User Guide

Hawk MKII 3-Axis Non-Contact Measurement Systems

INTRODUCTIONHAWK MKII 3-Axis Non-Contact Measurement Systems

Vision Engineering's Hawk family of 3-axis non-contact measuring systems are designed to achieve the highest levels

of accuracy and repeatability. With high precision measuring stages, and a range of illumination options to suit all

applications.

Health & Safety

Vision Engineering and its products conforms to the requirements of the EC Directives on Waste Electrical and

Electronic Equipment (WEEE) and Restriction of Hazardous Substances (RoHS).

EN61326-1:2006

FCC Part 15

EN61010-1:2010

WARNING: ALL EQUIPMENT PLUGGED INTO THIS UNIT MUST BE APPROVED TO EN60950-1:2001 AND

CHECK CURRENT RATING OF OUTPUT SOCKET IF USED.

HAWK EQUIPMENT – WARNING

This warning refers to CNC systems

Warning – hazardous moving parts.

To avoid entrapment, keep fingers and other body parts

away from moving parts

To stop all CNC movement in an emergency situation move the joystick in ANY direction.

This will interrupt the CNC programme and stop any movement.

In the case of a system failure or crash, to stop the CNC movement switch the Control Power Supply off or switch off

the mains power to the system.

WARNING

DISCONNECT THE MAINS POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE ROUTINE

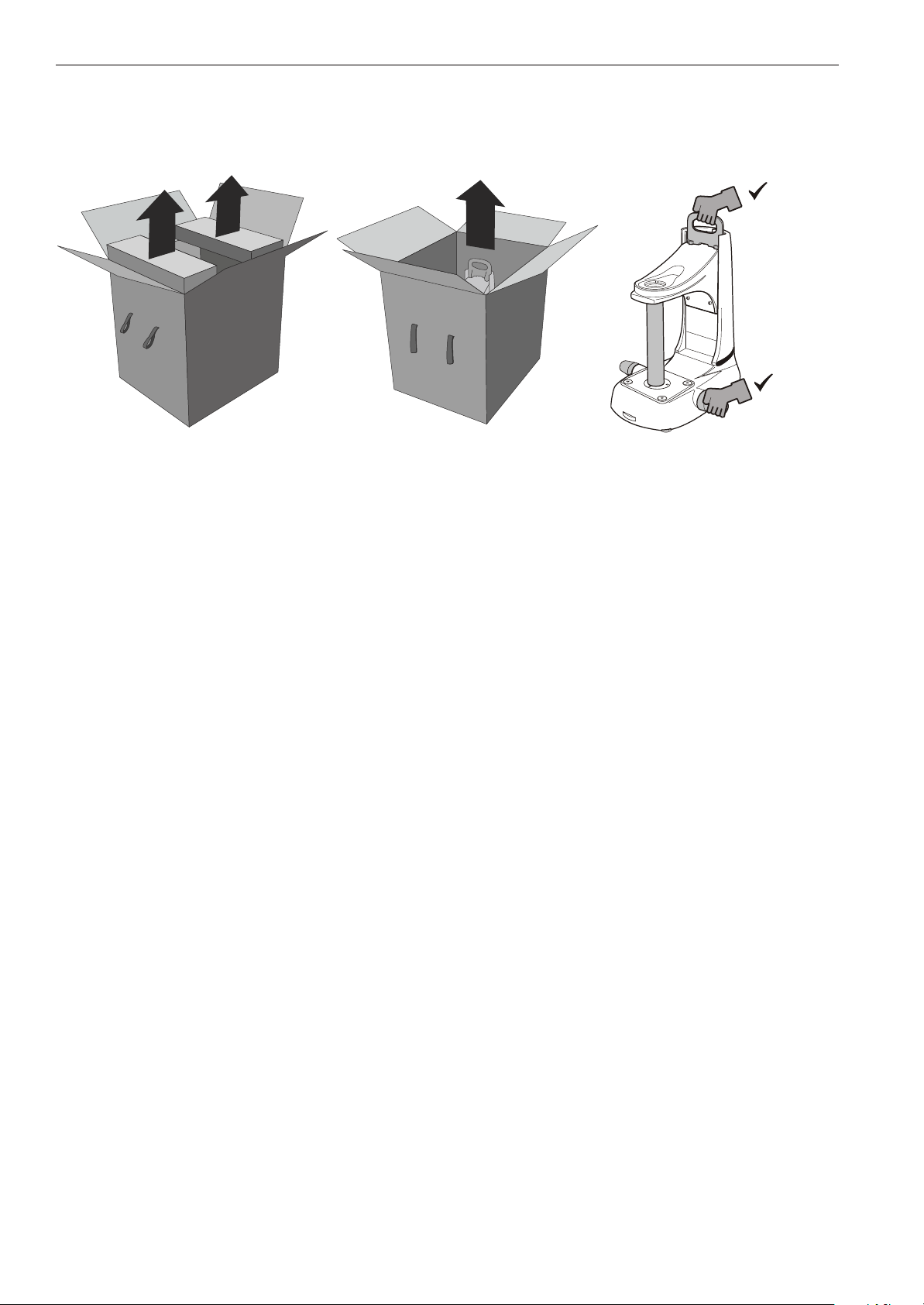

UNPACKING

UNPACKINGUnpacking the Hawk stand (all systems)

1

2

Hawk with M3 software manual system

Box 1 Stand

Box 2 Head

Box 3 PSU - Manual and lighting, and cables

Box 4 M3 software pre-installed PC, keyboard and mouse

Box 5 Monitor

Box 6 M3 USB interface box

Box 7 Manual stage (200mm x 150mm)

Box 8 Optional accessories

3

Hawk with M3-CNC software motorised system

Box 1 Stand

Box 2 Head

Box 3 PSU CNC, and cables

Box 4 Joystick

Box 5 Trackerball

Box 6 M3-CNC software pre-installed PC, keyboard, mouse

Box 7 Monitor

Box 8 M3-CNC USB interface box

Box 9 Motorised stage (200mm x 150mm)

Box 10 Optional accessories

Hawk QC-5000 manual system

Box 1 Stand

Box 2 Head

Box 3 PSU CNC, and cables

Box 4 Joystick

Box 5 Trackerball

Box 6 QC-5000 PC, keyboard and mouse

Box 7 Monitor

Box 8 Manual stage (150mm x 150mm or 200mm x 150mm)

Box 9 Optional accessories

Hawk QC-5000 motorised system

Box 1 Stand

Box 2 Head

Box 3 PSU CNC, and cables

Box 4 Joystick

Box 5 Trackerball

Box 6 QC-5000 PC, keyboard and mouse

Box 7 Monitor

Box 8 Motorised stage (200mm x 150mm)

