Page 1

VT300

Weighbridge Indicator

Technical Manual

Revision A4, September 2006 Doc # TM-VT300-EN

Page 2

Table of Contents

VT300 Technical Manual, Rev. A4 ii Doc # TM-VT300-EN

Table of Contents

TABLE OF CONTENTS ................................................................................ II

TABLE OF FIGURES .................................................................................VII

LEGAL NOTICE...................................................................................... VIII

WARRANTY.............................................................................................. IX

SAFETY INSTRUCTIONS.............................................................................X

DECLARATION OF CONFORMITY ............................................................. XII

ABOUT THIS DOCUMENT....................................................................... XIII

1 TECHNICAL SPECIFICATIONS......................................................... 15

1.1 GENERAL ........................................................................................... 15

1.2 ANALOG INPUT .................................................................................... 16

1.3 ANALOG OUTPUT (OPTIONAL)................................................................... 16

1.4 DIGITAL INPUT .................................................................................... 17

1.5 DIGITAL OUTPUTS ................................................................................ 17

2 INSTALLATION .............................................................................. 18

2.1 SITE REQUIREMENTS ............................................................................. 18

2.2 MOUNTING THE INDICATOR ...................................................................... 18

2.2.1 Desktop Model (Aluminum Enclosure).................................................. 18

2.2.2 Wall-Mount Model (Stainless Steel Enclosure) ....................................... 19

2.3 CONNECTING LOAD CELLS ....................................................................... 20

2.3.1 Desktop Model (Aluminum Enclosure).................................................. 20

2.3.2 Wall-Mount Model (Stainless Steel) ..................................................... 21

2.3.3 Load Cell Operating Parameters.......................................................... 21

2.4 SERIAL CONNECTIONS............................................................................ 22

2.4.1 Printer and PC Cables........................................................................ 22

2.4.2 RS485 Cable Connections .................................. ... ............................. 22

2.5 CONNECTING POWER ............................................................................. 23

Page 3

Table of Contents

VT300 Technical Manual, Rev. A4 iii Doc # TM-VT300-EN

3

DISPLAY, KEYS AND MENUS........................................................... 24

3.1 THE DISPLAY ...................................................................................... 24

3.1.1 Status Annunciators............................................................. ... ... ... .... 25

3.1.2 Common Messages Shown on the Display ............................................ 25

3.2 FRONT PANEL KEYS............................................................................... 26

3.2.1 Using Keys to Perform Operations ....................................................... 26

3.2.2 Using Keys to Enter Information ......................................................... 27

3.3 THE MENU ......................................................................................... 27

3.3.1 Using the Menu ................................................................................ 27

3.3.2 Menu Structure and Options Summary................................................. 28

Main Menu........................................................................... .........................................28

Main > WEIGH ...................... ... ...... ... ...... .... ...... ... ...... ... ....... ... ... ...... ... ...... .... ...... ... ...... .28

Main > VFILE ........... ...... .... ...... ... ...... ... ...... .... ... ...... ... ...... ... ....... ... ...... ... ...... .... ...... ... ... .29

Main > TFILE .......................................... ....... ... ...... ... ...... ... ....... ... ...... ... ...... .... ...... ... ....29

Main > MISC........................................................................ ... ...... ... ... ....... ... ...... ... ...... .30

Main > SYSTEM.......................................................................... ... ... ...... ... ....... ... ...... ... .30

Main > SYSTEM (cont.) ...................................... ...... ... ...... .... ...... ... ...... ... ....... ... ...... ... ... .31

4 CALIBRATION ................................................................................ 32

4.1 SELECTING CALIBRATION METHOD ............................................................. 32

4.2 CALIBRATION WITH STANDARD WEIGHTS...................................................... 33

4.2.1 Zero (Dead-Load) Calibration ............................................................. 33

4.2.2 Span Calibration............................................................................... 33

4.3 ELECTRONIC CALIBRATION (E-CAL) ........................................................... 34

4.3.1 Calculating Calibration Values............................................................. 34

4.3.2 Setting Zero Calibration (Dead-Load) Value.......................................... 35

4.3.3 Span (Max. Capacity) Calibration ........................................................ 35

4.4 STORING CALIBRATION DATA ................................................................... 35

4.5 LOCKING AND UNLOCKING CALIBRATION....................................................... 36

4.5.1 Sealing Indicator Enclosure with Stickers............................................. . 36

4.5.2 Securing Load Receptor........................................................ ... ... ... ... . 37

4.5.3 Checking Seal Status and Audit Trail Counter.............................. ... ... ... . 37

5 GENERAL SYSTEM PARAMETERS..................................................... 38

Page 4

Table of Contents

VT300 Technical Manual, Rev. A4 iv Doc # TM-VT300-EN

5.1 EDITING PARAMETERS ............................................................................ 38

5.2 SYSTEM > 1/2CAL > PAR MENU ............................................................ 39

5.2.1 Dual-scale Connecting And Parameter Settings ..................................... 41

5.3 SYSTEM > SET > OPER ...................................................................... 41

6 SERIAL COMMUNICATION.............................................................. 43

6.1 SERIAL PORTS CONFIGURATION................................................................. 43

6.1.1 RS232 Serial Port ................................. ... ... ... ... ................................ 43

6.1.2 RS485 Serial Port ................................. ... ... ... ... ................................ 43

6.2 SETTING PORT OUTPUT .......................................................................... 44

6.2.1 Setting Port 1 Output ........................................................................ 44

6.2.2 Setting Port 2 Output ........................................................................ 45

6.3 OUTPUT FORMATS................................................................................. 46

6.3.1 Continuous Weight Output ................................................................. 46

6.3.2 Continuous Weight Output with Dual Scale Operation............................. 47

6.3.3 Continuous Weight With Tare ............................................................. 47

6.3.4 Alibi Transmit................................................................................... 49

6.3.5 Alibi Mode Commands ....................................................................... 49

Transmit Displayed Weight .............................................................................................49

Command “ZERO” ............................................. ...... ... ...... ... ....... ... ... ...... ... ....... ... ...... ... .49

Character for Print-on-Demand .......................................................................................50

6.3.6 EDP Protocol Output.......................................................................... 50

6.3.7 Remote Printer Output....................................................................... 51

6.3.8 Master-Slave Protocol........................................................................ 51

Master-Slave Commands................................................................................................53

Gross-Tare-Net Weight Transmission .............................................................. .................56

6.4 DEFAULT TICKET FORMATS ...................................................................... 57

6.5 CUSTOM TICKET FORMATS ....................................................................... 58

6.5.1 Creating a Custom Ticket Format ........................................................ 58

6.5.2 Downloading and Uploading Custom Ticket Formats............................... 60

7 OUTPUTS AND DIGITAL INPUT....................................................... 62

7.1 SPECIFICATIONS .................................................................................. 62

7.1.1 Digital Outputs................................................................................. 62

Page 5

Table of Contents

VT300 Technical Manual, Rev. A4 v Doc # TM-VT300-EN

7.1.2

Analog Outputs ................................................................................ 62

7.1.3 Digital Input (Tilt Switch)................................................................... 62

7.2 CONNECTING DIGITAL OUTPUTS AND TILT SWITCH .......................................... 63

7.3 SETTING THRESHOLDS FOR DIGITAL SETPOINTS.............................................. 63

7.3.1 Setpoint Options............................................................................... 64

Setpoint On/Off Combinations........................................................................................ .64

