Page 1

WEIGH SYSTEM

TECHNOLOGY

BLH

DXp-40

Interface Manual

Allen-Bradley Remote I/O

TM014

Rev D

6/1/11

Doc 35105

Page 2

NOTICE

BLH makes no representation or warranties of any kind whatsoever with respect to the contents hereof

and specifically disclaims any implied warranties or merchantability or fitness for any particular purpose.

BLH shall not be held liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this publication or its contents.

BLH reserves the right to revise this manual at any time and to make changes in the contents hereof

without obligation to notify any person of such revision or changes.

Call (781) 298-2216 for BLH Field Service

Page 3

Table of Contents

SECTION 1. Introduction ..................................................................................................................... 1-1

1.1 RIO OVERVIEW

1.2 THE DXp-40 WEIGHT TRANSMITTER

1.3 ALLEN-BRADLEY PLC-5 PROGRAMMABLE CONTROLLER ................................................. 1-1

1.4 FIELD ENGINEERING

SECTION 2. The Remote I/O Interface ............................................................................................... 2-3

2.1 OPERATIONAL OVERVIEW

2.2 HARDWARE CONFIGURATIONS

2.3 DISCRETE DATA TRANSFER .................................................................................................. 2-5

2.3.1 Output Image Table ............................................................................................................... 2-5

2.4 BLOCK DATA TRANSFERS ...................................................................................................... 2-7

2.4.1 Interface Basics ...................................................................................................................... 2-7

2.4.2 Transfer Reads (BTRs) .......................................................................................................... 2-7

2.4.3 Block Transfer Writes (13-1111s) ........................................................................................... 2-7

2.4.4 A Perpetual Pointer ................................................................................................................ 2-7

2.4.5 Fault Evaluation...................................................................................................................... 2-7

2.4.6 Remote Filter Configuration ................................................................................................... 2-7

....................................................................................................................... 1-1

.................................................................................. 1-1

............................................................................................................. 1-1

................................................................................................... 2-3

.......................................................................................... 2-3

SECTION 3. Definitions and Explanations .......................................................................................... 3-1

3.1

INPUT IMAGE TABLE BITS ...................................................................................................... 3-1

3.2 OUTPUT

SECTION 4. Sample Ladder Logic Programs

4.1 INTRODUCTION ........................................................................................................................ 4-1

4.1.1 Scale Training Program ......................................................................................................... 4-1

4.1.2 ata Reads, Writes, and Transfers .......................................................................................... 4-1

4.1.3 Reference Tables ................................................................................................................... 4-1

4.2 SAMPLE PROGRAM AVAILABI LITY ....................................................................................... 4-1

4.2.1 Sample Program Disclaimer .................................................................................................. 4-1

Appendix A - Wiring Diagram

Trademark Usage Acknowledgment

Allen-Bradley, ENABLED, and PLC are trademarks of Allen-Bradley Company, Inc.

IMAGE

TABLE BITS

................................................................................................. 3-2

.................................................................................. 4-1

Page 4

SECTION 1. Introduction

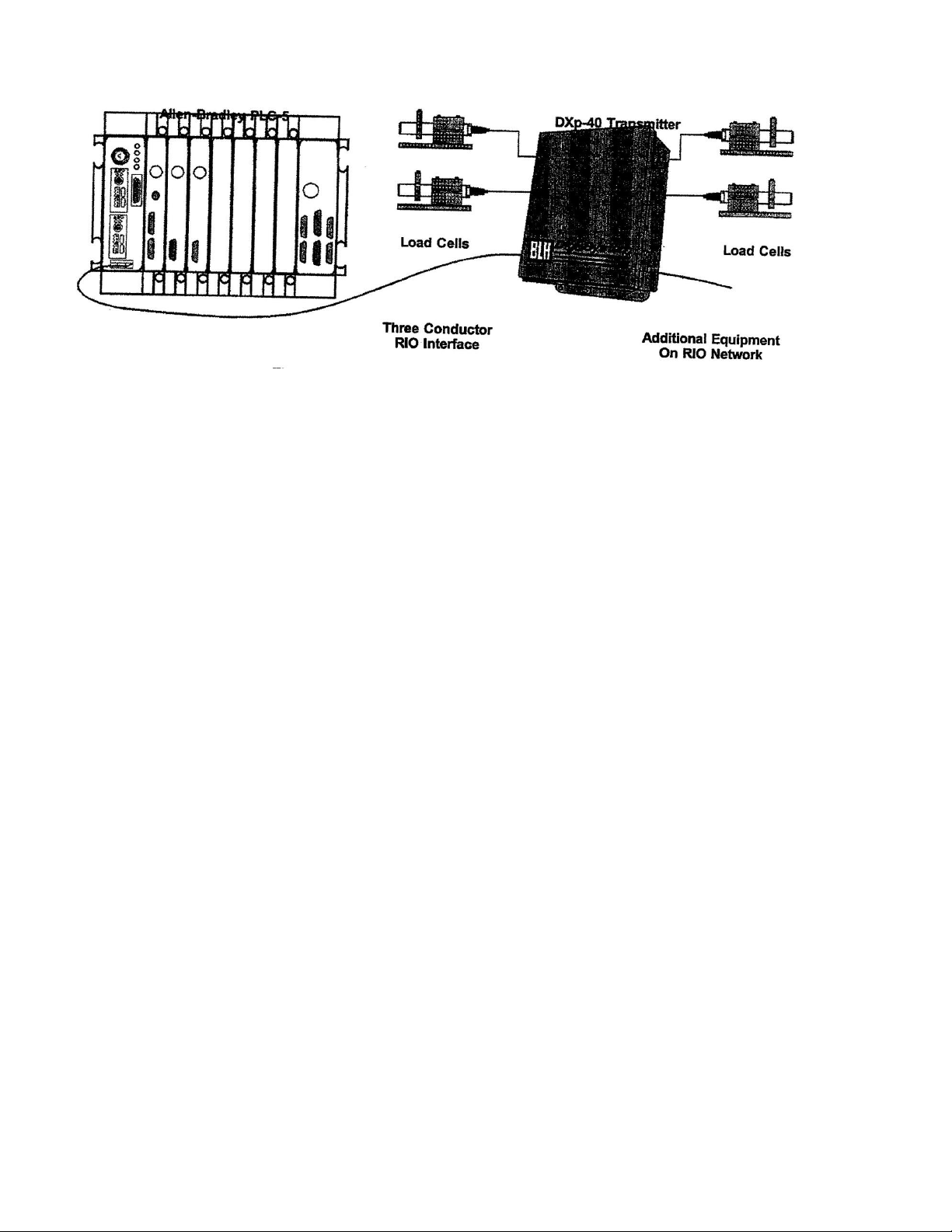

This manual describes an Allen-Bradley Remote I/O

(RIO) communication link between a BLH DXp-40

weight transmitter and an Allen-Bradley PLC-5 (Figure

1-1). This interface method uses technologies licensed

by BLH from Allen-Bradley. Functionally this digital

communication method provides a simple method of

transferring various type of weight data, status and

diagnostic information as well as the retrieval and

download of filter and other set-up parameters. Refer

to the standard DXp-40 manual, TM008, for DXp-40

operating procedures and parameter definitions.

