®

®

Vision

Components

The Smart Camera People

VCSBC4012

Operating Manual

Hardware specifications and special software functions of

VCSBC4012 Single Board Smart Cameras

Revision 2.0 April 2011

Document name: VCSBC4012.pdf

© Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf VCSBC4012 Single Board Smart Camera Operating Manual

2

Foreword and Disclaimer

This documentation has been prepared with most possible care. However Vision Components GmbH

does not take any liability for possible errors. In the interest of progress, Vision Components GmbH

reserves the right to perform technical changes without further notice.

Please notify

support@vision-components.com if you become aware of any errors in this manual or

if a certain topic requires more detailed documentation.

This manual is intended for information of Vision Component’s customers only. Any publication of this

document or parts thereof requires written permission by Vision Components GmbH.

Trademarks

Code Composer Studio and TMS320C6000, Windows XP, Total Commander, Tera Term, Motorola

are registered Trademarks. All trademarks are the property of their respective owners.

References

Since the VCSBC40XX smart camera family employs a TI processor, the programming environment

and functions for the VC20XX cameras can be used for this camera.

Please also consult the following resources for further reference:

“

Support News” for an overview of latest updates and support information

“

Knowledge Base / FAQ” for a searchable data base of SW and HW questions / answers

Description Title on Website Download Area

Quick start Manual for VC

camera set up and

programming

Getting Started VC Smart

Cameras with TI DSP

Public Download Area Getting Started

VC SDK Ti

Schnellstart VC – deutsche

Version of „Getting Started VC“.

Schnellstart VC Smart

Kameras

Customer Area Getting Started

VC20XX and VC40XX Cameras

Introduction to VC Smart Camera

programming

Programming Tutorial for

VC20XX and VC40XX

Cameras

Customer Area Getting Started

VC20XX and VC40XX Cameras

Demo programs and sample code

used in the Programming Tutorial

Tutorial_Code

Customer Area Getting Started

VC20XX and VC40XX Cameras

VC40XX Hardware Manual

VC40XX Smart Cameras

Hardware Documentation

Public Download Area Hardware

Documentation VC Smart Cameras

VCRT Operation System Functions

Manual

VCRT 5.0 Software Manual

Registered User Area Software

documentation VC Smart Cameras

VCRT Operation System TCP/IP

Functions Manual

VCRT 5.0 TCP/IP Manual

Registered User Area Software

documentation VC Smart Cameras

VCLIB 2.0 /3.0 Image Processing

Library Manual

VCLIB 2.0/ 3.0 Software

Manual

Registered User Area Software

documentation VC Smart Cameras

- The Light bulb highlights hints and ideas that may be helpful for a development.

- This warning sign alerts of possible pitfalls to avoid. Please pay careful attention

to sections marked with this sign.

!