7.4 CONFIGURING ANALOG OUTPUT................................................................. 65

7.4.1 Connecting PCB and Setting Jumper.................................................... 65

7.4.2 Setting Analog Output Parameters ...................................................... 66

7.4.3 Calibrating D/A Converter ............................... ... ... .... ... ... ... ... ... .......... 67

7.5 USING THE TILT SWITCH......................................................................... 68

7.5.1 Tilt Switch Options. ... ... ... ... ... ...................................... ... ... ... ... ... ... .... 68

8 SERVICE OPERATIONS AND TESTING ............................................. 69

8.1 SERVICE OPERATIONS ............................................................................ 69

8.1.1 Setting and Changing System and Operator Password (SYSTEM > PIN).... 69

8.1.2 Setting Date, Time and Serial Number (SYSTEM > DATE)....................... 70

8.1.3 Resetting Parameters (INIT)............................................................... 70

8.1.4 Displaying Remaining Battery Capacity (WEIGH > BATTERY)................... 71

8.1.5 Checking Calibration Seal (MISC > 1/2OIML)............... ... ...................... 71

8.1.6 Viewing Load Cell mV (TEST > CVM) ................................................... 71

8.1.7 Viewing A/D Count (TEST > A/D)........................................................ 71

8.1.8 Locking and Unlocking Keys ............................................................... 72

8.2 TESTING THE INDICATOR......................................................................... 72

8.2.1 Testing ROM/RAM Integrity (TEST > MEM) ........................................... 72

8.2.2 Testing the Keypad and Display (TEST > KBD, LCD) .............................. 73

8.2.3 Testing Digital Input and Outputs (TEST > I/O)........................... ... ... .... 73

8.2.4 Testing Data Received on Both Serial Ports (TEST > PORT)..................... 74

9 SPECIAL WEIGHBRIDGE OPERATIONS ........................................... 75

9.1 CUSTOMIZING WEIGHBRIDGE DESCRIPTIONS ................................................. 75

9.2 BATCH WEIGHING ................................................................................ 76

10 TROUBLESHOOTING....................................................................... 78

Page 6

Table of Contents

VT300 Technical Manual, Rev. A4 vi Doc # TM-VT300-EN

10.1 ERRORS, CAUSES AND REMEDIES............................................................... 78

10.1.1 Hardware and General Errors.............................................................. 78

10.1.2 Printing and EDP Protocol Errors ......................................................... 79

10.1.3 Weighing and Counting Errors ............................................................ 79

10.1.4 Alibi Memory and Accumulated Total Errors .......................................... 80

10.2 CHECKING LOAD CELL CONNECTION............................................................ 80

10.3 CHECKING POWER SUPPLY ....................................................................... 80

10.4 CHECKING DIGITAL OUTPUTS ................................................................... 80

APPENDIX A: TECHNICAL DRAWINGS ...................................................... 81

CONTACTING VISHAY TRANSDUCERS ...................................................... 86

Page 7

Table of Figures

VT300 Technical Manual, Rev. A4 vii Doc # TM-VT300-EN

Table of Figures

F

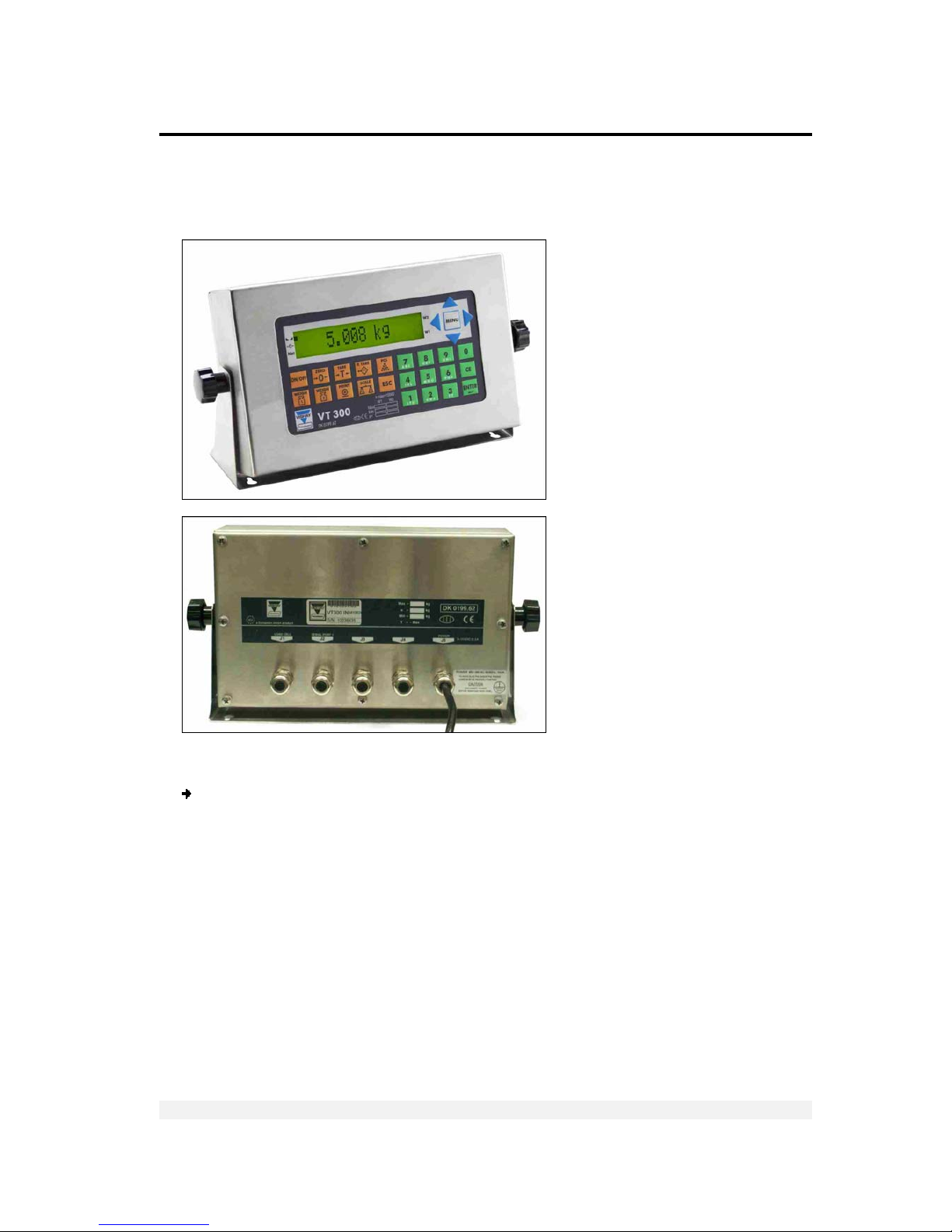

IGURE 1 – DESKTOP MODEL, FRONT AND REAR VIEW .................................................. 18

FIGURE 2 - WALL-MOUNT MODEL, FRONT AND REAR VIEWS ............................................ 19

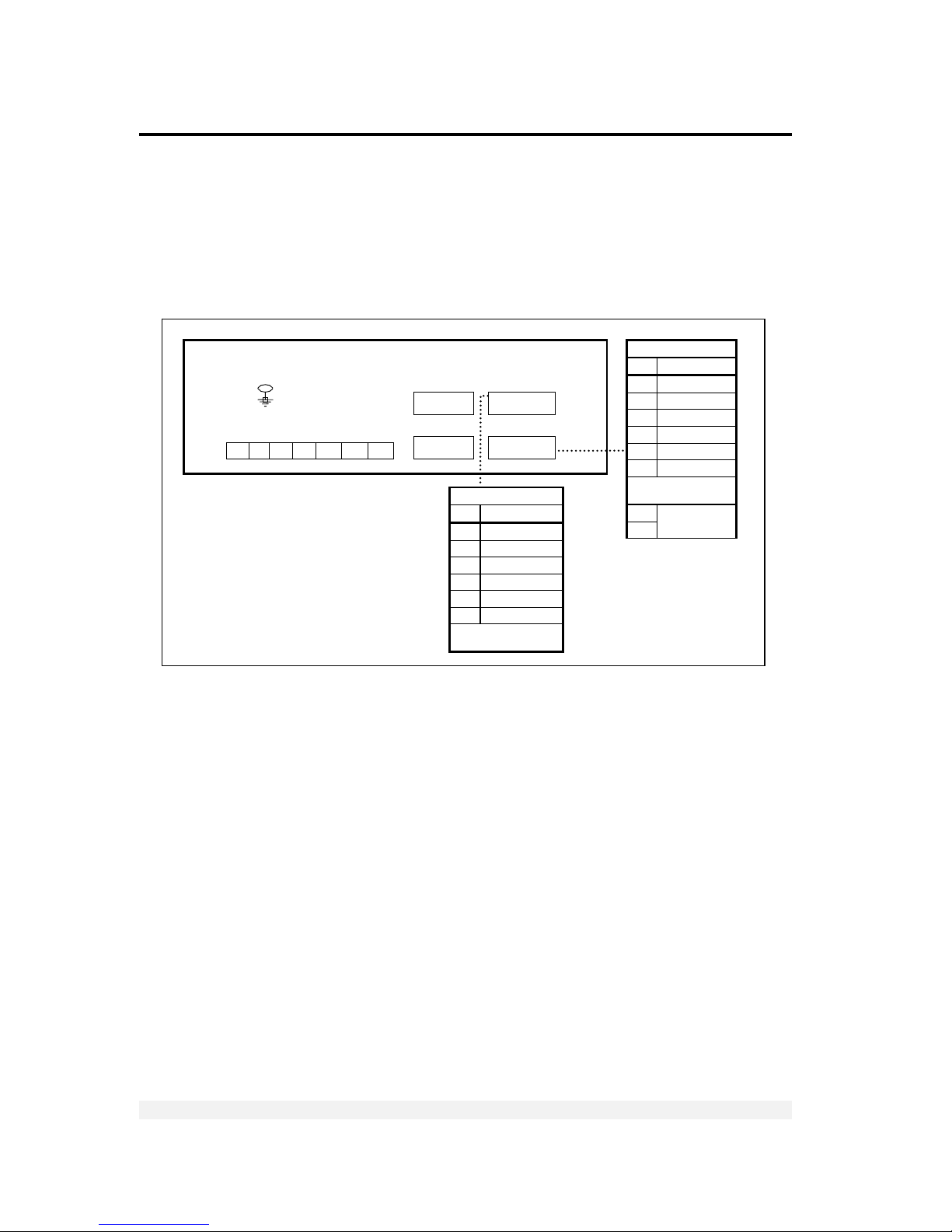

FIGURE 3 – LOAD CELL CONNECTION DIAGRAM FOR DESKTOP MODEL ................................. 20

FIGURE 4 – LOAD CELL CONNECTION DIAGRAM FOR WALL-MOUNT MODEL ............................ 21

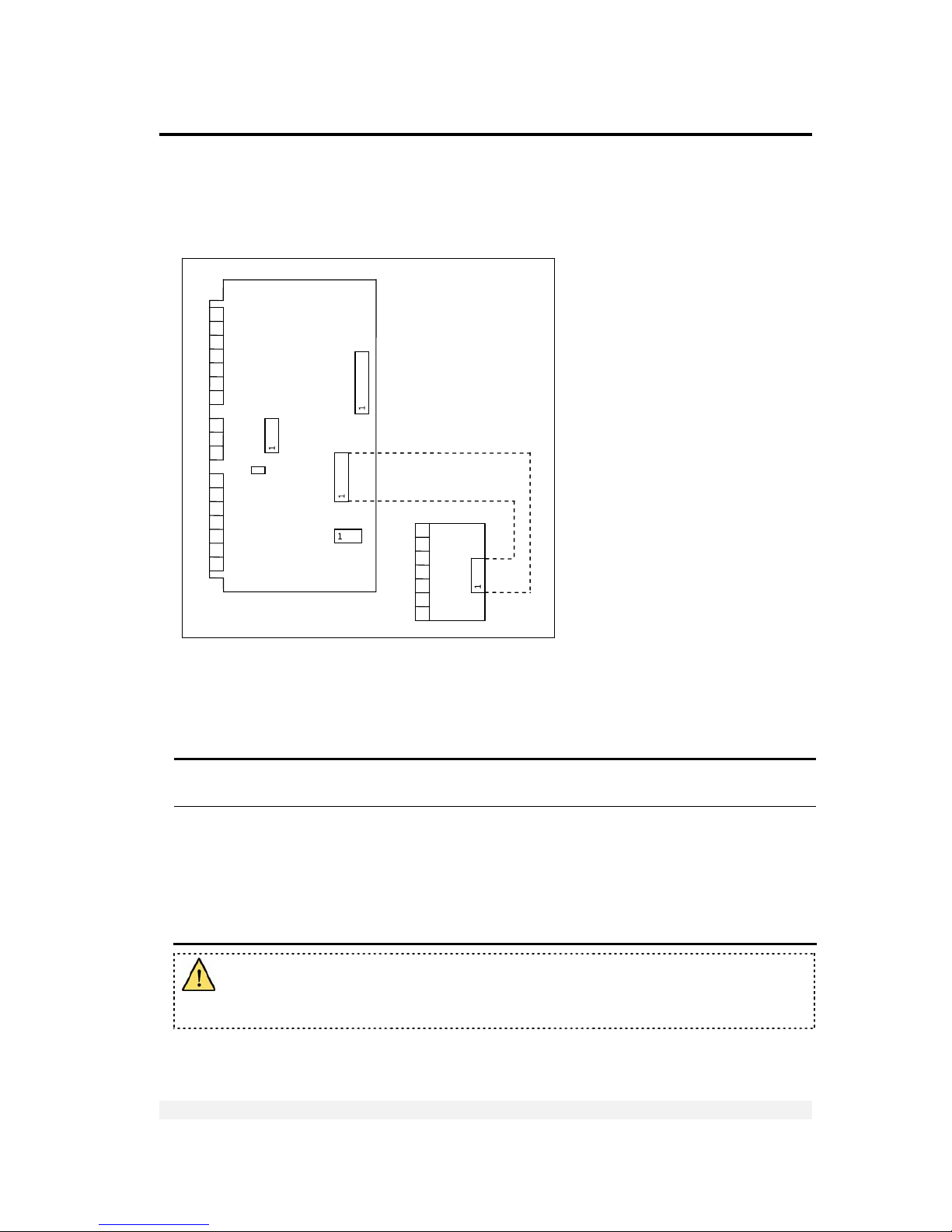

FIGURE 5 – PRINTER AND PC CABLES CONNECTION DIAGRAM ......................................... 22

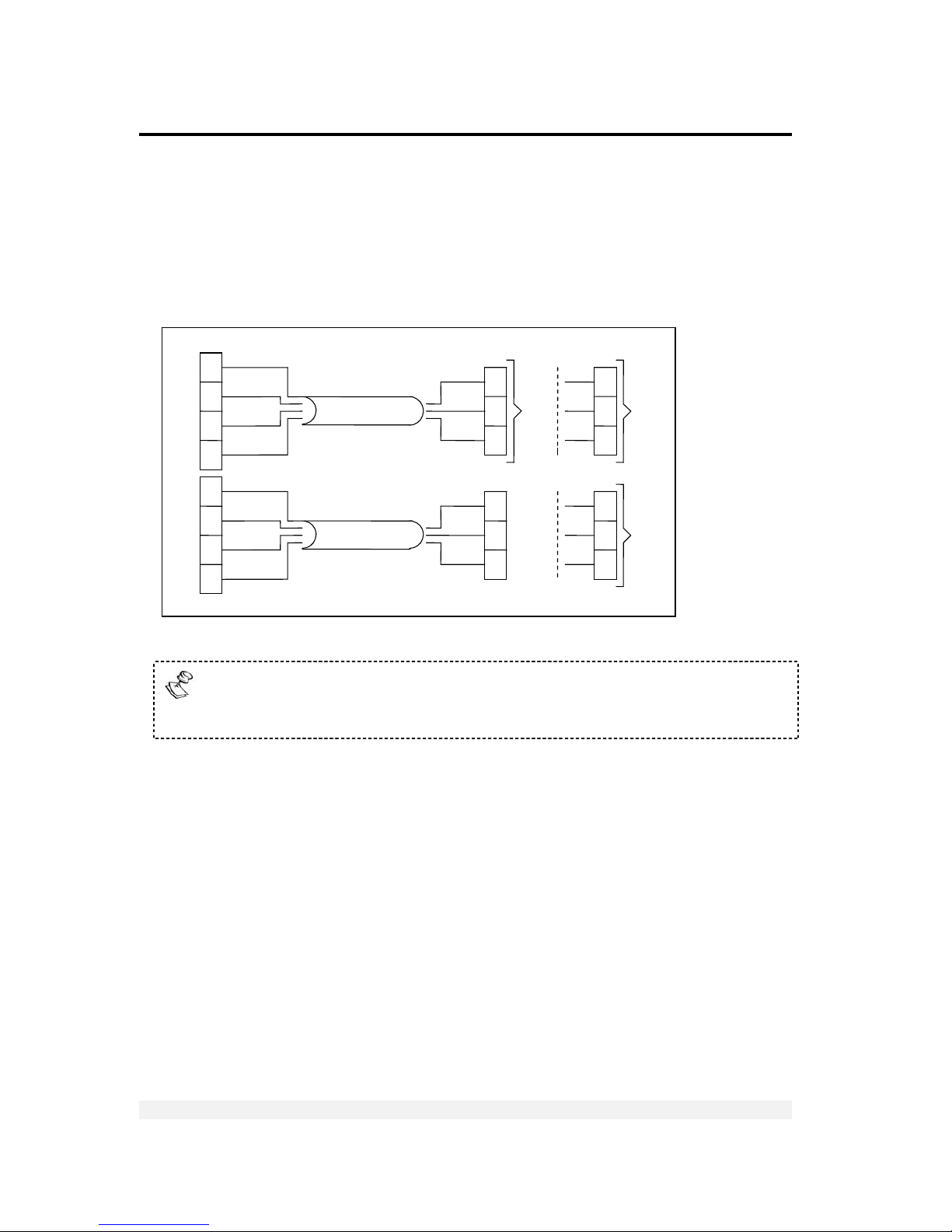

FIGURE 6 – RS485 CABLE CONNECTION DIAGRAM...................................................... 23

FIGURE 7 – POWER CABLE CONNECTION DIAGRAM ...................................................... 23

FIGURE 8 – NON-REMOVABLE STICKER ................................................................... 36

FIGURE 9 – LEAD WIRE SEAL / HARD PLASTIC STICKER ................................................. 36

FIGURE 10 - WALL MOUNT MODEL, SEALING INSTRUCTIONS ........................................... 37

FIGURE 11 – DIGITAL OUTPUT AND TILT SWITCH CONNECTION DIAGRAM............................. 63

Page 8

Legal Notice

VT300 Technical Manual, Rev. A4 viii Doc # TM-VT300-EN

Legal Notice

This manual contains information that is proprietary to Vishay Transducers Ltd.

(“VT”). No part of this publication may be reproduced in any form whatsoever

without prior written approval by VT.

Right, title and interest, all information, copyrights, patents, know-how, trade

secrets and other intellectual property or other proprietary rights relating to this

manual and to the VT300 (“the Product”), and any software components contained

therein, are proprietary products of VT protected under international copyright law

and shall be and remain solely with VT.

VT300 is a registered trademark of VT. No right, license, or interest to such

trademark is granted hereunder, and you agree that no such right, license, or

interest shall be asserted by you with respect to such trademark.

You shall not copy, reverse compile or reverse assemble all or any portion of the

Manual or the Product. You are prohibited from, and shall not, directly or indirectly,

develop, market, distribute, license, or sell any product that supports substantially

similar functionality as the Product, based on or derived in any way from the

Product. Your undertaking in this paragraph shall survive the termination of this

Agreement.

This Agreement is effective upon your opening of the packaging of the Product,

and shall continue until terminated. VT may terminate this Agreement upon the

breach by you of any term hereof. Upon such termination by VT, you agree to

return to VT the Product and all copies and portions thereof. For further

information contact VT at the address below or contact your local distributor.

Page 9

Warranty

VT300 Technical Manual, Rev. A4 ix Doc # TM-VT300-EN

Warranty

Vishay Transducers warrants all instruments it manufactures to be free from defect in materials and factory workmanship, and agrees to