Box 9 Optional accessories

CONTENTS

CONTENTSPACKING CONTENTS

Head pack 1

Stand pack 1

Stage pack 1

Control units 2

CNC control PSU 2

Joystick and trackerball 2

Control PSU manual and lighting control 2

Accessories 3

Macro 3

Micro 3

M3 USB Interface box 4

QC-5000 PC 4

ASSEMBLY

Removing the transit protection 5

Attaching the stage 5

Ringlight attachment 6

Macro EPI attachment 6

Macro EPI and ringlight attachment 7

Micro EPI and lens turret attachment 7

Attaching the head only 8

Mounting camera to rear 8

Attaching Unicam II 9

Attaching the anti-glare shield 9

Inserting the stage glass 10

Cable connection M3-VED (manual systems) 11

Cable connection M3-CNC (CNC systems) 12

Cable connection QC-5000 (manual systems) 13

Cable connection QC-5000 (CNC systems) 14

START UP / SHUT DOWN PROCEDURE

CNC start up procedure (PC / M3) 15

CNC shutdown procedure (PC /M3) 15

Manual lighting control PSU start up 15

Manual lighting control PSU shutdown 15

SETTING UP

Manual system controls 16

CNC system controls 17

Align head to stage 18

Stand levelling 18

Stage glass levelling 18

Camera Setup 18

CONTENTS

OPERATION

Objective lens 19

Episcopic illuminator 20

Symbols and icons 20

Manual and lighting controls 21

Ringlight control 22

Substage 23

ROUTINE MAINTENANCE

Graticule adjustment 24

Substage LED replacement 25

Episcopic LED replacement 25

General care 26

Consumable and replacement parts 26

Environmental conditions 26

ACCESSORIES & OPTIONS

SERVICE & CALIBRATION RECORD

WARRANTY

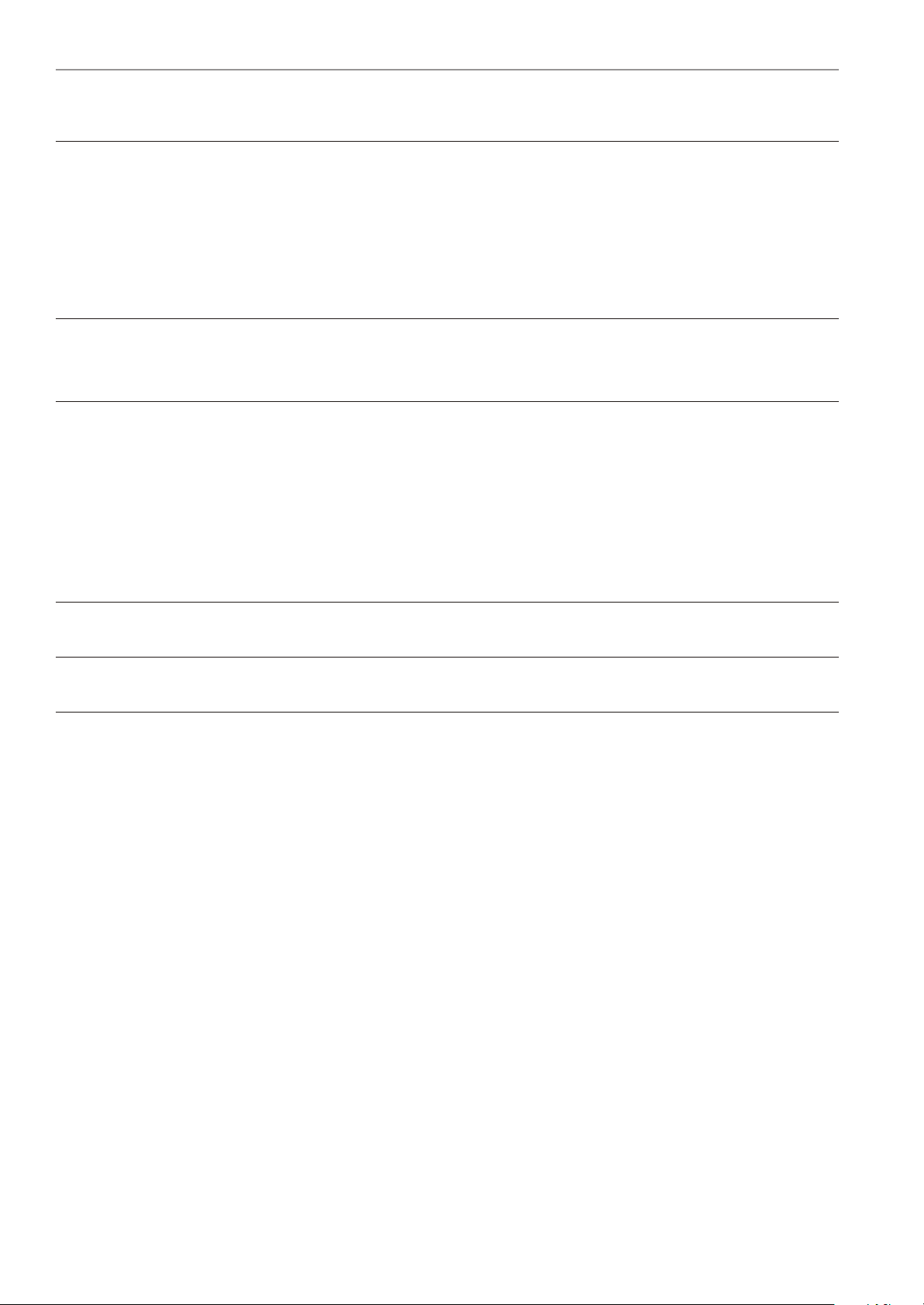

PACKING CONTENTSSee packing list to clarify contents of delivery.

1

2

1

2

3

3

4

4

Head pack

Stand pack

PACKING CONTENTS

Stage pack

150mm x 150mm

(manual)

200mm x 150mm

(manual)

200mm x 150mm

(motorised)

250mm X 150mm

(manual)

