Vision & Control Pictor M1606, 4-20-193, 4-20-194, pictor M41/EL Instructions For Use Manual

Instructions for Use

pictor M1606

Intelligent Camera

999.994.256.10-en-1.4

© Vision & Control GmbH 2014

pictor M1606

Impress

Publisher / Manufacturer Vision & Control GmbH

Mittelbergstraße 16

98527 Suhl, Germany

Telephone: +49 (0) 3681 / 79 74-0

Telefax: +49 (0) 3681 / 79 74-33

www.vision-control.com

Name of the document 999.994.256.10-en-1.4

Date of first issue 16.05.2014

Date modified 06.10.2014

Copyright © Vision & Control GmbH 2014

Copyright

It is forbidden to pass this document on to third parties, reproduce and

communicate its contents in as far as this has not been expressly authorized.

Offenders will be liable for damages.

All rights are reserved with respect to patent, utility sample and design patent

registrations, as well as for rights of use within the scope of copyright.

vicotar®, vicolux®, pictor®, vicosys® and vcwin® are registered trademarks of

Vision & Control GmbH.

The products and brand names of other manufacturers or suppliers are

mentioned for information only.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 2

pictor M1606

Validity

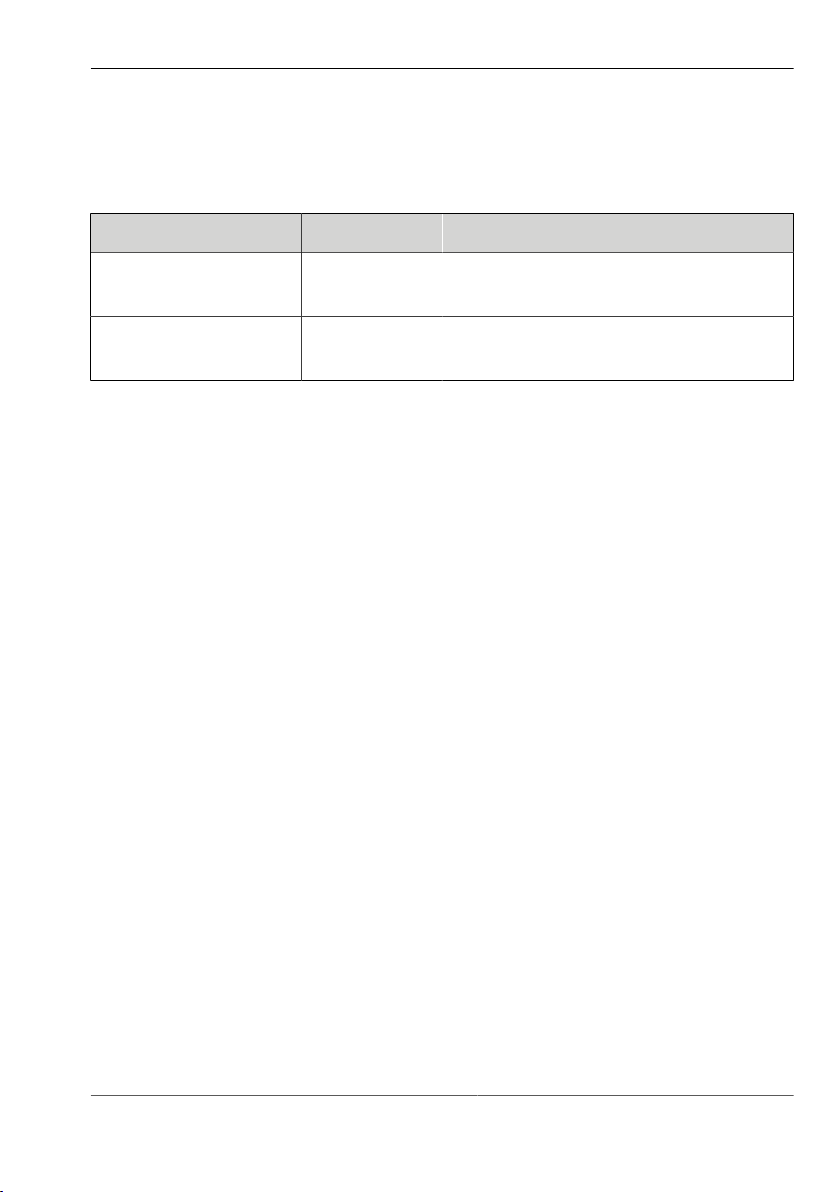

This manual is valid for the following devices:

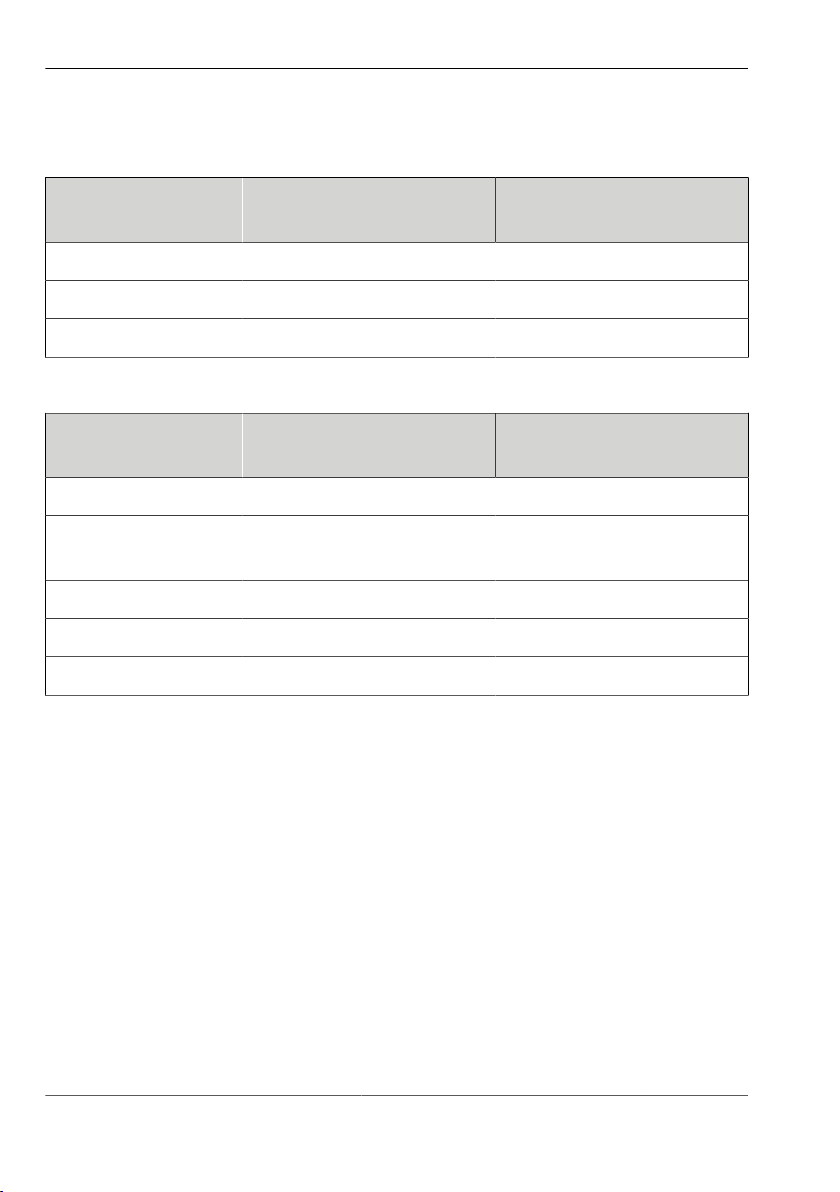

Device Order no. Description

pictor M1606/E 4-20-193 1/3"CCD, 640x480, 63fps, mono, IR

cut filter, SVGA-Out

pictor M1606/E 4-20-194 1/3"CCD, 640x480, 62fps, mono,

broadband filter, SVGA-Out

3 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Table of Contents

1. Important Information.................................................................................. 6

1.1. Information about the instructions of use.................................................... 6

1.2. Conventions of presentation........................................................................7

1.3. Presentation of Safety Instructions............................................................. 9

1.4. Proper and intended use...........................................................................10

1.5. Improper Use.............................................................................................11

1.6. Qualified Personnel................................................................................... 12

1.7. Warranty and liability................................................................................. 12

2. Safety Instructions..................................................................................... 13

2.1. Safe Handling of the Device..................................................................... 13

2.2. Environmental Protection.......................................................................... 14

3. Scope of Delivery and Accessories......................................................... 15

3.1. Scope of Delivery...................................................................................... 15

3.2. Accessories................................................................................................16

4. Product Description................................................................................... 19

4.1. Devices Views........................................................................................... 19

5. Product Data............................................................................................... 21

5.1. Interfaces................................................................................................... 23

5.1.1. Digital I/O-Interfaces.....................................................................23

5.1.2. Ethernet interface......................................................................... 24

5.1.3. RS232 interface............................................................................25

5.1.4. Trigger interface........................................................................... 26

5.2. Conditions for Operation, Storage and Transport..................................... 28

6. Operation software vcwin pro...................................................................29

6.1. System Requirements............................................................................... 29

6.2. Installing, Starting and Updating operating software vcwin pro................. 30

7. Commissioning........................................................................................... 31

7.1. Unpacking.................................................................................................. 31

7.2. Mounting.................................................................................................... 32

7.3. Connecting.................................................................................................34

7.3.1. Operating Voltage Supply............................................................ 34

7.3.2. Connecting the PLC/Power cable................................................ 35

7.3.3. Connecting the Ethernet cable..................................................... 38

7.3.4. Connecting the RS232 cable....................................................... 39

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 4

pictor M1606

7.3.5. Connecting the trigger cable........................................................ 40

7.3.6. Connecting the video cable..........................................................41

7.3.7. Connecting vicolux lighting...........................................................42

7.3.8. Connecting the Power supply...................................................... 44

8. Operation..................................................................................................... 45

8.1. Switching On and Off (Ready for Operation)............................................ 45

8.2. Operation from the Software Interface...................................................... 45

8.2.1. First steps.....................................................................................45

8.2.2. Interface Settings......................................................................... 46

8.2.3. Connect to the operation software............................................... 48

9. Maintenance and Service.......................................................................... 49

9.1. Maintenance.............................................................................................. 49

9.2. Service....................................................................................................... 50

10. Decommissioning..................................................................................... 51

10.1. Disconnect............................................................................................... 51

10.2. Dismount..................................................................................................52

11. Disposal..................................................................................................... 53

11.1. Disposal................................................................................................... 53

12. Appendix....................................................................................................54

12.1. EC Declaration of Conformity..................................................................54

12.2. Technische Zeichnungen.........................................................................55

12.3. Spectral sensitivity...................................................................................56

13. Indexes.......................................................................................................57

13.1. List of Figures..........................................................................................57

13.2. ................................................................................................................. 58

14. .................................................................................................................... 62

5 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Important Information

1 IMPORTANT INFORMATION

1.1 Information about the instructions of use

This document contains technical information, important instructions for correct

installation, commissioning and use, as well as product information which were

up-to-date at the time of going to press.

Using this document makes it easier for you to familiarise yourself with the

device and avoid malfunctions caused by improper operation.

Following the instructions of use:

•

Helps to avoid risks

•

Increases the reliability of the operation of the device

•

Lengthens the service life of the device

•

Reduces repair costs and downtimes

The instructions of use and the rules and regulations applicable at the place of

used must be observed.

Storage

To ensure a save and proper application, please read the instructions of use

carefully and keep for future reference.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 6

pictor M1606

Important Information

1.2 Conventions of presentation

The formatting and the symbols in this document help you to use the

instructions of use and the device quickly and safely.

