Vision

Components

®

The Smart Camera People

VisiCube Manual

Operating Instructions for VisiCube Sensor Smart Cameras

Revision 1.0 August 2007

Document name: VisiCube.pdf

© Vision Components GmbH Ettlingen,

Germany

VisiCube Manual

II

Foreword and Disclaimer

This documentation has been prepared with most possible care. However Vision Components GmbH

does not take any liability for possible errors. In the interest of progress, Vision Components GmbH

reserves the right to perform technical changes without further notice.

Please notify

support@vision-components.com if you become aware of any errors in this manual or

if a certain topic requires more detailed documentation.

This manual is intended for information of Vision Component’s customers only. Any publication of this

document or parts thereof requires written permission by Vision Components GmbH.

Trademarks

Code Composer Studio and TMS320C6000, Windows XP, Total Commander, Tera Term, Motorola

are registered Trademarks. All trademarks are the property of their respective owners.

References

Since the VC4XXX smart camera family employs a TI processor, the programming environment and

functions for the VC20XX cameras can be used for this camera.

Further References under “Support + Download” on

www.vision-components.com:

„Support News“ – for up to date information on VC Software and Documentation.

„

Knowledge Base / FAQ“ - searchable Database with latest software developments, frequently asked

questions and demo programs.

“

Download Areas” for all documentation and Software downloads – refer to the following table:

Description Title on Website Download Area

Quick start Manual for VC cameras,

English Version

Getting Started VC Smart

Cameras

Registered User Area

Getting Started VC SDK TI

Schnellstart VC Handbuch –

Deutsche Version

Schnellstart VC Smart

Kameras

Registered User Area

Getting Started VC SDK TI

Introduction to VC Smart Camera

programming

Programming T utorial for

VC20XX and VC40XX Cameras

Registered User Area

Getting Started VC SDK TI

Demo programs and sample code

used in the Programming Tutorial

Tutorial_Code

Registered User Area

Getting Started VC SDK TI

VC4XXX Hardware Manual

VC4XXX Smart Cameras

Hardware Documentation

Public Download Area Hardware

Documentation VC Smart Cameras

VCRT Operation System Functions

Manual

VCRT 5.0 Software Manual

Registered User Area Software

documentation VC Smart Cameras

VCRT Operation System TCP/IP

Functions Manual

VCRT 5.0 TCP/IP Manual

Registered User Area Software

documentation VC Smart Cameras

VCLIB 2.0 /3.0 Image Processing

Library Manual

VCLIB 2.0/ 3.0 Software

Manual

Registered User Area Software

documentation VC Smart Cameras

The Light bulb highlights hints and ideas that may be helpful for a development.

This warning sign alerts of possible pitfalls to avoid. Please pay careful attention to sections

marked with this sign.

!

Author: Peter Neuhaus, VC Support,

mailto:support@vision-comp.com

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

III

Table of Contents

1 General Information 1

2 Special Features of the VisiCube Sensor Smart Camera 2

2.1 Main differences of VisiCube and VC4018 2

2.2 Lenses 2

2.3 LED Lighting 3

3 Technical Specifications VisiCube Smart Camera 4

4 VisiCube Interfaces 5

4.1 Power Supply / SPS IO Interface and Trigger interface 5

4.2 LAN / Ethernet Interface 6

4.3 Data / RS422 Interface 7

5 Order Numbers of VisiCube and Accessories 8

6 Programming of special VisiCube Features 9

6.1 Using PLC Inputs and Outputs 9

6.2 Capturing Images with a Hardware Trigger Signal 9

6.3 Using the RS422 Data Interface of the VisiCube 10

6.4 Using the Status LEDs 10

6.5 Using the LED Lighting 11

7 Maintenance 12

7.1 Cleaning 12

7.2 Repair 12

Appendix A: Dimensional Drawings of VisiCube A

Appendix B: Using the PLC_INT event B

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

1

1 General Information

VisiCube Sensor Smart Camera in its Compact Housing

The VisiCube camera is with its very compact form factor of only 65 x 45 x 45 mm and 170g one of the

smallest Smart Cameras on the market. Already integrated into the robust IP67 protected housing are

lens and led lighting, so there is no need for additional enclosures or lighting, keeping the overall scale

of this industrial vision system very small and light.

