User Guide

2 or 3-Axis Manual Non-Contact

Measuring System

INTRODUCTIONHealth & Safety

Vision Engineering and its products conforms to the requirements of the EC Directives on Waste Electrical and

Electronic Equipment (WEEE) and Restriction of Hazardous Substances (RoHS).

CONTENTSPACKING CONTENTS

Head pack 1

Stand pack 1

Stage pack 1

Accessories packs 2

Illumination and objectives pack 2

QC-200/300 microprocessor pack 3

QC-5000 microprocessor pack 3

ASSEMBLY

Stage assembly 4

Ringlight attachment 5

Macro EPI attachment 5

Macro EPI and ringlight attachment 6

Micro EPI and lens turret attachment 6

Attaching the head only 7

Mounting camera to rear 7

Mounting camera to side for image capture 8

Attaching the anti-glare shield 8

Inserting the illuminator lamp 9

Inserting the stage glass 10

Connecting the fibre optic cable to the illuminator 11

QC-200/QC-300 microprocessor assembly 12

Cable connection points for the manual QC-200/QC-300 system 13

Interconnection diagram for manual Hawk system with QC-200 14

Interconnection diagram for manual Hawk system with QC-300 15

Interconnection diagram for Hawk system with manual QC-5000 16

Interconnection diagram for Hawk system with QC-5000 VED 17

SETTING UP

Manual system controls 18

Align head to stage 18

Stand levelling 19

Stage glass levelling 19

Camera Setup 19

OPERATION

Objective lens 20

Episcopic illuminator 21

LED Ringlight 21

Control box 22

LED illuminator specification 22

Substage 23

Taking a measurement (QC-200) 23

Taking a measurement (QC-300/QC-5000 VED) 24

Good working practices 24

CONTENTS

ROUTINE MAINTENANCE

Graticule adjustment 25

Changing the illuminator lamp 26

General care 27

Consumable and replacement parts 27

Environmental conditions 27

ACCESSORIES & OPTIONS

OTHER SOLUTIONS FROM VISION ENGINEERING

Stereo inspection systems 29

Non-contact measuring systems 30

SERVICE & CALIBRATION RECORD

WARRANTY

CONTENTS

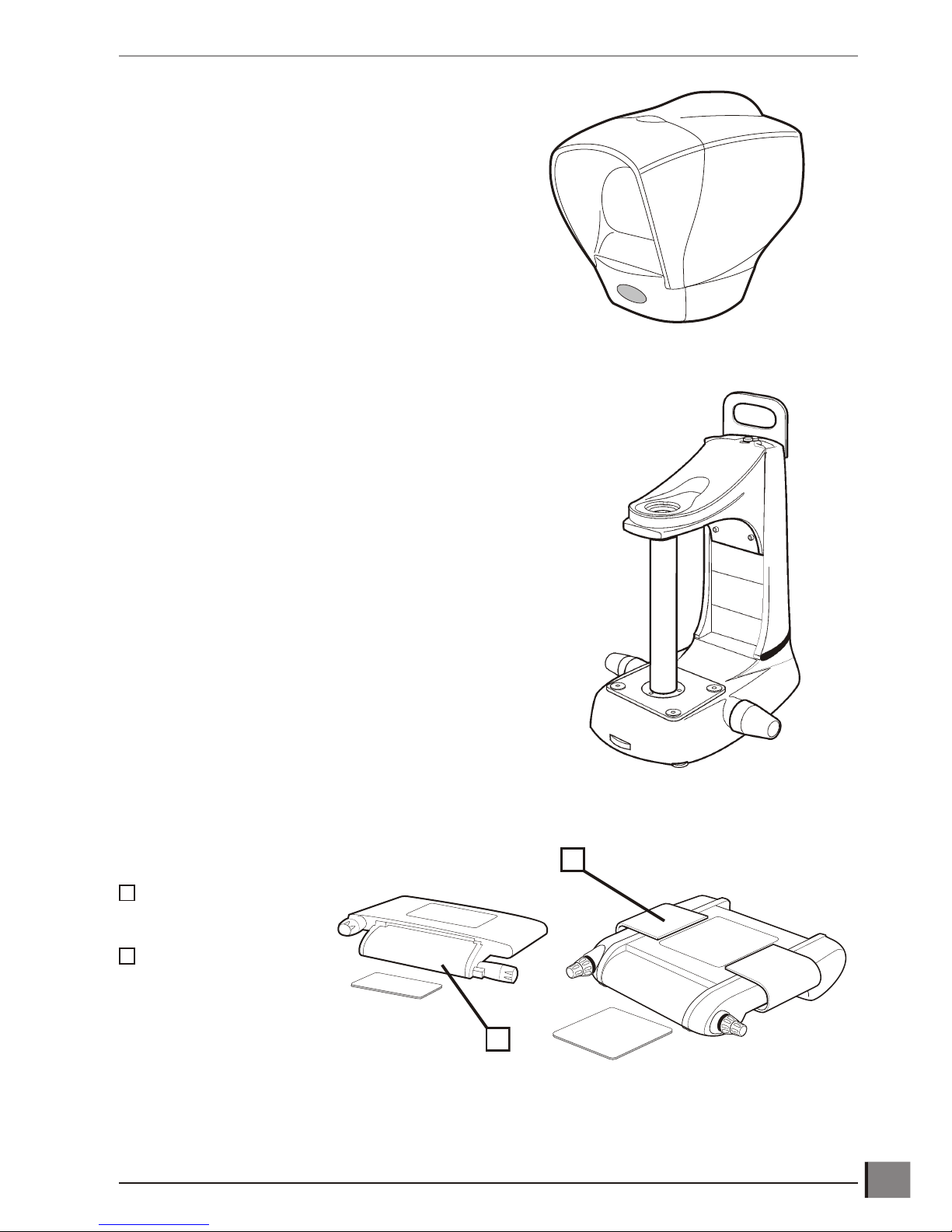

PACKING CONTENTSSee packing list to clarify contents of delivery.

Head pack

Stand pack

Stage pack

200mm x 150mm

(8" x 6")

150mm x 150mm

(6" x 6")

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

PACKING CONTENTS

1

1

2

1

2

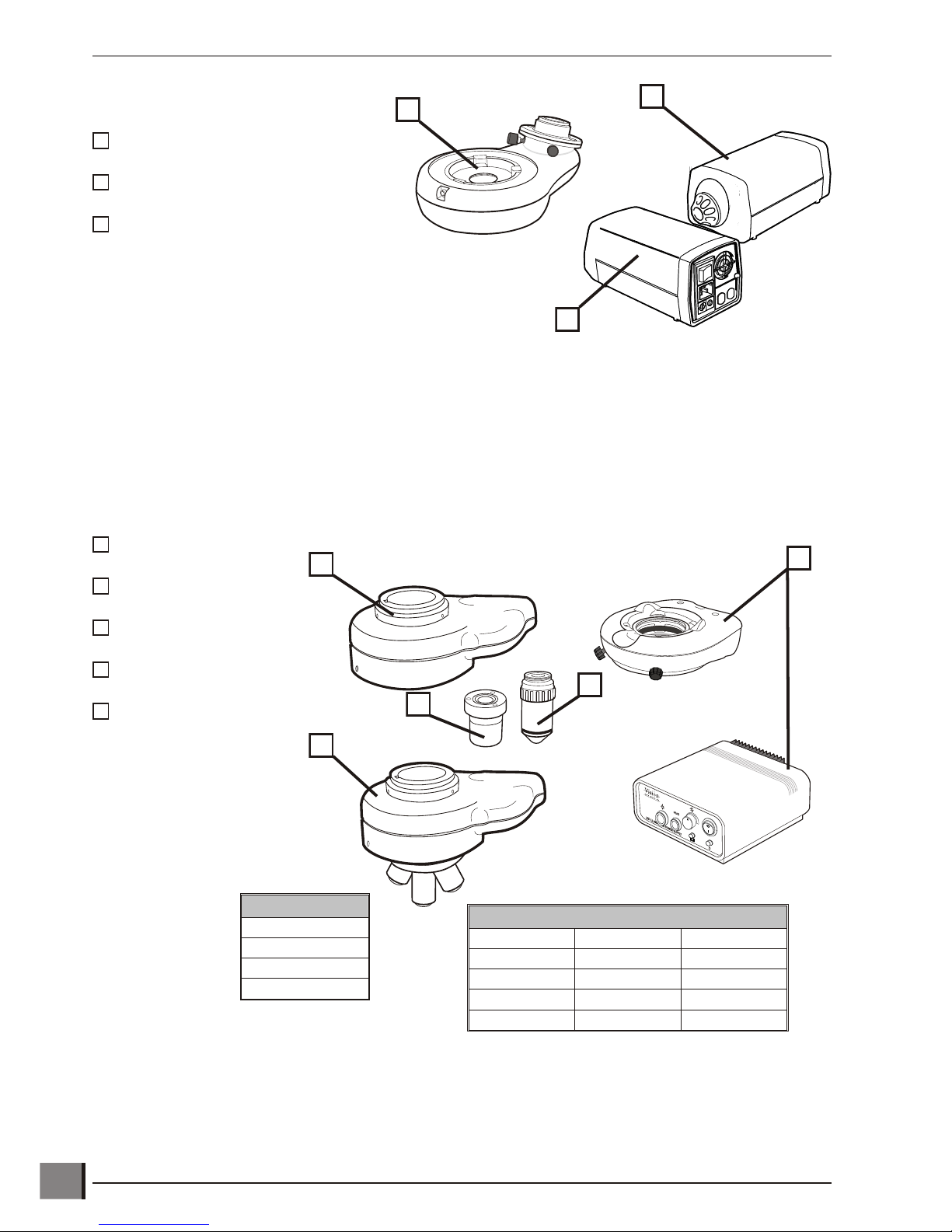

Accessories packs

Photographic adaptor

Illuminator

Power supply

Illumination and objectives pack

Macro EPI

Ringlight and Control box

Micro EPI/Turret Assembly

Macro Lens

Micro Lens

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

PACKING CONTENTS

2

Macro Lens Options

x1

x2

x5

x10

134

5

Micro Lens Options

Micro Micro LWD Micro SLWD

x5 x10 x20

x10 x20 x50

x20 x50

x50 x100

1231234

5

123

2

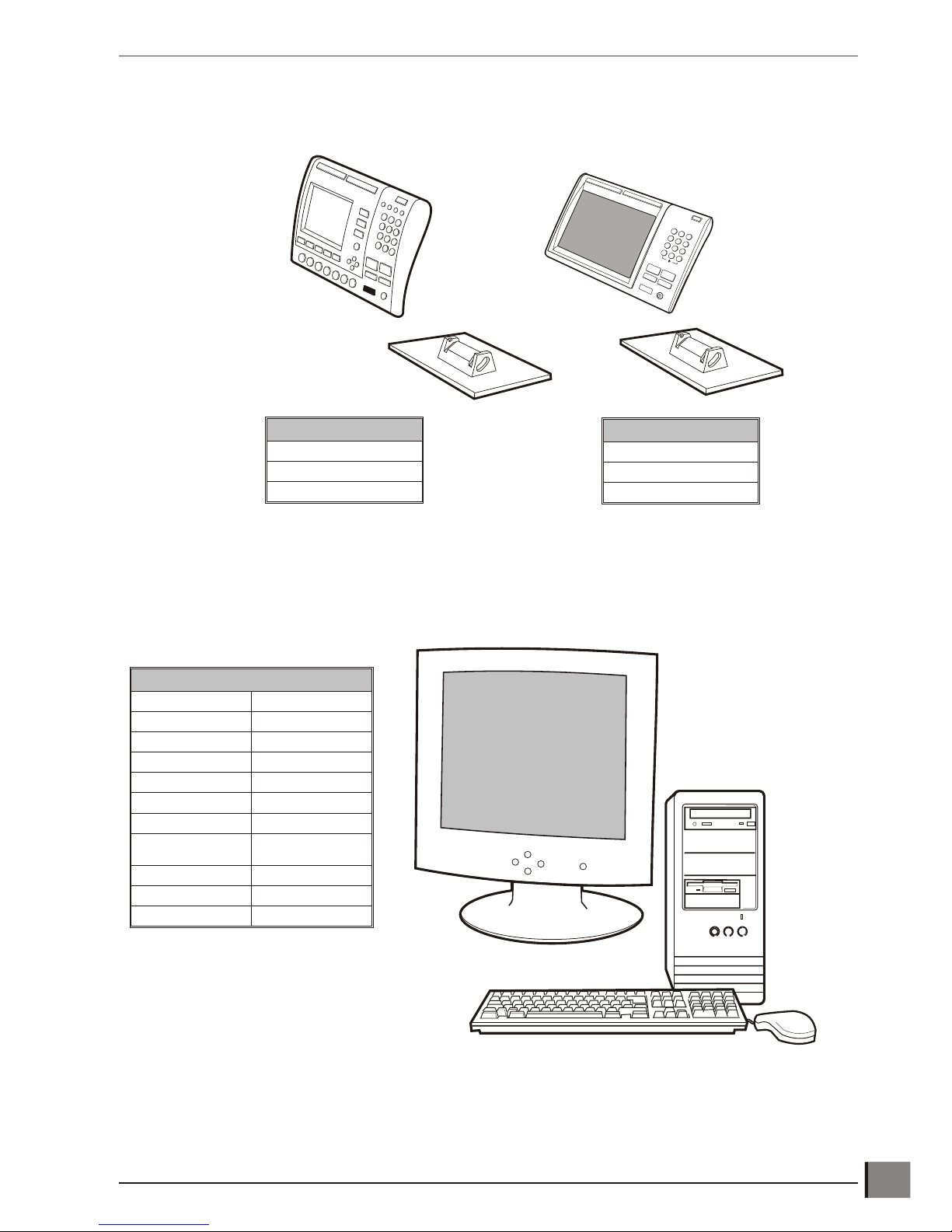

QC-200/300 microprocessor pack

QC-5000 microprocessor pack

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

PACKING CONTENTS

3

QC-200 items included:

Power lead

Instruction manual

QC Quickie Test Slide

QC-300 items included:

Power lead

Instruction manual

QC Quickie Test Slide

QC-5000 items included

Manual Optional Manual VED

Instruction Manual Instruction Manual

Encoder Cable Encoder Cable

RS232 Comms Cable RS232 Comms Cable

2 x Power Leads 2 x Power Leads

QC-5000 Software QC-5000 Software

Windows Software Windows Software

Graphics Card

(pre-installed)

Drivers Disc

Additional Monitor

S-Video Cable

ASSEMBLYThe following paragraphs provide instructions on how to assemble the Hawk Measuring System. In most instances

the illustrations are self explanatory; where necessary the illustrations are supported by text.

