Page 1

Page 2

Important Notices:

(1). This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

(2). Changes or modifications to this equipment not expressly approved by the

party responsible for compliance (Vishay Israel Ltd.) could void the user’s

authority to operate the equipment.

(3). The antenna used for the load cell transmitter must be installed to normally

provide minimum separation distance of at least 20 cm from all persons and must

not be co-located or operating in conjunction with any other antenna or

transmitter.

The handheld terminal is portable but restricted to occupational/controlled use

only. It is not authorized for consumer or general population use. Personnel using

the terminal must be trained regarding RF exposure and its control.

Vishay makes no representation or warranties of any kind whatsoever with respect to the contents

hereof and specifically disclaims any implied warranties or merchantability or fitness for any

particular purpose. Vishay shall not be held liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this publication or

its contents. Vishay reserves the right to revise this manual at any time and to make changes in the

contents hereof without obligation to notify any person of such revision or changes.

Cover photo courtesy of the USAF

Page 3

contentscontents

contents

contentscontents

Table of Contents

Section I - General Information

1.1 INTRODUCTION .................................................................................................................... 1-1

1.2 SYSTEM COMPONENT DESCRIPTIONS ............................................................................. 1-2

1.2.1 Wireless Handheld Terminal .......................................................................................................................... 1-2

1.2.2 Wireless Load Cells ......................................................................................................................................... 1-2

1.2.3 Load Cell Adapters .......................................................................................................................................... 1-2

1.2.4 Thermal Printer ................................................................................................................................................ 1-2

Section II - Pre-Operation

2.1 PRE-OPERATIONAL PROCEDURES.................................................................................... 2-1

2.1.1 Load Cell Jack Point Configuration ................................................................................................................ 2-1

2.1.2 Preparation for Aircraft Weighing .................................................................................................................. 2-1

2.2 TERMINAL SETUP ................................................................................................................ 2-2

2.2.1 Setup Screen Options ..................................................................................................................................... 2-2

2.2.2 Main .................................................................................................................................................................. 2-2

2.2.3 Gravity Factor Compensation ......................................................................................................................... 2-3

2.2.4 A/C .................................................................................................................................................................... 2-3

2.2.5 Channel ............................................................................................................................................................ 2-4

2.2.6 Changing Channel ID and Location ................................................................................................................ 2-4

Section III - Operation

3.1 LOAD CELL POWER UP ....................................................................................................... 3-1

3.2 TERMINAL POWER UP ......................................................................................................... 3-1

3.3 AIRCRAFT WEIGHING CYCLE ............................................................................................. 3-1

3.3.1 Zeroing ............................................................................................................................................................. 3-1

3.3.2 Lifting ................................................................................................................................................................ 3-3

3.3.4 Removing ......................................................................................................................................................... 3-5

3.3.5 Rezeroing ......................................................................................................................................................... 3-5

3.3.6 Weighment Report .......................................................................................................................................... 3-5

Section IV - Weighing History

4.1 RECALL A RECORD FROM THE HISTORY FILE................................................................. 4-1

4.2 RECALLING AIRCRAFT FROM THE LIBRARY .................................................................... 4-1

4.3 AIRCRAFT NOT RECORDED IN THE LIBRARY ................................................................... 4-1

Section V - Troubleshooting

5.1 TROUBLESHOOTING OVERVIEW ....................................................................................... 5-1

5.2 LED STATUS INDICATORS ................................................................................................... 5-1

5.3 TYPICAL PROBLEMS AND SOLUTIONS ............................................................................. 5-1

5.4 CHANGING RF CHANNELS .................................................................................................. 5-2