repair or replace any instrument that fails to perform as sp ecified within one year after date of shipment. Coverage of computers,

cameras, rechargeable batteries, and similar items, sold in conjunction with equipment manufactured by Vishay Transducers and bearing

the identifying name of another company, is limited under this warranty to one year after the date of shipment. The warranty on non-

rechargeable batteries and similar consumable items is li mited to the delivery of goods free from defects in materials and factory

workmanship.

This warranty shall not apply to any instrument that has been repaired, worked on or altered by persons unauthorized by Vishay

Transducers in such a manner as to injure, in our sole judgment, the performance, stability, or reliability of the instrument; subjected to

misuse, negligence or accident; or connected, installed, adjusted, or used otherwise than in accordance with the instructions furnished by

us.

At no charge, we will repair, at our plant, or at an authorized repair station, or at our option, replace any of our products found to be

defective under this Warranty.

This Warranty is in lieu of any other warranties, expressed or implied, including any implied warranties of merchantability or fitness for a particular

purpose. There are no warranties which extend beyond the description on the face hereof, Purchaser acknowledges that no salesman, agent,

employee or other person has made any such presentations or warranties or otherwise assumed for Vishay Transducers any liability in connection

with the sale of any goods to the purchase. Buyer hereby waives all rights Buyer may have arising out of any breach of contract or breach of

warranty on the part of Vishay Transducers, to any incidental or consequential damages, including but not limited to damages to property,

damages for injury to the person, damages for loss of use, loss of time, loss of profits or income, or loss resulting from personal injury.

Some states do not allow the exclusion or limitation of incidental or consequential damages for consumer products, so the above

limitations or exclusions may not apply to you.

The Purchaser agrees that the Purchaser is responsible for notifying any subsequent Buyer of goods manufactured by Vishay Transducers

of the warranty provisions, limitations, exclusions and disclaimers stated herein, prior to the time any such goods are purchased by such

Buyer, and the Purchaser hereby agrees to indemnify and hold Vishay Transducers harmless from any claim asserted against or liability

imposed on Vishay Transducers occasioned by the failure of the Purchaser to so noti fy such Buyer. This provision is not intended to afford

subsequent Purchasers any warranties or rights not expressl y granted to such subsequent Purchasers under the law.

Vishay Transducers reserves the right to make any changes in the design or construction of its instruments at any time, without incurring

any obligation to make any change whatever in units previously delivered. Vishay Transducers’ sole liabilities, and Buyer’s sole remedies,

under this agreement shall be limited to the purchase price, or at our sole discretion, to the repair or replacement of any instrument that

proves, upon examination, to be defective, when returned to our factory, transportation prepaid by the Buyer, within the applicable period

of time from the date of original shipment. Return transportation charges of repaired or replacement instruments under warranty will be

prepaid by Vishay Transducers.

Vishay Transducers is solely a manufacturer and assumes no responsibility of any form for the accuracy or adequacy of any test results,

data, or conclusions which may result from the use of its equipment.

The manner in which the equipment is employed and the use to which the data and test results may be put are completely in the hands of

the Purchaser. Vishay Transducers shall in no way be liable for damages consequential or incidental to defects in any of its products.

This warranty constitutes the full understanding between the manufacturer and buyer, and no terms, conditions, understanding or

agreement purporting to modify or vary the terms hereof shall be binding unless hereafter made in writing and signed by an authorized

official of Vishay Transducers.

Page 10

Safety Instructions

VT300 Technical Manual, Rev. A4 x Doc # TM-VT300-EN

Safety Instructions

The following instructions serve as a general guide for the safe operation and

maintenance of the VT300.

Safety Symbols

This symbol indicates potential safety hazards regarding product operation

or maintenance to operator or service personnel.

General Safety Practices

Do not touch or tamper with the power supply when the power cord is connected.

Line voltages may be present even when the product is powered off or a fuse is

blown.

Before working on equipment connected to power lines or to other devices, remove

jewelry or any other metallic object that may come into contact with energized

parts.

The product is intended to be grounded during normal use. Grounding is provided

by connecting the mains plug to a wall socket with a protective earth terminal. The

earth lug provided on the product should be connected to the protective earth at

all times, by a wire with a diameter of 18AWG or wider.

Always connect the ground first and disconnect it last. Do not connect data cables

to ungrounded equipment. Make sure that all other cables are disconnected before

disconnecting the ground.

Special Safety Warnings

Welding on or in the vicinity of the equipment is strictly prohibited.

Use reliable lightening conductors to prevent static loads caused by

thunderstorms.

Page 11

Safety Instructions

VT300 Technical Manual, Rev. A4 xi Doc # TM-VT300-EN

Connection of AC Mains

Make sure that the electrical installation complies with local codes. Always connect

the AC plug to a wall socket with a protective ground.

The maximum permissible current capability of the branch distribution circuit that

supplies power to the product is 16A. The circuit breaker in the building installation

should have high breaking capacity and must operate at short-circuit current

exceeding 35A.

Always connect the power cord first to the equipment and then to the wall socket.

If the power cord cannot be readily disconnected in case of emergency, make sure

that a readily accessible circuit breaker or emergency switch is installed in the

building.

Operating Environment

Ambient

Temperature

Storage temperature: -10C to +70C (14F to 158F).

Operating temperature: -10C to +40C (14F to 104F).

Humidity 40% to 90% RH (non condensing).