Author: VC Support,

mailto:support@vision-comp.com

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 3

Table of Contents

1 General Information 4

2 Basic Structure 5

3 Technical Specifications VCSBC4012 6

4 Camera Interfaces 7

4.1 J1: Power Supply and IO Interface 8

4.1.1 Pin Assignments J1 camera socket 8

4.1.2 Electrical specifications digital IO s J1 interface 8

4.1.3 Electrical specifications of the VCSBC4012 Power Supply J1 interface 10

4.2 J2: Expansion Port / Trigger Interface 11

4.2.1 Pin Assignments J2 camera socket 11

4.2.2 Matching connector and cable for J2 camera socket 12

4.2.3 Electrical specifications J2 camera socket 14

5 Accessories 16

5.1 Camera and Lens holder order numbers: 16

5.2 Further accessories available for the VCSBC4012: 16

6 Programming VCSBC4012 Camera 17

6.1 Special Software requirements for the VCSBC4012 17

6.2 Ethernet Communication 18

6.3 Using FTP with the VCSBC4012 18

6.4 Preventing Autoexec Execution / IP number reset 18

6.4.1 Resetting the Camera with help of the VCnet Recovery Tool 19

6.5 Special VCRT functions for programming VCSBC4012 cameras 20

6.5.1 Trigger Functions 20

6.5.2 Controlling the TTL IOs on socket J2 21

Appendix A: New VCRT Functions VCSBC4012 A

Appendix B: Drawing Circuit Board VCSBC4012 B

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 4

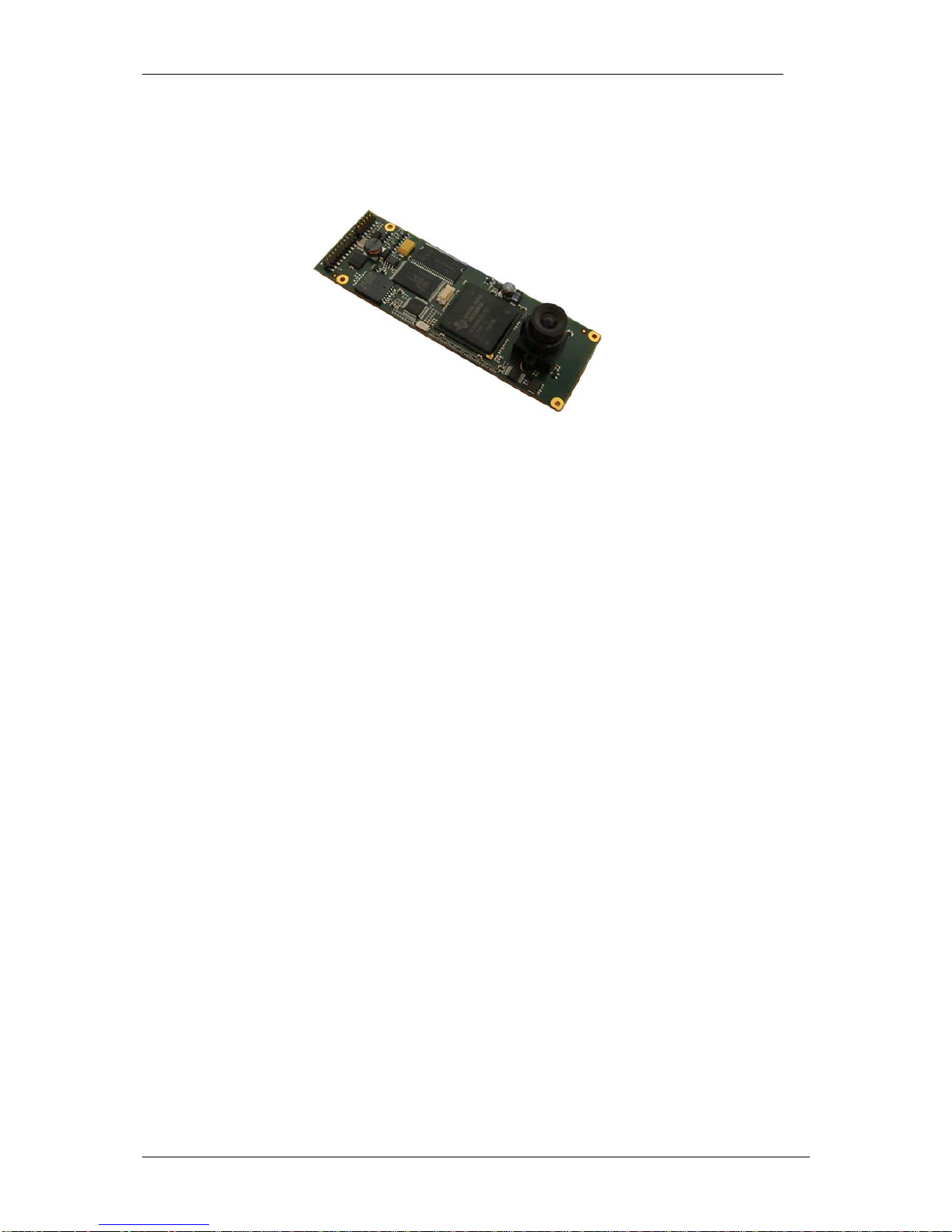

1 General Information

VCSBC4012 Single Board Camera

The VCSBC4012 has been designed for high resolution image processing with a very small form

factor. The VCSBC4012 is the ideal compromise between high performance and low system costs,

and thus expecially suited for high volume OEM applications. This makes it viable to use a smart

camera in even more products than before.

Employing a CMOS sensor, the image resolution can be changed to the ROI required.

Like with all VC Smart Cameras with Texas Instruments DSP, the operation system VCRT allows

multi- tasking. This means for instance that user interface commands can execute in parallel without

stopping the inspection process. It is also possible to transfer live images via TCP/IP using a

background task.

The VCSBC4012 camera offers an inexpensive entrance into the world of the high performance

intelligent cameras. It has a video output onto a PC via 100MBit Ethernet interface, a high speed

trigger input and output, 12-24 V digital Inputs and open collector outputs and additional TTL IOs.

The extermely low power consumption of only 1.5W makes this camera ideally suitable for use in

