Page 1

Page 1

ENGRAVING SYSTEMS

1612, 1624, 2424, 2448 Engravers

and 2424, 2448 Router

Table Users Manual

Vision Engraving & Routing Systems

17621 N. Black Canyon Hwy.

Phoenix, AZ 85023

Technical Support 602-439-0700

Fax 602-439-0500

www.visionengravers.com

Manual Revised 6-3-08

Page 2

Page 2

Page 3

Page 3

Liability Statement ________________________________________ 4

Safety ____________________________________________________ 5

Chapter 1: Table Description _____________________________ 7-12

Chapter 2: Setting Up The Table ____________________________ 13

Chapter 3: Engraving Head Removal Procedure __________ 15-16

Chapter 4: High Frequency Router Removal ______________ 17-19

Chapter 5: High Frequency Router Motor ____________________ 21

Chapter 6: Porter Cable Removal Procedure _____________ 23-24

Chapter 7: Porter Cable Router Connections ________________ 25

Chapter 8: Table Adjustments ___________________________ 27-30

Chapter 9: Table Maintenance __________________________ 31-36

Chapter 10: Troubleshooting ____________________________ 37-40

This manual is designed to provide you with information about your

Vi sion Engr aving and Routi n g Systems ta ble, begi nning wit h

the initial connection of your table and continuing through installation

and lifetime table maintenance. This manual does not attempt to

teach you how to engrave, how to use a computer, or how to use your

engraving software. Some previous knowledge of engraving terms and

the engraving process is assumed. For information on your individual

computer system, see your computer’s user manual or contact your

computer distributor.

For information on the engraving software you use to drive your engraving

system, see the manual for the individual software package supplied

by the software developer.

Table of

Contents

Table Of Contents

Page 4

Page 4

Copyright 2008 Vision Engraving & Routing Systems

(A Division of Western Engravers Supply, Inc.)

All Rights Reserved

This publication is protected by copyright, and all rights are reserved. No part of this manual may be reproduced or

transmitted by any means or in any form, without prior written consent from Vision.

Limits of Liability / Disclaimer of Warranty for this Table Manual:

The information contained within this manual has been carefully checked and is believed to be accurate, however,

Vision makes no representations or warranties for this manual, and assumes no responsibility for inaccuracies, errors,

or omissions that may be contained within this manual. In no event shall Vision be liable for any loss of profit including

(but not limited to) direct, indirect, special, incidental, consequential, or other damages resulting from any defect or

omission in this manual, even if previously advised of the possibility of such damages.

In the interest of continued product development, Vision reserves the right to make improvements to this manual and

the products it describes at any time, without notice or obligation.

Vision Engraving and Routing Systems Warranty For The Vision Table:

Vision Computerized Engraving and Routing Systems (Vision) warrants that for a period of two (2) years from the date

of shipment to the original purchaser of either a Phoenix, or Vision Engraving System (the System) that the System

will be free from defects in material and workmanship under normal use and service. Upon written notication we will

transfer the remaining warranty to a new customer. This warranty shall cover all elements except for items covered by

separate manufacturer’s warranties and consumable items. “Consumable” items include, but shall not be limited to,

belts, brushes, lubricants, and cutters furnished with the System, for which no warranty is provided.

In the event a defect is discovered during the warranty period, within thirty days of discovery, but in no event later

than the last day of the warranty period as described above, the user shall contact Vision for instructions regarding

disposition of the problem. Vision shall, at its option, either (1) repair the affected product with new or refurbished

parts or (2) provide a replacement. Any incidental costs, including the cost of shipment from the user’s location to the

point of repair and return, and any installation performed by the user, shall be at the expense of the user.

This warranty covers normal use only and shall be void in the event that the System is altered or modied without

authorization by Vision, or is subject to abuse, neglect, or other misuse by the user.

The warranties for Third-Party Hardware and Third-Party Software shall run directly from the manufacturers of

such hardware and software to the user. Vision makes no warranties, express or implied, with regard to Third-Party

Hardware or Third-Party Software. This includes NSK spindles, high frequency spindles and router motors.

Vision does not warrant any product, component, or part not manufactured by Vision that was not supplied by Vision.

(Third-party items, including but not limited to software, are subject to their own manufacturers warranties.) Vision

does not warrant defects caused by a failure to provide a suitable environment for the system, by unauthorized

attachments, by modications or repairs other than by Vision, by use of the System for other than its original intention,

or by other misuse or abuse of the System.

Lapse of Warranty

If an extended warranty is purchased after the original warranty expires, the Vision machine must be in full working

order for the extended warranty to be purchased for that machine. If the machine is not operational and the customer

would like to purchase an extended warranty, the machine must rst be repaired at a 20% discount for the repair work.

If the machine is in good operating condition the customer can purchase the extended warranty. If the machine has

problems, it must be repaired at the customers’ expense. If the customer then chooses to buy an extended warranty a

20% credit on the repair parts will be issued.

The above and foregoing is the only warranty of any kind, either express or implied, by statute or otherwise, regarding

the System, its tness, quality, merchantability, or otherwise. Any warranties implied by law are hereby expressly

disclaimed. No oral or written information or advice given by Vision, its Dealers, Distributors, Agents, or Employees

shall create a warranty or in any way increase the scope of this warranty. Neither Vision nor anyone else who has been

involved in the creation, production, or delivery of the System shall be liable for any direct, indirect, consequential,

or incidental damages (including damages for loss of business prots, business interruption, loss of business

information, and the like) arising out of the use of, or inability to use, the product.

Any software supplied by Vision in conjunction with the purchase of the System for use therewith shall be governed by

its own separate software license and warranty agreement.

For Warranty Service Call: (602) 439-0700

Page 5

Page 5

Safety

Safety Precautions

for Vision Engraving Tables

Keep hands clear of the spindle belt during operation.

Keep hands clear of the bottom of the spindle during operation.

Always stop the machine before making any adjustments.

Unlplug the power to the Vision controller and disconnect the table cable and

spindle drive cable before servicing.

Do not operate the system with covers removed.

Wear safety glasses when cutting any materials that emit chips. Use of the optional vacuum

system will help remove chips.

Use extreme caution when inserting or removing cutters, as cutter surfaces are very sharp.