i

Page 4

Section I - General Information

1.1 INTRODUCTION

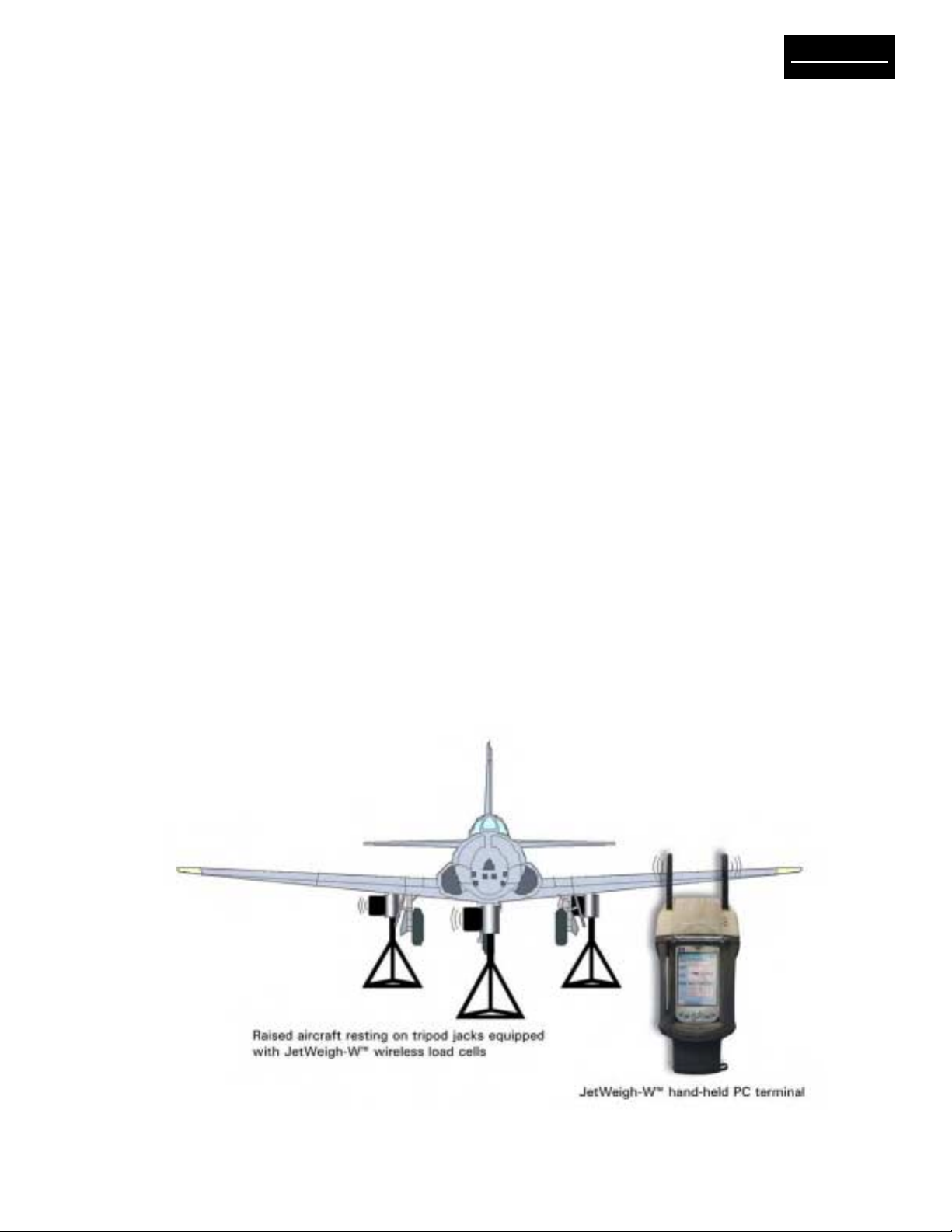

This manual provides information on the operation of

JetWeigh-W™ Wireless Aircraft Weighing System series aircraft electronic weighing kits manufactured by

Vishay SI Technologies. JetWeigh-W™ Wireless Aircraft Weighing Systems (Figure 1-1) integrate stateof-the-art wireless communication, digital weight processing, and high-accuracy hermetically sealed load

cells. Combined technologies from Vishay Revere

Transducers and Vishay RFWaves results in an accurate, high-reliability, robust, and easy to use Wireless

Aircraft Weighing System.

JetWeigh-W kits are designed primarily for the weighing of aircraft and aerospace vehicles, but can be

used for other precision weighing applications, as well

as for the calibration of force generating machines.

The kits have been calibrated using dead weight machines. These machines are maintained to better than

±0.001% with respect to the nominal weight value. The

degree of uncertainty for all of the individual weights

is approximately ±0.005% with respect to true values.

All readings are corrected to standard gravity factor

“g” as required by MlL-W-7327C.

High capacity JetWeigh-W kits with load cell capacities of 200,000 lb are calibrated on Vishay Revere’s

high capacity precision hydraulic transfer standard.

On completion of this calibration, the JetWeigh data is

verified on the dead weight machine up to the 100,000lb point. Maximum acceptable deviation between the

transfer standard and dead weight data is ±0.05%.

Both the dead weight machine and the transfer standard are secondary standards and are directly traceable to NIST.

It is recommended that the kit be returned to the factory for routine calibration every twelve (12) months or

sooner if trouble is observed or erroneous readings

are suspected.

The load imposed on a load sensor produces an

output signal directly proportional to the load applied.

The signal is transmitted through a wireless channel

to the JetWeigh handheld terminal where the measurement is processed. Analog load sensor signals

are processed digitally to remove linearity errors,

latitude and altitude effects. Presentation in pounds

or kilograms is selectable by the operator. An

integral printer provides a permanent record of all

pertinent weighment information including any

deviations that are accepted by the operator.

IntroductionIntroduction

Introduction

IntroductionIntroduction

Figure 1-1. Typical JetWeigh-W™ Aircraft Weighing System

Page 1-1

Page 5

IntroductionIntroduction

Introduction

IntroductionIntroduction

1.2 SYSTEM COMPONENT

DESCRIPTIONS

Each kit contains the necessary equipment for weighing an aircraft with the exception of specialized jacks .

Kit contents include 3 to 5 wireless load cells, a rugged handheld PC user terminal, a thermal printer, power

adaptors and a power cord, a center of gravity accessory kit, and a rugged fiberglass carrying case.

1.2.1 Wireless Handheld Terminal

The wireless handheld PC terminal features a graphic

color touch screen display, intuitive step-by-step operation, and advanced functions such as CG calculation, aircraft type library, weighing history, latitude and

altitude adjustment. It communicates with up to 5 remote wireless load cells thereby eliminating cumbersome interconnecting cables.

Units operate in a world wide license-free band - 2400

MHz to 2483.5 MHz and comply with all FCC, CE,

ETSI standards.

Synchronized sampling of all load cells ensures correct weighing even under severe vibration and oscillations conditions.

1.2.2 Wireless Load Cells

Each kit contains from 3 to 5 hermetically sealed wireless load cells. These cells are precision devices and

will withstand 150% overload without damage. Dropping a load cell, however, could damage the electronic box, the diaphragm, or other components affecting its operation or accuracy.

Each cell has a tapped hole on the bottom to receive a

plug or a ring jack adapter. The top surface has a ¾”

radius concave surface to receive either the spherical

surface of an adapter or the aircraft jack pad directly.

NOTE: Load cells of identical capacity are interchangeable. However, load cells and spherical adapters are

color coded as matched sets. When changing load

cell locations, make sure that the spherical adapter/

load cell combination remains intact.

1.2.3 Load Cell Adapters

For the purpose of mounting load cells under varying

physical arrangements, several adapters are provided

(See Figure 1-2):

Figure 1-2. Jack Adapters

b) Spherical adapters to allow interfacing transi-

tion between the cells and conical jack pads or

flat surfaces

c) Axle adapters which allow transition from the

cell to the cylindrical surface of the axle.