Vibration Severe vibration can affect the accuracy of weighing and damage components.

Air The air surrounding the product should be dust-free and should not contain

corrosive gasses or other materials that could adversely effect the product.

Electromagnetic

Fields

Heavy electrical equipment should not be installed near to the weighing

apparatus.

Incoming and

Outgoing Signals

Relays and contacts connected to the equipment must have reliable and

effective interference suppression. This also applies to other equipment within

3 meters of the equipment.

Page 12

Declaration of Conformity

VT300 Technical Manual, Rev. A4 xii Doc # TM-VT300-EN

Declaration of Conformity

Non-Automatic Weighing Instrument (III)

Manufacturer Vishay Transducers

Type/Model VT300

EC Type Approval

Certificate Number

DK 0199.62

Corresponds to the production model described in the EC Type Approval Certificate

and to the requirements of the Council Directive 90/384/EEC as amended and to

the requirements of the following EC Directives:

EN 45501:1994, The Metrological Aspects of Non-Automatic Weighing Machines.

EN 55022:1987, Limits and Methods of Measurement of Radio Interference

Characteristics of Information Technology Equipment.

EN 60950:1992, Safety of Information Technology Equipment.

Date

April 30, 2004

Signature

Benny Shaya, Director R&D/Operations Instruments

Being the responsible person employed and appointed by Vishay Transducers.

Page 13

About this Document

VT300 Technical Manual, Rev. A4 xiii Doc # TM-VT300-EN

About this Document

This document provides technical information for the VT300 Weighbridge Indicator.

It is intended for technical staff, and explains how to install, set up and configure

the indicator, as well as troubleshoot and service it.

For information on how to use the product, see the VT300 User’s Guide.

Chapters and Their Contents

1 Technical

Specifications

General indicator specifications; analog input/output

specs; and digital input/output specs.

Pg. 15

2 Installation Installing and connecting the indicator. Pg. 18

3 Display, Keys and

Menus

Using the VT300 display, keypad and menus;

detailed outline of menus, submenus and options.

Pg. 24

4 Calibration Performing standard weight calibration and

electronic calibration.

Pg. 32

5 General System

Parameters

General parameters in the SYSTEM > 1/2CAL > PAR,

SYSTEM > SET > OPER and SYSTEM > PRP menus.

Pg. 38

6 Serial Communication Setting up communication with printers, host PCs

and other external devices.

Pg. 43

7 Outputs and Digital

Input

Connecting and using the digital input (tilt switch),

digital outputs (setpoints) and analog output.

Pg. 62

8 Service Operations

and Testing

How to set a PIN number, set date and time, view

load cell mV, test the keypad and display, and

perform other service and testing operations.

Pg. 69

9 Special Weighbridge

Operations

Customizing weighbridge descriptions, and

performing batch weighings.

Pg. 75

10 Troubleshooting and

Service

Errors, causes and suggested corrective actions;

maintenance and service instructions.

Pg. 78

Page 14

About this Document

VT300 Technical Manual, Rev. A4 xiv Doc # TM-VT300-EN

Style Conventions

Verdana

Regular text.

Arial Bold

Commands, keys and other parts of the user interface.

Arial Italics

Names of classes, methods, arguments, exceptions, properties, etc. Also used

for special terms, the first time they appear.

Monospace

Text displayed on the LCD or on a computer attached to the product.

Notes, which offer an additional explanation or a hint on how to overcome a

common problem.

Warnings, which indicate potential safety hazards regarding product operation

or maintenance to operator or service personnel.

Page 15

Technical Specifications

General

VT300 Technical Manual, Rev. A4 15 Doc # TM-VT300-EN

1 Technical Specifications

1.1 General

CPU MCU 89C51RD, 64KB Flash ROM, 1KB RAM, 64KB serial EEPROM, real-time clock.

Communication • Serial port 1: RS232C Full duplex, 2400 baud, 1 start, 7 data bits/even parity

or 8 data bits/no parity.

• Serial port 2: (optional): RS232 or RS485 half duplex, 2400-57600 baud, no

or even parity, 7 or 8 data bits.

Display 16 character LCD display (14.5mm height).

Annunciators Net, no motion, minus sign, zero, range 1 and 2.

Keyboard 27-key membrane type with tactile feedback.

Approvals EU type approval, 10,000 divisions, 0199.62.

Accuracy class III.

Resolution Selectable up to 990.000dd (in accordance with regulations).

Max tare effect Full scale (100%).

Auto zero track Off or 0.5dd, setup-selectable.

Weight digits 4, 5 or 6.

Weight steps 1, 2, 5, 10, 20, 50, 100, 200.

Digital filter FIR automatically adjusted to conversion speed, plus post filtering (rolling

average of 1, 2, 4, 8, 16, 32 samples).

Calibration methods Dead load, span and scale parameters via keyboard commands. Calibration can

be performed either by weighing or by entering load cell mV values.

Self diagnostics Hardware and software – MCU watchdog.

Memory failure and I/O failure – program check.

Page 16

Technical Specifications

Analog Input

VT300 Technical Manual, Rev. A4 16 Doc # TM-VT300-EN

1.2 Analog Input

A second analog input may be added as an option, if no analog output is

needed. The same specifications apply.

Load cell excitation ±5V switched polarity or +5VDC with sense.

Connection 6-wire technique. Max 10 load cells, 350Ohm each.

Signal range -0.25 to 1.75mV (Gain=10), -0.25 to 3.75mV (Gain=20).

Sensitivity • Approved scales: min 0.4µV / digit (VSI).

• Non-approved scales: min 0.1µV / digit.

Input amplifier Input noise 0.3µVp-p, input bias current 10nA typical.

A/D Converter Sigma delta 550.000 internal counts max. Conversion speed: 3, 7, 14, 28, 57,

70Hz (selectable).

Linearity Within 0.002% of full scale.

Span temp coefficient

≤ 2ppm/°C.

Zero temp coefficient

≤ 2ppm/°C.

Long-term stability 0.005% of full scale per year.

1.3 Analog Output (Optional)

If no analog output is needed, a second analog input may be added (see 1.2

above). Analog Output is Powered by an external 24VDC (See section 7.1.2 for

specification).

Current or voltage

Selected via jumper JP1 on printed circuit board 761 (see section 7.4.1).

Current output 0-20mA or 4-20mA. Max load resistance 1KΩ (line + termination).

Voltage output 0.02-10V. Min load resistance 1KΩ.

Resolution • Internal: 16 bits.

• External: 16 bits, or in accordance with regulation.

Linearity Better than 0.01% of FSR.

Thermal stability 50ppm/°C typical.

Short-circuit

protection

25mA indefinite duration.

Page 17

Technical Specifications

Digital Input

VT300 Technical Manual, Rev. A4 17 Doc # TM-VT300-EN

1.4 Digital Input

Input voltage 9-24VDC, positive common, optoisolated to 2.5kV.

Input resistance 3.3KΩ.

On delay 2msec max.

Off delay 2msec max.

1.5 Digital Outputs

Output voltage 24VDC ±10% transistor (source) darlington, positive common.

Max current 100mA, leakage current 100µA.

Max off-state voltage 30VDC.

On delay 2msec max.

Off delay 2msec.

Page 18

Installation

Site Requirements

VT300 Technical Manual, Rev. A4 18 Doc # TM-VT300-EN

2 Installation

2.1 Site Requirements

The mounting location must be a stable surface, free of vibrations, heat or humidity.

Avoid direct sunlight on the front of the instrument. The unit should be placed at the

correct height to allow easy reading of the display and convenient keyboard

operation.

2.2 Mounting the Indicator

2.2.1 Desktop Model (Aluminum Enclosure)

All connections to the instrument are made through the rear panel connectors. Strainrelief clamps should be used. The shield should be connected to the metal frame of

the connector. The rear of the VT300 desktop model is shown in Figure 1.

Figure 1 – Desktop model, front and rear view

Page 19

Installation

Mounting the Indicator

VT300 Technical Manual, Rev. A4 19 Doc # TM-VT300-EN

2.2.2 Wall-Mount Model (Stainless Steel Enclosure)

Front and rear views of the unit are shown in Figure 2.

Figure 2 - Wall-mount model, front and rear views

To connect the indicator to the stainless steel wall-mount:

1. Remove the rear panel and lift it carefully.

2. Insert the cables via the cable glands. Strip and connect the cables, as detailed in

sections 2.3, 2.4 and 2.5.

3. Connect the cable shield, either between the plastic and the metal case of the cable

glands, or to the screws supporting the PCBs.

4. Re-install the rear panel.

Page 20

Installation

Connecting Load Cells

VT300 Technical Manual, Rev. A4 20 Doc # TM-VT300-EN

2.3 Connecting Load Cells

2.3.1 Desktop Model (Aluminum Enclosure)

Use 6 x 0.5mm2 shielded cable for load cell connections. Connect the load cells

according to the diagram below.