Page 6

Page 6

Page 7

Page 7

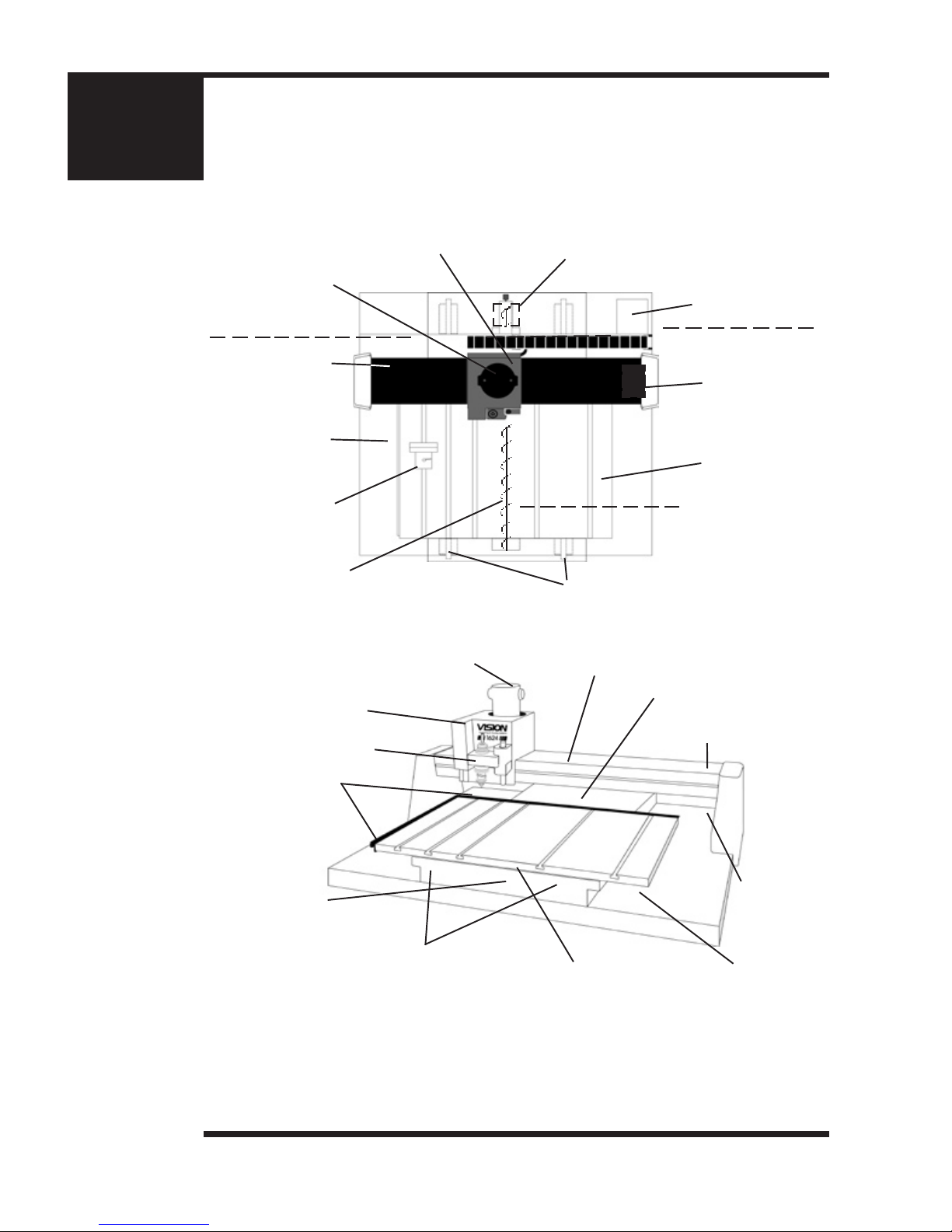

Chapter 1:

Table Description

This chapter briey describes the major components of the Vision table. Figure 1.1 (see page 8)

and Figure 1.3 (see page 11) show pictures of two typical engraving tables. This chapter will help

you identify the parts of your Vision table discussed elsewhere in the manual.* Find the model

number as referenced in the description for each type of table design.

*Optional equipment such as accessory vises, clamps, xtures or vacuum systems may have

been included with your system. For information regarding this equipment, see the individual

instructions for these options. For descriptions of controllers, computers, and software used in

your system, see the manuals from the manufacturers of these units.

TABLE SPECIFICATIONS:

Z-Axis Clearance

(denition: the distance between the bottom of the spindle and the work surface)

Vision engraving: Adjustable Clearance

Z-Axis Stroke

(denition: the travel distance of the Z-axis mechanism or spindle)

Vision Tables: 5 Inches (125 mm)

Table Resolution

(denition: the smallest controlled motion the table is capable of)

.0002 inch on all tables (when connected to a Vision Controller)

Engraving/ Engraving Overall Table Shipping

Routing Area Dimensions Type Weight

Table

VISION 1612 16”x12” 31.5”x21”x19” T-Slot 290lbs.

VISION 1624 16”x24” 31.5”x33”x19” T-Slot 290lbs.

VISION 2424 24”x24” 33”x42”x20” Flatbed (T-slot) 386lbs.

VISION 2448 24”x48” 33”x66”x20” Flatbed (T-slot) 532lbs.

VISION 2424 RT 24”x24” 40”x42”x27.5” T-Slot 534lbs.

VISION 2448 RT 24”X48” 40”X66”X27.5” T-Slot 734lbs.

DEFINITION OF TERMS

A. Tables With Moveable T-Slot Engraving Beds (VISION 16x12 and 16x24)

In this design, the T-slot table moves in the Y-axis direction while the gantry remains xed.

The carriage moves from left to right in the X-axis. There are no particular design advantages

or disadvantages to this style of table. The main engineering criteria in the development of

this design was the need to minimize the overall table footprint while providing the maximum

engraving area.

Chapter 1

approx. packaged

L x W x H

Page 8

Page 8

Chapter 1

(Figure 1.1) Moveable T-slot table format.

Shown here is the top view of the Vision 1624. The Vision 1612 has a similar design.

1. Table Base Plate

2. Y-Axis Linear Rails

5. Gantry Assembly

6. Carriage Assembly

7. 25 Pin Breakout

Box (underneath)

8. Y-Axis Stepper Motor (underneath)

4. Y-Axis Lead Screw

(under metal cover)

11. Engraving Motor

3. T-Slot Table

7. 25 Pin Breakout

Box (under cover)

1. Table Base Plate

2. Y-Axis Linear Rails

(under metal cover)

10. Material Guides

6. Carriage Assembly

4. Y-Axis Lead Screw

(under metal cover)

11. Engraving Motor

9. X-Axis Stepper

Motor

9. X-Axis Stepper Motor

(under metal cover)

3. T-Slot Table

8. Y-Axis Stepper Motor

(under metal cover)

12. Quick-Lock Vise

1. Table Base Plate. This is the large at plate upon which everything else is mounted.

All mechanical alignments are referenced to this plate, so the space upon which you place the

engraving table must be a reasonably level surface.

2. Y-Axis Linear Rails. Mounted on the table base plate are stainless steel rails with sealed

bearings, which allow the motion of the T-slot table in the Y-axis direction.

(Figure 1.1a) Series 3 T-slot table format. Shown here is front angled view of the

Series 3 Vision 1624.

5. Gantry Assembly

(under metal cover)

13. Spindle Housing

Page 9

Page 9

Chapter 1

3. T-Slot Table. Also referred to as the work surface, this aluminum bed supported by the

linear rails allows placement of the engraving material or special clamps and xtures. The

slots in this table are shaped with an upside-down T, with the bottom of the T being a single-

line slot across the top of the table (see g 1.1b). The slots are used to hold various accessory

holders, clamps, and jigs. All t-slot accessories are avaiable on at ww.visionengravers.com

4. Y-Axis Lead Screw. This is a threaded rod located underneath the T-slot table. Combined

with the stepper motor, the lead screw is rotated and causes the T-slot table to move along

the rails in the Y-axis direction (as seen in gure 1.1c). There is also a second lead screw

called the X-axis lead screw. The X-axis lead screw is contained within the gantry, and can be

accessed by removing the black sheet metal gantry cover. The X-axis lead screw is responsible

for X-axis motion of the carriage assembly, moving it left and right across the gantry.