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

1

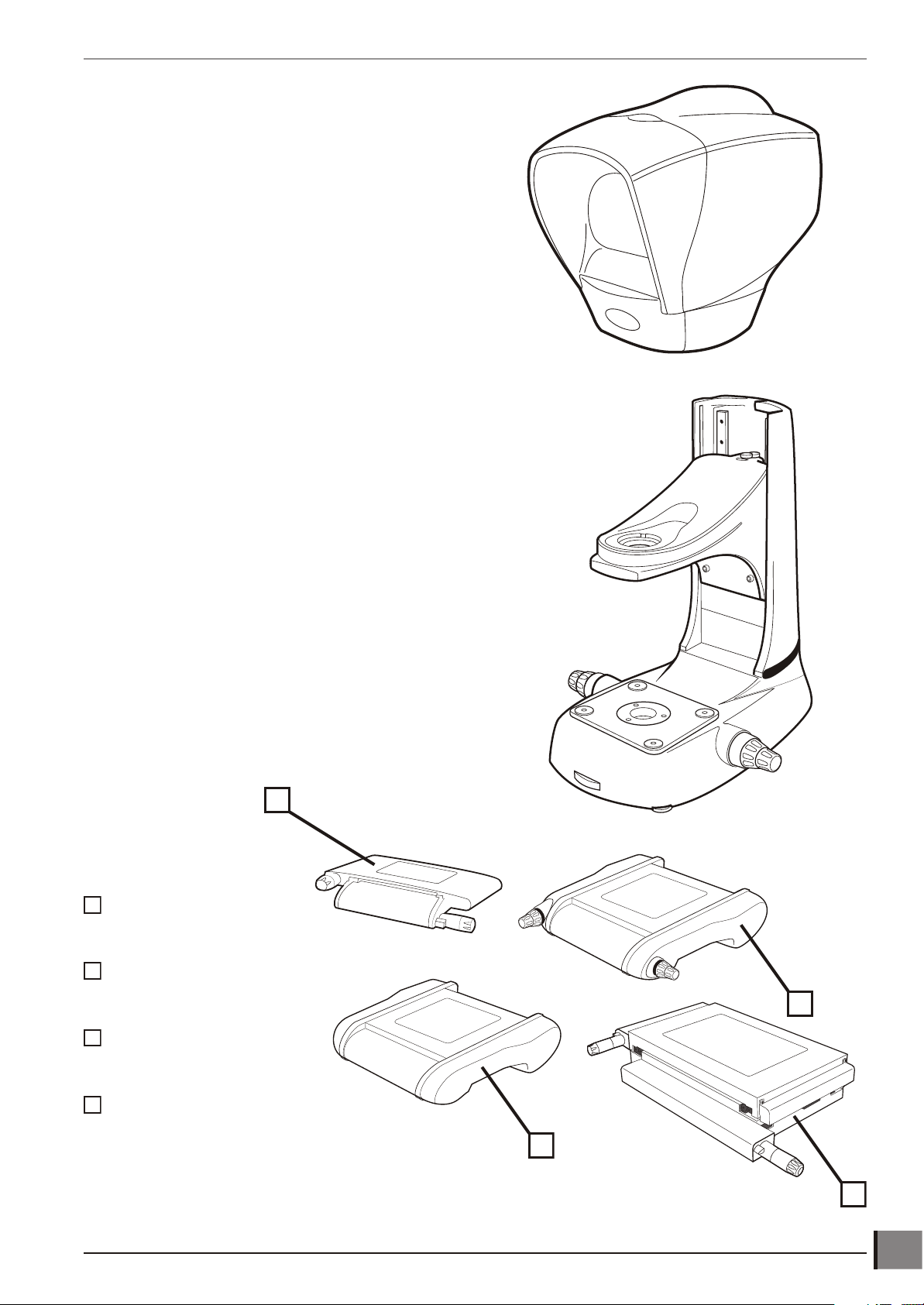

PACKING CONTENTS

Control units

CNC control PSU

Joystick and trackerball

Control PSU manual and lighting control

2

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

Accessories

Macro Micro

PACKING CONTENTS

Substage condenser lens

Object lenses Object lenses

Macro Lens Options

Macro Episcopic

LED illuminator

x1

x2

x5

x10

Substage condenser lens

Micro Lens Options

Micro Micro LWD Micro SLWD

x5 x10 x20

x10 x20 x50

x20 x50

x50 x100

Micro Episcopic

LED illuminator

Camera adaptor

Unicam II

Ringlight illuminator

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

3

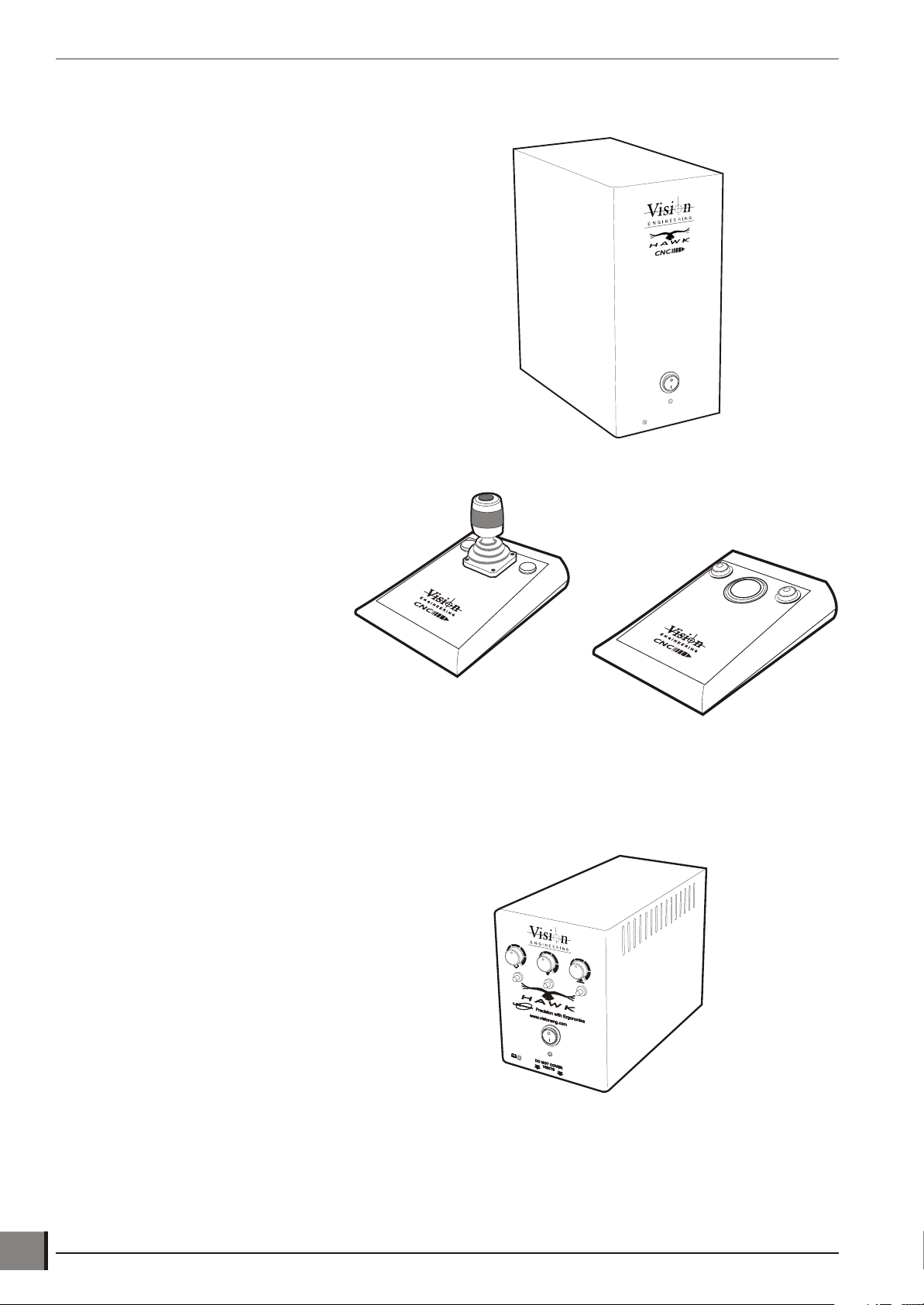

PACKING CONTENTS

213

123

M3 USB Interface box

M3 USB interface unit

Note: Please ensure your Windows® operating

system is kept up to date through

Windows® Update.

Note: In applications where the USB

signal/power is weak (i.e. with long leads

and some laptops) we recommend using a

powered hub or repeater cable (available

from your local PC retailer).

