Page 1

Power SMD LED in PLCC-2 Package

FEATURES

• Available in 8 mm tape

•

ESD-withstand voltage:

up to 2 kV according to

• Compatible with IR-reflow, vapor phase

and wave solder processes according to

CECC 00802 and J-STD-020C

• Preconditioning: acc. to JEDEC Level 2a

• Automotive qualified

19225

• Lead (Pb)-free device

• Component in accordance to RoHS 2002/95/EC

and WEEE 2002/96/EC

VLMK33..

Vishay Semiconductors

JESD22-A114-B

e3

DESCRIPTION

The VLMK33.. series is an advanced modification of

the Vishay VLMK33.. series. It is designed to incorporate larger chips, therefore, capable of withstanding a

50 mA drive current.

The package of the VLMK33.. is the PLCC-2 (equivalent to a size B tantalum capacitor).

It consists of a lead frame which is embedded in a

white thermoplast. The reflector inside this package is

filled up with clear epoxy.

APPLICATIONS

• Interior and exterior lighting

• Indicator and backlighting purposes for audio,

video, LCDs, switches, symbols, illuminated advertising etc.

• Illumination purpose, alternative to incandescent

lamps

• Automotive qualified

• General use

PARTS TABLE

PART COLOR, LUMINOUS INTENSITY ANGLE OF HALF INTENSITY (± ϕ) TECHNOLOGY

> (90 to 355) mcd

VLMK33Q2T1-GS08

VLMK33Q2T1-GS18

VLMK33R1S2-GS08

VLMK33R1S2-GS18

VLMK33S1T1-GS08

VLMK33S1T1-GS18

Red, I

V

Red, I

> (90 to 355) mcd

V

Red, I

= (112 to 280) mcd

V

Red, I

= (112 to 280) mcd

V

Red, I

= (180 to 355) mcd

V

Red, I

= (180 to 355) mcd

V

60° AlInGaP on GaAs

60° AlInGaP on GaAs

60° AlInGaP on GaAs

60° AlInGaP on GaAs

60° AlInGaP on GaAs

60° AlInGaP on GaAs

Document Number 81350

Rev. 1.0, 11-Aug-06

www.vishay.com

1

Page 2

VLMK33..