5. Gantry Assembly. The gantry or “bridge” is a large, rectangular bar suspended across

the width of the table in the X-axis. The carriage assembly is supported and rides on the

gantry in the X-axis.

6. Carriage Assembly. The carriage assembly houses the engraving spindle, Z-Axis

mechanism and engraving motor. The carriage moves along the gantry assembly on a set of

sealed bearing. The carriage assembly holds the engraving spindle; it raises and lowers the

spindle during the engraving process using a lead screw and stepper motor.

7. 25 Pin Breakout Box. This electrical access is used to connect the table to the system

controller. The breakout box and connector are located near the rear of the table and under

the base plate. (see page 13, g 2.1).

8. Y-Axis Stepper Motor. Drives the T-Slot table in the Y-Axis.

9. X-Axis Stepper Motor. Drives the carriage in the X-Axis. Located under the protective

sheet metal cover.

10. Material Guides. Used as a back and side stop for accurately locating material and

clamps during set-up.

11. Engraving Motor. Drives the spindle for rotary engraving.

12. Quick-Lock Vise. A “cam” type locking device that allows quick change of parts for

engraving.

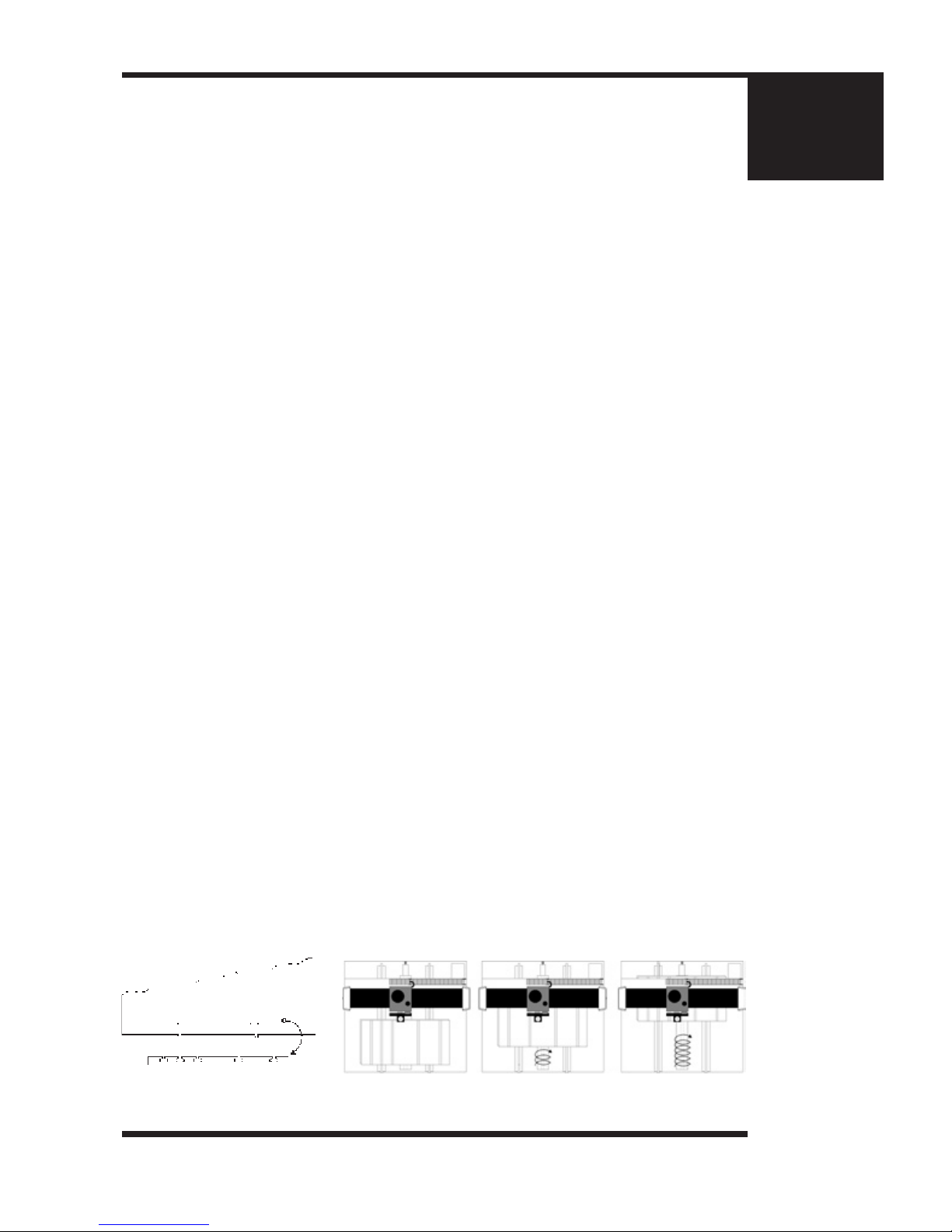

(Figure 1.1c) T-slot table motion

(Figure 1.1b) T-slot close up

Page 10

Page 10

1. Engraving Motor. The engraving motor or “spindle motor”, is the large black motor on

the top of the carriage assembly. The engraving motor drives a belt and pulley system, which

turns the engraving cutter during the engraving process.

2. Z-Axis Stepper Motor. The small motor under the carriage cover that provides the spindle

up and down motion of the spindle during the engraving process.

3. Spindle Assembly. The spindle mounted in its block; includes a pulley, housing,

micrometer, retainer ring, nose cone and associated hardware. The spindle assembly moves

up and down along a linear bearing, which attaches to the face of the carriage assembly.

4. Spindle Block. Houses the spindle assembly.

5. Z-Leadscrew. The threaded screw which raises and lowers the spindle during the

engraving process.

6. Engraving Motor Belt. Drive belt connecting the engraving motor to the spindle pulley.

B. Tables With Moveable Gantrys (“Flatbeds”-Vision 24x24, 24x48 on page 12)

The difference in design of the atbed table versus the moving T-slot type is that the atbed work

area does not move. In this design, the entire gantry travels the length of the X-axis and the

carriage moves in the Y-axis.