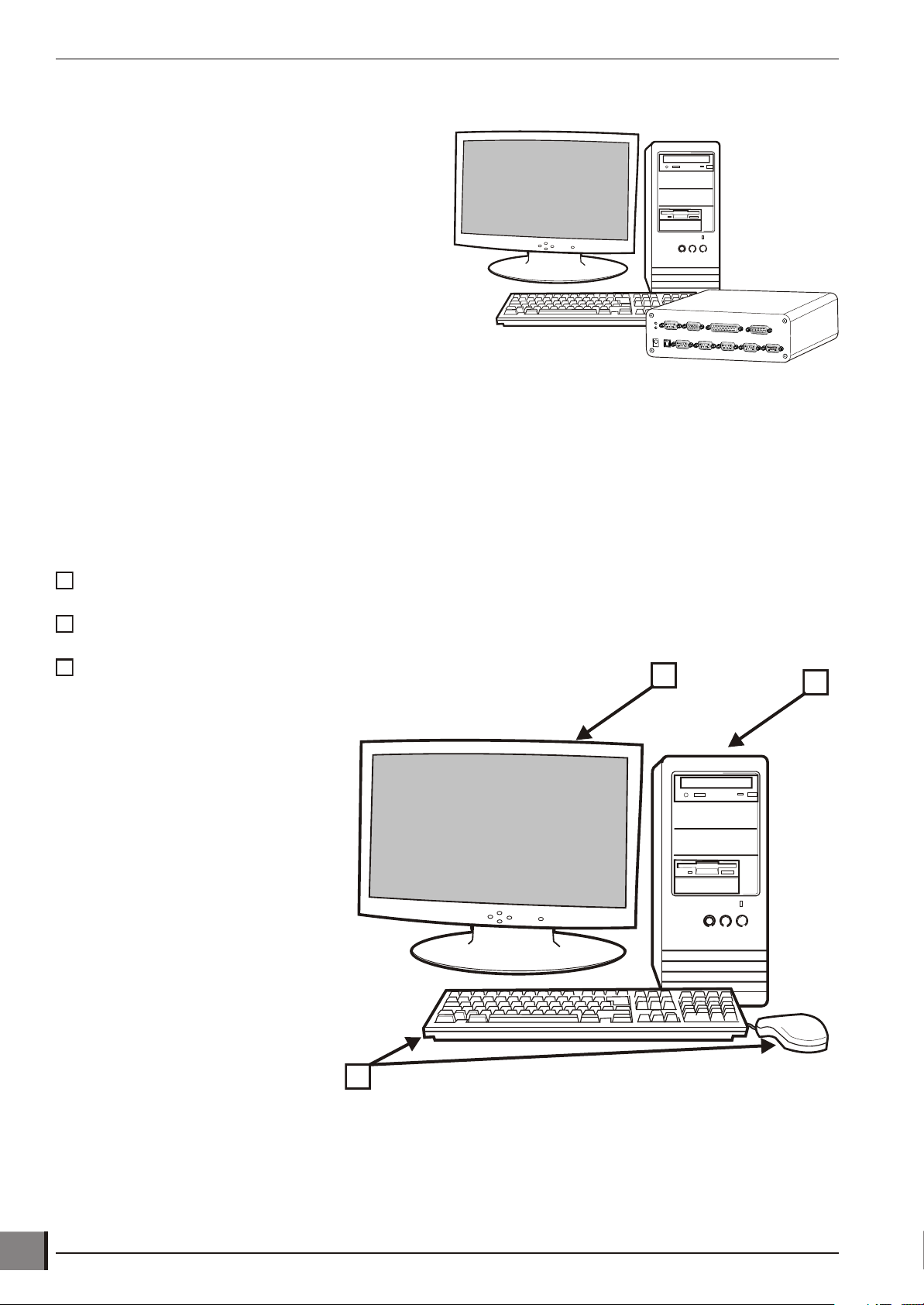

QC-5000 PC

QC-5000 PC

Monitor

Keyboard and mouse

Note: Please ensure your Windows®

operating system is kept up to date

through Windows® Update.

4

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

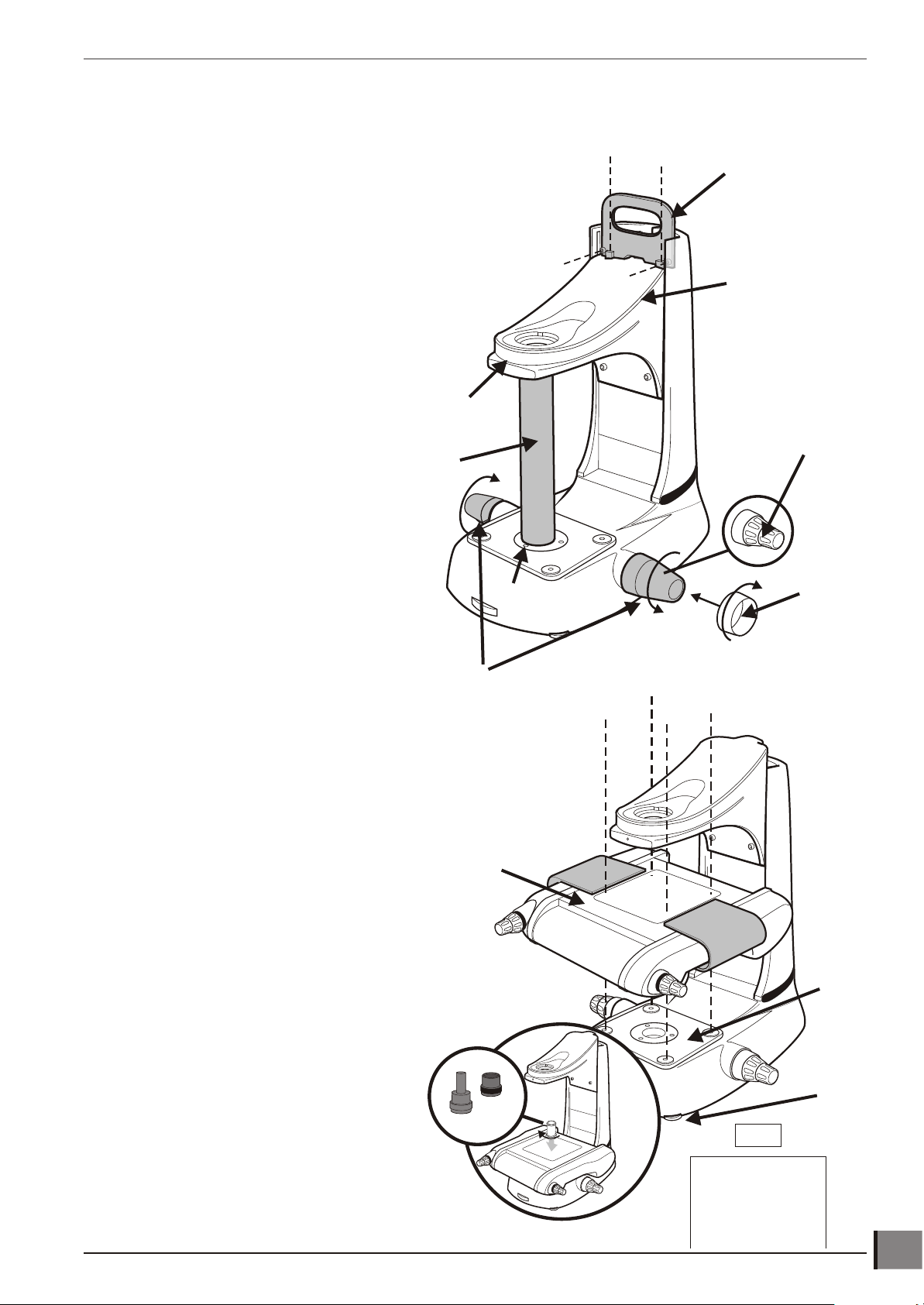

ASSEMBLY

Micro

Macro

Column

Stage Assembly

Logo

B4

B3B1

B2

ASSEMBLYThe following paragraphs provide instructions on how to assemble the Hawk Measuring System. In most instances

the illustrations are self explanatory; where necessary the illustrations are supported by text.