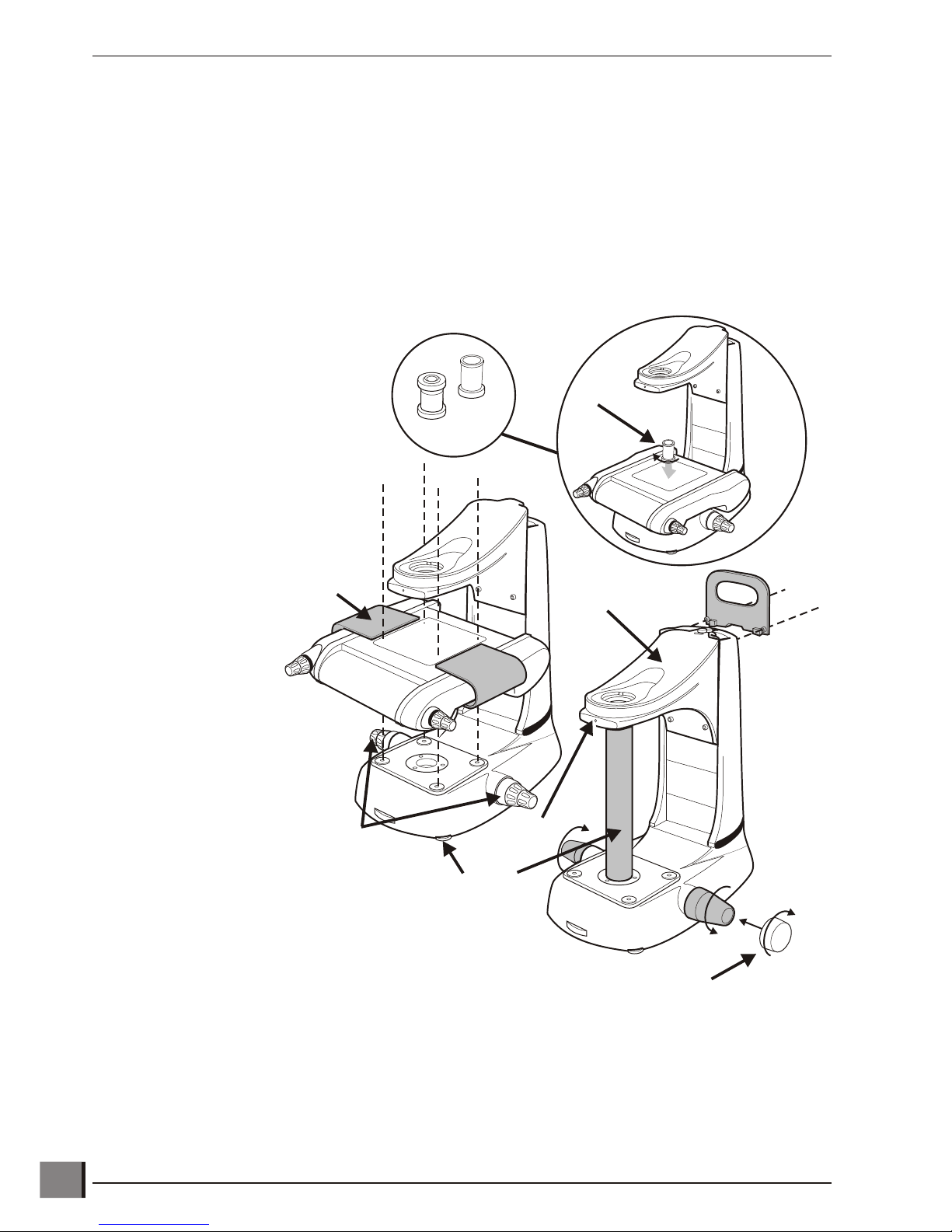

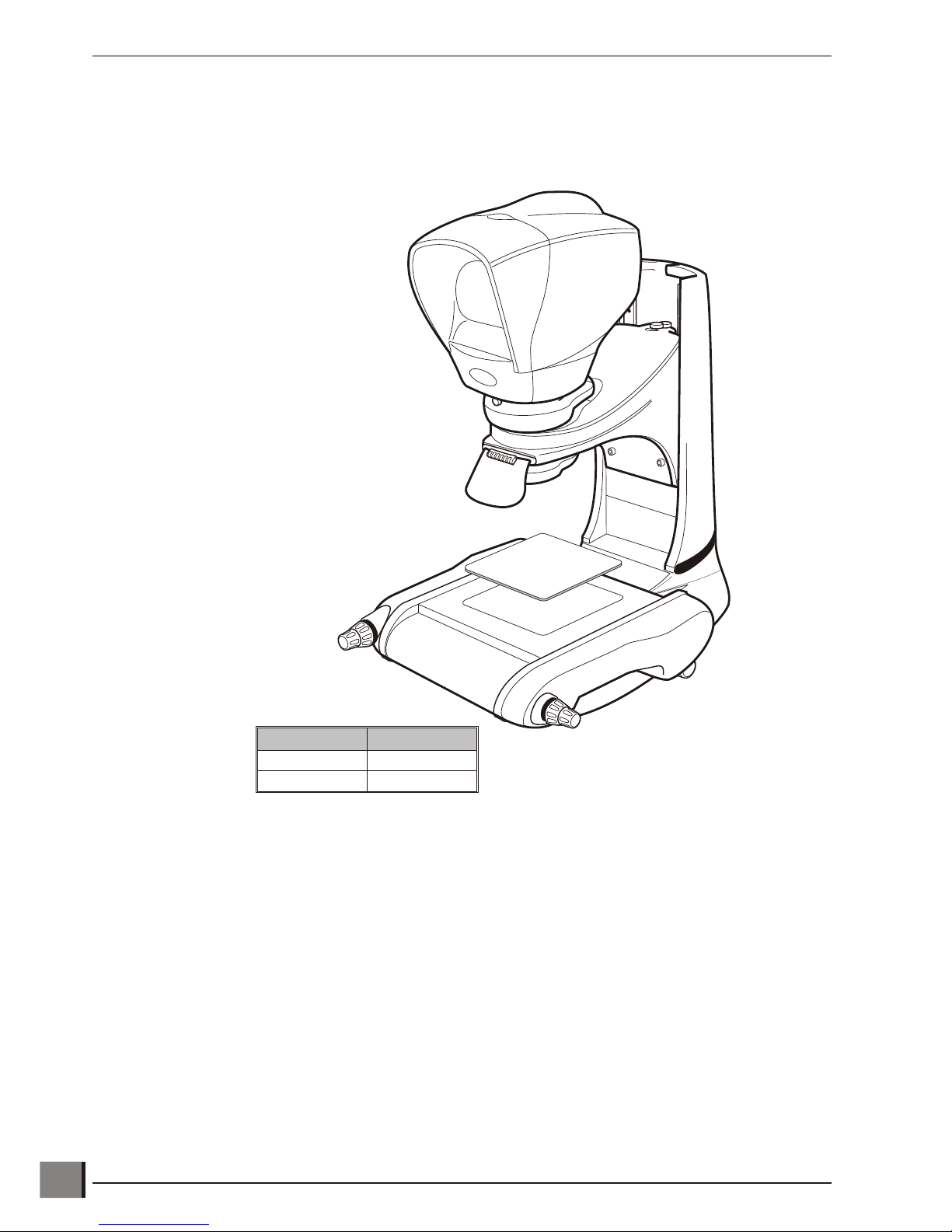

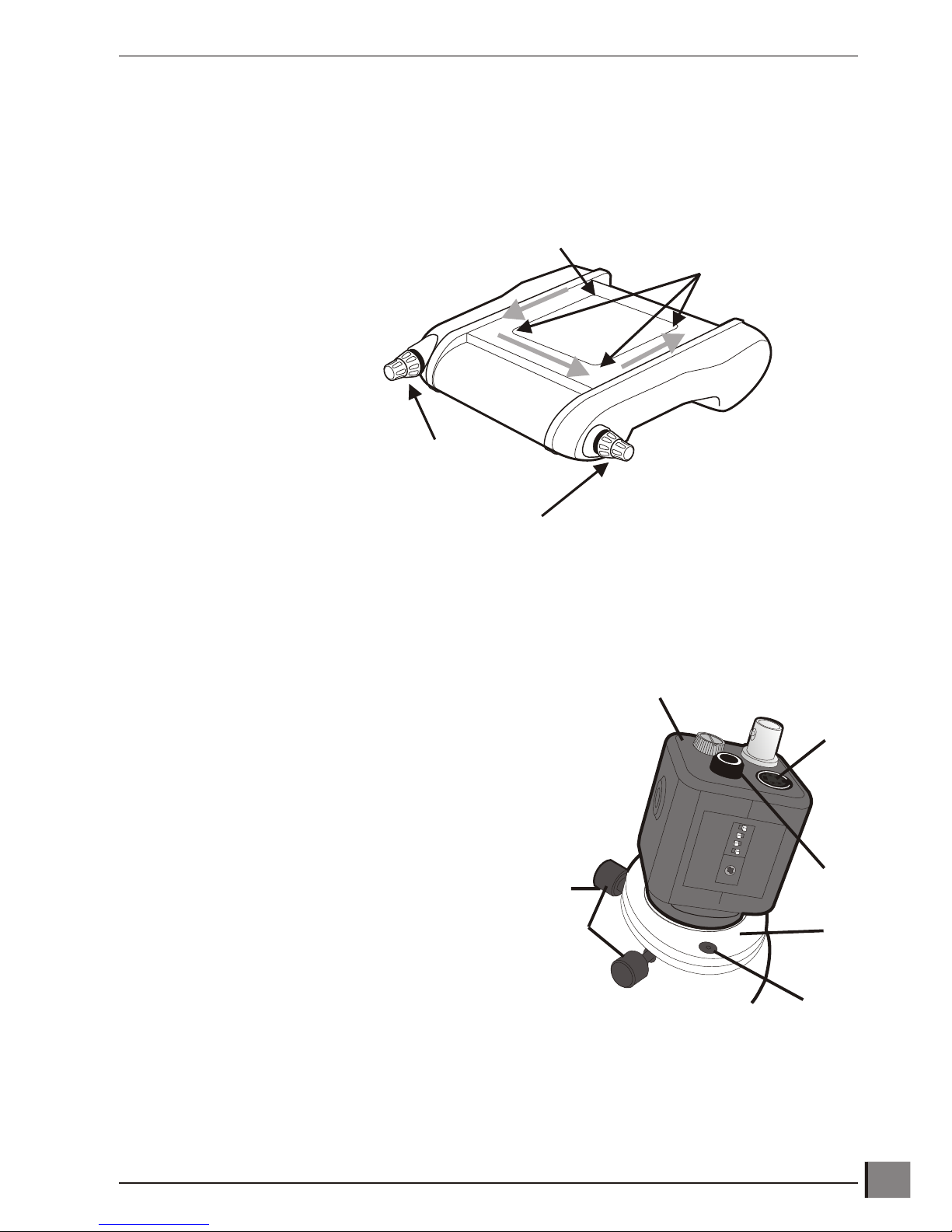

Stage assembly

To attach the Stage proceed as follows:

u Use the red transit handle and focus control covers to lift the stand into the required work position.

u Remove the red transit handle and focus

control covers. Screw the two focus

control collars u into position.

u Remove the grub screw v. Use the

focus controls w to raise the head

platform x until there is sufficient

room to unscrew and remove the

transit tube y.

u Using the red transit handles, lift the

stage into position and secure it

using the bolts provided

with the stand, not

the bolts that secure

the stage into the

transit box.

u Remove the stage

transit handles z.

u Adjust the stabilizing foot {

to support the stand base.

u Screw the required condenser

lens | through the stage and

into the stand.