Other benefits include a low power consumption of usually only 2.5W (without IOs), a choice of 6 and

12mm micro lenses that can be simply focused via a set screw at the back of the housing and cables

that are resistant to noise and flexing motions.

Interfaces include 100Mbit full duplex Ethernet, a serial RS422 interface and 24 V digital IOs.

Incorporating the 400MHz DSP with 3200 MIPS from Texas Instruments however ensures that a small

size does not limit the calculation capability. Together with using VC’s image processing libraries even

demanding applications can be achieved.

Apart from a few special functions, programming the VisiCube works the same way as for other

VC4XXX Smart Cameras – most programs developed for other VC cameras will run without any or

only minor adjustments.

This document describes therefore the Hard- and Software differences of this camera and refers to the

“Standard” manuals where possible.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

2

2 Special Features of the VisiCube Sensor Smart Camera

2.1 Main differences of VisiCube and VC4018

The board of the VisiCube camera is similar to the VCSBC4018 and VC4018 cameras.

The main differences are:

- RS 422 serial interface compared with the RS232 of the VC4018

- LED Sensor Display with the following indicators (also refer to the rear camera view below):

Name Color Meaning

Pwr. green Active low – programmable, refer to section 6.4

Err. red Active low – programmable, refer to section 6.4

Q1 yellow Active low – programmable, refer to section 6.4

Q2 yellow Active low – programmable, refer to section 6.4

- Inbuilt LED light that is active during exposure

- Hardware image trigger via PLC inputs (no special high-speed trigger input and output)

Programming of the special VisiCube features is detailed in section 6.

2.2 Lenses

The VisiCube camera is available with 12mm micro lenses of 2 different focal Length, f = 6mm and f =

12mm. The lens can be easily focused by turning the “Focus” screw at the back of the camera.

The minimum working distance for both lenses is 20mm.

Focusing can be done using the “imgX” image transfer programs and the ATX cl ient (available for

download from the “Customer Area -> Software Utilities”.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