1.1 RIO OVERVIEW

The Allen-Bradley Remote I/O (RIO) interface is a

communications link that supports remote, time critical

VO control communications between a master

processor and a remote I10 slave. It is typically used to

transfer I/O bit images between the master and slave.

The DXp-40 represents a quarter (1/4) Rack of

discrete I/O with 32 bits of input and output image files

to the scanning PLC. All weight data and status

information uses discrete reads and writes to

communicate scale information to the PLC in the

shortest time possible. Block transfers are used to

upload and download non-time critical information such

as diagnostic, status, and individual load cell data.

1.2 THE DXp-40 WEIGHT TRANSMITTER

The DXp-40 is a high performance weight transmitter

with features that make it suitable for both inventory

and process weighing applications. The transmitter

includes individual analog to digital conversion

channels for up to four load cells, microprocessor

based electronics to digitize the load cell signals, and a

serial RS-485 or Allen-Bradley Remote I/O

communication port. For field mount applications,

standard units are housed in a NEMA 4 epoxy painted

steel enclosure.

Optionally the DXp-40 is available with on-line

diagnostics, digital calibration, and Dynamic Digital

Filtering. Units also are available with Factory Mutual

Approval for installation in a Class I, II, III Division 2

hazardous locations.

Set-up and calibration procedures are accomplished

using a series of internal switches and the LCD display

(reference TM008). In operation, it provides up to three

million counts of weight resolution at an update rate of

50 milliseconds.

1.3 ALLEN-BRADLEY PLC-5 PROGRAMMABLE

CONTROLLER

The Allen Bradley PLC-5 series of mid-size

programmable controllers are used as part of

distributed process automation architecture. A variety

of 1771 series racks and I/O modules are available for

local or remote discrete and analog process control.

The PLC-5 can digitally communicate to other devices

using a conventional RS 232 or 423 serial port in

addition to special interface ports such as Data

Highway Plus, Scanner Communications, and Remote

I/O Adapter.

1.4 FIELD ENGINEERING

BLH will not accept any liability for faulty installation

and/or misuse of this product. Authorized BLH Field

Service Engineers are available around the world to

install DXp-40 transmitters and/or train factory

personnel to do so. The field service department at

BLH is the most important tool to assure the best performance from your application. Field service phone

numbers are listed below.

Notice: BLH makes no representation or warranties of

any kind whatsoever with respect to the contents

hereof and specifically disclaims any implied

warranties or merchantability or fitness for any

particular purpose. BLH shall not be held liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this publication or its contents.

BLH reserves the right to revise this manual at any

time and to make changes in the contents hereof

without obligation to notify any person of such revision

or changes.

1-1

Page 5

Figure 1-1. Allen-Bradley Remote I/O Network Interface

1-2

Page 6

SECTION 2. The Remote I/O Interface

2.1 OPERATIONAL OVERVIEW

The Allen-Bradley Remote I/O (RIO) interface is

standard on many PLC-2, 3, and 5 series

programmable logic controllers. The technology

used in the interface and licensed by Allen-Bradley

to BLH enables the DXp-40 transmitter to

communicate weight information to the PLC as if it

were a 1/4 rack of discrete I/O. By using the

standard RIO interface port and representing

weight data as simple discrete I/O, a low cost

reliable communication link between the PLC and

weigh system is established. Standard PLC ladder

logic instructions convert binary weight data to an

integer or floating point weight value without

special software drivers and scan delays that occur

when data block transfers are used. The DXp-40

also communicates status information, diagnostics,

and calibration data to the PLC.

CONFIGURATIONS:

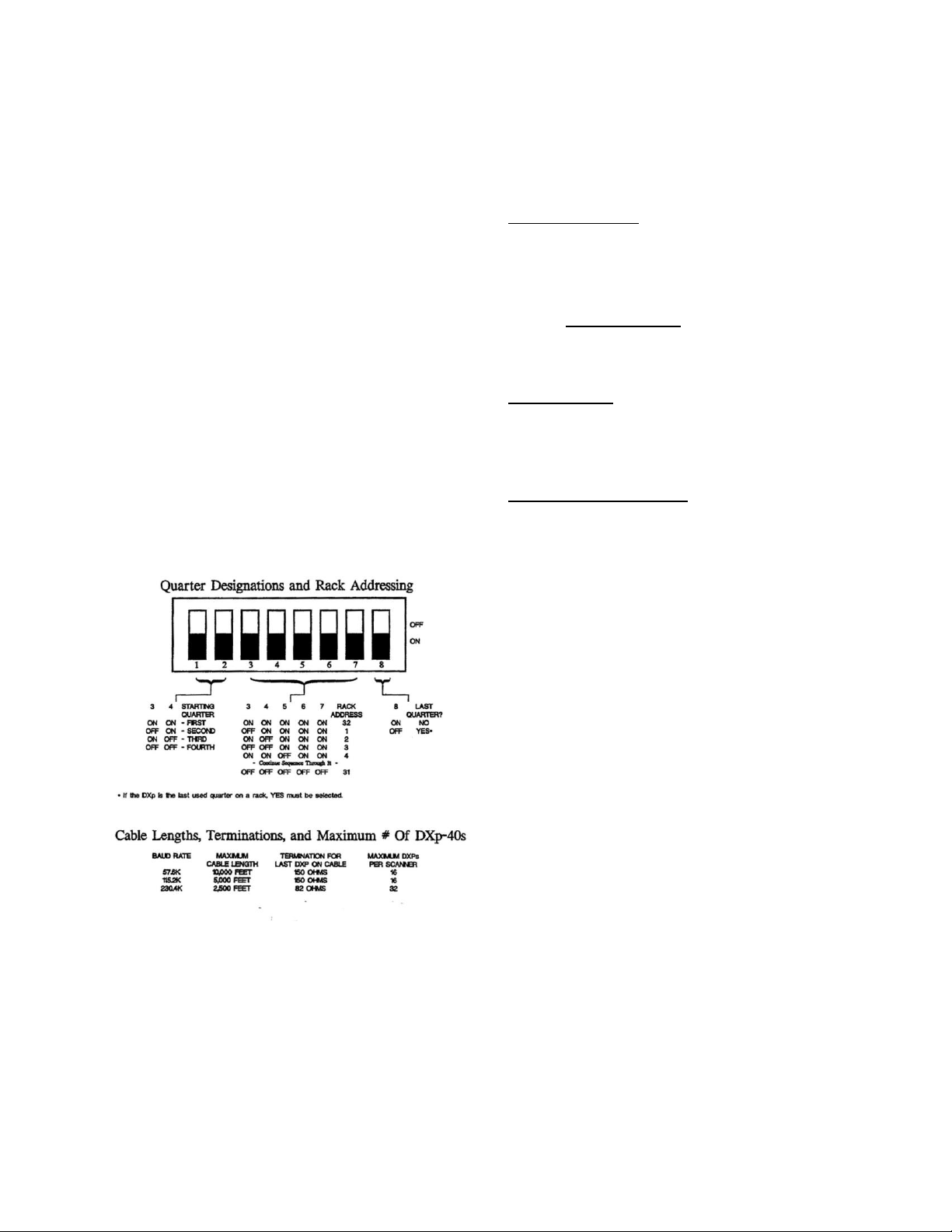

Figure 2-1. RIO Communication DIP Switch

Settings

One Quarter Rack. The DXp-40 is configured to

act as 1/4 rack of I/O using 2 input words and 2

output words in the PLC's I/O image table. DXp-40

addressing supports racks 1-32. Four DXp-40s

constitute 1 full rack, each using a different starting

quarter. Discrete Transfer, Weight data and operating

status information transmitted through discrete

transfer using the PLC's Remote I10 image table.

Block Transfer, Block data transfers are initiated by

the PLC ladder logic program to obtain more in

depth status, diagnostic, and individual load cell

data.

Word Integrity Is Ensured. The DXp-40 will always

transmit both input image table words intact. To

ensure word integrity on the PLC side, immediate

writes to the output image table should be written

low word first.

2.2 HARDWARE CONFIGURATIONS

Rack address and starting quarter designations are

all configured using a row of DIP switches in the

DXp-40 (Figure 2-1). The DXp-40 is able to be

addressed up to rack number 32. Whenever the

DIP switch settings are changed, the unit must be

reset to allow the processor to read the new switch

settings.

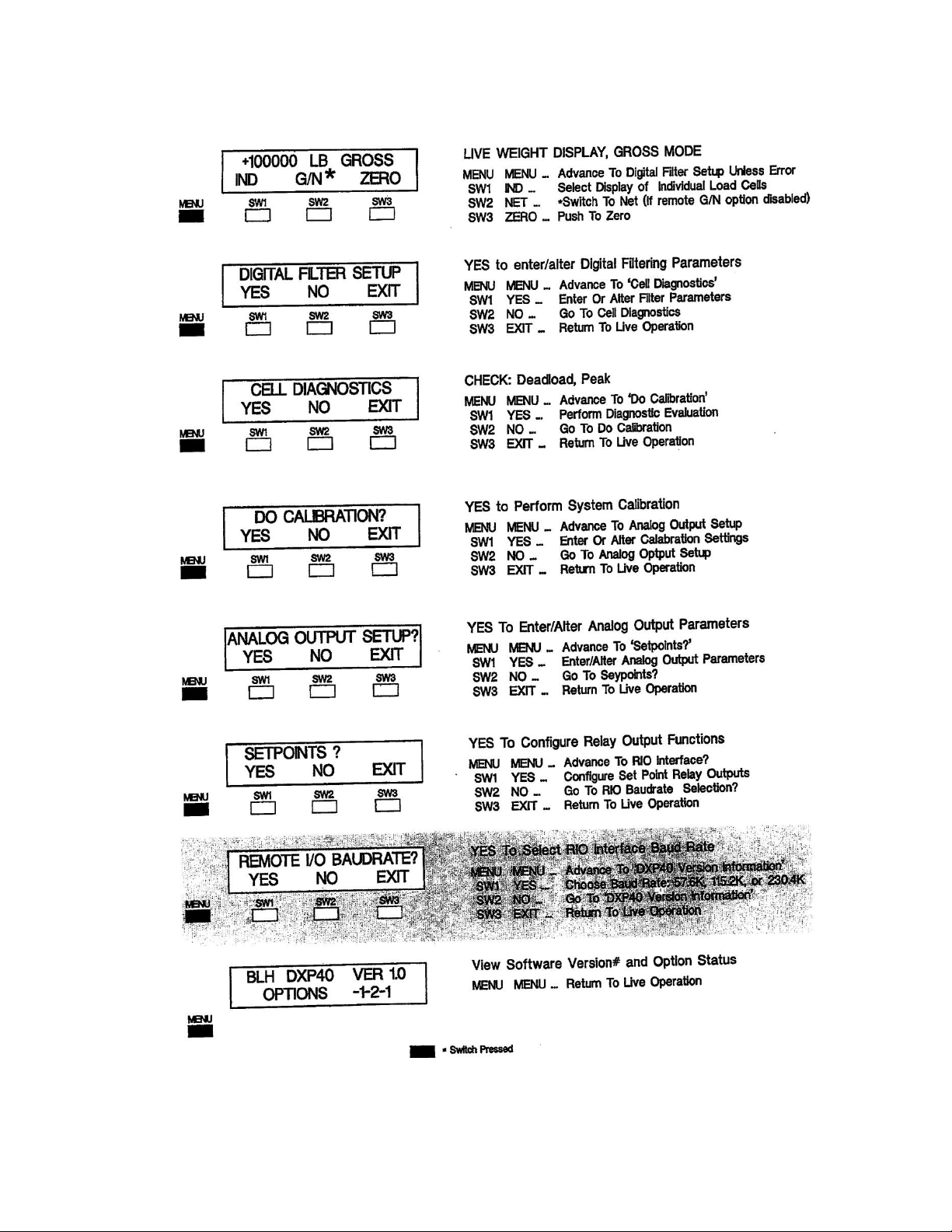

RIO interface baud rate selections are available

through the DXp-40 main menu (Figure 2-2).

Recommended cable lengths are presented in

Figure 2-1.

2-3

Page 7

Main Menu (Accessed from Operation Mode)

