T1090P

E

B

查询"T1090P"供应商

Vishay Semiconductors

Silicon NPN Phototransistor

FEATURES

• Package type: chip

• Package form: single chip

• Dimensions (L x W x H in mm): 0.53 x 0.53 x

0.185

• High photo sensitivity

• High radiant sensitivity

• Suitable for visible and near infrared radiation

• Fast response times

21650

DESCRIPTION

T1090P is a silicon NPN phototransistor chip with high

radiant sensitivity, sensitive to visible and near infrared

radiation.

GENERAL INFORMATION

The datasheet is based on Vishay optoelectronics sample testing under certain predetermined and assumed conditions, and is

provided for illustration purpose only. Customers are encouraged to perform testing in actual proposed packaged and used

conditions. Vishay optoelectronics die products are tested using Vishay optoelectronics based quality assurance procedures and

are manufactured using Vishay optoelectronics established processes. Estimates such as those described and set forth in this

datasheet for semiconductor die will vary depending on a number of packaging, handling, use, and other factors. Therefore sold

die may not perform on an equivalent basis to standard package products.

• Compliant to RoHS directive 2002/95/EC and in

accordance to WEEE 2002/96/EC

APPLICATIONS

• Detector in electronic control and drive circuits

PRODUCT SUMMARY

COMPONENT Ica (mA) ϕ (deg) λ

T1090P 0.43 to 0.77 ± 60 440 to 1070

Note

Test condition see table “Basic Characteristics”

0.1

(nm)

ORDERING INFORMATION

ORDERING CODE PACKAGING REMARKS PACKAGE FORM

T1090P-SD-F

Note

MOQ: minimum order quantity

Wafer sawn on foil with disco

frame

MOQ: 50 000 pcs Chip

ABSOLUTE MAXIMUM RATINGS

PARAMETER TEST CONDITION SYMBOL VALUE UNIT

Collector emitter voltage V

Emitter collector voltage V

Collector current I

Junction temperature T

Operating temperature range T

Storage temperature range T

Storage temperature range on foil T

Note

T

= 25 °C, unless otherwise specified

amb

Document Number: 81123 For technical questions, contact: optochipsupport@vishay.com

Rev. 1.4, 29-Mar-10 1

CEO

ECO

C

j

amb

stg1

stg2

70 V

5V

50 mA

100 °C

- 40 to + 100 °C

- 40 to + 100 °C

- 40 to + 50 °C

www.vishay.com

T1090P

Vishay Semiconductors

查询"T1090P"供应商

BASIC CHARACTERISTICS

(1)

Silicon NPN Phototransistor

PARAMETER TEST CONDITION SYMBOL MIN. TYP. MAX. UNIT

Collector emitter breakdown voltage I

Collector emitter dark current V

Collector light current

(Vishay selection type

3

)

= 1 mW/cm2, λ = 950 nm,

E

e

Wavelength of peak sensitivity λ

Range of spectral bandwidth λ

Rise time V

Fall time V

= 5 V, IC = 2 mA, RL = 100 Ω tr, t

CE

= 5 V, IC = 2 mA, RL = 100 Ω tr, t

CE

= 1 mA V

C

= 20 V, E = 0 I

CE

V

= 5 V

CE

(BR)CEO

CEO

I

ca

p

0.1

f

f

70 V

1nA

0.43 0.77 mA

825 nm

440 to 1070 nm

4.3 µs

7.7 µs

Note

(1)

T

= 25 °C, unless otherwise specified

amb

(2)

The measurements are based on samples of die which are mounted on a TO-header without resin coating

(3)