1.2.4 Thermal Printer

JetWeigh-W systems ship with a high speed thermal

printer. At the end of each weighment, aircraft specifications, resultant weight data, and all other calculations can be printed and stored for future reference.

The printer is compact, easy to install, and require

minimal maintenance. A complete reference manual

for the printer is included with the kit.

a) Plug and ring adapters for securing the cell to

the hydraulic jack.

Page 1-2

Page 6

Section II - Pre-Operation

Pre-operationPre-operation

Pre-operation

Pre-operationPre-operation

2.1 PRE-OPERATIONAL PROCEDURES

Section II presents all procedures that must be performed

prior to actual aircraft weighment. Since the JetWeighW system is completely wireless, no cable connection/

installation procedures are required. With an operating

range of 220 feet (70 meters), it should be easy to locate all load cells and the handheld terminal in functional

proximity to one another.

2.1.1 Load Cell Jack Point Configuration

JetWeigh-W Systems accommodate jack point configurations for 3-point, 4-point (helicopter or fixed wing) and

5-point aircraft. Recommended deployment of the load

cells is shown in Table 2-1. Make sure to match the load

cells and the mechanical adapters to ensure good repeatability of weighments.

2.1.2 Preparation for Aircraft Weighing

1. Review the Equipment List of the aircraft being

weighed. Update the list as required. Make sure the

particular equipment, which will normally be installed,

but is missing at the time of the weighing, is added in

the later calculations.

2. Remove all equipment, which will not be included in

the above list.

CAUTION

Use proper adapters to prevent jacks from

slipping or buckling. Damage to the aircraft or

inaccurate weight readings may result if improper

adapters are used. Never apply load to the rim of

the cell.

Color coded spherical adapters must be used in

conjunction with color coded load cells.

9. It is recommended that the load sensors be exercised prior to performing an actual weighment.

Exercise the load sensors 2 – 3 times by lifting the

aircraft with the load sensors and jacking system in

place.

10. The JetWeigh-W is programmed to identify left,

right, nose, or the sum of both sensors on a bogie.

This requires that specific channels (load cells) be

dedicated to a specific location when preparing for

a weighment. These location identifiers will normally appear on the printout. However, they will not

appear during 1 and 2 channel operation. Table 2-1

shows the recommended layout for various configurations.

Table 2-1. Jack Point Configuration

3. Clean the aircraft to remove accumulated dirt, grease

and trapped water.

4. Fill the oil tanks to a known quantity. Fill all reservoirs, such as anti-icing fluid, to capacity.

5. Drain fuel tanks. If draining is not practical, fill the

tanks to capacity. Add or account for unusable fuel.

6. Determine the unit weight of fuel. Obtain a sample

from the fuel tank with the supplied fuel dipper (CG

kit) and pour the sample into the test tube. Using the

hydrometers (CG kit), the weight of fuel in pounds per

gallon can be observed. Variations in fuel weight, particularly in the case of jet aircraft, can cause

appreciable difference in the final empty weight and

CG determinations. Be alert for partially filled nonsymmetrical fuel tanks.

7. With tricycle gear aircraft, it is often desirable to

level the aircraft as closely as possible before lifting

on the jacks. Changing oleo strut extensions can do

this.

8. A stabilizing period of 20 minutes running concurrently with warm-up period is advisable. When using

jack adapters, be sure the adapter is fully threaded into

the cell. With ring adapters, make sure it is centered

flush on the ram before tightening the set screws.

3 Load Cells

Channel 1 Red Left

Channel 2 Yellow Right

Channel 3 Blue Nose

4 Load Cells Helicopter Fixed Wing

Channel 1 Red Fwd Left Left

Channel 2 Yel Fwd Right Right

Channel 3 Blue Aft Left Nose

Channel 4 Orng Aft Right Spare

5 Load Cells

Channel 1 Red Left (1)

Channel 2 Yellow Right (1)

Channel 3 Blue Left (2)

Channel 4 Green Right (2)