Vishay Semiconductors

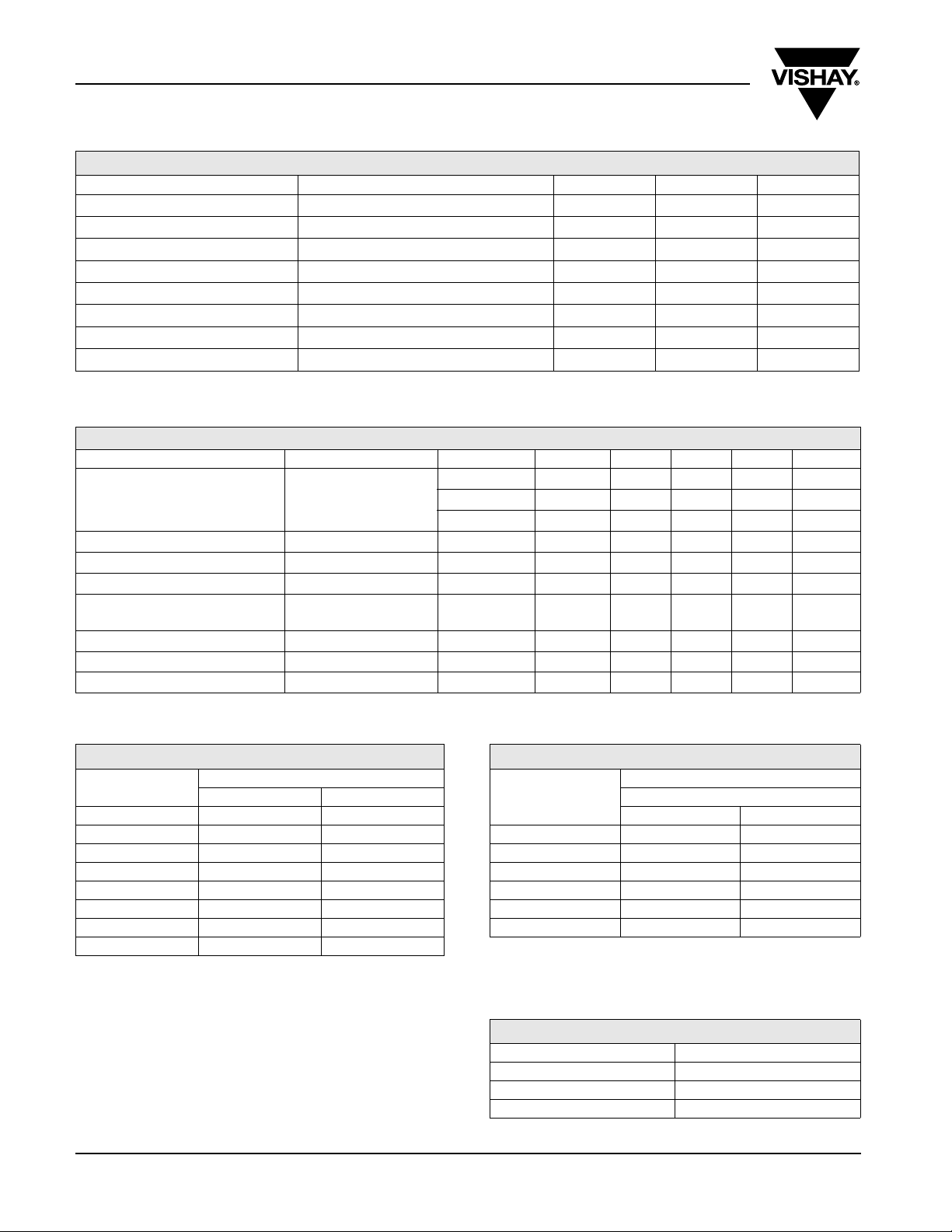

ABSOLUTE MAXIMUM RATINGS1) VLMK33..

PARAMETER TEST CONDITION SYMBOL VALUE UNIT

Reverse voltage

DC Forward current I

Power dissipation P

Junction temperature T

Operating temperature range T

Storage temperature range T

Soldering temperature t ≤ 5 s T

Thermal resistance junction/ambient mounted on PC board (pad size > 16 mm

Note:

1)

T

= 25 °C unless otherwise specified

amb

2) Driving LED in reverse direction is suitable for a short term application

OPTICAL AND ELECTRICAL CHARACTERISTICS1), VLMK33.., RED

PARAMETER TEST CONDITION PART SYMBOL MIN TYP. MAX UNIT

Luminous intensity I

Luminous flux/Luminous intensity

Dominant wavelength

Peak wavelength

Spectral bandwidth

at 50 % I

Angle of half intensity

Forward voltage

Reverse current

Note:

1)

T

= 25 °C unless otherwise specified

amb

rel max

2)

2

)R

= 20 mA

F

VLMK33Q2T1

VLMK33R1S2

VLMK33S1T1

= 20 mA λ

I

F

= 20 mA λ

I

F

φ

I

V

I

V

I

V

V/IV

d

p

V

amb

stg

thJA

R

F

V

j

sd

5V

50 mA

130 mW

125 °C

- 40 to + 100 °C

- 40 to + 100 °C

260 °C

400 K/W

90 355 mcd

112 280 mcd

180 355 mcd

3.14 mlm/mcd

611 617 624 nm

624 nm

IF = 20 mA Δλ 18 nm

= 20 mA

I

F

I

= 20 mA V

F

= 5 V V

V

R

ϕ ± 60 deg

F

R

1.9 2.5 V

0.01 10 μA

LUMINOUS INTENSITY CLASSIFICATION

GROUP

Q1 71 90

Q2 90 112

R1 112 140

R2 140 180

S1 180 224

S2 224 280

T1 280 355

T2 355 450

Note:

Luminous intensity is tested at a current pulse duration of 25 ms and

an accuracy of ± 11 %.