Product name

The instructions of use are valid for the products listed at the beginning. If not

referred to expressly by the specific product name, the products described are

referred to as "devices".

Advice

ADVICE

Indicates tips for users and useful additional information.

Enumeration

Indicates a listing of issues or possibilities:

Heading or topic of the enumeration

•

Example list item 1

•

Example list item 2

Operating steps

Listing of work steps, the given order of which must be followed. Numbering

starts at 1. for each individual sequence.

1. Example work step 1

Result work step 1

2. Example work step 2

Cross-references

Cross-references help you to make quick reference to particular sections of the

manual, providing valuable supplements of information. The cross-reference

shows you the page of the relevant section. Example: see "Conventions of

presentation", Page 7

7 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Important Information

Links

Links lead to documents outside the instructions for use. Expressly, no

guarantee or liability is accepted for the accuracy and security of these

documents (such as Internetpages). Links are only active in online-help and

the PDF version and with a connection to the Internet. Example: www.vision-

control.com

Spelling

Commands, menus and dialogues are highlighted in bold. The spelling Utilities

indicated the menu Utilities.

References to subordinate entries are indicated by arrows.The spelling

Utilities > I/O Test indicates the command I/O Test in the Utilities menu.

The character formatting TEXT Indicates instructions, commands, and names

that you need to enter as shown.

Buttons are marked with square brackets. [OK] indicates the OK button.

Images and Tables

Figures and tables shown as such are numbered consecutively. Individual

details in figures are marked by item numbers and lines. Each item number is

explained in the legend accompanying the figure.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 8

pictor M1606

Important Information

1.3 Presentation of Safety Instructions

Each safety instruction is introduced by a key word and colour highlighted.

The key word indicates the degree of danger. The danger and its cause are

described, and then the measures to prevent conceivable consequences of the

danger. These measures must be taken.

Level of risk

DANGER

This key word indicates an imminent danger with high risk,

resulting in severe injuries or death if not avoided.

WARNING

This key word indicates a hazardous situation with medium risk,

possibly resulting in severe injuries or death if not avoided.

CAUTION

Signal word for a hazardous situation with low risk, resulting in

minor or medium injuries if not avoided.

Note on equipment damage

DAMAGE OF PROPERTY

Indicates a situation that may result in property damage, the impracticality of

the device or loss of data.

9 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Important Information

1.4 Proper and intended use

The devices are designed as an industry-standard image processing system

for quality assurance and process automation.

The devices may only be used if they are in technically faultless condition and

only for their intended purpose, and only in accordance with the specifications

in this instructions of use by authorised operative personnel, who are aware of

the safety rules and hazards.

Areas of application

Use for the intended purpose is regarded as use in enclosed spaces for quality

assurance and process automation in the following industries:

•

Automotive

•

Mechanical engineering

•

Electrical engineering

•

Plastics industry

•

Solar industry

•

Packaging industry

•

Robotics

•

Pharmacy

•

Food industry

•

Automation technology.

The device can only function correctly and safely if it is stored, transported and

installed correctly, and operated carefully.

If the device is planned to be used for any other purpose or in a different

environment, the express authorisation of the manufacturer must be obtained

in advance. Any modifications or adaptations required may only be made by

the manufacturer.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 10

pictor M1606

Important Information

1.5 Improper Use

All unintended use and all device-related activities not described in this

operating manual is to be deemed as unauthorised misuse outside the legal

limits of indemnity of the manufacturer

Improper usage

Reasonably foreseeable misuse is:

•

Non-compliance with the instructions for use,

•

Faulty operation,

•

Operating by personnel not qualified or instructed,

•

Operating the device if it is not in a proper technical condition,

•

Operating the device in ambient conditions differing from the corresponding

specifications in the instructions of use

•

Operating the device with voltages differing from the corresponding

specifications in the instructions of use,

•

Using spare parts which are not original parts from the manufacturer,

•

Using incompatible accessory components,

•

Improper maintenance and repair works,

•

Unauthorised modifications to the device.

11 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Important Information

1.6 Qualified Personnel

The device may only be assembled, commissioned, operated, maintained,

installed, set up, cleaned, repaired and transported by qualified skilled

personnel.

Qualified personnel

A qualified person is deemed to be someone who has been trained and

instructed for his/her activities with the device, and who has proven his/her

capability to the purchaser. The operating personnel must be authorised by the

purchaser for those activities at the device.

For the installation and operation of the device, the skilled personnel must

know and comply with the applicable guidelines and standards for handling

control equipment, electrical installations and working materials.

1.7 Warranty and liability

The contents of this document have been checked carefully and correspond to

current legislation and best practise at the time of going to press.

However, the manufacturer shall not be liable for any damage arising from the

use of this edition of the manual, and rejects any warranty derived therefrom.

Within the bounds of the legal requirements, the manufacturer shall only

be responsible for the technical safety characteristics of the device if the

maintenance, repairs and modifications to the device are performed by himself

or by authorised skilled personnel in accordance with his instructions.

Loss of warranty

The manufacturer shall accept no liability or warranty in the event of improper

use, opening of the device or incorrect maintenance.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 12

pictor M1606

Safety Instructions

2 SAFETY INSTRUCTIONS

Read the following applicable safety instructions carefully and completely.

Follow the instructions for your own safety, the safety of other people, and to

avoid damage to the device and the connected technical equipment. Hazards

going beyond the general safety instructions are referred to separately at the

relevant points in this manual.

2.1 Safe Handling of the Device

Electric shock

CAUTION

Risk of injury due to electric shock.

•

Before starting work on the device, disconnect it from the

operating voltage supply.

•

Follow all applicable safety regulations for the preparation

and operation of electrical devices.

Short circuit

DAMAGE OF PROPERTY

Destruction of the device as a result of a short circuit at the outputs.

•

Ensure that the connections are made with the correct polarity.

•

Do not overload the outputs (heat generation).

13 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Safety Instructions

Electrostatic discharge

DAMAGE OF PROPERTY

Damage to semiconductor components and modules caused by

electrostatic discharge.

•

Do not open the device! Sensitive electronic components and modules

can be destroyed by unauthorised interference. Opening the device leads

to loss of warranty.

Transport damage

DAMAGE OF PROPERTY

Damage to the device as a result of improper transport.

•

Ship the device only in its original or adequately padded packaging.

•

Unscrew the lens and accessories before transporting the device, and

attach and close all covers and lids.

•

Do not allow the device to fall.

2.2 Environmental Protection

Conservation of nature is one of our major tasks. Properly disposed devices

avoid negative impacts on human beings and the environment and allows

reusing our precious resources.

Recycling

To dispose of the device in a manner that will not harm the environment follow

the instructions on "Disposal", Page 53.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 14

pictor M1606

Scope of Delivery and Accessories

3 SCOPE OF DELIVERY AND ACCESSORIES

Power supply and communication cables are required to operate the device.

Because of the many possible configurations, the cables are listed in the

accessories rather than included in the scope of delivery.

Please contact the manufacturer regarding lenses and lighting components

suitable for your field of application, or select them yourself at www.vision-

control.com.

3.1 Scope of Delivery

Designation Quantity

Device pictor M1606 1 x

Product DVD with:

•

Operating software vcwin pro

•

Instructions for use pictor M1606 as PDF

•

Instructions for use vcwin pro as PDF

•

Accesories technical data sheets as PDF

Instructions for use pictor M1606 as A5 book 1 x

Table 1: Scope of delivery

15 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

1 x

pictor M1606

Scope of Delivery and Accessories

3.2 Accessories

Description Lenght Order no.

PLC/power cable, 12-pin HIROSE socket /

open cable end

PLC/power cable, 12-pin HIROSE socket /

open cable end

PLC/power cable, 12-pin HIROSE socket /

open cable end

Table 2: Accessories PLC/power cable

Description Lenght Order no.

Ethernet cable, 6-pin HIROSE plug / RJ45

plug

Ethernet cable, 6-pin HIROSE plug / RJ45

plug

Ethernet cable, 6-pin HIROSE plug / RJ45

plug

Table 3: Accessories Ethernet cable

5 m 4-40-223

10 m 4-40-224

25 m 4-40-225

5 m 4-40-203

10 m 4-40-204

20 m 4-40-205

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 16

pictor M1606

Scope of Delivery and Accessories

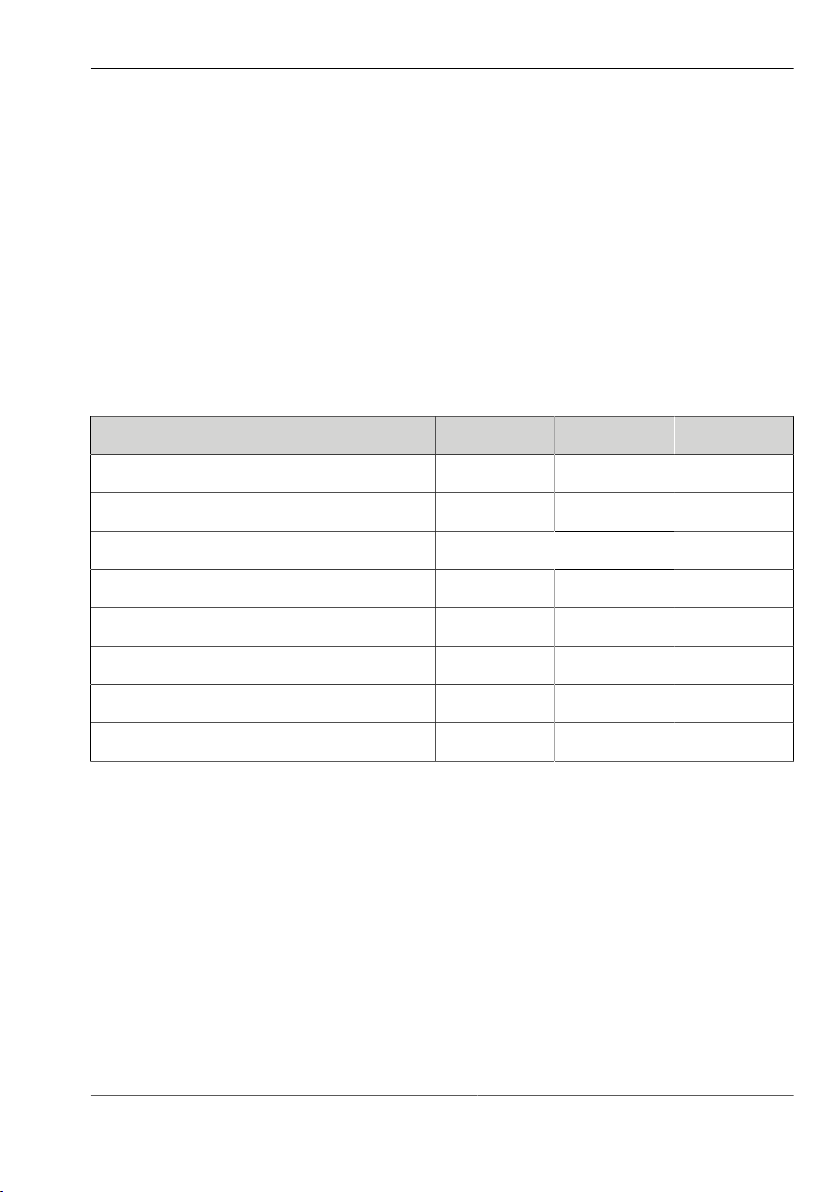

Description Lenght Order no.

SVGA cable for monitor, 10-pin HIROSE

5 m 4-40-240

plug / 15-pin Sub-D socket

SVGA cable for monitor, 10-pin HIROSE

10 m 4-40-241

plug / 15-pin Sub-D socket

SVGA cable for monitor, 10-pin HIROSE

25 m 4-40-242

plug / 15-pin Sub-D socket

Table 4: Accessories SVGA cable for monitor

Description Lenght Order no.

