Page 1

ENGINEERING

Ster eo

Page 2

Page 3

The instrument that you have just received is manufactured by Vision Engineering.

Vision Engineering is the world leader in the manufacture of Microscopes without eyepieces (known as

DYNASCOPES or LYNX), Microscopes with Expanded Pupils (known as COBRA) and stereo magnifiers

(known as MANTIS).

MANTIS, LYNX, COBRA and DYNASCOPES are available in a range of stereo and mono configurations.

They are used in a wide range of manufacturing industries, workshops and laboratories.

The systems are used for manual assembly and finishing, inspection, dimensional measurement and rework.

They also have considerable research, laboratory and biomedical uses.

Vision Engineering has manufacturing and distribution subsidiaries world-wide as follows:

GREAT BRITAIN:

Manufacturing Base and Headquarters

Vision Engineering Limited Tel: +44 (0) 1483 223417

Send Road Fax: +44 (0) 1483 223297

Send e-mail: 100721.1202@compuserve.com

WOKING

Surrey GU23 7ER

Commercial

Vision Engineering Limited Tel: +44 (0) 1483 248300

Monument House Fax: +44 (0) 1483 248317

Monument Way West e-mail: 100721.1202@compuserve.com

WOKING

Surrey GU21 5EN

U.S.A.:

Vision Engineering Inc Tel: +1 860 355 3776

570 Danbury Road Fax: +1 860 355 0712

New Milford e-mail: info@visioneng.com

Connecticut 06776

USA

Vision Engineering Inc Tel: +1 714 974 6966

745 West Taft Avenue Fax: +1 714 974 7266

Orange e-mail: alsilva@visioneng.com

California 92865

USA

ENGINEERING

Page 4

GERMANY: SWITZERLAND: AUSTRIA: CZECH REPUBLIC: SLOVAKIA:

Vision Engineering Limited Tel: +49 (0) 8141 40 1670

Anton Pendele Strasse 3 Fax: +49 (0) 8141 40 16755

D-82275 Emmering e-mail: sales@vision-eng.de

Germany

NORTH GERMANY: BENELUX: DENMARK: NETHERLANDS:

Vision Engineering Limited Tel: +49 (0) 2129 91 5900

Am Ideck 28 Fax: +49 (0) 2129 91 5903

D-42781 Haan

Germany

FRANCE:

Vision Engineering Limited Tel: +33 (0)1 64 46 90 82

Miniparc du Verger Fax: +33 (0)1 64 46 31 54

1 Rue de Terre Neuve e-mail: 100772.1206@compuserve.com

ZA Courtaboeuf

91967 Les Ulis Cedex

France

JAPAN:

Nippon Vision Engineering Tel: +81 (0) 45 472 1004

No. 6 Shinyokohama Hayama Building Fax: +81 (0) 45 472 1177

1-28-8 Shinyokohama e-mail: info@vision-eng.co.jp

Kohoku-ku

Yokohama-shi

Japan

All other countries are covered by distributors. Our contracted distributors are all fully trained in installation

and service and hold sales and service stock.

Your local distributor is:

