Vision Engineering Hawk QC-200, Hawk QC-300, Hawk QC-5000 User Manual

User Guide

2 or 3-Axis Manual Non-Contact

Measuring System

INTRODUCTIONHealth & Safety

Vision Engineering and its products conforms to the requirements of the EC Directives on Waste Electrical and

Electronic Equipment (WEEE) and Restriction of Hazardous Substances (RoHS).

CONTENTSPACKING CONTENTS

Head pack 1

Stand pack 1

Stage pack 1

Accessories packs 2

Illumination and objectives pack 2

QC-200/300 microprocessor pack 3

QC-5000 microprocessor pack 3

ASSEMBLY

Stage assembly 4

Ringlight attachment 5

Macro EPI attachment 5

Macro EPI and ringlight attachment 6

Micro EPI and lens turret attachment 6

Attaching the head only 7

Mounting camera to rear 7

Mounting camera to side for image capture 8

Attaching the anti-glare shield 8

Inserting the illuminator lamp 9

Inserting the stage glass 10

Connecting the fibre optic cable to the illuminator 11

QC-200/QC-300 microprocessor assembly 12

Cable connection points for the manual QC-200/QC-300 system 13

Interconnection diagram for manual Hawk system with QC-200 14

Interconnection diagram for manual Hawk system with QC-300 15

Interconnection diagram for Hawk system with manual QC-5000 16

Interconnection diagram for Hawk system with QC-5000 VED 17

SETTING UP

Manual system controls 18

Align head to stage 18

Stand levelling 19

Stage glass levelling 19

Camera Setup 19

OPERATION

Objective lens 20

Episcopic illuminator 21

LED Ringlight 21

Control box 22

LED illuminator specification 22

Substage 23

Taking a measurement (QC-200) 23

Taking a measurement (QC-300/QC-5000 VED) 24

Good working practices 24

CONTENTS

ROUTINE MAINTENANCE

Graticule adjustment 25

Changing the illuminator lamp 26

General care 27

Consumable and replacement parts 27

Environmental conditions 27

ACCESSORIES & OPTIONS

OTHER SOLUTIONS FROM VISION ENGINEERING

Stereo inspection systems 29

Non-contact measuring systems 30

SERVICE & CALIBRATION RECORD

WARRANTY

CONTENTS

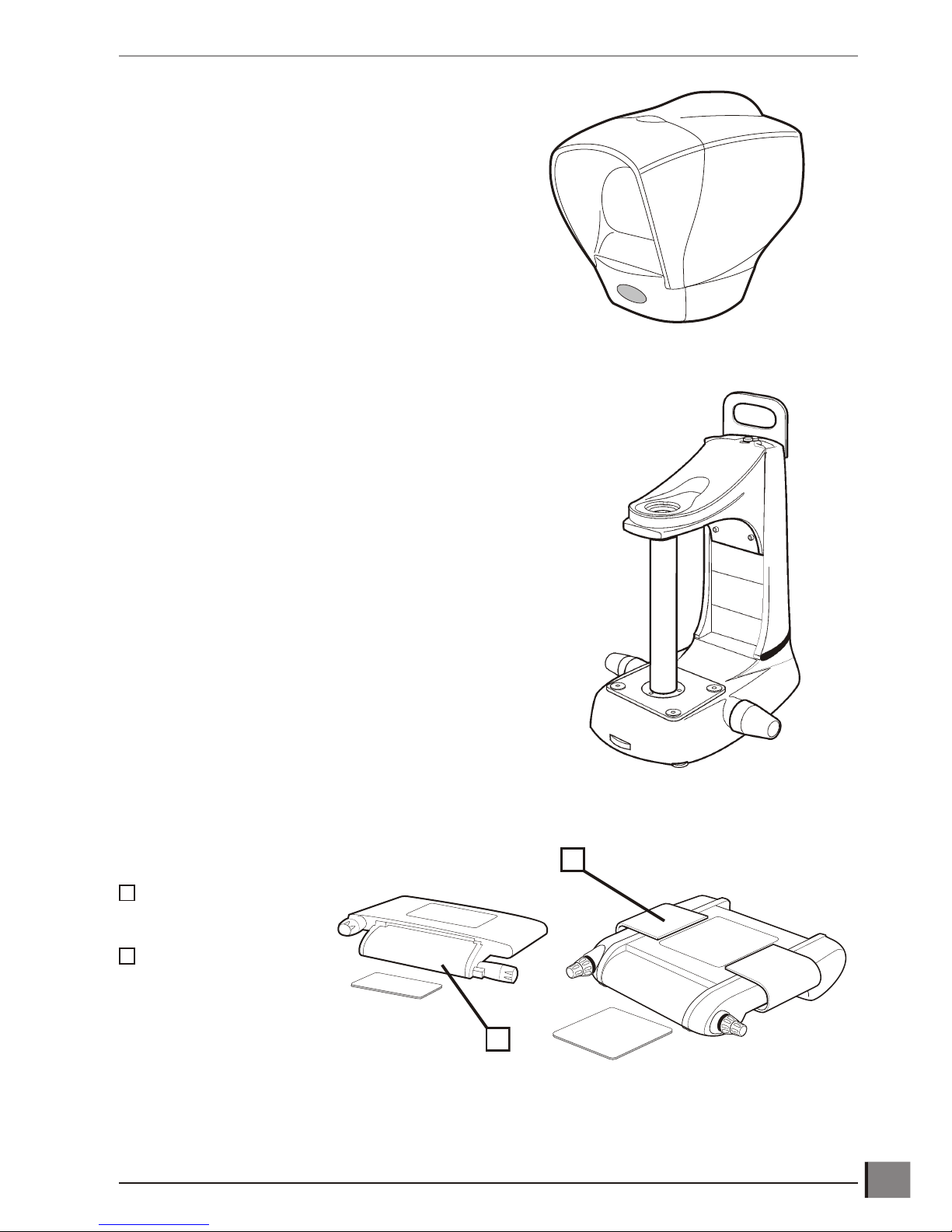

PACKING CONTENTSSee packing list to clarify contents of delivery.

Head pack

Stand pack

Stage pack

200mm x 150mm

(8" x 6")

150mm x 150mm

(6" x 6")