mobile devices.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 5

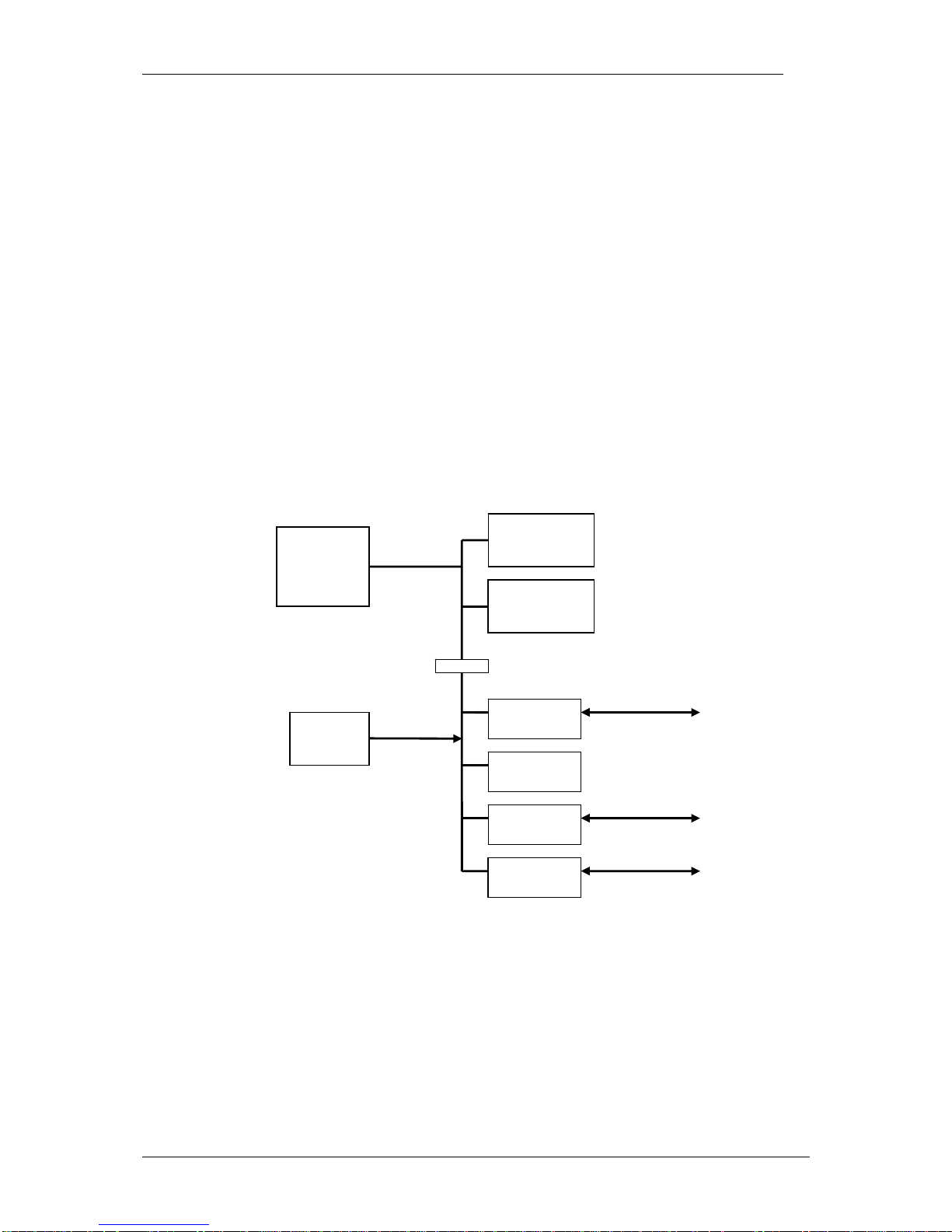

2 Basic Structure

The image is formed by a high-resolution 5 mega pixel CMOS sensor. The image is then stored in

SDRAM memory, which has been increased to 64MB, due to the large camera image.

Unlike most other Vision Component Smart Cameras, the VCSBC4012 does not have a direct video

output. However if monitoring of the camera image is required, this can be done by downloading via

Fast Ethernet port to PC and display on screen (see

“Image Transfer” demo software under

“Support -> Customer Area -> Software Utilities”

).

The TMS320C64xx DSP is one of the fastest 32bit DSPs. It features a RISC-like instruction set, up to

8 instructions can be executed in parallel, two L1 cache memories (16 Kbytes each) and a 128 Kbytes

L2 cache on chip. Its high speed 64-channel DMA controller gives additional performance. The DSP

uses fast external SDRAM as main memory. A flash EPROM provides non-volatile memory.

Block diagram VCSBC4012 Camera

4 MB Flash

Eprom

CMOS

Sensor

Trigger In/

Out

Control/

Status Reg.

Open

collector IOs

64 MB SDRAM

TMS

C64XX

DSP

Bus Controller

Trigger In/ Out

24V In /

Open collector Out

Ethernet

Ethernet

10/100

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 6

3 Technical Specifications VCSBC4012

Component / Feature Specification

CMOS Sensor: 1/ 2.5" Micron MT9P031 - also available with color sensor (Bayer Filter)

eff. no. of pixels: 2592(H) x 1944(V)

Pixel size: 2.2(H) x 2.2(V) µm

Chip size: 5.70(H) x 4.28(V) mm

High-speed shutter: “Electronic rolling shutter” (ERS) and “Global Reset Release” (GRR),

15µs, 45µs, 75 µs, … in steps of 30 µs

Low-speed shutter: up to 30 sec. adjustable integration time

Integration: ERS / GRR

Picture taking: program-controlled, full-frame / 11.6 frames per second, external high

speed trigger

Parallel image acquisition Not available

Clamping: Internal to sensor

A/D conversion: 80 MHz / 12 bit, only the 8 most significant bits used for grey values

Input LUT none

Image Display Via 100 Mbit Ethernet onto PC

Processor: Texas Instruments TMS320C64XX signal processor 400 MHz,

3200MIPS

RAM: 64 Mbytes SDRAM (synchronous dynamic RAM)

Memory capacity: Up to 13 full-size grey value images in format 2592 x 1944

Flash EPROM: 4 Mbytes flash EPROM (nonvolatile memory) for programs and data, in-

system programmable, 3 MB available to user

SD card: Not available

Process interface: 2 inputs / 4 outputs, outputs 4x80 mA

Additional LVTTL IOs: 4 Inputs, 4 Outputs, I2C Clock and Data signals (I2C also used internally

for Sensor control), trigger Input, Flash output

Ethernet interface: 10/100 Mbit

CE certification: No CE Certification from Vision Components as the OEM customer is

required to certify entire system (including housing, cabling, etc.).

Storage Conditions Temperature: -20 to 60 deg C, Max. humidity: 90%, non condensing.

Operating Conditions Temperature: 0… +55 deg C, Max. humidity: 80%, non condensing.

Power Supply 12V… 24V

Power Consumption ≈1.5W (current drawn from PLC outputs or onboard 3.3 V signal

additional)

