Page 1

1

2.54

2.54

7.5

c

b

a

3

b

c

a

9.3

2.54

2.54

1

2.54

2.54

1

7.5

c

b

a

3

(2)

•

•

•

•

•

•

•

•

查询TS63供应商

TS63

Vishay Sfernice

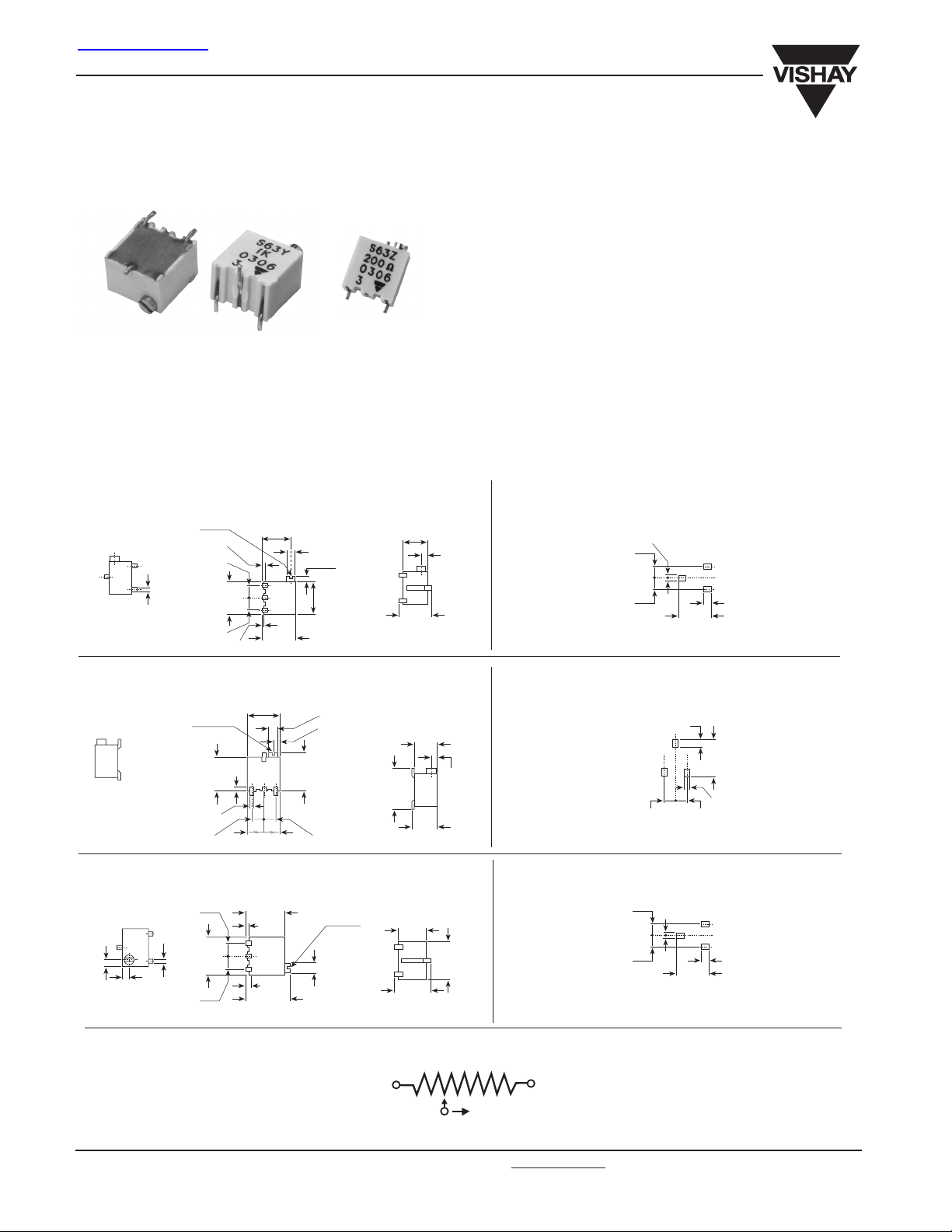

Miniature 1/4” Square Cermet Trimmers, Fully Sealed

The TS63 multiturn trimmer has been designed for use in

PCB surface mounting applications.

Three variations are available according to the positioning of

the control screw and contact positions.

The cermet track gives a high stability performance with an

extended ohmic capacity of 10 Ω to 2M Ω .