3

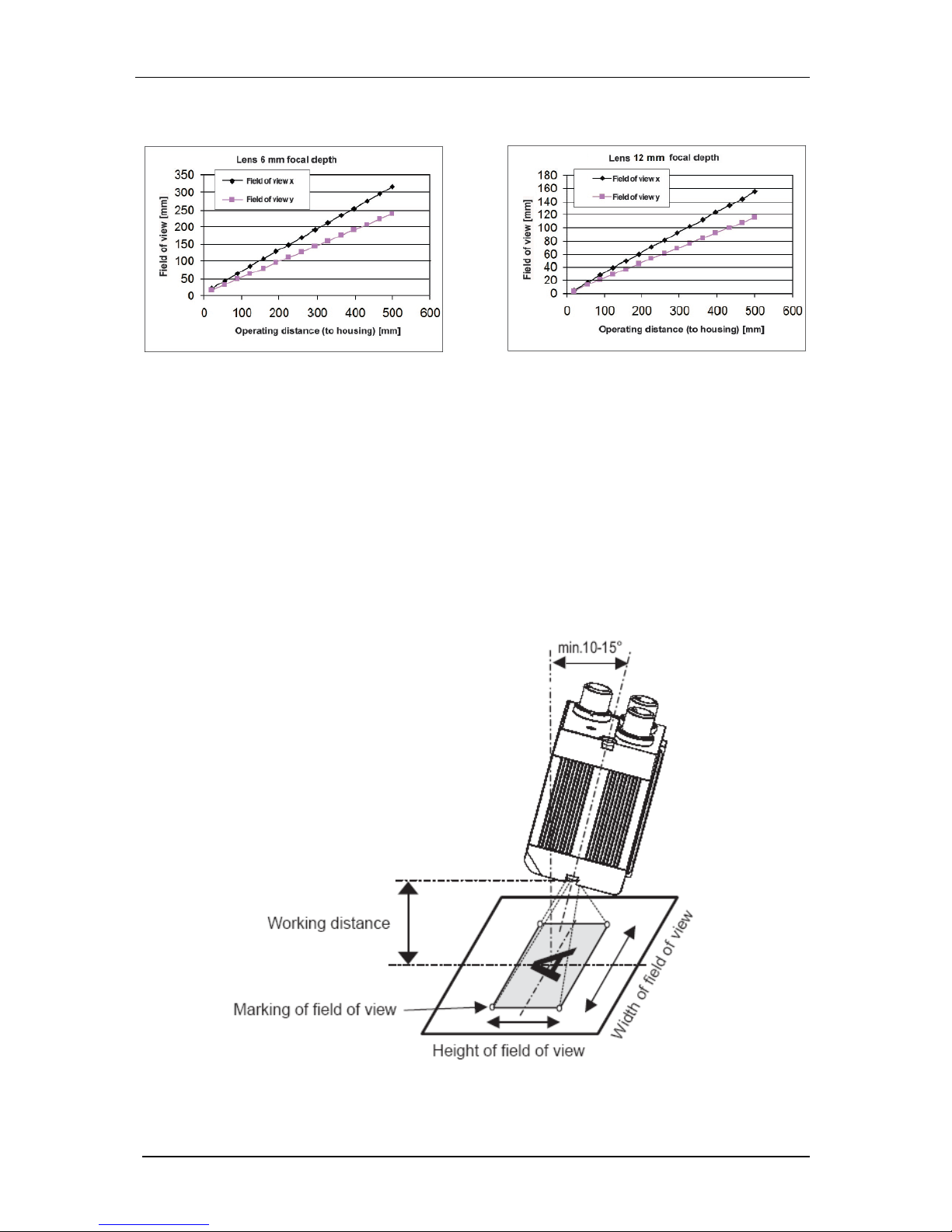

The following Table shows the image size for both lenses depending on the working distance.

Min. field of view X * Y in mm: 18 * 14 Min. field of view X * Y in mm: 8 * 6

Both lenses are adjustable to infinity. Depth of focus approx. ± 5% of scan distance

2.3 LED Lighting

The inbuilt led light allows it to go without external lighting for most applications with working distances

of up to 100mm. 2 red LEDs have been added to the 6 high power white ones In order to compensate

for the typical blue domination in white LED light.

In order to avoid light reflections it is recommended to mount the camera with a slight deviation angle

form the vertical direction as shown below.

Programming of the LED light is detailed in section 6.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

4

3 Technical Specifications VisiCube Smart Camera

Component / Feature Specification

CCD Sensor: 1/4" SONY ICX098BL

eff. no. of pixels: 640(H) x 480(V)

Pixel size: 5.6(H) x 5.6(V) µm

Chip size: 4.6(H) x 3.97(V) mm

High-speed shutter: 36.21, 98.6, 161 microseconds, increasing with steps of 62.4

microseconds (full-frame shutter)

Low-speed shutter: up to 2 sec. adjustable integration time

Integration: full-frame

Picture taking: program-controlled, trigger controlled (interrupt); full-frame / 32 frames

per second, external high speed trigger

Clamping: zero offset digital clamping

A/D conversion: 12.5 MHz / 10 bit, only the 8 most significant bits used for grey values

Input LUT none

Image Display Via 100 Mbit Ethernet onto PC

Processor: Texas Instruments TMS320C64XX signal processor 400 MHz,

3200MIPS

RAM: 32 Mbytes SDRAM (synchronous dynamic RAM)

Memory capacity: Up to 100 full-size images in format 640x480

Flash EPROM: 4 Mbytes flash EPROM (nonvolatile memory) for programs and data, in-

system programmable, 3 MB available to user

MMC: Not available

Process interface: 2 inputs / 4 outputs, outputs 4x200 mA

Illumination Controller: LEDs on during exposure, user controlled, boost mode, see section 6.5

Ethernet interface: 100 Mbit Full Duplex, changeable to 10 Mbit, changeable to half duplex

CE certification: CE Certification tested and approved

Storage Conditions Temperature: -20 to 60 deg C, Max. humidity: 90%, non condensing.

Operating Conditions Temperature: 0… +50 deg C (ambient temperature, if LEDs exposure

controlled and not in boost mode), Max. humidity: 80%, non condensing.