Channel 5 White Nose

Page 2-1

Page 7

Pre-operationPre-operation

Pre-operation

Pre-operationPre-operation

2.2 TERMINAL SETUP

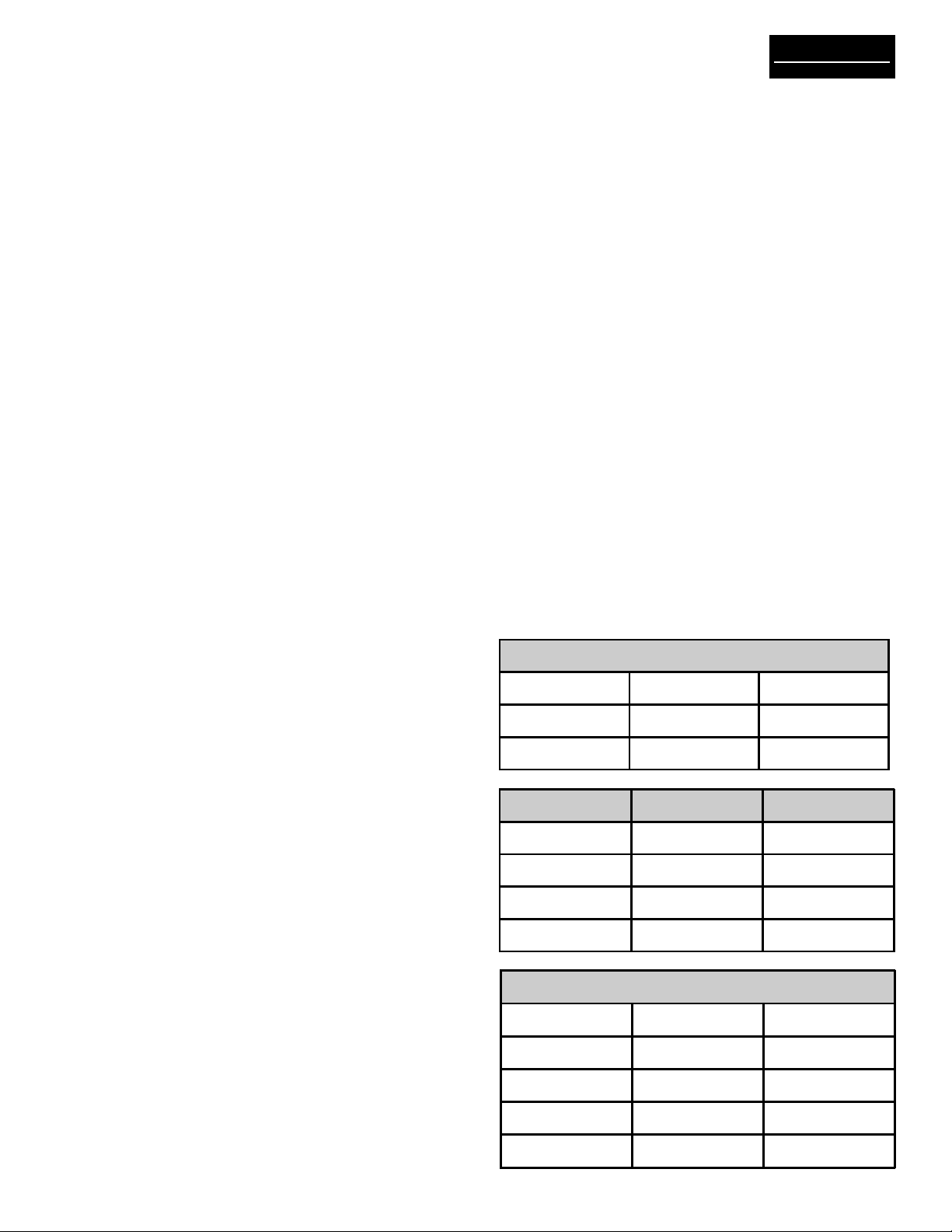

Figure 2-1 shows the default power up screen for the

handheld terminal. Three primary function modes;

Setup, Weighing, and System, are accessed by touching the associated soft keys at the bottom of this screen.

In this Section, system setup is defined prior to actual

aircraft weighing. Touch (with stylus - throughout) setup

on the lower left corner of the screen to enter setup

mode. Vishay recommends that setup be performed

with the power adapter plugged in to conserve battery

charge for actual wireless weighment.

NOTE: The Handheld Terminal will operate for approximately eight hours on battery power alone.

Figure 2-1. Initial Power Up Display

2.2.1 Setup Screen Options

Setup mode consists of four sub-menu selections located on the left side of the screen. Step through each

Main

sub-menu sequentially, starting with

ing to

Gravity,A/C

parameters for each sub menu, the system is ready

for “live” weighing operation.

, and

Channel

. After entering valid

and proceed-

Figure 2-2. Data Entry Keypad Displayed

2.2.2 Main

Touch “

fundamental system parameters (Figure 2-3).

Main

” on the left margin of the screen to enter

a). Units – use the drop-down menu to select

lb (pounds) or kg (kilograms)

b). Date – use the drop-down menu to set the

correct date

NOTE: For screens that require data entry, touch the

data entry box and an alphanumeric keypad will appear as shown in Figure 2-2.

Figure 2-3. Main Parameter Selections

Page 2-2

Page 8

Pre-operationPre-operation

Pre-operation

Pre-operationPre-operation

c). Stability – use the drop-down menu to select

Normal, Relaxed, or User. Ambient air currents

always affect weighments to some extent. If the

aircraft is weighed indoors (hanger environment),

select normal to compensate for minor air current

uplift effects. If the plane is out of doors, select

relaxed (twice normal) to achieve slightly more

compensation. Selecting user allows specific time

and amplitude values to be entered for precise

compensation (see “d”).

d). “T” represents the duration period and “A” repre-

sents the amplitude of an interference that will

not be considered as a change in weight. As long

as the weight readings are within the rectangular

TxA, weight readings are considered to be stable.

e). Averaging - use the drop-down menu to select 1,

2, 5, 10, or 50 conversion averaging. Averaging

applies a low-pass filter on the weight readings to

eliminate the effect of vibrations.

f). Zero tracking – touch the Zero Tracking check box

to activate the zero tracking function. Zero

tracking eliminates minor electronic variations

around the calibrated zero value.