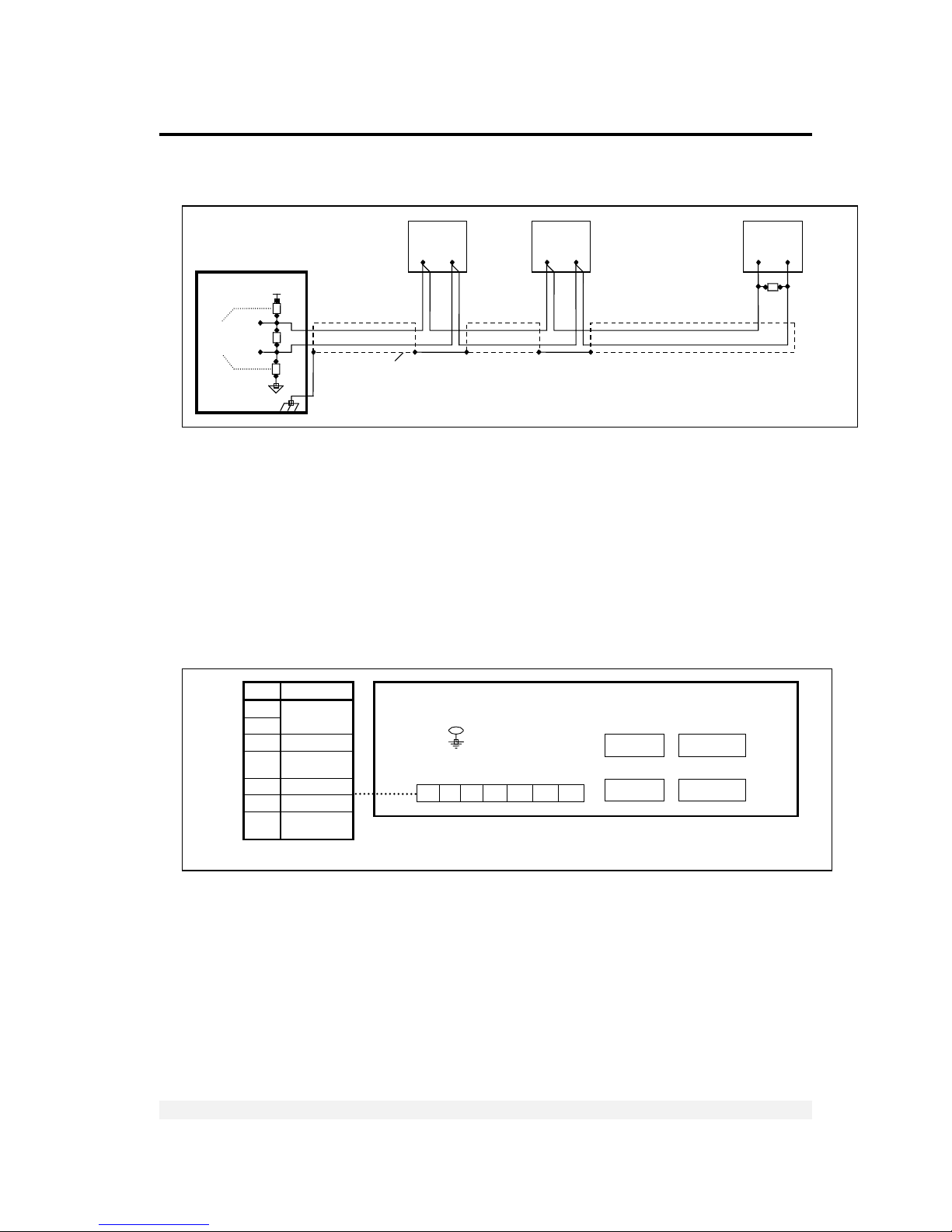

Figure 3 – Load cell connection diagram for des kto p model

1 2 3 4 5 6 7

+ - I1 CI O1 O2 +Co

LOAD CELL 1

Pin Description

1 Excitation (-)

2 Sense (-)

3 Sense (+)

4 Excitation (+)

5 Signal (-)

6 Signal (+)

D-Type Metal Case

(Shield)

7

8

Calibration

Enable

COM 2

COM 1

Load Cell 2

or

Analo

g

Output

Load Cell 1

DB9 fem

DB9 male

DB15

fem/male

DB15 fem

L

OAD CELL 2 (DB15 F)

Pin Description

1 Excitation (-)

2 Sense (-)

3 Sense (+)

4 Excitation (+)

5 Signal (-)

6 Signal (+)

D-Type Metal Case

(Shield)

Page 21

Installation

Connecting Load Cells

VT300 Technical Manual, Rev. A4 21 Doc # TM-VT300-EN

2.3.2 Wall-Mount Model (Stainless Steel)

Use 6 x 0.5mm2 shielded cable for load cell connections. Connect the load cells

according to the diagram below.

Figure 4 – Load cell connec tion diagram for wall-mou nt model

2.3.3 Load Cell Operating Parameters

The load cell utilization ranges are listed in the table below.

Excitation 5VDC, fixed or alternating polarity (setup-selectable) for 10 load cells of 350Ω

each.

Gain / input ranges • For load cell output of 10mV, gain permitted is between -0.25 and 1.75mV/V.

• For load cell output of 20mV, gain permitted is between -0.25 and 3.75mV/V.

The load cells must be chosen so that the input signal to the controller is at

least 0.4µV per scale increment. For load cell output less than 0.4µV/digit, the

controller will still be stable but the full temperature range accuracy is not

guaranteed.

Do not run signal cables together with power cables. Connect the shielding only

where indicated in the drawing. Never use a Megger to check wiring. Never use

plastic insulating tape on load cell connections.

+

POWER

¯

JP1

+

INPUT

¯

OUT1

OUT2

COM

TX RX

SGND

SHIELD

+ SIG

– SIG

+ EX

+ SEN

- SEN

- EX

PCB 801

PCB

765

SHLD

+SIG

–SIG

+EX

+SEN

–SEN

–EX

7 6 5

4

3 2 1

7 6 5

4

3 2 1

7 6 5

4

3 2 1 3 2

1

Page 22

Installation

Serial Connections

VT300 Technical Manual, Rev. A4 22 Doc # TM-VT300-EN

2.4 Serial Connections

For RS232C connection, use 3 x 0.34mm

2

shielded cable.

For RS485 connection, use 2 x 0.34mm

2

shielded twisted pair cable.

2.4.1 Printer and PC Cables

Figure 5 – Printer and PC cables connection diagram

Only the aluminum enclosure has a DB9 connector. The steel enclosure has a

screw terminal on the internal card, to which you should attach the individual

wires.

2.4.2 RS485 Cable Connections

The terminal block on the RS485 board enables connecting two pairs of wires (A, B):

One wire pair for connecting the incoming cable.

A second wire pair for a daisy-chain connection to the next unit on the RS485

bus.

Max 15m

Max 15m

T

o

PC

DB25 Female

Printer DB25 Male

DB9

Metal

Case

3

5

2

3

5

2

DB9

Fem

DB9

Metal

Case

DB9

Fem

Shield

TX GRN

GND BRN

DTR WHI

Shield

TX GRN

GND BRN

DTR WHI

GRN RX

BRN GND

WHI

DTR

GRN RX

BRN GND

WHI

DTR

RX

GND

T

X

RX

GND

DTR

3

7

20

2

5

3

3

7

2

3

7

2

Printer DB25 Male

OR

T

o

Serial

Printer

DB9 Female OR

Page 23

Installation

Connecting Power

VT300 Technical Manual, Rev. A4 23 Doc # TM-VT300-EN

The RS485 cabling configuration is illustrated in Figure 6 below.

Figure 6 – RS485 cable connection diagram

2.5 Connecting Power

VT300 indicators are powered by 85-265VAC, via an internal power supply board. The

mains power cable is supplied with the instrument.

Power should be isolated from other data processing equipment.

Verify that the AC power socket outlet is properly protected. For optimum EMC

performance, keep the length of cable shielding inside the enclosure as short as

possible.

Figure 7 – Power cable connection diagram

1 2 3 4 5 6 7

+ - I1 CI O1 O2 +Co

Pin Description

1

2

Power

9-15 VDC

3 Input 1

4

Input

Common (-)

5 Output 1

6 Output 2

7

Output

Common (+)

COM 2

COM 1

Load Cell 2

or

Analog Outp ut

Load Cell 1

DB9 fem

DB9 male

DB15

fem/male

DB15 fem

Network

Biasing

Resistors

Chassis

Earth

470R

150

R

470R

A

B

RT

+V

White

Shield

Slave #1

(

VT x00)

Slave #2

(

VT x00)

(Up to 30

slaves)

…

Slave #30

(VT x00)

A

B

A

B A B

RT

120R

Termination

Resistor

2X0.34mm2 twisted pair shielded

Max cable length: 1000m

Maste

r

Page 24

Display, Keys and Menus

The Display

VT300 Technical Manual, Rev. A4 24 Doc # TM-VT300-EN

3 Display, Keys and Menus

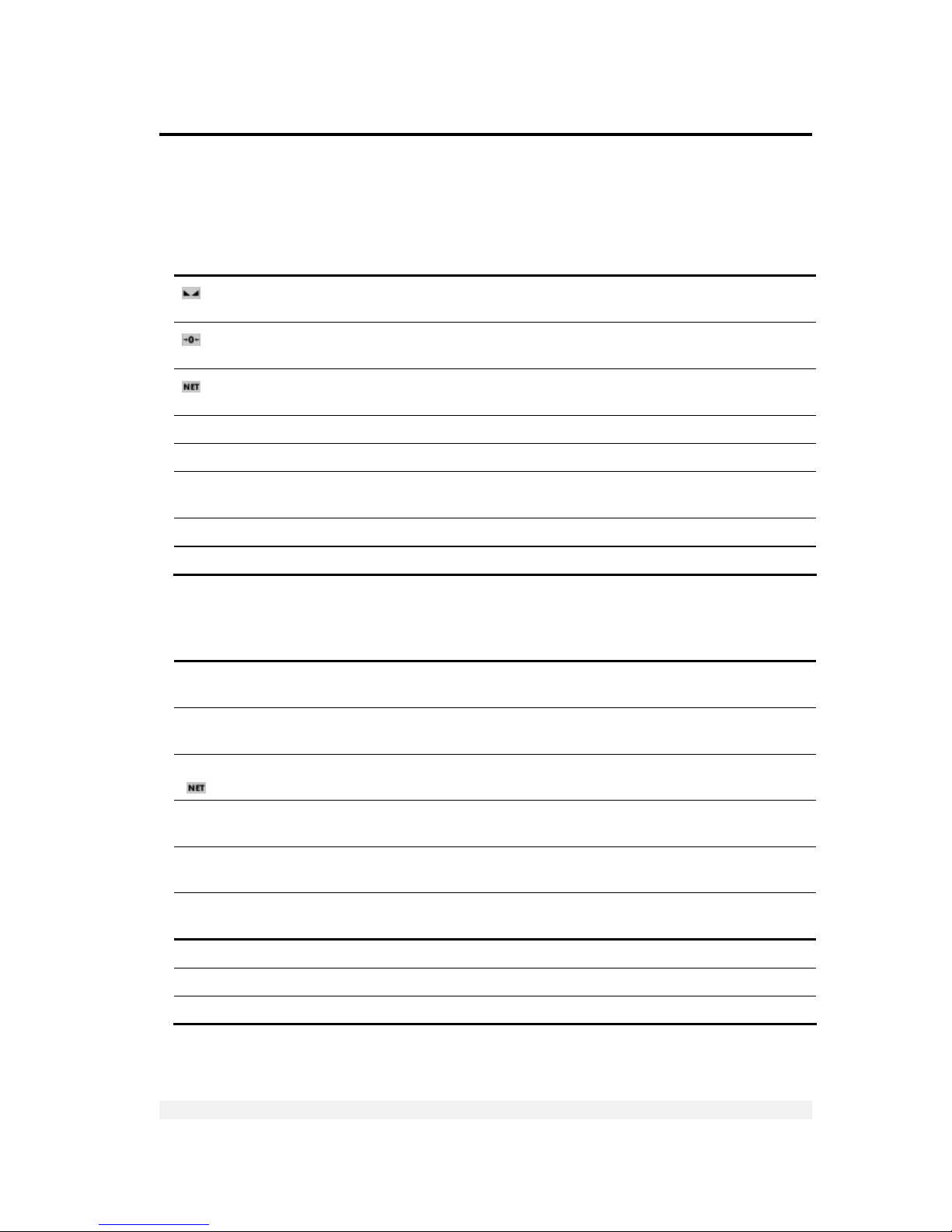

The VT300 front panel can be divided into four areas:

A sixteen-character dot matrix display shows weight information, status

information, and the names of menus and functions.

The function keypad, with ten orange keys, allows you to turn the unit on and off

and perform the most common operations.

A navigation area (to the right of the display) allows you to access and navigate

the menu, which contains more advanced operations.

An alphanumeric keypad, with 12 green keys, allows you to enter numbers and

letters.

3.1 The Display

The VT300 has an LCD display. There are three status annunciators on the left of the

display and two more on the right of the display. Small dots (status annunciators) may

appear next to one or more of these, to show status information such as whether the

scale has been tared or not.