Chapter 1

(Figure 1.2) Close up of the Vision

table carriage

Shown is 3/4 view, without

sheetmetal top cover

1. Engraving Motor

2. Z-Axis Stepper Motor

6. Engraving

Motor Belt

5. Z Lead Screw

3. Spindle Assembly

4. Spindle Block

Page 11

Page 11

Chapter 1

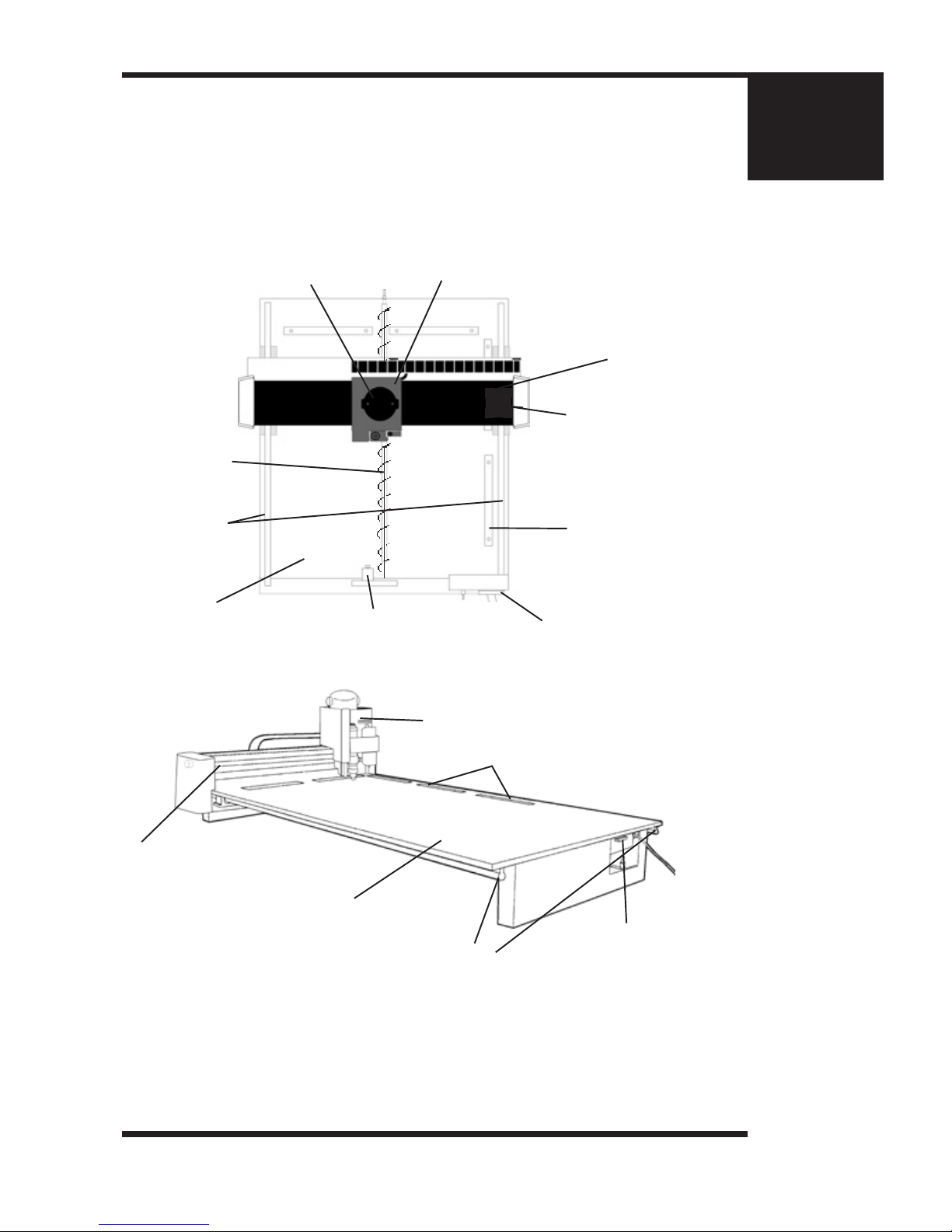

(Figure 1.3) Moveable gantry atbed table format.

Shown here is a top view of the Vision 2424.

1. Table Base Plate

2. X-Axis

Linear Rails

4. Gantry Assembly

5. Carriage Assembly

6. 25 Pin

Breakout Box

7. Y-Axis

Stepper Motor

8. X-Axis

Stepper Motor

9. Material Guides

10. Engraving Motor

3. X-Axis

Lead Screw

6. 25 Pin

Breakout Box

1. Table Base Plate

2. X-Axis Linear Rails

9. Material Guides

5. Carriage Assembly

4. Gantry Assembly

1. Table Base Plate. This is the large at plate upon which everything else is mounted. All

mechanical alignments are referenced to this plate, so the space upon which you place the

engraving table must be a reasonably level surface.

(Always carry the table by the base plate only.) An optional t-slot table may be installed on the

table base plate. Router tables include a t-slot table as standard.

2. X-Axis Linear Rails. Mounted under the table base plate are steel rails with sealed

bearings, which allow the motion of the gantry in the X-axis direction.

(Figure 1.3a) Front angled view of the Vision 2448

Page 12

Page 12

Chapter 1

3. X-Axis Lead Screw. This is a threaded rod located underneath the table baseplate.

Combined with the stepper motor, the lead screw is rotated and causes the gantry to move

along the rails in the X-axis direction (see g 1.3b). There is also a second lead screw called

in the Y-axis lead screw. The Y-axis lead screw is contained within the gantry, and can be

accessed by removing the black sheet metal gantry cover. The Y-axis lead screw is responsible

for motion of the carriage assembly, moving it left and right across the gantry.

4. Gantry Assembly. The gantry or “bridge” is a large, rectangular bar suspended across the

width of the table. It travels down the table along the X-axis (see g 1.3b).

5. Carriage Assembly. The carriage

assembly houses the engraving

spindle, the Z-axis mechanism and the

engraving motor. The carriage moves

along the gantry assembly on a set of

sealed bearings in the Y-axis (see g

1.3b). The carriage assembly raises

and lowers the engraving spindle

during the engraving process using a

lead screw and stepper motor.

6. 25 Pin Breakout Box. This

electrical access is used to connect

the table to the system controller.

The breakout box and connector are

located near the rear right side of the

table. It is also underneath the table

baseplate.

7. Y-Axis Stepper Motor. Drives the

carriage in the Y-Axis.

8. X-Axis Stepper Motor. Drives the

gantry in the X-Axis.

9. Material Guides. Used as a back

and side stop for accurately locating

material and clamps during set-up.

10. Engraving Motor. Drives the

spindle for rotary engraving.

(Figure 1.3b) Gantry movement along the X-axis

X-Axis

Page 13

Page 13

Connection of Power, Cables, and Controllers

Additional boxes may have been shipped along with your table, depending on the system ordered.

These will typically include a control unit and associated cables. The proper connection of these

cables is essential. Check the appropriate user’s manuals for your controller before attempting to

connect them it to the table. After connection of the cables as directed by your controller manual,

power can be connected to the system. It is suggested that a surge protector be used.

An “Auxiliary” Power Strip may have been included with your purchase. This strip is used for

automatically starting and stopping accessories via the Vision Series 3 controller’s “AUX ON/

OFF” button. Typical uses include: Vacuum Systems, Air-Assist units, oiler, lighting, 3.25 HP

Router motor (Porter cable Only) etc. Please DO NOT plug any of your Vision equipment (except

the vacuum system) into this strip, as it will not function unless the Vision Series 3 controller is

powered on. This is not possible with the “Auxiliary” strip, because it is always OFF unless the

controller is powered on and “AUX ON/OFF” is green.

Chapter 2

Chapter 2:

Setting Up The Table

(Figure 2.1) Breakout box with 25-pin connection to the Vision Series 3 controller

Back view of the

Vision Series 3

controller

Breakout box

Page 14

Page 14

Notes

Page 15

Page 15

Chapter 3

Engraving Head

Assembly

Connector

Vacuum Hose Hanger

Spindle Block

Plate

Router Housing

Router Rail Plate

Dowel Pins

1. Make sure that the Engraving Head

Assembly and the electrical power to the

Controller is disconnected before you begin

any disassembly

2. Then unplug the Connector from behind

the Router Housing and rest it on the

Vacuum Hose Hanger

3. Insert the two Dowel Pins through the two

holes on the Spindle Block Plate and into

the Router Rail Plate.