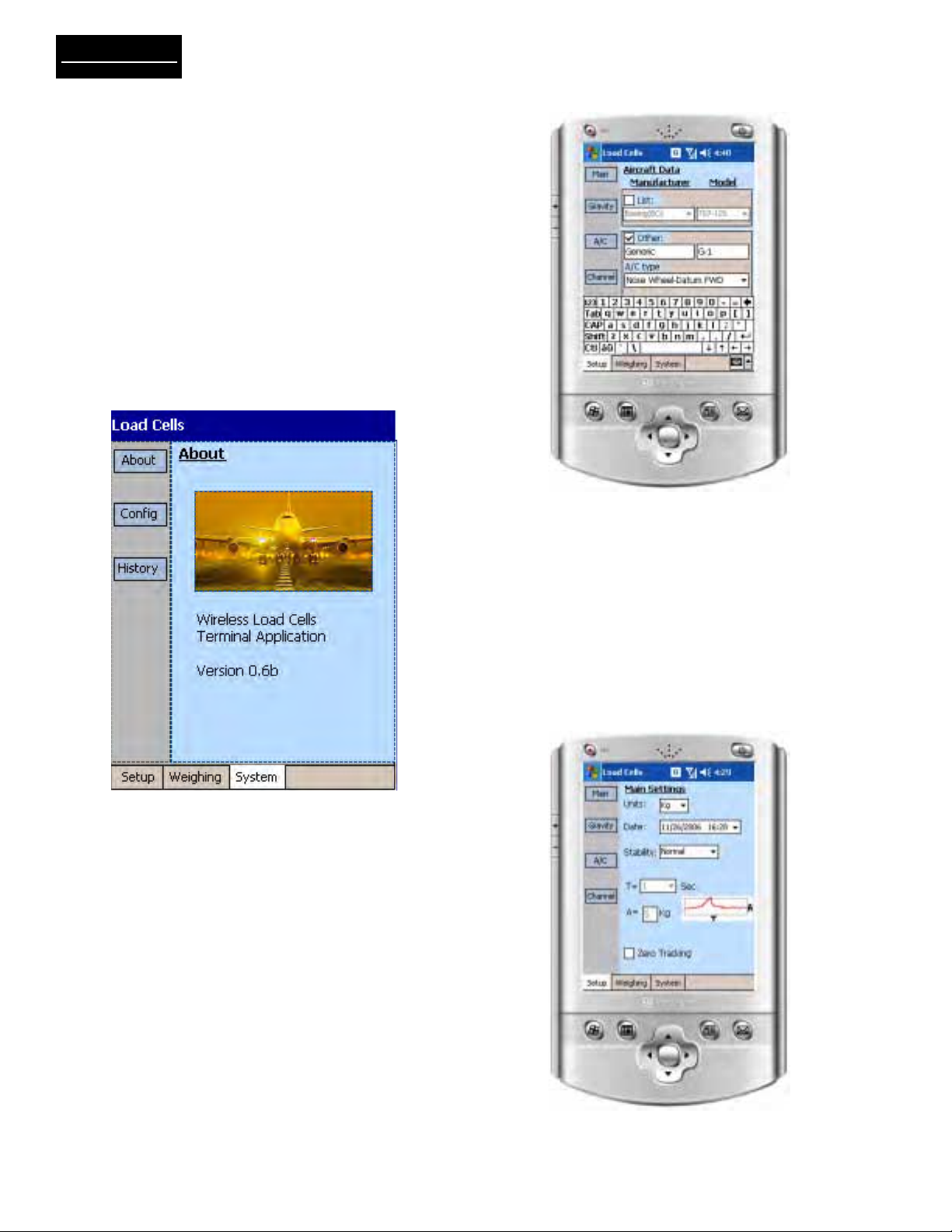

2.2.4 A/C

The

A/C

menu (Figure 2-5) allows users to choose

from a predefined list of over 200 aircraft, or define

the dimensions of a custom (“Other”) aircraft. This

menu also allows the entry of the aircraft serial number and the user’s ID for printouts and future reference, if saved.

2.2.3 Gravity Factor Compensation

The Figure 2-4

text boxes that display the calibration location data, and

two enabled text boxes for entry of the operation latitude

and elevation. Enter the exact latitude and elevation of

your installation location.

Gravity

menu consists of two grayed out

Figure 2-5. Aircraft (A/C) Parameter Selections

a). Touch list and then model to view aircraft types

and configurations.

b). Touch the “Other” checkbox to activate entry of

a new Manufacturer/Model combination. Key in

the manufacturer and model number in the

respective boxes beneath “Other”.

c). Use the A/C type drop-down menu to select the

new aircraft type.

d). Key in the serial number and user ID for the

new aircraft configuration. All entered information will be included in the final weighment

printout.

Figure 2-4. Gravity Parameter Selections

Page 2-3

Page 9

Pre-operationPre-operation

Pre-operation

Pre-operationPre-operation

2.2.5 Channel

Touch the

2-6) to choose from one of five standard aircraft configurations. The selections are:

Channel Selection

drop-down menu (Figure

a). 3 sensors (load cells – throughout)

b). 4 sensors – helicopter

c). 4 sensors – fixed wing aircraft

d). 5 sensors

After selection, the configuration is displayed as a

wheel-by-wheel, or jack point-by- jack point schematic

diagram and the channel allocation table reflects exact placement locations. Double touching a channel

ID number changes the channel allocation table and

schematic to a new aircraft (based upon ID entry in

segment “d” of paragraph 2.2.4).

After completing all sequential parameter entries, the

JetWeigh-W System is ready for “live” weighing operation.

2.2.6 Changing Channel ID and Location

To change logical channels, as shown in Figure 2-7,

double click the ID field at the channel selection table.

This opens an editable field at that ID, and a numeric

keypad will pop up.

Using the numeric keypad, you can assign any channel to that location. Channel input termination is completed by touching the enter key on the numeric keypad.

NOTE: Users are responsible for maintaining the logical integrity of each assigned location ( making sure

that a single channel is allocated to a single location).

Figure 2-6. Load Cell Channel Configuration

Figure 2-7. Changing Channel ID Information

Page 2-4

Page 10

Section III - Operation

3.1 LOAD CELL POWER UP

Place load cell equipped jacks in position beneath aircraft jack points as shown in Figure 3-1. Orient the

load cell transmitter housing (rectangular box attached

to the cylindrical cell) of each cell parallel to the neutral axis of the aircraft. Walk to each cell and press the

power “ON” button. Check the green LED on each cell

transmitter housing to see that it is illuminated and

blinking at a rate of approximately one Hz (once per

second).

NOTE: If the green LED is blinking at a rapid rate, this

indicates that load cell internal battery capacity is low

- approximately one hour of work is left (without charging). Recharge the cell battery as soon as possible.

OperationOperation

Operation

OperationOperation

Figure 3-1. Aircraft with Jacks Positioned

3.2 TERMINAL POWER UP

Figure 3-2 depicts the handheld terminal in its RF

equipped carrying case. Press the terminal power button and observe the initial screen as depicted at right.

NOTE: The Operation LED should remain in the off

state until actual weighment begins.