Page 25

Display, Keys and Menus

The Display

VT300 Technical Manual, Rev. A4 25 Doc # TM-VT300-EN

3.1.1 Status Annunciators

There are several icons at the left of the display. A dot shows up next to these to

indicate the current status of the scale or indicator. Status annunciators are often

important to understand what is being shown on the display.

Stable

Active – the scale is stable (necessary for ZERO, T and PRINT).

Inactive – the scale is not stable.

Center of Zero Active – the current weight is at center of zero (or at manual zero).

Inactive – the scale is above or below center of zero.

Net Weight Active – the display is showing net weight.

Inactive – the display is showing gross weight.

S1

Scale 1 Appears on the right of the display to show that the indicator is set to scale 1.

S2

Scale 2 Appears on the right of the display to show that the indicator is set to scale 2.

S0

Sum of Scales Appears on the right of the display to indicate that the display shows the sum of

the weight on scales 1 and 2.

W1 The scale is currently in weight range 1.

W2 The scale is currently in weight range 2.

3.1.2 Common Messages Shown on the Display

Message type Meaning

352.0

Weight of the item on the scale.

24509

Approximate number of units on the scale.

319.0

(

active)

Net weight, or number of units calculated after subtracting the container’s weight.

OVER RANGE

Over range. The item on the scale weighs more than the maximum capacity of the

scale, or the load cell signal is too high.

UNDER RANGE

Under range. The item on the scale weighs less than the minimum capacity of the

scale, or the load cell signal is too low.

E15: PWRUP

ZERO

An error has occurred (see section 10.1.1). In some cases, you can ignore the error

and continue working by pressing ESC.

xxxxxx

Software model number, shown during the power-up sequence.

xxxxxx

Software version issue date, shown during the power-up sequence.

ZERO SCALE

Automatic zeroing, performed at the end of the power-up sequence.

Other types of messages may be shown when you perform specific operations, such

as editing the tare value or displaying battery status.

Page 26

Display, Keys and Menus

Front Panel Keys

VT300 Technical Manual, Rev. A4 26 Doc # TM-VT300-EN

3.2 Front Panel Keys

The keys on the VT300 front panel can serve two functions:

Performing common operations and accessing the menu.

Entering alphanumeric information.

3.2.1 Using Keys to Perform Operations

Key Description Related operations Refer to

Press to zero the scale*. Only works within the zero

range.

Manual zeroing User’s Guide,

section 3.1

Press once to tare the scale*. Press again to view

gross weight.

Taring using current

weight

User’s Guide,

section 3.2

Press to enter a preset tare. Enter the tare value

using the alphanumeric keypad and press ENTER. To

cancel and view gross weight, press ESC.

Preset tare User’s Guide,

section 3.3

When you press this key, the current weight* is

printed to the printer, output to an attached

computer, and added to the accumulated total.

Printing

Section 6.2.1

Press to switch between Weighing Mode and

Counting Mode.

Counting pieces,

weighing

User’s Guide,

chapters 4, 6

Press to turn the indicator on, or to switch it off

when it is running.

Starting the indicator -

Press to perform a first weighing of a vehicle with

unknown tare.

Weighing, printing User’s Guide,

section 5.1.2

Press to weigh a vehicle with known tare, or to

perform a second weighing.

Weighing, printing User’s Guide,

chapter 5

Toggles between scale 1, scale 2 and the sum of

both scales (if two scales are connected).

Two-scale operation -

Enters the menu. The arrows around this button allow you to navigate the

menu.

Section 3.3

Cancels the current operation, exits a menu or exits

a mode.

- -

* If the scale is not stable, the current weight cannot be used for this operation.

Page 27

Display, Keys and Menus

The Menu

VT300 Technical Manual, Rev. A4 27 Doc # TM-VT300-EN

3.2.2 Using Keys to Enter Information

Key Description

0-9 Press a key to enter a digit. When you enter a second digit, the first digit moves to the left and

the new digit takes its place. If you make a mistake, press CE to clear the display.

Press a key twice or more, quickly, to toggle the letters assigned to that key. For example, to

enter the letter ‘b’, press 7 / abc three times quickly (the first time shows the number 7). To enter

‘c’, press 7 / abc four times.

Confirms the current operation or the information entered.

Clears the characters entered.

3.3 The Menu

The menu, accessed by pressing the MENU key ( ), allows you to perform advanced

operations like high-resolution weighing, printing and viewing alibi memory.

This subchapter explains how to use the menu and provides a summary of its

functions. All operations are explained in more detail further in this document.

3.3.1 Using the Menu

To access a function on th e m en u:

1. Press the MENU button, located to the right of the display.

2. Use the S and T arrows to scroll through the menu options.

3. Press ENTER to drill down into a submenu. You can then use the S and T arrows

to scroll through the menu or submenu options.

4. Press ESC to return to a higher menu or submenu level.

5. When you reach the desired menu option, press ENTER to confirm.

Page 28

Display, Keys and Menus

The Menu

VT300 Technical Manual, Rev. A4 28 Doc # TM-VT300-EN

3.3.2 Menu Structure and Options Summary

Main Menu

Menu option Description Refer to

WEIGH

Weighing options. Section 3.3.2,

MAIN > WEIGH

VFILE

V-File and weighbridge options. Section 3.3.2,

MAIN > VFILE

TFILE

Accumulated total options. Section 3.3.2,

MAIN > TFILE

MISC

Viewing calibration lock, viewing battery status, switching

weight display to high resolution.

Section 3.3.2,

MAIN > MISC

SYSTEM

Editing date, setting PINs, general parameters, calibration,

analog output settings, communication settings, ticket

customization, weighbridge customization, tilt switch settings,

setpoint settings, test operations.

Section 3.3.2,

MAIN > SYSTEM

Main > WEIGH

Menu option Submenu option Description Refer to

BATCH WEIGH -

Prints a series of truck weighings as a

unified ticket.

Section 9.2

PCS CNT -

Switches to Counting Mode. User’s Guide,

chapter 6

SETP -

Shows setpoint values and allows editing.

Section 7.3.1

COPY -

Copies last weighing ticket. User’s Guide,

section 7.1.1

ALIBI VIEW

Shows or prints specific alibi memory

records.

User’s Guide,

section 8.1

PRINT

Prints entire alibi memory. User’s Guide,

section 8.2

CSUM

Alibi memory functions. User’s Guide,

section 8.3

Page 29

Display, Keys and Menus

The Menu

VT300 Technical Manual, Rev. A4 29 Doc # TM-VT300-EN

Main > VFILE

Menu options Submenu options Description Refer to

PRINT TARE

Prints all truck tare values. User’s Guide,

section 9.2.1

FIRST

Prints all first weighings. User’s Guide,

section 9.2.2

ALL

Prints the entire V-File. User’s Guide,

section 9.2.3

SELECT

Prints a record for a specific truck. User’s Guide,

section 9.2.4

EDIT TARE -

Creates a new vehicle record. User’s Guide,

section 9.1

CSUM -

Checks V-File memory. User’s Guide,

section 9.3

DEL TARE

Deletes all truck tare values. User’s Guide,

section 9.4

FIRST

Deletes all first weighings. User’s Guide,

section 9.4

ALL

Deletes the entire V-File. User’s Guide,

section 9.4

SELECT

Deletes a record for a specific truck. User’s Guide,

section 9.4

SIZE

Shows the number of records stored in

the V-File, and space available.

User’s Guide,

section 9.5

Main > TFILE

Menu option Description Refer to

STOT Subtotal of net weights. Press PRINT to print, CE to reset.

User’s Guide,

section 4.3.2

TOTAL Accumulated total of net weights. Press PRINT to print, CE to reset.

User’s Guide,

section 4.3.2

Page 30

Display, Keys and Menus

The Menu

VT300 Technical Manual, Rev. A4 30 Doc # TM-VT300-EN

Main > MISC

Menu option Description Refer to

INFO

Displays the indicator model and serial number. -

1OIML

Displays the audit trail counter for scale 1.

Section 4.5.3

2OIML

Displays the audit trail counter for scale 2.

Section 4.5.3

BATTERY

Displays remaining battery capacity as % of max capacity.

Section 8.1.4

HIGH RES

Increases the weight display resolution 10 times. User Guide,

section 4.2

Main > SYSTEM

Menu option Submenu option Description Refer to

SYSTEM DATE

Allows editing date, time and serial print

number (user password protected).

Section 8.1.2

PIN PIN SYS

Setting and changing system password.

Section 8.1.1

PIN OPER

Setting and changing operator password.

Section 8.1.1

PRP Contains one parameter: S.EMPTY.

Chapter 5

1CAL PAR

Scale 1 parameters, including number of

display digits, position of decimal points,

A/D gain, zero range.

Section 5.2

ZERO

Dead-load calibration (standard or

electronic) for scale 1.

Sections 4.2.1,

4.3.2

SPAN

Maximum weight calibration (standard or

electronic) for scale 1.

Sections 4.2.2,

4.3.3

INIT

Resets calibration parameters for scale 1.

Section 8.1.3

WRITE

Stores scale 1 calibration parameters in

persistent memory.

Section 4.4

2CAL PAR

Scale 2 parameters.

Section 5.2

ZERO

Dead-load calibration for scale 2.

Sections 4.2.1,

4.3.2

SPAN

Maximum weight calibration for scale 2.

Sections 4.2.2,

4.3.3

INIT

Resets calibration parameters for scale 2.

Section 8.1.3

WRITE

Stores scale 2 calibration parameters in

persistent memory.

Section 4.4

Page 31

Display, Keys and Menus

The Menu

VT300 Technical Manual, Rev. A4 31 Doc # TM-VT300-EN

Main > SYSTEM (cont.)

Menu option Submenu option Description Refer to

D/A CAL -

Analog output parameters, including

current/voltage, net/gross, resolution.

Section 7.4.2

SET OPER

Operational parameters, including data

format, display brightness, custom print

formats enable/disable, totalizer

enable/disable.

Section 5.3

1COM

Output format and parameters for

communication port 1.

Section 6.2.1

2COM

Output format and parameters for

communication port 2.

Section 6.2.2

INIT Resets all parameters in the SET menu.

Section 8.1.3

FORM (DOWNLOAD,

DEFAULT)

Downloads custom ticket formats and

resets ticket formats to default.

Section 6.5

REFR (EDIT)

Allows viewing and editing weighbridge

descriptions.

Section 9.1

TILT

Tilt switch settings.

Section 7.5

SETP

Allows viewing and editing setpoint

values (both setpoints).

Section 7.3.1

LOCK KEY

Allows locking and unlocking keys on the

keypad.

Section 8.1.8

TEST A/D

Shows A/D converter count.

Section 8.1.7

CVM

Shows load cell mV output.

Section 8.1.6

I/O

Tests outputs and digital input.

Section 8.2.3

KBD

Tests keypad.

Section 8.2.2

LCD

Tests display.

Section 8.2.2

MEM

Tests ROM/RAM integrity.

Section 8.2.1

PORT

Tests communication ports.

