Standard SMD LED in PLCC-2

FEATURES

• SMD LEDs with exceptional brightness

• Luminous intensity categorized

• EIA and ICE standard package

• Available in 8 mm tape

• Low power consumption

• Low profile package

• Compatible with IR reflow, vapor phase and wave

solder processes according to CECC 00802 and

94 8553

J-STD-020

• Compatible with automatic placement equipment

• Non-diffused lens: excellent for coupling to light

pipes and backlighting

• Luminous intensity ratio in one packaging unit

I

Vmax./IVmin.

≤ 1.6

• Preconditioning: acc. to JEDEC level 2a

•

ESD-withstand voltage: up to 2 kV according to

JESD22-A114-B

• Compliant to RoHS directive 2002/95/EC and in

accordance to WEEE 2002/96/EC

VLMG31..

Vishay Semiconductors

DESCRIPTION

These devices have been designed to meet the

increasing demand for surface mounting technology.

The package of the VLMG31-series is the PLCC-2.

It consists of a lead frame which is embedded in a

white thermoplast. The reflector inside this package is

filled up with clear epoxy.

APPLICATIONS

• Automotive: backlighting in dashboards and

switches

• Telecommunication: indicator and backlighting in

telephone and fax

• Indicator and backlight for audio and video

equipment

• Indicator and backlight in office equipment

PRODUCT GROUP AND PACKAGE DATA

• Product group: LED

• Flat backlight for LCDs, switches and symbols

• General use

• Package: SMD PLCC-2

• Product series: standard

• Angle of half intensity: ± 60°

PARTS TABLE

PART COLOR, LUMINOUS INTENSITY TECHNOLOGY

VLMG31K1L2-GS08

VLMG31K1L2-GS18

VLMG31K1M2-GS08

VLMG31K1M2-GS18

VLMG31L1M2-GS08

VLMG31L1M2-GS18

Green, I

Green, I

Green, I

Green, I

Green, I

Green, I

= (7.1 to 18) mcd

V

= (7.1 to 18) mcd

V

= (7.1 to 28) mcd

V

= (7.1 to 28) mcd

V

= (11.2 to 28) mcd

V

= (11.2 to 28) mcd

V

GaP on GaP

GaP on GaP

GaP on GaP

GaP on GaP

GaP on GaP

GaP on GaP

Document Number 81323

Rev. 1.2, 14-Sep-09

For technical support, please contact: LED@vishay.com

www.vishay.com

1

VLMG31..

Vishay Semiconductors

ABSOLUTE MAXIMUM RATINGS 1) VLMG31..

PARAMETER TEST CONDITION SYMBOL VAL UE UNIT

Reverse voltage

DC forward current T

Surge forward current t

2)

≤ 60 °C I

amb

≤ 10 µs I

p

Power dissipation P

Junction temperature T

Operating temperature range T

Storage temperature range T

Thermal resistance junction/

ambient

Note:

1)

T

= 25 °C, unless otherwise specified

amb

2)

Driving LED in reverse direction is suitable for short term application.

mounted on PC board

(pad size > 16 mm

2

)

OPTICAL AND ELECTRICAL CHARACTERISTICS 1) VLMG31.., GREEN

PARAMETER TEST CONDITION PART SYMBOL MIN. TYP. MAX. UNIT

VLMG31K1L2

Luminous intensity

2)

Dominant wavelength

Peak wavelength

Angle of half intensity

Forward voltage

Reverse voltage

Junction capacitance

Note:

1)

T

= 25 °C, unless otherwise specified

amb

2)

In one packing unit I

Vmax./IVmin.

≤ 1.6

IF = 10 mA

VLMG31K1M2

VLMG31L1M2

= 10 mA λ

I

F

= 10 mA λ

I

F

= 10 mA

I

F

= 20 mA V

I

F

= 10 µA V

I

R

= 0, f = 1 MHz C

V

R

R

V

R

F

FSM

V

amb

stg

thJA

6V

30 mA

0.5 A

100 mW

j

100 °C

- 40 to + 100 °C

- 40 to + 100 °C

400 K/W

I

V

I

V

I

V

d

p

7.1 18

7.1 28

11.2 28

562 575 nm

565 nm

ϕ ± 60 deg

F

R

j

615 V

2.2 2.8 V

15 pF

mcd

mcd

mcd

LUMINOUS INTENSITY CLASSIFICATION

GROUP LIGHT INTENSITY (mcd)

STANDARD OPTIONAL MIN. MAX.

K

L

M

Note:

Luminous intensity is tested at a current pulse duration of 25 ms and

an accuracy of ± 11 %.

