperl+Fuchs offers a range of services as well as technical support via its website.

For further information, visit our website at www.pepperl-fuchs.com.

2 Safety regulations

2.1 Electrical safety

This product meets the applicable requirements stipulated by the European standard

EN 60950 on electrical safety in the version valid at the time of production.

2.2 Laser safety

The following information is listed for compliance with the rules defined by the

international authorities and refers to the proper use of the VB34 reader.

2.2.1 Standard regulations

This reader is provided with a low-energy laser diode. Even though, according to the

current state of knowledge, directly looking into the laser beam does not cause any

biological damage, you should avoid doing this as for all strong light sources such as

the sun.

Do not direct the laser beam, neither directly nor indirectly, e.g. via mirrors, into the

eyes of other people.

This product meets the applicable requirements of the European standard EN 608251 and the standard CDRH 21 CFR1040 in the version valid at the time of production.

The reader is classified as a class 2 laser product according to EN 60825-1 and as a

class II laser product according to the CDRH regulations.

Before opening the device for maintenance or installation purposes, switch off the

voltage supply in order to avoid exposure to dangerous laser radiation.

The device is equipped with a safety device, which only switches on the laser if the

motor has reached the minimum rotational speed for read mode.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

4

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Safety regulations

The use of different controls or settings as well as carrying out

operations other than those described here may cause exposure to

dangerous, visible laser radiation.

Warning

Laser radiation is visible to the human eye and is emitted through the window in the

head of the reader (Figure 3.1 and Figure 3.2).

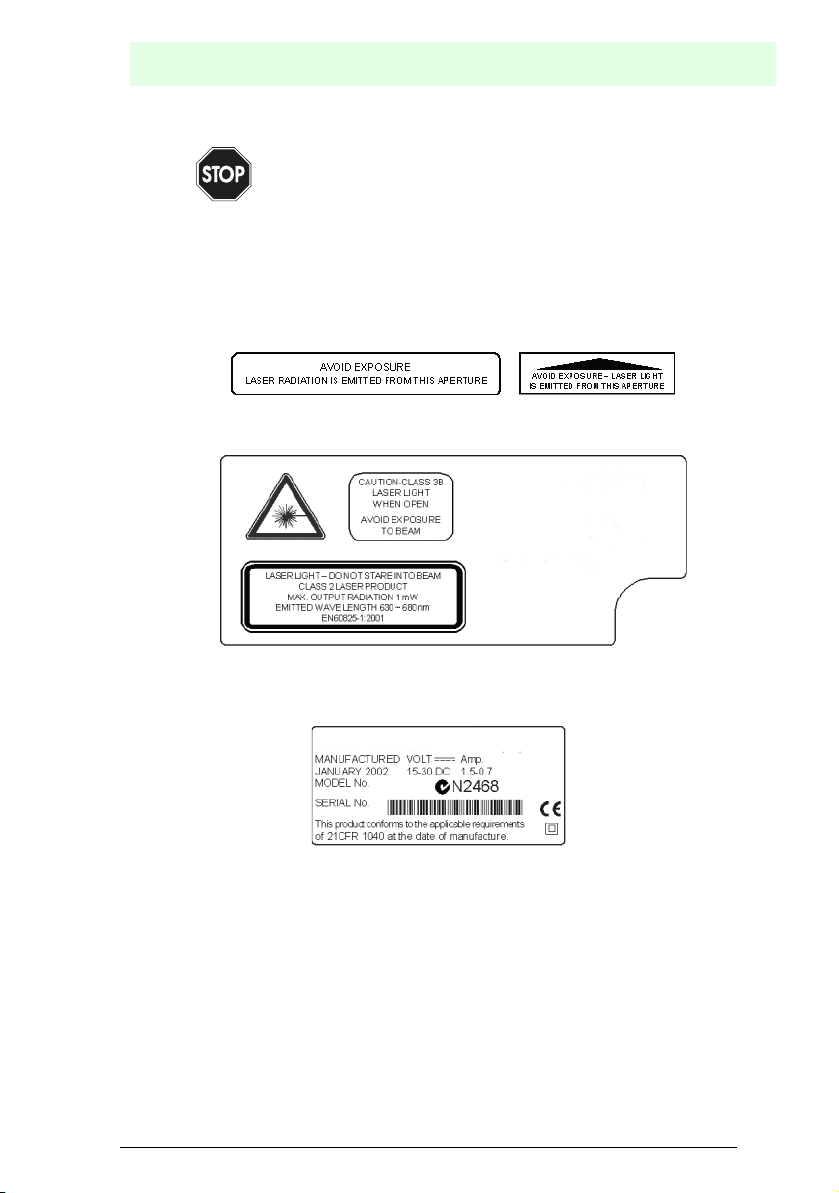

Warning labels that draw attention to the dangers of laser radiation and to the device

classification are located on the head of the reader (Figure 3.1 and Figure 3.2):

Figure 2.1 Laser safety labels for oscillating mirror and standard models

Figure 2.2 Warning and device classification labels

The name plate is located on the lower part of the reader (Figure 3.1):

Figure 2.3 Name plate

The laser diode used by this device is classified as a class 3B laser product according

to EN 60825-1 and as a class IIIb laser product according to the CDRH regulations.

As it is not possible to attach a label to the laser diode used by this device, the

following label is alternatively shown here:

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

5

Barcode reader VB34

Device views

Figure 2.4 Classification label of the laser diode

Opening the optical components may cause radiation to be emitted with the maximum

power of the laser diode (35 mW at 630~680 nm).

2.3 Voltage supply

This product may be installed by qualified personnel only.

All VB34 models:

This device is designed for supply by a UL-listed power pack with the classification

“Class 2” or by a low-voltage power pack, which connects the supply voltage directly

via the 25/26-pin connector to the reader.

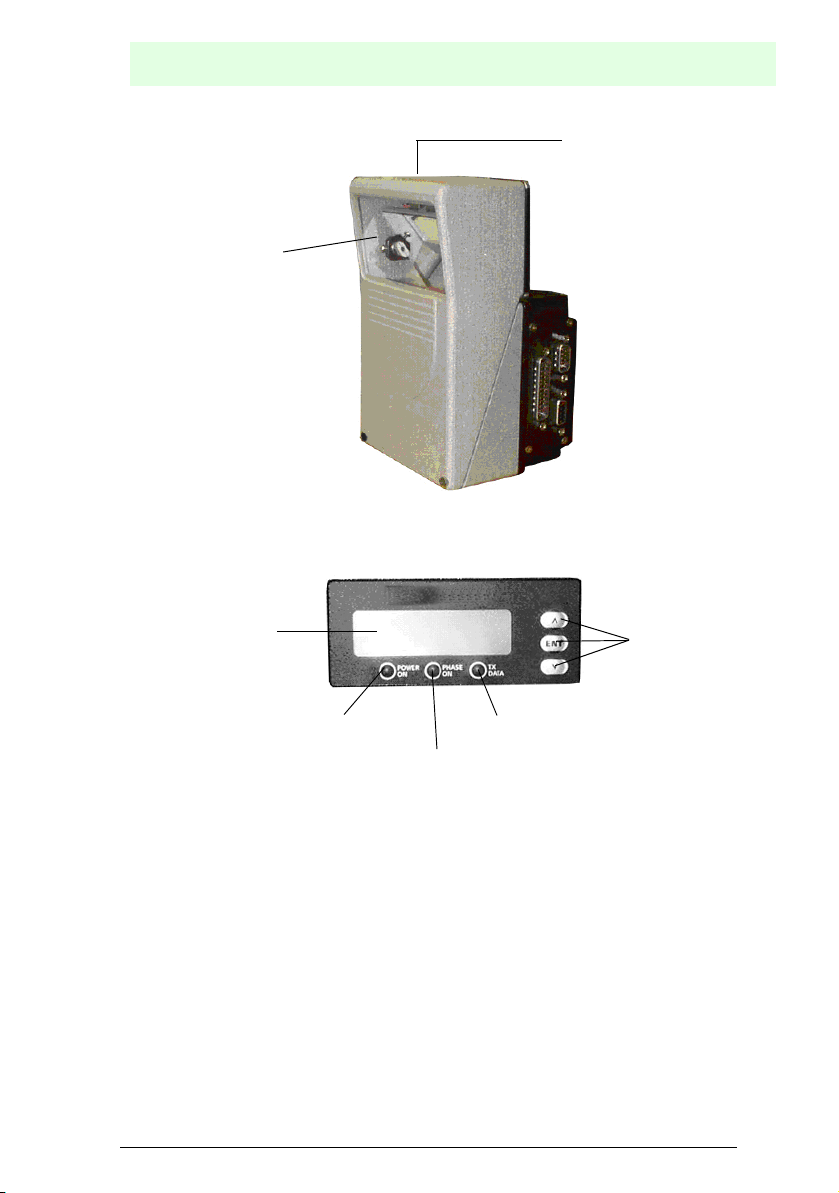

3 Device views

Laser safety label

Laser exit window

Name plate

Warning and device classification label

Display and

key pad

Figure 3.1 Device view VB34

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

6

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Service connection

Connector cover

Date of issue 06/13/2005

Laser exit window

Figure 3.2 Device view VB34 reflex mirror version

Barcode reader VB34

Device views

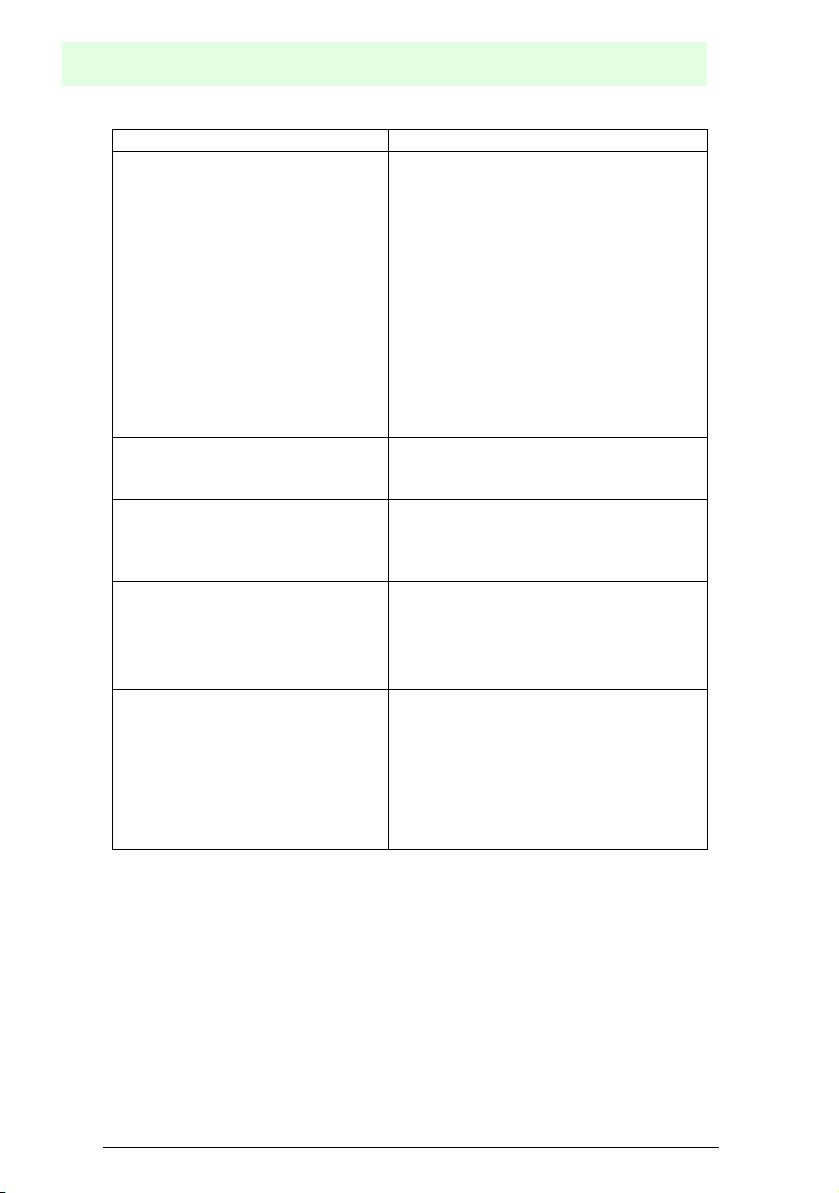

Laser safety label

LCD display

Power on LED

TXD data LED

Phase on LED

Program key pad

Figure 3.3 Partial view of display and key pad

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

7

Barcode reader VB34

Device views

25-pin Sub-D connector for primary/

secondary interface

9-pin Lonworks socket

Figure 3.4 View of connector cover for master/slave models

26-pin Sub-D connector for primary/

secondary interface

9-pin Lonworks socket

Figure 3.5 View of connector cover for Ethernet models

26-pin Sub-D connector for primary/

secondary interface

9-pin Lonworks connector

RJ45 connector for Ethernet

interface

5-pin DeviceNet connector

9-pin Lonworks socket

Figure 3.6 View of connector cover for DeviceNet models

26-pin Sub-D connector for primary/

secondary interface

9-pin Profibus socket

9-pin Lonworks socket

Figure 3.7 View of connector cover for Profibus models

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

8

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Installation overview

4 Installation overview

4.1 Point-to-point installation

The following overview can also be used as a check list. It lists all the steps that are

required for a complete installation of the VB34 reader.