Section 8.2.4

Page 32

Calibration

Selecting Calibration Method

VT300 Technical Manual, Rev. A4 32 Doc # TM-VT300-EN

4 Calibration

Before you can calibrate the scale, you must ensure that jumper JP1 is not in the

sealed position (see section 4.5). You must also select a calibration method, using the

CAL MODE scale parameter (see section 4.1). The following methods are available:

Standard weights calibration, in which you record the center of zero, and then

place a known weight on the scale and enter its weight (see section 4.2).

Electronic calibration, in which you enter the mV value of the minimum and

maximum weight (see section 4.3).

Calibration (either standard or electronic, depending on your CAL MODE selection) is

performed using the SYSTEM > 1CAL or SYSTEM > 2CAL menu.

If you have two scales connected to the indicator, each scale has its own

calibration parameters; all the parameters in the 1CAL menu relate to scale 1,

while all the parameters in the 2CAL menu relate to scale 2.

After calibrating the scale, you must store calibration data in persistent memory (see

section 4.4), and seal the calibration lock (see section 4.5).

4.1 Selecting Calibration Method

Before calibrating the scale, you should select the calibration method – standard or

electronic – using the instructions below.

To select a calibration method:

1. Press MENU and navigate to the SYSTEM > 1CAL > PAR menu. Or, if you want to

set the calibration method for scale 2, navigate to SYSTEM > 2CAL > PAR.

2. Scroll through the parameters until you reach CAL MODE. Press ENTER.

3. Use S and T to select one of the options:

WEIGHT – standard weight calibration.

ELECTR – electronic calibration.

4. Press ENTER to confirm your selection.

If you selected WEIGHT, proceed to section 4.2 to perform standard

calibration.

If you selected ELECTR, proceed to section 4.3 to perform electronic

calibration.

Page 33

Calibration

Calibration with Standard Weights

VT300 Technical Manual, Rev. A4 33 Doc # TM-VT300-EN

4.2 Calibration with Standard Weights

To perform calibration with standard weights, you must set the CAL MODE scale

parameter to WEIGHT (see section 4.1).

Calibration with standard weights is done in two stages:

Zero calibration, in which you take a weight measurement when there is nothing

on the scale (see section 4.2.1). This is also called dead-load adjustment.

Span calibration, in which you place a known weight on the scale, and manually

enter its correct weight (see section 4.2.2).

You must perform both of the above for the scale to be calibrated properly.

After calibrating the scale, you must save the values in permanent memories by

entering the setup menus and selecting the WRITE option (see section 4.4). It

is also advised to lock calibration (see section 4.5).

4.2.1 Zero (Dead-Load) Calibration

To perform zero calibration:

1. Press MENU and navigate to SYSTEM > 1CAL > ZERO. Or, if you wish to calibrate

scale 2, navigate to SYSTEM > 2CAL > ZERO.

2. Press ENTER. The display shows EMPTY SCALE. Clear the scale, and wait about 10

seconds.

3. Press ENTER to record the zero position. The display shows WAIT… as 64

measurements are taken and an average calculated. This should take about 10

seconds.

4. The display should now show 0. If the zero point is not accurate, press ESC and go

back to step 1.

4.2.2 Span Calibration

To perform span calibration:

1. Press MENU and navigate to SYSTEM > 1CAL > SPAN. Or, if you wish to calibrate

scale 2, navigate to SYSTEM > 2CAL > SPAN.

2. Press ENTER. The display shows WEIGHT, followed by the maximum capacity of the

scale. Enter the correct calibration weight using the numeric keypad.

3. Press ENTER to confirm the calibration weight. The display shows LOAD SCALE.

4. Place the calibration weight on the scale, and wait about 10 seconds.

5. Press ENTER. The display shows WAIT… as 64 measurements are taken and the

span coefficient calculated. This should take about 10 seconds.

6. Span calibration is now complete. If the weight shown is not accurate, press ESC

and go back to step 1.

Page 34

Calibration

Electronic Calibration (E-CAL)

VT300 Technical Manual, Rev. A4 34 Doc # TM-VT300-EN

4.3 Electronic Calibration (E-CAL)

To perform electronic calibration, you must set the CAL MODE scale parameter to

ELECTR (see section 4.1).

Electronic calibration involves setting two values, using the indicator keypad:

The signal level in mV, corresponding to the zero, or dead-load point (see section

4.3.2).

The signal level in mV, corresponding to the maximum capacity of the scale (see

section 4.3.3).

To learn how to calculate these values from the load cell specifications provided by

the manufacturer, see section 4.3.1 below. You must perform both of the above for

the scale to be calibrated properly.

After calibrating the scale, you must save the values in permanent memories by

accessing the calibration menu and selecting WRITE (see section 4.4). It is also

advised to lock calibration (see section 4.5).

4.3.1 Calculating Calibration Values

Consider the following example. A scale has maximum capacity 30/60kg,

e=0.010/0.020kg, with 4 load cells, each with rated capacity 50kg (2mV) and dead

load 1.940kg. The load cell data, as noted in the manufacturer data sheet, is shown

in the following table.

Load cell Output at 50kg Zero balance

L/C1 1.9793mV 0.0257 mV

L/C2 1.9392mV 0.0276 mV

L/C3 1.9577mV 0.0553 mV

L/C4 1.9640mV -0.0022 mV

To calculate the dead-load and span calibration values:

1. Calculate an average of the load cells’ rated output. In the example above, this

equals (1.9793+1.9392+1.9577+1.9640)/4=1.9600mV.

2. Calculate the combined output of the load cells when the scale is at maximum

capacity. In the example above, this equals 1.9600x60/4x50=0.5880mV. This is

the span calibration value.

3. Calculate an average of the load cells’ zero balance. In the example above, this

equals [0.0257+0.0276+0.0553+(- 0.0022)]/4=0.0266mV.

4. Calculate the scale dead-load. In the example above, this equals

1.9600mV*[1.940Kg/(4*50Kg)]=0.0190mV.

Page 35

Calibration

Storing Calibration Data

VT300 Technical Manual, Rev. A4 35 Doc # TM-VT300-EN

5. Calculate the overall dead-load by adding together the load cell zero balance and

the scale dead-load (calculated in step 4). In the example above, this equals

0.0266+0.0190=0.0456mV. This is the dead-load calibration value.

4.3.2 Setting Zero Calibration (Dead-Load) Value

To set the zero calibration value electronically:

1. Press MENU and navigate to SYSTEM > 1CAL > ZERO. Or, if you wish to calibrate

scale 2, navigate to SYSTEM > 2CAL > ZERO.

2. Press ENTER. The display shows DEAD LOAD: 00000.

3. Enter the overall mV of the dead-load, using the numeric keypad (see section 4.3.1

to learn how to calculate it).

4. Press ENTER to record the zero calibration value. The display shows the

corresponding weight.

4.3.3 Span (Max. Capacity) Calibration

To set the span calibration value electronically:

1. Press MENU and navigate to SYSTEM > 1CAL > SPAN. Or, if you wish to calibrate

scale 2, navigate to SYSTEM > 2CAL > SPAN.

2. Press ENTER. The display shows L/C OUT: 00000.

3. Enter the overall mV of the scale’s maximum capacity, using the numeric keypad

(see section 4.3.1 to learn how to calculate it).

4. Press ENTER to confirm the maximum capacity calibration value. The display shows

the corresponding weight.

4.4 Storing Calibration Data

After calibrating the scale (using either standard or electronic calibration), calibration

data is stored in volatile memory only, and so it is lost when the indicator powers

down. To store the calibration data permanently, follow the procedure below.

To store calibration data:

1. Press MENU and navigate to SYSTEM > 1CAL > WRITE. Or, if you calibrated scale

2, navigate to SYSTEM > 2CAL > WRITE.

2. Press ENTER. The display shows O.K.? AE=Y , CE=N.

3. Press ENTER to confirm. Calibration data is stored in persistent memory, and the

indicator restarts.

Page 36

Calibration

Locking and Unlocking Calibration

VT300 Technical Manual, Rev. A4 36 Doc # TM-VT300-EN

4.5 Locking and Unlocking Calibration

An internal jumper (JP1, located on the main printed circuit board next to the analog

circuit) must be removed to allow access to configuration and calibration parameters.

One way to seal the indicator is to prevent access to this jumper. This is done by

placing a brittle plastic sticker over one of the screws that keeps the cabinet closed.

The indicator also has an Audit Trail Counter, which is incremented every time weight

parameters or calibration data are changed, regardless of whether the change was

saved in EEPROM or not. This counter allows the authorities to check if any calibration

attempt has been made since the last inspection.

A label with an inscribed count (all digits are permanently printed and suffixed

by a hyphen) is placed on the rear side of the instrument. The label is

designated CAL-Nr, and may not be removed without destroying it.

Seals bear the verification mark of a notified body, or an alternative mark of

the manufacturer, according to Annex II, section 2.3 of Directive 90/384/EEC.

4.5.1 Sealing Indicator Enclosure with Stickers

After calibration, you can seal the indicator with two stickers:

A non-removable label, to prevent unauthorized opening of the indicator

enclosure (Figure 8)

A lead wire seal or hard plastic sticker, to prevent unauthorized tampering with

the load cell connector (Figure 9)

Figure 8 – Non-removable sticker

Figure 9 – Lead wire seal / hard plastic sticker

Page 37

Calibration

Locking and Unlocking Calibration

VT300 Technical Manual, Rev. A4 37 Doc # TM-VT300-EN

To seal the indicator:

For the wall-mount (stainless steel) model, refer to Figure 10 below.

Figure 10 - Wall mount model, sealing instructions

For the desktop (aluminum) model, either apply a non-removable sticker to

the load cell connector and to the left edge of the front panel; or fix a lead

seal to the load cell connector on one end, and to the left edge of the front

panel on the other end.

4.5.2 Securing Load Receptor

You can inscribe the serial number of the load receptor as part of the indicator

identification label.

The load receptor bears the serial number of the indicator on its data plate.

4.5.3 Checking Seal Status and Audit Trail Counter

In order to check whether the jumper is still in the sealed position, and that the audit

trail counter has not changed.

To check seal status and audit trail counter:

1. Press MENU and navigate to MISC > 1OIML. Or, if you want to check scale 2,

navigate to MISC > 2OIML.

2. Press ENTER. If JP1 is currently in the sealed position, the word SEALED appears on

the display briefly. Following this, the audit trail counter is displayed.

Lead

seal

Non-

removable

sticker

Page 38

General System Parameters

Editing Parameters

VT300 Technical Manual, Rev. A4 38 Doc # TM-VT300-EN

5 General System Parameters

Several submenus in the SYSTEM menu provide access to general system

parameters, which affect how the scale operates:

The SYSTEM > 1/2CAL > PAR menu contains parameters including the number of

display digits, the position of the decimal point, the A/D gain and the zero range

(see section 5.2).

The SYSTEM > SET > OPER menu contains parameters that effect user

operations. For example, if allows you to enable and disable the totalizer and alibi

memory storage; specify LCD brightness; specify auto power-off time delay, etc.

(see section 5.3).