3.3 AIRCRAFT WEIGHING CYCLE

Prior to weighment, Vishay recommends that the aircraft be raised and lowered 2 or 3 times (“dry runs”)

to acclimate system load cells. Actual weighing is accomplished in six steps; Zeroing, Lifting, Weighing,

Removing, Rezeroing, and Reporting using the weighing menu. Each step must be performed sequentially

and successfully before proceeding to the next step.

To begin, touch the

tool bar with the stylus and observe the

depicted in figure 3-3.

3.3.1 Zeroing

Under ideal conditions, with load cells powered up and

in a no load condition (no jack contact with aircraft

jack points) the reading for each channel should be

zero. However, in reality, it is often necessary to “zero

out” minor variances in any or all of the system cells.

The zeroing screen (Figure 3-3) allows for individual

or complete zeroing of any/all system cells.

Weighing

menu block on the lower

Zeroing

screen

Figure 3-2. Handheld Terminal Enclosure

During the zeroing process, the terminal retrieves calibration, serial number, and other critical data from

each load cell. If data cannot be accessed, one of the

Figure 3-4 error screens (next page) will appear. Any

weighment which does not include all vital data from

each cell will not be valid, so the user is prompted and

given the choice/chance to try again.

Figure 3-3. Zeroing Screen/Menu

Page 3-1

Page 11

OperationOperation

Operation

OperationOperation

NOTE: A reading of NA for any valid channel indicates that the load cell is malfunctioning or in the “OFF”

state. Zeroing is not valid. If the problem persists, refer to the Section IV - Troubleshooting.

NOTE: When a poor RF link conditions exists, a red

antenna symbol will appear to the right of the channel

ID of the cell experiencing the problem, as shown in

Figure 3-5.

NOTE:

If a red “battery” symbol appears to the left of any

channel ID, the load cell battery must be recharged

and the zeroing process repeated.

Once zero is established, touch Next> to advance to

the lifting menu.

Figure 3-4. Load Cell Data Not Acquired Messages

Page 3-2

Page 12

3.3.2 Lifting

At this juncture, the aircraft must be jacked up so that

it is resting exclusively on the load cell based jacks.

Jacking should be done in accordance with aircraft

manufacturer specifications, if provided. During the

jacking or lifting phase, the Lifting menu (Figure 3-5)

displays the successive measurements from all active

channels and indicates the stability of the measurements. Once the aircraft is jacked up (Figure 3-6) and

readings are stable, touch Next> to advance to the

weighing screen.

OperationOperation

Operation

OperationOperation

Figure 3-6. Aircraft Fully Jacked

NOTE: the unstable condition report will be included

in the final report and in the printout of the weighment

results.

NOTE: When a poor RF link conditions exists, a red

antenna symbol will appear to the right of the channel

ID of the cell experiencing the problem, as shown in

Figure 3-5.

Figure 3-5. Screen Display During Lifting

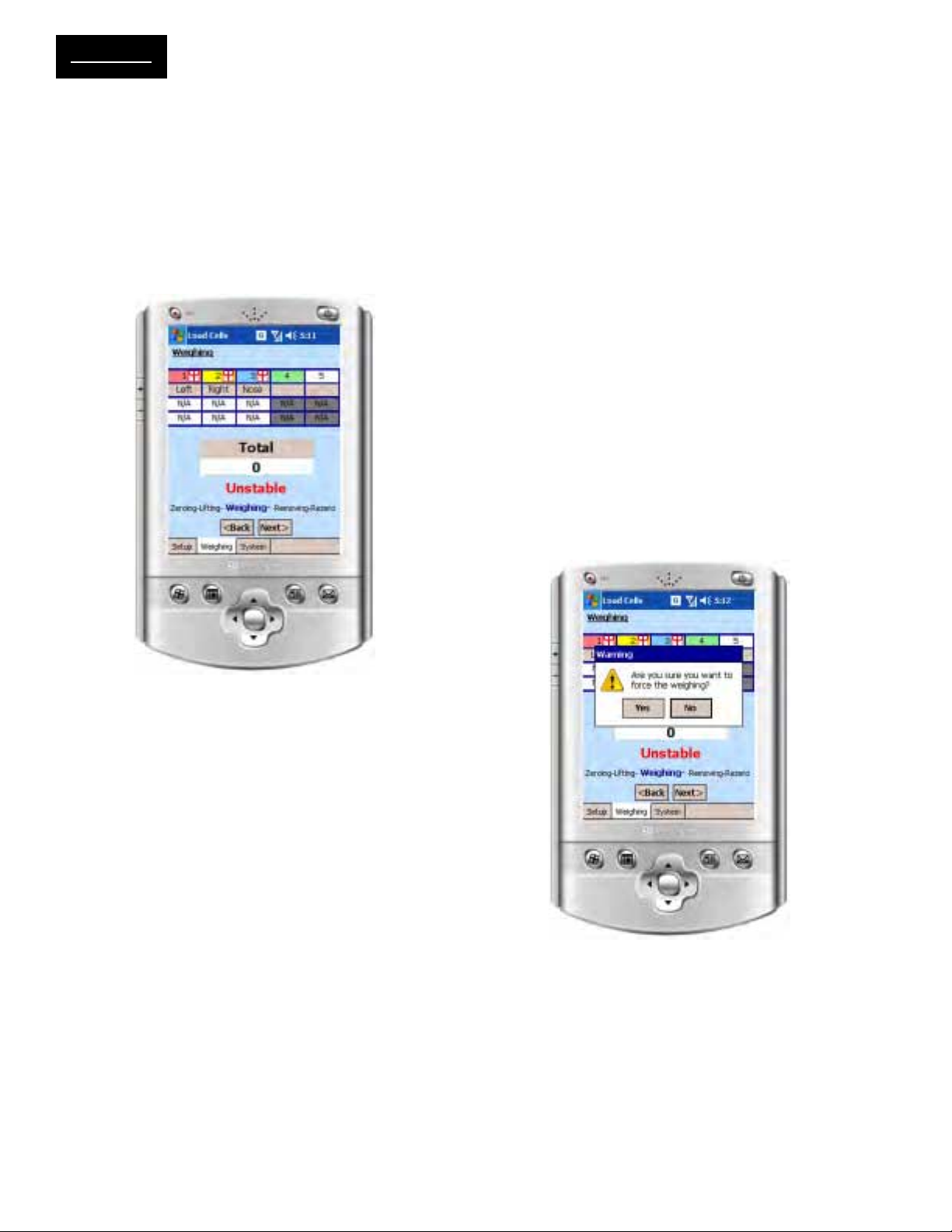

If the weight readings are changing during lifting, a

warning “UNSTABLE” appears at the bottom of the

weights table. This is normal during the lifting process.