1. Read all the information in section "Safety instructions" at the beginning of this

manual.

2. Install the reader using the supplied mounting material (Chapter 6.2.2).

3. Adjust the reader to the correct reading distance for your model (Chapter 6.5).

4. Wire the VB34 reader according to the following steps:

a) Connect the VB34 reader to a C-BOX 100 (Chapter 5.5) using one of the

accessory cables.

b) Wire the C-BOX 100 with all system signals and voltages required by your

application (trigger, inputs, outputs).

• Layout: Point-to-point, RS232 master/slave, Lonworks or fieldbus. For further information, please refer to the sections in Chapter 6.7.

• Cabling: supply, primary serial interface – RS232, RS485 half duplex,

RS485 full duplex, 20 mA current loop, secondary interface, inputs, outputs

etc. For further information, please refer to the sections in Chapter 6.3.

5. Configure the VB34 reader by installing and executing the configuration software

from the enclosed CD-ROM. The most important steps are:

• Select the codes to be read

• Configure the communication parameters

• Define the data format parameters

• In the test mode, adjust your VB34 reader to the application as described

6. Complete the configuration program and start your application.

The installation is now complete.

in the configuration software.

4.2 Lonworks master/slave installation

The following overview can also be used as a check list. It lists all the steps that are

required for a complete installation of the VB34 reader.

1. Perform steps 1 to 3 of the point-to-point installation.

2. Wire the VB34 reader according to the following steps:

a) Connect the VB34 master reader to a C-BOX 100 (Chapter 5.5) using one of

the accessory cables.

b) Connect the BTK-6000 termination network to the VB34 master reader as

described under “Local Lonworks network” (Chapter 6.3.2).

c) Install and wire all slave readers required for your system configuration

(Chapter 6.7).

d) Connect the BTK-6000 termination network to the last VB34 slave reader as

described under “Local Lonworks network” (Chapter 6.3.2).

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

9

Barcode reader VB34

Installation overview

Configure the VB34 slave readers using one of the following methods:

a) Define the addresses of all VB34 slave readers via the key pad on the reader

(Chapter 6.9).

b) Configure all VB34 slave readers by installing and executing the configuration

software from the enclosed CD-ROM (Chapter 7.2.2).

Configure the VB34 master readers using one of the following methods:

c) Configure the VB34 reader as the master using the key pad of the reader

(Chapter 6.9).

d) Configure the VB34 reader as the master using configuration software

(Chapter 7.2.2).

3. Establish a connection to the VB34 master reader in order to configure the

network layout using the configuration software.

4. Configure all VB34 slave readers using the configuration software. The most

important steps are:

• Select the codes to be read

• Configure the communication parameters

• Define the data format parameters

All slave readers can also be configured externally using the

configuration software and the master reader.

Note

5. In the test mode, adjust your VB34 reader to the application as described in the

configuration software™.

The installation is now complete.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

10

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

5 Introduction

5.1 Product description

The VB34 is the high-performance laser scanner in the VISOLUX family of barcode

readers for industrial applications. With its completely new hardware and software

platform, it offers innovative and modular solutions regarding performance,

communication and maintenance.

Easy installation and operation as well as high flexibility were the most important

features during the development of the VB34. Together with the Step-a-Head™

technology, for which a patent has been applied, the innovative mechanics makes it

possible to turn the read head and the decoder base assembly independently of each

other. Step-a-Head™ makes it possible to always install the VB34 in the ideal position

by changing the position of the base assembly while the read head with the laser

maintains its optimum position. This minimises the space requirements and simplifies

the installation.

Another innovation of the VB34 is the linear motor, which can be used to control the

reading position of the scanner via software. This dynamic system with the name

Flash™ is able to assume any reading position from the minimum position to the

maximum position in less than 10 ms. In typical applications with a reading distance

of less than 1 m, the reading position is reached in 4 ms.

Thanks to a new generation of decoders with StrongARM CPU and ACR technology

(ACR™ 3 reconstruction), the VB34 reads all current barcodes, even under

demanding ambient conditions.

The reader is also available in a version with an integrated, software-programmable

oscillating mirror.

Another focus in the system design was the communication capacity of the readers.

As interfaces, Lonworks, Profibus, DeviceNet and Ethernet were each integrated into

a separate version of the decoder base assembly.

Some of the significant features of the VB34 are:

• Read rate of up to 1200 read processes/second

• 2 serial interfaces

• Reading all current codes

• Operating voltage of 15 to 30 V DC

• All electrical connections pluggable

• Fast Lonworks interface for master/slave configurations

• Supports Profibus, DeviceNet and Ethernet

• 5 operating modes for an optimum adjustment to different application requirements

• Light source: laser diode with a wave length of 630 to 680 nm

• IP64-protected housing (for Ethernet models not yet available)

Auto-ID applications are traditionally used in the area of production. With increasing

marketability, standard solutions and a dynamic competition develop. The VB3x

family with the model VB33 also has its roots in production applications. The VB34

opens up new areas of application such as, for example, transport and logistics

applications, in which the practical advantages of the new technologies come to the

Date of issue 06/13/2005

fore.

Barcode reader VB34

Introduction

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

11

Barcode reader VB34

Introduction

Feature Practical use

Modular solution with separate head

and base assembly as well as StepA-Head™ function

Reading pallets or large objects over

greater distances and with a large

field of view

Reading objects on conveyor belts • VB34 implements Packtrack™ function-

Master is used as multiplexer in fast

Lonworks environments

Configuration software • Short learning time thanks to integrated

• Combination of the ideal head and base

assemblies for a given application

• Scaleable solution

• Reduced tool life, as the decoder base

remains functional even when the head

has been removed.

• Simple maintenance: All configuration

parameters remain saved in the base

assembly. When the read head is

replaced, the scanner is configured automatically.

• Simple installation with minimum space

requirement

• VB34 with dynamic focussing system

Flash™.

ality in order to increase the production

of the plant by a higher system throughput.

• Economically, a very attractive offer as

there are no costs for the external multiplexer.

• High data throughput of 1.2 Mbit/s on a

sturdy, industry-proof bus.

wizard

• Multi-language platform

• All configuration parameters are saved in

the reader.

• Independent of the installed hardware

interface

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

12

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Introduction

5.2 Available models

The VB34 scanner is available in various versions, which differ in the following

features:

• Optical system (head)

• Decoder (base assembly)

The following models are available:

VB34 - xxxx - OM - y

Max. distance Decoder model (base assembly)

__ = master/slave

Optical model (head) P = Profibus

_ = Standard B12 = Ethernet

OM = Oscillating mirror B7 = DeviceNet

5.3 Displays

The VB34 decoder base assembly has an LCD display for system messages and

menus of the configuration software. The three keys on the side of the display are

used for navigating in the menus of the configuration software (Figure 3.3).

The three status LEDs have the following functions:

Power ON (Red) indicates that the reader is switched on (Figure 3.3)

Phase ON (Yellow)indicates that the presence sensor is activated (Figure 3.3).

TX Data (Green)indicates that the primary serial interface transmits data

without errors (Figure 3.3).

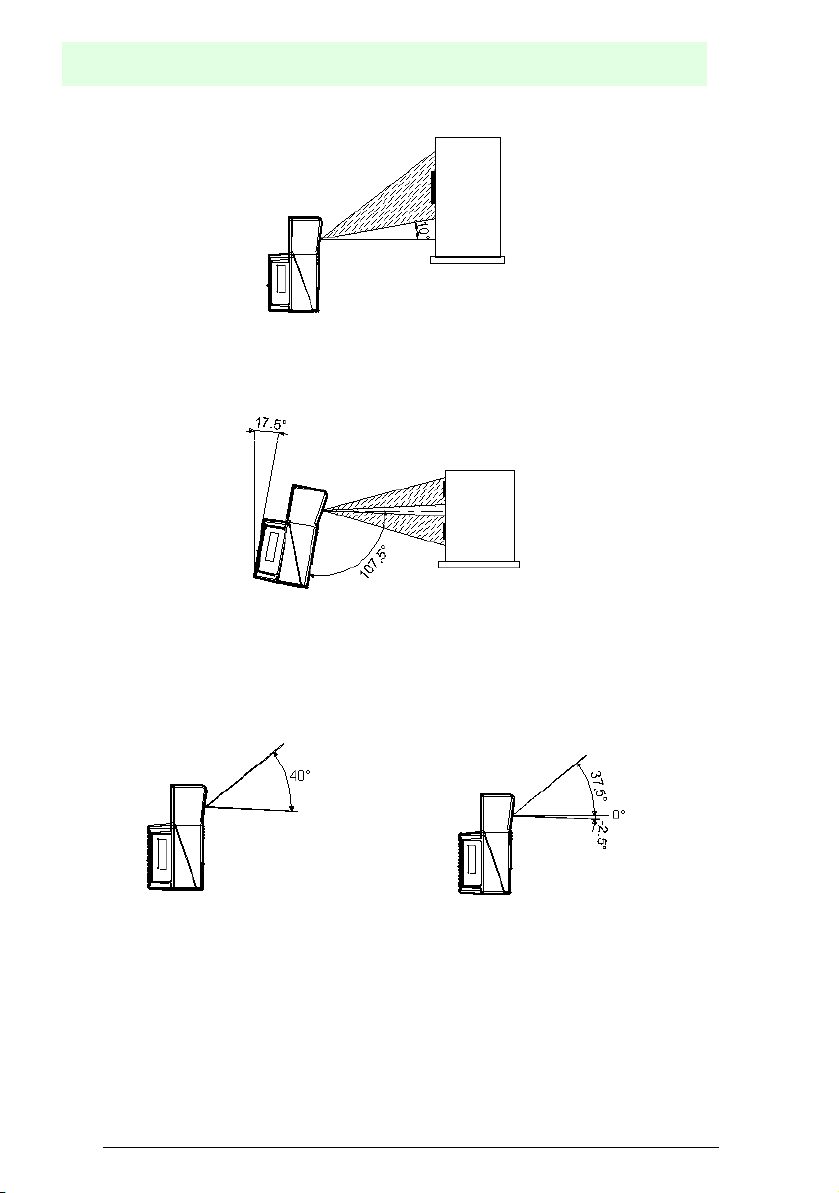

5.4 Oscillating mirror models

Oscillating mirror models are used when large reading areas must be covered, mainly

in the case of horizontal barcodes (picket fence barcodes).

The VB34 contains a special optical head with an integrated oscillating mirror, which

is driven by a linear motor. Speed, precision, repeatability and reliability of this drive

technology guarantee a high performance.