The SYSTEM > PRP menu contains one parameter, S.EMPTY. This parameter

defines the maximum weight, in kilograms, that will be considered as “empty” by

the indicator.

If you have two scales connected to the indicator, parameters you define in the

latter two menus (OPER and PRP) apply to both of them. Parameters you define

in SYSTEM > 1CAL > PAR refer to scale 1 only, and parameters defined in

SYSTEM > 2CAL > PAR refer to scale 2 only.

Other menus allow you to calibrate the scale (see chapter 4); set communication

parameters (see chapter 6); and set input/output parameters (see chapter 7).

5.1 Editing Parameters

To edit parameters in one of the menus:

1. Press MENU and navigate to the menu you need, using S and T. To enter the

menu press ENTER. To return to a higher menu press ESC.

2. The names of parameters are shown on the display. Use S and T to scroll to the

parameter you wish to edit.

3. To edit the parameter, do one of the following:

If the parameter has two or more preset values, the display will show the

current value (e.g. YES). Use W and X to scroll to the value you need, and

press ENTER to confirm it.

If the parameter is numeric, enter a new value using the numeric keypad.

Press ENTER to confirm the new value.

4. If the parameter is in the 1CAL > PAR or 2CAL > PAR menu, you must perform a

WRITE operation to save the new settings to persistent memory (see section 4.4).

Page 39

General System Parameters

SYSTEM > 1/2CAL > PAR Menu

VT300 Technical Manual, Rev. A4 39 Doc # TM-VT300-EN

5.2 SYSTEM > 1/2CAL > PAR Menu

# Parameter Description Values

00 2SCL ENABLE

(only appears

in 1CAL menu)

Scale 2 enable. Activates the second scale input. This

option only appears in the 1CAL menu. If set to NO,

parameters in the 2CAL menu are ignored.

YES, NO

01 S1+S2 ENABLE

(only appears

in 2CAL menu)

*

Sum of two scales.

YES specifies that the

key should toggle between scale

1 weight, scale 2 weight and the sum of both scales.

NO specifies that the

key should only toggle between

scale 1 weight and scale 2 weight.

YES, NO

02 DISP.DIGITS Number of display digits. 4, 5, 6

03 DEC.POINT * Number of digits after decimal point. Defines the

position of the decimal point.

0-5

04 SCALE DIV. * Display resolution. 1, 2, 5, 10, 20, 50,

100, 200

05 WEIG.RANGE Two most significant digits of full load. 00-99

06 DIG. FILTER Digital filter. If x is entered, filter averages 2x samples. 0

is considered low, 3 is normal and 5 is high.

0-5

07 CONV. RATE * Number of conversions per second. If there are two

scales connected, the sum of their conversion rates

(6P+6P) must be less than 70. Otherwise the unit sets

CONV.RATE=14 for each scale.

3, 7, 14, 28, 57, 70

08 MOTION

SAMPLES

No-motion samples. Number of samples for no-motion

detection. 1 is considered low; 7 is considered high.

1-7

09 AUTO Z TRACK Auto-zero tracking, with a maximum of 0.5 display

divisions per second.

YES, NO

10 INIT ZERO Auto-zero at power up. If enabled, sets the instrument

to zero on power-up. It the starting weight is outside the

zero range, E.15 is displayed (see chapter 10).

YES, NO

11 DUAL FILTER Dual digital filter (anti-flicker). The digital filter increases

automatically when the scale is not in motion.

YES, NO

12 A/D AUTO CON Automatic clearing of A/D converter errors.

NO specifies that, when the A/D converter is enabled,

errors are automatically cleared when the cause is no

longer present.

YES specifies that A/D converter errors should remain on

the display until the operator presses ESC.

YES, NO

13 BATTERY Battery conversion. Enables battery conversion, for

battery-powered models.

YES, NO

Page 40

General System Parameters

SYSTEM > 1/2CAL > PAR Menu

VT300 Technical Manual, Rev. A4 40 Doc # TM-VT300-EN

# Parameter Description Values

14 LEAD Z BLANK Leading zero blank. Enables and disables leading zeroes

in the display.

YES, NO

15 A/D GAIN Load cell amplifier gain adjustment (A/D Gain)

2mV/V setting allows maximum utilization of 1.75mV/V.

4mV/V setting allows maximum utilization of 3.75mV/V.

10=2mV/V

(1.75mV/V utilization)

20=4mV/V

(3.75mV/V utilization)

16 AC EXC. AC/DC excitation.

YES specifies polarity should be switched at a rate

determined by the conversion rate. Switching excitation

results in a more stable zero.

NO sets load cell excitation to DC.

YES=AC

NO=DC

17 ZERO RANGE Zero range. The zero range can be set to 2% or 10% of

maximum capacity.

2%, 10%

18 DUAL MODE * Dual interval or range.

INTERV specifies that the lower display division should be

selected at the defined internal value.

RANGE specifies that the lower display division should be

selected at zero weight.

INTERV, RANGE

19 DUAL RANGE First two digits defining the limit between the two

ranges where the lower display division will be selected

automatically (Max1).

00 - 99

20 PR. BELOW

MIN

Do not print weights below minimum.

YES specifies that weights below 20 scale divisions should

not be printed.

NO specifies that weights below 20 scale divisions should

be printed.

YES, NO

21 CAL MODE Calibration method. Sets calibration to standard weights

(WEIGHT) or electronic (ELECTR). This affects the

calibration dialogs 1/2CAL > ZERO and 1/2CAL > SPAN.

WEIGHT, ELECTR.

22 UNIT SELECT Unit selection. Specifies unit used for measurement:

kilograms or pounds.

KG, LB

* Refer to Section 5.2.1 for how to set parameters when using two scales.

Page 41

General System Parameters

SYSTEM > SET > OPER

VT300 Technical Manual, Rev. A4 41 Doc # TM-VT300-EN

5.2.1 Dual-scale Connecting And Parameter Settings

To connect and set up VT300 for dual-scale operations:

1. Set parameter 2SCL ENABLE(00) to YES, DUAL RANGE(19) to 00, and CONV.RATE

(07) to a value less than 70.

2. Ascertain that the first scale is calibrated and working properly.

3. Connect the second scale to ST5, 7 pins socket in the one side and in the other

side using the mounting posts/spacers provided to:

Stainless Steel Enclosure – The main board.

Aluminum Enclosure – To the indicator’s rear panel.

4. Ascertain that the Scale 2 values for parameters DEC.POINT (02) and SCALE.DIV (03)

are the same as those for Scale 1.

5. After checking that the S2 annunciator is on,(switching with the SCALE key)

calibrate the second scale.

6. The device is now ready to work in dual-scale mode.

7. Use the SCALE key for switching between Scale1(S1 on the display) , Scale2(S2

on the display) or sum of Scale1 and Scale2(S0 on the display).

5.3 SYSTEM > SET > OPER

# Parameter Description Values

01 TOTALIZING M Enable totalizer. YES enables the accumulated total

function for users. NO disables it.

YES, NO

02 WEIGHING MEM Store first weighing in memory. If set to NO, first

weighing information is discarded and cannot be accessed

through the FIRST submenu in the VFILE menu.

YES, NO

03 REFR CODE Number of descriptions for weighbridge operations.

Specifies the number of descriptions (reference codes) the

user is prompted for during first and second weighings. By

default these are VEHICLE, CLIENT and PRODUCT.

If set to 0, weighbridge descriptions are disabled

altogether. In any event, only the first two descriptions are

stored in memory.

0-4

0=disable

descriptions

04 CODE MEM Remember last weighbridge description. Specifies

whether or not the first and second weighing dialogs

should display, for each description such as VEHICLE and

CLIENT, the value entered by the user in the previous

weighing operation.

YES, NO

Page 42

General System Parameters

SYSTEM > SET > OPER

VT300 Technical Manual, Rev. A4 42 Doc # TM-VT300-EN

# Parameter Description Values

05 WAIT UNLOAD Wait for weight to unload before printing again.

YES specifies that after printing, the indicator should not

allow the user to print again, until the scale has been

unloaded.

NO specifies that the user should be able to print again,

even if the scale has not been unloaded.

YES, NO

06 1stW PRINT Print first weighing ticket automatically.

YES specifies that the first weighing data should be

automatically printed.

NO specifies that the user should be prompted to print the

first weighing ticket, and will have the option of canceling

the printing.

Regardless of what is selected here, first weighing data is

saved to memory, unless WEIGHING MEM=NO.

YES, NO

07 USER FORMS Custom weighbridge descriptions and printing

formats.

YES specifies that service personnel should be able to

define custom weighbridge descriptions (reference codes)

and custom print formats.

NO specifies that only the default weighbridge descriptions

and print formats should be available.

YES, NO

08 KEY IN TIME Time for character selection entry (in 0.1 seconds).

00 disables alpha characters.

0-99

09 BRIGHTNESS LCD backlight brightness. Low is the least bright, MID1

is brighter, MID2 is brighter still, HIGH is brightest.

LOW, MID1,

MID2, HIGH

10 DATE FORMA Date format. Select either day-month-year (D-M-Y) or

month-day-year (M-D-Y). In either case, the numbers in

the date will be separated by hyphens (“-”).

D-M-Y, M-D-Y

11 AUTO PWR OFF Power off interval. Specifies the idle time, in minutes,

that should pass before the indicator automatically

switches itself off.

00-99

00=disable

power off

Page 43

Serial Communication

Serial Ports Configuration

VT300 Technical Manual, Rev. A4 43 Doc # TM-VT300-EN

6 Serial Communication

6.1 Serial Ports Configuration

VT300 has two serial ports, designated port 1 and port 2. Port 1 is an RS232 port.

Port 2 is an optional port installed on order, and can be either RS232 or RS485.

6.1.1 RS232 Serial Port

The port is used to connect to serial printers or personal computers.

General Asynchronous serial ASCII, RS232C standard, full duplex.

Protocol 2400 baud, 1 start, 7 data/even parity or 8 data/no parity, 1 stop bit.

OR transmit only, 9600 baud, 1 start, 7 data/even parity or 8 data/no parity, 1 stop bit.

Handshake DTR BUSY per character for fanfold printers or REQUEST PAPER END STATUS for EPSON

TM-295 slip printer.

Connection Cable gland: stainless steel enclosure or DB9 male on rear panel, aluminum enclosure

(J1 or J3). Three-conductor shielded cable, max distance 15m.

Tx = Pin 3

Rx/DTR = Pin 2

GND = Pin 5

6.1.2 RS485 Serial Port

Used to connect to a host computer, remote printer, remote display, etc.

General Asynchronous serial ASCII, RS485 half duplex.

Protocol 2400 to 57600 baud, 1 start, 7 or 8 data, 1 even parity, 1 stop bit.

Connection Cable gland: stainless steel enclosure or DB9 female on rear panel, aluminum enclosure

(J3). Two-conductor twisted-pair shielded cable, max distance 1000m. A termination

resistor 120R may be connected by shorting pins 8 and 9.

A = Pin 6

B = Pin 7

Page 44

Serial Communication

Setting Port Output

VT300 Technical Manual, Rev. A4 44 Doc # TM-VT300-EN