Power Supply 24V ± 10%, absolute maximum 18V – 30V

Power Consumption ≈2.4W (current drawn from PLC outputs additional)

1

From CPLD file version 4 – check with shell command “ver”.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

5

4 VisiCube Interfaces

4.1 Power Suppl y / SPS IO Interface and Trigger interface

PIN Color Use

1 White IN1 (external trigger)

2 Brown +UB(24 V DC)

3 Green OUT3 (pattern good/bad)

display LED = Q1

4 Yellow OUT2

5 Grey IN2

6 Pink OUT1 (Trigge r of external illumination)

7 Blue GND

8 Red OUT4 (position good / bad)

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

6

Electrical data Power Supply / SPS IO and Trigger interface

Operating voltage UB 24 V DC ± 10% (absolute maximum 18 - 30 V)

Residual ripple < 5 Vss

Current consumption (no

I/O

max. 200 mA

Inputs IN1 / IN2

high 10 V

.. +U

B

(+10%), low 0 ... 3 V

Input resistance

> 20

kOhm

Trigger input rising edge, 10 V ... UB

Outputs OUT1 - 4 PNP (closer, pull up MOSFET)

Output current (per

output)

200 mA (>> max. 9,6 W)

Maximum output current

(per output)

1,5 A in case of short circuit

Short-circuit protection

(all outputs)

yes

Protection against inverse

connection

yes

Interfaces Ethernet (LAN) RS422

Protection system 2

Readiness delay approx. 6 sec. after power on

4.2 LAN / Ethernet Interface

PIN

(M12)

Color PIN

(RJ45)

Use

1 White/blue 5

2 White /blue 7

3 Brown 8

4 Orange 2 TxD5 White/green 3 RxD+

6 White/orange 1 TxD+

7 Blue 4

8 Green 6 RxD-

Pin Assignment and cable core colors

The IP Address adjustment works equivalent as with all other current VC Smart Camera models.

Refer to the “Getting Started VC…” Documentation for details.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

7

4.3 Data / RS422 Interface

PIN Color Use

1 White RxD2 Brown RxD+

3 Green TxD+

4 Yellow TxD-

5

GND

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

8

5 Order Numbers of VisiCube and Accessories

Description

VK.- Number

VisiCube with f = 6mm Micro lens VK000327

VisiCube with f = 12mm Micro lens VK000328

Description Type VK.- Number

Mounting clamp, dovetail FA45 MK 45 VK000320

Mounting angle FA45 MA 45 VK000322

Mounting rod 20 cm FA45 MST 45-20 VK000325

Mounting rod 30 cm FA45 MST 45-30 VK000340

Mounting rod 40 cm FA45 MST 45-40 VK000339

Mounting hinge FA45 MG 45 VK000321

Mounting plate FA45 MP 45 VK000323

Mounting link FA45 MZ 45 VK000324

Connection cable, 2 m, straight, shielded C L8FSK-2m-G-PUR VK000318

Connection cable, 5 m, straight, shielded C L8FSK-5m-G-PUR VK000338

Connection cable, 2 m, 90°, shielded C L8FSK-2m-W-PUR VK000337

Connection cable, 5 m, 90°, shielded C L8FSK-5m-W-PUR VK000336

Ethernet cable, 3 m M12, 8pin./RJ45,

shielded

CI L8FSK/RJ45S-3mGG-PVC-G

VK000319

Interface cable 3 m, straight CI L5FK-3m-G-PUR VK000334

Interface cable 3 m, 90° CI L5FK-3m-W-PUR VK000335

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

9

6 Programming of special VisiCube Features

6.1 Using PLC Inputs and Outputs

Using the PLC IOs works like with all other VC Smart cameras, so the demo program “port.c” can be

used as a reference.

Differences to other VC Smart Cameras:

- The naming convention is slightly different for the VisiCube, with the 4 outputs ranging from

OUT1 to OUT 4 (so OUT0 in the port demo program corresponds to OUT1 in 4.1 (pin

allocation of VisiCube Power Supply / IO interface).

- Like the VCSBC40XX, the VisiCube has only 2 digital inputs (IN1 and IN2). The registers for

IN3 and IN4 are set to high.