Note: Micro condensers should only be used with micro

lenses when viewing a subject at stage glass level.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

4

Micro

Macro

u

v

w

x

y

z

{

|

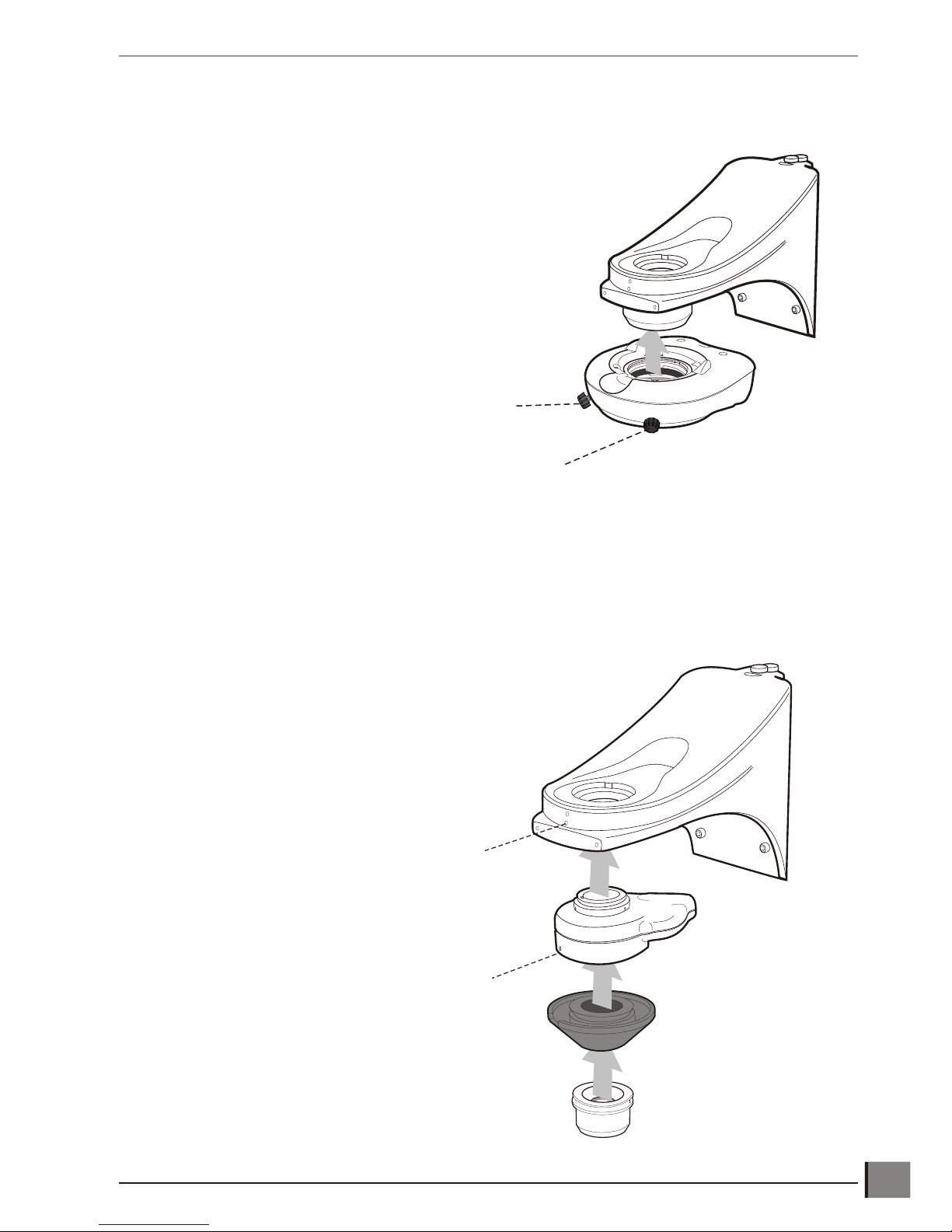

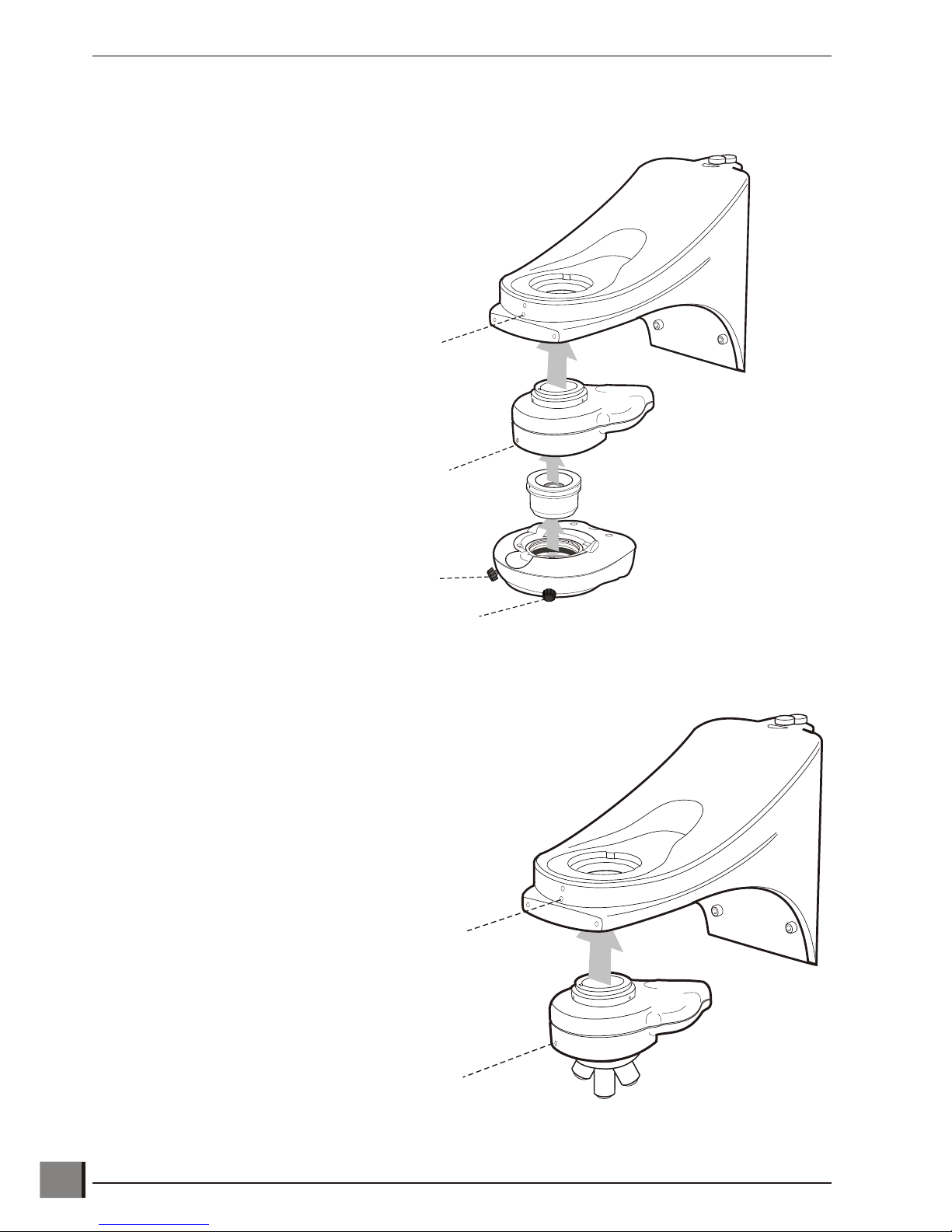

Ringlight attachment

Macro EPI attachment

Note: The same procedure is used to fit either the Macro EPI (illustrated) or the Micro EPI. The Micro

EPI cannot have an Objective Holder or Ringlight fitted.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

5

Securing Screw

Grub Screw

Grub Screw

Securing Screw

Macro EPI and ringlight attachment

Micro EPI and lens turret attachment

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

6

Grub Screw

Securing Screw

Grub Screw

Securing Screw

Grub Screw

Grub Screw

Attaching the head only

Mounting camera to rear

u Position photographic attachment between

the viewing head and its arm.

u Secure with the grub screws.

u Attach the adapter to the camera

and tighten 3 x grub screws if not

already fitted.

u Locate camera and adapter to the locking

plate (the locking plate must not be

overtight, but enough to hold).

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

7

Head

Connector

Head

Socket

Grub

Screw

Photographic

Attachment

Grub

Screws

Locking

Plate

Camera

Adapter

Mounting camera to side for image capture

Attaching the anti-glare shield

CAUTION: The Anti-Glare Shield is made of plastic and

must not be over tightened.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

8

Photographic

Attachment

Camera

Interface

Centring

Screws

Focus

Adjustment

Head

Connector

Head Socket

Securing

Screws

Grub Screws

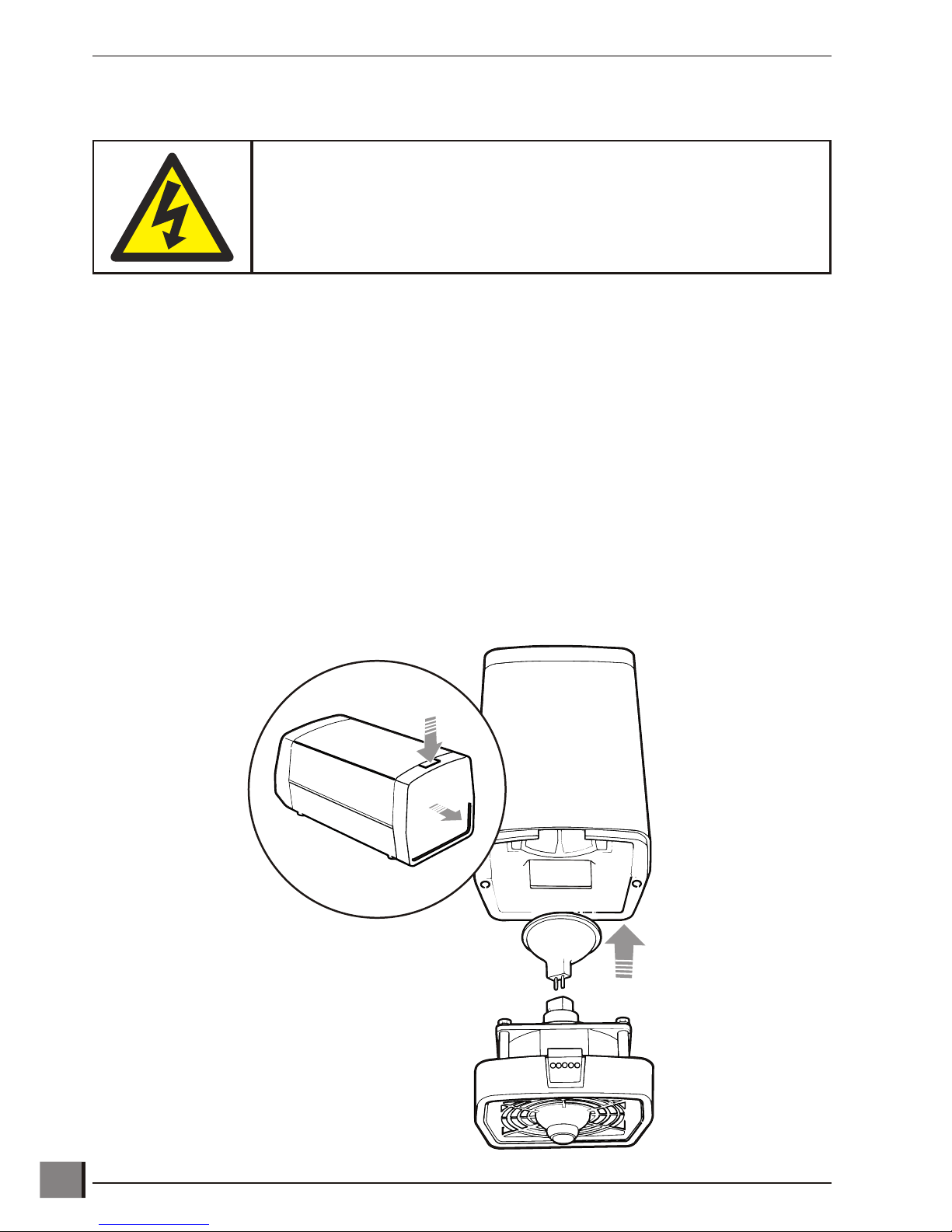

Inserting the illuminator lamp

u Press down the lamp/fan assembly release button u.

u Lift out the lamp/fan assembly v.

u Insert the lamp as shown w.

u Check that it is fully

pushed into the

lamp holder.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

9

u

v

w

Inserting the stage glass

Note: The stage glass must be handled with care to avoid any fingerprint marks.

u Align the glass with it's bevelled edges against the springs.

u Check that the stage glass is in contact with all

four supports.

u To level the stage glass, refer to page 19.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