V24 serial cable C4 (RS232), 6-pin HIROSE

5 m 4-40-181

plug / 9-pin Sub-D socket

V24 serial cable C4 (RS232), 6-pin HIROSE

10 m 4-40-182

plug / 9-pin Sub-D socket

V24 serial cable C4 (RS232), 6-pin HIROSE

25 m 4-40-183

plug / 9-pin Sub-D socket

Table 5: Accessories V24 serial cable C4 (RS232)

Description Lenght Order no.

Trigger cable, 6-pin HIROSE plug / open

5 m 4-40-200

cable end

Trigger cable, 6-pin HIROSE plug / open

10 m 4-40-201

cable end

Trigger cable, 6-pin HIROSE plug / open

25 m 4-40-202

cable end

Table 6: Accessories Trigger cable

17 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Scope of Delivery and Accessories

Description Quantity Order no.

Key-Pad, incl. V24 serial cable C4 (RS232),

1 4-40-207

5 m, for the monitor menu

Key-Pad, without cable 1 4-40-204

Key-Pad, V24 serial cable C4 (RS232), 5 m 1 4-40-208

Table 7: Accessories Key-Pad

Description Quantity Order no.

Power supply, 24V DC/0.63 A, 12-pin

1 4-40-209

HIROSE-socket / 230V AC power plug

Table 8: Accessories Power supply

Properties of cable

You will find more detailed technical information about the cables on the data

sheets in the product catalog under www.vision-control.com or on the Product

DVD.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 18

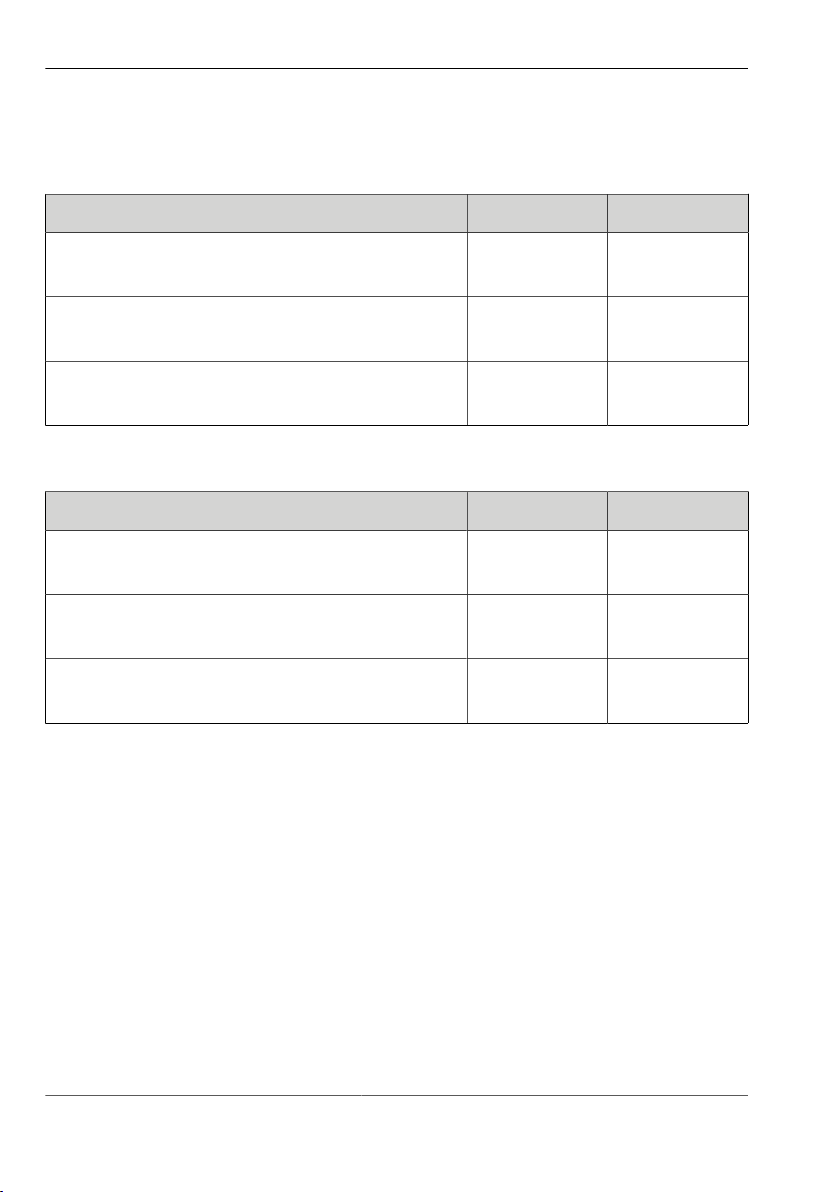

4 PRODUCT DESCRIPTION

Holder for filter

C-Mount lens connection

Imager

Mounting block

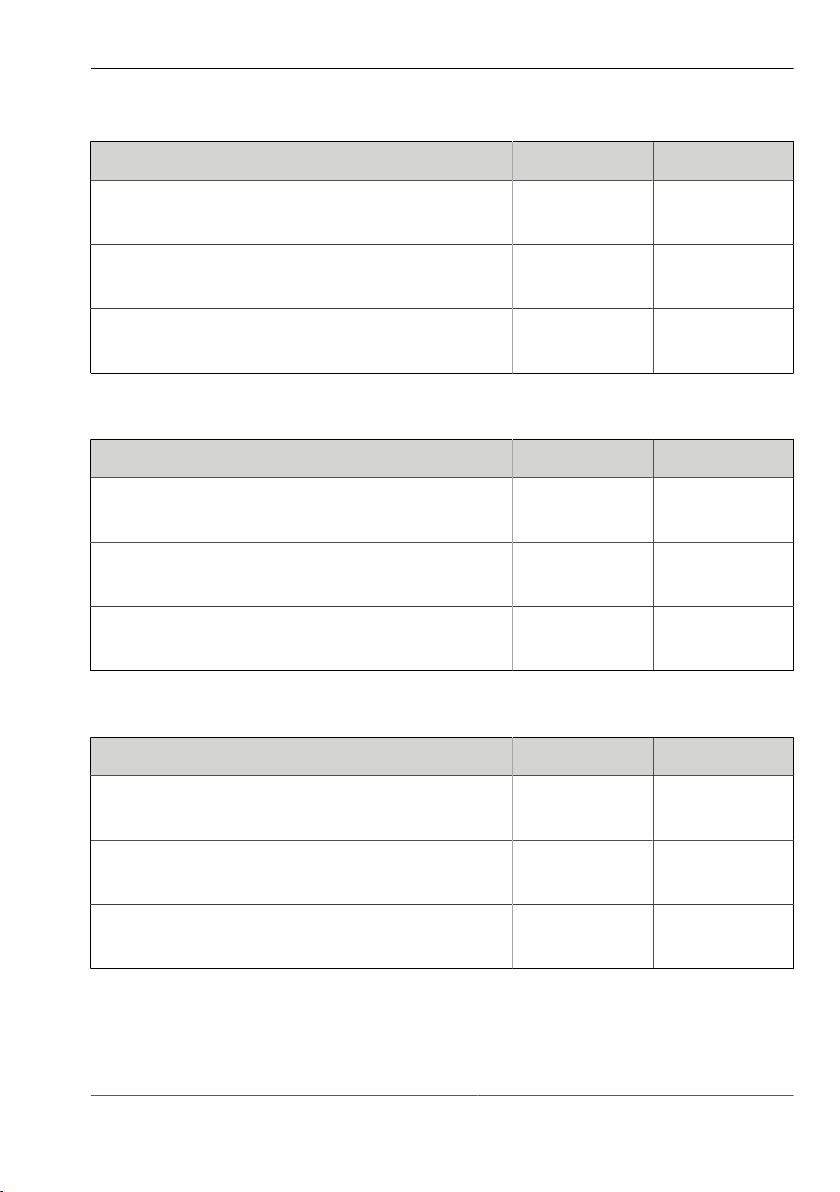

Video

LAN

Trig.