Page 5

CONTENTS

Introduction

Packing Contents

Head Pack 1

Stand Pack or Platform Pack 1

Zoom Assembly Pack & Accessories 2

Assembly

Platform/Bench Assembly 3

Head to Tubular Support Assembly 3

Column to Stand Assembly 4

Column Attachment Assembly 5

Attaching Head 6

Objective Lens 6

Attaching 6 Point Ringlight 6

Attaching Spot Illuminator 7

Photographic Attachments 7

Zoom Multiplier 8

Mains Connection 8

Inserting Graticule 8

Operator Controls

Main System Controls 9

Graticule Adjustment 9

Routine Maintenance

General Maintenance Points 10

Sub-Stage Lamp Changing 11

Illuminator Lamp Changing 11

Page 6

Magnification & Optical Information

Lynx Magnification Table 12

Product Family

Family Tree 13

Warranty

Page 7

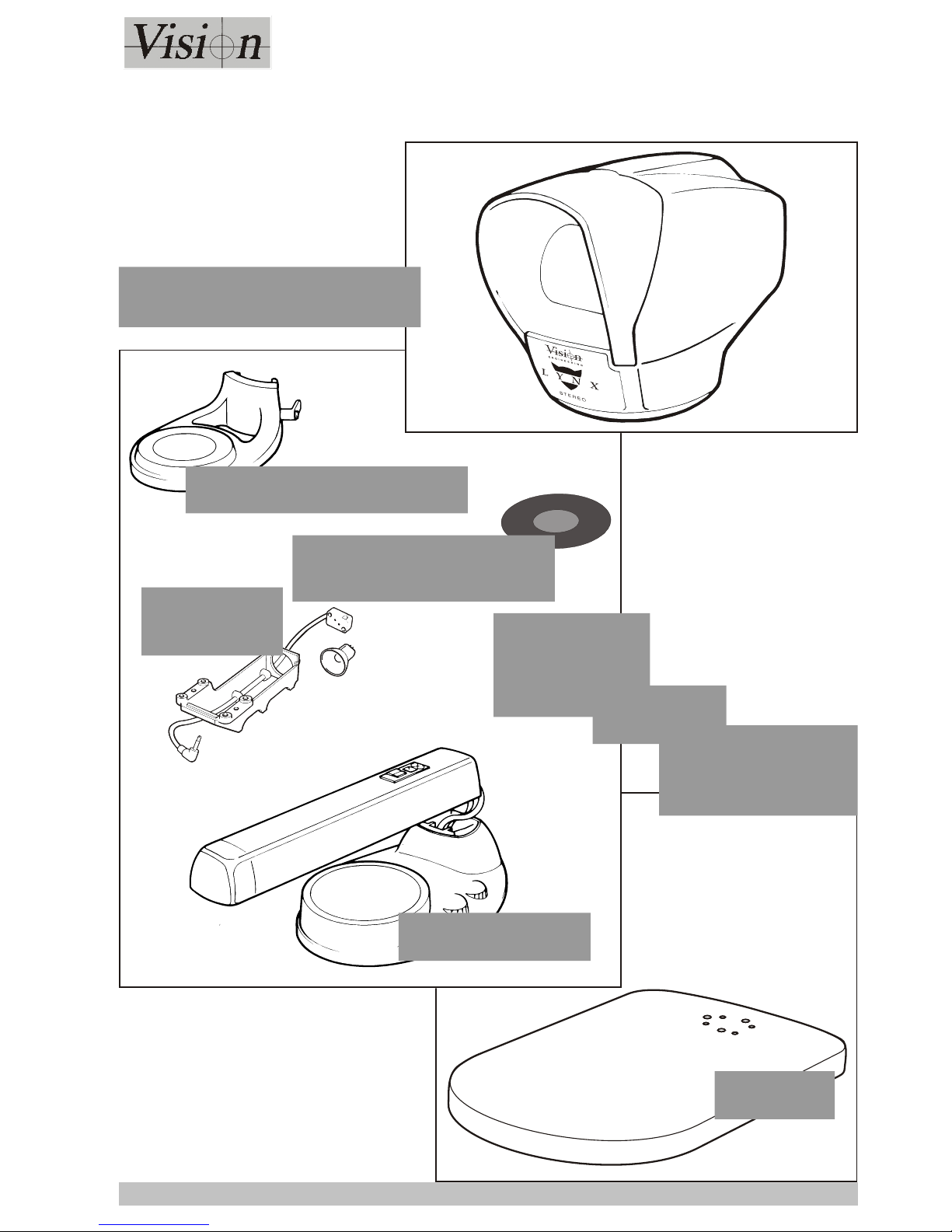

Please look for the following parts in each pack. Each pack has a check

list on the outside of its contents

PACKING CONTENTS

Page 1

PACKING CONTENTS

STAND

PACK

Column & Stand

Platform

Adjustable Subject Platform

HEAD PACK

Substage

Illuminator

PLATFORM

PACK

OR

Condenser Assembly with

Diffuser

Page 8

Page 2

PACKING CONTENTS

x 0.3

x 0.7

x 1.0

x 2.0

x 1.5

x 0.5

ZOOM PACK

Spot Lamp

Assembly

6 Point Ringlight,

Illuminator &

Power Supply

Objective

Lenses

Zoom/Focus

Assembly

Anti-glare

Shield

Spare Lamp

ACCESSORIES

PACKS

Zoom

Multiplier

Photographic

Adaptors &

Photo Arm

Upright &

Horizontal Boom

Bars

Stage

Boom Mount

Bracket

Page 9

ASSEMBLY

ASSEMBLY

Page 3

ASSEMBLY

3

4

Securing Bolts

& Pressure Cups

Bench Drilling Template

9mm Dia.