Removing the transit protection

u Use the red transit handle u and either of the focus control covers v

to lift the stand into the required work position.

u Remove the red transit handle and focus control

covers. Screw the two focus control collars w

(one each side) into position.

u Remove the transit handle by removing the

screws that secure it to the stand.

x

u Loosen screws x and y. Use the focus

controls z to raise the head platform {

until there is sufficient room to remove the

transit tube |. Unscrew dovetail from

item | as required.

|

y

u

{

z

w

v

Attaching the stage

u Check the stand base plate u and the underside of the 200mm x

150mm stage v are clean and free of any debris.

u Using the red stage transit handles w, lift the stage into position and

secure it using the bolts provided with the stand, not the bolts that

secure the stage into the transit box.

v

u Use the Allen key supplied to progressively tighten all 4

screws x in the numbered sequence (shown in the

diagram y below) to a torque of 2.8Nm. This is

approximately equal to bolt touch down, plus a quarter

of a turn.

u Remove the stage transit handles.

u Adjust the stabilizing foot z to support

the stand base.

{

w

x

x

x

x

w

u

z

u Screw the required condenser lens {

through the stage and into the stand.

Note: Micro condensers should only be used

with micro lenses when viewing a subject at

stage glass level.

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

y

5

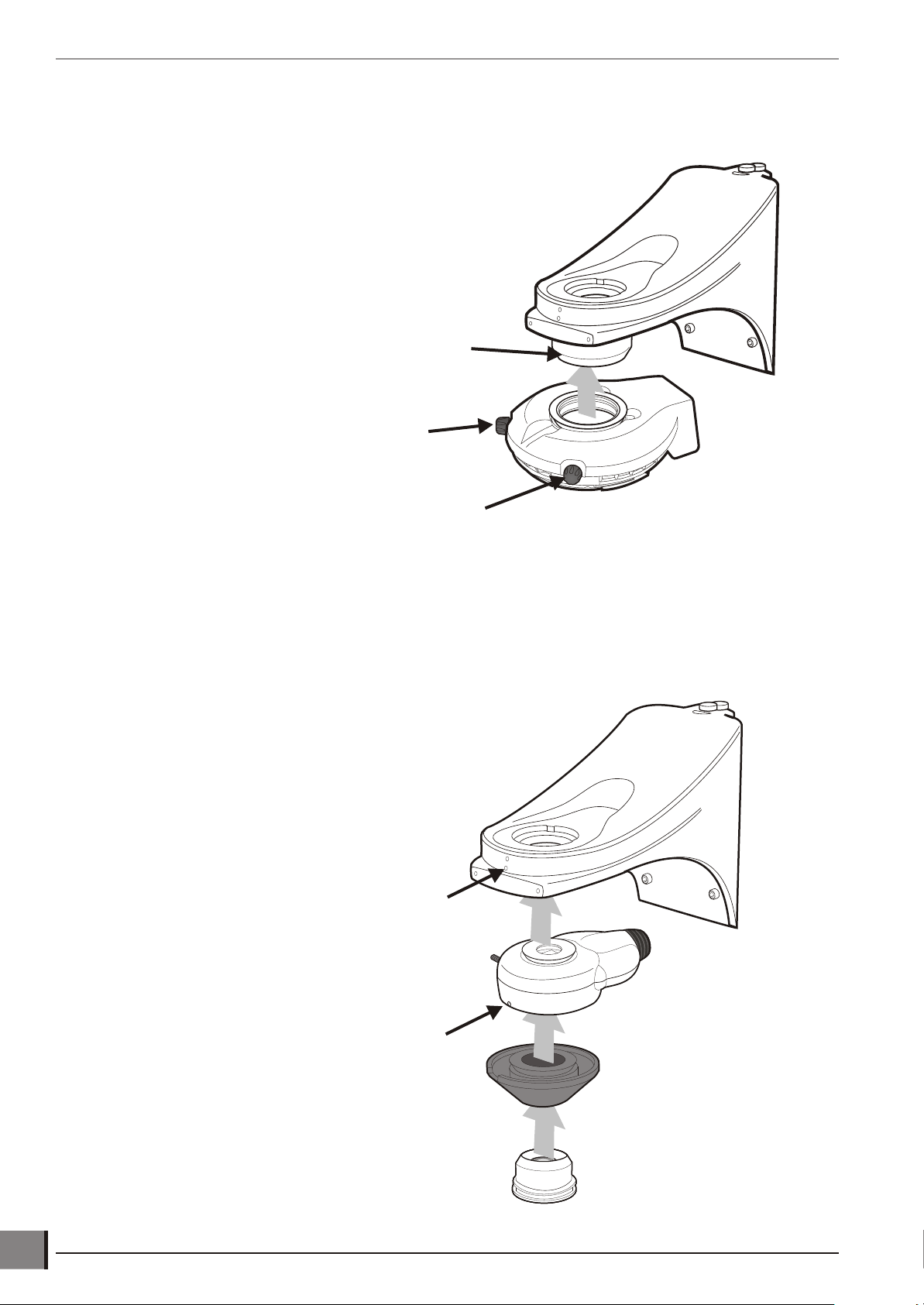

ASSEMBLY

Ringlight attachment

Securing Screw

3G Ringlight adapter

Securing Screw

Macro EPI attachment

Note: The same procedure is used to fit either the Macro EPI (illustrated) or the Micro EPI. The Micro

EPI cannot have an Objective Holder or Ringlight fitted.

Grub Screw

Grub Screw

6

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

Macro EPI and ringlight attachment

Grub Screw

ASSEMBLY

Grub Screw

Securing Screw

Securing Screw

Micro EPI and lens turret attachment

Grub Screw

Grub Screw

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

7

ASSEMBLY

Head

Connector

Head

Socket

Grub

Screw

Camera

Attachment

Grub

Screws

Locking

Plate

Camera

Adapter

Attaching the head only

Mounting camera to rear

u Position camera attachment between the

viewing head and its arm.

u Secure with the grub screws.

u Attach the adapter to the camera

and tighten 3 x grub screws if not

already fitted.

u Locate camera and adapter to the locking

plate (the locking plate must not be

overtight, but enough to hold).

8

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

Attaching Unicam II

Unicam

Securing

Screws

Head

Power

Lead

ASSEMBLY

Attaching the anti-glare shield

CAUTION: The Anti-Glare Shield is made of plastic and

must not be over tightened.

Screws

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

9

ASSEMBLY

P

O

Inserting the stage glass

Note: The stage glass must be handled with care to avoid any fingerprint marks.

u Align the glass with it's bevelled edges against the

springs (see table below for spring location and

diagram u for the correct orientation of

the stage glass).

u Check that the stage glass is in contact with

all four supports.

u To level the stage glass, refer to page 18.

Stage size Spring location

150 x 150mm Left & Back

200 x 150mm Left & Front

u

10

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

RINGLIGHT

EPI

HEAD

VREF

DISPLAY I/O

X Y Z

MAINS POWER IN

MAINS POWER IN

PC USB

KEY

Mains Power

Lighting/Power

X, Y and Z

PC USB

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

Cable connection M3-VED (manual systems)

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

11

ASSEMBLY

KEY

Mains Power

USB

Display

Lighting/Power

X, Y and Z

CNC

MAINS POWER IN

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

Cable connection M3-CNC (CNC systems)

All connectors must be engaged fully and secured with the screws.

recommend using a powered hub or repeater cable (available from your local PC retailer).