Figure 2-2. Revised DXp-40 Main Menu w/Baud Rate Selection

2-4

Page 8

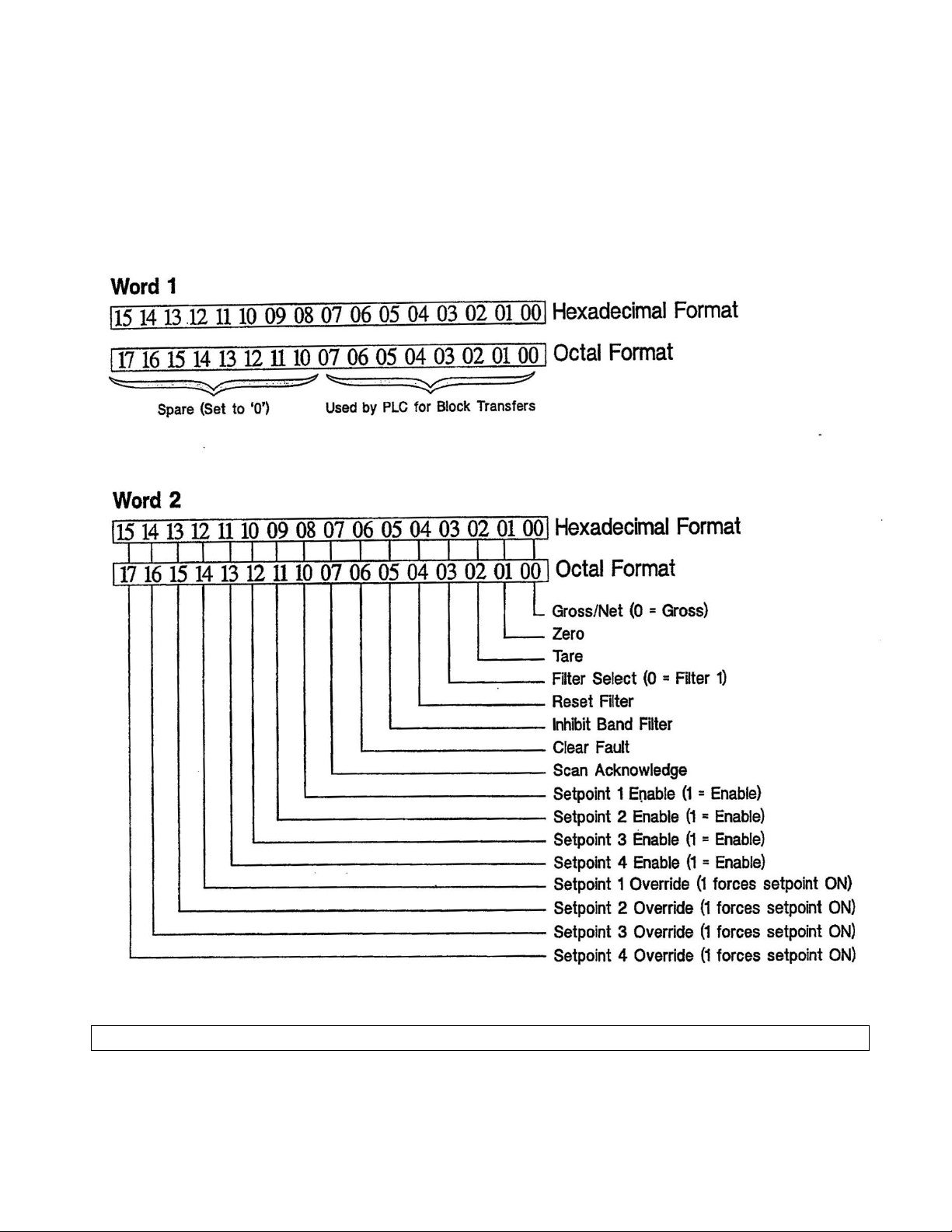

2.3 DISCRETE DATA TRANSFER

2.3.1 OUTPUT IMAGE TABLE

The PLC-5 initiates the communication interface by

transmitting two words from the output image table

(Figure 2-3). The first word is regarded as a 'spare'

by the DXp-40.

The second word contains the commands that the

PLC-5 expects the DXp-40 to perform. Word 2

controls set points, filter selection, filter operation,

and DXp-40 operating mode status.

Figure 2-3. The Output Image Table

NOTE: Octal and hexadecimal address formats are shown to cover PLC-5 and SLC-500 devices

2-5

Page 9

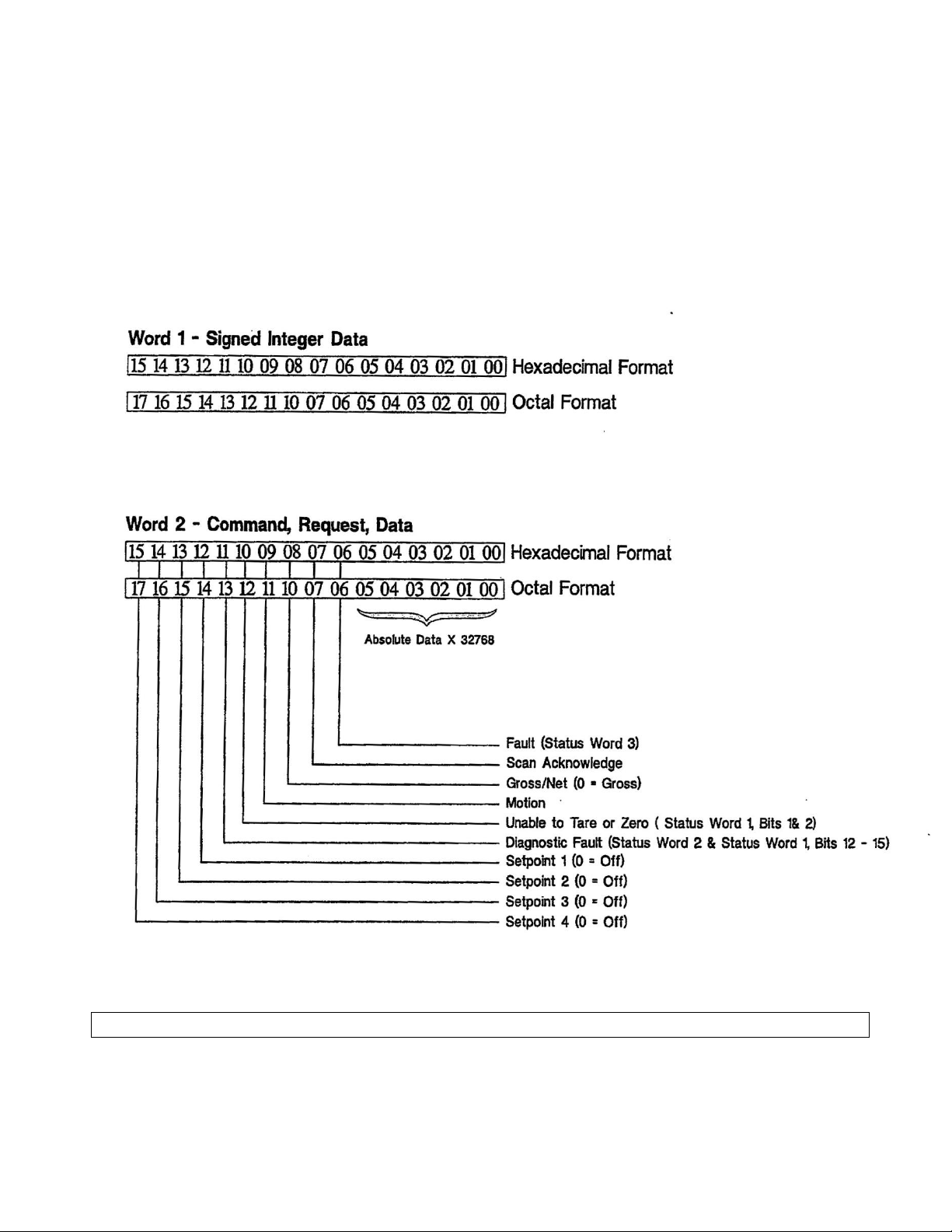

2.3.2 Input Image Table

After evaluating the contents of the output

image table, the DXp-40 responds by

transmitting two words to the input image

table (Figure 2-4). The first word contains

signed integer weight data. The second word

contains the upper order data bits, system

status, error condition, and set point status

information.