The new oscillating mirror is completely software-controlled and programmable. The

configuration™ software makes it possible to adjust the speed of the linear motor (and

thus the oscillation frequency) as well as the upper and lower end position for the

oscillation process as an angle.

If the oscillating mirror is programmed to read barcodes at a very small angle, position

the reader in such a way that the visual angle is at least 10° (Chapter 6.4). This angle

mirrors the smallest deflection or the scanning line that is closest to the horizontal. All

other scanning lines have a visual angle of more than 10°. This prevents a direct

reflection of the laser beam emitted by the reader.

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

13

Barcode reader VB34

Introduction

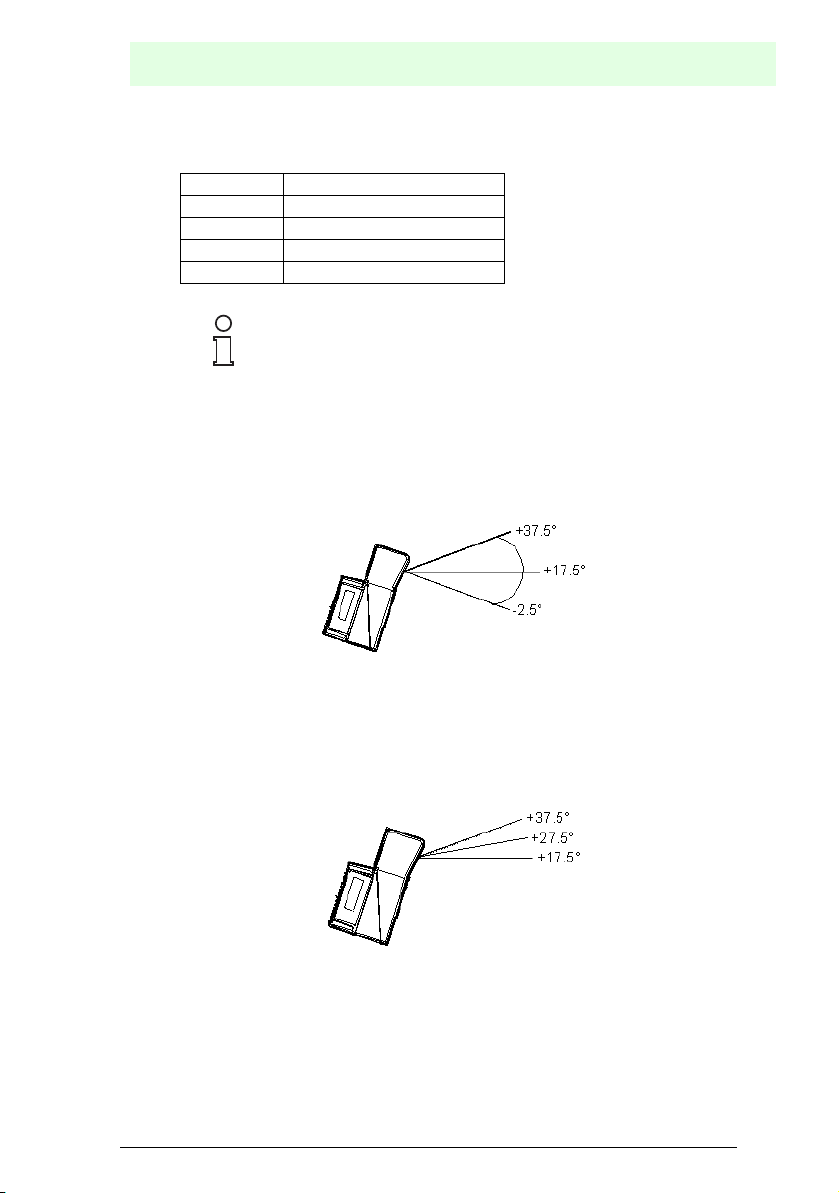

Figure 5.1 Visual angle for oscillating mirror models

Otherwise, the scanner can be installed with a tilt angle of 17.5° in order to achieve a

horizontally symmetric deflection range.

Figure 5.2 Reading position of the oscillating mirror

In the above example, the zone in which the scanning lines meet the reflecting surface

vertically corresponds to a neutral area in the middle of the reading field.

The mirror can be deflected by up to 40°. In relation to the central axle of the exit

window, the deflection angle is asymmetric.

Figure 5.3 Maximum deflection and asymmetry of the oscillating mirror

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

14

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Introduction

By configuring the oscillating mirror speed to 19 Hz, a raster for recording and reading

quickly moving objects can be reproduced.

Hz Max. deflection

0 ... 5 40°

6 ... 10 30°

11 ... 15 20°

16 ... 19 10°

The number of scans on a given reading area can be increased by

limiting the raster width to the required minimum.

Note

The oscillating angles are selected in the software. The minimum and maximum

values are –2.5° and +37.5° respectively.

The scanner can be tilted so that the software setting of 17.5° lies on the horizontal

as a 0° reference.

Figure 5.4 End angle position for the oscillating mirror

These models have a higher read rate (1200 read processes/second) than the

standard models, which is not influenced by the oscillating mirror.

The following example shows a setting of +10° for the lower line and an angle of +20°

for the upper line (see figure below).

Figure 5.5 Oscillating mirror operation

For details on mounting oscillating mirror model, please refer to Chapter 6.2.1.

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

15

Barcode reader VB34

Installation

5.5 Accessories

For the VB34, the following accessories can be ordered:

Accessories Description

CAB-6002 SH3339 Cable on C-BOX 100, 2 m length

CAB-6005 SH3339 Cable on C-BOX 100, 5 m length

CAB-6012 SH3339 Cable on C-BOX 100, 2 m length (VB34 fieldbus version)

CAB-6015 SH3339 Cable on C-BOX 100, 5 m length (VB34 fieldbus version)

CAB-6102 Master/slave cable, 2 m length

CAB-6105 Master/slave cable, 5 m length

CAB-6112 Master/slave cable, without supply, 2 m

CAB-6115 Master/slave cable, without supply, 5 m

INT-60 20 mA interface card

GFC-600 90° near range deflecting mirror

C-BOX 100 Passive connection box

C-BOX 300 Profibus DP connection box

BTK-6000 Termination networks set (5 units)

FBK-6000 Quick mounting bracket (2 parts)

GFC-60 90° deflecting mirror

US-60 Mounting angle set (5 units) for multiple-side stations

6 Installation

To install the system, proceed as follows

• Select the installation location for the VB34.

• Install the VB34 reader.

• Establish all electrical connections to the system.

• Direct the reader to the barcodes.

• Install the configuration software on the PC.

• Configure the dynamic Flash™ focussing using the configuration software.

If in your system the VB34 reader is connected to a C-BOX100,

please refer to the details in section "Additional documentation".

Note

6.1 Contents of the package

When opening the packaging, make sure that the VB34 reader is undamaged and

that all parts of the following packing list are contained in the packaging. This packing

list contains:

• VB34 reader

• Instruction manual

• CD-ROM with the configuration software

• Mounting angle and screws

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

16

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

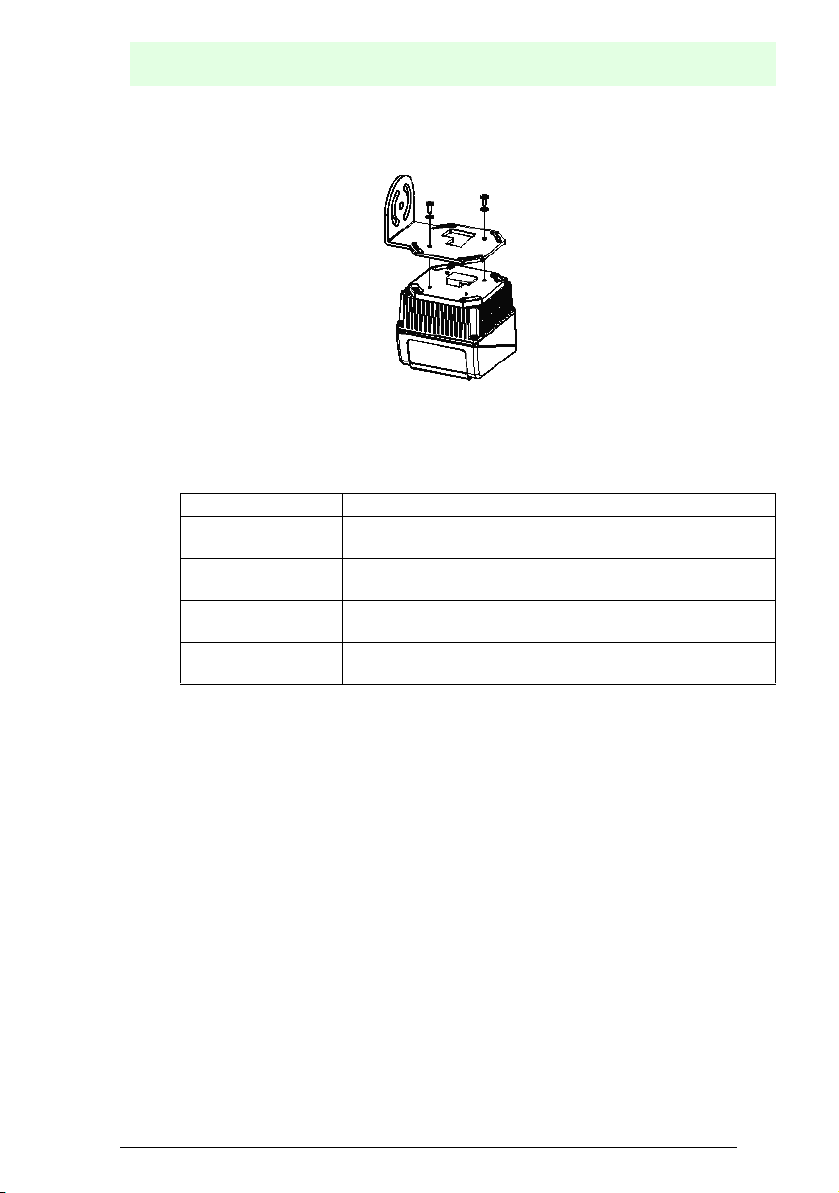

Figure 6.1 VB34 - contents of the package

6.2 Mechanical installation

6.2.1 Installation of the reader

Thanks to Step-a-Head™, the VB34 reader can be adjusted and installed in the ideal

reading position. By separating the head and the base assembly, you can change the

adjustment of the decoder base assembly and thus of the display, key pad and

connectors, while the head with the optical reading system maintains its optimum

position. The head and the base assembly can be turned independently of each other,

thus making a successful installation possible even in critical environments .