The above type Numbers represent the order groups which include

only a few brightness groups. Only one group will be shipped on

each reel (there will be no mixing of two groups on each reel). In order to ensure availability, single brightness groups will be not orderable. In a similar manner for colors where wavelength groups are

measured and binned, single wavelength groups will be shipped on

any one reel. In order to ensure availability, single wavelength

groups will be not orderable.

www.vishay.com

2

LUMINOUS INTENSITY (MCD)

MIN MAX

COLOR CLASSIFICATION

DOMINANT WAVELENGTH (NM)

GROUP

RED

MIN MAX

1 611 618

2 614 622

3

4

5

6

Note:

Wavelength are tested at a current pulse duration of 25 ms and an

accuracy of ± 1 nm

CROSSING TABLE

VISHAY OSRAM

VLMK33Q2T1 LAT676-Q2T1

VLMK33R1S2 LAT676-R1S2

VLMK33S1T1 LAT676-S1T1

Document Number 81350

Rev. 1.0, 11-Aug-06

Page 3

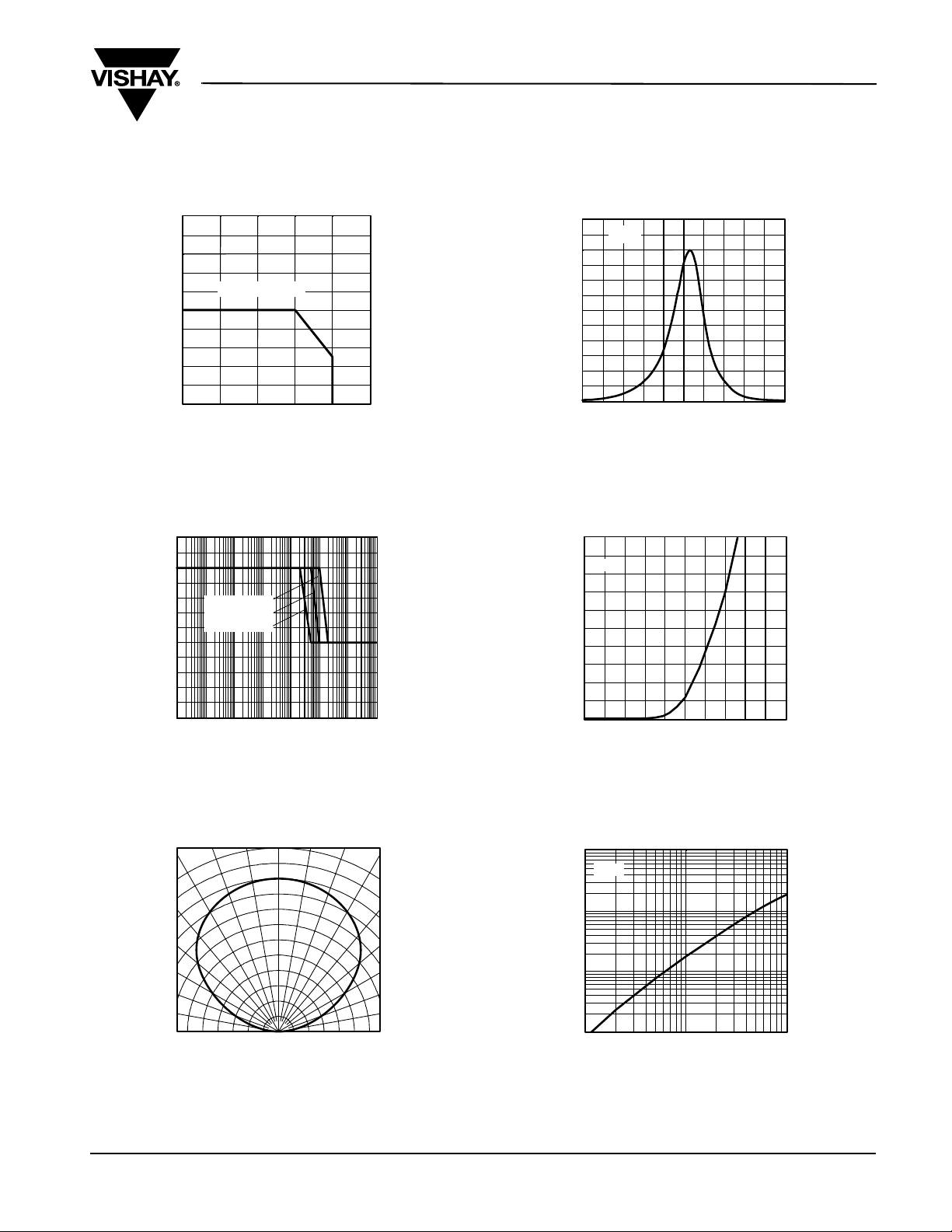

TYPICAL CHARACTERISTICS

T

= 25 °C unless otherwise specified

amb

VLMK33..