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 7

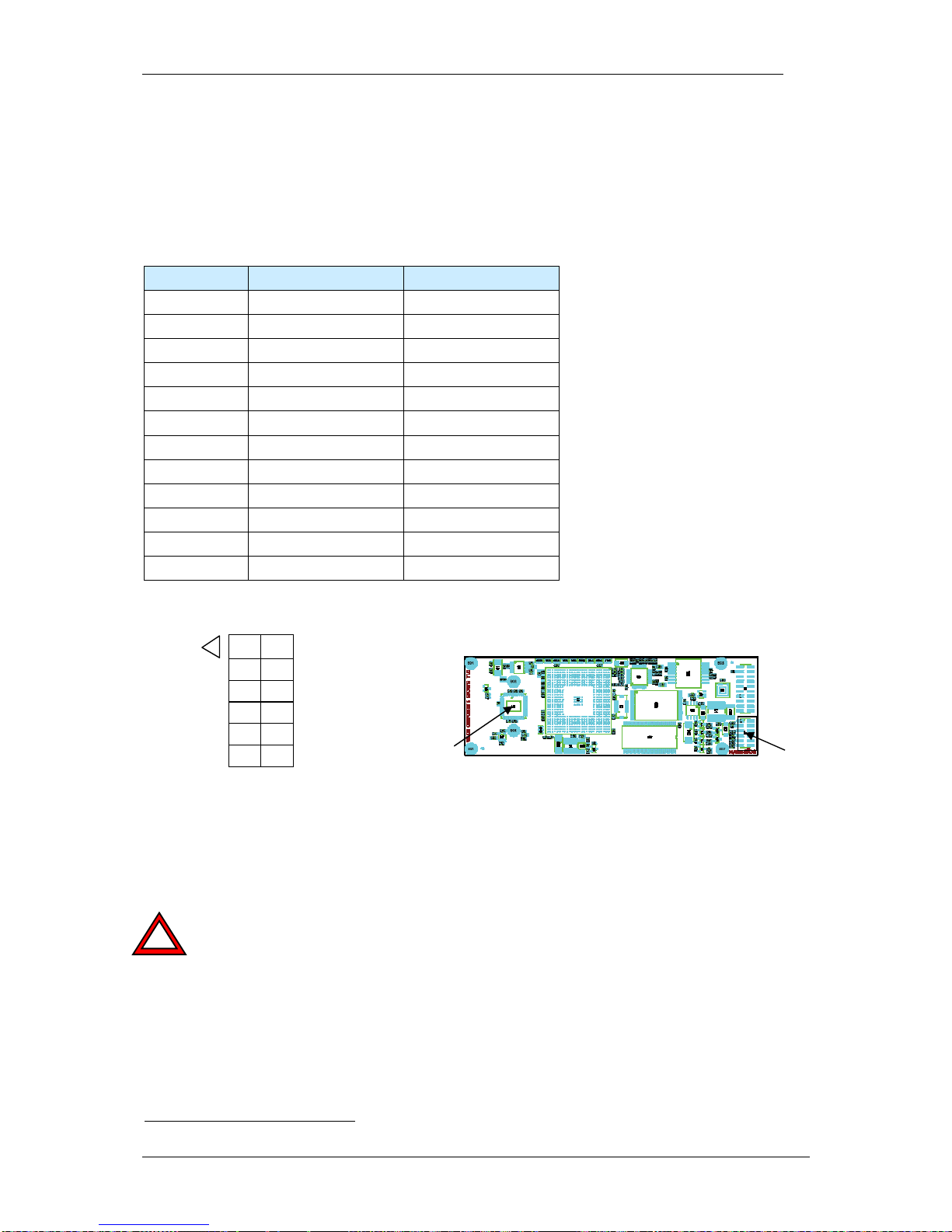

4 Camera Interfaces

J2

J3

J1

The VCSBC4012 camera board incorporates the following connector interfaces:

J 1 : VCSBC4012/ VCSBC50 Power and IO Connector

J 2: Ethernet, trigger and Expansion Port Connector

J 3: Emulator Connector

The pin assignments, electrical specifications as well as available accessories are sho wn for each

interface connector in the following sections.

Please refer to Please refer to “Appendix B: Drawing Circuit Board VCSBC4012” for the pin 1

orientation of the camera board sockets.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 8

4.1 J1: Power Supply and IO Interface

The J1 connector includes the camera power supply and the digital IOs.

4.1.1 Pin Assignments J1 camera socket

Pin Number Signal Core Color

1

1 Out0 Blue

2 Power (24V) Red

3 Out1 purple

4 Power GND Black

5 Out2 Grey/ red

6 In0 Green

7 Out3 Blue/ red

8 In1 Yellow

9 GND grey

10 GND white

11 N.C. pink

12 3.3V out brown

J1 Standard VCSBC4012 socket:

Molex: 8783212-20

Note that the pin allocation differs

from the J3 connector of the

VCSBC4018/16 board cameras!

Pin Locations

1 2

3 4

5 6

7 8

9 10

11 12

If board orientation as shown below:

Sensor

J1

4.1.2 Electrical specifications digital IO s J1 interface

The camera has two PLC compatible inputs and four PLC compatible open-collector outputs for

controlling machines and processes.

Inputs and outputs are not galvanically separated from the supply voltage.

!

A protective diode ensures, the poles of the supply voltage from the power supply of the PLC can not

be swapped.

The outputs are floating when high – external pull up resistor required.

1

According to matching Power / PLC Cable VK000173

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 9

Input Signals IO interface

Nominal voltage: 12 – 24 V

Absolute maximum voltage: voltages greater than 40 V can destroy the inputs

Type: Circuit GND directly connected

Input current: 1 mA @ 24V

Threshold value: 10 V

Internal signal delay: - No delay for direct IO access

- 10ms delay for DSP polling

The PLC-compatible inputs (24-V level, the positive signal is detected) include input protection circuits.

A minimum voltage of 10V is required to reliably sense a logic high signal.

Output Signals IO Interface

Operating voltage: Depends on external output supply

Absolute maximum voltage: voltages greater than 40 V can destroy the outputs

Type: BC850 open collector

Switching voltage: negative switching (NPN), output high switching to GND

Current: max. 80 mA per output

Absolute maximum current:

total currents greater than 80 mA per output can destroy

plugs and cables

no inductive/ capacitive load allowed

Switching power: max. 1.0 W per output

Protection against inductive

loads:

no

Resistance when switched on: 20 Ohm

Short circuit protection: No protection

Suggested external circuit for using camera outputs NPN

GND

R pull- up, 1k – 10k,

depending on Voltage

(5V: 1k – 24V: 10k)

Camera output circuit

(internal)

External output circuit

external supply

Output signal voltage

output transistor

switching to GND

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 10

4.1.3 Electrical specifications of the VCSBC4012 Power Supply J1 interface

Nominal Voltage: 12V – 24V

Nominal Power Consumption2: 1.5W

Minimum operational voltage (including ripple): 9V

Minimum nominal Operating voltage and

corresponding current:

12V

116mA

3

Maximum nominal Operating voltage and

corresponding current:

24V

70mA

3

Maximum operational Voltage (including ripple): 30V

Power must be connected to the 12 pin J1 I/O connector.