10

Stage size Spring location

150 x 150mm Left & Back

200 x 150mm Left & Front

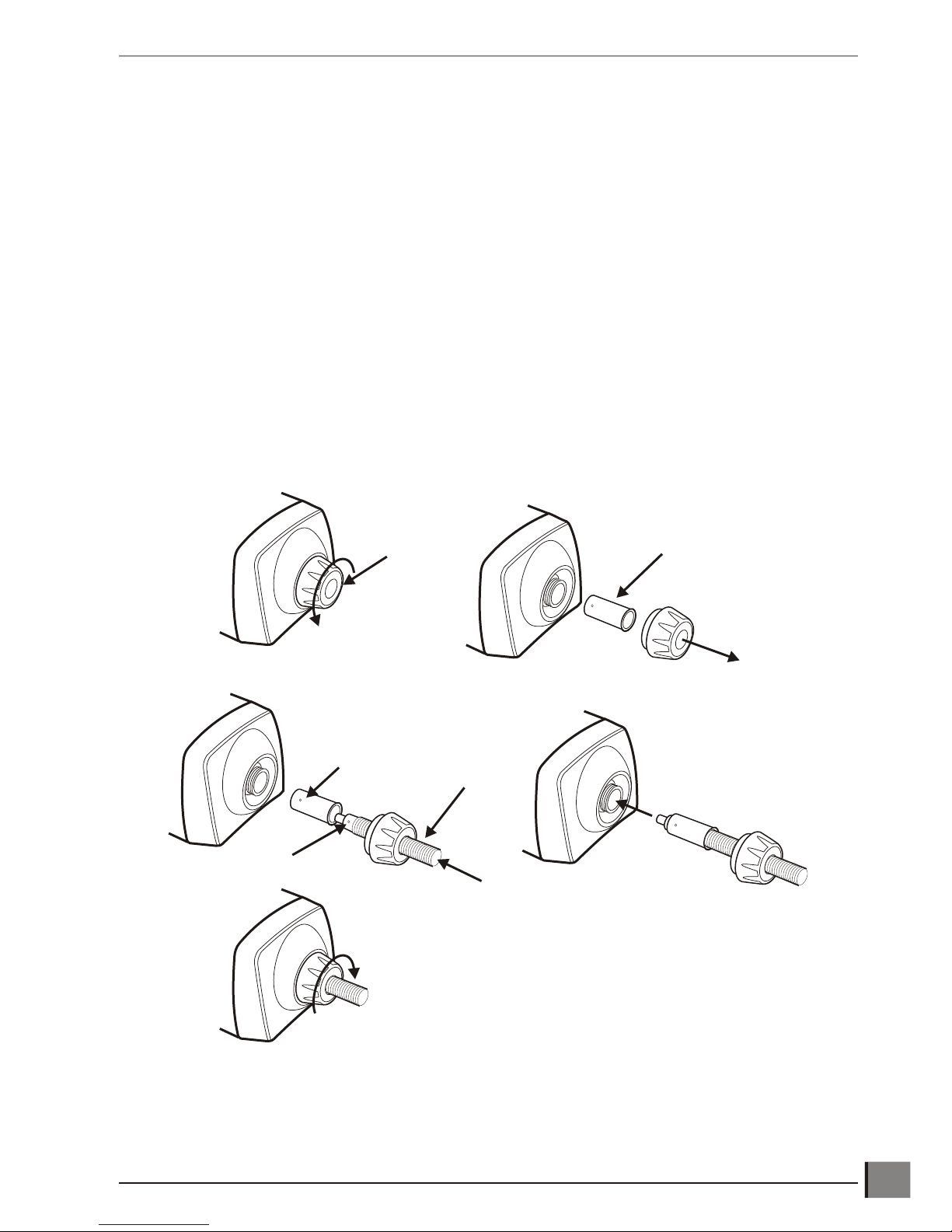

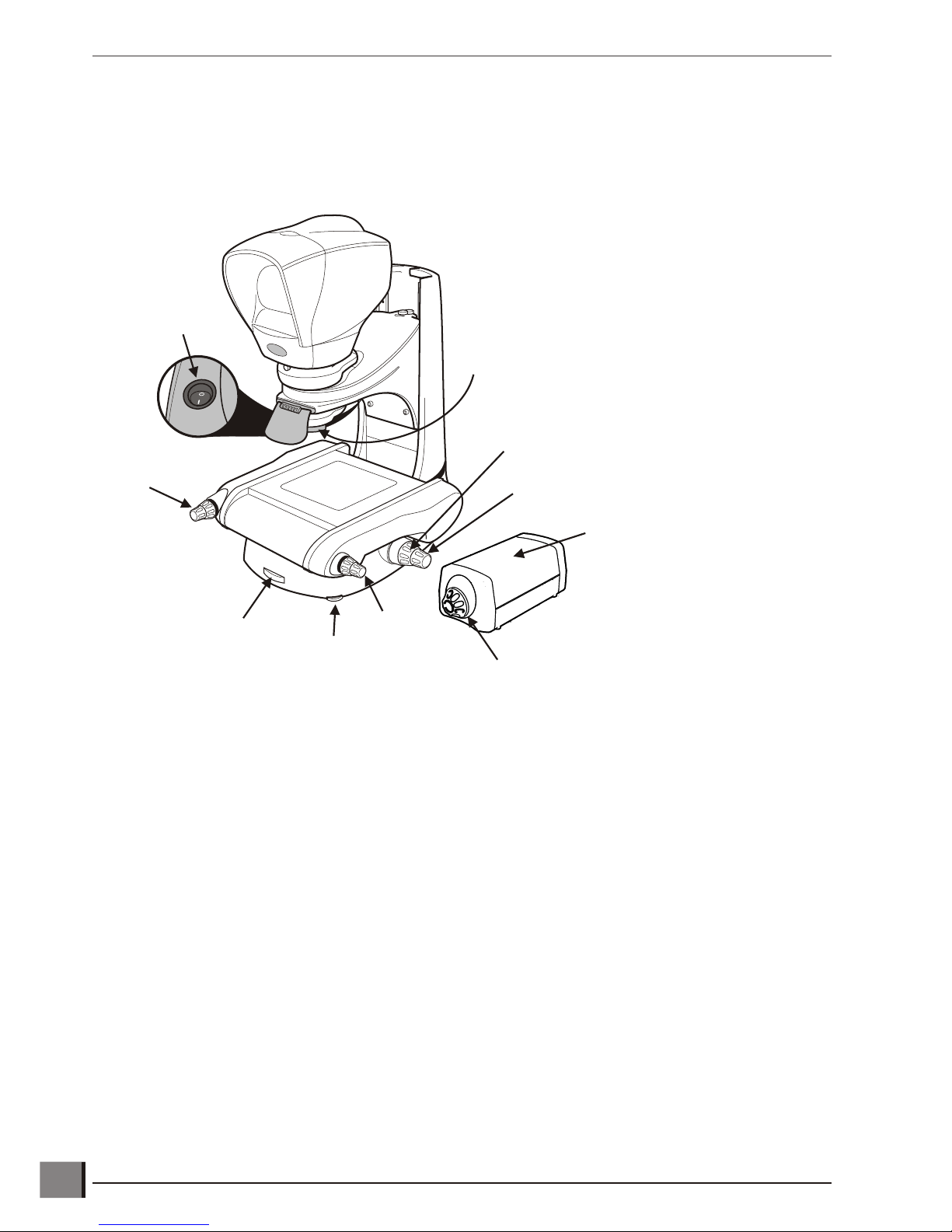

Connecting the fibre optic cable to the illuminator

u Unscrew the locking collar.

u Remove the locking collar and ferrule.

u Insert the fibre-optic cable through the locking collar and ferrule. Align the grub screw with the indent on the

cable and tighten the screw with the hexagonal/Allen key provided.

Note: The hexagonal/Allen key is taped to the base of the illuminator.

u Insert the cable and ferrule into the illuminator.

u Tighten the locking collar.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

11

2

3

4

5

Fibre-Optic

Cable

Indent

Grub

Screw

Ferrule

1

Locking

Collar

QC-200/QC-300 microprocessor assembly

Cable connection points are shown on page 13.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

12

Stand

Standard

Bolt

Shoulder

Bolt

Locking

Washer

NOTE:

Do Not Over-tighten

Spacer

Stand

Microprocessor

Microprocessor

Stand

Microprocessor

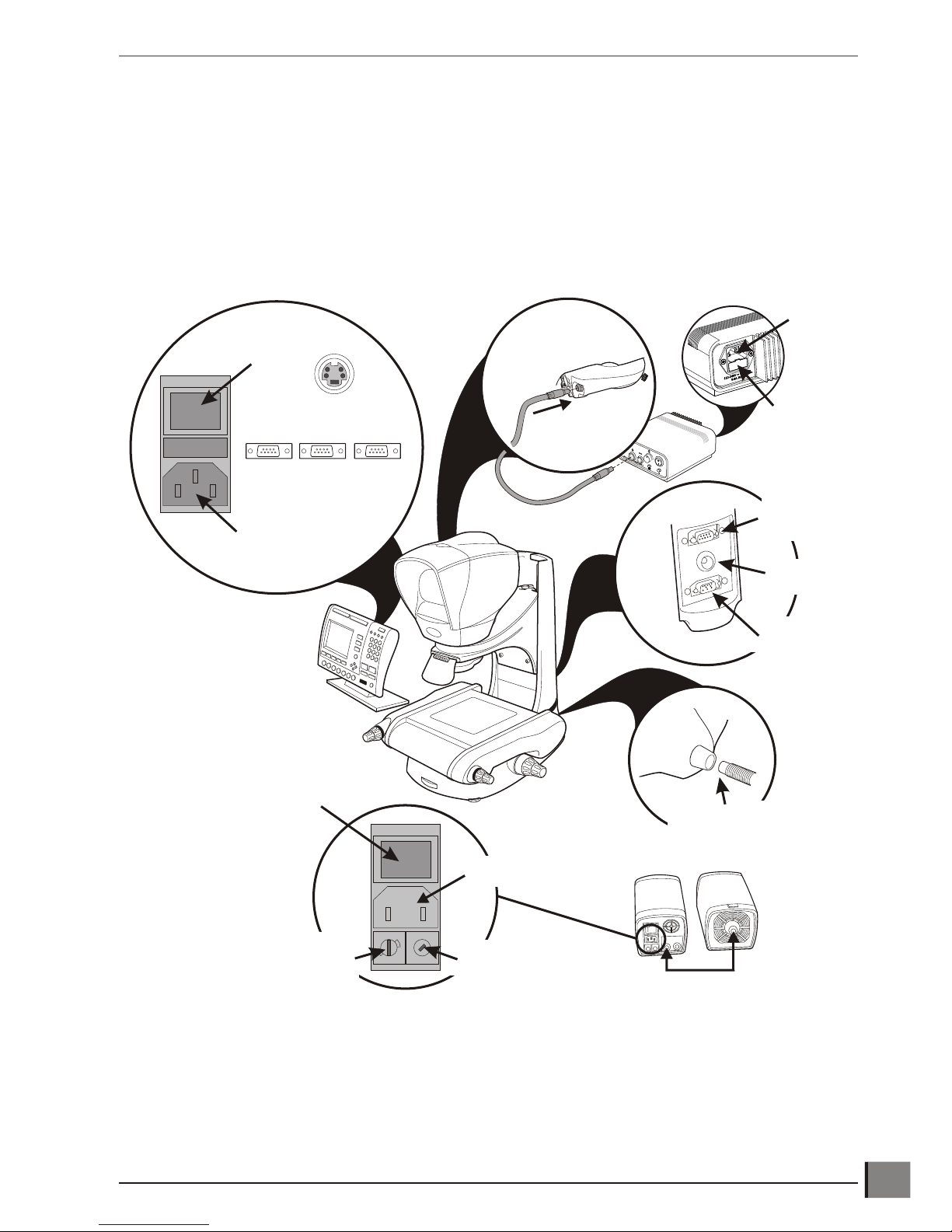

Cable connection points for the manual QC-200/QC-300 system

Refer to pages 14 and 15 for detailed connections.