DIMENSIONS in millimeters

TS63X

Multi-Turn Surface Mount

FEATURES

0.25 Watt at 85°C

GAM T1

Industrial grade

Multi-turn operation

A low contact resistance variation

Tight tolerances

Low end contact resistance

Full sealing

RECOMMENDED

SOLDERING AREAS

b

TS63Z

TS63Y

1.3 ± 0.1

b

1 ± 0.10

slot 0.5 x 0.5

c

Ø 0.45

slot 0.5 x 0.5

6.85 max

Ø 0.45

2.54

c

2.54

Ø 0.45

2.54

a

5.8 ± 0.10

0.25

2.54

2.54

6.85 max

0.25

6.85 max

0.3

8 max

Ø 1.8

0.7

6.85 max

0.20

6.85 max

Ø 1.8

1.3 ± 0.1

7.6 max

2.54

slot 0.5 x 0.5

Ø 1.8

5 max

1 ± 0.10

6.7 max

5 max

1 ± 0.1

8.85 max

5.3 max

5 max

6.85 max

6.7 max

CIRCUIT DIAGRAM

a

(1)

www.vishay.com For technical questions, contact: sf

30 Revision: 05-Aug-04

b

cw

c

(3)

er@vishay.com Document Number: 51011

Page 2

10 Ω

1 Ω

M

∆

M Ω

∆

∆

∆

∆

TS63

Miniature 1/4” Square Cermet Trimmers, Fully Sealed

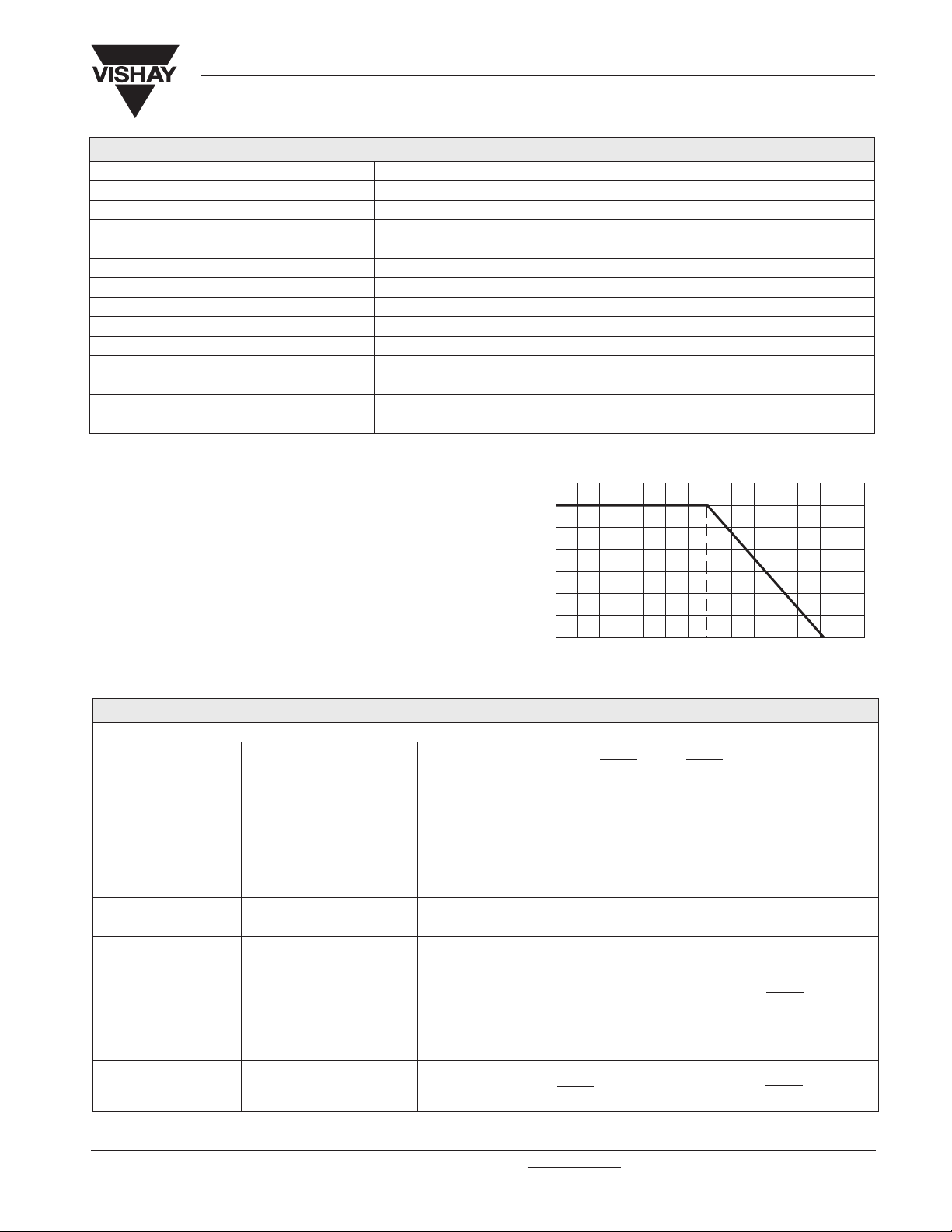

ELECTRICAL SPECIFICATIONS

Resistive Element

Electrical Travel

Resistance Range

Standard Series

Tolerance Standard

On request

Power Rating Linear

Logarithmic

Temperature Coefficient

Limiting Element Voltage (Linear Law)