Vishay Semiconductors

100

90

80

70

R

60

= 400 K/W

thJA

50

40

30

20

- Forward Current (mA)

F

I

10

0

10 25 50 75 100 125

T

16784

- Ambient Temperature (°C)

amb

Figure 1. Forward Current vs. Ambient Temperature

0.12

0.10

0.08

0.06

tp/T = 0.005

0.05

0.5

0.04

F

I- Forward Current (A)

0.02

0.00

10-510-410-310-210-110010110

17044

t

- Pulse Length (s)

p

2

Figure 2. Forward Current vs. Pulse Length

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

Vrel

I - Relative Luminous Intensity

0.1

0.0

16007

Red

570 580 590 600 610 620 630 640 650 660 670

λ - Wavelength (nm)

Figure 4. Rel. Luminous Intensity vs. Angular Displacement

100

90

Red

80

70

60

50

40

30

F

20

I - Forward Current (mA)

10

0

1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 2.4

17047

V

- Forward Voltage (V)

F

Figure 5. Forward Current vs. Forward Voltage

0°

10° 20°

1.0

0.9

0.8

- Relative Luminous Intensity

0.7

V rel

I

95 10319

0.4 0.2 0 0.2 0.4

0.6

0.6

Figure 3. Rel. Luminous Intensity vs. Angular Displacement

Document Number 81350

Rev. 1.0, 11-Aug-06

30°

40°

50°

60°

70°

80°

10.00

Red

1.00

0.10

V rel

I - Relative Luminous Intensity

0.01

1.00 10.00 100.00

17037

- Forward Current (mA)

I

F

Figure 6. Change of Dominatn Wavelenght vs. Forward Current

www.vishay.com

3

Page 4

VLMK33..

Vishay Semiconductors

2.5

Red

2.0

1.5

1.0

0.5

V rel

I - Relative Luminous Intensity

0.0

- 50 - 25 0 25 50 75 100

17035

T

- Ambient Temperature (°C)

amb

Figure 7. Relative Luminous Intensity vs. Amb. Temperature

6

Red

4

2

0

- 2

250

200

150

50 mA

Re d

100

30 mA

50

0

10 mA

- 50

- 100

- 150

F

V - Change of Forward Voltage (mV)

- 200

- 50 - 25 0 25 50 75 100

17034

T

- Ambient Temperature (°C)

amb

Figure 9. Change of Forward Voltage vs. Ambient Temperature

- 4

- Change of Dom. Wavelength (nm)

d

- 6

- 50 - 25 0 25 50 75 100

- Ambient Temperature (°C)

T

17036

amb

Figure 8. Change of Dominant Wavelength vs.

Ambient Temperature

PACKAGE DIMENSIONS IN MM

3. 5 ± 0.2

0.10

1.75 ±

Pin identification

CA

+ 0.15

2.8

Ø 2.4

+ 0.15

3

Drawing-No. : 6.541-5025.01-4

95 11314-1

Issue: 8; 22.11.05

2.2

technical drawings

according to DIN

specifications

0.9

Mounting Pad Layout

2.6 (2.8)

1.6 (1.9)

Dimensions: IR Reflow and Vaporphase

(Wave Soldering)

1.2

4

area covered with

solder resist

4

www.vishay.com

4

Document Number 81350

Rev. 1.0, 11-Aug-06

Page 5

METHOD OF TAPING/POLARITY AND TAPE AND REEL

VLMK33..

Vishay Semiconductors

SMD LED (VLM3 - SERIES)

Vishay’s LEDs in SMD packages are available in an

antistatic 8 mm blister tape (in accordance with

DIN IEC 40 (CO) 564) for automatic component insertion. The blister tape is a plastic strip with impressed

component cavities, covered by a top tape.

Adhesive Tape

Blister Tape

Component Cavity

94 8670

TAPING OF VLM.3..

5.75

5.25

2.2

2.0

4.0

8.3

7.7

3.6

0.25

94 8668

3.5

Anode

Cathode

1.6

1.4

3.1

3.6

3.4

1.85

1.65

2.05

1.95

4.1

3.9

4.1

3.9

Figure 10.Tape dimensions in mm for PLCC-2

REEL PACKAGE DIMENSION IN MM FOR

SMD LEDS, TAPE OPTION GS08

(= 1500 PCS.)

10.0

13.00

12.75

14.4 max.