Head screws

Installation

Fixing screws

Figure 6.2 Step-a-Head™ function

To turn the head of the reader, perform the following steps:

1. Remove the head from the base by the unscrewing the four fixing screws.

2. Turn the head into the desired position.

3. Unscrew the two screws on the head.

4. Fix the head on the base assembly by tightening the four fixing screws again.

5. Tighten the two screws on the head.

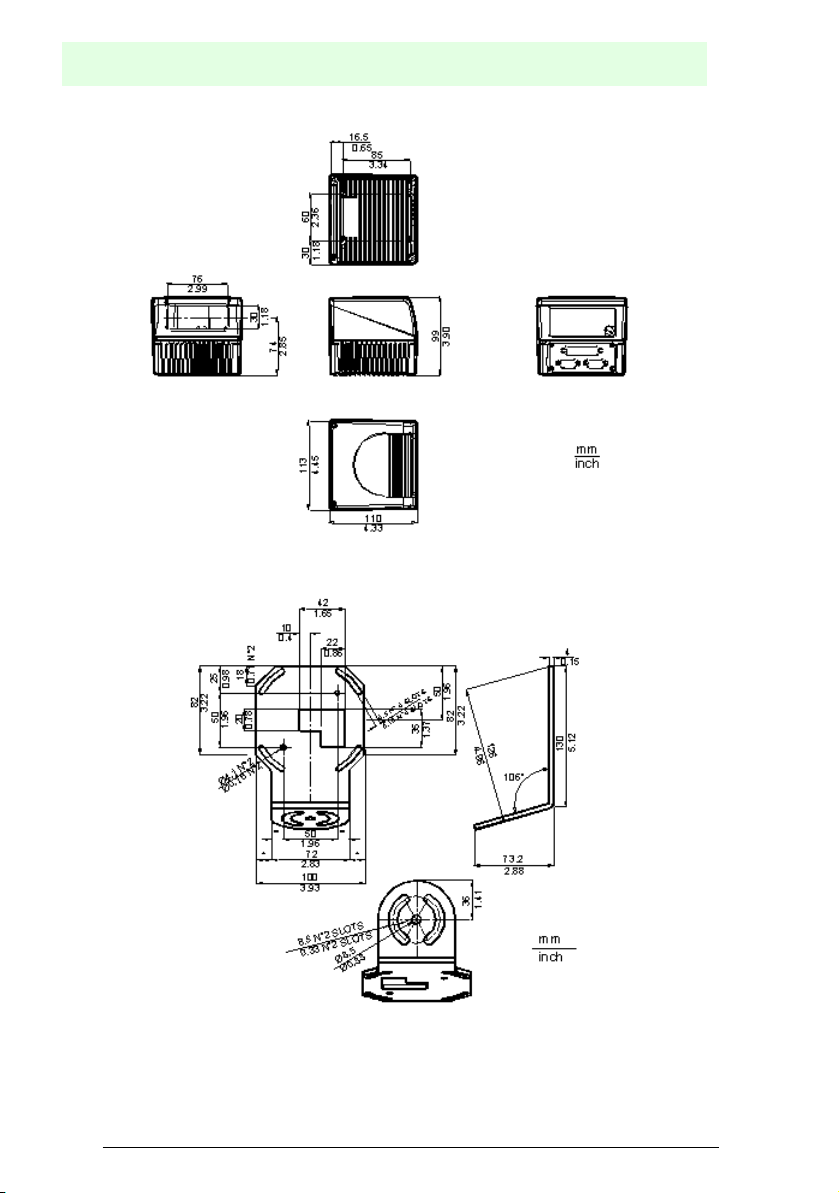

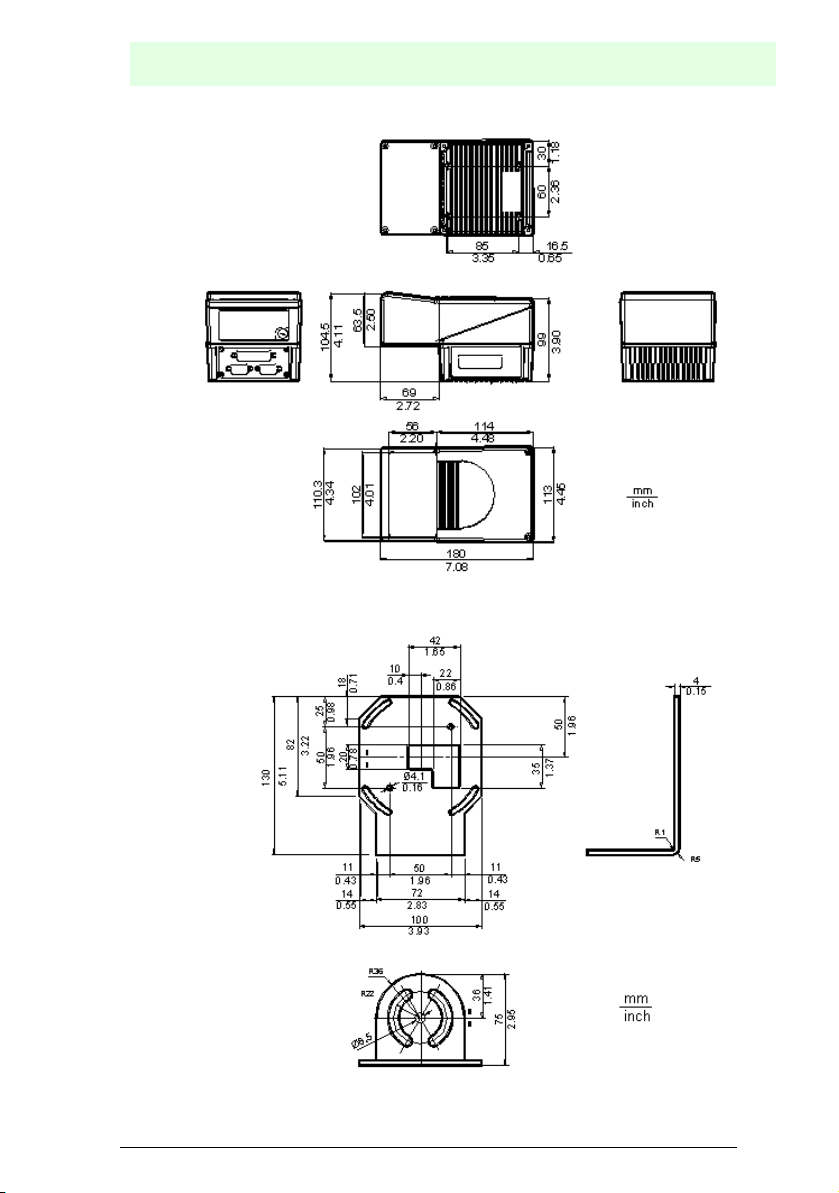

The following figures show the total dimensions of the standard model, the oscillating

mirror model and the mounting angles for installation. For a description of the

alignment of the reader in relation to the read zone, please refer to Chapter 6.5.

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

17

Barcode reader VB34

Installation

Figure 6.3 Dimensions VB34

Figure 6.4 Dimensions of mounting angle ST-237

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

18

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Figure 6.5 Dimensions of VB34 oscillating mirror model

Barcode reader VB34

Installation

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Figure 6.6 Dimensions of mounting angle ST-210

19

Barcode reader VB34

Installation

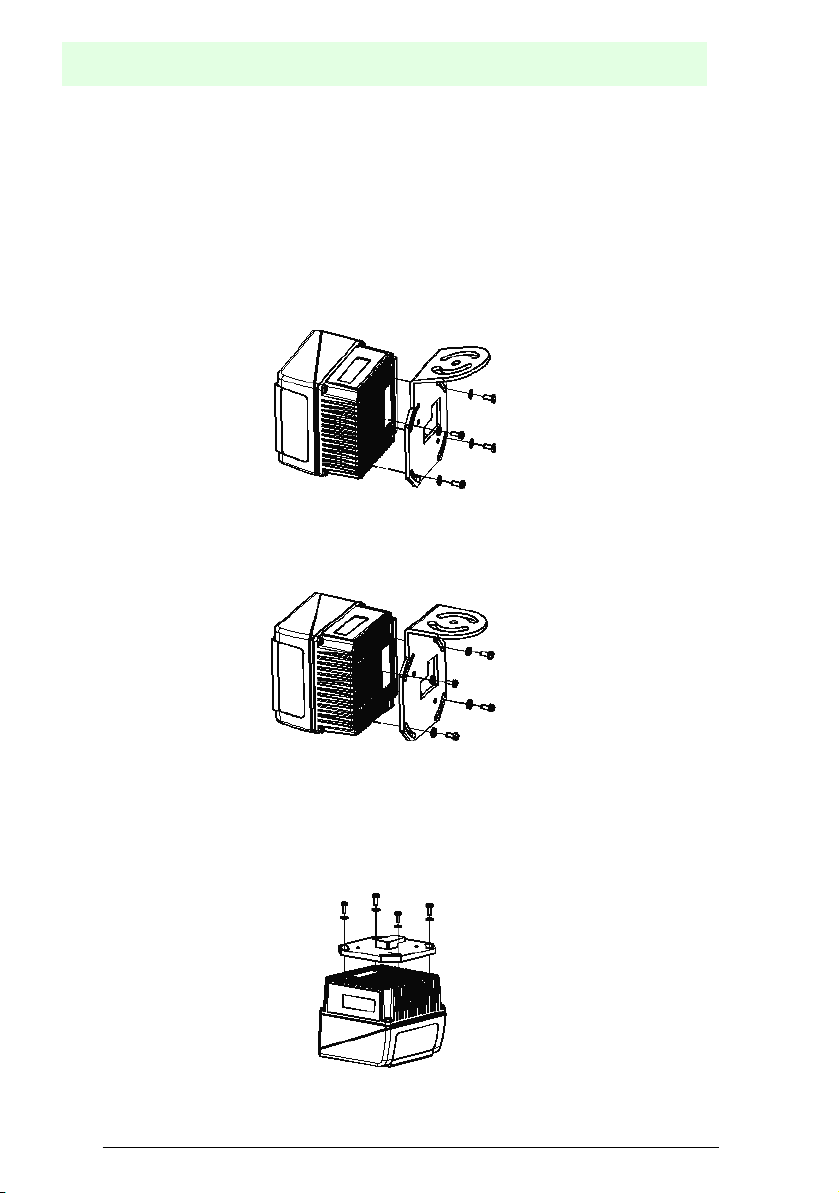

6.2.2 Installation of the reader with accessories

The following accessories make it possible to install the VB34 reader in the ideal

position for network layout:

• ST-237 mounting angle

• ST-210 mounting angle

• FBK-6000 quick mounting bracket

ST-237 is a mounting angle with 105° for mounting the reader as shown in the

following figure:

Figure 6.7 Fixing the ST-237 mounting angle

ST-210 is a mounting angle with 90° for mounting the reader as shown in the following

figure:

Figure 6.8 Fixing the ST-210 mounting angle

FBK-6000 is a quick mounting bracket set for easily and quickly mounting the reader

in ST-210 or ST-237 mounting angles.

First, the FBK-6000 mounting bracket must be fixed to the VB34 reader by means of

the screws:

Figure 6.9 Fixing the FBK-6000 mounting bracket to the reader

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

20

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Afterwards, fix the assembly to the mounting angle by hanging the hook into the

recess of the mounting angle. Fix the assembly by means of 2 screws:

Figure 6.10 Fixing the assembly to the mounting angle

6.3 Electrical connections

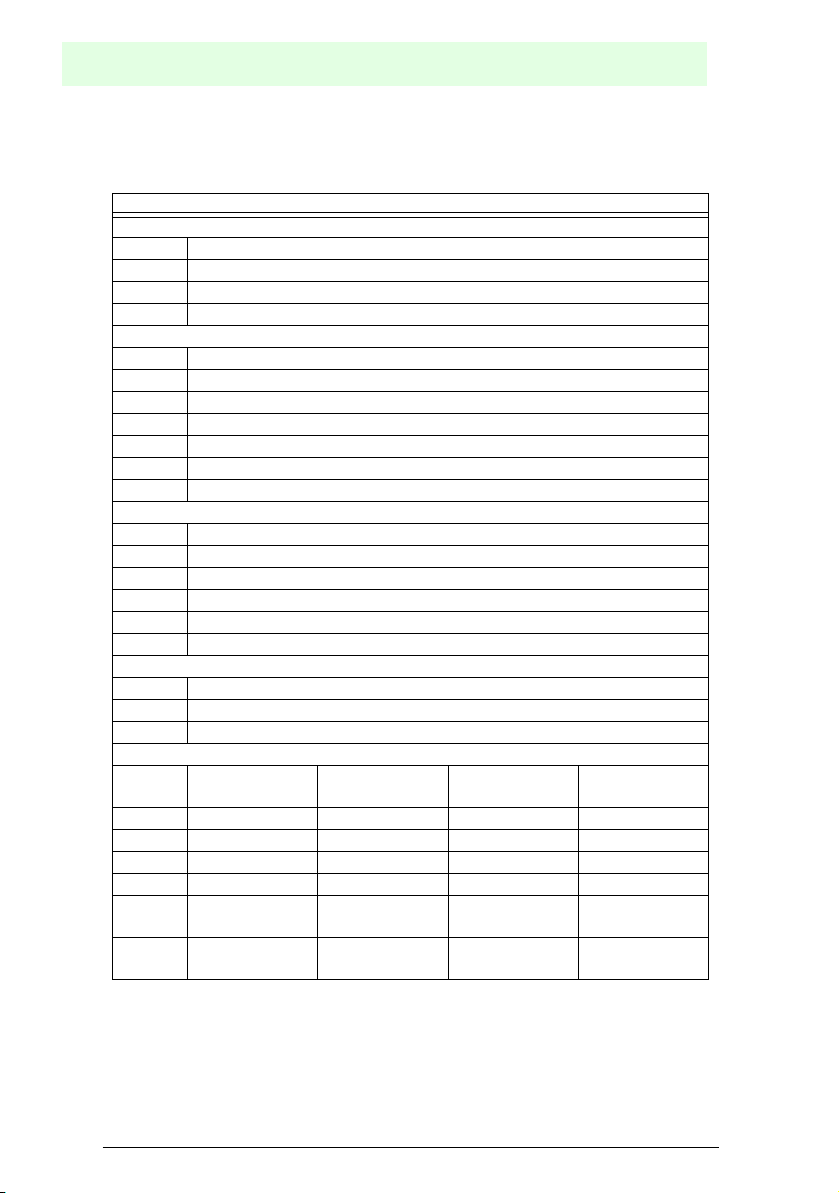

The individual reader models have the following connectors:

Reader model Connector

Master/slave 25-pin connector for interface and input/output connections

9-pin connector, Lonworks 9-pin socket, Lonworks

EtherNet 26-pin connector for interface and input/output connections

9-pin socket, Lonworks RJ45 connector

DeviceNet 26-pin connector for interface and input/output connections

9-pin socket, Lonworks 5-pin connector

Profibus 26-pin connector for interface and input/output connections

9-pin socket, Lonworks 9-pin socket, Profibus

Installation

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

21

Barcode reader VB34

Installation

The following table shows the assignment of the connectors on the terminal block of

the C-BOX 100. Use this connection layout if the VB34 reader is connected to a network via the C-BOX 100:

Connectors on the terminal block of the C-BOX 100

Power supply

1, 3, 5 VS

2, 4, 6 GND

7, 8 Grounding

20, 40 Reserved

Inputs

27 EXT TRIG A (polarity exchangeable)

28 EXT TRIG B (polarity exchangeable)

29 IN 2A (polarity exchangeable)

30 IN 2B (polarity exchangeable)

31, 33 IN 3A (polarity exchangeable)

32, 34 IN 4A (polarity exchangeable)

36 IN 3B/IN 4B reference earth (polarity exchangeable)

Outputs

21 Out 1+

22 Out 123 Out 2+

24 Out 225 Out 3A (polarity exchangeable)

26 Out 3B (polarity exchangeable)

Secondary interface

35 TX AUX

37 RX AUX

38, 39 GND

Primary interface

RS232 RS485

full duplex

11, 15 TX232 TX485+ RTX485+ CLOUT+

12, 16 RTS232 TX485- RTX485- CLOUT-

17 RX232 RX485+ CLIN+

18 CTS232 RX485- CLIN-

10, 14,

19

SGND

Signal ground

SGND

Signal ground

9, 13 RS485

Shielding

RS485

half duplex

SGND

Signal ground

RS485

Shielding

(only INT-60)

20 mA

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

22

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

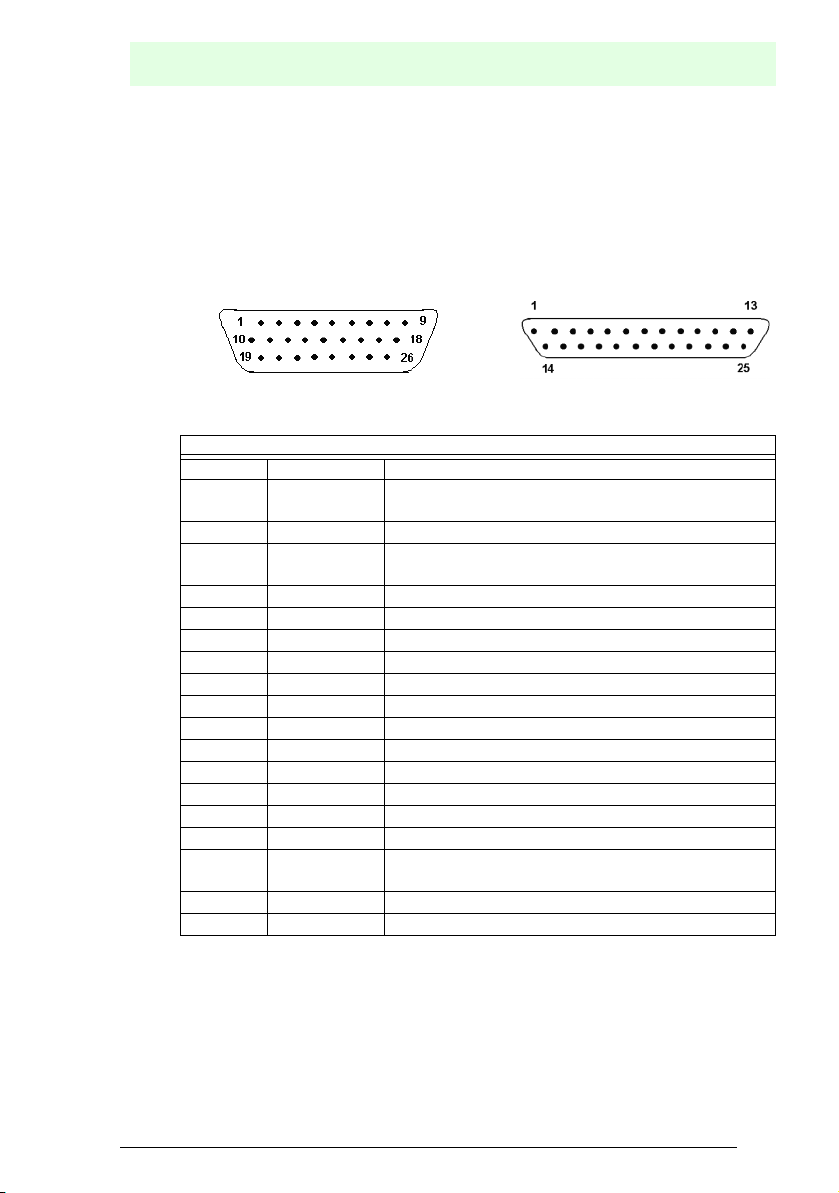

6.3.1 Primary/secondary interface and I/O connections

The VB34 reader has a 25-pin Sub-D connector for connection to computer, voltage

supply and input/output signals.

The fieldbus models (Ethernet, DeviceNet and Profibus) of the VB34 are equipped

with a 26-pin connector instead of the 25-pin connector.

The connection layout of this connector is shown in the following table:

Figure 6.11 26-pin connector 25-pin connector

VB34 connection layout of the 25/26-pin Sub-D connector

Pin Description Function

1 Shield The shielding is internally connected with chassis

ground via a capacitor.

20 RXAUX Received data of the RS232 interface (ground-related)

21 TXAUX Transmitted data of the RS232 interface (ground-

related)

8 Out 1+ Plus lead of the digital output 1

22 Out 1- Minus lead of the digital output 1

11 Out 2+ Plus lead of the digital output 2

12 Out 2- Minus lead of the digital output 2

16 Out 3A Digital output 3 - polarity exchangeable

17 Out 3B Digital output 3 - polarity exchangeable

18 EXT_TRIG A External trigger (polarity exchangeable)

19 EXT_TRIG B External trigger (polarity exchangeable)

6 IN 2A Input signal 2 (polarity exchangeable)

10 IN 2B Input signal 2 (polarity exchangeable)

14 IN 3A Input signal 3 (polarity exchangeable)

15 IN 4A Input signal 4 (polarity exchangeable)

24 IN_REF Common reference earth for IN3 and IN4 (polarity

exchangeable)

9, 13 VS Supply voltage - plus

23, 25, 26* GND Supply voltage - minus (ground)

* Pin 26 is only present on fieldbus models (Ethernet, DeviceNet or Profibus).

Installation

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

23

Barcode reader VB34

Installation

Connection layout of the connector for the primary interface

Pin RS232 RS485

full duplex

2 TX TX485+ RTX485+ CLOUT+

3 RX RX485+ CLIN+

4 RTS TX485- RTX485- CLOUT5 CTS RX485- CLIN7 GND_ISO GND_ISO GND_ISO GND**

** For 20 mA current loop, GND lies on the ground potential of the

reader voltage supply.

Primary interface

The primary serial interface supports the following interface standards:

• RS232

• RS485 full duplex

• RS485 half duplex

• 20 mA current loop

The 20 mA interface is only available if the INT-60 accessory option is installed. This

accessory interface replaces the RS232/RS485 interface.

Interface type and transmission parameters (baud rate, data bits etc.)

are configured using the configuration software. For further

information, please refer to section "Main Serial Port" in the online

Note

help.

RS485

half duplex

(only INT-60)

20 mA

For details on the connection and mode of operation of the primary interface, please

refer to the following sections.

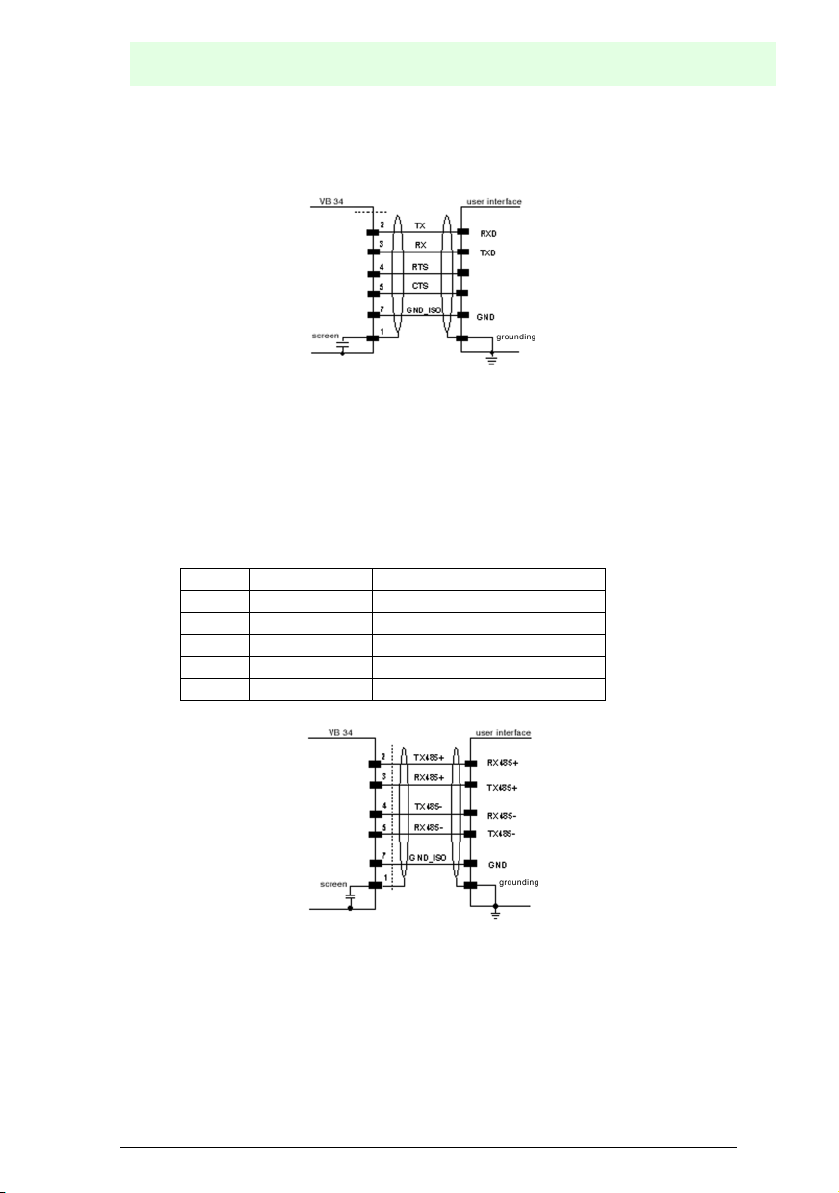

RS232 interface

In conjunction with a computer, the data of read codes and the configuration of the

reader are transmitted via this interface.