Figure 2-4. The Input Image Table

NOTE: Octal and hexadecimal address formats are shown to cover PLC-5 and SLC-500 devices

2-6

Page 10

2.4 BLOCK DATA TRANSFERS

2.4.1 INTERFACE BASICS

Block data transfers are initiated by the ladder

logic program write (BTW) and read (BTR)

commands. The transfer sequence begins when

the PLC sends the DXp40 a one word (16 bit

integer) write command containing a register

location pointer. This pointer is the 16 bit integer

value of the first register the PLC wishes to read

(factory default upon shipment is register 1).

Table 2-1 presents all available single and

double word register locations. After establishing

the starting register location, the PLC then

transmits a read transfer block command telling

the DXp--40 how many words of information are

needed.

and the second word being the new set point

value. Parameter guidelines for writing data to

the DXp-40 are presented in Table 2-2.

2.4.4 A PERPETUAL POINTER

One advantage to DXp-40 block transfers is that

the register pointer is retained in DXp-40

EEPROM. When a write block selects (points to)

a register location, that location may be

accessed (read) repeatedly without having to rewrite the register location word. Of course the

register pointer can be changed as often as

needed, but the last written location will always

be remembered, even during power down. This

feature saves a lot of BTWs when the PLC is

monitoring a particular register or block of

registers over a period of time.

2.4.2 TRANSFER READS (BTRS)

Once

the register location pointer value is

established, the PLC logic program must issue a

block transfer read command to obtain DXp-40

information. A BTR can request up to 64 words

of DXp-40 information (see Table 2-1). The

DXp-40 will respond to the BTR by transmitting

the number of words requested, starting at the

pointer location. NOTE: The first word

transmitted by the DXp-40 will be the register

pointer value. The DXp-40 adds this word at the

beginning of the transmission to 'echo' the

pointer value prior to transmitting requested

data. Therefore, the BTR command MUST add

1 to the number of words requested. If the PLC

needs four words of DXP information, the BTR

request must be for five words (Figure 2-5).

2.4.3 BLOCK TRANSFER WRITES (13

1111S)

Some of the DXp-40 registers may be written to

by the PLC (indicated by an '" in table 2-1). This

allows parameters such as filter, set point, and

diagnostic values to be down loaded on-the-fly

by the PLC ladder logic program. When writing

to the DXp-40, the first word must be the register

location pointer. Therefore, the program MUST

always add 1 to the BTW command length

(Figure 2-6). For example, to change a set point

value, the BTW length must equal 2 with the first

word being the set point register location pointer

2.4.5 FAULT EVALUATION

Three status words, register locations 1, 2, and

3, provide detailed explanations of error

conditions encountered by the DXp. When a

fault is detected, either bit 6 (fault) or bit 11

(diagnostic fault) in word 2 of the input image table is set to a '1' to alert the PLC of an error

condition. The PLC must then perform a BTR of

the appropriate status register to evaluate and

correct the error. If bit six (fault) is set, check

status word 3 for the error explanation. If bit 11

(diagnostic fault) is active, check status word 2

and status word 1 bits 12 - 15 for the error

explanation. Table 2-3 gives the status word bit

definitions.

2.4.6 REMOTE FILTER CONFIGURATION

DXp-40 transmitters equipped with the optional

-

Dynamic Digital Filter can be instructed by the

PLC to change filter settings on-the-fly. This

unique feature allows optimal, pre-determined

filtering parameters to be implemented at critical

moments during a dynamic weigh process.

Changing filter parameters throughout the

process ensures data stability and maximum

system response to actual weight changes.

Filter parameters are stored at register locations

59-70 (Table 2-1). Table 2-2 defines the filter

parameters that can be written to these registers

in the DXp-40. Request BLH technical note TD071 for a detailed description of Dynamic Digital

Filtering.