Note: Ensure that the voltage selector is turned to the correct setting.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

13

Mains

Input

Mains

On/Off

Switch

Fuse

Z Axis

Encoder

Head Power

Transformer

Z Axis

Motor

Sub-Stage Illuminator

Fibre-Optic Connector

DC Connection

red = 100W

blue = 150W

EPI = 100W

Sub-Stage = 100W

X Axis Y Axis Z Axis

S-Video (QC-300 only)

1

1

5

230

Voltage

Selector

Input

Power

Fuse

Mains

On/Off

Switch

Mains

Input

Ringlight Connection

Mains

Input

Input

Power

Fuse

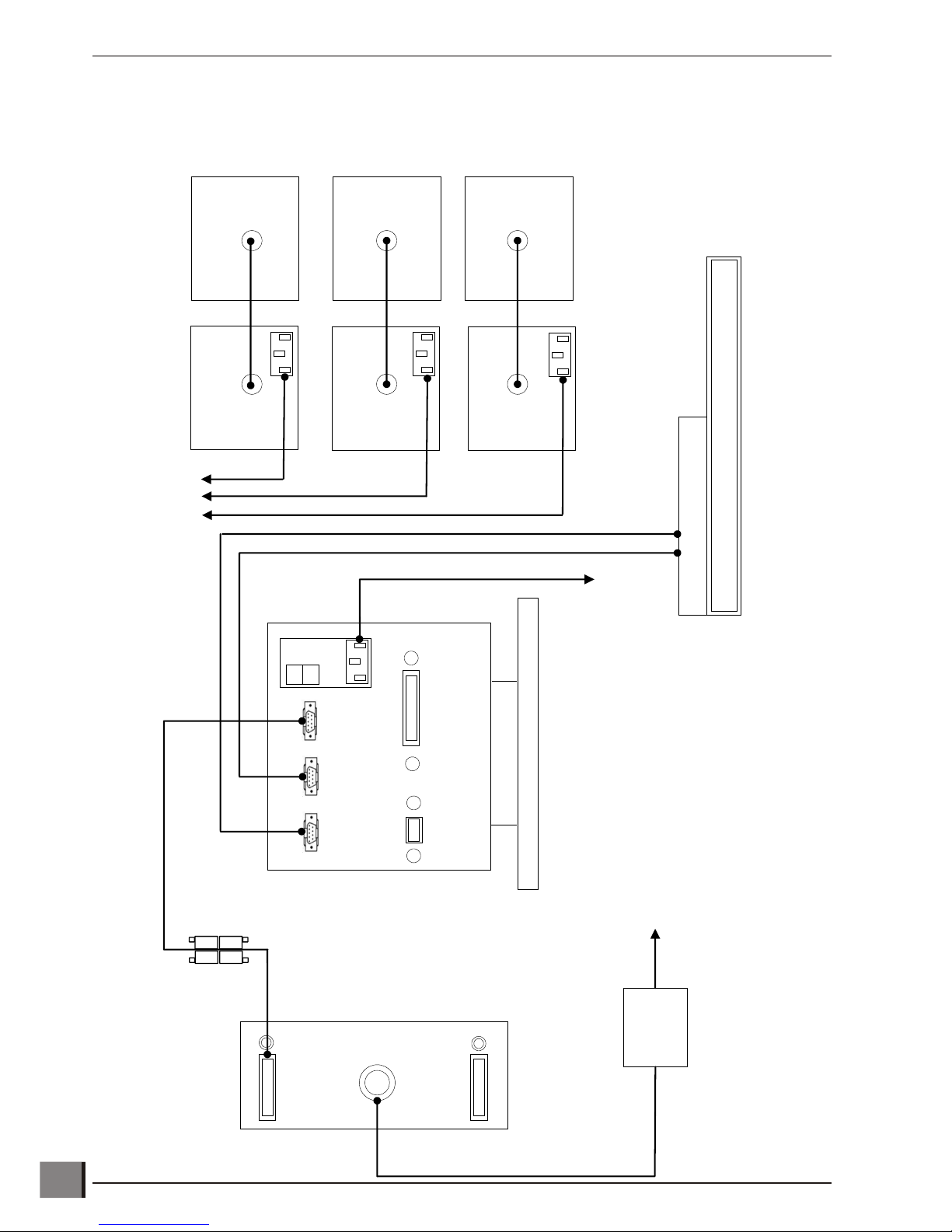

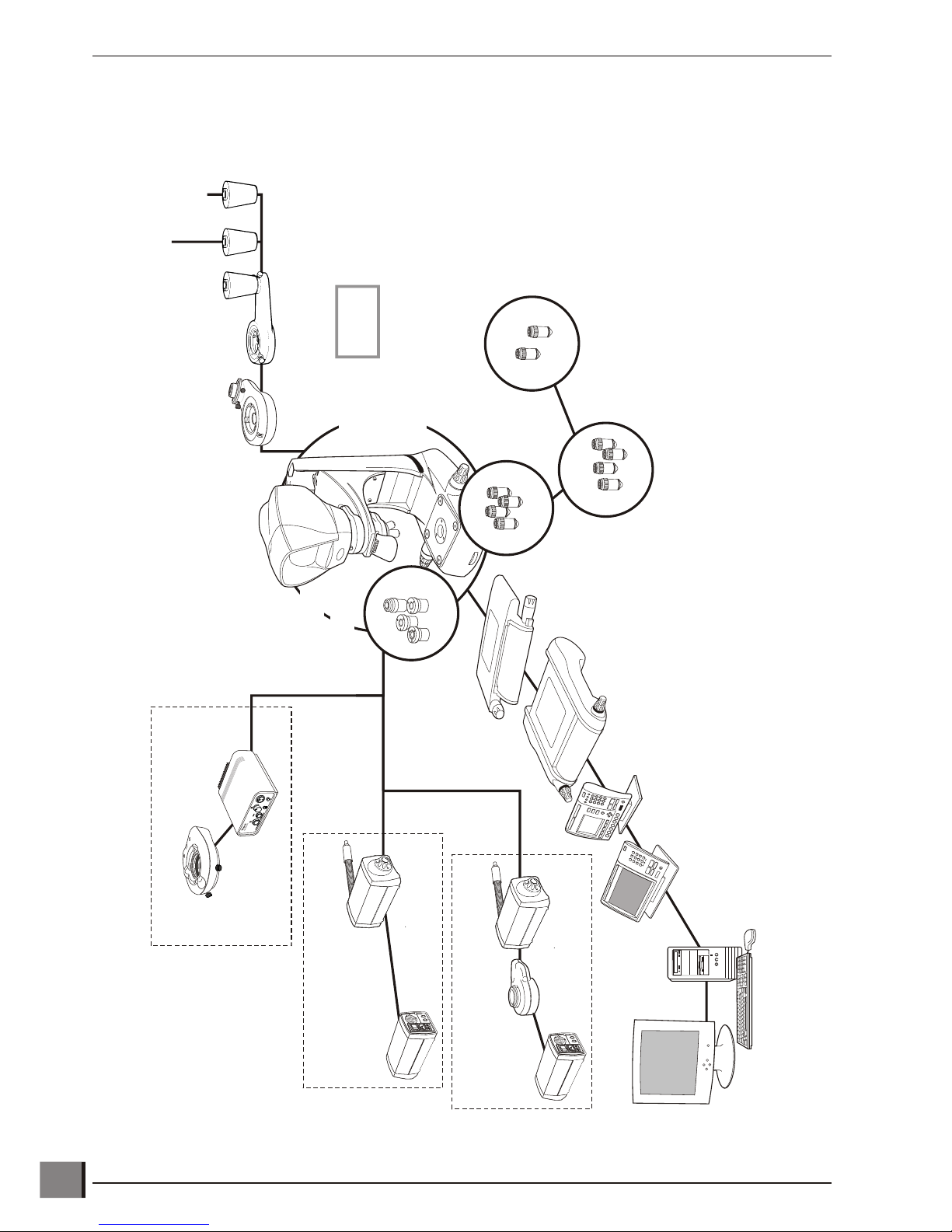

Interconnection diagram for manual Hawk system with QC-200

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

14

Substage Illumination

Light Source

LED Ringlight

Illuminator

Episcopic Illumination

Light Source

Substage PSU

LED Ringlight

Control Box

EPI PSU

XZY

XY

Mains Supply

Z Axis Encoder

Z Axis Motor

Hawk Stand

QC-200

Stage Encoders

Mains Supply

Mains Supply

Transformer

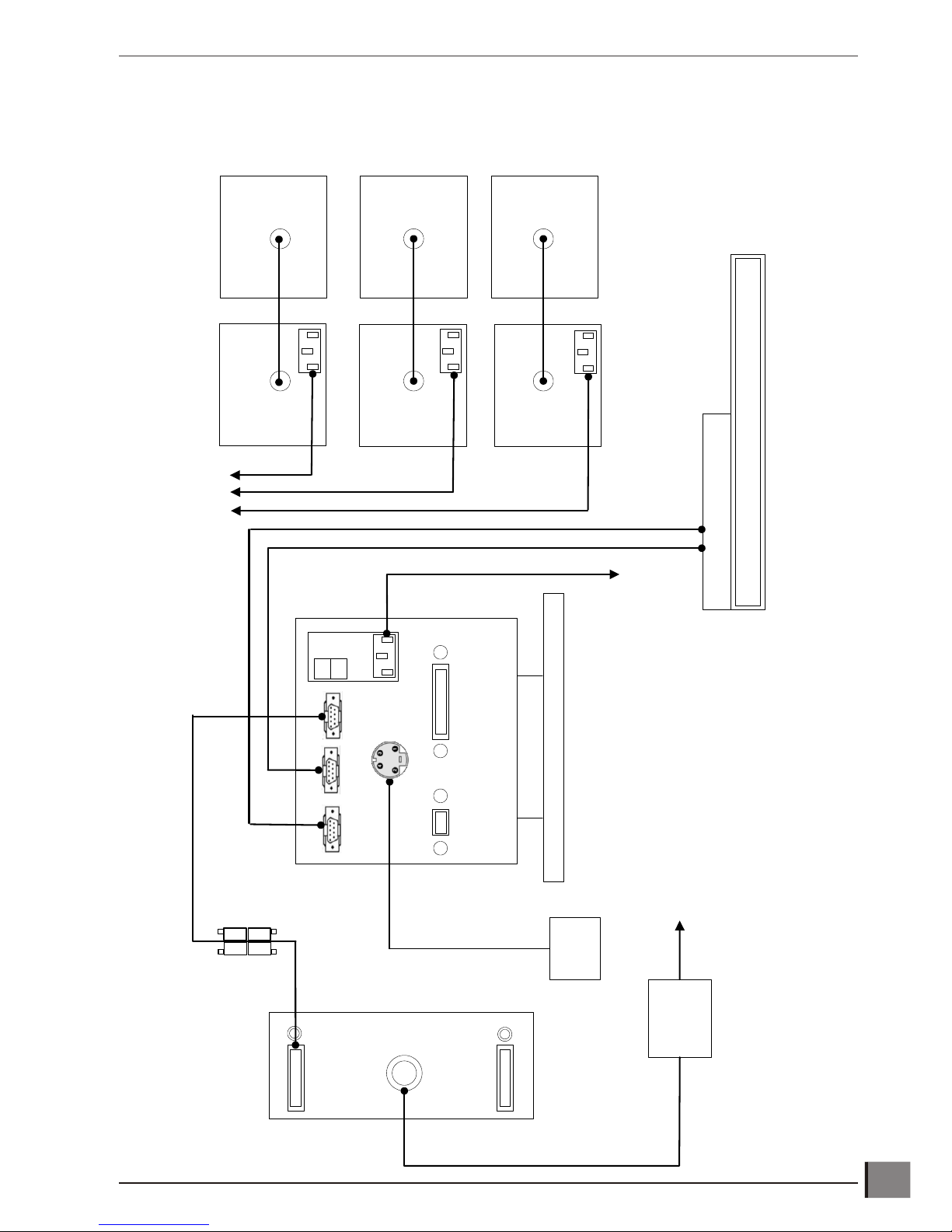

Interconnection diagram for manual Hawk system with QC-300

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

15

Substage Illumination

Light Source

Episcopic Illumination

Light Source

Substage PSU

EPI PSU

XZY

XY

Mains Supply

Z Axis Encoder

Z Axis Motor

Hawk Stand

QC-300

Stage Encoders

Mains Supply

Mains Supply

Transformer

Camera

S-Video Cable

LED Ringlight

Illuminator

LED Ringlight

Control Box

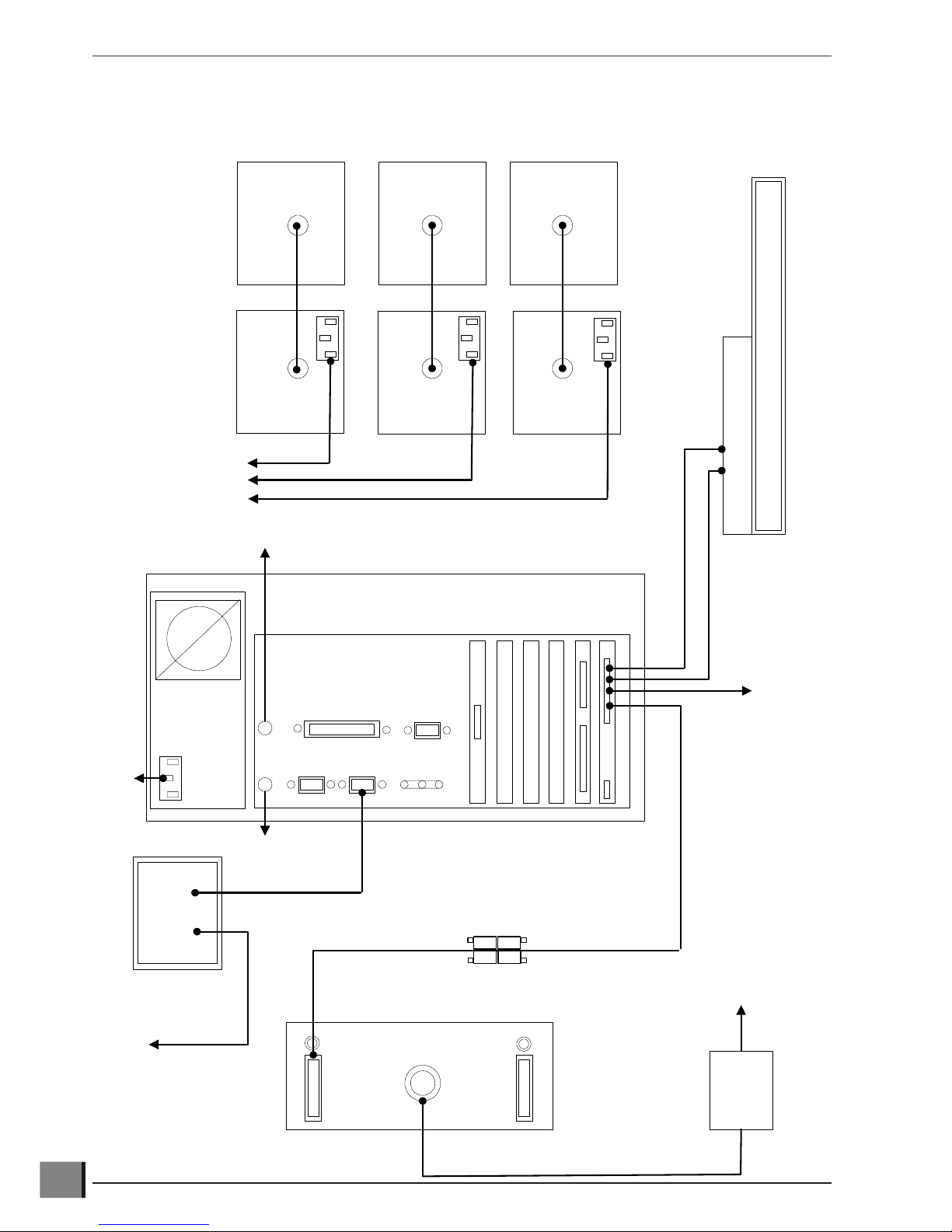

Interconnection diagram for Hawk system with manual QC-5000

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ASSEMBLY

16

Substage Illumination

Light Source

Episcopic Illumination

Light Source

Substage PSU

EPI PSU

X

Y

Mains Supply

Z Axis Encoder

Z Axis Motor

Hawk Stand

Stage Encoders

Mains Supply

Monitor

Transformer

To Footswitch

Keyboard

Mouse

Mains Supply

Head Power

Mains Supply

LED Ringlight

Illuminator

LED Ringlight

Control Box

Interconnection diagram for Hawk system with QC-5000 VED

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ASSEMBLY

17

Substage Illumination

Light Source

Episcopic Illumination

Light Source

Substage PSU

EPI PSU

X

Y

Mains Supply

Z Axis Encoder

Z Axis Motor

Hawk Stand

Stage Encoders

Mains Supply

Monitor No 1

Transformer

To Footswitch

Keyboard

Mouse

Mains Supply

Head Power

Mains Supply

Monitor No 2

Camera

S-Video Cable

LED Ringlight

Illuminator

LED Ringlight

Control Box

SETTING UPManual system controls

Turn on the illuminator power supplies and check that the LED at the centre of the head is illuminated.

The manual system controls are identified below.

Align head to stage

u Ensure that an objective lens is fitted.

u Ensure the head is switched on and then loosen it using an hexagonal/Allen key.

u Align the front edge of the gauge block (or straight edge) with the front edge of the stage glass.

u Rotate the head until the horizontal cross line is parallel with the rear edge of the gauge block (or straight edge).

u Lock the head in position with the hexagonal/allen key.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

SETTING UP

18

Fine

Focus

Control

Coarse

Focus

Control

Y Axis

Control

On/Off

Switch

X Axis

Control

Substage

Iris Control

Levelling

Foot

Illuminator Dimmer

Illuminator

Power Supply

Objective Lens Macro - Open Iris - decrease depth of field

- Close Iris - increase depth of field

Micro (EPI) - turn dial clockwise - decrease depth of field

- turn dial anticlockwise - increase depth of field

Stand levelling

u Adjust the levelling foot until the stand is stable.

Stage glass levelling

u Adjust the X and Y axis controls to bring the rear

left-hand corner of the stage glass (fixed corner) into

view.

u Adjust the coarse/fine focus control to bring

the glass surface into sharp focus.

u Adjust the X and Y axis controls to

bring the front left-hand corner

into view.

u Use the relevant adjustable glass

support to bring the surface of the

glass into sharp focus.

u Repeat the above procedure for the

remaining two corners.

Camera Setup

u Loosen hexagonal headed screws u on locking plate v and continue to

turn camera w until it is in the correct position.

u Connect the camera from its video connector x to the Quadra-Chek system

using S-Video cable.

u Attach power lead to camera's power socket y and

switch on.

u Bring the target/slip into focus within the head, as centrally

aligned to crosshair as possible.

u Match the view on the monitor with that in the head - move the

camera by using the thumbscrews z.

u Tighten the hexagonal headed screws on the locking plate to hold camera

in position.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

SETTING UP

19

X Axis

Control

Fixed

Corner

Adjustable

Glass Supports

Y Axis

Control

u

v

w

x

y

z

OPERATIONTo achieve the optimum results from the Hawk Measuring System, the illumination and optics need to be adjusted to