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

12

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ASSEMBLY

RINGLIGHT

EPI

CAMERA

Input

110-240V 50-60Hz

HEAD

Fuse

T1.0AH 240V

T2.0AH 110V

VREF

DISPLAY I/O

SUB-STAGE ILLUMINATION

DISPLAY I/O

Y XZ

PC

(rear)

USB

KEY

Mains Power

USB

Display

Lighting/Power

X, Y and Z

MAINS POWER IN

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

Cable connection QC-5000 (manual systems)

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

13

ASSEMBLY

JJOOYYSSTTIICCKK

VREFVREF

CCNNCC

DISPLAY I/ODISPLAY I/O

Z-AXIS MOTOR Z-AXIS MOTOR Y-AXIS MOTOR Y-AXIS MOTOR X-AXIS MOTOR X-AXIS MOTOR

RINGLIGHT

EPI

JOYSTICK

TRACKERBALL

CAMERA

DISPLAY I/O

Y XZ

PC

(rear)

USB

CNC

KEY

Mains Power

USB

Display

Lighting/Power

X, Y and Z

CNC

MAINS POWER IN

All connectors must be engaged fully and secured with the screws.

Note: In applications where the USB signal/power is weak (i.e. with long leads and some laptops) we

recommend using a powered hub or repeater cable (available from your local PC retailer).

Note: Please ensure your Windows® operating system is kept up to date through Windows® Update.

Cable connection QC-5000 (CNC systems)

WARNING:To comply with safety regulations, easy access to the mains socket must be maintained.

14

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

START UP / SHUT DOWN PROCEDURE

START UP / SHUT DOWN PROCEDUREWARNING: ENSURE THE RELEVANT START UP AND SHUT DOWN PROCEDURES ARE ALWAYS FOLLOWED

TO AVOID DAMAGE TO SYSTEM.

CNC start up procedure (PC / M3)

Before the PC/M3 or Hawk power supply unit is switched on:

u Plug in all the cable connections and accessories to the HAWK microscope system.

(see appropriate connection diagrams – pages X, Y, Z).

u Turn on PC, or PC and M3 interface box.

u Turn on the HAWK PSU, (NEVER disconnect cables while the unit is switched on).

u Start up the measurement software.

u The system is now ready for use.

CNC shutdown procedure (PC /M3)

When you are ready to shut down:

u Close down the measurement software.

u Turn off the HAWK PSU.

u Shut down the PC or PC and M3 interface box.

u The System is now off and the cables may be safely disconnected if required.

Manual lighting control PSU start up

Before anything is switched on:

u Plug in all the cable connections and accessories to the HAWK microscope system.

(see appropriate connection diagrams – pages X, Y, Z).

u Turn on PC or PC and M3 interface box.

u Turn on the Manual lighting control PSU, (NEVER disconnect cables while the unit is switched on).

u Start up measurement software (if applicable).

u System is now ready for use.

Manual lighting control PSU shutdown

u Close down the measurement software (if applicable).

u Turn off the Hawk PSU.

u Shut down the PC or PC and M3 interface box (if applicable).

The System is now off and the cables may be safely disconnected if required.

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

15

SETTING UP

Fine

Focus

Control

Illumination

Power Supply

Illumination

Controls

Coarse

Focus

Control

Y Axis

Control

ON/OFF

Switch

X Axis

Control

Substage

Iris Control

Levelling

Foot

Objective Lens Macro - Open Iris - decrease depth of field

- Close Iris - increase depth of field

SETTING UPManual system controls

Turn on the illuminator power supplies and check that the LED at the centre of the head is illuminated.

The manual system controls are identified below.

16

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

CNC system controls

Z

X

Y

ON/OFF

Switch

Substage

Iris Control

Levelling

Foot

Objective Lens Macro - Open Iris - decrease depth of field

- Close Iris - increase depth of field

X

Y

SETTING UP

Default Joystick button functions:

u = Enter

v = Speed Toggle

w = Finish

Default Trackerball button functions:

v = Speed Toggle

w = Finish

u

v

w

v

w

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

17

SETTING UP

X Axis

Control

Fixed

Corner

Adjustable

Glass Supports

Y Axis

Control

Align head to stage

u Ensure that an objective lens is fitted.

u Ensure the head is switched on and then loosen it using an hexagonal/Allen key.

u Align the front edge of the gauge block (or straight edge) with the front edge of the stage glass.

u Rotate the head until the horizontal cross line is parallel with the rear edge of the gauge block (or straight edge).

u Lock the head in position with the hexagonal/Allen key.

Stand levelling

u Adjust the levelling foot until the stand is stable.

Stage glass levelling

u Adjust the X and Y axis controls to bring the rear left-hand

corner of the stage glass (fixed corner) into view.

u Adjust the coarse/fine focus control to bring the

glass surface into sharp focus.

u Adjust the X and Y axis controls to

bring the front left-hand corner

into view.

u Use the relevant adjustable glass

support to bring the surface of the

glass into sharp focus.

u Repeat the above procedure for the

remaining two corners.

Camera Setup

u Loosen hexagonal headed screws u on locking plate v and continue to turn

camera w until it is in the correct position.

u Connect the camera to the PC and power supply as required.

w

u Bring the target/slip into focus within the head, as centrally aligned to

crosshair as possible.

u Match the view on the monitor with that in the head - move the

camera by using the thumbscrews x.

u Tighten the hexagonal headed screws on the locking plate to hold

camera in position.

x

18

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

v

u

OPERATION

OPERATIONWARNING: ENSURE THE RELEVANT START UP AND SHUT DOWN PROCEDURES ARE ALWAYS FOLLOWED

TO AVOID DAMAGE TO SYSTEM (SEE PAGE 15).

To achieve the optimum results from the Hawk Measuring System, the illumination and optics need to be adjusted to

provide the best possible image to the operator. Certain lighting options are better for some applications than others.

Illumination and focus should be adjusted until the image is clear and bright, with good contrast. Maximum contrast

gives the best image resolution and allows for the highest level of accuracy and repeatability.

Contact the nearest Vision Engineering branch/distributor for further advice.

Objective lens

Iris control

Each Macro objective lens has an adjustable iris which restricts the aperture of the lens. By rotating the control ring

on the bottom of the objective lens, the iris opens and closes. Adjusting the objective lens aperture slightly increases

or decreases the depth of field. This feature is useful for subjects where greater surface definition is required. The

same results can be achieved with a Micro objective lens by adjusting the iris wheel in the Episcopic illuminator.

Closing the Substage Iris improves ability to locate an edge on a cylindrical component/raised profile.