Contact Resistance Variation

End Resistance (Typical)

Dielectric Strength (RMS)

Insulation Resistance

MECHANICAL SPECIFICATIONS

Mechanical Travel

Operating Torque (max. Ncm) 1.5

End Stop Torque

Unit Weight (max. g)

15 turns ± 5

clutch action

0.5

Multi-Turn Surface Mount

See Standard Resistance Element Data

POWER RATING CHART

0.25

Cermet

13 turns ± 2

to 2M Ω

1 - 2 - 5

±10%

± 5%

0.25W at 85°C

not applicable

250V

2% Rn or 2 Ω

1000V

6

10

Ω

Vishay Sfernice

ENVIRONMENTAL SPECIFICATIONS

Temperature Range

Climatic Category

Sealing

– 55°C to + 155°C

55 / 125 / 56

sealed container

solder immersion IP67

PERFORMANCE

CECC 41100 TYPICAL VALUES AND DRIFTS

TESTS CONDITIONS

Phase A dry heat 125°C

Climatic Sequence

Long Term Damp Heat

Rotational Life

(Electrical, Mechanical)

Load Life

Thermal Shock

Shock

Vibration

Phase B damp heat

Phase C cold – 55°C

Phase D damp heat 5 cycles

56 days

200 cycles at rated power

1000 h at rated power

90’/30’ - ambient temp. 85°C

5 cycles

– 55°C to + 125°C

50 g at 11m secs

3 successive shocks

in 3 directions

10-55Hz

0.75mm or 10 g

for 6 hours

0.125

RATED POWER IN WATT

0

0 50 85 100

AMBIENT TEMPERATURE IN DEGREES CELSIUS

∆ RT

(%) REQUIREMENTS

RT

± 2% ± 3% ± 0.5% ± 1%

± 2% ± 3% ± 0.5% ± 1%

Dielectric strength: 250 V RMS

Insulation resistance: > 100 M Ω

± 2 % ± 2 %

Contact res. variat.: < 3% Rn Contact res. variat.: < 1% Rn

± 2% ± 4% ± 1% ± 2%

Contact res. variat.: < 3% Rn Contact res. variat.: < 1% Rn

± 1.5%

± 1% ± 2% ± 0.1% ± 0.2%

± 1%

R

1-2

R

1-2

V

1-2

V

1-3

V

1-2

V

1-3

± 1% ± 0.5%

± 2% ± 0.1 %

∆ RT

(%)

(%)

RT

Dielectric strength: 1000 V RMS

Insulation resistance: > 10

∆ R

V

V

V

V

R

1-2

1-3

1-2

1-3

1-2

1-2

155

(%)