Specific selection types possible

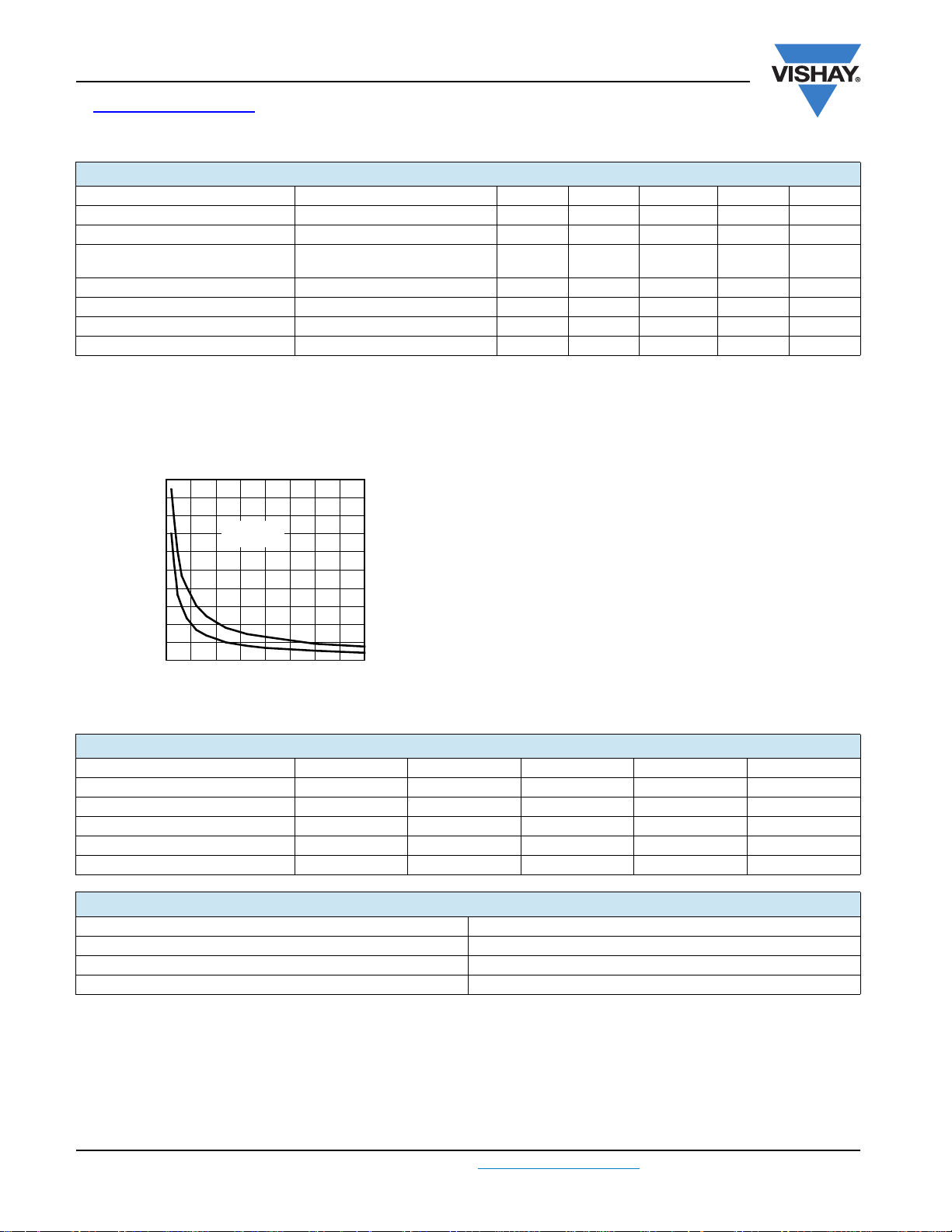

BASIC CHARACTERISTICS

T

= 25 °C, unless otherwise specified

amb

100

90

80

70

60

50

40

30

- Rise/Fall Time (µs)

f

t

/t

t

20599

r

r

20

10

0

0 250 500 750 1000 1250 1500 1750 2000

RL = 100 Ω

t

f

- Collector Current (µA)

I

C

Fig. 1 - Rise/Fall Time vs. Collector Current

MECHANICAL DIMENSIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Length of chip edge (x-direction) L

Length of chip edge (y-direction) L

x

y

Die height H 0.185 mm

Diameter of bond pad base d 0.1 mm

Bond pad emitter a x b 0.1 x 0.1 mm

ADDITIONAL INFORMATION

(1)

Frontside metallization, base (B), emitter (E) Aluminum

Backside metallization, collector AuSb

Dicing Sawing

Die bonding technology Epoxy bonding

Note

(1)

All chips are checked in accordance with the Vishay Semiconductor, specification of visual inspection FVOV6870.

The visual inspection shall be made in accordance with the “specification of visual inspection as referenced”. The visual inspection of chip

backside is performed with stereo microscope with incident light and 40x to 80x magnification.

The quality inspection (final visual inspection) is performed by production. An additional visual inspection step as special release procedure

by QM is not installed.

www.vishay.com For technical questions, contact: optochipsupport@vishay.com

2 Rev. 1.4, 29-Mar-10

0.52 mm

0.52 mm

2

Document Number: 81123

T1090P

查询"T1090P"供应商

Silicon NPN Phototransistor

Vishay Semiconductors

HANDLING AND STORAGE CONDITIONS

• The hermetically sealed shipment lots shall be opened in temperature and moisture controlled cleanroom environment only. It

is mandatory to follow the rules for disposition of material that can be hazardous for humans and environment.

• Product must be handled only at ESD safe workstations. Standard ESD precautions and safe work environments are as defined

in MIL-HDBK-263.

• Singulated die are not to be handled with tweezers. A vacuum wand with non metallic ESD protected tip should be used.

PACKING

Chips are fixed on adhesive foil. Upon request the foils can be mounted on plastic frame or disco frame. For shipment, the wafers

are arranged to stacks and hermetically sealed in plastic bags to ensure protection against environmental influence (humidity and

contamination).

Use for recycling reliable operators only. We can help getting in touch with your nearest sales office. By agreement we will take

back packing material, if it is sorted. You will have to bear the costs of transport. We will invoice you for any costs incurred for

packing material that is returned unsorted or which we are not obliged to accept.

Document Number: 81123 For technical questions, contact: optochipsupport@vishay.com

Rev. 1.4, 29-Mar-10 3

www.vishay.com

Legal Disclaimer Notice

查询"T1090P"供应商

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 18-Jul-08 1

Loading...

Loading...