I/O

Monitor interface

Ethernet interface

PLC/Power interface

Trigger-/RS232 interface

Mounting block

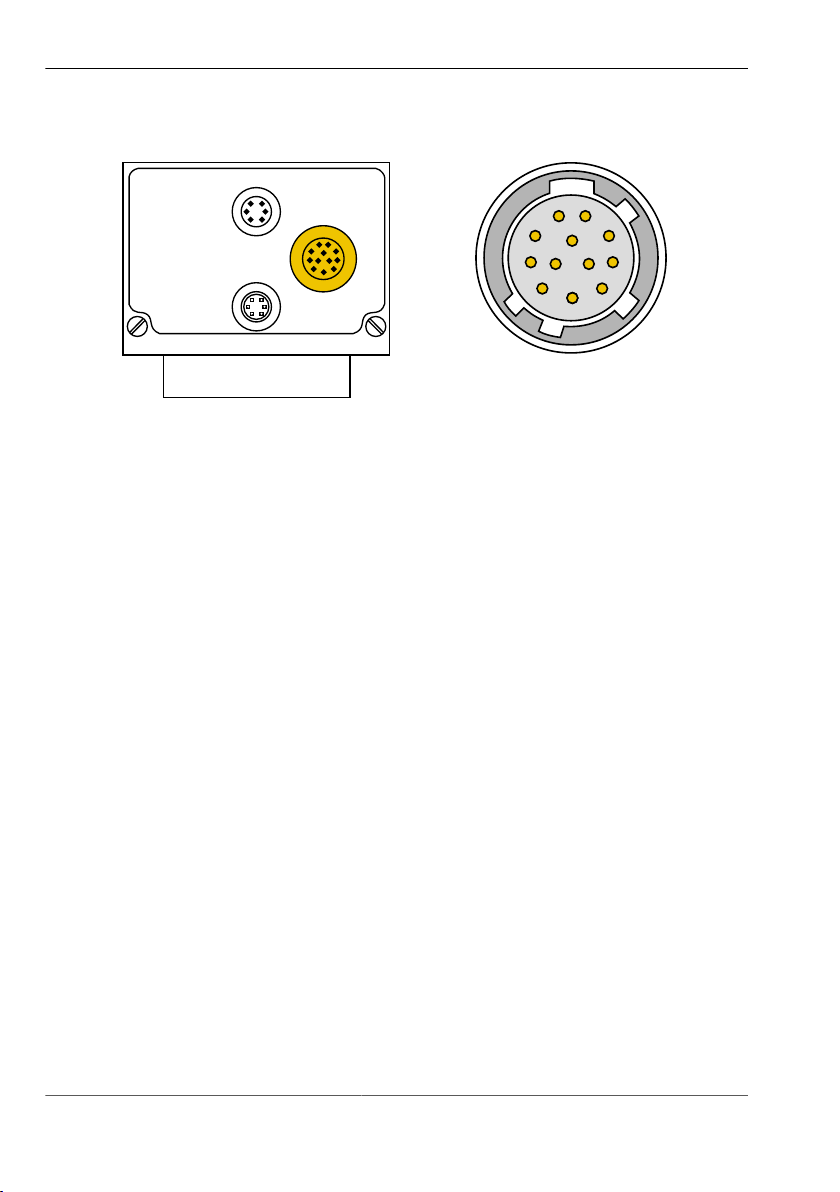

4.1 Devices Views

Front view

Image 1: Front view

pictor M1606

Product Description

Rear view

Image 2: Rear view

19 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

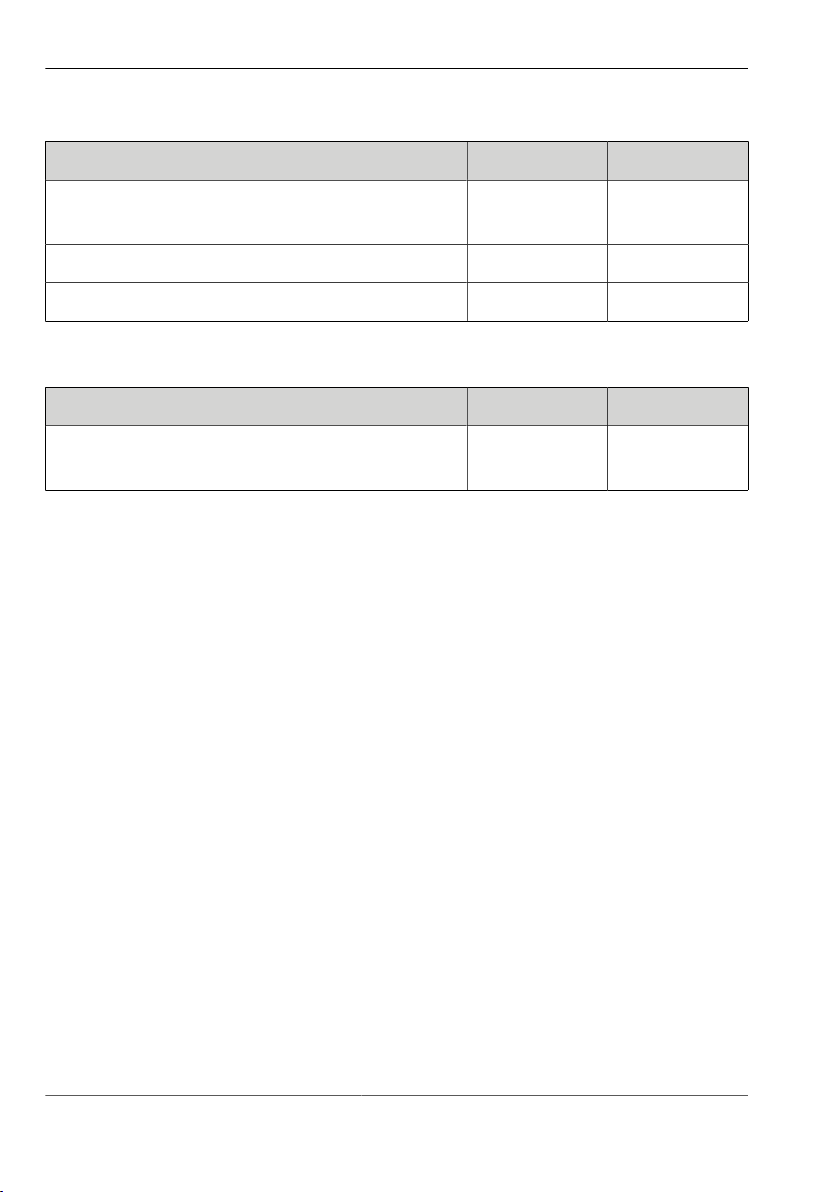

Type: pictor M1606E

No.: E6380152

98527 Suhl, Germany

Vision & Control

Label

2 x M6 thread

1 x 1-32 UN2A thread

Product Description

Bottom view

Image 3: Bottom view

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 20

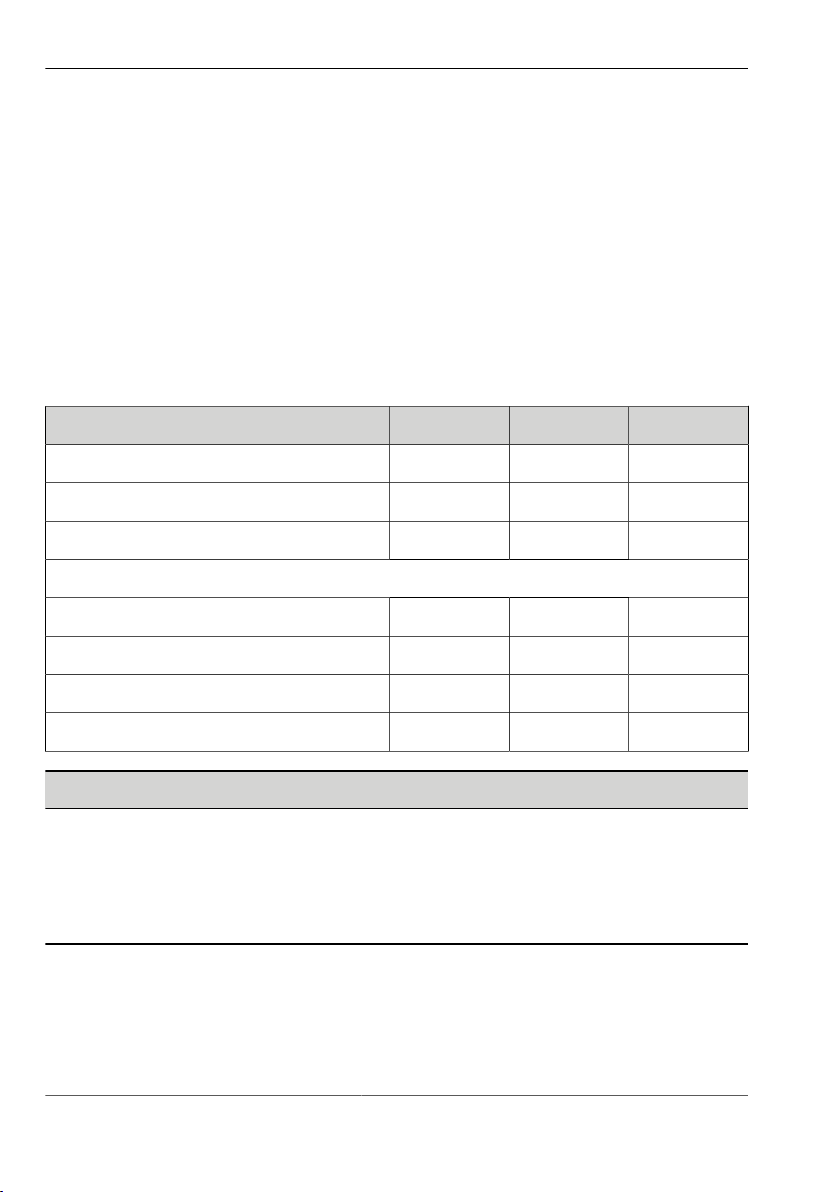

5 PRODUCT DATA

Technical Data

Image Sensor

pictor M1606

Product Data

Device

Order number

Sensor 1/3" CCD, global shutter, progressive scan

Type mono

Filter IR cut filter broadband filter

Number of pixels 640 x 480

Pixel size 7.4 µm x 7.4 µm

Sensor size 5.79 mm x 4.89 mm

max. Frame rate 63 fps

Shutter 5 µs to 8 s

Processor

Device

Order number

Processor 3200 MIPS, 400 MHz Texas

pictor M1606

4-20-193

pictor M1606

4-20-193

Instruments TMS320C64xx

pictor M1606

4-20-194

Sony ICX424AL

pictor M1606

4-20-194

RAM 64 MB SDRAM

ROM 4 MB Flash-EPROM for programs and data

Storage media internal 1 GB SD card for user data

21 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Product Data

Interfaces

Device

Order number

Communication 1 x RS232, 1 x Ethernet, 1 x TTL Trigger

Digital I/Os 4 x Digital IN, 4 x Digital OUT

Video out SXGA Monitor 800 x 600

General

Device

Order number

Housing material Aluminium alloy

Mounting At bottom: mounting block with 2 x M6 thread

Lens mount C-Mount

Dimensions / Weight 110 mm x 50 mm x 35 mm / 400 g

Protection class IP50

pictor M1606

4-20-193

pictor M1606

4-20-193

(outside) and 1 x 1/4" UNC thread (centre)

pictor M1606

4-20-194

pictor M1606

4-20-194

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 22

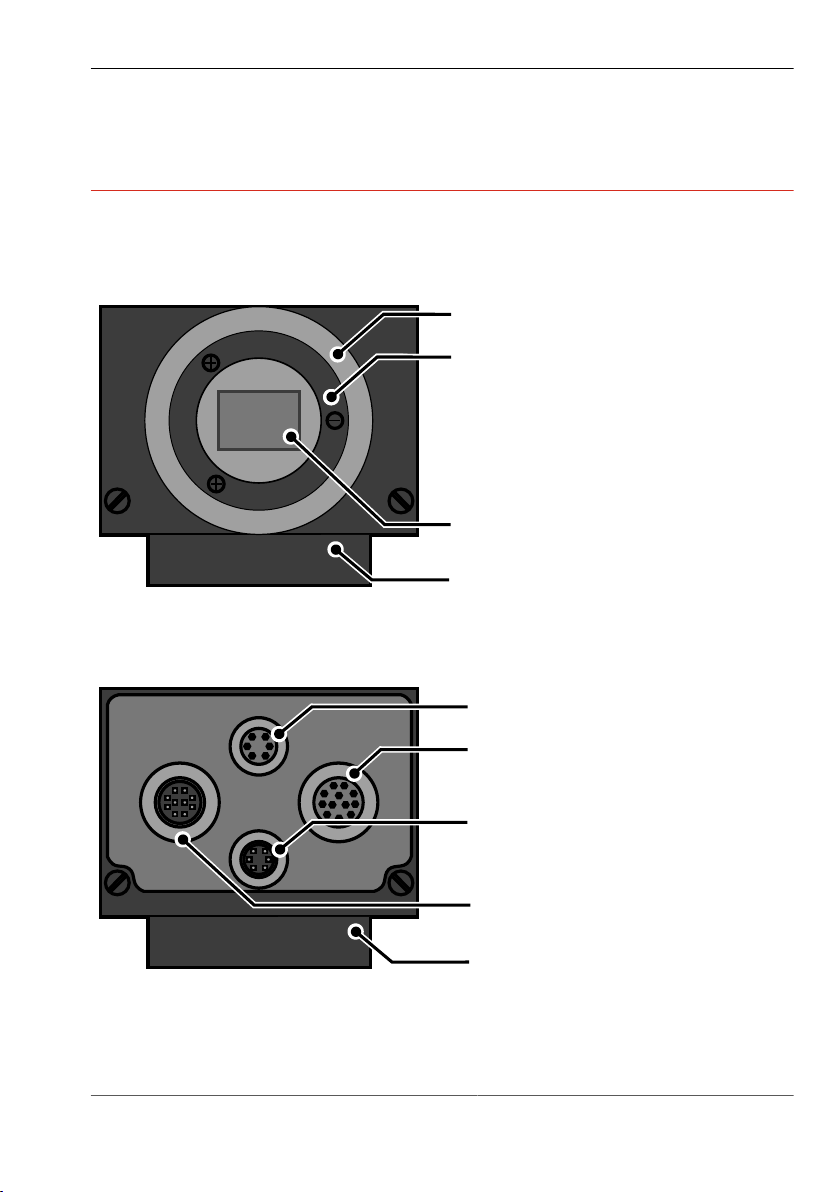

5.1 Interfaces

Video

LAN

Trig.

I/O

LAN / Ethernet interface

PLC and power interface

Trigger, RS232 or Key-Pad interface

Video-Out (SVGA/SXVGA)

Overview of Interfaces

Image 4: Overview of interfaces

5.1.1 Digital I/O-Interfaces

pictor M1606

Product Data

The digital I/O interfaces are only available if the device is connected via the

Power/ PLC cable. In this case, the device is connected to the digital inputs

and outputs of a control unit and to the voltage supply.