After the aircraft was fully jacked up and all vibrations

and oscillations ceased down this indication should

change to “STABLE”.

Should the “STABLE” condition not be reached after

a few minutes or in case of external causes (wind,

etc.), the user can force the system to proceed to the

WEIGHING stage by touching the NEXT> soft key. A

warning message will appear on the screen as shown

in Figure 3-7. To continue with forced operation touch

the “YES” key.

NOTE:

If a red “battery” symbol appears to the left of any

channel ID, the load cell battery must be recharged

and the zeroing process repeated.

NOTE: If weight reading(s) for any channel(s) appear in a yellow box, less than 50% of the updates

required for averaging have been received. If weight

reading(s) for any channel(s) appear in a red box,

this indicates that the load cell(s) is in low power mode.

Turn off the terminal, recharge the low power cell(s),

and restart the terminal to clear the red data indication.

Page 3-3

Figure 3-7. Weighing Lift Warning

Page 13

OperationOperation

Operation

OperationOperation

3.3.3 Weighing

Weighing (Figure 3-8) displays the current weight and

percent of load readings for each channel (load cell).

Weight values for each channel are recorded on the

upper line with percentage equivalents directly beneath.

With a stable reading displayed, touch Next> to record

the weighment and advance to the Removing screen/

menu.

NOTE:

The operator must be satisfied that the weighment

is valid in addition to the instruments “stable”

prompt. Operator acceptance takes into consideration factors such as: the aircraft is completely clear

of the ground (floor) and all items aboard are accounted for, etc. The scale will enter the “stable”

condition after an undisturbed period regardless of

the amount of load applied. The operator is free to

change the loading until a final weighment is acceptable on the display. Any outside force, wind on

control surfaces, vibration, etc., may keep the scale

from reaching a “stable” condition. It is important

for the operator to exercise good judgment at this

point. The scale can only recognize stability and

has no way to confirm that loading is complete and

acceptable.

Figure 3-8. Channel Weight and Percentage Values

Should the “STABLE” condition not be reached after

a few minutes or in case of external causes (wind,

etc.), the user can force the system to proceed to the

Removing stage by touching the NEXT> soft key. A

warning message will appear on the screen as shown

in Figure 3-9. To continue with forced operation touch

the “YES” key.

.

Figure 3-9. Unstable Weighment Warning Screen

Page 3-4

Page 14

3.3.4 Removing

Removing is the reverse of lifting. At this time, lower

the aircraft to its original resting position and make

sure there is no contact between the load cells and the

jack points. Touch Next> to advance to the rezeroing

menu.

3.3.5 Rezeroing

The rezeroing menu displays the after-weighment zero

reference for each cell. Ideally, all cells should return

to their original no-load zero value.

NOTE: DO NOT REMOVE ANY INTERFACE HARDWARE. It is important that all load sensors are clear

of the aircraft to provide a good zero return. The

JetWeigh-W performs automatic checks to assure a

good zero return (zero tracking if selected) and compensate for minor tolerance variations during zero return. If the return is not satisfactory for any reason,

an error condition will result. The weighmaster must

review all error messages and the data on the printout

tape to decide if the weighment can be accepted or

the aircraft must be re-weighed.

OperationOperation

Operation

OperationOperation

Figure 3-10. Typical Aircraft Weighing Report

Touch Next> to view a complete report of the aircraft

weighment cycle

3.3.6 Weighment Report

Figure 3-10 depicts the screen view of a typical aircraft weighment report. All calculations, aircraft identifiers, and weighment results are available for visual

review and hard copy printout. Data may also be saved

for future reference by touching the screen “Save”

button.

If a data save is not desired/required, simply continue

without touching the save button. A message will appear asking the operator to confirm that data is not

being saved (Figure 3-11).

At this point, the weighment is complete. It is recommended that load cell batteries and the handheld terminal be recharged using the supplied power adapter

cords. Once recharging is complete, the system may

be readied for the next aircraft weighment or repacked

in its storage case.

Page 3-5

Figure 3-11. Data Not Saved Warning Message

Page 15

Section IV - Weighing History

4.1 RECALL A RECORD FROM THE

HISTORY FILE

Access the “System” tab, and press “History” to get to

the history page display shown in Figure 4-1. The upper table displays a list of past reports. These reports

can be sorted by Time, by Aircraft ID, and by Serial

Number, using the “Sort:” drop down list. This table

also accesses reports belonging to a specific aircraft

by entering its serial number at the “filter” field and

touching the “Filter” button. To revert to the unfiltered

state, clear the filter field and touch the filter button.

The lower text box will display the report currently selected at the history table. To print an aircraft data

report, connecting the handheld terminal to the printer

and touch the “Print” button.

historyhistory

history

historyhistory

Figure 4-1. JetWeigh-W History Screen

4.2 RECALLING AIRCRAFT FROM THE

LIBRARY.

Many standard aircraft configurations are recorded in

the JetWeigh-W Library. To choose a configuration

from the library, view the drop down list at the Setup/

Aircraft Data page, as shown in Figure 4-2.