Check Status on PLC inputs:

print("INP0=%d ",inPLC()&0x01); // query status of Input 1

print("INP1=%d ",inPLC()&0x02); // query status of Input 2

Set and Re-Set PLC outputs:

setPLC0(); resPLC0(); //set and re-set Output 1

setPLC1(); resPLC1(); //set and re-set Output 2

setPLC2(); resPLC2(); //set and re-set Output 3

setPLC3(); resPLC3(); //set and re-set Output 4

6.2 Capturing Images with a Hardw are Trigger Signal

The VisiCube does not incorporate a dedicated HW trigger interface, so images have to be triggered

using one of the digital PLC inputs IN1 or IN2.

while ( wait(PLC_INT, 100) != 1); // wait for change on PLC inputs while freeing CPU time

If (inPLC()&0x01) ==1) ; //check if status of PLC input 1 has changed

tpict(); // take image

Refer to Appendix B: Using the PLC_INT event.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

10

6.3 Using the RS422 Data Interface of the VisiCube

Demo Program t132.c – order the corresponding “Interface Cable” for instance VK000334, interface

cable straight, 3m (see section 5).

#include <register.h>

#include <vcrt.h>

#include <sysvar.h>

main()

{

FILE *tty;

//unsigned xbaud=115200;

unsigned xbaud=9600;

char c=0;

print("TEST RS422 serial I/O\n");

tty = fopen("ittya:", (void *)0); /* open RS422 */

io_ioctl(tty,IO_IOCTL_SERIAL_SET_BAUD,&xbaud);

write(tty,"abcdefg",7);

rs232rcv();

while(c != 0x1b)

{

c=rs232rcv();

// c=io_fgetc(tty);

io_fputc(c, tty);

c=io_fgetc(tty);

rs232snd(c);

}

fclose(tty); /* close RS422 */

}

6.4 Using the Status LEDs

The following macro sets the LED register:

LED_OUT(x)

3 2 1 0 Bits

Q2 Q1 Err. Pwr Name

The bit logic is inverted, so x = 0 turns all LEDs on, x = 15 switches all LEDs off.

Use an additional variable (for instance “private sysvar” to store the actual LED status since this

register is write only!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

11

6.5 Using the LED Lighting

Per default the illumination LED’s are on during exposure (at low level – not “boost level”).

The following macros turn the LEDs off during exposure:

ILLU_USR(); // turning the LEDs into “User mode”

ILLU_POS(); // turning the LEDs on – program controlled

ILLU_NEG(); // turning the LEDs on – program controlled

The following macros then turn the LEDs on again during exposure:

ILLU_EXP(); // turning the LED Illumination into “Exposure Mode”

ILLU_POS(); // LEDs are on during exposure (ILLU_NEG() means LEDs are on when not exposing).

SET_BOOST(); // sets the Illumination LEDs to “boost level” (for example 233 mean grey value

instead of 171).

RES_BOOST(); // sets the Illumination LEDs back to “normal (default) level”.

!

Do not use the “boost” mode at high surrounding temperatures as can lead to overheating of

the camera.

Use the LED lighting only if required (i.e. during image acquisition) in order to extend their

lifetime.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

12

7 Maintenance

7.1 Cleaning

- Clean the FA45 Object-Detection Sensor with a clean dry cloth.

- Do not use solvents or petrol.

- Do not use sharp objects.

- Do not scratch

.

7.2 Repair

- In case of a suspected hardware fault, please contact at first your distributor/ point of

purchase for assistance.

- If the problem cannot be solved locally, please use the following link to fill in the RMA form

on the website under “Support + Download”:

Support + Download

Send Camera for

Repair

- Please provide a detailed fault description and also let us know how you have tested this

fault in case the defect is not obvious.

- Carefully select if your country of residence is within or without the EU. This aut omatically

prints the correct shipment address on the RMA result sheet (important for customs

clearance).

- Login on to the VC website automatically fills in your address details.

- Clicking the “submit” button displays the RMA result sheet with the RMA number and a

summary of your fault description and details. This summary page is also sent to your

email address.