Parameters Digital inputs

Parameter Min Nom Max

Number of inputs 4

Input voltage (DC) 0 V 24 V 28 V

Input current at 24 V DC 3.5 mA

Input voltage Low (DC) 0 V

Input voltage High (DC) 8 V 28 V

Overvoltage protection present

23 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Product Data

Parameter Digital Outputs

Parameter Min Nom Max

Number of outputs 4

Power supply* 9.8 V 24 V 28 V

Switched potential power supply

Output current per output 500 mA

Output current all outputs 1 A

Switching power 24 V DC, 500 mA 12 W *

Protection against short circuit present

* external via Pin 1 and Pin 9 Digital IN

5.1.2 Ethernet interface

The device has an Ethernet interface for communicating with a host computer

or network.

•

Manage up to 16 simultaneous TCP / IP connections

•

Server port 8500 (initialization with vcwin pro)

•

Data rate: 100 Mbit

IP configuration in the as-supplied state

The device first attempts to have an IP address assigned from a DHCP. If an IP

address is not assigned by a DHCP server, the device has to be configured as

follows:

•

Static configuration

•

IP address 192.168.0.65

•

Subnet mask 255.255.255.0

•

Gateway 192.168.0.254

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 24

pictor M1606

Product Data

5.1.3 RS232 interface

The device has a RS232 interface for serial communication with a process

control system (PLC, computer). The baud rate is set in the factory to 9.600

kbit/s. It can be adjusted from the software user interface.

The device can be parameterised with vcwin pro via the RS232.

The sending of measured values via the RS232 has to be activated /

parameterised by using of the vcwin pro software.

Parameters RS232 interface

Parameter Min Nom Max

Quantity 1

Baud rate 9.6 kbit/s 115.2 kbit/s

Protocol depends on the software used

Number of Bits 8

Number of stop-bits 1

Parity none

Flow control none

Galvanic isolation present

Key pad

For operation via the monitor menu the key pad (accessory) can be connected

to the RS232 interface. The power supply of the key pad is done automatically

by the device using the D-sub connector of the connecting cable. For details on

the key pad, please refer to the corresponding data sheet.

25 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Product Data

5.1.4 Trigger interface

The device has a special trigger interface, a dedicated fast TTL trigger input

(for use as image capture trigger) and a fast TTL trigger output (Strobe

Trigger).

Both signals are very fast and have a very low signal to noise ratio, it is

recommended to keep the cable as short as possible. Use only shielded cables

for this purpose.

Parameters Trigger interface

Parameter Min Nom Max

Quantity 1

Output voltage 7 V DC

Output current 50 mA

Switching level

Input voltage Low 0 V DC 0.8 V DC

Input voltage High 2 V DC 5 V DC

Output voltage Low 0 V DC 0.4 V DC

Output voltage High 2.4 VDC 5 V DC

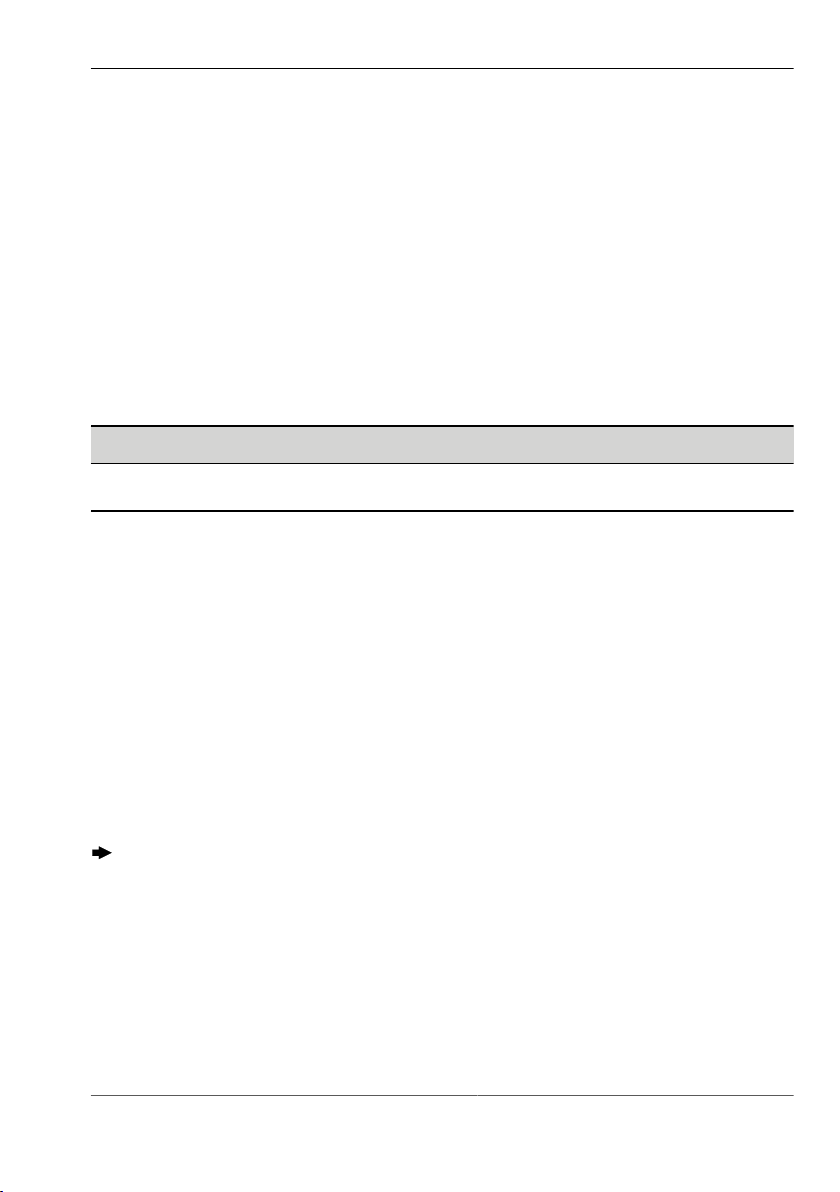

ADVICE

Neither the trigger input is nor the trigger output has an in-built in photo

coupler.

Ensure that the electrical specifications of this section are met and provide

galvanic isolation to trigger input and output if necessary.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 26

pictor M1606

Product Data

ADVICE

Input and output are not protected against over current.

The output is neither protected against short circuit nor reverse voltage

spikes from inductive loads.

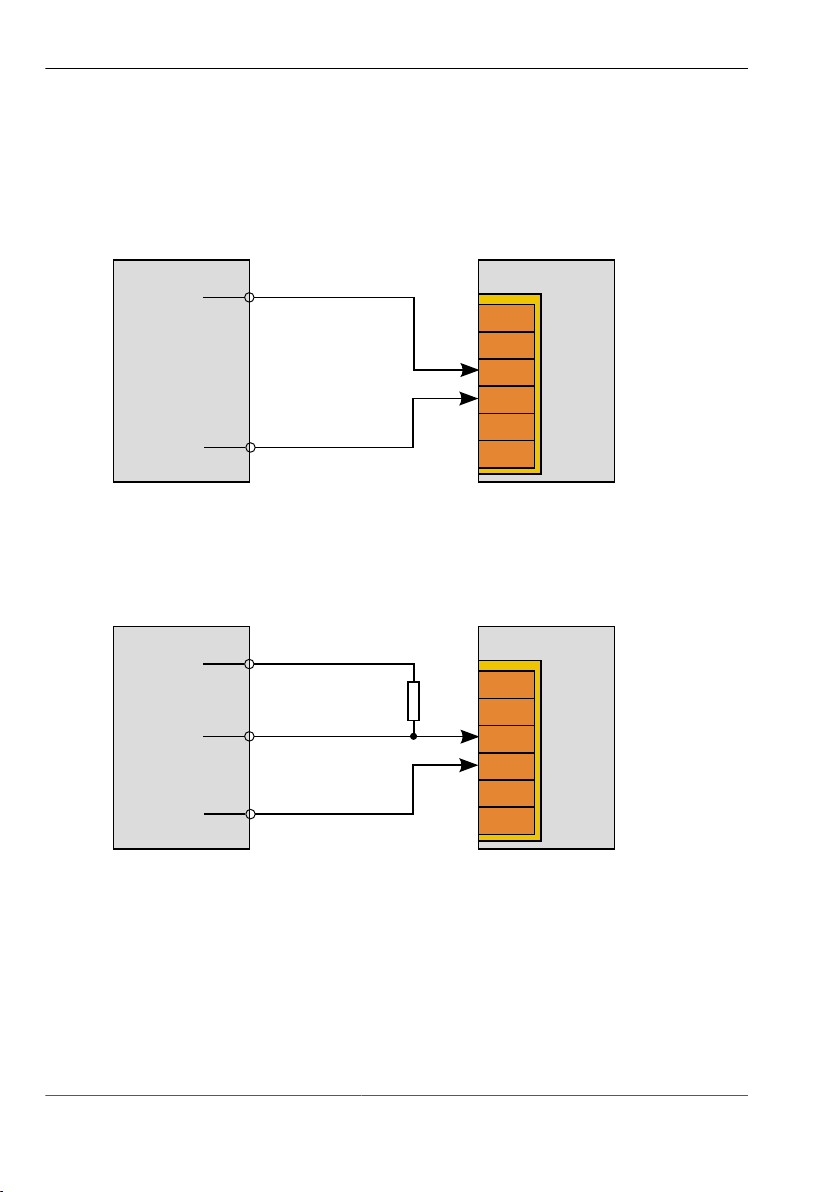

Block diagram of trigger input

Image 5: Trigger input NPN

Image 6: Trigger input PNP

27 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Product Data

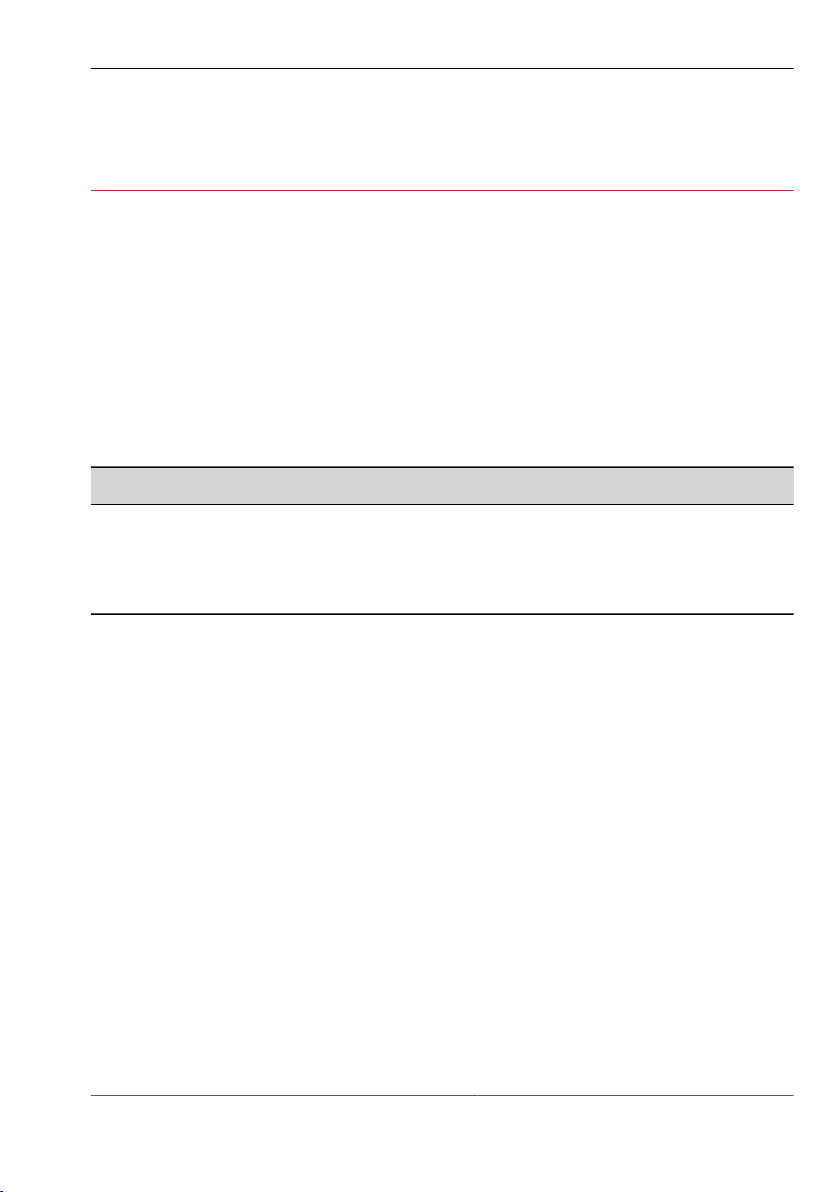

Block diagram of trigger output

Image 7: Trigger output

5.2 Conditions for Operation, Storage and Transport

The following ambient conditions for operation, storage and transport must be

maintained:

Conditions that must be maintained

Ambient conditions Operation Storage and transport

Temperature 0 °C to + 50 °C - 20 °C to + 60 °C

Air humidity 20 % to 80 % 20 % to 90 %

Condensation water not permissible not permissible

Observe the relevant specific instructions for accessories and connected

devices and components stated in the corresponding manuals and operating

instructions.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 28

pictor M1606

Operation software vcwin pro

6 OPERATION SOFTWARE VCWIN PRO

If the device is connected Ethernet interface, it can be immediately controlled,

parameterised and configured with the vcwin pro operation software.