Figure 4-2. Recall Aircraft Screen

4.3 AIRCRAFT NOT RECORDED IN THE

LIBRARY

In order to use aircraft not available on the drop down

list, touch the “Other” check box, and input the aircraft

parameters manually, as shown in Figure 4-3.

Page 4-1

Figure 4-3. Input Aircraft Screen

Page 16

Section V - Troubleshooting

1.1 TROUBLESHOOTING OVERVIEW

Section V provides troubleshooting information for the

JetWeigh-W system. In many cases, simple battery

charging or recharging will resolve communication and

operation problems.

1.2 LED STATUS INDICATORS

Many operational problems can be resolved by noting

the LED status indicators on both the handheld terminal case and each individual load cell. Table 5-1 defines LED status indication for each device.

TroubleshootTroubleshoot

Troubleshoot

TroubleshootTroubleshoot

Table 5-1. LED Status Indication

System

Status

OFF OFF OFF

St and by

Weighing Always On Blinks Every 1.2 Sec.

Load Cell LED

State

Blinks Every 1.5

Sec.

Handheld Terminal

LED State

OFF

3.3 TYPICAL PROBLEMS AND

SOLUTIONS

Table 5-2 presents typical JetWeigh-W problems and

their simple solutions. As mentioned in paragraph 1.1,

simply checking the battery status on all devices and

recharging as needed resolves many JetWeigh-W

problems.

Table 5-2. JetWeigh-W Problems and Solutions

Problem/Error Cause Solution

No weighing results received form a

single load cell - 1

No weighing results received form a

single load cell - 2

No weighing results received form a

single load cell - 3

Load cell is turned off

Load cell battery needs recharging

Poor wireless link

Low Battery

Blinks Every 0.5

Sec.

Turn the load cell on and verify that it is

in standby mode

a). Check for a low battery indication at

the load cell and the terminal (see LED

Status Table 5-1)

b). Charge any/all low batteries

a). Move terminal closer to the load cell

b). Check the antenna connection on

the load cell

c). Change the RF channel in the

terminal

d). Improve the line-of-sight between

the terminal and the failing cell

e). Remove large metal objects from

the load cell vacinity

Blinks Every 0.2 Sec.

No weighing results received form all

load cells -1

No weighing results received form all

load cells -2

A load cell doesn't turn on Load cell battery is drained out Connect the load cell to a charger

Handheld terminal doesn't turn on IPAQ battery is drained out Recharge IPAQ battery

Handheld terminal doesn't respond IPAQ Windows fault

Terminal is in low battery mode

Poor wireless link conditions

Page 5-1

a). Check for low battery indication at

terminal

b). Connect terminal to charger.

a). Check the antenna connection on

the terminal

b). Change the RF channel in the

terminal

Remove the IPAQ from the case and

perform a hardware reset using the

stylus pen. The reset key is on the back

of the IPAQ.

Page 17

troubleshoottroubleshoot

troubleshoot

troubleshoottroubleshoot

3.4 CHANGING RF CHANNELS

Communication problems are often resolved by switching to a different RF channel. Figure 5-1 shows the

Switch Channel button. Touching this button toggles

the label caption between channels. Save the optimal

channel settings by touching the Save Settings button.

Figure 5-1. Changing RF Channels

Page 5-2

Page 18

Contacting Vishay Systems

Americas

Vishay Systems Americas

The McMullen Building - 138 Baltimore St.

Suite 204, Cumberland, MD USA

PH: +1-

FAX: +1-301-722-7330

E-MAIL: vsi.usa@vishaymg.com

301-722-6000

Asia

Vishay Systems Taiwan (Asia except

China)

th

15 Fl, No. 86, Sec. 1 Shintal 5

Sijhih City, Taipei, Taiwan 22102

PH: +886-2-2696-0168

FAX: +886-2-2696-4965

E-MAIL: v

s.roc@vishaymg.com

Rd.

Europe

Vishay Systems Germany

Tatschenweg 1, 74078

Heilbronn, Germany

PH: +49-7131-3901-260

FAX: +49-7131-3901-2666

E-MAIL: v

s.de@vishaymg.com

Vishay Systems Canada

#1106-1765 Springfield Rd., Kelowna, BC V1Y 5V5

Canada

PH: +1-800-989-1499; +1-250-860-8450

FAX: +250-762-9811

E-MAIL: v

Vishay Systems China

No. 5 Binguan Nan Dao Youyi Rd., Hexi District,

Tianjin China, Code 300061

PH: +86-22-2835-3503

FAX: +86-22-2835-7261

E-MAIL: v

Vishay Systems UK

Stroudley Road, Basingstoke, Hampshire

RG24 8FW, United Kingdom

PH: +44-125-646-2131

FAX: +44-125-647-1441

E-MAIL: v

si.can@vishaymg.com

s.prc@vishaymg.com

s.uk@vishaymg.com

Vishay Systems France

16 Rue Francis Vovelle, 28000 Chartres, France

PH: +33-2-37-33-31-20

FAX: +33-2-37-33-31-29

E-MAIL:

Vishay Systems Sweden

P.O. Box 423, SE-691 27 Karlskoga, Sweden

PH: +46-586-63000

FAX: +46-586-63099

E-MAIL: v

vs.fr@vishaymg.com

s.se@vishaymg.com

Vishay Systems Norway

Brobekkveien 80, 0582 Oslo,

Norway

PH: +47-22-88-40-90

FAX: +47-22-88-40-99

E-MAIL: vs.se@vishaymg.com

Vishay Systems Israel

8A Hazoran Street, P.O. Box 8381,

New Industrial Zone, Netanya 42506, Israel

PH: +972-9-863-8888

FAX: +972-9-863-8800

E-MAIL: vs.il@vishaymg.com

Loading...

Loading...