105mm Dia.

90.9mm

1

PLATFORM/BENCH ASSEMBLY

If bench mounting, drill holes in the

bench using the template shown 1 left.

Allow room for the horizontal support bar

to protrude behind the Lynx.

Feed the stand

securing bolts up

through the

pressure cups

and secure into

the stand base

(see 2 left).

Attach the horizontal

support bar to the

vertical bar as shown

in 3 above.

Slide the securing

collar up and lock it

into the desired

position (see 4

above).

HEAD TO TUBULAR

SUPPORT ASSEMBLY

Attach clamps to the horizontal post (see right).

Page 10

Page 4

ASSEMBLY

Stage

Blanking

Plate

Stage

Glass

1

Fan

Column

Securing Screws

Securing

Screw

Connector

COLUMN TO STAND

ASSEMBLY

Insert the Fan, connect it and lock it in position

with its securing screw (see inset 1).

Raise the column into the upright position and

secure it with the four column securing screws.

Remove the Blanking

Plate.

Remove the stage

glass and lower the

Stage onto the Stand.

Secure it with the 4

bolts supplied.

Page 11

Page 5

ASSEMBLY

1

2

Mirror

Blanking

Plate

Column

Connector

Column

Cap

Zoom/Focus

Assembly

Adjustable Subject

Platform

Sub-Stage

Illuminator

Condenser

Plate &

Diffuser

COLUMN

ATTACHMENT

ASSEMBLY

Sub-stage illuminator Remove the protective film from

the mirror (see right). Fit the

bulb (see 1 and 2 right).

Remove the Blanking Plate.

Slide the sub-stage illuminator

into position and secure it with

the two bolts supplied. Connect

the assembly. Put the

condenser plate into position

and fit the diffuser in either the

base or subject platform as

required.

Adjustable Subject Platform -

Slide the platform on to the

column, position it as required

and secure it in position.

OR

Slacken the securing clamp

until the platform can be

pushed on to the column.

Re-tighten the clamp with the

platform in the required

position.

Zoom/Focus Assembly Remove the Column Cap. Slide

the assembly on to the column

just enough to allow the column

connector to be attached to the

male connector at the rear of

the assembly. Replace the

Column Cap.

Position the Zoom/Focus

Assembly as required

and secure it.

Page 12

Page 6

ASSEMBLY

Head

Connector

Head

Socket

Alignment Pin

Securing Screw

Insert the Head

Connector in the Head

Socket. Place the Head

on to the Zoom/Focus

Assembly, ensuring the

alignment pin in the

Zoom/Focus Assembly

lines up with the relevant

slot in the Head. Tighten

the securing screw.

ATTACHING HEAD

Securing

Screws

Objective

Lens

6 Point

Ring Light

Beam

Converger

(only for 1.5x or 2x lens)

Place the ringlight into position and tighten the

securing screws. Clip the Beam Converger (only

required if using a 1.5x or 2x objective lens) into

place and attach the fibre optic cable to the

illuminator.

ATTACHING

6 POINT RINGLIGHT

Objective

Lens

Lens

Securing Screw

OBJECTIVE LENS

Page 13

Page 7

ASSEMBLY

Head

Connector

Photographic

Attachment

Camera

Interface

Head

Socket

Securing Screw

Head

Securing Screw

Remove the Head.

Place the

Photographic

Attachment

Assembly into

position and tighten

the securing screw.

Replace the head

on to the assembly

and tighten the

Head Securing

Screw.

Attach the

appropriate Camera

interface to the

Photographic

Attachment and

tighten the securing

screws.

NOTE

Adapters for the

Polaroid, 35mm

and CCTV/Digital

cameras are

different.

The camera

attaches to the

interface.

PHOTOGRAPHIC

ATTACHMENTS

Objective Lens

Spot Illuminator

Connector

Spot

Illuminator

Securing

Screws

Place the Spot Illuminator into position and

tighten the securing screws. Insert the

illuminator’s connector into the socket

underneath the Zoom/Focus Assembly.

ATTACHING

SPOT ILLUMINATOR

Page 14

Page 8

ASSEMBLY

Securing Clip

Retaining Knobs

Graticule

Connect Mains

at Rear

1

15

2

3

0

Mains

On/Off

Switch

Anti-glare

Shield

Mains

Input

Voltage

Selector

Fuse

MAINS

CONNECTION

Head

Connector

Zoom

Multiplier

Head

Socket

Securing Screw

Head

Securing Screw

ZOOM MULTIPLIER

Remove the Head. Place the Zoom

Multiplier Assembly into position and

tighten the securing screw.