provide the best possible image to the operator. Certain lighting options are better for some applications than others.

Illumination and focus should be adjusted until the image is clear and bright, with good contrast. Maximum contrast

gives the best image resolution and allows for the highest level of accuracy and repeatability.

Contact the nearest Vision Engineering branch/distributor for further advice.

Objective lens

Iris control

Each Macro objective lens has an adjustable iris which restricts the aperture of the lens. By rotating the control ring

on the bottom of the objective lens, the iris opens and closes. Adjusting the objective lens aperture slightly increases

or decreases the depth of field. This feature is useful for subjects where greater surface definition is required. The

same results can be achieved with a Micro objective lens by adjusting the iris wheel in the Episcopic illuminator.

Closing the Substage Iris improves ability to locate an edge on a cylindrical component/raised profile.

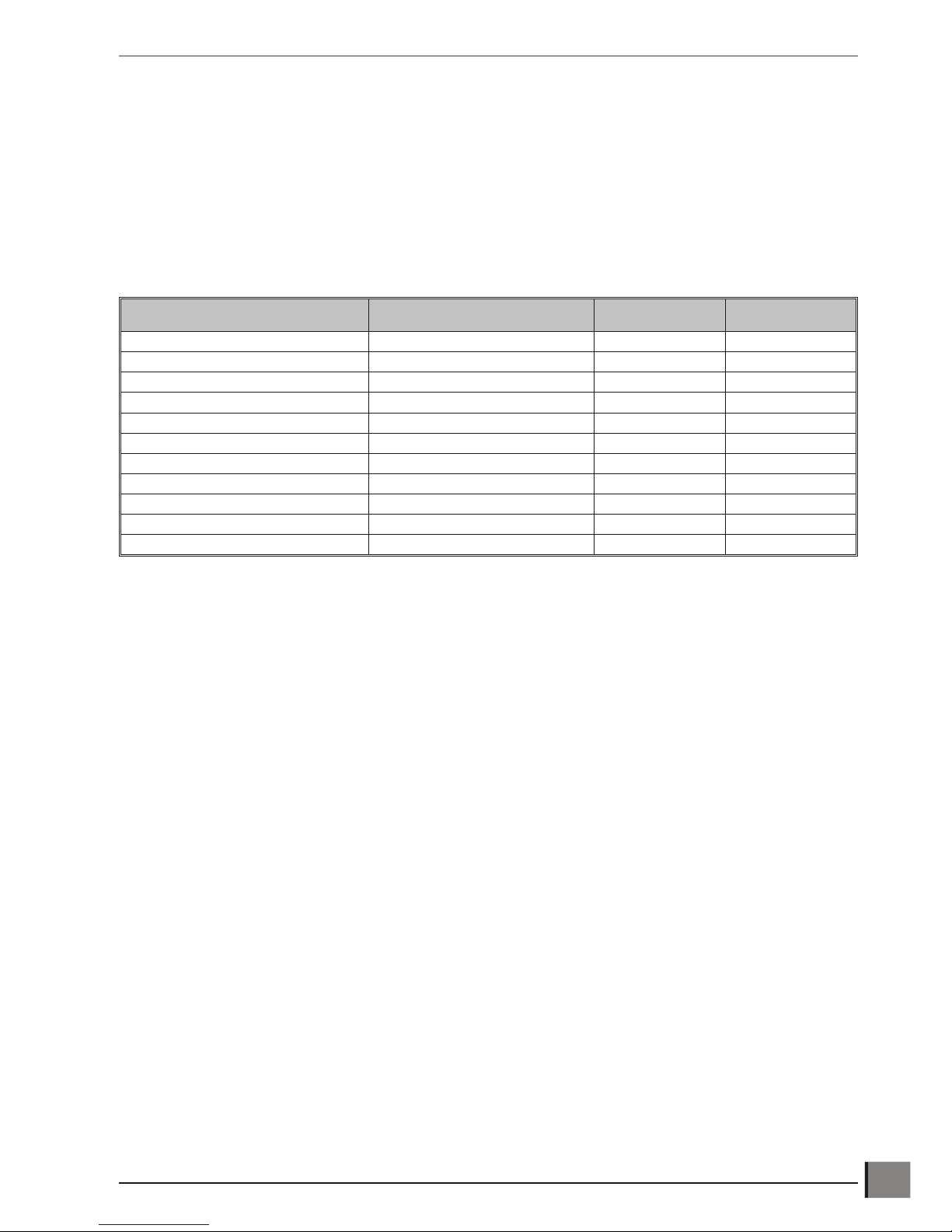

Magnification tables

Macro Lenses

Part No. Objective Lens Total Magnification Working Distance

Field of View

(diameter)

Depth of Field

H-007 x1 10x 84mm 14.2mm 270µm

H-008 x2 20x 81mm 7.1mm 67µm

H-009 x5 50x 61mm 2.8mm 10µm

H-0010 x10 100x 32mm 1.4mm 6µm

Standard Working Distance Micro Lenses

Part No. Objective Lens Total Magnification Working Distance

Field of View

(diameter)

Depth of Field

H-110 x5 50x 20.0mm 4.4mm 12.22µm

H-100 x10 100x 10.1mm 2.2mm 3.06µm

H-101 x20 200x 3.1mm 1.1mm 1.3µm

H-103 x50 500x 0.66mm 0.44mm 0.3µm

Long Working Distance Micro Lenses

Part No. Objective Lens Total Magnification Working Distance

Field of View

(diameter)

Depth of Field

H-104 x10 100x 21.0mm 2.2mm 4.4µm

H-105 x20 200x 12.0mm 1.1mm 1.72µm

H-106 x50 500x 10.6mm 0.44mm 1.10µm

H-107 x100 1000x 3.4mm 0.22mm 0.43µm

Super Long Working Distance Micro Lenses

Part No. Objective Lens Total Magnification Working Distance

Field of View

(diameter)

Depth of Field

H-108 x20 200x 21.0mm 1.1mm 2.24µm

H-109 x50 500x 15.0mm 0.44mm 1.36µm

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

OPERATION

20

Episcopic illuminator

The Episcopic illuminator provides through the lens illumination for measuring deep surface features, holes and blind

bores. The light follows the optical path through the objective lens. The following adjustment can be made:

• Ad just the sur face light ing to suit the com po nent by us ing the thumbwheel and the beam split mir ror.

• Adjust light intensity by rotating the dial control on the light power supply unit.

• Adjust the depth of field of the objective lens by rotating the iris control thumbwheel (a smaller iris increases

the depth of field).

• To change the image contrast fully engage the beam split mirror control lever.

LED Ringlight

The Ringlight illuminator is used as follows:

• To il lu mi nate op ti cally dif fi cult sur faces/sur face fea tures.

• For use with Macro ob jec tive lenses.

• The Ringlight gives a shadow free im age.

• Can be used with Episcopic and Substage il lu mi na tion.

To adjust the light intensity rotate the dial control on the control box (see page 22).

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

OPERATION

21

Control Lever

Macro EPI

Thumbwheel

Control box

Icons

The icons on the front panel of the control box symbolise the following:

On/Off switch

Power on indicator

Illuminator intensity control

Ringlight connection point

Refer to manual

HEAD Power for viewing unit (boom mount only)

Controls

The LED ringlight, which can be used with substage

illumination, provides above stage il lu mi na tion and is used

for illuminating sur face fea tures, blind holes, etc.

u Switch the unit on u and adjust intensity by

rotating the dimmer control v.

u The LED illuminator is provided with a temperature

protection system w to ensure long term LED

performance is not compromised by overheating.

u If the temperature protection indicator illuminates,

the power to the LED's will gradually reduce until the temperature

stabilises. If the indicator remains illuminated, remove the illuminator and

ensure neither the air inlet around the objective, nor the fan outlet are obstructed.

LED illuminator specification

The LED illuminator unit has an integral power supply with the following specification:

Input voltage: 110 to 240v ~ 50/60Hz 0.9A max

Fuse rating: 110v 1.0A anti-surge

230v 0.5A anti-surge

The fuse is located in the IEC mains connector on the rear of the control box (see page 13).

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

OPERATION

22

0

1

v

w

u

Substage

The Substage illumination is used for the accurate measurement of through holes, profiles and edge features etc.

The depth of field is adjusted by rotating the thumbwheel on the Hawk base.

The illumination can be used with spotlight, ringlight and EPI illumination systems.