- Please print out this page and include it with your camera shipment.

- Please always use courier services (FedEx, UPS, DHL, etc) for shipping, since we are

unable to get customs clearance if cameras are sent by normal mail services.

!

Repair / Hardware Upgrade Costs:

- Warranty repairs are free of charge if not due to camera misuse.

- After expiry of the warranty period most repairs or upgrades are done at a small flat fee.

Check with your distributor for details.

Hardware or SW fault?

- To save time and costs, please only send cameras with definite hardware faults.

- Please ensure the failure is not due to:

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

13

- A SW problem (for instance most suspected Flash errors are SW problems /

Communication errors are often due to wrong IP settings, etc.)

- Hardware failure of accessories (cables, connected sensors, etc.)

Please check the VC documentation and the Knowledge Base / FAQ for possible SW errors.

If in doubt please contact

Vision Components Support for assistance prior to shipping!

Vision Components can only accept products for repair that have been directly purchased form

us or one of our authorized distributors.

Please contact your point of sale, if you have purchased a VC Smart Camera from another

vendor!

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

A

Appendix A: Dimensional Drawings of VisiCube

Mounting Brackets:

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

B

Appendix B: Using the PLC_INT event

//////////////////////////////////////////////////////////////////////

// 6. Using PLC_INT event for detecting status change at PLC inputs //

//////////////////////////////////////////////////////////////////////

print("\nPress any key to start waiting for PLC event (timeout 5s) \n Press 'q' to stop \n");

getchar();

// waiting for the PLC event does not require processing time (as polling of inputs does) parallel processes can execute

// the PLC_INT reacts to changes (transition from low to high or high to low) at any PLC

inputs

do

{

if (kbhit())

{

key = rs232rcv();

}

do

{

x = wait(PLC_INT, 5000); // waits until next event "PLC Event" occurs, timeout 5s

} while((x!=1)&&(x!=-1)&&(x!=2)); // wait returns 2 and does not wait for

the next event, if the event has occurred before wait was called

print("INP0=%d ",inPLC()&0x01);

print("INP1=%d ",inPLC()&0x02);

switch(x)

{

case 1:

print("PLC_INT event occurred\n");

break;

case 2:

print("PLC_INT event event has occurred before wait was called\n");

break;

case -1:

print("PLC_INT event has timed out\n");

break;

default:

print("Return value wait(EXP_READY,x) = %d \n", x);

}

}while(key != 'q');

}

/*******************************************************************/

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

C

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

VisiCube Manual

D

Visit the Vision Components site www.vision-components.com for further information and

documentation and software downloads:

Web Site Menu Links Content

Contact

Distributor list / Enquiry forms

Home

Latest News from VC

Our Company

VC Company Information

News and Events

Trade Show dates

VC Publications

Sign in for free VC Seminars

VC Network

Description of Partner Companies

Application Overview

3

rd

Party Hard- and SW Products for VC Smart

Cameras

Products

VC Smart Camera Overview

Product Overview:

VC44XX High End Camera Series

VC40XX Standard Camera Series

VC4016 / 18 Entry Level Cameras

VC4002L Line Scan Camera

VCSBC Single Board Cameras

VC20XX Smart Cameras

VCSBC Board Cameras

VCM + Viscube Camera Sensors

VC Smart Camera Software

VC Software Development Kit Ti: VCRT Operating System

VCLIB Image Processing Library

VC Special Libraries: M200 Data Matrix Code Reader

VCOCR Text Recognition Library

Color Lib

Support:

Support News (User Registration required) Tech News – new SW and Documentation

Knowledge Base / FAQ (User Registration

required)

Searchable FAQ Database with programming

Examples and Demo Code

Download Area Download of:

Public Download Area

(free Access)

- Product Brochures

- Camera Manuals

Registered User Area

(User Registration required)

-

Getting Started

- Programming Manuals

- Tr aining Manuals and Demo Code

Customer Download Area

(User- and SW License

Registration required)

- Software Updates

- Demo Code

RMA Number Form Form for Allocation of Repair Numbers.

© 1996-2007 Vision Components GmbH Ettlingen, Germany VisiCube.pdf

Loading...

Loading...