Magnification tables

Macro Lenses

Part No. Objective Lens Total Magnification Working Distance

H-007 x1 10x 84mm 14.2mm 270µm

H-008 x2 20x 81mm 7.1mm 67µm

H-009 x5 50x 61mm 2.8mm 10µm

H-010 x10 100x 35mm 1.4mm 6µm

Standard Working Distance Micro Lenses

Part No. Objective Lens Total Magnification Working Distance

H-110 x5 50x 20.0mm 4.4mm 12.22µm

H-100 x10 100x 10.1mm 2.2mm 3.06µm

H-101 x20 200x 3.1mm 1.1mm 1.3µm

H-103 x50 500x 0.66mm 0.44mm 0.3µm

Long Working Distance Micro Lenses

Part No. Objective Lens Total Magnification Working Distance

H-104 x10 100x 21.0mm 2.2mm 4.4µm

H-105 x20 200x 12.0mm 1.1mm 1.72µm

H-106 x50 500x 10.6mm 0.44mm 1.10µm

H-107 x100 1000x 3.4mm 0.22mm 0.43µm

Field of View

(diameter)

Field of View

(diameter)

Field of View

(diameter)

Depth of Field

Depth of Field

Depth of Field

Super Long Working Distance Micro Lenses

Part No. Objective Lens Total Magnification Working Distance

H-108 x20 200x 21.0mm 1.1mm 2.24µm

H-109 x50 500x 15.0mm 0.44mm 1.36µm

Field of View

(diameter)

Depth of Field

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

19

OPERATION

Control Lever

LED EPI

Thumbwheel

Episcopic illuminator

The Episcopic illuminator provides through the lens illumination for measuring deep surface features, holes and blind

bores. The light follows the optical path through the objective lens. The following adjustment can be made:

• Ad just the sur face light ing to suit the com po nent by us ing the thumbwheel and the beam split mir ror.

• Adjust light in ten sity.

• Adjust the depth of field of the objective lens by rotating the iris control thumbwheel (a smaller iris increases

the depth of field).

• To change the image con trast, fully engage the beam split mirror control lever.

Symbols and icons

Key to symbols and icons

The symbols and Icons below are shown where applicable:

Ringlight

Sub-stage

Episcopic illumination

Display I/O Connection to PC or M3 interface box

Refer to manual

HEAD Viewing Head power

VREF Video reference

CNC Connection to PC or M3 interface box

JOYSTICK Connection to Joystick controller

X,Y, Z AXIS

MOTOR Connection to the HAWK motor connections

20

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

OPERATION

Manual and lighting controls

Lighting is controlled by toggle switch and dimmer knob in Manual mode. Note that the manual lighting controls will

not operate the lighting if the PC lighting control cable is connected to the ‘Display I/O’ port at the back of the unit.

Ringlight illumination

Dimmer Knob

Illumination

ON/OFF switches

Sub stage

illumination

Ringlight status LED

Episcopic illumination

Mains On/Off

Power LED

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

21

OPERATION

Ringlight control

The LED Ringlight, which can be used with Sub-stage illumination, provides above stage illumination and is used for

illuminating surface features, blind holes, etc.

u Switch the unit on and adjust intensity as required (QC or PC software).

u The LED illuminator is provided with a temperature protection system to ensure long term LED performance is not

compromised by overheating.

u The Ring light status LED u operates as follows:

Solid Green: The controller is fully operational

Off: The LED Ringlight is not connected

Flashing Green/Amber: The unit is in thermal protection mode, the LEDs will gradually reduce until the temperature

stabilises. Once stabilised the LED will return to green but the maximum brightness level will remain limited, protecting

the Ringlight, until the unit is switched off. If the status persists, remove the illuminator and ensure neither the air inlets

nor the fan outlet are obstructed. If operating the Ringlight under PC control changing the quadrant status will return

the Ringlight to full brightness, ensuring sufficient light under all options.

Solid Red: The unit is in thermal shutdown mode to protect the life of the LEDs. The LEDs have reached a critical

temperature and the controller is unable to stabilise them. The unit will remain in shutdown until a safe

temperature is reached, at this point it will return to normal operation (indicated by the status LED being green).

If the problem persists allow the Ringlight to cool down, remove the illuminator and ensure neither the air inlets

nor the fan outlet are obstructed. If the problem cannot be resolved please contact your nearest representative

(see back page).

u In the above Solid Red condition, remove the illuminator and ensure neither the air inlet v around the

objective, nor the fan outlet w are obstructed.

w

u

v

22

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

v

The Ringlight illuminator is used as follows:

Thumbwheel

u

Á

• To il lu mi nate op ti cally dif fi cult sur faces/sur face

• For use with Macro ob jec tive lenses.

• The Ringlight gives a shadow free im age.

• Can be used with Episcopic and Substage il lu mi na tion.

u To adjust the light intensity rotate the dial control on the control box (see page 21).

u To diffuse the light, move the diffuser control u to position À for diffused light or to position Á for no diffusion.

À

fea tures.

Substage

The Substage illumination is used for the accurate measurement of

through holes, profiles and edge features etc. The depth of field is

adjusted by rotating the thumbwheel on the Hawk base.

The illumination can be used with spotlight, ringlight and

EPI illumination systems.

Adjust light intensity by rotating the dial control on the

illumination power supply unit.

Best practice

To ensure the most accurate measurements are taken it is recommended that during the measurement process these

following guidelines are followed:

• When se lect ing points on fea tures the point should al ways be ap proached in the same fash ion, e.g. al ways

work to ward a point on the X axis first, mov ing from left to right and then move to wards a point in the Y axis,

mov ing from top to bot tom. This pro ce dure will in crease re peat abil ity.

• If looking to measure the form of a feature, it is best to take at least eight points to achieve the most

repeatable re sult.

• En sure fans exhaust areas are not blocked or ob structed.

• Do not lean on or shake the upper arm of your Hawk product.

Note: Contact your local Vision Engineering representative for full details of available training

programs.

Note: To achieve the very best from your Hawk non-contact measuring system, you should carry out

regular routine maintenance as well as undertaking a schedule of service and calibration (see

service and calibration record, at the end of this user guide).

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

23

ROUTINE MAINTENANCE

Graticules

Gauge

Crossline

Graticule Lock Nuts & Grubscrews

(2 per Graticule)

Retaining Knobs

Securing Clip

WARNING

DISCONNECT THE MAINS POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE ROUTINE

Routine maintenance is important for the longstanding of the Hawk Measuring System. For more complex

ROUTINE MAINTENANCE

maintenance contact the local Vision Engineering representative.

Graticule adjustment

u Undo the securing clip at the base of the front cover and lift the cover off.

u To focus and centralize each graticule, loosen the appropriate retaining knob and move the graticule up or down

to focus. Re-tighten the retaining knob.

u To adjust the graticules, place a known 90º gauge (slip gauge or crossline) on the stage and focus the image.

Close one eye and locate the crossline on the corner of the gauge by unlocking and adjusting the grubscrews.

Once the image is located, lock the grubscrews with the locking nuts.

u Repeat the procedure using the other eye. Make the adjustment so that the graticules overlay each other.

Note: If the image is uncomfortable to the eyes, repeat the above procedure.

24

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

Substage LED replacement

u Take off the substage LED cover plate u by

removing its 3 securing screws.

u Pull out and separate the LED

connector v.

ROUTINE MAINTENANCE

w

u Loosen the 2 grub screws w that

secure the LED assemby x and remove it.

u The replacement procedure is the reversal of

the above.

Episcopic LED replacement

u Remove the episcopic assembly u from the

Hawk and carefully place it on a workbench

as shown.

u Pull its power lead v clear of the socket.

u Loosen the 2 securing screws w and pull

the LED assembly x clear of the

illuminator.

x

u

v

u

w

v

u The replacement procedure is the reversal

of the above.

x

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

25

ROUTINE MAINTENANCE

General care

• Cover the Hawk with a dust cover when not in use.