Replace the Head on to the assembly

and tighten the Head Securing

NOTE

Ensure the Voltage Selector is

turned to the correct setting.

For Japan and some Far

Eastern markets the voltage

selector is marked 100 - 110V.

INSERTING

GRATICULE

Squeeze the securing

clip at the base of the

front cover and lift the

cover off. Loosen the

appropriate retaining

knob (the graticule

can be placed on

either side of the

head), slide the

graticule into position

and re-tighten the

knob. Replace the

front cover.

Attach the anti-glare shield as

shown left.

Page 15

ASSEMBLY

OPERATOR

CONTROLS

Page 9

OPERATOR CONTROLS

Securing Clip

Graticule

Retaining Knobs

Rotation Spigot

Focus

Control

Head Height

Adjuster

Subject Platform

Height Adjuster

Top Illuminator

Dimmer

Substage Illuminator

Dimmer

Zoom

Control

Magnification

Control

Low

(1x)

High

(1.5x or 2x)

MAIN SYSTEM CONTROLS

ORDER OF SETTINGS

1. Turn the Zoom

control to maximum.

2. Set the Focus

control to obtain the

best clarity.

The focus will now be

maintained throughout

the Zoom range.

Squeeze the securing

clip at the base of the

front cover and lift the

cover off.

To focus and centralize

the graticule, loosen the

appropriate retaining

knob and move the

graticule up or down for

focus and sideways to

centralize. Re-tighten

the retaining knob.

To adjust the graticule

rotationally, remove the

rotation spigot from its

storage position in the

graticule, insert it in the

rotation ring as shown

and rotate it until the

correct position is

obtained. Replace the

spigot and close the

front cover.

GRATICULE ADJUSTMENT

Page 16

ROUTINE MAINTENANCE

Page 10

ROUTINE MAINTENANCE

Viewing

Screen

1

1

5

2

3

0

Voltage

Selector

Input

Power

Fuse

Base

Securing

Screws

Rubber

Feet

Sub-Stage

Fuse

Securing Clip

Retaining Knobs

Graticule

Clean the viewing screen periodically with optical cloth.

GENERAL

MAINTENANCE

POINTS

If, after cleaning the

viewing screen, the

picture quality is

below standard,

remove and clean the

graticule if fitted.

If the graticule

requires adjustment

after it has been

cleaned, see page 9.

NOTE

Ensure the Voltage Selector is

turned to the correct setting.

For Japan and some Far

Eastern markets the voltage

selector is marked 100 - 110V.

Changing the

Sub-Stage Fuse:

Remove the 4 rubber

feet from the base

(push fit).

Remove the 5 base

securing screws.

Replace the fuse with

an 800mA quick

blow type.

NOTE

When the base is

replaced, ensure

the heat slots line

up with the heatsink

and substage bulb.

Page 17

ROUTINE

MAINTENANCE

Page 11

ROUTINE MAINTENANCE

Condenser &

Diffuser

Plate

Sub-Stage

Illuminator Bulb

20W/12V

Dichroic Lamp

(2000 hour)

2

3

1

150W/21V

Halogen Lamp

(200 hour)

NOTE:

ENSURE THE ILLUMINATOR

IS NOT HOT.

Press down the bulb/fan

assembly release button (see

1 above).

Lift out the bulb/fan assembly

(see 2 above).

Disconnect the lamp as

shown in 3 above.

When relocating a lamp,

ensure it is fully pushed into

the lamp holder.

SUB-STAGE LAMP CHANGING

ILLUMINATOR

LAMP

CHANGING

NOTE:

The 250W

Halogen lamp

version (60 hours)

has the same

lamp change

procedure

Page 18

Page 12

MAGNIFICATION & OPTICAL INFORMATION

PART

NUMBER

MAGNIFICATION RANGE

WITH 1.5x

MULTIPLIER

(C-040)

WITH 2x

MULTIPLIER

(C-041)