Depending on the model, the following pins the 25 or 26-pin connector are used for

the RS232 interface:

Pin Description Function

2TX Send

3RX Receive

4RTS RTS (request to send)

5CTS CTS (clear to send)

7 GND_ISO Signal ground

The RTS and CTS signals control the data transmission and ensure the

synchronisation of the two communication partners.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

24

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Installation

If the RTS/CTS handshake protocol is active, the VB34 reader sets the RTS output in

order to indicate that it wants to transmit a message. The receiver activates the CTS

to start the transmission.

Figure 6.12 Connection layout of the RS232 interface

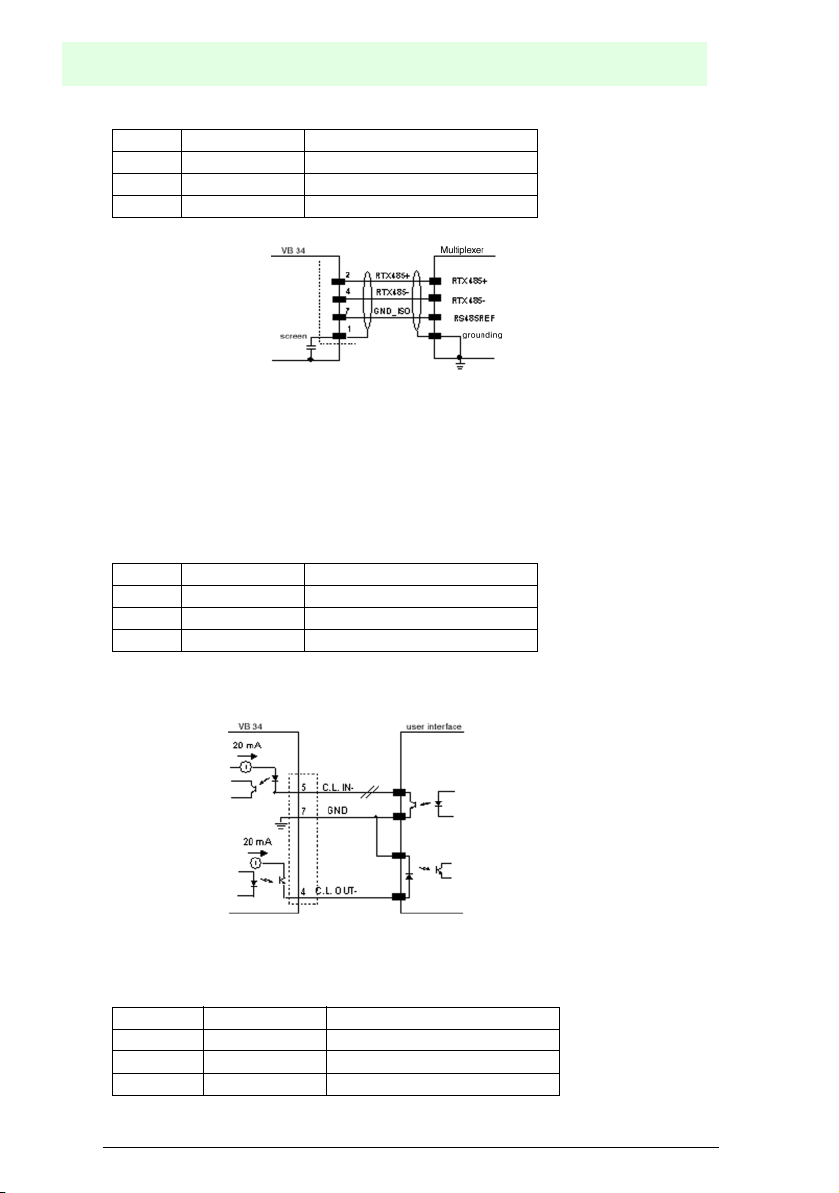

RS485 interface (full duplex)

The RS485 full-duplex interface is suited for continuous (not running in dialog

operation) communication protocols in point-to-point configuration. In this case,

greater distances and a higher tolerance towards electrical interfering signals

compared with the RS232 interface can be realised.

In full-duplex operation, the RS485 interface uses the following pins of the 25-pin or

26-pin connector:

Pin Description Function

2 TX485+ RS485 output (+)

3 RX485+ RS485 input (+)

4 TX485- RS485 output (-)

5 RX485- RS485 input (-)

7 GND_ISO Signal ground

Figure 6.13 Connection layout of the RS485 interface (full duplex)

RS485 interface (half duplex)

The RS485 interface in half-duplex operation is suited for Multidrop connections with

a VISOLUX Multiplexer or for master/slave configurations.

In half-duplex operation, the RS485 interface uses the following pins of the 25-pin or

26-pin connector:

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

25

Barcode reader VB34

Installation

Pin Description Function

2 RTX485+ RS485 input/output (+)

4 RTX485- RS485 input/output (-)

7 GND_ISO Signal ground

Figure 6.14 Connection layout of the RS485 interface (half duplex)

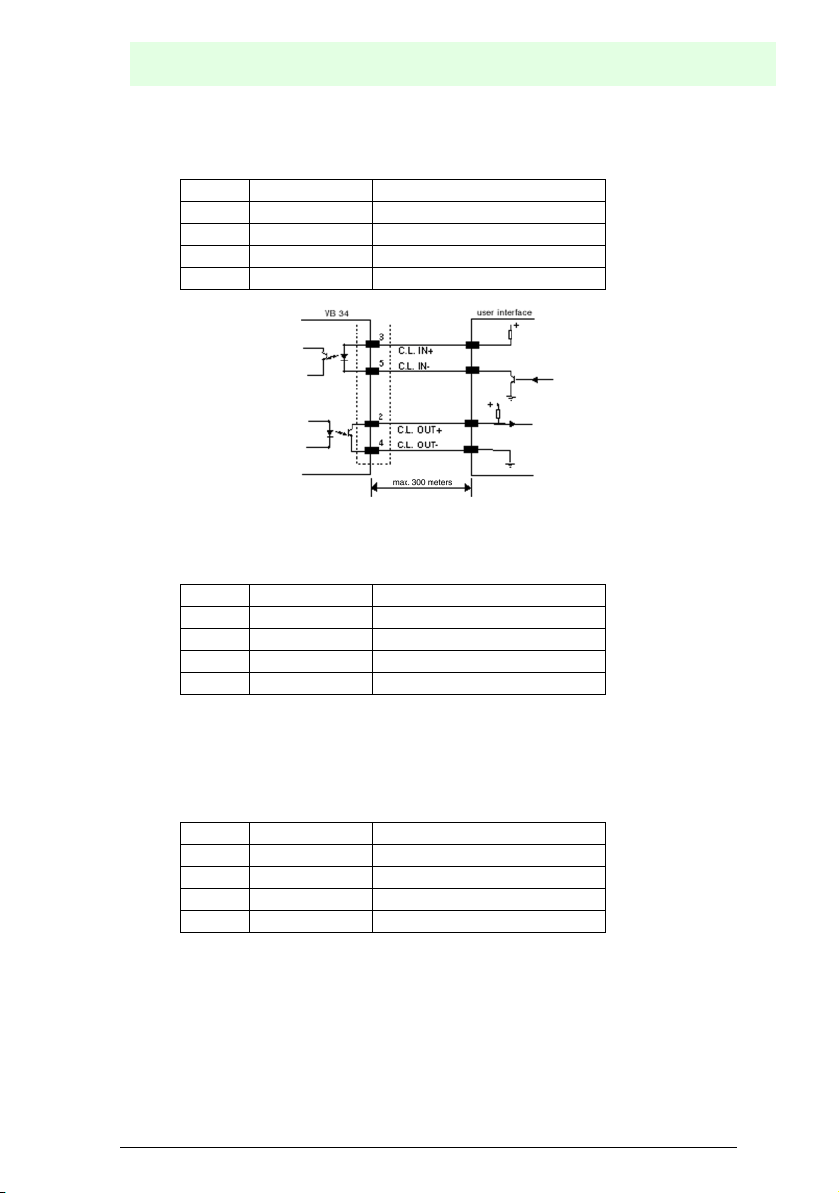

20 mA current loop (only with INT-60 accessory option)

If the INT-60 accessory card is installed, the VB34 has a 20 mA current loop as the

interface. The INT-60 card supports the operation as passive or as active current loop,

i.e. as sink or source.

Wiring as source

In the case of an operation as source, the 26-pin connector is wired as follows:

Pin Description Function

4 CLOUT- Current loop output (-)

5 CLIN- Current loop input (-)

7 GND Grounding*

** For 20 mA current loop, GND lies on the ground potential of the

reader voltage supply.

Figure 6.15 20 mA current loop, wiring as source (active)

If the VB34 reader is connected to a C-BOX 100 via a CAB-61X0, the signals are

connected to the following terminals of the C-BOX 100:

Pin Description Function

12, 16 CLOUT- Current loop output (-)

5 CLIN- Current loop input (-)

10, 14, 19 GND Grounding*

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

26

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Installation

Wiring as sink

In the case of an operation as sink, the 26-pin connector is wired as follows:

Pin Description Function

2 CLOUT+ Current loop output (+)

4 CLOUT- Current loop output (-)

3 CLIN+ Current loop input (+)

5 CLIN- Current loop input (-)

Figure 6.16 20 mA current loop, wiring as sink (passive)

If the VB34 reader is connected to a C-BOX 100 via a CAB-61X0, the signals are

connected to the following terminals of the C-BOX 100:

Pin Description Function

11, 15 CLOUT+ Current loop output (+)

12, 16 CLOUT- Current loop output (-)

17 CLIN+ Current loop input (+)

18 CLIN- Current loop input (-)

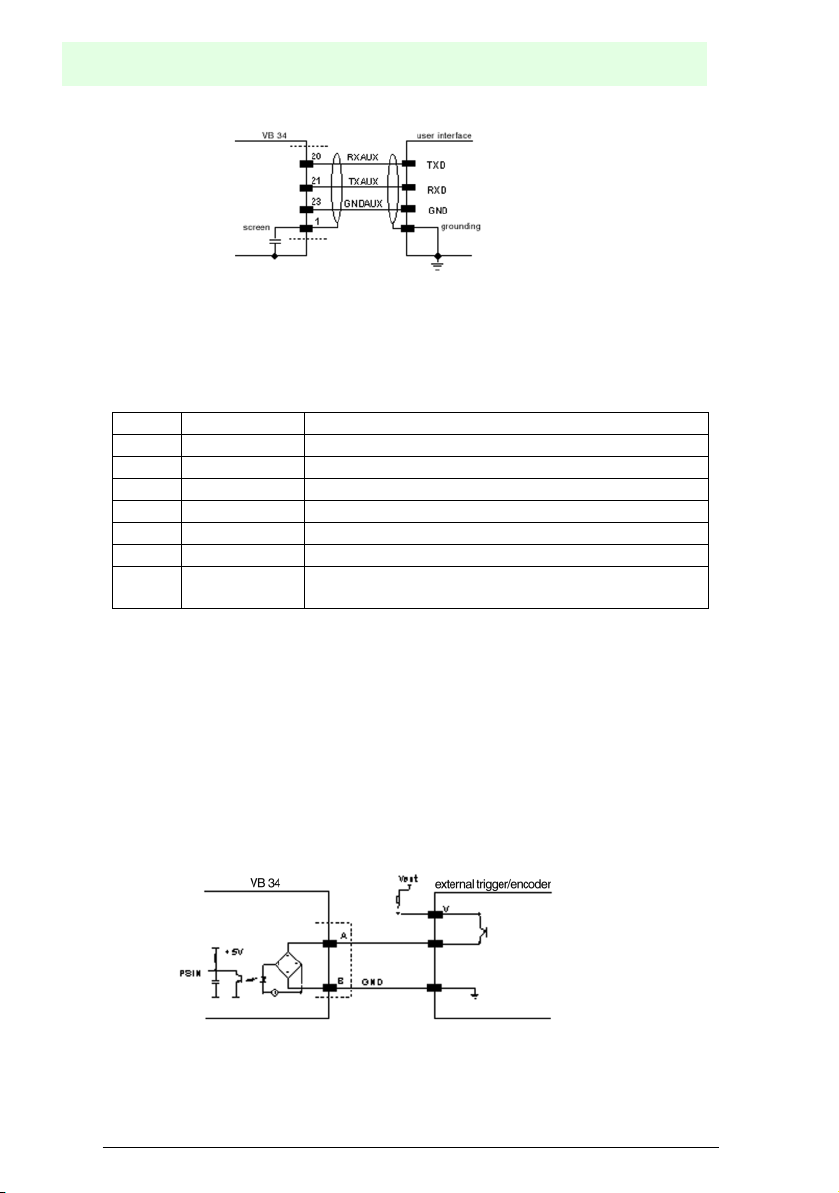

Secondary interface

The secondary serial interface is designed as a fixed RS232 full-duplex interface. The

interface is configured using the configuration software.