2-7

Page 11

WORD 1

WORD

2

WORD

3

WORD

4

WORD

5

Register

Address

4

Gross

Weight

Cell 1

Gross

Weight

Cell 2

Gross

Weight

Cell 3

Gross

Weight

Cell 4

WORD 1

WORD 2

Register

Address 55

Set Point

Value

Block Transfer Write Sample: One word desired

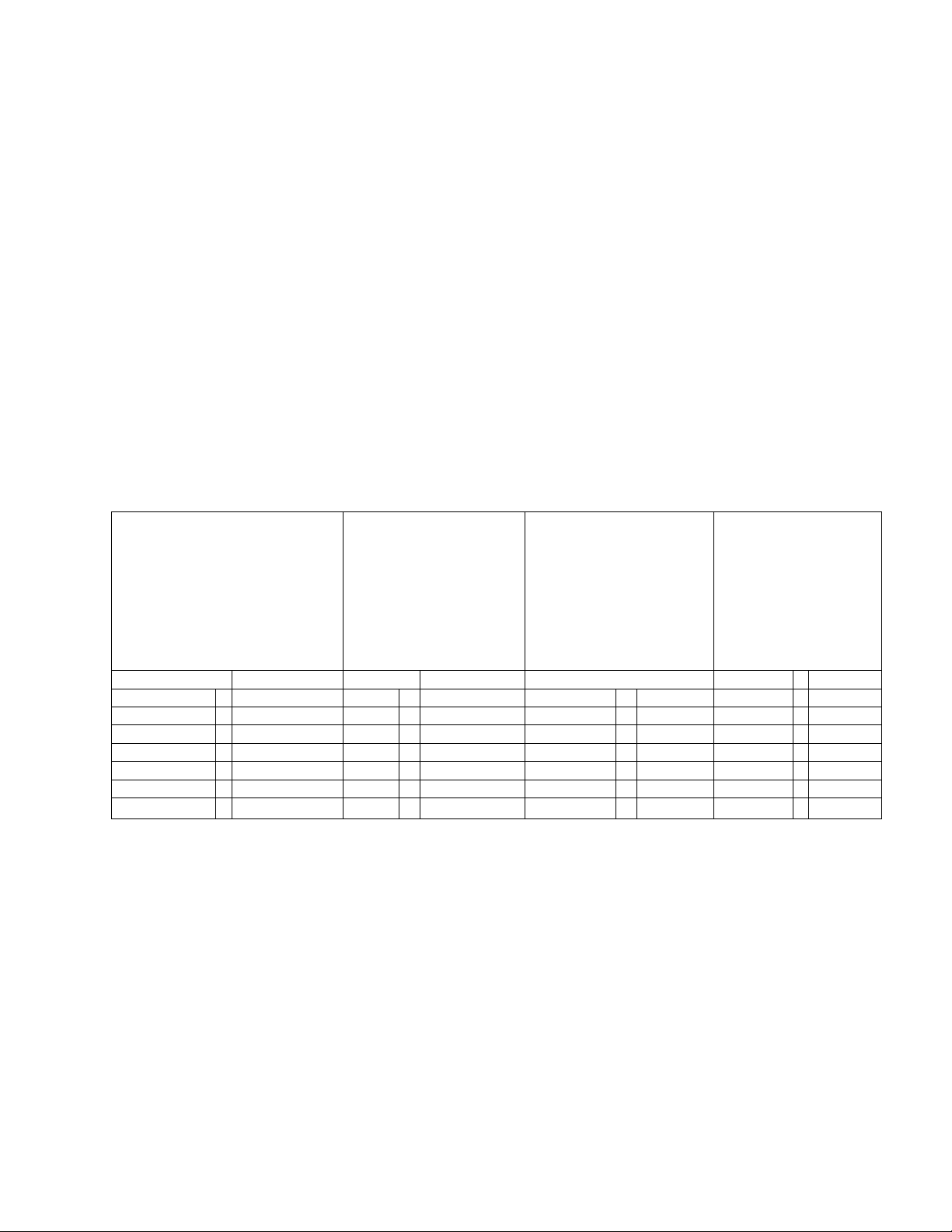

Table 2-1. Single & Double Word Register Pointer Locations

Single Word Registers Double Word Registers

01

STATUS 3

100 GROSS TOTAL

02

STATUS 2

102 GROSS CELL 1

03

STATUS 1

104 GROSS CELL 2

04

GROSS CELL 1

106 GROSS CELL 3

05

GROSS CELL 2

108 GROSS CELL 4

06

GROSS CELL 3

110 NET TOTAL

07

GROSS CELL 4

112 NET CELL 1

08

NET CELL 1

114 NET CELL 2

09

NET CELL 2

116 NET CELL 3

10

NET CELL 3

118 NET CELL 4

11

NET CELL 4

120 MV/V CELL 1

12

MV/V/10 CELL 3

122 MV/V CELL 2

13

MV/V/10 CELL 2

124 MV/V CELL 3

14

MV/V/10 CELL 3

126 RAVN CELL 4

15

MV/V/10 CELL 4

128 PEAK TOTAL

16

% LOAD CELL 1

130 PEAK CELL 1

17

% LOAD CELL 2

132 PEAK CELL 2

18

% LOAD CELL 3

134 PEAK CELL 3

19

% LOAD CELL 4

136 PEAK CELL 4

20

PEAK TOTAL

138 TARE

21

PEAK CELL 1

140 TARE CELL 1

22

PEAK CELL 2

142 TARE CELL 2

23

PEAK CELL 3

144 TARE CELL 3

24

PEAK CELL 4

146 TARE CELL 4

25

TARE 148 ZERO

26

TARE CELL 1

150 ZERO CELL 1

27

TARE CELL 2

152 ZERO CELL 2

28

TARE CELL 3

154 ZERO CELL 3

29

TARE CELL 4

156 ZERO CELL 4

30

ZERO 158* SETPOINT 1

31

ZERO CELL 1

160* SETPOINT 2

32

ZERO CELL 2

162* SETPOINT 3

33

ZERO CELL 3

164* SETPOINT 4

34

ZERO CELL 4

166* OVERLOAD CELL 1

35

% SENSITIVITY CELL 1

168* OVERLOAD CELL 2

36

% SENSITIVITY CELL 2

170* OVERLOAD CELL 3

37

% SENSITIVITY CELL 3

172* OVERLOAD CELL 4

38

V. SENSITIVITY CELL 4

39

1 LOAD SHIFT CELL 1

40

% LOAD SHIFT CELL 2

41

1 LOAD SHIFT CELL 3

* Word(s) can be written to by PLC

42

1 LOAD SHIFT CELL 4

43

POS DRIFT CELL 1

44

POS DRIFT CELL 2

45

POS DRIFT CELL 3

46

POS DRIFT CELL 4

47

MEG DRIFT CELL 1

48

NEG DRIFT CELL 2

49

NEG DRIFT CELL 3

50

NEG DRIFT CELL 4 NOISE CELL 1

Table 2-1 Notes:

52

NOISE CELL 2

53

NOISE CELL 3

1).Single word register integer data = -32768 to + 32767

54

NOISE CELL 4

55*

56*

SETPOINT 1

SETPOINT 2

2). Double word integer data must be converted to floating point using the

following equation:

(set point#1 weight value) requires two word write

command (1st word is set point #1 address).

Figure 2.5. Block Transfer Read

Figure 2-6. Block Transfer Write (BTW)

Sample

2-8

Page 12

57*

SETPOINT 3

58*

SETPOINT 4

59*

FILTER 1 LENGTH

((word 2) x 32768.0) + word 1

60*

FILTER 1 BAND

61*

FILTER 1 RESPONSE

range = -9,999,999 to 9,999,999

62*

FILTER 1 BAND AVERAGE

63*

FILTER 1 MOTION

64*

FILTER 1 MOTION TIMER

65*

FILTER 2 LENGTH

66*

FILTER 2 BAND

67*

FILTER 2 RESPONSE

68*

FILTER 2 BAND AVERAGE

69*

FILTER 2 MOTION

70*

FILTER 2 MOTION TIMER

71*

DIAG SHIFT UMIT

72*

DIAG ZERO SHIFT UMIT

73*

DIAG DRIFT UMIT

74*

DLAG NOISE UMIT

75*

OVERLOAD CELL 1

76*

OVERLOAD CELL 2

77*

OVERLOAD CELL 3

78*

OVERLOAD CELL 4

Table 2-2. Block Transfer Write Parameters

Diagnostic Entries

Diagnostic Shift Limit

Zero Shift Limit

Drift Limit

Noise Limit

Filter Parameter Entries

Filter Length

0 to 99 (0% to 99%)

0 to

9,999,999

0 to 99

counts* 0 to

99 counts

Motion

Motion Timer

00 =

50ms

00 = 2 00 = OFF

00

=

1/2 sec

01

=

100 ms

01 = 4

01

=

1 count

01

=

1 sec

02

=

200 ms

02 = 8

02

=

2 counts

02

=

2 sec

03

=

400 ms

03 = 16

03

=

3 counts

03

=

3 sec

04

=

800 ms

04 = 32

04

=

5 counts

05

=

1600 ms

05 = 64

05

=

10 counts

06

=

3200 ms

06 = 128

06

=

20 counts

07

=

6400 ms

07 = 256

07

=

50 counts

Set Point Entries - 0 to 9,999,999

Band Filter - 0 to 250 counts

Filter Response - 0 to 250 counts

Overload - 0 to 9,999,999

* Counts refers to displayed counts. If displayed weight is counting by 2 lb increments, then a selection of

nine counts will equal 18 lb.