The devices are parameterised with the vcwin pro operation software via the

Ethernet interface (recommended) or the RS232 interface. The software also

enables test sequences to be created.

6.1 System Requirements

Minimum requirements of the computer

•

Operating systems: Windows Vista, Windows 7, Windows 8.1- Both 32 and

64 bit versions (Windows RT is not supported)

•

DVD drive (for installation from DVD) or Internet connection (for installation

after download)

•

Minimum 1 GB free RAM

•

Monitor with a resolution of at least 800 x 600 pixels

•

Ethernet interface

•

Serial interface (optional for sending and receiving via RS232)

29 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Operation software vcwin pro

6.2 Installing, Starting and Updating operating software vcwin pro

ADVICE

Administrator rights are required to install the operating software.

Installing vcwin pro

1. Insert the supplied DVD into the drive of the host computer

2. Select option "Open Autorun menu" or double click the "start.exe" file.

3. Select language.

4. Select menu item "Software".

5. Select the operating software vcwin pro and install on the computer by

clicking [Install]. Follow the instructions given by the installation program,

and change the target directory if desired.

The software also installs an optional icon on the Windows Desktop, and

creates entries in the start menu.

Starting vcwin pro

The operating software can be started by double clicking the icon on the

Desktop or by selecting it from the start menu. Registration is not required.

Updating vcwin pro

The software version which is current at the time of delivery is always supplied

with the device. There is no automatic update.

The operating software vcwin prois continually further developed to adapt and

extend its scope of functions to meet customer requirements. New versions of

the operating software can be downloaded from: www.vision-control.com.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 30

pictor M1606

Commissioning

7 COMMISSIONING

7.1 Unpacking

DAMAGE OF PROPERTY

Damage or destruction of the device caused by condensation and large

temperature differences!

•

Do not subject the device to large temperature fluctuations.

•

After storage and transport, allow the device to adjust slowly to the

ambient temperature at the place of use.

•

Do not open the lens cover during the acclimatisation (to prevent the

formation of condensation water).

ADVICE

Unpack the device in a dry, dust-free environment.

1. Lift the cardboard, together with the device, out of the carton.

2. Fold out the tucked in sides on the bottom of the cardboard.

Loosening the film and forming an insertion pocket.

3. Remove the device out of the insection pocket.

4. Dispose the packing material (see "Disposal", Page 53).

31 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Commissioning

7.2 Mounting

DAMAGE OF PROPERTY

Cable damaged by a bending radius that is too small and the lack of a

strain relief clamp.

•

Comply with the specified minimum bending radius.

•

Cables must generally be mounted with a strain relief clamp.

•

Use cables corresponding to the specification (see data sheet).

Mounting of cables

When mounting the cable to the device, hold the device and plug the cable into

the connector.

Mounting the device

To install the device, a mounting block with two tapped holes M6 and a 1-32

UN 2A thread is located at the bottom.

Distance between the tapped holes 25 mm

Maximum screwed-in depth 7 mm

Maximum tightening torque 10 Nm

Table 9: Properties of the tapped holes

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 32

Mounting holes

17.5

30.0

42.5

25.0

M6 M61-32 UN 2A

17.5

28.5

55.5

8.0

pictor M1606

Commissioning

Image 8: Mounting holes for mounting the device

Mounting the Lens

1. Remove the protective film / cap.

2. Screw on the selected lens.

Working distance and recording range

The working distance, recording range and size of the image field are flexible

and dependent on the selected lens.

33 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Commissioning

7.3 Connecting

The operating voltage is supplied via the PLC/Power cable or the power plug.

Communication takes place via the PLC/Power cable and/or Ethernet, RS232.

7.3.1 Operating Voltage Supply

The operating voltage is supplied through the PLC/Power Cable (accessories)

or the power supply (accessories).

When using the power supply, the digital I/O interfaces of the device can not be

used.

Requirements on the operating voltage source

•

protective earth contact,

•

earthing.

Parameter

Parameter Min Nom Max

Operating voltage 9 V 24 V 28 V

Current consumption at 24 V DC 125 mA 350 mA

Power consumption at 24 V DC 5.5 W

Table 10: Parameters of the operating voltage supply

ADVICE

The power supply of the camera and the power supply to the digital I/O

channels are separated internally.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 34

Connection of the operating voltage supply

IN GND

CAM PWR

+

2

3

Image 9: Connection of the operating voltage supply

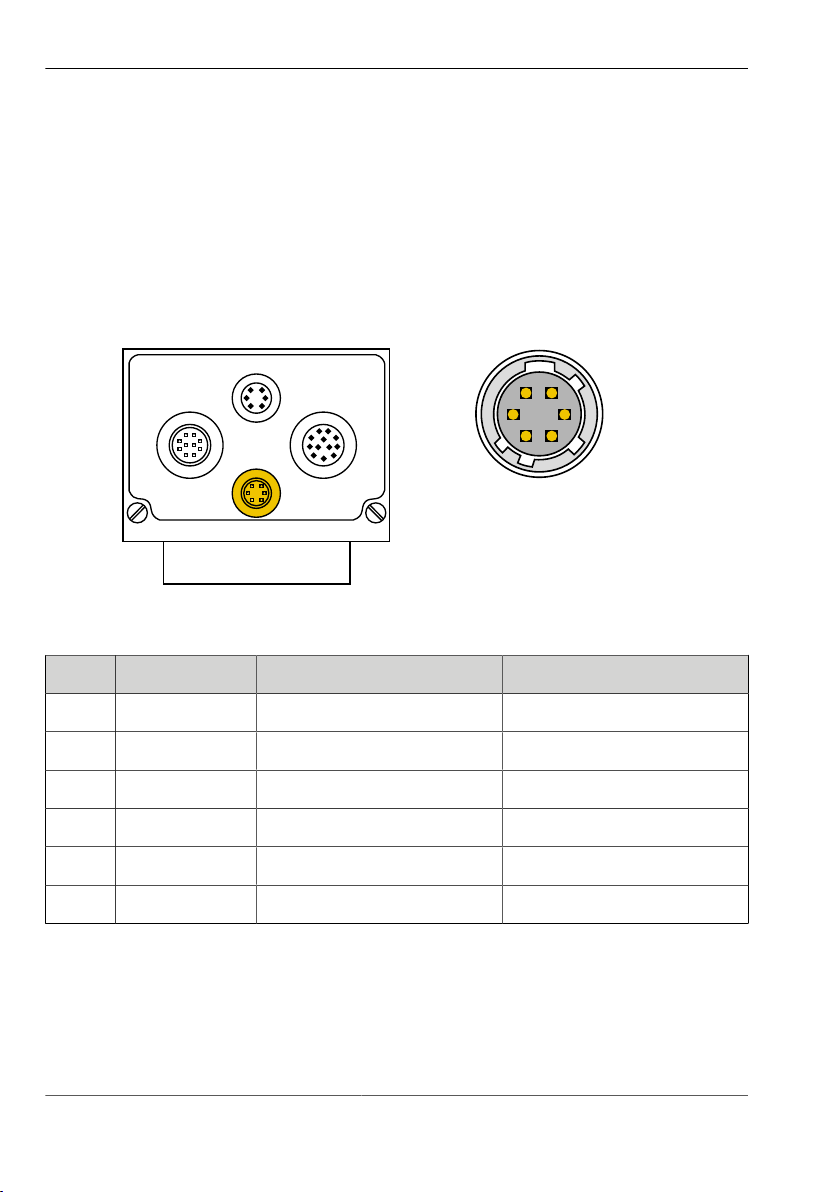

7.3.2 Connecting the PLC/Power cable

pictor M1606

Commissioning

Perform the following steps only in de-energiesed state.

1. Plug the 12-pin Hirose plug of the PLC/Power cable into the I/O socket on

the device.

2. Connect the open end of the PLC/Power cable to control unit.

35 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

LAN

Trig.

I/O

1

2

3

4

5

6

7

8

9

10

11 12

Commissioning

Image 10: PLC/Power cable

connection

Image 11: View: socket on camera

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 36

Commissioning

Pin assignments PLC/Power cable

Pin Colour Assignment Open cable end

1 red 24 V PLC* + 24 V dig. input and output

2 red / blue +UB Operating voltage + 24 VDC

3 black GND Operating voltage GND

4 pink IN 2 Digital input 2

5 yellow OUT 4 Digital output 4

6 green OUT 3 Digital output 3

7 brown OUT 2 Digital output 2

8 white OUT 1 Digital output 1

9 grey / pink 24 V PLC* + 24 V dig. input and output

10 violet IN 4 Digital input 4

pictor M1606

11 blue IN 3 Digital input 3

12 grey IN 1 Digital input 1

* The PLC output voltage is separated from the supply voltage. There is a

common ground for PLC output voltage and supply voltage.

Table 11: Pin assignment PLC/Power cable

37 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Video

LAN

Trig.

I/O

1

2

3

4

5

6

Commissioning

7.3.3 Connecting the Ethernet cable

Perform the following steps only in de-energiesed state:

1. Insert the 6-pin HIROSE plug of the Ethernet cable into the LAN socket on

the device.

2. Connect the RJ45 plug to a free Ethernet interface on the host computer or

the network.

Image 13: View: socket on camera

Image 12: Ethernet cable

connection

Pin assignment Ethernet cable

Pin Designation Description RJ45 plug pin

1 TX- Send data - 2

2 TX+ Send data + 1

3 NC not connected

4 NC not connected

5 RX- Received data- 6

6 RX+ Received data+ 3

Table 12: Pin assignment Ethernet cable

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 38

pictor M1606

Video

LAN

Trig.

I/O

1

2

3

4

5

6

Commissioning

7.3.4 Connecting the RS232 cable

Perform the following steps only in de-energiesed state:

1. Insert the 6-pin HIROSE plug of the RS232 cable into the Trig. socket on the

device.

2. Plug the D-Sub plug into a free serial port (COM) of the process control

system or the key pad, and screw tight.

Pin assignment RS232 cable

Pin Signal Description D-Sub pin

1 TxD Send data 2

2 + 5 VDC Out Power + 5 V DC* *

3 GND Ground 5

4 RxD Receive data 3

5 Trigger Out Trigger output* *

6 +5 V TTL Trigger input* *

* Only for key pad.