WORKING

DISTANCE

FIELD OF VIEW

AT MAX. ZOOM

FIELD OF VIEW

AT MIN. ZOOM

NOTES

C-050 x0.3 x2.1 - x12 x3.2 - x18 x4.2 - x24 312mm 12mm 77mm

Requires diverging lens when

used with 6 point ringlight

C-055 x0.5 x3.5 - x20 x5.3 - x30 x7.0 - x40 175mm 7mm 46mm

C-051 x0.7 x4.9 - x28 x7.4 - x42 x9.8 - x56 127mm 5mm 33mm

C-052 x1.0 x7.0 - x40 x10.5 - x60 x14 - x80 85mm 3.5mm 24mm

C-053 x1.5 x10.5 - x60 x15.8 - x90 x21 - x120 45mm 2.5mm 16mm Requires converging lens (Part

No. C-034) when used with 6

point ringlight

C-054 x2.0 x14 - x80 x21 - x120 x28 - x160 25mm 1.75mm 12mm

Note: Above figures without

multipliers fitted. To

calculate field of view =

140mm

magnification

MAGNIFICATION & OPTICAL INFORMATION

LYNX MAGNIFICATION TABLE

Page 19

PRODUCT FAMILY

Page 13

PRODUCT FAMILY

STANDARD

Core Instrument

Stereo Zoom

C-002

Head L-001

Bench

Stand

C-010

6-Point Ringlight C-023/024

& 150W Illuminator C-030

150W/21V Transformer

(Head & Ringlight)

C-031 100V

115V

220V

240V

Coaxial (through

the lens illuminator)

C-139

250W Illuminator

C-028

250W/24V

Transformer

(Head & Ringlight)

C-029

60W/12V

Dual Transformer

(Head & Spots)

C-034 100V

115V

220V

240V

Spot Illuminator

C-021

Diffuser

Plate

Clear Glass

Insert

Condensor

Base

Adaptor

High Intensity

Substage Illuminator

& Diffuser Kit

C-020

Floating

Stage

C-070

Zoom

Multiplier

(x1, x1.5)

Zoom

Multiplier

(x1, x2)

25° Angle

Adjuster

Dust Cover

C-103

Photographic

Attachment

C-069

Polaroid Camera

C-061

Digital Camera/

CCTV Camera

C-063

35mm Camera

C-062

Adjustable

Subject

Platform

C-011

C-040

C-041 C-152

Objective

Lenses

0.3x C-050

0.5x C-055

0.7x C-051

1.0x C-052

1.5x C-053

2.0x C-054

Boom Mount

C-145

Lynx Stereo

FOR INSPECTION AND GENERAL MICROSCOPE APPLICATIONS

ENGINEERING

Platform Base

for Boom Mount

C-155

Boom Mount

mounted on

work surface

or Platform Base

C-145

Polariser Kit

C-096

50mm x 50mm (2“ x 2”)

Measuring Stage

C-136

Cross Line NE8 Graticule

C-134

In line Viewing

Adaptor

C-147

Boom Mount/

Stereo Zoom

OEM C-146

OEM Mounting Clamp

(available separately)

C-149

Head L-001

Mounting Brackets for Transformer and Illuminators

when used with Boom Mount (2 required)

C-148

FAMILY TREE

Page 20

Page 21

WARRANTY

This product is warranted to be free from defects in material and workmanship for a period of one year from the date of

invoice to the original purchaser.

If, during the warranty period the product is found to be defective, it will be repaired or replaced at facilities of Vision

Engineering or elsewhere, all at the option of Vision Engineering. However, Vision Engineering reserves the right to

refund the purchase price if it is unable to provide replacement, and repair is not commercially practicable or cannot

be timely made. Parts not of Vision Engineering manufacture carry only the warranty of their manufacturer.

Expendable components such as lamps and fuses carry no warranty.

This warranty does not cover damage caused in transit, damage caused by misuse, neglect, or carelessness, or

damage resulting from either improper servicing or modification by other than Vision Engineering approved service

personnel. Further, this warranty does not cover any routine maintenance work on the product described in the

instruction manual or any other minor maintenance work which is reasonably expected to be performed by the

purchaser.

No responsibility is assumed for unsatisfactory operating performance due to environmental conditions such as

humidity, dust, corrosive chemicals, deposition of oil or other foreign matter, spillage, or other conditions beyond the

control of Vision Engineering.

Except as stated herein, Vision Engineering MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED BY LAW,

WHETHER OR MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE. Further, Vision

Engineering shall not under any circumstances be liable for incidental, consequential or other damages.

ENGINEERING

Loading...

Loading...