NOTE: Refer to the standard DXp-40 manual, TM008, for DXp-40 parameter definitions.

2-9

Page 13

Table 2-3. Status Word Bit Definitions

STATUS 1 (GENERAL STATUS)

BIT 0 ACTIVE FILTER, (0) = FILTER 1, (1) = FILTER 2

BIT 1 UNABLE TO TARE/ZERO BECAUSE OF MOTION

BIT 2 UNABLE TO ZERO BECAUSE OF LIMIT

BIT 3 GROSS ZERO JUST ACQUIRED

BIT 4 NET TARE JUST ACQUIRED

BIT 5 IN CAL

BIT 6 SPARE

BIT 7 SPARE

BIT 8 INPUT 1

BIT 9 INPUT 2

BIT 10 INPUT 3

BIT 11 INPUT 4

BIT 12 OVERLOAD LIMIT CELL 1

BIT 13 OVERLOAD LIMIT CELL 2

BIT 14 OVERLOAD LIMIT CELL 3

BIT 15 OVERLOAD LIMIT CELL 4

STATUS 2 (DIAGNOSTIC ERRORS)

BIT 0 LOAD SHIFT CELL 1

BIT 1 LOAD SHIFT CELL 2

BIT 2 LOAD SHIFT CELL 3

BIT 3 LOAD SHIFT CELL 4

BIT 4 ZERO SHIFT CELL 1

BIT 5 ZERO SHIFT CELL 2

BIT 6 ZERO SHIFT CELL 3

BIT 7 ZERO SHIFT CELL 4

BIT 8 DRIFT CELL 1

BIT 9 DRIFT CELL 2

BIT 10 DRIFT CELL 3

BIT 11 DRIFT CELL 4

BIT 12 NOISE CELL 1

BIT 13 NOISE CELL 2

BIT 14 NOISE CELL 3

BIT 15 NOISE CELL 4

STATUS 3 (FAULTS)

BIT 0 POWERUP

BIT 1 2EEPROM CODE ERROR - DEFAULT DATA OVERLOAD

BIT 2 EEPROM READ ERROR

BIT 3 EEPROM WRITE ERROR

BIT 4 LOST ZERO

BIT 5 LOST TARE

BIT 6

BIT 7

BIT 8 A/D UNDERLOAD1 CELL 1

BIT 9 A/D OVERLOAD2 CELL 1

BIT 10 A/D UNDERLOAD CELL 2

BIT 11 A/D OVERLOAD CELL 2

BIT 12 A/D UNDERLOAD CELL 3

BIT 13 /D OVERLOAD CELL 3

BIT 14 A/D UNDERLOAD CELL 4

BIT 15 A/D OVERLOAD CELL 4

1 Underload = input signal too low

2 Overload = input signal too high

2-10

Page 14

SECTION 3. Definitions and Explanations

3.1

INPUT IMAGE TABLE BITS

A table is provided to explain the Input Image

Table presented in Figure 2-4. Table 3-1

defines the bit structure of both input words.

Word 1 BITS 0 - 15 WEIGH DATA (signed integer, -32768 to + 32767)

Signed integer.

Word 2

BITS 0 - 5 ABSOLUTE OVERFLOW DATA x 32768

Word 2 bits 0-5 is absolute overflow data from word 1 used if absolute weigh data is greater than 32,767. These 5 bits are

combined with the word 1 integer in a floating point register by the following steps.

1. Do a Masked move of Word 2 bits 0- 5 to an integer register.

2. Multiply the integer register by 32768.0 and put the result in a floating point register.

3. Negate the floating point result if the word 1 integer is negative.

4. Add the word 1 integer to the floating point result.

BIT 6 FAULT

Is set if there is a fault causing weigh data to be incorrect. This bit is cleared or suppressed by setting the clear fault bit in word 2 of

the output image table.

Table 3-1. Input Image Table Word 'Bit' Definitions

BIT 7 SCAN ACKNOWLEDGE

This bit is a copy of the same bit in the output Image table. When the D440 receives the output image table data it copies this bit to

the same location in the input image table. The plc can thus know if the remote I/O DXp40 has received the last write to the output

image table.

BIT 8 G/N, GROSS/NET DATA ID.

If this bit = 0 the weigh data in word 1 and bits 0-5 of word 2 is gross data. If this bit = 1 the weigh data is net weigh data.

BIT 9 MOTION

Is set If the weigh data is in motion as determined by the motion settings.

BIT 10 UNABLE TO TARE OR ZERO

Is set if the dxp40 is unable to tare or zero the data after receiving a zero or tare command from bits 1 or 2 of word 2 of the output

image table. The reasons for not being able to zero of tare are found in status #1 register bits 1 8, 2. This status register is

accessible through a block transfer read.

BIT 11 DIAGNOSTIC FAULT

Is set if any of the diagnostic fault bits are satin the status #1 register bits 12 -15 or status #2 register bits 0 -15. These status registers are accessible through a block transfer read.

BIT 12 SETPOINT #1

Is set if setpoint #1 output is on. If word 2 bit 8 of the output image table = 1 the setpoint #1 output is controlled by the dxp40. ff

word 2 bit 8 of the output image table = 0 the setpoint #1 output is controlled by word 2 bit 12 of the output image table.

BIT 13 SETPOINT # 2

Is set if setpoint #2 output is on. If word 2 bit 9 of the output image table = 1 the setpoint #2 output is controlled by the dxp40. If

word 2 bit 9 of the output image table = 0 the setpoint #2 output is controlled by word 2 bit 13 of the output image table.

BIT 14 SETPOINT #3

Is set if setpoint #3 output Is on. If word 2 bit 10 of the output image table = 1 the setpoint #3 output is controlled by the dxp40. If

word 2 bit 10 of the output image table = 0 the setpoint #3 output Is controlled by word 2 bit 14 of the output image table.

BIT 15 SETPOINT # 4

Is set if setpolnt #4 output is on. If word 2 bit 11 of the output image table = 1 the setpoint #4 output is controlled by the cbq340. If

word 2 bit 11 of the output image table = 0 the setpoint #4 output is controlled by word 2 bit 15 of the output image table.

3-1

Page 15

3.2 OUTPUT

IMAGE

TABLE BITS

Table 3-2 shows the structure and bit definition of

each Output Image Table word. Reference Figure 2-3

to view word breakouts.

Table 3-2. Output Image Table Word/Bit Definitions

Word 1 Unused

Word 2

BIT 0 GROSS/NET (0= GROSS)

Used for requesting total gross or net weigh data. If = 0 gross weigh data will be returned to the input image table. If = 1 net weigh

data will be returned.