Adjust light intensity by rotating the dial control on the illumination power supply unit.

Taking a measurement (QC-200)

Select the correct lens for the component being measured, based on the size of the component and field of view

requirements (refer to magnification tables on page 20).

Focus on the component or feature being measured, firstly use the Z axis coarse control and then the fine control until

the component or feature is in focus.

A measurement is made by moving the stage and subject under the cross-line graticule, visible through the

dynascopic viewing head.

Features and dimensions are measured by aligning the cross-line with the desired feature and entering the preset

number of points evenly distributed around the feature.*

A point is measured by aligning the cross-line on a single point.

Lines can be measured by aligning the cross-line at a minimum of two points.

Circles can be measured by aligning the cross-line at a minimum of 3 points on its circumference.

The software will calculate the result based on the points entered and display in the results window. Distances are

calculated by selecting relevant features and selecting the distance function.

The accuracy of the stage movement is achieved by the application of NLEC (Non Linear Error Correction) which

compensates for any mechanical stage errors across the calibrated stage area. The unique NLEC file, relating to the

relevant stage is stored in the Quadra-Chek.

*Further Details on taking measurements can be found in the relevant Quadra-Chek user guide.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

OPERATION

23

Thumbwheel

Taking a measurement (QC-300/QC-5000 VED)

Select the correct lens for the component being measured, based on the size of the component and field of view

requirements (refer to magnification tables on page 20).

Focus on the component or feature being measured. Use the Z axis control until the component or feature is in focus.

A measurement is made by moving the stage so that subject or the start of the subject is within the field of view,

dependent on the feature being measured.*

A point is measured by aligning the simple tool on a single point. Lines can be measured by aligning the simple tool

on two points (minimum) on the line. Circles can be measured by aligning the simple tool on three points (minimum)

around the circle. A point can also be measured by selecting the single or multipoint tool on the QC-300 and probing

single or multiple points on selected features.

Features and dimensions are measured by selecting the appropriate QC-5000 video tool, from the toolbar, aligning

the tool over the feature being measured. After performing a simple tool teach the tool is fired and the

predetermined number of points will scan across the tool area and find the edge of the feature.

The software will calculate the result based on the points entered and display in the results window. Distances are

calculated by selecting relevant features and selecting the distance function.

*Further Details on taking measurements can be found in the relevant Quadra-Chek user guide.

Good working practices

When selecting points on features the point should always be approached in the same fashion, e.g. always work

towards a point in the X axis first, moving from left to right and then move towards a point in the Y axis, moving from

top to bottom.

This procedure will increase repeatability. If looking to measure the form of a feature, it is best to take at least eight

points to achieve the most repeatable result.

Note: Contact your local Vision Engineering representative for full details of available training

programs.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

OPERATION

24

ROUTINE MAINTENANCE

Routine maintenance is important for the longstanding of the Hawk Measuring System. For more complex

maintenance contact the local Vision Engineering representative.

Graticule adjustment

u Undo the securing clip at the base of the front cover and lift the cover off.

u To focus and centralize each graticule, loosen the appropriate retaining knob and move the graticule up or down

to focus. Re-tighten the retaining knob.

u To adjust the graticules, place a known 90º gauge (slip gauge or crossline) on the stage and focus the image.

Close one eye and locate the crossline on the corner of the gauge by unlocking and adjusting the grubscrews.

Once the image is located, lock the grubscrews with the locking nuts.

u Repeat the procedure using the other eye. Make the adjustment so that the graticules overlay each other.

Note: If the image is uncomfortable to the eyes, repeat the above procedure.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ROUTINE MAINTENANCE

25

Graticules

Gauge

Crossline

Graticule Lock Nuts & Grubscrews

(2 per Graticule)

Retaining Knobs

Securing Clip

WARNING

DISCONNECT THE MAINS POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE ROUTINE

Changing the illuminator lamp

CAUTION: Allow the illuminator to cool down before carrying out this task.

u Press down the lamp/fan assembly release button u.

u Lift out the lamp/fan assembly v.

u Remove the lamp as shown w.

u Insert the replacement lamp and check that it is fully pushed into the lamp holder.

Note: DO NOT touch the base, pins or filament assembly of the new bulb during installation. Oil from

hands can cause premature bulb failure. The bulb should only be held by its reflector.

u Periodically inspect the cooling fan and its vents for debris build-up. The front and rear vents must be clean to

allow adequate airflow. Inadequate airflow will result in increased operating temperatures and reduced bulb life.

The fan should be running whenever power is supplied to the illuminator.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ROUTINE MAINTENANCE

26

WARNING

REMOVE POWER FROM THE SYSTEM BEFORE OPENING THE CASE.

u

v

w

General care

• Cover the Hawk with a dust cover when not in use.

• Remove dust with a soft brush or cleaning cloth.

• The viewing screen and lenses should be cleaned with a lens cleaning cloth.

• Keep accessories in a dust-free environment when not in use.

Consumable and replacement parts

Item Specification

Quantity

in Pack

Part

Number

Substage/Episopic Bulb (Illuminator Bulb) 100w/12v Halogen Lamp 1 LAM-1770

Spotlight Bulb 20w/12v Lamp 1 LAM-1300

Stage Glass 150x150mm 1 201-B0686

Stage Glass 200x150mm 1 184-B0227

Stage Glass 300x225mm 1 159-B0394

Stage Glass 400x300mm 1 159-B0452

Anti-Glare shield Hinged Anti-Glare shield 1 188-A1001/A

100W PSU Fuse 1.6 amp Anti-Surge 1 FUS-0243

100W PSU Fuse 800 ma Anti-Surge 1 FUS-0255

150W PSU Fuse 2.5 amp Anti-Surge 1 FUS-0395

150W PSU Fuse 1.5 amp Anti-Surge 1 FUS-2367

Environmental conditions

Hawk is an accurate, industrial gauging instrument. To achieve the optimum accuracy and repeatability, the following

considerations should be taken into account:

• Po si tion the Hawk on a firm, rigid ta ble.

• Do not position the instrument near any source of vi bra tion.

• Ensure that the illuminator power supplies have sufficient ven ti la tion.

• Do not position the instrument close to a radiator or similar heating sys tem.

• Do not position the instrument in direct sunlight, or where bright reflections will prevent a com fort able viewing

position.

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

ROUTINE MAINTENANCE

27

ACCESSORIES & OPTIONS

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

ACCESSORIES & OPTIONS

28

STANDARD

Core Instrument

Head

Assembly H-001

100W/12V Transformer

(EPI)

100V

115V

220V

240V

100W/12V Transformer

100V

115V

220V

240V

Fibre Optic

H-017

Fibre Optic

H-017

100W Illuminator

H-043

PSU

H-044

EPI

H-015/H-016

PSU

H-044

Substage Illuminator

H-043

200mm x 150mm

Manual Precision Stage

H-081

150mm x 150mm

Manual Stage

H-080

Dust Cover

H-200

Photographic

Attachment

H-070

Photographic

Attachment

H-011

Camera Adaptor

(C-mount)

H-074

Canon A620 Adaptor

K-027

Macro

Lenses

10x H-007

20x H-008

50x H-009

100x H-010

Standard Working Distance

Micro Lenses

50x H-110

100x H-100

200x H-101

500x H-103

Long Working Distance

Micro Lenses

100x H-104

200x H-105

500x H-106

1000x H-107

Super Long Working Distance

Micro Lenses

200x H-108

500x H-109

QC 200

2 axis - H-050

3 axis - H-051

QC 300

2-Axis (VED) H-047

3-Axis (VED) H-048

3-Axis H-046

QC 5000

3 axis - H-052

Monitor

H-054

Bench

Stand

H-002

complete with

High Intensity

Substage Illuminator

& Diffuser Kit

x 10

x 20

x 50

x 100

x 100

x 200

x 500

x 50

x 100

x 500

x 200

x 1000

x 200

x 500

LED Ringlight

LED Control Box

H-078

OTHER SOLUTIONS FROM VISION ENGINEERINGVision Engineering manufactures a wide range of stereo inspection and non-contact measuring systems. The

following tables provide a summary of the products utilising Vision's technology. For more information on any of

these products either visit the website or contact the nearest Vision Engineering branch/distributor.

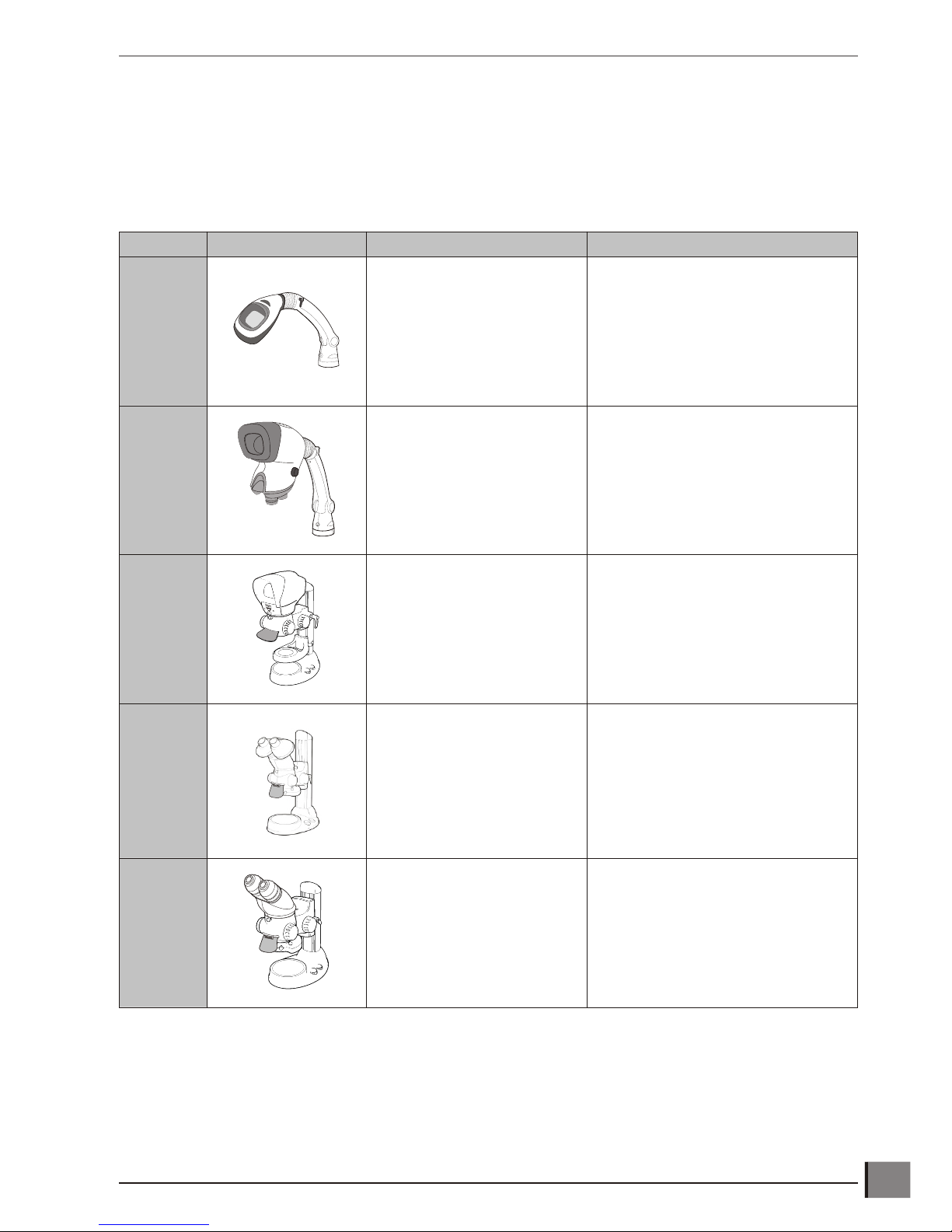

Stereo inspection systems

Product Picture Features Description

Lentis

• 2.5 dioptres

• Multi lay ered anti re flec tive

coated lens

A state of the art bench magnifier for

inspection, manipulation and material

rework.

Mantis

• x2 - x20 Mag ni fi ca tion

• Shadow-free LED cold

il lu mi na tion, both sur face and

substage

• Long work ing dis tances,

large depth of field

The Mantis family is a unique range of

optical systems without eyepieces, for

intricate tasks requiring superb quality

viewing over long periods of use.

Available with universal arm or rigid

bench stand option.

Lynx

• X2.1 - X120 mag ni fi ca tion

• Camera op tion

• Optical viewing head

(re places con ven tional

eye pieces).

Advanced optical system (without

eyepieces) stereo zoom microscope.

Available in boom and rigid stand

configuration with a wide range of

optional accessories (e.g. lighting,

cameras).