9.0

94 8665

63.5

60.5

Identification

Label:

Vishay

Type

Group

Tape Code

Production

Code

Quantity

180

178

120°

4.5

3.5

2.5

1.5

Figure 11.Reel dimensions - GS08

REEL PACKAGE DIMENSION IN MM FOR

SMD LEDS, TAPE OPTION GS18

(= 8000 PCS.) PREFERED

10.4

13.00

12.75

14.4 max.

8.4

62.5

60.0

18857

Identification

Label:

Vishay

Type

Group

Tape Code

Production

Code

Quantity

120°

4.5

3.5

2.5

1.5

321

329

Figure 12.Reel dimensions - GS18

Document Number 81350

Rev. 1.0, 11-Aug-06

www.vishay.com

5

Page 6

VLMK33..

255

240 °C

217 °C

Vishay Semiconductors

SOLDERING PROFILE BARCODE-PRODUCT-LABEL

EXAMPLE:

IR Reflow Soldering Profile for lead (Pb)-free soldering

Preconditioning acc. to JEDEC Level 2a

300

255 °C

250

200

150

Temperature (°C)

100

max. Ramp Up 3 °C/s

50

0

0 50 100 150 200 250 300

19885

max. 120 s

Time (s)

max. 100 s

max. Ramp Down 6 °C/s

Figure 13.Vishay Lead (Pb)-free Reflow Soldering Profile

(acc. to J-STD-020C)

300

250

200

150

100

Temperature (°C)

50

0

TTW Soldering

235 °C...260 °C

first wave

ca. 200 K/s

100 °C...130 °C

0

(acc. to CECC00802)

5 s

2 K/s

forced cooling

50

100

second

wave

ca. 2 K/s

Time (s)

Lead Temperature

dotted line: process limits

150

max. 260 °C

245 °C

max. 30 s

max. 2 cycles allowed

948626-1

full line: typical

ca. 5 K/s

200

106

A

B C D E F G

A) Type of component

B) Manufacturing Plant

C) SEL - Selection Code (Bin):

e.g.: Q2 = Code for Luminous Intensity Group

D) Date Code year/week

E) Day Code (e.g. 2: Tuesday)

F) Batch No.

G) Total quantity

H) Company Code

250

VISHAY

H

37

19988

Figure 14.Double wave soldering of opto devices (all packages)

www.vishay.com

6

Document Number 81350

Rev. 1.0, 11-Aug-06

Page 7

VLMK33..

Vishay Semiconductors

OZONE DEPLETING SUBSTANCES POLICY STATEMENT

It is the policy of Vishay Semiconductor GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating

systems with respect to their impact on the health and safety of our employees and the public, as well as their

impact on the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances (ODSs).

The Montreal Protocol (1987) and its London Amendments (1990) intend to severely restrict the use of ODSs and

forbid their use within the next ten years. Various national and international initiatives are pressing for an earlier ban

on these substances.

Vishay Semiconductor GmbH has been able to use its policy of continuous improvements to eliminate the use of

ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2. Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency (EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C (transitional substances) respectively.

Vishay Semiconductor GmbH can certify that our semiconductors are not manufactured with ozone depleting

substances and do not contain such substances.

We reserve the right to make changes to improve technical design

and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use Vishay Semiconductors products for any unintended or

unauthorized application, the buyer shall indemnify Vishay Semiconductors against all claims, costs,

damages, and expenses, arising out of, directly or indirectly, any claim of personal damage, injury or death

associated with such unintended or unauthorized use.

Vishay Semiconductor GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Document Number 81350

Rev. 1.0, 11-Aug-06

www.vishay.com

7

Page 8

Legal Disclaimer Notice

Vishay

Notice

Specifications of the products displayed herein are subject to change without notice. Vishay Intertechnology, Inc.,

or anyone on its behalf, assumes no responsibility or liability for any errors or inaccuracies.

Information contained herein is intended to provide a product description only. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Vishay's

terms and conditions of sale for such products, Vishay assumes no liability whatsoever, and disclaims any express

or implied warranty, relating to sale and/or use of Vishay products including liability or warranties relating to fitness

for a particular purpose, merchantability, or infringement of any patent, copyright, or other intellectual property right.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications.

Customers using or selling these products for use in such applications do so at their own risk and agree to fully

indemnify Vishay for any damages resulting from such improper use or sale.

Document Number: 91000 www.vishay.com

Revision: 08-Apr-05 1

Loading...

Loading...