The above Type Numbers represent the order groups which include

only a few brightness groups. Only one group will be shipped on

each reel (there will be no mixing of two groups on each reel). In

order to ensure availability, single brightness groups will not be

orderable.

In a similar manner for colors where wavelength groups are

measured and binned, single wavelength groups will be shipped on

any one reel.

In order to ensure availability, single wavelength groups will not be

orderable.

www.vishay.com

2

1 7.1 9

2 9 11.2

1 11.2 14.0

2 14.0 18.0

1 18.0 22.4

2 22.4 28.0

For technical support, please contact: LED@vishay.com

COLOR CLASSIFICATION

GREEN

GROUP

DOM. WAVELENGTH (nm)

MIN. MAX.

3 562 565

4 564 567

5 566 569

6 568 571

7 570 573

8 572 575

Note:

Wavelengths are tested at a current pulse duration of 25 ms and an

accuracy of ± 1 nm.

CROSSING TABLE

VISHAY OSRAM

VLMG31K1L2 LGT670-K1L2

VLMG31K1M2 LGT670-K1M2

VLMG31L1M2 LGT670-L1M2

Document Number 81323

Rev. 1.2, 14-Sep-09

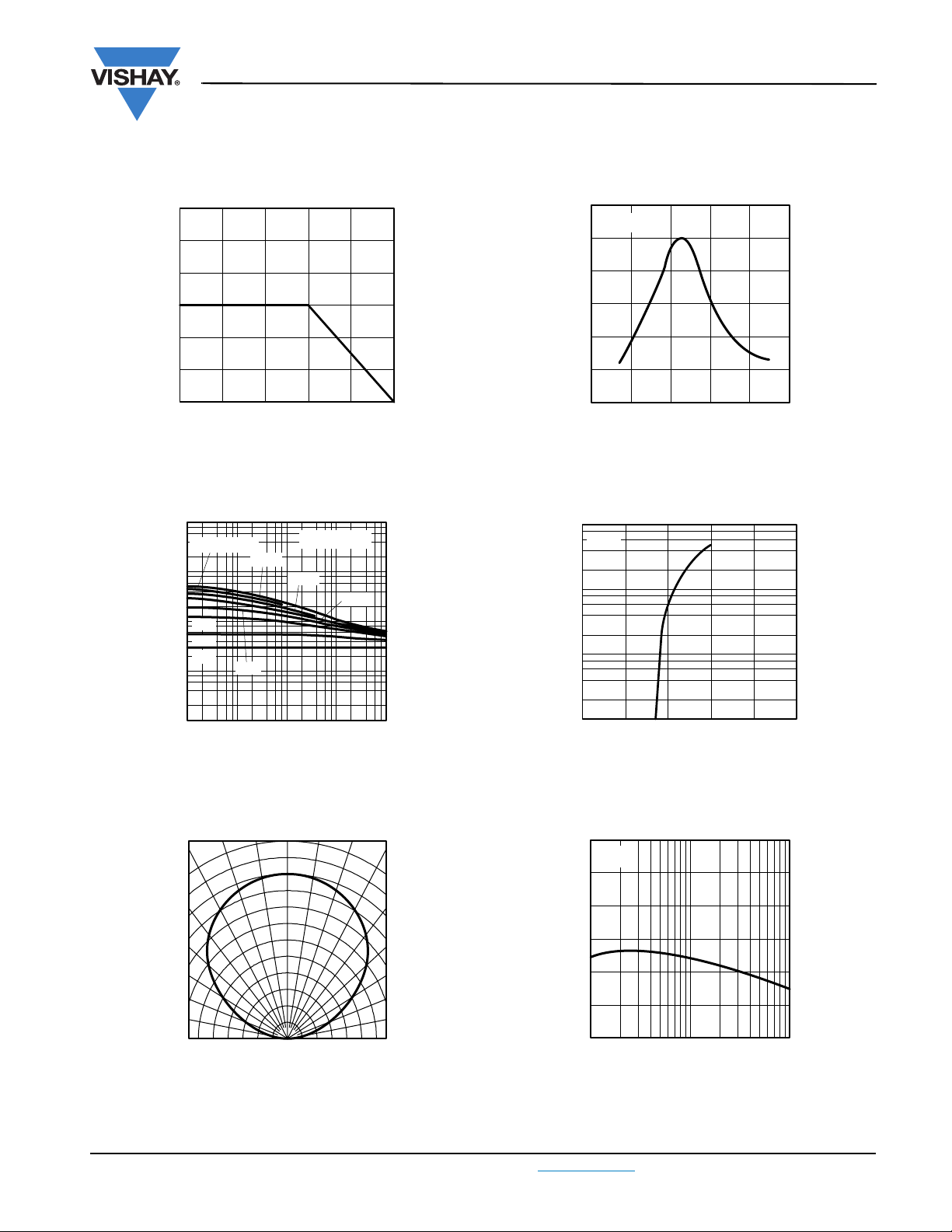

TYPICAL CHARACTERISTICS

T

= 25 °C, unless otherwise specified

amb

VLMG31..