Table 13: Pin assignment RS232 cable

39 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Video

LAN

Trig.

I/O

1

2

3

4

5

6

Commissioning

7.3.5 Connecting the trigger cable

Perform the following steps only in de-energiesed state:

1. Insert the 6-pin HIROSE plug of the trigger cable into the Trig. socket on the

device.

2. Connect the open end of the trigger cable to control unit.

Pin assignment trigger cable

Pin Colour Assignment Open cable end

1 green RS232 TxD Out Send data

2 brown +5 V DC Out Power +5 V

3 white GND Ground

4 violet RS232 RxD Receive data

5 grey Trigger Out Output trigger

6 yellow +5 V TTL Input trigger

Table 14: Pin assignment trigger cable

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 40

pictor M1606

Video

LAN

Trig.

I/O

9

8

7

6

5

4

3

2

1

10

Commissioning

7.3.6 Connecting the video cable

Perform the following steps only in de-energiesed state:

1. Insert the 10-pin Hirose plug of the video cable into the video socket on the

device.

2. Connect the 15-pin D-Sub plug with a monitor.

Image 15: View: socket on camera

Image 14: Video cable connection

Pin assignments video cable

Pin Signal Description Pin Signal Description

1 G GND Ground signal green 2 G OUT Signal green

3 R GND Ground signal red 4 R OUT Signal red

5 VS GND Ground Vertical Sync 6 VS OUT Vertical Sync

7 HS GND Ground Horizontal Sync 10 HS OUT Horizontal Sync

8 B GND Ground signal blue 9 B OUT Signal blue

Table 15: Pin assignments video cable

41 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

vicolux ®

+5 V

Trig. Out

Camera

+Trg.

-Trg.

vicolux ®

+5 V

Trig. Out

Camera

+Trg.

-Trg.

GND

R

Commissioning

7.3.7 Connecting vicolux lighting

Connecting a vicolux® lighting with TTL trigger via HIGH/LOW status transition

Image 16: Connection option HIGH/LOW edge

Connecting a vicolux® lighting with TTL trigger via LOW/HIGH status transition

Image 17: Connection option LOW/HIGH edge

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 42

pictor M1606

vicolux ®

GND

Trig. Out

Camera

+ PLC

- PLC

+ 24 V

vicolux ®

Trig. Out

Camera

GND

R

+ PLC

- PLC

+ 24 V

Commissioning

Connecting a vicolux® lighting with 24 V PLC control and LOW/HIGH edge at

the Trigger Out

Image 18: Connection option with PLC and HIGH/LOW edge

Connecting a vicolux® lighting with 24 V PLC control and HIGH/LOW edge at

the Trigger Out

Image 19: Connection option with PLC and LOW/HIGH edge

43 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Commissioning

7.3.8 Connecting the Power supply

ADVICE

When using the power supply (AC adapter), the digital I/O interfaces of the

device can not be used.

Perform the following steps only in de-energiesed state.

1. Plug the 12-pin HIROSE connector of the power supply into the I/O socket

on the device.

2. Plug the power supply into a socket.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 44

pictor M1606

Operation

8 OPERATION

8.1 Switching On and Off (Ready for Operation)

The device is switched on with the operating voltage supplied via the PLC/

Power cable.

Disconnecting the device from the operating voltage supply switches the device

off.

8.2 Operation from the Software Interface

ADVICE

To operate the device from the software, please read the corresponding

instructions of use for the operation software vcwin pro.

This also describes the scope of functions and test functions of the software.

8.2.1 First steps

1 Connect the device to a host computer (RS232 or Ethernet cable). See:

"Connecting the RS232 cable", Page 39 / "Connecting the Ethernet cable",

Page 38

2 Connect the device to a control monitor (optional). See: "Connecting the

video cable", Page 41

3 Connect the device with a 24 V DC power supply. See: "Connecting the

PLC/Power cable", Page 35

4 Start the operation software vcwin pro on the computer.

45 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

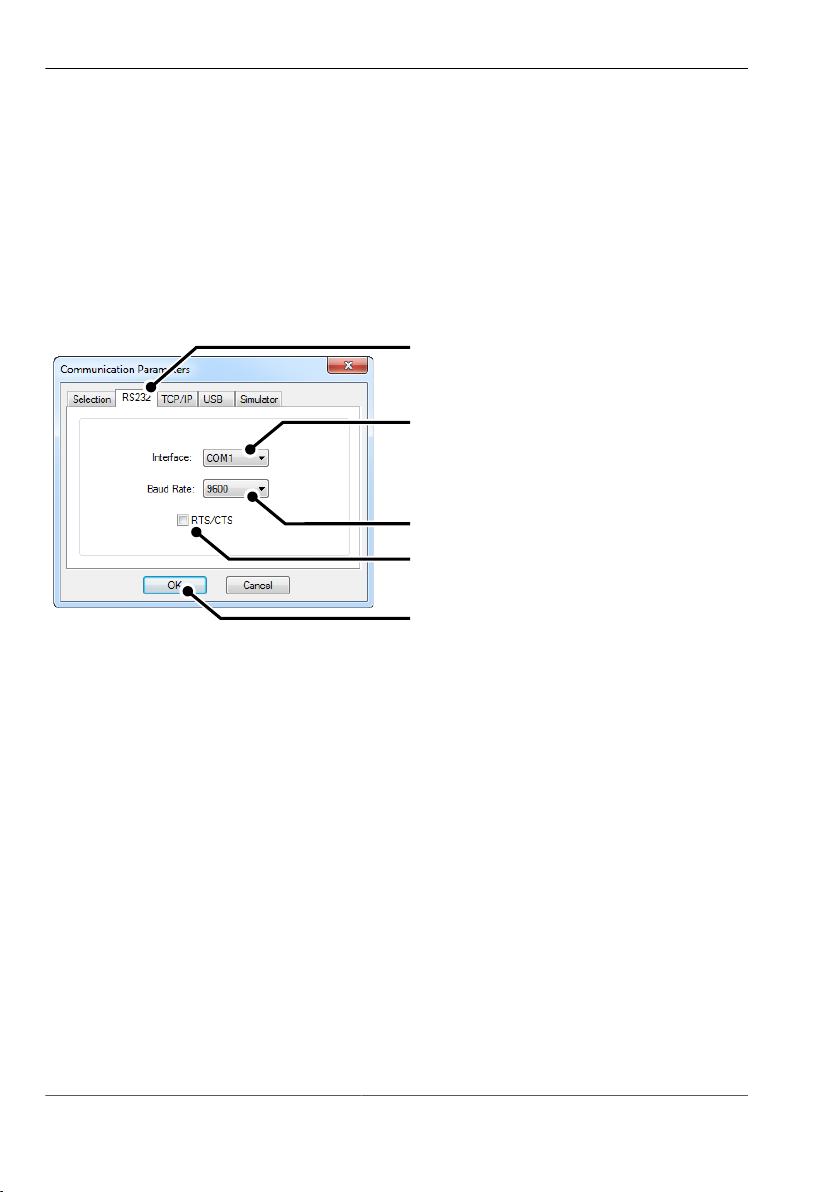

1

2

3

4

5

Operation

8.2.2 Interface Settings

Use Menu Communication > Interface to configure the interface for

communication between the host computer and the device.

Settings made here are used in every connection with vcwin pro.

Serial connection with the device

Image 20: vcwin pro dialogue: Communication Parameters RS232

1. Switch to the RS232 tab.

2. Select the the COM interface of your computer.

3. Set the baud rate to 9600. After connecting the baud rate can be adjusted.

4. Deactivate RTS/CTS (Hardware handshake of the RS232 interface).

5. Click the [OK] button to accept the values.

The device can now be connected to vcwin pro.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 46

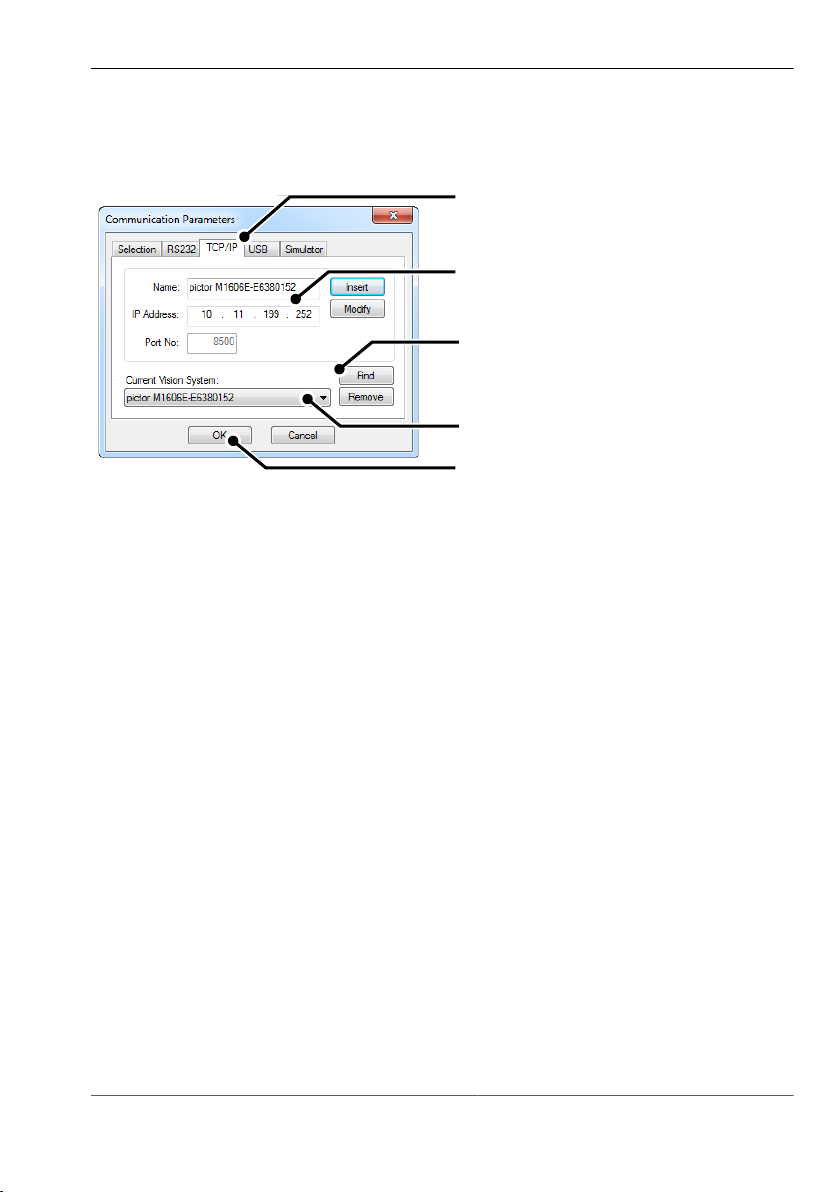

pictor M1606

1

4

2

3

5

Operation

ICP/IP connection with the device

Image 21: vcwin pro dialogue: Communication Parameters TCP/IP

1. Switch to the TCP/IP tab.

2. With the [Search] button, all available devices, on the same subnet, are

displayed (UDP broadcast to all participants).

3. Select the appropriate device.

4. Optionally, you can also enter the name and IP address of your device.

5. Click the [OK] button to accept the values.

The device can now be connected to vcwin pro.

47 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Operation

8.2.3 Connect to the operation software

Connect the device with the operation software vcwin pro via:

•

Menu: Communication > Connect

or

•

Toolbar

The initialisation of the host computer interface sets up a connection with the

device via vcwin pro. The Run Mode is interrupted and the system resources

are queried. vcwin pro uses the initialisation to recognise all the geometry

variables, results, contour buffer, counters, image memory pages and I/O

hardware available from the device connected. After initialising, the system is in

Command Mode and vcwin commands may be used.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 48

pictor M1606

Maintenance and Service

9 MAINTENANCE AND SERVICE

9.1 Maintenance

The device is maintenance-free. Depending on the operating environment, it

may have to be cleaned.