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

PACKING CONTENTS

1

1

2

1

2

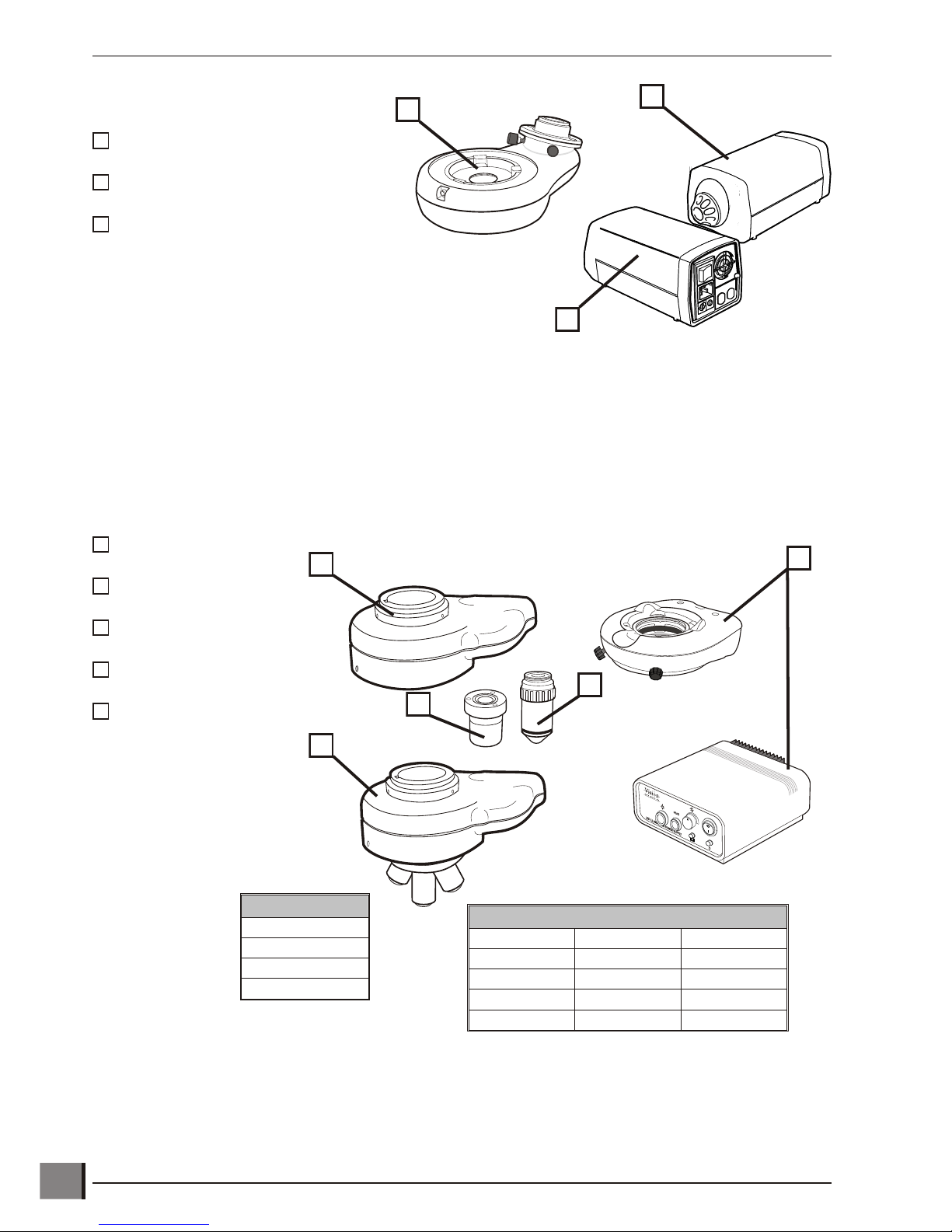

Accessories packs

Photographic adaptor

Illuminator

Power supply

Illumination and objectives pack

Macro EPI

Ringlight and Control box

Micro EPI/Turret Assembly

Macro Lens

Micro Lens

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

PACKING CONTENTS

2

Macro Lens Options

x1

x2

x5

x10

134

5

Micro Lens Options

Micro Micro LWD Micro SLWD

x5 x10 x20

x10 x20 x50

x20 x50

x50 x100

1231234

5

123

2

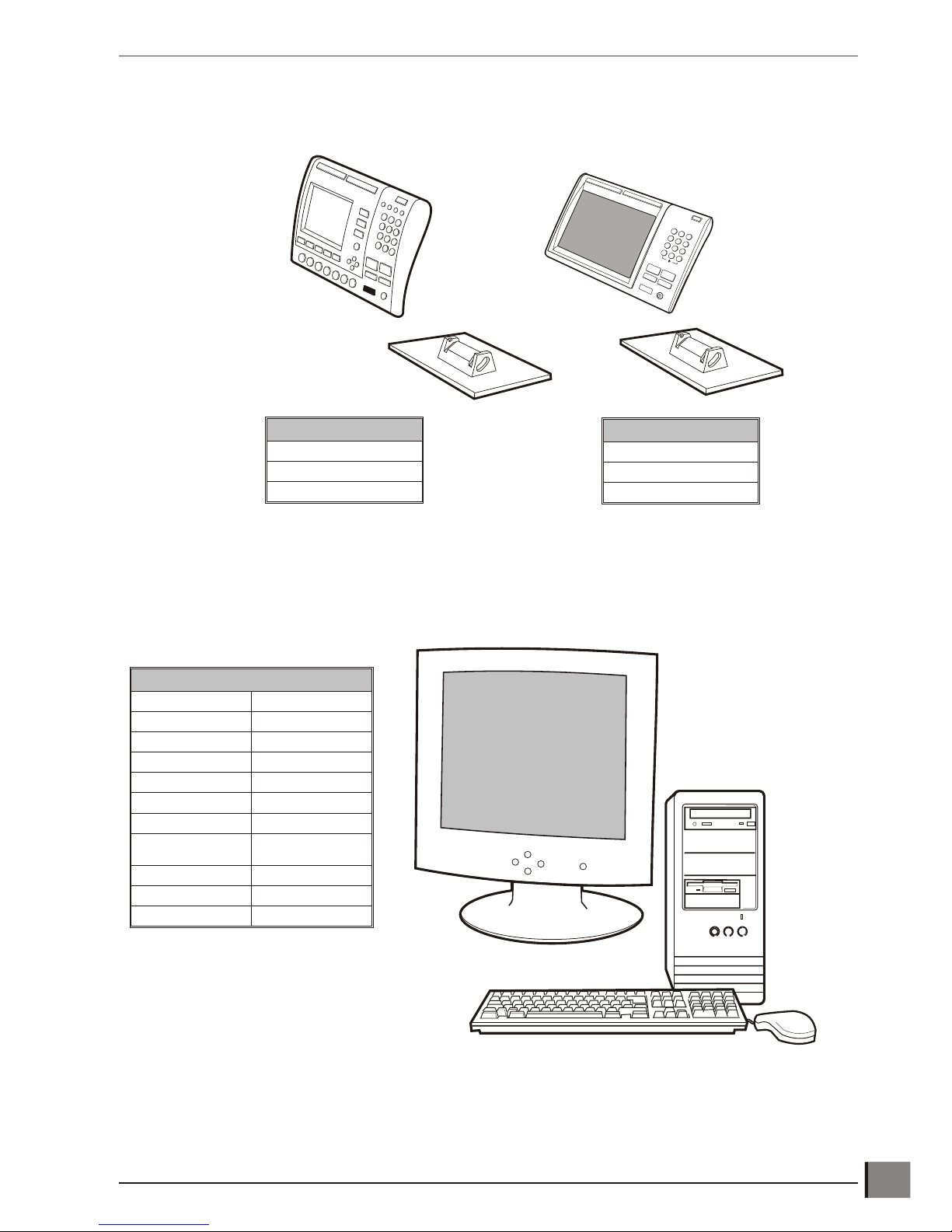

QC-200/300 microprocessor pack

QC-5000 microprocessor pack

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

PACKING CONTENTS

3

QC-200 items included:

Power lead

Instruction manual

QC Quickie Test Slide

QC-300 items included:

Power lead

Instruction manual

QC Quickie Test Slide

QC-5000 items included

Manual Optional Manual VED

Instruction Manual Instruction Manual

Encoder Cable Encoder Cable

RS232 Comms Cable RS232 Comms Cable

2 x Power Leads 2 x Power Leads

QC-5000 Software QC-5000 Software

Windows Software Windows Software

Graphics Card

(pre-installed)