Vishay Semiconductors

60

50

40

30

20

- Forward Current (mA)

F

I

10

95 10905

0

T

- Ambient Temperature (°C)

amb

100806040200

Figure 1. Forward Current vs. Ambient Temperature

10 000

T

< 60 °C

amb

0.02

0.05

1000

100

10

- Forward Current (mA)

F

I

tp/T = 0.005

0.2

0.5

DC

0.01

0.1

1.2

green

1.0

0.8

0.6

0.4

- Relative Intensity

0.2

rel

I

0

520 540 560 580600

95 10038

λ - Wavelength (nm)

Figure 4. Relative Intensity vs. Wavelength

100

green

10

1

F

I- Forward Current (mA)

620

1

0.01 0.1 1 10

95 9985

tp - Pulse Length (ms)

100

Figure 2. Pulse Forward Current vs. Pulse Duration

0°

10° 20°

1.0

0.9

0.8

0.7

- Relative Luminous Intensity

V rel

I

0.4 0.2 0

95 10319

0.6

Figure 3. Rel. Luminous Intensity vs. Angular Displacement

Document Number 81323

For technical support, please contact: LED@vishay.com

Rev. 1.2, 14-Sep-09

30°

40°

50°

60°

70°

80°

ϕ - Angular Displacement

0.1

95 9986

V F - Forward Voltage (V)

52103

4

Figure 5. Forward Current vs. Forward Voltage

2.4

green

2.0

1.6

1.2

0.8

- Specific Luminous Intensity

0.4

spec

I

0

10 20 50 100 200

95 10263

0.5 0.2 0.1 0.05 0.021

500

IF (mA)

/T

t

p

Figure 6. Specific Luminous Intensity vs. Forward Current

www.vishay.com

3

VLMG31..

Vishay Semiconductors

2.0

green

1.6

1.2

0.8

0.4

v rel

I- RelativeLuminous Intensity

0

95 10320

Figure 7. Rel. Luminous Intensity vs. Ambient Temperature

PACKAGE DIMENSIONS in millimeters

20 40 60 800 100

T

-Ambient Temperature (°C)

amb

± 0.2

3.5

± 0.1

1.75

0.9

Pin identification

± 0.15

CA

2.8

Ø 2.4

+ 0.15

3

2.2

Drawing-No.: 6.541-5067.01-4

Issue: 5; 04.11.08

20541

2.6 (2.8)

1.6 (1.9)

technical drawings

according to DIN

specifications

Mounting Pad Layout

1.2

4

area covered with

solder resist

4

www.vishay.com

4

For technical support, please contact: LED@vishay.com

Document Number 81323

Rev. 1.2, 14-Sep-09

VLMG31..

Vishay Semiconductors

METHOD OF TAPING/POLARITY AND TAPE

AND REEL

SMD LED (VLM3 - SERIES)

Vishay’s LEDs in SMD packages are available in an

antistatic 8 mm blister tape (in accordance with

DIN IEC 40 (CO) 564) for automatic component

insertion. The blister tape is a plastic strip with

impressed component cavities, covered by a top tape.

Adhesive tape

Blister tape

Component cavity

94 8670

TAPING OF VLM.3..

3.5

3.1

5.75

5.25

3.6

3.4

1.85

1.6

1.4

4.1

3.9

2.05

1.95

4.1

3.9

1.65

Figure 8. Tape Dimensions in mm for PLCC-2

2.2

2.0

4.0

8.3

7.7

3.6

0.25

94 8668

REEL PACKAGE DIMENSION IN MILLIMETERS

FOR SMD LEDS, TAPE OPTION GS08

(= 1500 PCS.)

10.0

13.00

12.75

14.4 max.

9.0

63.5

60.5

94 8665

Identification

Label:

Vishay

type

group

tape code

production

code

quantity

120°

4.5

3.5

2.5

1.5

180

178

Figure 9. Reel Dimensions - GS08

REEL PACKAGE DIMENSION IN MILLIMETERS

FOR SMD LEDS, TAPE OPTION GS18

(= 8000 PCS.) PREFERRED

10.4

13.00

12.75

14.4 max.