Cleaning the outer face

The housing can be cleaned according to the conditions applicable to the given

protection class.

Clean the outside with a damp cloth and a gentle cleanser.

Cleansers must not be applied directly to the housing, and the housing must

not be bathed.

Do not use any corrosive cleansers, such as lyes, MEK cleanser (methyl ethyl

ketone), benzine or similar substances!

The device must not be opened. The port sockets must be clean and dry

before the device is connected and brought into operation.

Cleaning the protective glass / filter

Do not scratch and keep dust and grease off the protective glass! Do not touch

the glass!

If it is heavily soiled, clean the protective glass with a cotton bud soaked in

ethyl, methyl or isopropyl alcohol. The alcohol must not be applied directly to

the protective glass.

Clean and care for the lenses as described in the guide for the relevant lens.

Cleaning by the manufacturer

The device can be sent to the manufacturer for cleaning (for a fee). Please

contact our Technical Support.

49 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Maintenance and Service

9.2 Service

Technical Support

Please contact our Technical Support if you have any technical questions

concerning our products. Competent employees will deal with your problems

and questions.

We will be glad to be of service:

Monday to Thursday 8:00 to 17:00, and Friday 8:00 to 15:00.

Phone: +49 (0) 3681/ 7974 - 20

Defective device

If the device has a defect, the manufacturer can repair or exchange it. Please

contact your local sales partner or Technical Support.

Firmware update

The device can be sent to the manufacturer for a firmware update (for a fee).

Please contact our Technical Support.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 50

pictor M1606

Decommissioning

10 DECOMMISSIONING

ADVICE

The device is decommissioned in the same way as it was commissioned, but

in reverse order.

The order of the points "Disconnect" and "Dismount" is decided by the

accessibility of the device when mounted in the operating environment.

10.1 Disconnect

ADVICE

Only disconnect the device when it is not processing.

1. Disconnect the device from the operating voltage supply.

2. Disconnect communication:

°

Disconnect the PLC/power cable from the control unit.

°

Remove the RJ45 plug of the Ethernet cable from the host computer.

°

Remove the D-Sub plug of the RS232 cable from the process control

system.

°

Remove the D-Sub plug of the SVGA-cable from the monitor.

3. Disconnect all cables from the device.

51 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Decommissioning

10.2 Dismount

1. Secure or hold the device firmly.

2. Unscrew the screws holding the device in the holder.

3. If applicable, unscrew the lens.

4. Put the cover on the lens mount.

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 52

pictor M1606

Disposal

11 DISPOSAL

11.1 Disposal

The device and its accessories and packaging must be sent for

environmentally compatible recycling.

Do not throw electrical devices or tools into the household waste!

According to European Directive 2002/96/EC on waste electrical and electronic

equipment and its implementation in national law, unusable electric tools must

be collected separately, and sent for environmentally compatible recycling.

Disposal, including that of individual components, must also always be in a way

that does not harm the environment, that is it must be done in accordance with

the currently valid legal regulations.

Please contact the manufacturer, your local specialist dealer or the relevant

national authority for the proper disposal of old devices.

The electrical and electronic components must be sent to a specialist recycling

company or to the manufacturer for proper disposal.

53 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Appendix

12 APPENDIX

12.1 EC Declaration of Conformity

Vision & Control GmbH

Mittelbergstraße 16

D-98527 Suhl, Germany

Representative: Dr. Jürgen Geffe, Managing director

We, Vision & Control GmbH Suhl, declare that the products described below

•

pictor M1606/E

have been manufactured in accordance with the following standards and

normative documents:

•

2004/108/EC – Electromagnetic compatibility

•

DIN EN 61000-6-2:2005 – Immunity for industrial environments

•

DIN EN 61326-1:2006 – Electrical equipment for measurement, control and

laboratory use

Suhl, 01.03.2013

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 54

12.2 Technische Zeichnungen

Dimensions

pictor M1606

Appendix

Image 22: Dimensions

55 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Appendix

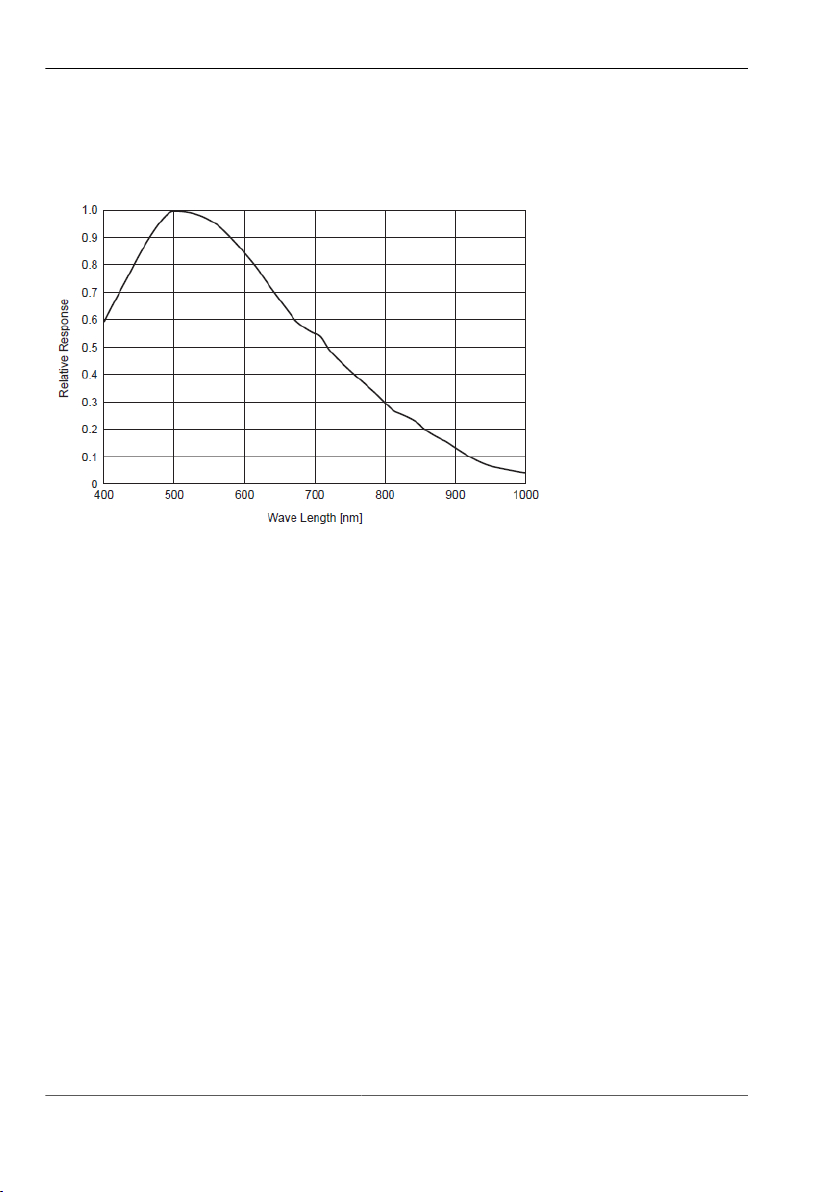

12.3 Spectral sensitivity

Image 23: Spectral sensitivity M1606/E

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 56

pictor M1606

Indexes

13 INDEXES

13.1 List of Figures

Image 1: Front view....................................................................................19

Image 2: Rear view.................................................................................... 19

Image 3: Bottom view.................................................................................20

Image 4: Overview of interfaces.................................................................23

Image 5: Trigger input NPN....................................................................... 27

Image 6: Trigger input PNP........................................................................27

Image 7: Trigger output.............................................................................. 28

Image 8: Mounting holes for mounting the device ....................................33

Image 9: Connection of the operating voltage supply................................35

Image 10: PLC/Power cable connection...................................................... 36

Image 11: View: socket on camera..............................................................36

Image 12: Ethernet cable connection...........................................................38

Image 13: View: socket on camera..............................................................38

Image 14: Video cable connection............................................................... 41

Image 15: View: socket on camera..............................................................41

Image 16: Connection option HIGH/LOW edge...........................................42

Image 17: Connection option LOW/HIGH edge...........................................42

Image 18: Connection option with PLC and HIGH/LOW edge.....................43

Image 19: Connection option with PLC and LOW/HIGH edge.....................43

Image 20: vcwin pro dialogue: Communication Parameters RS232............ 46

Image 21: vcwin pro dialogue: Communication Parameters TCP/IP........... 47

Image 22: Dimensions.................................................................................. 55

Image 23: Spectral sensitivity M1606/E....................................................... 56

57 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Indexes

A

Accessories...................................................................................................... 16

Air humidity .................................................................................................... 28

Ambient conditions.......................................................................................... 28

C

Communication.......................................................................................... 22, 34

Connecting....................................................................................................... 34

Connecting the interface................................................................................. 48

D

Decommissioning............................................................................................. 51

Devices Views................................................................................................. 19

Digital I/O-Interfaces........................................................................................ 23

Digital I/Os....................................................................................................... 22

Digital inputs.................................................................................................... 23

Digital Outputs................................................................................................. 24

Dimensions ..................................................................................................... 22

Dismount.......................................................................................................... 52

E

Electrostatic discharge.................................................................................... 14

Ethernet cable........................................................................................... 16, 38

Ethernet interface............................................................................................ 24

F

Frame rate....................................................................................................... 21

G

General............................................................................................................ 22

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 58

pictor M1606

Indexes

H

Housing material.............................................................................................. 22

I

ICP/IP connection............................................................................................ 47

Image Sensor.................................................................................................. 21

Interfaces................................................................................................... 22, 23

K

Key pad........................................................................................................... 25

Key-Pad........................................................................................................... 18

L

Lens................................................................................................................. 33

Lens mount...................................................................................................... 22

M

Mounting.................................................................................................... 22, 32

N

Number of pixels............................................................................................. 21

O

operating voltage....................................................................................... 34, 45

Operating Voltage Supply................................................................................ 34

P

photo thread.................................................................................................... 32

Pixel size......................................................................................................... 21

PLC/power cable.......................................................................... 16, 34, 35, 45

Power supply............................................................................................. 18, 44

59 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

pictor M1606

Indexes

Processor......................................................................................................... 21

Product name.................................................................................................... 7

Protection class............................................................................................... 22

R

Ready for Operation........................................................................................ 45

rigger cable...................................................................................................... 40

RS232 cable.................................................................................................... 39

RS232 interface............................................................................................... 25

S

Scope of Delivery............................................................................................ 15

Sensor.............................................................................................................. 21

Serial connection............................................................................................. 46

Shutter............................................................................................................. 21

storage............................................................................................................. 28

SVGA cable for monitor.................................................................................. 17

T

tapped holes.................................................................................................... 32

trademarks......................................................................................................... 2

transport........................................................................................................... 28

Trigger cable.................................................................................................... 17

Trigger interface............................................................................................... 26

V

V24 serial cable C4 (RS232).......................................................................... 17

vcwin

Interface configuration................................................................................. 46

vcwin pro......................................................................................................... 25

vicolux lighting................................................................................................. 42

video cable...................................................................................................... 41

Video out......................................................................................................... 22

© Vision & Control GmbH 2014 999.994.256.10-en-1.4 60

pictor M1606

Indexes

W

Weight.............................................................................................................. 22

Working distance............................................................................................. 33

61 999.994.256.10-en-1.4 © Vision & Control GmbH 2014

Loading...

Loading...