The Dowel Pins will help you to keep

everything safely in place as you begin to

remove the 4 Screws holding the Engraving

Head Assembly onto the Router Rail Plate.

(Continued on Pg. 16)

Chapter 3: Engraving Head Removal Procedure

Chapter 5: Engraving Head Removal Procedure (Part 1 of 2)

Page 16

Page 16

Chapter 3

4. Loosen all 4 Screws until you feel the

Spindle Block Plate has detached from the

Router Rail Plate.

5. Then remove all 4 Screws (2 on the Right

and 2 on the Left) and detach the Engraving

Head Assembly from the Router Rail Plate.

Remove these 2 Screws on the

Left (then 2 on the Right Side)

Engraving Head

Assembly

Spindle Block

Plate

Router Rail Plate

Chapter 3: Engraving Head Removal Procedure (Part 2 of 2)

Page 17

Page 17

Chapter 4

Chapter 4: High Frequency Router Removal

Chapter 6: High Frequency Router Removal (Part 1 of 3)

High Frequency Router

Assembly

Router Vacuum Head

Router Vacuum Hose

Connector

Vacuum Hose Hanger

Router Bracket

Plate

Router Housing

1. Make sure that the High Frequency

Router Assembly and the electrical power is

disconnected before you begin any

disassembly.

2. Then unplug the Connector from behind

the Router Housing and rest the cable on

the Vacuum Hose Hanger.

3. Disconnect the plastic Vacuum Hose Pipe

from the Router Vacuum Head and place it

safely away from the Router.

(Continued on Pg. 18)

Router Rail Plate

Page 18

Page 18

Chapter 4

Chapter 4: High Frequency Router Removal (Part 2 of 3)

Dowel Pins

Thumbscrew

Thumbscrew

Router Rail

Plate

Router Vacuum Head

High Frequency Router

Assembly

4. Loosen the two Thumbscrews and

remove the Router Vacuum Head from the

High Frequency Router Assembly.

5. Insert the two Dowel Pins through the two

holes on the High frequency Motor Plate

and into the Router Rail Plate.

The Dowel Pins will help you to keep

everything safely in place as you begin

to remove the 6 Screws holding the High

Frequency Router Assembly onto the Router

Rail Plate. (Continued on Pg. 19)

High Frequency

Motor Plate

Page 19

Page 19

Chapter 4

Chapter 4: High Frequency Router Removal (Part 3 of 3)

6. Loosen all 6 Screws until you feel the

High Frequency Motor Plate has

detached from the Router Rail Plate.

7. Then remove all 6 Screws (3 on the Right

and 3 on the Left) and detach the High Fre-

quency Router Assembly from the Router

Rail Plate.

High Frequency

Motor Plate

Router Rail Plate

Remove these 3 Screws on the

Right (then 3 on the Left Side)

High Frequency Router

Assembly

Page 20

Page 20

Notes

Page 21

Page 21

Chapter 5

Chapter 5: High Frequency Router Motor

Chapter 5: High Frequency Router Motor (Part 1 of 1)

25 Pin Table Cable showing the “Female” end on the

left. This connects with the Router Table. The “Male”

end (on the right ) connects to the interface labelled

“TABLE” on the Vision 3 Serial Controller.

Spindle/4th Axis Cable showing the “Male” end. This connects

from the Router Table to the interface labelled “SPINDLE/4TH

AXIS” on the Vision 3 Serial Controller.

Spindle/4th Axis Cable showing the “Female” end. This

connects

from the Router Table to the interface beneath the High

Frequen

cy Inverter which is also mounted to the Router Table.

High Frequency Cable showing the “Female” end. This is part

of the cable that connects from the interface beneath the High

Frequency Inverter to the interface labelled “HIGH FREQ” on the

Vision 3 Serial Controller.

This is the 220

single phase A/C

plug that connects to the high voltage

elec

trical outlet. This is the other part of the cable that

connects

from

the interface beneath the High Frequency Inverter is

mounted to

the Router Table.

Vision 3 Serial Controller

Router Table

High Frequency

Inverter

Schematic Diagram showing the Cable Connections for the

High Frequency Spindle on the 2424/ 2448 Router Table

(Items shown are not to scale.)

To electrical

outlet

Page 22

Page 22

Notes

Page 23

Page 23

Chapter 6

Chapter 6: Porter Cable Router Removal Procedure

Chapter 6: Porter Cable Router Removal Procedure (Part 1 of 2)

Porter Cable Router Assembly

Router Vacuum Head

Dowel Pins

Router Vacuum Hose

Router Bracket

Plate

Connector

Vacuum Hose Hanger

Router Rail Plate

Router Housing

1. Make sure that the Porter Cable Router

Assembly and the electrical power is discon-

nected before you begin any disassembly.

2. Then unplug the Connector from behind

the Router Housing and rest it on the

Vacuum Hose Hanger.

3. Disconnect the plastic Vacuum Hose Pipe

from the Router Vacuum Head and place it

safely away from the Router.

4. Insert the two Dowel Pins through the two

holes on the Router Bracket Plate and into

the Router Rail Plate.

The Dowel pins will help you to keep every-

thing safely in place as you begin to remove

the 6 Screws holding the Porter Cable

Router Assembly onto the Router Rail Plate.

(Continued on Pg. 24)

Page 24

Page 24

Chapter 6

Chapter 6: Porter Cable Router Removal Procedure (Part 2 of 2)

5. Loosen all 6 Screws until you feel the

Porter Cable Router Assembly has

detached from the Router Rail Plate.

6. Then remove all 6 Screws (3 on the Right

and 3 on the Left) and detach the Porter

Cable Router Assembly from the Router Rail

Plate.

Porter Cable Router Assembly

Router Bracket

Plate

Router Rail Plate

Remove these 3 Screws on the

Right (then 3 on the Left Side)

Page 25

Page 25

Chapter 7

Chapter 7: Porter Cable Router Connections

Chapter 7: Porter Cable Router Connections (Part 1 of 1)

25 Pin Table Cable showing the “Female” end on the

left. This connects with the Router Table. The “Male”

end (on the right ) connects to the interface labelled

“TABLE” on the Vision 3 Serial Controller.

Spindle/4th Axis Cable showing the “Male” end. This connects

from the Router Table to the interface labelled “SPINDLE/4TH

AXIS” on the Vision 3 Serial Controller.

Spindle/4th Axis Cable showing the “Female” end. This connects

from the Router Table with the “Male” end of the Porter Cable

AC Power Cable.

This is the Plug end of the Porter Cable AC Power Cable. This is

plugged into a regular, three prong electrical outlet.

Vision 3 Serial Controller

Router Table

Schematic Diagram showing the Cable Connections for the

Porter Cable Router on the 2424/ 2448 Router Table

(Items shown are not to scale.)

To electrical

outlet

This is the “Male” end of the Porter Cable AC Power Cable.