8.4

62.5

60.0

18857

Identification

Label:

Vishay

type

group

tape code

production

code

quantity

321

329

120°

4.5

3.5

2.5

1.5

Figure 10. Reel Dimensions - GS18

SOLDERING PROFILE

IR Reflow Soldering Profile for Lead (Pb)-free Soldering

300

255 °C

250

240 °C

217 °C

200

150

Temperature (°C)

100

50

0

0 50 100 150 200 250 300

19885

Figure 11. Vishay Lead (Pb)-free Reflow Soldering Profile

300

250

200

150

100

Temperature (°C)

948626-1

Figure 12. Double Wave Soldering of Opto Devices (all Packages)

Preconditioning acc. to JEDEC Level 2a

max. 30 s

max. 120 s

max. ramp up 3 °C/s

Time (s)

max. 100 s

max. ramp down 6 °C/s

max. 2 cycles allowed

(acc. to J-STD-020)

TTW Soldering (acc. to CECC00802)

5 s

235 to 260 °C

first wave

ca. 200 K/s

100 to 130 °C

50

0

0 50 100 150 200 250

2 K/s

forced cooling

Time (s)

lead temperature

second

full line: typical

wave

dotted line: process limits

ca. 2 K/s

ca. 5 K/s

max. 260 °C

245 °C

Document Number 81323

Rev. 1.2, 14-Sep-09

For technical support, please contact: LED@vishay.com

www.vishay.com

5

VLMG31..

Vishay Semiconductors

BAR CODE PRODUCT LABEL

EXAMPLE:

106

A

BC D E F G

VISHAY

H

19788

37

A) Type of component

B) Manufacturing plant

C) SEL - selection code (bin):

e.g.: K1 = code for luminous intensity group

4 = code for color group

D)Date code year/week

E) Day code (e.g. 2: Tuesday)

F) Batch no.

G) Total quantity

H) Company code

DRY PACKING

The reel is packed in an anti-humidity bag to protect

the devices from absorbing moisture during

transportation and storage.

Aluminum bag

Label

Reel

RECOMMENDED METHOD OF STORAGE

Dry box storage is recommended as soon as the

aluminium bag has been opened to prevent moisture

absorption. The following conditions should be

observed, if dry boxes are not available:

• Storage temperature 10 °C to 30 °C

• Storage humidity ≤ 60 % RH max.

After more than 672 h under these conditions moisture

content will be too high for reflow soldering.

In case of moisture absorption, the devices will recover

to the former condition by drying under the following

condition:

192 h at 40 °C + 5 °C/- 0 °C and < 5 % RH

(dry air/ nitrogen) or

96 h at 60 °C + 5 °C and < 5 % RH for all device

containers or

24 h at 100 °C + 5 °C not suitable for reel or tubes.

An EIA JEDEC standard JESD22-A112 level 2a label

is included on all dry bags.

CAUTION

1. Shelf life in sealed bag 12 months at <40°C and < 90% relative humidity (RH)

2. After this bag is opened devices that will be subjected to infrared reflow,

vapor-phase reflow, or equivalent processing (peak package body temp.

260°C) must be:

a) Mounted within

b) Stored at <1

3. Devices require baking before mounting if:

a) Humidity Indicator Card is >10% when read at 23°C +

b) 2a or 2b is not met.

4. If baking is required, devices may be baked for:

192 hours

96 hours

24 hours

Bag Seal Date: ______________________________

(If blank, see bar code label)

This bag contains

MOISTURE –SENSITIVE DEVICES

672 hours

0% RH.

at 40°C + 5°C/-0°C and <5%RH (dry air/nitrogen)

at 60±5

at 100±5°C Not suitable for

Note: LEVEL defined by EIA JEDEC Standard JESD22-A113

at factory condition of <

o

Cand <5%RH For

all

device containers or

L E V E L

2a

30°C/60%RH or

5°C or

reels or tubes

or

19786

Example of JESD22-A112 level 2a label

15973

FINAL PACKING

The sealed reel is packed into a cardboard box. A

secondary cardboard box is used for shipping

purposes.

www.vishay.com

6

For technical support, please contact: LED@vishay.com

ESD PRECAUTION

Proper storage and handling procedures should be

followed to prevent ESD damage to the devices

especially when they are removed from the antistatic

shielding bag. Electro-static sensitive devices warning

labels are on the packaging.

VISHAY SEMICONDUCTORS STANDARD

BAR CODE LABELS

The Vishay Semiconductors standard bar code labels

are printed at final packing areas. The labels are on

each packing unit and contain Vishay Semiconductors

specific data.

Document Number 81323

Rev. 1.2, 14-Sep-09

Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 18-Jul-08 1

Loading...

Loading...