In full-duplex operation, the RS232 interface uses the following pins of the 25-pin or

26-pin connector:

Pin Description Function

20 RXAUX Received data

21 TXAUX Transmitted data

23 SGND AUX Signal ground

5

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

27

Barcode reader VB34

Installation

Figure 6.17 Connection layout of the RS232 interface

Inputs

The inputs of the reader are lead through on the 25-pin or 26-pin connector (Figure

6.11) of the VB34.

The inputs are labelled EXT_TRIG, IN2, IN3 and IN4.

Pin Description Function

18 EXT_TRIG A External trigger (polarity exchangeable)

19 EXT_TRIG B External trigger (polarity exchangeable)

6 IN2A Input signal 2 (polarity exchangeable)

10 IN2B Input signal 2 (polarity exchangeable)

14 IN3A Input signal 3 (polarity exchangeable)

15 IN4A Input signal 4 (polarity exchangeable)

24 IN_REF Common reference earth for IN3 and IN4 (polarity

exchangeable)

IN2 is normally used as encoder input. In the PackTrack™ operating mode, this input

is used to measure the speed of the band.

EXT_TRIG is the primary presence sensor. An active signal at this input informs the

reader that a code is to be read and decoded. A (yellow) LED indicates that the

EXT_TRIG signal is active.

IN3 and IN4 can be used as stop signal for the read cycle.

All inputs are galvanically isolated by means of optocouplers, independent of polarity

and are supplied via a constant current generator. The control signal is lead via a

debounce filter with a delay of 5 ms or 500 ms. EXT_TRIG, IN3 and IN4 work with the

same filter constant, which is usually set to 5 ms for photo cells, whereas IN2 is

operated with a filter constant of 500 ms if an encoder is connected.

Figure 6.18 Input wiring with control via PNP signal

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

28

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Figure 6.19 Input wiring with control via PNP signal

Figure 6.20 Input wiring with control via NPN signal

Barcode reader VB34

Installation

Figure 6.21 Input wiring with control via NPN signal

Figure 6.22 Input wiring with control via PNP signals

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

29

Barcode reader VB34

Installation

Figure 6.23 Input wiring with control via NPN signals

The inputs can be powered via the VS signal of the reader (pin 9).

For a galvanic isolation of control and reader, however, a supply with external voltage

(Vext) instead of the voltage connected to pin 9 of the 25/26-pin connector is required.

For reasons of simplicity, the control logic for the input signals can be powered via the

supply voltage of the reader, which is connected to the pins A (VS) and B (GND) of

the connector. In this case, however, there is no galvanic isolation.

The voltage on pins A and B of the input connector is identical to the supply voltage

of the scanner.

The characteristic values of these inputs are:

Maximum voltage 30 V

Maximum current 10 mA

Outputs

Three outputs are available:

Pin Description Function

8 Out 1+ Plus lead of the digital output 1

22 Out 1- Minus lead of the digital output 1

11 Out 2+ Plus lead of the digital output 2

12 Out 2- Minus lead of the digital output 2

16 Out 3A Digital output 3 - polarity exchangeable

17 Out 3B Digital output 3 - polarity exchangeable

The function of the three outputs OUT1+, OUT2+ and OUT3+ can be defined by the

user.

Please refer to the online help for further information.

In the default setting, OUT1+ is connected with the COMPLETE READ event, which

activates the output after a code has been read correctly. If the reader was

programmed to read multiple codes in a read cycle, the event is triggered and the

output is activated after all codes have been read.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

30

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Installation

OUT2+ is linked with the NO READ event, which indicates that no code has been

read.

OUT3+ is linked with the NONE event, i.e. no event. This means that the output

always maintains its status.

The characteristic electrical values of the outputs OUT1+ and OUT2+ are:

Maximum collector-emitter voltage 30 V

Maximum collector current 130 mA

Saturation voltage(VCE) 1 V at 10 mA max.

Maximum power loss 90 mW at T

The limit defined by the maximum power loss is more important than the limit defined

by the maximum collector current: if one of these outputs is continuously deactivated,

the maximum current must not exceed 40 mA, even if up to 130 mA is permissible for

pulsed operation.

Figure 6.24 Connection layout of output 1 and output 2

OUT3+ is designed as a bidirectionally semiconductor relay with integrated current

limit and has thus different characteristic electrical values. At an ambient temperature

of 25°C, the maximum current through this output in continuous operation must not

exceed 200 mA, in pulsed operating, up to 300 mA is permissible. At a maximum

ambient temperature of 50°C, the maximum current is reduced to 160 mA

(continuous) and 240 mA (pulse).

The characteristic electrical values of OUT3+ are as follows:

Maximum voltage 100 V

Maximum collector current (pulse) 240 mA

R

on

R

off

6 – 15 Ohm

> 500 Ohm

Leakage current in Off status < 1 µA

Maximum power loss 550 mW in T

= 50 °C

U

= 50 °C

U

Figure 6.25 Connection layout of output 3

The control signal runs through a filter with a delay of 50 µs for OUT1+ and OUT2+

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

31

Barcode reader VB34

Installation

as well as for 1 ms for OUT3+.

If the load is powered by an external voltage supply, the voltage must be less than

30 V.

6.3.2 Lonworks connector

The network used by VB34 is based upon a Lonworks communication system, for

which only two leads (with exchangeable polarity) are required for a connection.

Furthermore, the supply voltage is lead through to the connectors. In this way, all the

slave readers can be supplied via the VISOLUX standard cable by the master.

For applications, in which an increased range of functions is required for

synchronization, the VB34 master issues two system signals with the descriptions

Sys_I/O and Sys_Enc_I/O to the slave devices. If, for example, an application works

with an encoder, the signal is received by the master and transmitted via the cable

directly to all slave devices.

The internal circuits, which generate the system signals, are powered externally via

the pins VS_I/O and REF_I/O and are galvanically isolated from the voltage supply of

the reader.

These system circuits do not have to be used in all operating modes (see section 1.7

for additional information). To ensure that the system works without errors, only

original cables and accessories should be used. The wiring must be in accordance

with the example configurations (see section 1.7 for details).

Figure 6.26 9-pin local Lonworks connectors

VB34 electrical connections of the 9-pin Lonworks connectors

Pin Description Function

1 Shield Shielding of the cable

9 VS Supply voltage - plus

2 GND Supply voltage - minus (ground)

6 VS_I/O Supply voltage of the I/O circuit

3 Ref_I/O Reference voltage of the I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

7 LON A Lonworks lead (polarity exchange able)

8 LON B Lonworks lead (polarity exchange able)

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

32

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Installation

Network termination

When constructing a Lonworks system, it is important to terminate the network

correctly. For this, a BTK-6000 termination network is connected to the VB34 master

reader as well as to the last VB34 slave reader.

This termination network is equipped with two connectors and can be connected to

the 9-pin connector of the master or to the 9-pin socket of the last slave reader.

Figure 6.27 BTK-6000 termination network

For fieldbus models no external termination is required for the reader

as this is already integrated.

Note

Lonworks Interface

The Lonworks network consists of readers with input and output, which can be

connected to a multiple side or station-wide system.

Generally, the VB34 master uses the 9-pin socket as the output to the first slave

reader, while the 9-pin connector is completed with a BTK6000 termination network

(see Chapter 6.7.2 for details). With a T network configuration, both connector plugs

of the master are used for the two lead branches to the slave readers.

Both connections are always used to connect slave readers. For this purpose, the 9pin socket is used as the output and the 9-pin connector is used as the input. The

socket on the last reader is terminated to complete the network.

The following figure shows the connection of a VB34 as the master with a VB34 as

the slave reader.

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

33

Barcode reader VB34

Installation

Socket Connector

Figure 6.28 VB34 master/slave Lonworks connection

The maximum current consumption of a slave reader via the master is

2 A. Therefore, it makes sense to supply at the most 3 readers

Attention

The following figure shows the two network connections of the BTK-6000. In the

figures, the termination is shown as T. The following figure shows the switching of the

termination network.

(master + 2 slave devices) with a 24 V power pack.

Figure 6.29 Circuit diagram of the BTK-6000 termination network

The following figure shows the termination of a VB34 operated as the master with a

BTK-6000 termination network.

Figure 6.30 Termination of a VB34 master

The following figure shows the termination of a VB34 operated as the slave with a

BTK-6000 termination network.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

34

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Installation

Figure 6.31 Termination of a VB34 slave

The following figure shows the connection of a VB34 fieldbus model, which always

acts as the master, with a VB34 reader operated as the slave.

Figure 6.32 VB34 master/slave Lonworks connection

6.3.3 Ethernet connector

This connector is only available with VB34 Ethernet models and allows for an Ethernet

connection between the host and the reader.

Figure 6.33 RJ45 cable connector

Figure 6.34 VB34 RJ45 socket

Connector and electrical connections (see the following table) correspond to IEEE

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

802.3 10 BaseT and IEEE 802.3U 100 BaseTx.

35

Barcode reader VB34

Installation

VB34 electrical connections of the RJ45 socket

Pin Description Function

1 TX + Transmitted data (+)

2 TX - Transmitted data (-)

3 RX + Received data (+)

6 RX - Received data (-)

4, 5, 7, 8 N.C. unoccupied

Ethernet interface

The Ethernet interface (NIC) can be used for the TCP/IP-based communication with

external or local computers in a network or for the direct connection of a PC to the

reader.

The following example shows the network connection via a hub with an uncrossed

cable (standard network cable) :

Figure 6.35 Uncrossed cable

The following example shows the direct connection of the reader to a PC with a

crossover cable:

Figure 6.36 Crossover cable

For additional information, refer to document “Ethernet.pdf”, which is available as

additional documentation.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

36

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

6.3.4 DeviceNet connector

When the DeviceNet is used, the primary serial interface is

deactivated and must not be interfaced with another device.

Note

The 5-pin connector is only available with the DeviceNet model of the VB34 and

allows for a connection between the reader and a higher-level system:

Figure 6.37 5-pin DeviceNet connector

VB34 electrical connections of the 5-pin DeviceNet connector

Pin Description Function

2 V + Supply voltage - plus

5 CAN_L CAN bus data lead – L

1 Shield Shield

4 CAN_H CAN bus data lead – H

3 V - Supply voltage - minus

Installation

The supply voltage to the pins V+ and V- is only used to supply the

part of the DeviceNet card, which is directly connected to the bus. It is

galvanically isolated from the supply of the VB34, which has to be

Note

connected to the pins 9 and 13 as well as 23 and 25 of the 26-pin

connector.