Camera power is regulated, so only an unregulated power source of 12 V to 24V is required. The

camera is, however, very sensitive to power supply interruption. Please make sure, that the voltage

never exceeds the limits of < 9V, > 30V even for a short period of time. In case of trouble it is

recommended to backup the power supply by a capacitor or a battery large enough to prevent power

interruptions.

Power consumption depending on suply voltage

3

:

Supply

Voltage

[V]

Current

drawn

[mA]

Power

3

Consumption

[W]

9 153 1.37

10 138 1.38

12 116 1.39

14 100 1.40

16 90 1.44

18 80 1.44

20 72 1.44

22 66 1.45

24 62 1.48

26 57 1.48

28 54 1.51

30 51 1.53

2

Typical power consumption without using the onboard 3.3V supply.

3

Current drawn from the 3.3V on board signal needs to be added to these figures.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 11

4.2 J2: Expansion Port / Trigger Interface

Note that the LVTTL IOs are very sensitive. Only use driving electronics suitable for LVTTL IO’s!

4.2.1 Pin Assignments J2 camera socket

Pin Number Signal

1

I2C_Clock

2

I2C_Data

3

Trig_in

4

Trig_out

5

Q00

6

I01

7

Q01

8

I01

9

Q02

10

I02

11

Q03

12

I03

Core Colors Ethernet

13

TxD+ Blue

14

TxD- Red

15

GND N.C.

16

GND N.C.

17

RxD+ Pink / black

18

RxD- Green

19

GND N.C.

20 GND N.C.

Cable colors shown valid for using VC’s Ethernet cables – see the accessory overview in section 5.

Signal description:

Q00 – Q03 digital LVTTL outputs

I00 – I03: Digital LVTTL input (without pull-up resistor)

I2C_Clock and I2C_Data I2C serial Bus Interface for additional peripherals (Refer to the Texas

Instruments documentation

4

for further details)

Note that the I2C Bus is used internally to program the sensor!

Caution is advised when programming the I2C in order not to block

system tasks!

Trig_in and

Trig_out

Trig_in and Trig_out – are not opto isolated, so special care must be

taken or Isolation has to be done externally!

4

“TMS320C6000 DSP Inter-Integrated Circuit (I2C) Module Reference Guide”, Literature Number:

SPRU175A, Oct. 2002

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 12

Pin Locations

1 2

3 4

5 6

7 8

9 10

11 12

top part of J2 interface for I2C Bus, Trigger Interface and additional LVTTL

13 14

15 16

17 18

19 20

lower part of socket for Ethernet

Please refer to “Appendix B: Drawing Circuit Board VCSBC4012” for the pin 1 orientation on the

camera board socket.

4.2.2 Matching connector and cable for J2 camera socket

4.2.2.1 Manufacture own cable / pcb that sits on top of camera board

The socket J2 has the following part number: 8775967-2050, manufacturer Molex (

www.molex.com)

The matching connector has the following part number: 51110-2050

Vision Components does not currently manufacture a cable for this connector. Please order the

matching connector from the manufacturer Molex.

4.2.2.2 Using VC’s wide Ribbon Cable covering J1 and J2

There is a new Ribbon Cable available using a 24 pin Molex conector that connects to all 12 J1 and

20 J2 pins. This cable can be ordered with one connector / open and 2 female molex connectors.

For further details please contact sales at this stage:

sales@vision-comp.com .

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 13

4.2.2.3 Use Power and Ethernet cable side by side

Alternatively an additional 12 pin Power Supply /PLC and a 8 pin Ethernet cable (Cable set for

VCSBC4018, VK000229 see section 5) can be used next to each other to cover all contacts. Since

only pin 1,2,5 and 6 of the 8 pin Ethernet connector are connected, place these two plugs on the J2

sockets as shown below:

Pin 1-12 use J1 cable Pin 13-20 use one of the Ethernet calbes, (pin number of connector given

here):

2 4 6 8 10 12 2 NC 6 NC

1 3 5 7 9 11 1 NC 5 NC

∇

Please refer to section 4.1.1, section 4.2.1 and sectio 5 for details on these cables.

Pin assignment Ethernet cable VK000251:

PIN (J4) Cable Color (J4) Signal Cable Color (RJ45) PIN (RJ45)

1 blue TXD+ Orange/ white 1

2 red TXD- Orange 2

3 N/C GND N/C

4 N/C GND N/C

5 Pink / black RXD+ Green/ white 3

6 green RXD- Green 6

7 N/C GND N/C

8 N/C GND N/C

The change of core colors results from connecting two cables (VK000206 and a standard

Ethernet cat 5 cable).

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 14

4.2.3 Electrical specifications J2 camera socket

All Signals are Low Level TTL (3.3V), not opto isolated.

The electrical specifications given for the trigger input and output are also valid for the remaining

LVTTL IOs.

The following Signals have a 1k5 pull up resistor on board:

-

I2C_Clock

- I2C_Data

- Trig_in

Trigger IO Specifications:

The board features a dedicated fast TTL trigger input (for use as image capture trigger) and a fast TTL

trigger output (as strobe-light trigger). Since both signals are fast at a very low noise margin, it is

recommended to keep the cable as short as possible. Use twisted pair or even coaxial cable for this

purpose. The trigger input assures a constant image capture delay without jitter.

Electrical Specification of trigger input

5

:

input voltage: Signal LOW -0.3V – 0.8V (LVTTL)

Input voltage: Signal HIGH 2V – 3.9V (LVTTL)

input current: N/A

limiting resistor: 1K5 pull up

reverse voltage protection: none

switching delay: none

Image trigger on rising or falling input signal works as before – see section 6.5.1 for details.

The trigger input and output are very sensitive and not galvanically separated. Opto

isolation of the driving circuit is therefore strongly recommended. The following page

shows suitable circuits for trigger input and output.