Page 26

Page 26

Notes

Page 27

Page 27

Chapter 8

Spindle Assembly Description

Chapter 8:

Table Adjustments

(Figure 8.1)

The Series 3 Top-Loading

Spindle Assembly

1. Pulley

2. Inner Spindle Housing (under sleeve)

3. Outer Spindle Sleeve

4. Pressure Spring Adjuster

5. Pressure Spring

6. Pointer

7. Micrometer

8. Retainer Ring

(Figure 8.2) The Series 3 Top and

Bottom-Loading Collet Spindle

Assembly

1.

2.

3.

4.

5.

6.

7.

8.

10.

9.

13.

12.

11.

9. Nose Cone

10. Cutter

11. Solid Collet (Optional)

12. Split Collet (Optional)

13. Draw Bar (Optional)

14. Cutter Knob

15. Cutter Knob Setscrew

14.

15.

Page 28

Page 28

Chapter 8

(Figure 8.3)

(Figure 8.3) Tightening the

cutter knob in the draw bar.

Zeroing Cutters for Top-Loaded Spindles (see page 15, gure 3.1)

1. Turn the micrometer to zero. This provides a starting point and reference for setting the

depth accurately. It’s important to note that the micrometer should be threaded onto the

spindle housing sufciently to prevent excessive play in the micrometer and nosecone. If there

are too few threads holding the micrometer in place it will move during the engraving process.

The best starting position is 3 or 4 complete revolutions from the top.

CAUTION: When you loosen the setscrew in this step, the cutter may easily fall out of

the spindle and can cause cutter tip damage. Use one hand to hold the cutter before

loosening.

2. With the appropriate cutter installed in the spindle, loosen the setscrew in the brass cutter

knob with a spline wrench (commonly referred to as the cutter wrench).

3. Gently place a piece of metal against the bottom of the nosecone so as to push the cutter

even with the bottom of the nosecone. Now the cutter should be ush with the nosecone.

Retighten the cutter knob setscrew. Your cutter is now zeroed. Rotating the micrometer clock-

wise will adjust the depth of the cut. Each click of the micrometer = .001”.

A full revolution is .025”.

Zeroing Cutters for Top-and-Bottom-Loaded Collet Spindles (see page 15, gure 8.2)

The collet spindle can be used for either top loaded or bottom loaded cutters. To install a top

loaded cutter in the collet spindle, rst set the micrometer to zero. Loosen the knurled draw bar

on the very top of the spindle slightly. Remove the cutter knob from the cutter, and slide the cutter

into the spindle. Place a piece of at material against the bottom of the nosecone and lower the

cutter until it rests against the material. Tighten the draw bar around the cutter, make sure it is

tight. Then reattach the cutter knob to the top of the cutter and screw

it in counterclockwise until secure. Be careful screwing the cutter

knob in, as counterclockwise is the direction to unscrew the draw

bar (see g 8.3). Never use pliers! The cutter depth can be adjusted

by turning the micrometer counter clockwise. Note: If using 2” short

cutters, install them from the bottom. Use the draw bar on the very

top of the spindle to tightly secure the cutter.

A solid collet, if purchased, can be installed in place of the split

collet for burnishing. Install the collet in the bottom of the spindle

and tighten the draw bar rmly. The spindle now acts as a normal

top loaded spindle for ease of operation. The split collet can be

reinstalled when required.

Page 29

Page 29

Chapter 8

Diamond Engraving

To install a diamond drag adapter, remove the retainer ring and nose cone from the bottom of the

spindle and replace with the diamond drag adapter. (See g. 8.4 on the next page) For diamond

drag engraving, the engraving motor is turned off and the cutter “drags” across the material. This

is accomplished with the motor on/off switch in the “off” position. Down pressure against the

material can be reduced or increased as necessary by adjusting the spring pressure adjuster as

described in the next section.

Proximity Sensing Device

All current Vision Table Models come standard with a proximity-sensing device.

Below is an explanation and the procedure for operating a Vision engraving machine equipped

with a proximity-sensing device.

Advantage of this feature

The advantage of this device is that it eliminates the need to perform a surface setting before

zeroing the cutter. It is used when using a nose cone or diamond drag. It cannot be used without a

nose cone, in cases such as burnishing or setting multiple pass depths in the software.

Procedure

1. Make sure that the proximity switch is in the “On” position on the controller front panel. Ensure

that some travel is allowed to “oat” the spindle on the pressure spring. The pressure spring

adjuster must be backed off.

2. Zero the cutter in the spindle and dial in the desired depth on the nose cone micrometer.

3. Send the job down to the controller via the computer.

4. Press the “Start” button on the controller front panel to begin engraving.

IMPORTANT NOTES:

“Nose-riding” - WITH proximity sensor

Engraving with the proximity sensor can only be performed with a nose cone attached, or when

diamond drag engraving.

“Non-nose-riding” - WITHOUT proximity sensor

When setting a depth in the computer engraving program, the proximity sensor should be in the

“Off” position on the controller front panel. Also, make sure that there is no “oat” on the spindle

by locking the pressure spring adjuster all the way down. Locking is especially important when

engraving into hard surfacesor materials like brass and stainless steel.

Page 30

Page 30

Chapter 8

(Figure 8.4) Series 3 Spindle Shown With Diamond Drag Adapter

Pulley

Spindle Housing

Micrometer

Diamond Drag

Adapter

Pressure Spring

Adjuster

Page 31

Page 31

Chapter 9

Chapter 9:

Table Maintenance

The Vacuum Chip Removal System

The optional vacuum chip removal system is designed to simplify the engraving process and

minimize wear and tear on the engraver. The vacuum chip removal system uses a vacuum nose

cone to remove chips created during the engraving process before they have the chance to create

problems. The quiet pump, coupled with the microne-layered lters assures that your unwanted

chips are whisked away effortlessly. The vacuum pump canister uses replaceable lters that can

also be reused, to assure maximum efciency and cost-effectiveness.

Vision strives for the highest quality in their manufacturing process to provide you with

the most cost effective, reliable engraving machine in use today. Please remember

that proper maintenance and care is necessary to achieve maximum product life

expectancy.

The engraving environment generates small plastic and metal chips as well as other particles

during operation. As with any machinery, your engraving system should be kept as clean as

possible to minimize wear and tear, and to improve nal quality of the engraved product.

REMOVING CHIPS

A portable vacuum is suggested for chip removal, but applying direct suction to the spindle area

is not recommended. Note that this cleaning can be minimized and greatly simplied through the

use of the optional vacuum chip removal system. The vacuum chip removal system removes chips

and dust created by engraving. This system can also extend the life of other components in the

system, as prompt removal of chips reduces contamination and overheating in the spindle area.

The vacuum chip removal system also keeps the nose cone from skipping over letters due to chips

on the engraving surface.

REPAIRS, REPLACEMENTS, AND ADJUSTMENTS

How to replace a belt

A belt is used to drive the spindle engraving system. It runs between a drive pulley

and the spindle pulley (see Fig.9.1). If it needs replacement, remove the old belt

by rolling it to the top of the spindle pulley, and give it a slight stretching motion to

snap it off the end. Once loose, it can easily be removed from the machine. Now

position the new belt around the drive pulley, then stretch it to snap over the top of

the pulley.

NOTE: Be sure to puchase the specied replacement belt from Vision

Engraving Systems. Having the correct belt size is extremely important to the

functionality of the motor. NEVER STRETCH THE BELT!