6.3.5 Profibus connector

The 9-pin Profibus socket is only available with the Profibus model of the VB34 and

allows for a connection between the reader and a higher-level system:

Figure 6.38 9-pin Profibus socket

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

37

Barcode reader VB34

Installation

VB34 electrical connections of the 9-pin Profibus socket

Pin Description Function

1 Shield* Shield or protective earth

2 - unoccupied

3 B-LINE (RXD/TXD-P) Received / transmitted data P

4 CNTR-P** Repeater control signal

5 DGND Signal ground (M5V)

6 +5 V 5 V voltage plus (P5V)

7 - unoccupied

8 A-LINE (RXD/TXD-N) Received / transmitted data

9 CNTR-N** Repeater control signal

* optional

** optional, RS485 level

Profibus interface

The Profibus interface is used for communication with a higher-level system and

allows for an extended network and remote diagnosis functionality of the reader.

For additional information, refer to the document “Profibus_Fam6k.pdf”, which is

available as additional documentation.

6.3.6 Voltage supply

The supply voltage of an individual reader must lie between 15 and 30 V DC.

In master/slave configurations, VISOLUX recommends a voltage supply with at least

24 V DC.

The power consumption of the different VB34 models is slightly different.

When several VB34 readers are connected in a master/slave configuration, the

maximum power consumption per reader is 15 W. Starting the motor results in a peak

demand of approx. 20 W for 5 to 10 seconds.

Figure 6.39 Voltage supply via the 25-/26-pin connector

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

38

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

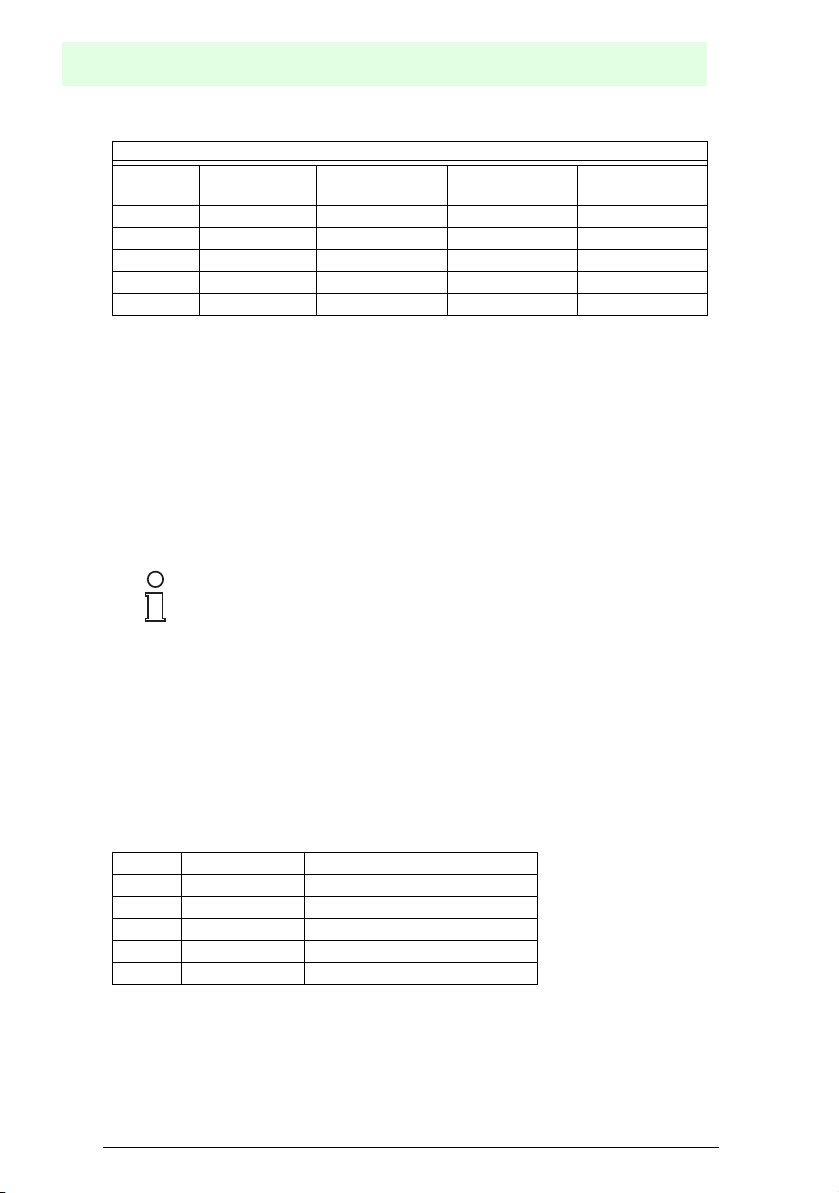

6.4 Operator interface

RS232 connection assignment to the PC

9-pin connector 25-pin connector

Pin Description Pin Description

2RX3RX

3TX2TX

5 GND 7 GND

7 RTS 4 RTS

8CTS5CTS

How to set up a simple test cable:

The following figure shows a simple test cable with supply, an external trigger (push

button) and the connection of the RS232 interface to a PC.

Installation

Figure 6.40 VB34 test cable

6.5 Adjusting the reader

The VB34 reader is able to read labels at most angles, however, a strong distortion

can have an unfavourable effect on reading performance.

When assembling the VB34, note the following three ideal angles for the label

position:

Tilt angle 0°, angle of rotation 10° to 30° and rotation 0°.

Follow the proposals in the next paragraph how best to position the reader:

The tilt angle is represented by the value P, see figure 41. Adjust the reader in such

a way that the tilt angle is held as low as possible.

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

39

Barcode reader VB34

Installation

Figure 6.41 Tilt angle

The angle of rotation is represented by the value S, see figure 42. Adjust the reader

in such a way that the angle of rotation is at least 10°. This prevents a direct

reflection of the laser beam emitted by the reader.

With oscillating mirror models, this angle mirrors the smallest deflection or the

scanning line that is closest to the horizontal. All other scanning lines have an angle

of rotation of more than 10°.

Figure 6.42 Angle of rotation

The tilt angle is represented by the value T, see Figure 6.43.

Figure 6.43 Tilt angle

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

40

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

6.6 Typical installations

6.6.1 Standard installation

The VB34 reader is fitted on a ST-237 mounting angle with 105° (see figure 4), which

ensures an angle of rotation (S in the following figure) of 15° to the level of the image.

(Generally, the angle of rotation should lie between 10° and 20°.) This prevents a

direct reflection of the laser beam emitted by the reader. Furthermore, the mounting

angle allows for an adjustment of the tilt angle (T in the following figure, generally 0°)

for an optimum alignment of the reader:

Figure 6.44 Standard installation

Installation

6.6.2 Installation with an angle of rotation of 45°

The VB34 reader is fixed with a ST-210 90° mounting angle (Figure 6.6). Adjust the

guides of the mounting angle in such a way that an angle of rotation (S in the following

figure) 45° is achieved in order to avoid a direct reflection from the laser beam

emanated from the reader.

Figure 6.45 Installation with an angle of rotation of 45°

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

41

Barcode reader VB34

Installation

With the installation with an angle of rotation of 45° it is not ensured

that the reader will achieve the same efficiency (see reading fields in

Attention

Note

6.7 Typical hardware configurations

The following sections show typical examples for the system hardware configurations,

for which a corresponding software configuration is required. For more detailed

information, please refer to Chapter 7.2.

For other hardware configurations, a VB34 reader with a special decoder base

assembly may be required.

The illustrated cable and accessories are original products. To ensure the functional

capability and smooth operability of the system, it is recommended that you only use

these products.

6.7.1 Point-to-point

In a point-to-point arrangement, the data is transmitted both via the primary and

secondary interface. The primary interface can be adjusted to the full-duplex

communication in accordance with the RS232 or RS485 standard.

Depending on the VB34 model, various hardware configurations are possible.

Figure 8.3.1) as in the standard installation with angles of rotation

between 10° and 20°.

The mounting angle ST-210 is contained as an accessory for the

VB34 standard model in the US-60 set.

Master/slave models

During online operation, the reader is activated by an external trigger (light barrier)

when an object enters the reading zone. In the following example, the signal is

created via a C-BOX 100 to the VB34 reader, which also supplies the system.

*) Presence sensor connected to the external trigger input.

Figure 6.46 Point-to-point arrangement for master/slave models

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

42

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

Fieldbus models

In this case, no external trigger is used. The C-BOX 100 is used only to supply the

reader. The VB34 reader (as an Ethernet, DeviceNet or Profibus model) is connected

to an external fieldbus host. It can be activated by a signal from the external host or

always be active in automatic operation mode.

*) Light barrier (presence sensor) connected to the external trigger input .

Figure 6.47 Point-to-point arrangement for fieldbus models

6.7.2 Loops

With the loop arrangement via the secondary interface, all VB34 models can be

integrated into a network with different readers, without the need for a Lonworks

interface.

In this loop arrangement, two or more readers can be connected to a single external

serial interface. Each VB34 reader also provides the messages, which it received on

the secondary (RS232) interface, via the primary interface (also RS232).

In this arrangement, several readers can be switched in series. The message passes

through all the stations in the chain up to the host. The read cycles of the individual

readers are independent of those of the other readers. In loop configurations, each

reader has an own external trigger (several light barriers).

For this purpose, a portable reader can also be included via the secondary serial

interface in order to read codes manually.

The maximum cable length for RS232 connections is 15 m.

The following figure shows several VB34 readers in a loop arrangement.

Installation

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

43

Barcode reader VB34

Installation

*) Light barrier (presence sensor) connected to the external trigger input .

Figure 6.48 Loop arrangement for VB34 master/slave models

*) Light barrier (presence sensor) connected to the external trigger input .

(1) Primary serial interface

(2) Secondary serial interface

Figure 6.49 Loop arrangement for fieldbus models

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

44

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 06/13/2005

Barcode reader VB34

6.7.3 RS232 master/slave

In the RS232 master/slave arrangement, all VB34 models can be integrated into a

network with different readers, without the need for a Lonworks interface.

The readers operated as the slave only communicate via the primary and secondary

RS232 interfaces. Each slave device also provides the messages, which it received

on the secondary interface, via the primary interface. All messages are transmitted to

the master.

The master reader is connected via the primary RS232 interface and a C-BOX 100 to

a computer. If the INT-60 accessory option is installed, a 20 mA current loop can be

used.

For the RS232 master/slave arrangement, a central external trigger signal is used (a

light barrier).

The VB34 reader (master/slave variant only), which is used as the

Note

master in a RS232 network

Lonworks network

with VB34 slave readers. When assigning slave

addresses, note that the number of the first Lonworks slave must

follow on seamlessly to the number of the last slave reader in the

RS232 network. If, for example, the RS232 network consists of the

devices slave 1 and slave 2 , the first slave device in the Lonworks

network is slave 3 (not slave 1).

, can simultaneously be connected to a

Installation

*) Light barrier (presence sensor) connected to the external trigger input .

(1) Primary serial interface

(2) Secondary serial interface

Figure 6.50 RS232 master/slave for VB34 master/slave models

Date of issue 06/13/2005

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

45

Barcode reader VB34

Installation

*) Light barrier (presence sensor) connected to the external trigger input .

(1) Primary serial interface

(2) Secondary serial interface

Figure 6.51 RS232 master/slave for VB34 master/slave fieldbus models

6.7.4 Multiplexer

The Multiplexer layout serves to integrate VB34 slave readers into a Multidrop

network, which consists of different readers without a Lonworks interface .

All the readers are connected via the primary interface to a Multiplexer.

In this instance, the primary interface is configured as the RS485 half duplex

interface.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

46