!

Please note that input and output are not protected against over current. The output is neither

protected against short circuit nor reverse voltage spikes from inductive loads.

Use the VC4018 or VC4016 cameras if you can not provide a suitable trigger input driving

circuit. These cameras include the same hardware as the VCSBC4018 / -16, but opto isolation

of the trigger input and output is already included.

5

The electrical specifications given for the trigger input and output are also valid for the

remainingLVTTL IOs.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 15

Recommended driving circuit for the trigger input:

Camera side:

Pin 15 Trig In

Electrical Specification of trigger output

6

:

output voltage signal LOW: 0.4 V with 2mA output current

0.2 V with 1mA output current

output voltage signal HIGH: 2.9 V with 8mA output current

3.1 V with 1mA output current max. 3 V LVTTL

Maximum output current: max. 8 mA (high), 2mA (low)

pull-up resistor: none, LVTTL push-pull output

Caution: Place the connectors at the correct position – not reversed or shifted.

Recommended circuit for trigger output:

Camera side:

Pin 16 Trig Out

6

The electrical specifications given for the trigger input and output are also valid for the

remainingLVTTL IOs.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 16

5 Accessories

For interface cables and connectors available also consult the corresponding section in chapter 4 of

this manual.

5.1 Camera and Lens holder order numbers:

Product / Service description Order Number

VCSBC4012 Single Board Smart Camera without lens holder, b/w CCD VK000368

VCSBC4012 Single Board Smart Camera without lens holder, Bayer CCD VK000369

Lens holder C Mount incl. adjustment (IR Filter EK000625 included) VK

Lens holder 12mm (Clear glass window EK000624 included) VK

5.2 Further accessories available for the VCSBC4012:

Product description Order Number

Power adapter for rail mounting, Input Voltage 100 – 240VAC 50/60 Hz

Output Voltage DC 24V +/-5%, max. 300 mA (7.5 W)

Equipped with connecting clamps for AC input and 24V output, CE cert.

Using this power supply with VCSBC4018 and VCSBC4016 is only

possible when booting by switching the 24V secondary side! 15W

power supply needed if switching the mains supply!

VK000036

Cable for Expansion Port J2 (use cable set VK000229 see section 4.2) It is

recommended to manufacture matching circuit board

VK000229

Power Supply and IO Interface cable for J1 VK000173

Ethernet OEM Cable for J2 (0.5m length, 4 single cores) VK000206

Ethernet testing Cable for J2 (2.5m length, other end with RJ45 connector) VK000251

Emulator Adaptor Cable for J3 VK

Cable set for VCSBC4012 (contains VK000206 and VK000173) VK000229

Cable for Emulator interface J3 VK

Clear glass protective sensor window (replaces IR filter in camera head) EK000624

IR cut filter (camera is shipped with this filter mounted) refer to Appendix B EK000625

!

All cable lengths are 0.5m unless stated otherwise.

Please also refer to the VC website

www.vision-components.com for an up to date list of

accessories.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 17

6 Programming VCSBC4012 Camera

The VCSBC4012 operating system includes some additional functions, mainly for the control of the

additional interfaces. Without direct VGA output some video control functions are not implemented for

this camera.

This manual describes the differences between the standard VCRT 5 operating system functions and

the special function library of the VCSBC40. For programming please also consult the

VCRT 5 and

VCLIB 2.0 and VCLIB 3.0 manuals (see the list of references at the beginning of this manual).

6.1 Special Software requirements for the VCSBC4012

The following table shows the minimum compatible setup options using the VCSBC4012 camera:

Code Composer Studio

Version

VCRT PC Lib Version VCLIB Version VCRT Camera OS

Version:

CCS 3.1 (C6000) or

CCS 3.3 (C6000)

VCRT 5.27 VCLIB 3.0 VCRT 5.27

Refer to the “Support News” section, under “Support and Download” on the VC website for an

overview of the latest compatible set up.

The VCRT PC lib Operation System PC library, the VCLIB Image Processing Library as well as the

VCRT Camera Operation System can be downloaded from Support section of the Vision Components

Website.

Software manuals are located in the “Registered User Area”. This download area can be a ccessed

after registration and log in on the VC Website.

Software updates are available from the “Customer Area”. For access to the customer area please

register your Vision Components development software for VC cameras with TI processor. Software

registration can be done after logging in using the license key code shipped with each development

bundle. For this please follow the “Register your Software” link under the “User Menu”.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 18

6.2 Ethernet Communication

The default camera IP address is 192.168.0.65 – as with all Ethernet cameras from VC.

The IP address can be changed to a different loading a #IP file into camera memory.

Refer to the “Getting Started VC Smart Cameras” guide for further details.

The camera supports DHCP server IP address allocation. In order to use DHCP allocation, the entry

“DHCP” needs to be added to the #IP file as shown:

DHCP

IP: 192.168.0.81

MSK: 255.255.255.0

GTW: 192.168.0.1

The camera uses the specified IP address if DHCP allocation is not successful. If no IP address is

specified in the #IP file, the camera falls back to the default address:

192.168.0.65

Please use DHCP server functions to determine the IP address allocated to the camera. Most

server show a list of mac addresses and corresponding IP addresses or allow to allocate fixed

IP addresses to a certain mac address. Determine the mac address of the camera using the

shell command “type #ID” to prior to using DHCP IP address allocation!

The “Getting Started VC Smart Cameras” and section 6.4.1 include advice on re-setting a camera with

unknown or invalid IP Address.

6.3 Using FTP with the VCSBC4012

With VCRT 5.18 and higher, the use of any standard ftp client is now possible. The following server

commands have been added: SYSTEM,PWD,CWD,LIST,DEL

Programs have to be uploaded as “out” files into the camera flash memory. Ascii files like the

autoexec or #IP files can be uploaded as “*.txt” files – the conversion into *.msf” files is not required.