4

< ± 1%

< ± 0.2%

Document Number: 51011 For technical questions, contact: sf

Revision: 05-Aug-04 31

er@vishay.com www.vishay.com

Page 3

TS63

Ω

Y

Vishay Sfernice

Multi-Turn Surface Mount

Miniature 1/4” Square Cermet Trimmers, Fully Sealed

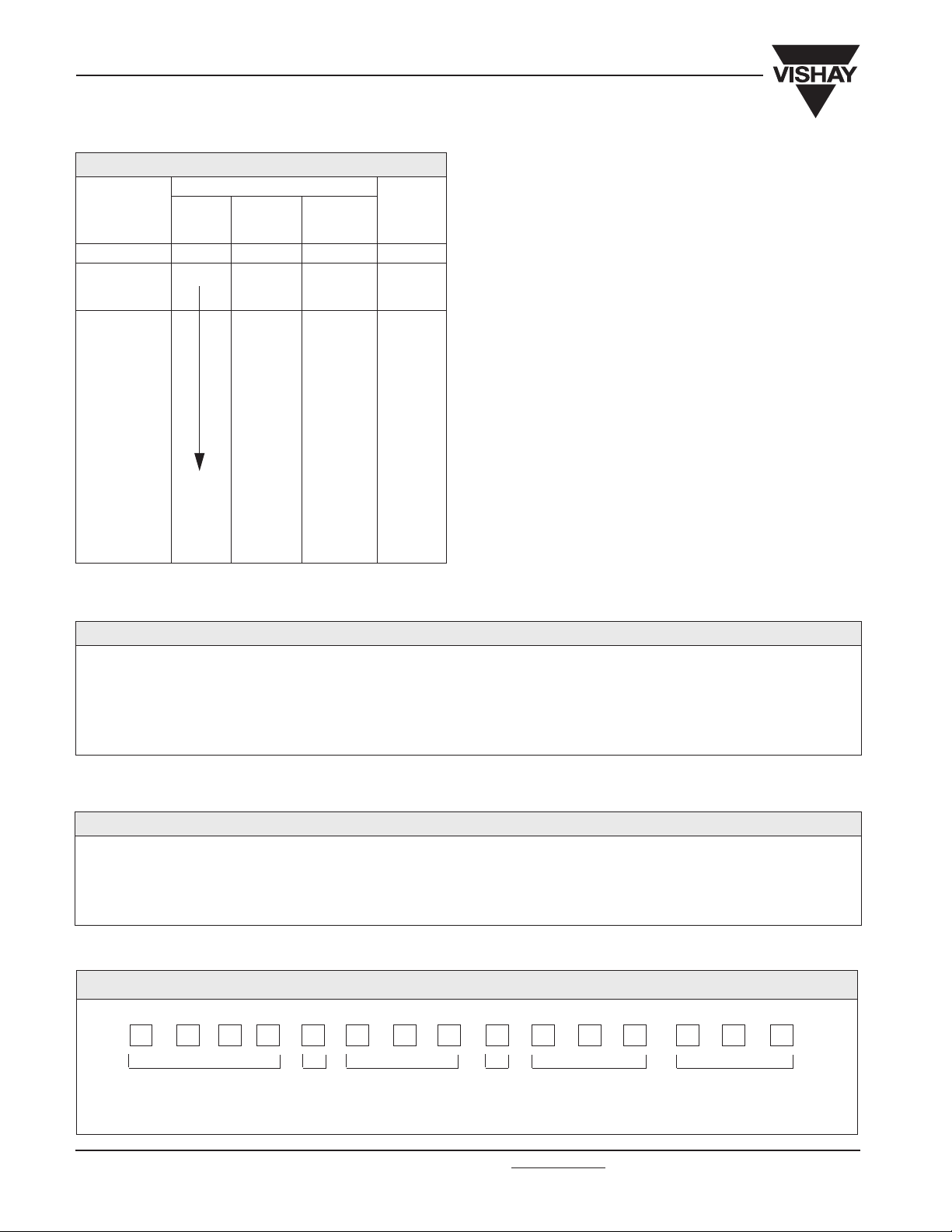

STANDARD RESISTANCE ELEMENT DATA

STANDARD

RESISTANCE

VALUES

10

20

50

100

200

500

1k

2k

5k

10k

20k

25k

50k

100k

200k

250k

500k

1M

2M

MAX.

POWER

AT 85°C

0.25 1.58

0.25

0.25

0.13

0.06

0.03

LINEAR LAW

MAX.

WORKING

VO LTAGE

W V mA ppm/°C

2.23

3.53

7.07

11.2

15.8

22.3

35.3

50

70.7

79

112

158

224

250

250

250

250

5

MAX. CUR.

THROUGH

ELEMENT

158

112

77

50

35

22

15.8

11.2

7.1

5

3.5

3.2

2.2

1.6

1.1

1.1

0.50

0.25

0.125

T.C.

–55°C

+125°C

+ 200

± 100

MARKING

Printed: VISHAY trademark, series, style, ohmic value (in Ω ,

k Ω , M Ω ), tolerance (in %) only if non standard,

manufacturing date, marking of terminal 3.

SOLDERING RECOMMENDATIONS

0

Soldering cycle: 2 mn at 215°C or 5 seconds at 260°C or with

an IRON 40 W: 3 seconds at 350°C.

Soldering is recommended by reflow and vapor phase.

PACKAGING

– X, Y and Z types : on tape and reel (Dia. 330mm) of 500 pieces, code TR500.

– On request in magazine pack by 50 pieces (Tube) code TU.

ORDERING INFORMATION

TS63

SERIES

STYLE

500K Ω

OHMIC VALUE

TOLERANCE

SAP PART NUMBERING GUIDELINES

TS63Y504 KR10

MODEL

STYLE OHMIC

VALUE

TOL

PACKAGING

± 10%

CODE

TR500

PACKAGING

TR500: Tape and reel

On request: TU50: Tube

SPECIAL

(IF APPLICABLE)

See the end of this data book for conversion tables

www.vishay.com For technical questions, contact: sf

32 Revision: 05-Aug-04

er@vishay.com Document Number: 51011

Page 4

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...