Alpha

• x2.1 – x160 mag ni fi ca tion

• Cam era op tion

• Ex panded Pu pil eye pieces

Expanded Pupil eyepiece stereo zoom

microscope. Available in boom and

bench stand configuration with a wide

range of optional accessories (e.g.

lighting, cameras)

Beta

• x2.1 – x160 mag ni fi ca tion

• Cam era op tion

• Con ven tional eye pieces

Conventional eyepiece stereo zoom

microscope. Available in boom and

bench stand configuration with a wide

range of optional accessories (e.g.

lighting, cameras)

www.visioneng.com/support Hawk 2 or 3-Axis Manual Non-Contact Measuring System

29

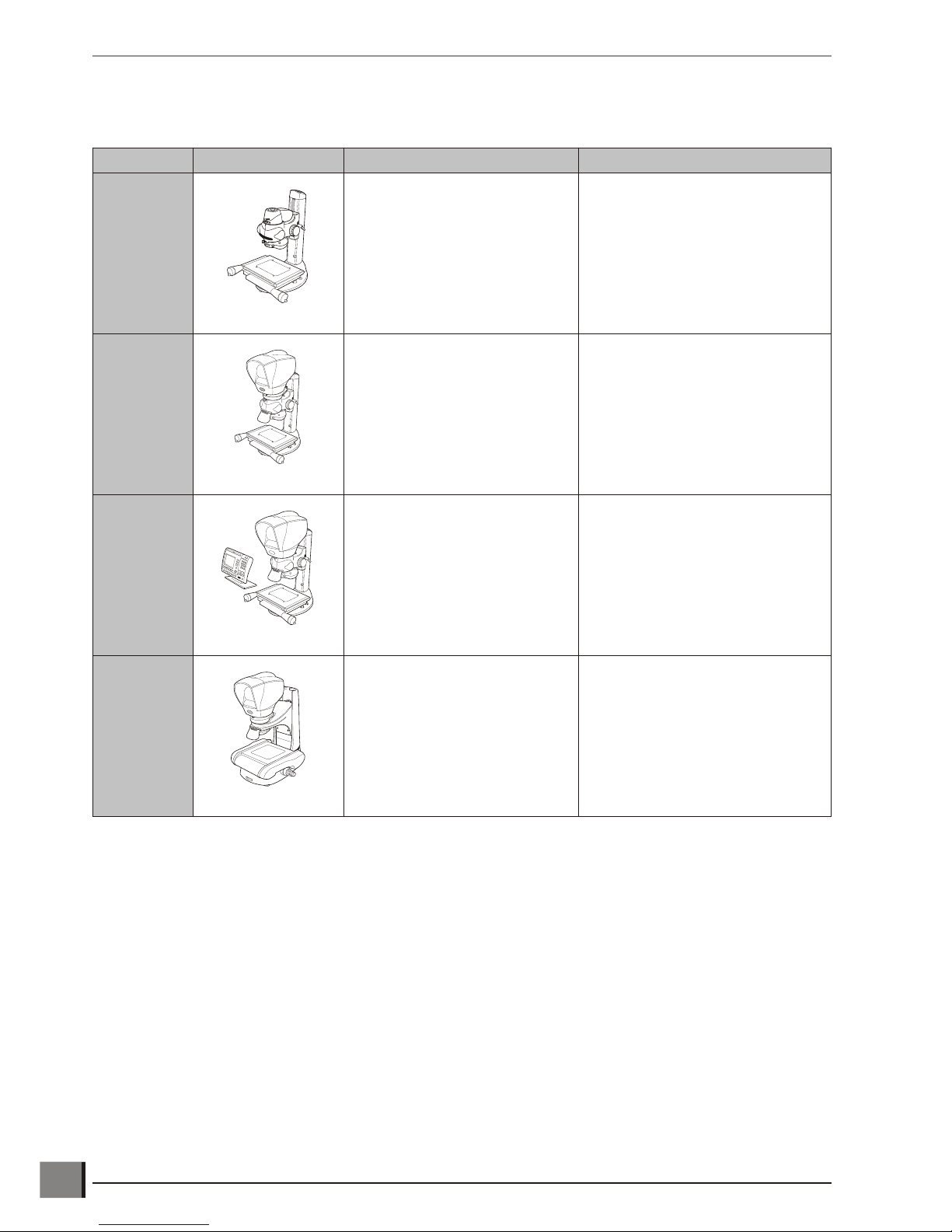

OTHER SOLUTIONS FROM VISION ENGINEERING

Non-contact measuring systems

Product Picture Features Description

Merlin

• 150mm x 100mm stage

• x10 - x50 mag options

• QC-300 Microprocessor

• Manual/Automatic Video Edge

Detection

2-axis video measuring system with

touch screen video processor.

Powerful yet simple to use, ideal for a

wide range of gauging applications.

Peregrine

• 150mm x 100mm stage

• x10 - x50 mag op tions

• QC-300 Mi cro pro ces sor

• Au to mated video edge de tec tion

2-axis video measuring system with

optical and video measurement

capability. Simple to use, allowing for

quick results every time.

Kestrel

• 150mm x 100mm stage

• x10 - x50 mag options

• QC200 Mi cro pro ces sor

• Op ti cal view ing head

(re places con ven tional

eye piece)

Entry level, 2-axis measuring system.

Ideal for shop floor gauging

applications.

Hawk

automatic

• 200mm x 150mm stage

• x10 - x100 mag options

• Video Edge De tec tion

• Motor ised stage move ment

• 2 or 3 axis ca pa bil ity

Automated measuring system

combining optical viewing head with

PC based Video Edge Detection. 2

and 3 axis motorised stage

movement controlled by QC5000 PC

software.

Hawk 2 or 3-Axis Manual Non-Contact Measuring System www.visioneng.com/support

30

OTHER SOLUTIONS FROM VISION ENGINEERING

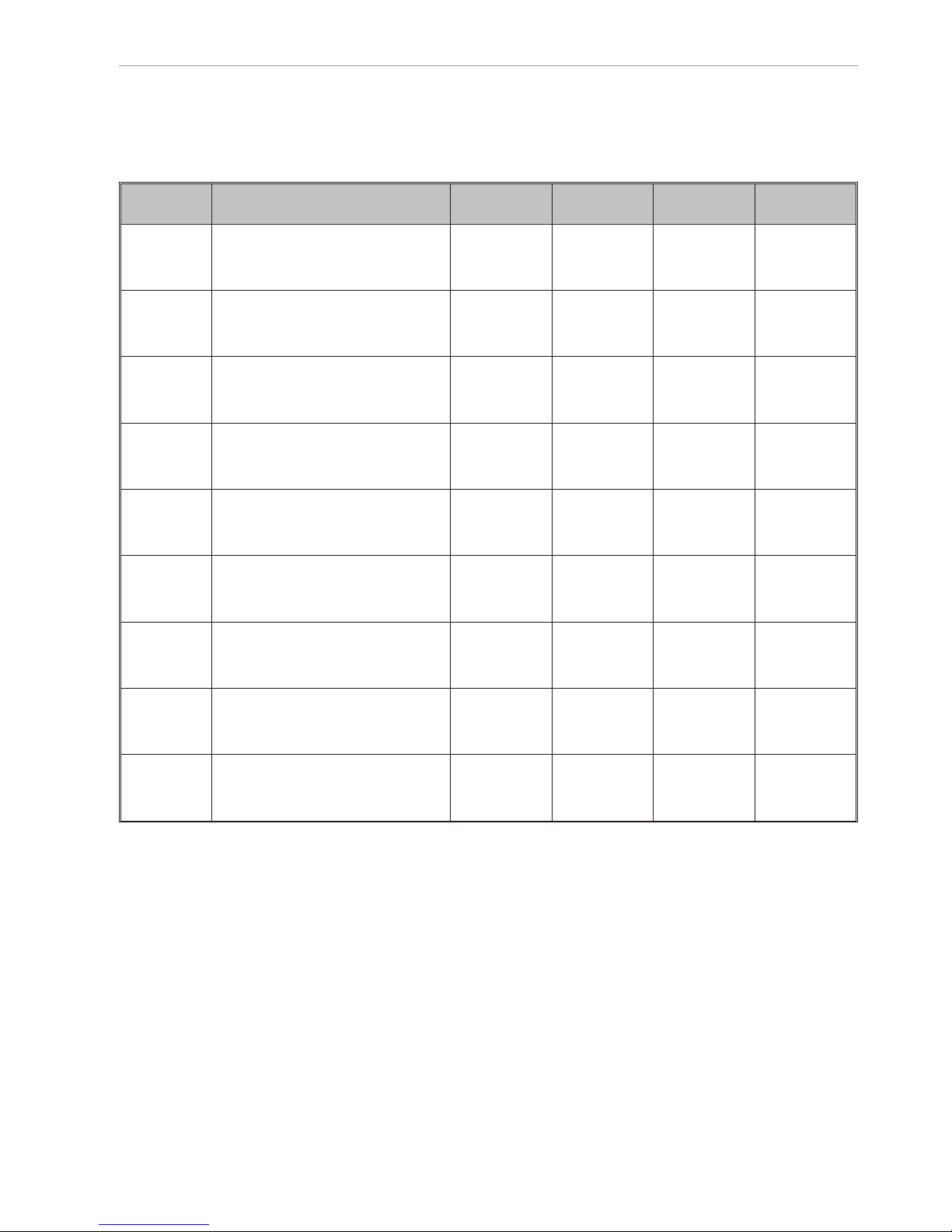

SERVICE & CALIBRATION RECORDHawk serial number ________________

Stage serial number ________________

Service type Comments

Date of

service

Date of next

service

Company Signature

SERVICE & CALIBRATION RECORD

WARRANTY

WARRANTY

This product is warranted to be free from defects in material and workmanship for a period of one year from the date of

invoice to the original purchaser.

If during the warranty period the product is found to be defective, it will be repaired or replaced at facilities of Vision

Engineering or elsewhere, all at the option of Vision Engineering. Shipment costs for warranty repairs, to and from Vision

Engineering facilities will not, normally, be borne by Vision Engineering. However, Vision Engineering reserves the right to

refund the purchase price if it is unable to provide replacement, and repair is not commercially practicable or cannot be

timely made. Parts not of Vision Engineering manufacture carry only the warranty of their manufacturer. Expendable

components such as fuses carry no warranty.

This warranty does not cover damage in transit, damage caused by misuse, neglect, or carelessness, or damage resulting

from either improper servicing or modification by other than Vision Engineering approved service personnel. Further, this

warranty does not cover any routine maintenance work on the product described in the user guide or any minor

maintenance work which is reasonably expected to be performed by the purchaser.

No responsibility is assumed for unsatisfactory operating performance due to environmental conditions such as humidity,

dust, corrosive chemicals, deposition of oil or other foreign matter, spillage, or other conditions beyond the control of

Vision Engineering.

Except as stated herein, Vision Engineering makes no other warranties, expressed or implied by law, whether for resale,

fitness for a particular purpose or otherwise. Further, Vision Engineering shall not under any circumstances be liable for

incidental, consequential or other damages.

Distributor

Visit our multi-lingual website:

LIT 1719 R2.1/02/08

www.visioneng.com

For more information...

Vision Engineering has a network of offices and technical distributors around the world. For more information,

please contact your Vision Engineering branch, local authorised distributor, or visit our website.

Vision Engineering Ltd.

(Manufacturing)

Send Road, Send, Woking,

Surrey, GU23 7ER, England

Tel: +44 (0) 1483 248300

Fax: +44 (0) 1483 223297

Email: generalinfo@visioneng.com

Vision Engineering Ltd.

(Commercial)

Monument House, Monument Way West,

Woking, Surrey, GU21 5EN, England

Tel: +44 (0) 1483 248300

Fax: +44 (0) 1483 248301

Email: generalinfo@visioneng.com

Vision Engineering Inc.

(Manufacturing & Commercial)

570 Danbury Road, New Milford,

CT 06776 USA

Tel: +1 (860) 355 3776

Fax: +1 (860) 355 0712

Email: info@visioneng.com

Vision Engineering Inc.

(Commercial West Coast USA)

745 West Taft Avenue, Orange,

CA 92865 USA

Tel: +1 (714) 974 6966

Fax: +1 (714) 974 7266

Email: info@visioneng.com

Vision Engineering Ltd.

(Central Europe)

Anton-Pendele-Str. 3,

D-82275, Emmering, Germany

Tel: +49 (0) 8141 40167-0

Fax: +49 (0) 8141 40167-55

Email: info@visioneng.de

Nippon Vision Engineering

(Japan)

272-2 Saedo-cho, Tsuduki-ku,

Yokohama-shi, 224-0054, Japan

Tel: +81 (0) 45 935 1117

Fax: +81 (0) 45 935 1177

Email: info@visioneng.jp

Vision Engineering Ltd.

(France)

1 Rue de Terre Neuve, ZA Courtaboeuf,

91967 Les Ulis Cedex, France

Tel: +33 (0) 164 46 90 82

Fax: +33 (0) 164 46 31 54

Email: info@visioneng.fr

Vision Engineering Ltd Italia

(Italy)

20092 Cinisello Balsamo MI, Italy

Tel: +39 02 6129 3518

Fax: +39 02 6129 3526

Email: info@visioneng.it

Via Cesare Cantù, 9

Vision Engineering Ltd

(China)

11J, International Ocean Building,

720 Pudong Avenue, Shanghai,

200120, P.R. China

Tel: +86 (0) 21 5036 7556

Fax: +86 (0) 21 5036 7559

Email: info@visioneng.com.cn

Vision Engineering

(India)

Tel: +91 (022) 2613 0699

Fax: +91 (022) 2610 3845

Email: info@visioneng.co.in

Loading...

Loading...