6.4 Preventing Autoexec Execution / IP number reset

Preventing the execution of an Autoexec file by attempting a connection with the camera (as

described in the programming tutorial) does not work, due to the increased proc essor speed.

Resetting the camera using a keypad as with the VC20XX cameras is also not possible.

There are three ways of preventing the Autoexec execution and resetting the IP address:

Option 1:

1. Upload an empty autoexec/ #IP file via FTP into the camera memory, overwriting the existing

file(s).

2. Hardware reset of camera.

Option 2: CPU reset with help of an Emulator.

Option 3: Resetting the camera with help of the “VCnet Recovery Tool” as described in the following

section.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 19

6.4.1 Resetting the Camera with help of the VCnet Recovery Tool

A new tool – the “Vcnet Recovery Tool” is provided for resetting the IP address of the VCSBC4012

and VC4012 cameras. Vcnet Recovery is supported from camera OS VCRT 5.21.

In order to use the VCnet Recovery tool, follow the steps below:

1. Download and install the “

Java(TM) 2 Runtime Environment, Standard Edition 1.4.XX” on

your PC (Download from

www.sun.com - > Downloads - > J2SE v 1.4.2_11 JRE ).

2. Download VCnet Recovery Tool for VC4012 and VCSBC4012 from www.vision–

comp.com -> Support ->

Customer Area Software Utilities

3. Unpack the “vcnet1.2.zip” folder a directory on your hard drive (for instance C:\ti\Util…).

4. Open the Dos command line window and change to the directory containing “vcnet.jar”.

5. Execute the following command from the DOS Window "java -jar vcnet.jar -snr 5912345" , by

specifying the camera serial number as shown. This command sends vcp packets via UDP

broadcast for the next 15 seconds. Sending this command resets the corresponding camera

to the default IP address and bypasses Autoexec execution. Further options below.

6. Boot the corresponding camera (power on) during the next 15 seconds. During start up the

camera listens 0.5 seconds for cvp pac ket s send with vcnet.jar.

7. If a valid vcp packet is received from camera an answer packet is sent (see example below).

The camera continues booting in standard configuration:

Default IP address: 192.168.0.65

Mask: 255.255.255.0

Gateway: none

An autoexec in flash memory is not executed.

Example of resetting a VCSBC4012, S/N 0100151:

C:\Programme\VCnet>java -jar vcnet.jar -snr 0100151

VCnet Recovering Tool Version 1.2 - Copyright Vision Components 2005

Recovering Serial Number = 100151

Listening on port 67 for incoming packets!

Packet 2 from: /0.0.0.0

===Data as Text:===

model: VC4018E

S/N: 0100151

DC: 06/10/05 09:23:06

MAC: 00-06-1F-01-87-37

IP: 192.168.0.81

MSK: 255.255.255.0

GTW: 192.168.0.1

….

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 20

6.5 Special VCRT functions for programming VCSBC4012 cameras

This sections explains the

specifics of programming VCSBC4012 cameras.

6.5.1 Trigger Functions

Apart form the inverse TTL logic (see section 4.2.3) and the different status register shown below, the

trigger works like with the VC4XXX cameras.

Please refer to the VCRT5.pdf manual – available form the Registered User Area of the VC website.

To query the trigger input, use the following command (see demo program trigin.c):

…

if (TRIGINP_PIN)

print("external trigger = 1\n");

else

print("external trigger = 0\n");

…

A capture can be triggered on rising edge with TRIGINP_POS() and on falling edge with

TRIGINP_NEG().

Signal Trigger Mode

TRIGINP_POS()

Rising Edge Trigger Signal

TRIGINP_NEG()

Falling Edge Trigger Signal

Trigger input

t

V

Threshold

Trigger input

t

V

Threshold

The trigger output can be set to exposure controlled mode – for instance to control a light source. With

TRIGOUT_EXP() combined with TRIGOUT_POS(), the trigger output is high during expo sure.

TRIGOUT_EXP() combined with TRIGOUT_NEG(), the trigger output is low during exposure.

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf – VCSBC4012 Single Board Smart Camera Operating Manual 21

Trigger Output Signal in Exposure Controlled

Mode:

TRIGOUT_EXP();

AND

Trigger output set positive:

TRIGOUT_POS();

t

V

Trigger Output

The trigger macros are also described in our programming tutorial.

!

The use of TRIGOUT_USR(), SET_TRIGOUT() and RES_TRIGOUT() is limited on the VCSBC4012

camera! Use only with slow applications and long shutter times (the sensor needs several

milliseconds to execute the signal change).

6.5.2 Controlling the TTL IOs on socket J2

Setting and reading the 4LVTTL inputs and outputs is done with help of the hardware registers.

The following macros are available for easier operation (see “vcrt.h”):

- Setting the 4 outputs is done with help of a 4 bit value:

#define TTL_OUT(x) *((volatile int *)FA40_LED) = x /* SBC4018 TTL output */

- For queering the TTL inputs use the following function:

#define GET_TTL_IN() (*((volatile int *)FA40_TTL) & 0x0F) /* SBC4018 TTL input */

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC4012.pdf VCSBC4012 Single Board Smart Camera Operating Manual

A

Appendix A: New VCRT Functions VCSBC4012

New VCRT functions (see section 6 and vcrt.h):

#define GET_HW_STATUS() (*((volatile int *)FA40_STATUS) & 0x3F) /* CPLD relase number*/