Drivers Disc

Additional Monitor

S-Video Cable

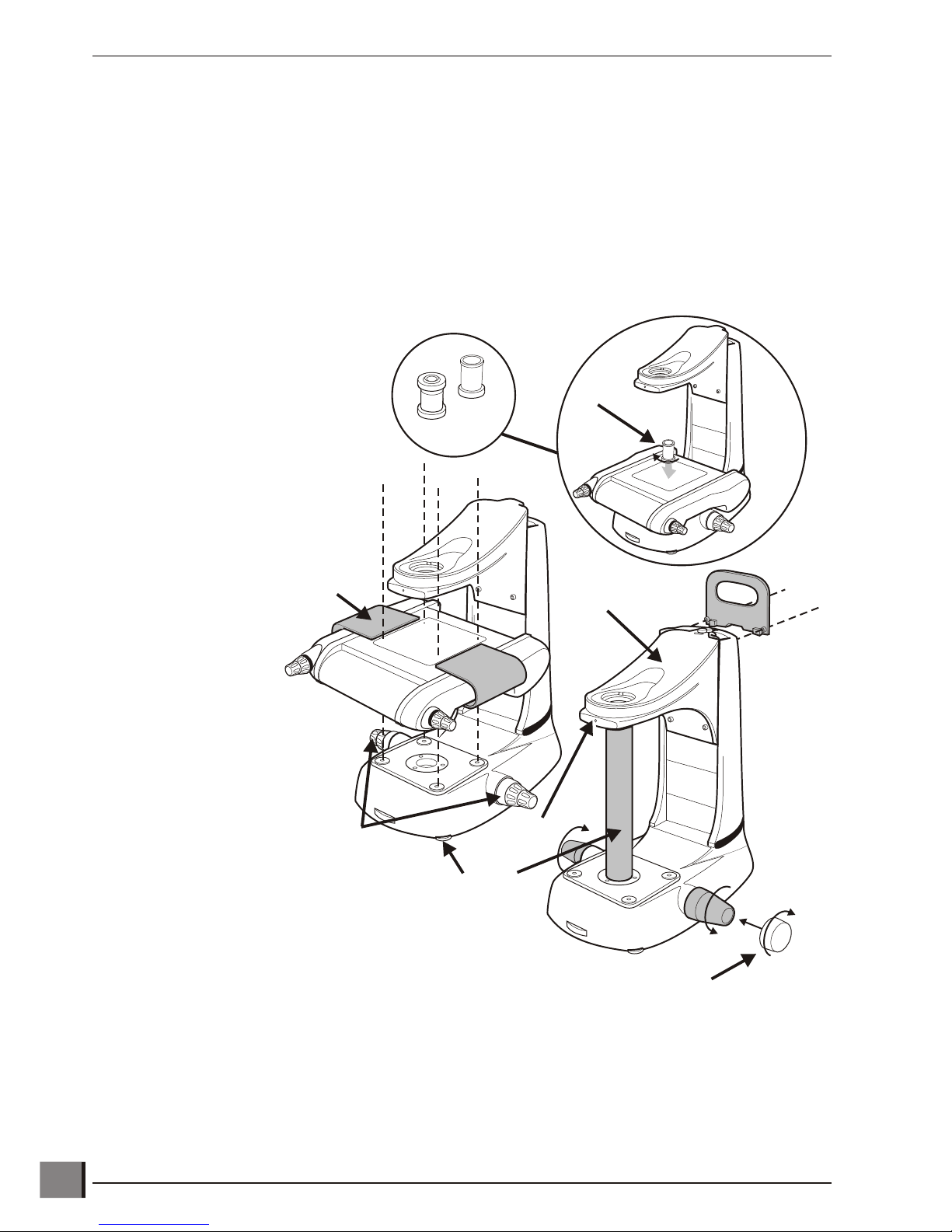

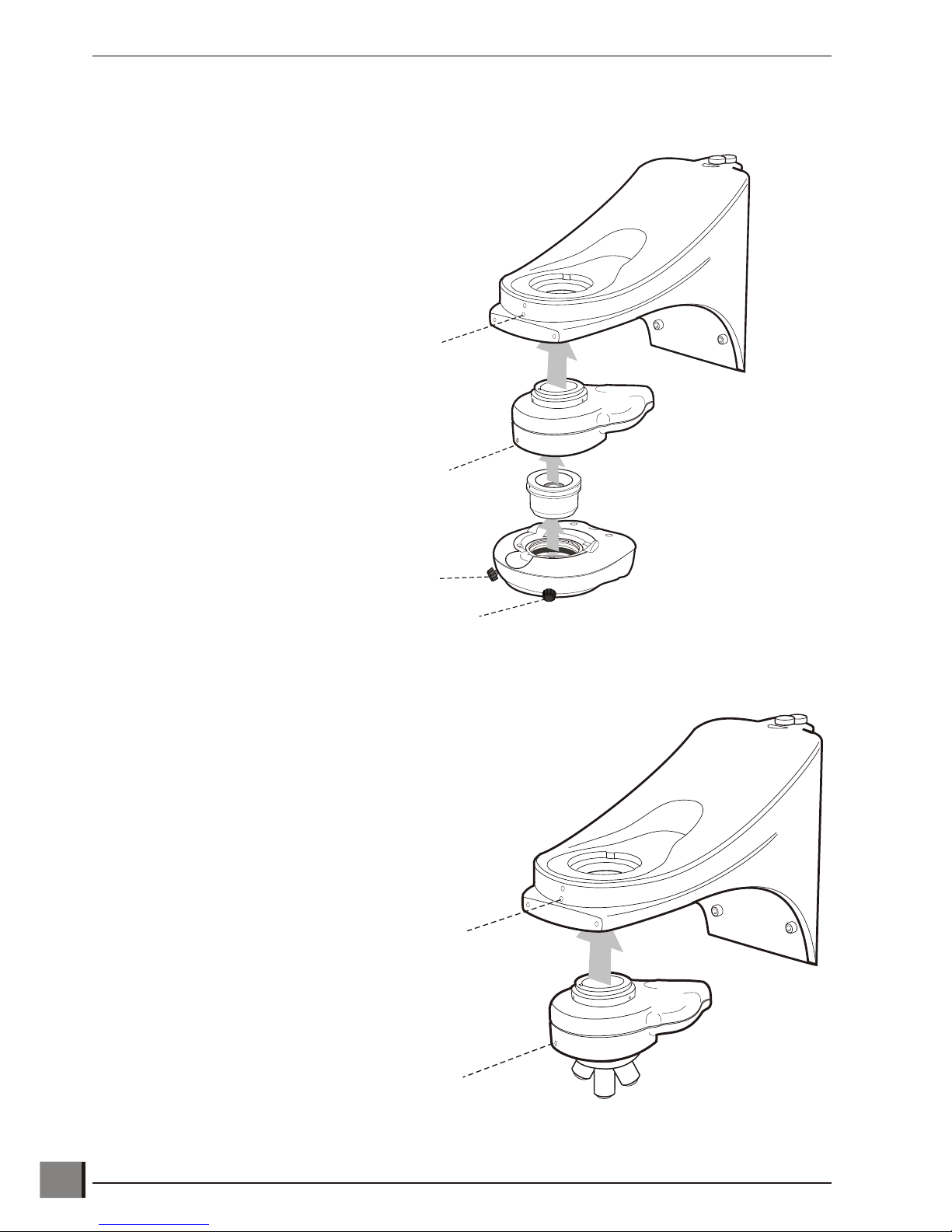

ASSEMBLYThe following paragraphs provide instructions on how to assemble the Hawk Measuring System. In most instances

the illustrations are self explanatory; where necessary the illustrations are supported by text.

Stage assembly

To attach the Stage proceed as follows:

u Use the red transit handle and focus control covers to lift the stand into the required work position.

u Remove the red transit handle and focus

control covers. Screw the two focus

control collars u into position.

u Remove the grub screw v. Use the

focus controls w to raise the head

platform x until there is sufficient

room to unscrew and remove the

transit tube y.

u Using the red transit handles, lift the

stage into position and secure it

using the bolts provided

with the stand, not

the bolts that secure

the stage into the

transit box.

u Remove the stage

transit handles z.

u Adjust the stabilizing foot {

to support the stand base.

u Screw the required condenser

lens | through the stage and

into the stand.