BIT 1 ZERO

If this bit changes from 0 to 1 the dxp40 will zero the gross weight If not currently in "motion" as determined by the motion status bit or if not outside

the settable zero band. If the zero function is successful the GROSS ZERO JUST ACQUIRED bit (3) in the status 1 register will be set for approx. 2

seconds. If not successful bit 10, UNABLE TO TARE OR ZERO, in word 2 of the input image table and either bit 1, UNABLE TO TARE/ZERO

BECAUSE OF MOTION, or bit 2, UNABLE TO ZERO BECAUSE OF LIMIT, of the status 1 register will be set for approx 2 seconds.

BIT 2 TARE

If this bit changes from 0 to 1 the dxp40 will tare the net weight if not currently in "motion- as determined by the motion status bit. If the tare function

is successful the NET TARE JUST ACQUIRED bit (4) in the status 1 register will be set for approx. 2 seconds. If not successful bit 10, UNABLE TO

TARE OR ZERO, in word 2 of the input image table and bit 1 UNABLE TO TARE/ZERO BECAUSE OF MOTION, of the status 1 register will be set

for approx 2 seconds.

BIT 3 FILTER SELECT (0= FILTER 1, 1 = FILTER 2)

This bit is ored with the discrete filter select input as shown in the following table:

INPUT BIT 3 FILTER

SELECT SELECTED

FILTER 1 0 FILTER 1

FILTER 1 1 FILTER 2

FILTER 2 0 FILTER 2

FILTER 2 1 FILTER 2

BIT 4 RESET FILTER

If this bit changes from 0 to 1 the dxp40 win reset or restart the filter using data from the current aid conversion. This may be helpful in overcoming

time lags caused by heavy averaging.

BIT 5 INHIBIT BAND FILTER

When this bit is set to 1 the band filter Is inhibited. Set to 1 for a minimum of 50 milliseconds and then reset to 0 resets the band filter. If the band is

wide, and heavy averaging is applied this will quicken the response to small signal changes which fall within the band width. When the band fitter is

reset quick centering algorithms will rapidly find the center of a noisy input signal.

BIT 6 CLEAR FAULT

Setting this bit will clear all fault bits in status register 3 except for eeprom faults. Eeprom faults require the dxp40 to be reset. If the a/c1 over/underrange faults persist the corresponding fault flags will be set again when this bit returns to 0.

BIT 7 SCAN ACKNOWLEDGE

This bit is set or reset by the plc to achieve data transfer synchronization between the plc's program scan and the remote I/O scan. When the DXp40

receives the output image table data it copies this bit to the same location in the input image table. The plc can thus know if the remote i/o DXp40

has received the last write to the output image table.

BIT 8 SETPOINT #1 ENABLE (1= ENABLE)

Setting this bit to 1 enables the dxp40 setpoint #1 output to be controlled by the cbcp40. If reset to 0 the setpoint #1 output is controlled by BIT 12.

BIT 9 SETPOINT #2 ENABLE (1= ENABLE)

Setting this bit to 1 enables the dxp40 setpoint #2 output to be controlled by the dxp40. If reset to 0 the setpoint #2 output is controlled by BIT 13.

BIT 10 SETPOINT #3 ENABLE (1= ENABLE)

Setting this bit to 1 enables the dxp40 setpoint #3 output to be controlled by the cbcp40. If reset to 0 the setpoInt #3 output is controlled by BIT 14.

3-2

Page 16

Table 3-2 (Cont.) Output Image Table Bit Definitions

BIT 11 SETPOINT #4 ENABLE (1 = ENABLE)

Setting this bit to 1 enables the dxp40 setpoint #4 output to be controlled by the dxp40. If reset to 0 the setpoint #4 output is controlled by BIT 15.

BIT 12 SETPOINT # 1 OVERRIDE

If BIT 8 = 0 the state of this bit controls the setpolnt # I output. A 1 turns on the setpoint #1 output.

BIT 13 SETPOINT #2 OVERRIDE

If BIT 9 = 0 the state of this bit controls the setpoint #2 output. Al turns on the setpoint #2 output.

BIT 14 SETPOINT #3 OVERRIDE

If BIT 10 = 0 the state of this bit controls the setpoint #3 output. A 1 turns on the setpoint #3 output.

BIT 15 SETPOINT #4 OVERRIDE

If BIT 11 = 0 the state of this bit controls the setpoint #4 output. A 1 turns on the setpoint #4 output

3-3

Page 17

SECTION 4. Sample Ladder Logic Programs

4.1 INTRODUCTION

This section provides several sample programs (page

4-2) that show how the Allen-Bradley PLC

communicates with the DXp-40 through the RIO

interface. These programs are presented as guides to

simplify the development of customer PLC programs.

4.1.1 SCALE TRAINING PROGRAM

The first sample program, 'MAIN PROG', begins on

page 4-3 and continues to page 4-7. MAIN PROG is a

scale training program designed to 'exercise' most of

the RIO interface actions and responses. Each block

of the program defines the function being performed

and then shows individual register and bit allocations.

4.1.2 ATA READS, WRITES, AND TRANSFERS

Following 'MAIN PROG' are several smaller program

segments that deal with data reads, writes, and block

transfers. Read, write, and block transfer programs

run from page 4-8 to page 9-22. These programs

define both single and double register transactions.

4.1.3 REFERENCE TABLES

Pages 4-23 to 4-27 provide reference tables to be

used in conjunction with the sample programs. Use

these tables to clarify program references.

4.2 SAMPLE PROGRAM AVAILABI LITY

Sample programs are available on disk in either AB

6200 or ICOM format. Contact BLH at (781) 289-2000

for disk copies and/or application assistance, if

needed.

4.2.1 SAMPLE PROGRAM DISCLAIMER

The sample programs presented in this section were

developed and tested by an authorized Allen-Bradley

systems integrator for BLH. BLH makes no warranty

or claim that these programs are without faults or

suitable for a particular purpose. Always consult the

appropriate Allen-Bradley systems programming

documentation as the final authority on programming

issues.

4-1

Page 18

4-2

Page 19

4-3

Page 20

4-4

Page 21

4-5

Page 22

4-6

Page 23

4-7

Page 24

4-8

Page 25

4-9

Page 26

4-10

Page 27

4-11

Page 28

4-12

Page 29

4-13

Page 30

4-14

Page 31

4-15

Page 32

4-16

Page 33

4-17

Page 34

4-18

Page 35

4-19

Page 36

4-20

Page 37

4-21

Page 38

4-22

Page 39

4-23

Page 40

4-24

Page 41

4-25

Page 42

4-26

Page 43

4-27

Page 44

APPENDIX A

Outline and Wiring Drawings

Customer Wiring Page A-2

DXp-40 Outline Dimensions Page A-3

A-1

Page 45

A-2

Page 46

A-3

Page 47

BLH

3 Edgewater Drive

Norwood, MA 02062

Phone (781) 298-2200

Fax (781) 762-3988

www.vishaypg.com

U.S.A

Loading...

Loading...