• Remove dust with a soft brush or cleaning cloth.

• The viewing screen and lenses should be cleaned with a lens cleaning cloth.

• Keep accessories in a dust-free environment when not in use.

Consumable and replacement parts

Item Specification

Stage Glass 150x150mm 1 201-B0686

Stage Glass 200x150mm 1 184-B0227

Stage Glass 250x150mm 1 H-161

Anti-Glare shield Hinged Anti-Glare shield 1 188-A1001/D

Substage Illuminator LED LED and heat sink assembly 1 2011095

Episcopic Illuminator LED LED and heat sink assembly 1 2011096

Control PSU CNC T2.0AH 240V 1 FUS4662

Control PSU CNC T4.0AH 110V 1 FUS4853

Control PSU Manual T1.6AH 240V 1 FUS4752

Control PSU Manual T3.15AH 110V 1 FUS4637

Ringlight LED array 8 point LED 1 FUS4662

Ringlight Fan assembly Fan 1 2050307

Quantity

in Pack

Part

Number

Environmental conditions

Hawk is an accurate, industrial gauging instrument. To achieve the optimum accuracy and repeatability, the following

considerations should be taken into account:

• Po si tion the Hawk on a firm, rigid ta ble.

• Do not position the instrument near any source of vi bra tion.

• Ensure that the illuminator power supplies have sufficient ven ti la tion.

• Do not position the instrument close to a radiator or similar heating sys tem.

• Do not position the instrument in direct sunlight, or where bright reflections will prevent a com fort able viewing

position.

26

HAWK MKII 3-Axis Non-Contact Measurement Systems www.visioneng.com/support

ACCESSORIES & OPTIONS

Hawk Stand

200mm x 150mm

Precision Measuring Stage

H-082

OR

OR

QC-5000 PC

QC-5000 PC

Key

Mandatory Parts

Optional Parts

150mm x 150mm

Manual Stage

H-080

250mm X 150mm

Manual Precision Stage

H-160

M3 USB Interface box

(VED)

H-081

H-002

200mm x 150mm

Manual Precision Stage

Manual Stages Motorised Stage

H-001

Head

Objective Lens

Low Magnification

Objective Lens

High Magnification

M3 USB Interface box

(CNC)

Control PSU

Manual

H-132

JoystickJoystick

Control PSU CNC

TrackerballTrackerball

JoystickJoystick TrackerballTrackerball

H-038

Footswitch

EPI Macro

Ringlight

EPI Micro

Unicam II

Camera Arm

FIL-1570

Substage filter

H-200

Dust Cover

FIL-1570

H-200

Dust Cover

H-224

H-148

H-149

H-147

H-070

H-131

H-131

H-143

H-143

H-144

H-144

Control PSU

Manual

Control PSU CNC

H-132

ACCESSORIES & OPTIONS

www.visioneng.com/support HAWK MKII 3-Axis Non-Contact Measurement Systems

27

SERVICE & CALIBRATION RECORDHawk serial number ________________

Stage serial number ________________

SERVICE & CALIBRATION RECORD

Service type Comments

Date of

service

Date of next

service

Company Signature

WARRANTY

WARRANTY

This product is warranted to be free from defects in material and workmanship for a period of one year from the date of

invoice to the original purchaser.

If during the warranty period the product is found to be defective, it will be repaired or replaced at facilities of Vision

Engineering or elsewhere, all at the option of Vision Engineering. Shipment costs for warranty repairs, to and from Vision

Engineering facilities will not, normally, be borne by Vision Engineering. However, Vision Engineering reserves the right to

refund the purchase price if it is unable to provide replacement, and repair is not commercially practicable or cannot be

timely made. Parts not of Vision Engineering manufacture carry only the warranty of their manufacturer. Expendable

components such as fuses carry no warranty.

This warranty does not cover damage in transit, damage caused by misuse, neglect, or carelessness, or damage resulting

from either improper servicing or modification by other than Vision Engineering approved service personnel. Further, this

warranty does not cover any routine maintenance work on the product described in the user guide or any minor

maintenance work which is reasonably expected to be performed by the purchaser.

No responsibility is assumed for unsatisfactory operating performance due to environmental conditions such as humidity,

dust, corrosive chemicals, deposition of oil or other foreign matter, spillage, or other conditions beyond the control of

Vision Engineering.

Except as stated herein, Vision Engineering makes no other warranties, expressed or implied by law, whether for resale,

fitness for a particular purpose or otherwise. Further, Vision Engineering shall not under any circumstances be liable for

incidental, consequential or other damages.

Vision Engineering Ltd.

(Central Europe)

Anton-Pendele-Str. 3,

82275 Emmering, Deutschland

Tel: +49 (0) 8141 40167-0

Email: info@visioneng.de

Vision Engineering Ltd.

(France)

ZAC de la Tremblaie, Av. de la Tremblaie

91220 Le Plessis Paté, France

Tel: +33 (0) 160 76 60 00

Email: info@visioneng.fr

Vision Engineering Ltd.

(Italia)

Via Cesare Cantù, 9

20092 Cinisello Balsamo MI, Italia

Tel: +39 02 6129 3518

Email: info@visioneng.it

Vision Engineering

(Brasil)

Tel: +55 11 4063 2206

Email: info@visioneng.com.br

Nippon Vision Engineering

(Japan)

272-2 Saedo-cho, Tsuduki-ku,

Yokohama-shi, 224-0054, Japan

Tel: +81 (0) 45 935 1117

Email: info@visioneng.jp

Vision Engineering

(China)

11J, International Ocean Building,

720 Pudong Avenue, Shanghai,

200120, P.R. China

Tel: +86 (0) 21 5036 7556

Email: info@visioneng.com.cn

Vision Engineering

(S.E. Asia)

Tel: +603 80700908

Email: info@visioneng.asia

Vision Engineering

(India)

Email: info@visioneng.co.in

Distributor

Visit our website:

www.visioneng.com

For more information...

Vision Engineering has a network of offices and technical distributors around

the world. For more information, please contact your Vision Engineering

branch, local authorised distributor, or visit our website.

Disclaimer – Vision Engineering Ltd. has a policy of continuous development and reserves the right to change or

update, without notice, the design, materials or specification of any products, the information contained within

this brochure/datasheet and to discontinue production or distribution of any of the products described.

Vision Engineering Ltd.

(Manufacturing)

Send Road, Send,

Woking, Surrey, GU23 7ER, England

Tel: +44 (0) 1483 248300

Email: generalinfo@visioneng.com

Vision Engineering Ltd.

(Commercial)

Monument House, Monument Way West,

Woking, Surrey, GU21 5EN, England

Tel: +44 (0) 1483 248300

Email: generalinfo@visioneng.com

Vision Engineering Inc.

(Manufacturing & Commercial)

570 Danbury Road,

New Milford, CT 06776 USA

Tel: +1 (860) 355 3776

Email: info@visioneng.com

Vision Engineering Inc.

(West Coast Commercial)

745 West Taft Avenue,

Orange, CA 92865 USA

Tel: +1 (714) 974 6966

Email: info@visioneng.com

874TIL 31/10/0.1R 8

Loading...

Loading...