Note: Micro condensers should only be used with micro

lenses when viewing a subject at stage glass level.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

4

Micro

Macro

u

v

w

x

y

z

{

|

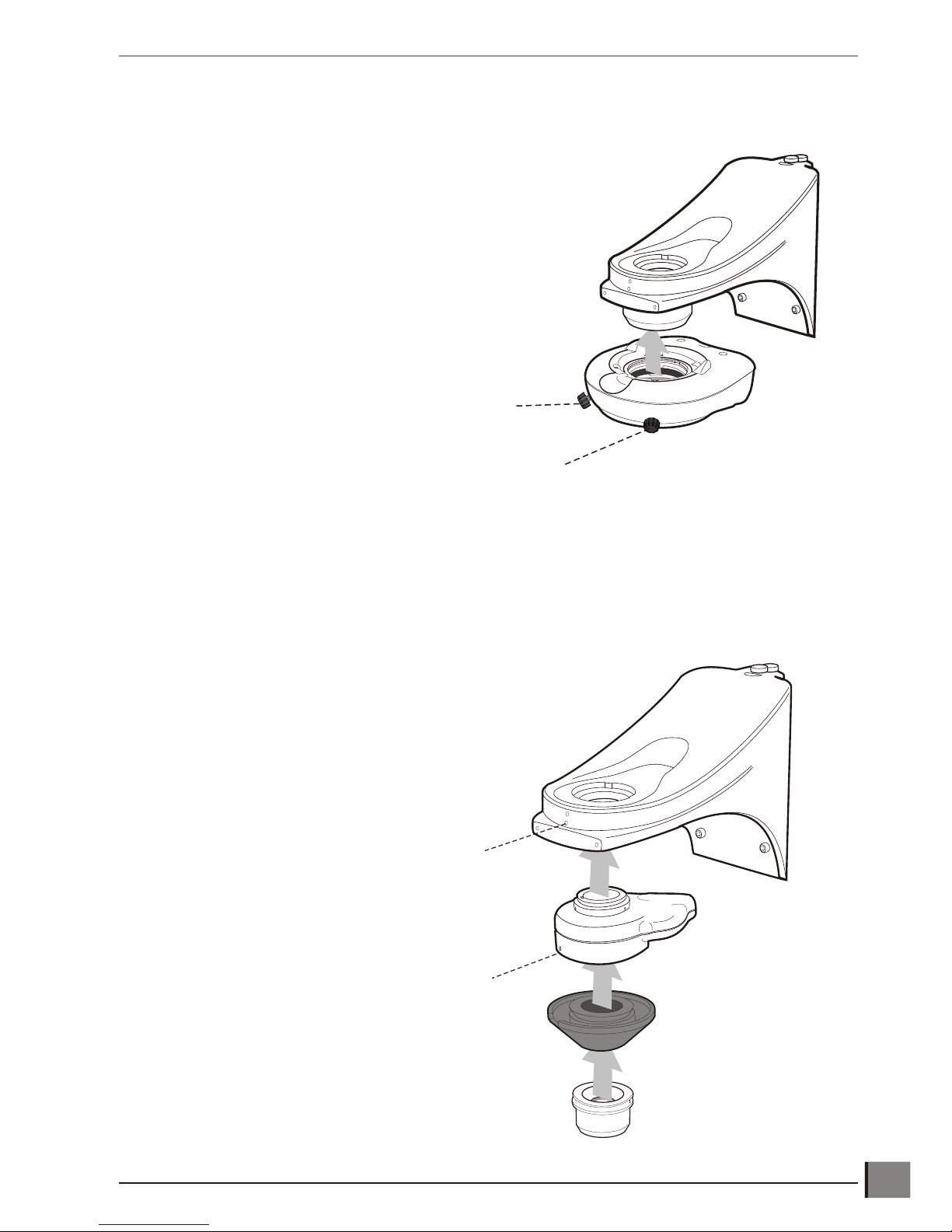

Ringlight attachment

Macro EPI attachment

Note: The same procedure is used to fit either the Macro EPI (illustrated) or the Micro EPI. The Micro

EPI cannot have an Objective Holder or Ringlight fitted.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

5

Securing Screw

Grub Screw

Grub Screw

Securing Screw

Macro EPI and ringlight attachment

Micro EPI and lens turret attachment

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

6

Grub Screw

Securing Screw

Grub Screw

Securing Screw

Grub Screw

Grub Screw

Loading...

Loading...