(Figure 9.2)

The engraving motor and brushes

Shown from front and side view

(Figure 9.1)

Page 32

Page 32

Chapter 9

The motor brushes on the engraving motor should be inspected regularly, and replaced when

worn. Two brush assemblies are included with the accessories package.

(One for each side of the motor.)

Inspect the brushes for possible replacement at least every six months. (see gure 9.2)

The engraving motor is the large, black motor (where applicable) on the top of the carriage

assembly. Unplug the speed controller to remove power to the motor. Perform the inspection (one

brush at a time) to simplify reinstallation. At the top of the motor are two round extensions looking

similar to ears. Using a at-blade screwdriver, carefully remove the small threaded brush cap

from the center of one of the “ears”. If you screw it in the wrong direction, the cap will descend

into the ear instead of rise out. Remove the metal U-shaped bracket connected to the spring and

carbon brush. It will be found underneath the brush cap. Observe how you remove the brush, so

that reinstallation will be easier. Examine the brush for wear by comparing it to a new brush, or

by measuring the length of the carbon brush. If the carbon brush is less than a quarter of an inch

long, replace the entire assembly. Do not attempt to separate the carbon brush from the wire,

spring and bracket. Reinstall the old or new bracket/spring/brush assembly followed by the

plastic brush cap. Repeat the inspection procedure for the brush on the other side of the motor.

NOTE: If either brush needs to be replaced, replace both brushes as a set.

Page 33

Page 33

Chapter 9

LUBRICATION

Lubricating the X-Axis, Y-Axis and Z-Axis lead screws

(ALL MODELS)

A light lubrication of the X and Y and Z lead screws should

be performed after every month of usage (see schedule on

next page). Use silicone lubricant spray only. Spray a light

coating along the entire lead screw.

Note: A nozzle extender attached to the aerosol spray

can help facilitate this procedure and may eliminate

the need to remove the metal covers.

DO NOT use any lubricant other than silicone, as it

may become sticky and cause a buildup that will

cause mechanical failure.

What NOT to lubricate

Many of the bearings and assemblies in your engraving

machine are sealed and/or coated using special low-

friction methods and should not be lubricated.

DO NOT attempt to lubricate the spindle or the spindle bearings. If you suspect

lubrication problems, call Vision for instructions, as further lubrication

may harm the machine.

DO NOT lubricate the X or Y stepper motors.

Lead

Screw

Carriage and

gantry covers are removed.

(Fig 9.4)

Silicone

Lubricant

Silicone

Lubricant

Silicone

Lubricant

Silicone

Lubricant

Silicone

Lubricant

(Fig 9.3)

Page 34

Page 34

Chapter 9

Spindle Lubrication (for Series 3 Vision Tables only)

The spindle assembly in the Series 3 Vision Tables requires a

monthly lubrication of the housing (as shown in Fig.9.5). Simply

push the spindle up until there is a 1/3” gap between the

spindle block and the “lip” of the housing. Lubricate with

2 to 3 drops of 3 in 1 oil.

DO NOT OVER LUBRICATE!

Never lubricate the spindle bearings!

This wil cause the spindle to stick.

MAINTENANCE SCHEDULE

The following is a suggested maintenance schedule. Remember that in conditions of

prolonged use, unusual environments, or unusual applications, maintenance items

may need to be performed more frequently than suggested in this schedule.

Spindle Housing “Lip”

Spindle Block

Frequency Maintenance Items

As needed 1. Vacuum and/or brush

2. Clean vacuum canister lters

Every Day 1. Remove chips form the spindle if

you do not have a vacuum chip

removal assembly.

Every Month 1. Lubricate the Z-Axis lead screw

2. Lubricate the Spindle Housing

3. Lubricate steel X, Y lead screws

Every Six Months 1. Check the motor brushes and

replace if necessary.

2. Lubricate the Z-Axis linear bearing

(Figure 9.5)

Page 35

Page 35

Chapter 9

Riser Block Extensions

The optional riser block kit allows you to raise the entire gantry assembly quickly and simply. Each

end of the gantry assembly is supported by two tower blocks stacked on top of each other. Riser

blocks are installed between the two tower blocks, and add height to the gantry.

Riser Block Installation (See Fig 9.6)

Determine the extra height required, and select riser blocks of appropriate height. One end of the

gantry has long threaded rods topped by washers and nuts. Loosen the nuts on the threaded rods.

On the other end of the gantry, loosen the bolts. Raise the gantry for clearance, and slide a riser

in between the two tower blocks on each end of the gantry. For higher extensions use the longer

bolts and additional riser extensions as needed. Always add the same height to each end of

the gantry. When nished installing the riser blocks, be sure to retighten all bolts and

threaded rods.

(Figure 9.6) Riser Blocks Installation

Nut

Washer

Threaded

rod

Riser

Right side

gantry

support

Blown up area

NOTE: With the tan colored Vision Tables,

the gantry covers cannot be replaced after

the risers have been installed.

Page 36

Page 36

Chapter 9

Cutter

Draw

Bar

Diamond Drag

Adapter

w/ Diamond

Series 3

Collet

Spindle

Spindle Options

Increase your prots and engraving quality with the split collet spindle (see g 9.7). Designed to be

extremely accurate and durable, the collet spindle is simple to use. This collet retracts around the

cutter gripping it at the bottom, while rmly holding on the top. By holding the cutter in two places

the cutter is virtually vibration-free and nearly eliminates play and runout. The split collet spindle

can engrave with excellent clarity and resolution while averaging a longer product life than any

other spindle.

The collet spindle accepts both top loaded and bottom loaded cutters, including 2” short shank

cutters such as drill bits, router bits, dremel tools etc. Should you ever want your split collet

spindle to act like a standard spindle, simply install our solid collet in the spindle

(available separately).

Diamond Drag Adapters

Using your plastic cutters to engrave metal can seriously damage them. There is a better option;

Vision offers high-quality diamond drag adapters. Don’t burn out your bearings on a job that can

be done just as easily as cutting plastic. The diamond drag adapter engraves virtually all-metallic

surfaces, at high resolution and high speed. The results achieved with a diamond drag adapter

can be even more amazing when used with double- and triple-line fonts.

(Figure 9.7) Split Collet Top-and-Bottom

Loading Spindles

Page 37

Page 37

Chapter 10:

Troubleshooting

ENGRAVING PROBLEMS

Problem: Engraving on the plate is “slanted”.

Possible solutions:

1. Check material for squareness. Maybe your shear does not cut squarely.

2. Check to see if the material on the table is indeed at a true home and is square to your scale

bars or stops.

3. If your table is equipped with scale bars insure that they are secure and ush to your T-Slot

table.

Hint: Always inspect your job before removing your plate from the system. You may be able to

salvage it by re-engraving the job, or at a minimum, you may be able to analyze the problem and

prevent repeating it. Perhaps the plate moved during engraving. Removing it without inspection

would prevent you from detecting this problem.

Problem: You are using a nosecone, but your engraving is “shallow” across the top or left margin

of your plate. It engraves properly when the spindle is away from the edge.

Possible solutions:

1. Your nosecone is riding on the scale bars or side stops. Loosen and

lower the scale bars so that they are below the level of your material

surface. Retighten the thumbscrews.