#define TTL_OUT(x) *((volatile int *)FA40_LED) = x /* SBC4012 TTL output*/

#define GET_TTL_IN() (*((volatile int *)FA40_TTL) & 0x0F) /* SBC4012 TTL input*/

© 1996-2011 Vision Components GmbH Ettlingen, Germany

VCSBC40XX.pdf – VCSBC4012 Single Board Smart Camera Operating Manual B

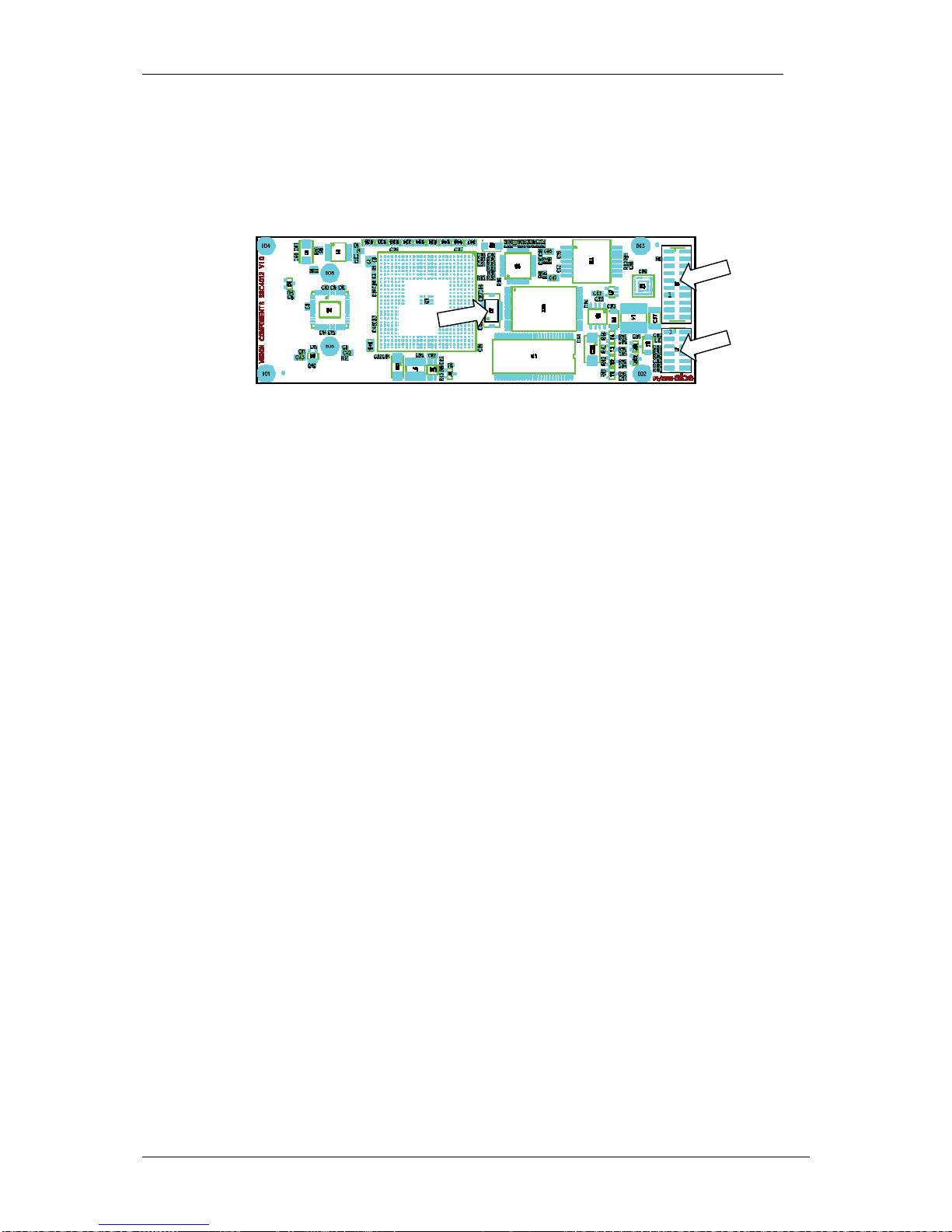

Appendix B: Drawing Circuit Board VCSBC4012

The red dot marks the Pin 1 position of each connector.

Correct placement

Of Emulator adapter

board

All mounting holes:

∅ 2.2mm for M2

Tolerances: All circuit board dimensions: +/- 0.1mm

© 1996-2011 Vision Components GmbH Ettlingen, Germany

C

Visit the Vision Components site www.vision-components.com for further information,

documentation and software downloads:

Web Site Menu Links Content

Contact

Distributor list / Enquiry forms

Home

Latest News from VC

Our Company

VC Company Information

News and Events

Trade Show dates

VC Publications

Sign in for free VC Seminars

VC Network

Description of Partner Companies

Application Overview

3

rd

Party Hard- and SW Products for VC Smart

Cameras

Products

VC Smart Camera Overview

Product Overview:

VC44XX VC Optimum

VC40XX VC Professional Family

VC4016 / 18 VC Base Family

VC4002L Line Scan Camera

VCSBC Single Board Cameras

VC20XX Smart Cameras

VCSBC Board Cameras

VCM + Viscube Camera Sensors

VC Smart Camera Software

VC Software Development Kit Ti: VCRT Operating System

VCLIB Image Processing Library

VC Special Libraries: M200 Data Matrix Code Reader

VCOCR Text Recognition Library

Color Lib

Support:

Support News (User Registration required) Tech News – new SW and Documentation

Knowledge Base / FAQ (User Registration

required)

Searchable FAQ Database with programming

Examples and Demo Code

Download Area Download of:

Public Download Area

(free Access)

- Product Brochures

- Camera Operat ing Manuals

Registered User Area

(User Registration required)

- Getting Started

- Programming Manuals

- Tr aining Manuals and Demo Code

Customer Download Area

(User- and SW License

Registration required)

- Software Updates (Libs and camera OS)

- Demo Code

- Utility Software

RMA Number Form Form for Allocation of Repair Numbers.

Loading...

Loading...