2. Check to see if your material is riding on the scale bars or side stops. It’s not hard to miss during set-up especially if the plate is thin material.

Problem: You are using a nosecone and your engraving is uneven.

Possible solutions:

1. Your spindle is not “zeroed” to your material. Follow the steps in “Chapter 3” to zero your

spindle.

2. You are not using enough oat and need to adjust the down stroke until your nosecone touches

the material with some pressure.

3. You may be engraving too fast for the type of material you are cutting. Check the manufacturer’s

recommendation. The cutter may be bouncing on the surface. Some hard materials may exhibit

this problem.

4. You may have a defective or broken cutter. Replace it.

5. Your material may be defective.

6. Your vac chip removal system is plugged and engraving chips are caught between the nosecone

and the material.

7. The nosecone or vac nose is loose.

Problem: “Shadowing” occurs while engraving certain materials.

Possible solutions:

1. Leave the protective lm on the engraving material during engraving.

2. Use a plastic nosecone instead of a metal one.

3. The nosecone may be damaged. Inspect for burrs or roughness. Try using an emory cloth to

polish the nose.

4. Back off on the spring pressure. Excessive down pressure will leave a rub mark on almost any

plastic material.

Chapter 10

Page 38

Page 38

Problem: You are not using a nosecone and you have uneven engraving.

Possible solutions:

1. Switch to a nose-riding method.

2. Use a different method of holding the material. If you use double sided tape, it may be thick

enough to change your surface atness by a few thousandths.

3. Parcel the job if possible so that you can have more direct control over the depth of each specic area. This may be effective if you have uneven material or a large engraving bed.

4. Table tolerances may not be able to maintain the accuracy level you want.

5. Table may not be on a level surface.

Hint: While it’s true that you can do non-nose riding engraving, it’s not easy to hold any controlled

accuracy on the depth. This takes at material, a very at bed and some degree of skill and condence. It also takes an application where some amount of uneven engraving may be tolerated.

Problem: I’m getting “tails” or “swirls” in the corners of my engraving.

Possible solutions:

1. Your cutter speed is too fast relative to your x-y speed. Slow your spindle speed down or increase your table speed.

2. Your cutter is worn or damaged. Replace.

3. Turn down the dwell speed.

Problem: I’m getting “fuzz”, “fur” or can see lines in the bottom of my cut showing each cutter

path. I can even see steps in the bottom of my cut.

Possible solutions:

1. This problem is tough. Sometimes caused by dull cutters, the wrong cutter, or not enough overlap for each cut. Try changing cutter size slightly. You may get better clean up.

2. Try taking a second pass cut at .001-.002 deeper. This may clean up the roughness.

3. Resharpen the cutter. There are various cutter angles that can cause these kinds of problems.

There is a relief angle that if too great can cause noticeable ridges in the bottom of the cut.

4. Ensure that the spindle is square in the mount or block. An unsquare spindle means an unsquare cutter to the material surface.

5. Turn spindle speed up.

Problem: Poor letter quality.

Possible solutions:

1. You may be engraving too fast. Engraving quality improves with the right engraving and spindle

speeds.

2. If you are diamond drag engraving, you have too much down pressure or you are engraving too

deep. Also, check the grain of the material; it should be left to right.

3. You may have a worn or dull cutter.

4. Your material is not securely fastened to the table.

Probelm: Ragged Type.

Possible solutions:

1. If the quality of cut is ragged or exhibits steps, you may have play in the cutter.

Chapter 10

Page 39

Page 39

Chapter 10

This could be in the gap between the cutter and the spindle shaft. Maybe the shaft is worn or

the spindle bearings need to be replaced. Once a shaft starts to wear and a cutter is loose, the

problem can worsen quickly.

2. The spindle is loose in the housing or block.

3. The carriage is loose or has excessive play, check the z-axis bearings or slide.

4. Lubricate lead screws with recommended lubricant.

Problem: My baseline is off.

Possible solutions:

1. You’re not at the mechanical or software home. Maybe the table or carriage was bumped during

set-up. Maybe the previous job was cut short and the system did not return back to its mechanical

home or limit switches. Move the table, bridge or carriage physically to home or send it

home via the software.

2. Check your software layout for keystroke errors.

Problem: While burnishing aluminum I have voids or non-engraved areas.

Possible solutions:

1. Try re-engraving the same plate again. Some of the anodized aluminum plates have very hard

surfaces and two passes are required.

2. Switch to a diamond burnisher. The more common carbide tools may have difculty getting

through the tough surface and are more easily worn down, thus sometimes skipping across the

surface.

3. Increase the pressure of the z-axis or burnishing adaptor.

4. Try other materials. Same reasons as above. Some materials, from some vendors, are just plain

tough.

Hints:

Always try to solve the problems yourself before seeking help. A little patience goes a long way.

Never work on any problem that gets you so frustrated that you become irritated at the machine,

the service technician, or the salesman. It’s only a machine, don’t let it get the best of you.

Contact your dealer.

MECHANICAL PROBLEMS

Problem: No X, Y or Z-Axis movement.

Possible solutions:

1. Check that the controller power is on.

2. Check that the drives are turned on.

3. Check the table cable for a solid connection. It may be helpful to remove the cable,

reconnect and tighten the hold down screws to ensure a good connection.

4. Ensure that the job has been transferred to the controller (Green start light is ON).

5. Ensure that the emergency STOP button is not depressed, then turn the drives on.

Page 40

Page 40

Problem: System has no movement in any one axis.

Possible solutions:

1. Try to jog the problem axis using the X/Y/Z jog keys on the control unit. If OK, retry the job.

2. Check the table cable for a solid connection.

3. Call service technician for further instructions.

Problem: Unusually loud noises during the engraving process.

Possible solutions:

1. Isolate the cause of the unusual noise by:

a. Remove the cutter.

b. Turn the engraving motor to OFF.

c. Run the engraving job, or X/Y jog the system.

If the noise persists, it may be conned to the X, Y or Z-axis. Check for proper lubrication of

lead screws. Follow lubrication instructions in chapter 4.

If the noise goes away and to further isolate the cause, do the following:

a. Remove the motor belt.

b. Run the engraving motor without starting a job. Loose motor belts may cause some

noises, so removal will narrow down the problem. If the noise is present with the

spindle motor on, check the motor brushes.

If there is no unusual noise when running the spindle motor with no belt attached,

do the following:

a. Attach the motor belt.

b. Run the spindle motor and vary the RPM by changing the control unit potentiometer.

Noise levels may vary. If the noise persists, check the spindle for overheating. Excessive

overheating of the outside housing of the spindle is a sign of defective bearings. The noise may

be caused by the bearings.

Problem: Spindle is hot.

Possible solutions:

1. Ensure that the nose cone area is free of debris. Check the vacuum system (if used)

for clogging.

2. Inspect the spindle for other obstructions that may prevent proper rotation.

3. Bearings may need to be replaced.

Problem: Spindle motor will not come on.

Possible solutions:

1. Check the auto/on/off switch to ensure the proper operational mode.

2. Check motor brushes.

Problem: Motor belt will not stay on pulley.

Possible solutions:

1. Motor belt is probably worn and needs to be replaced.

Chapter 10

Loading...

Loading...