P-Channel 20-V (D-S) MOSFET

T

Si5447DC

Vishay Siliconix

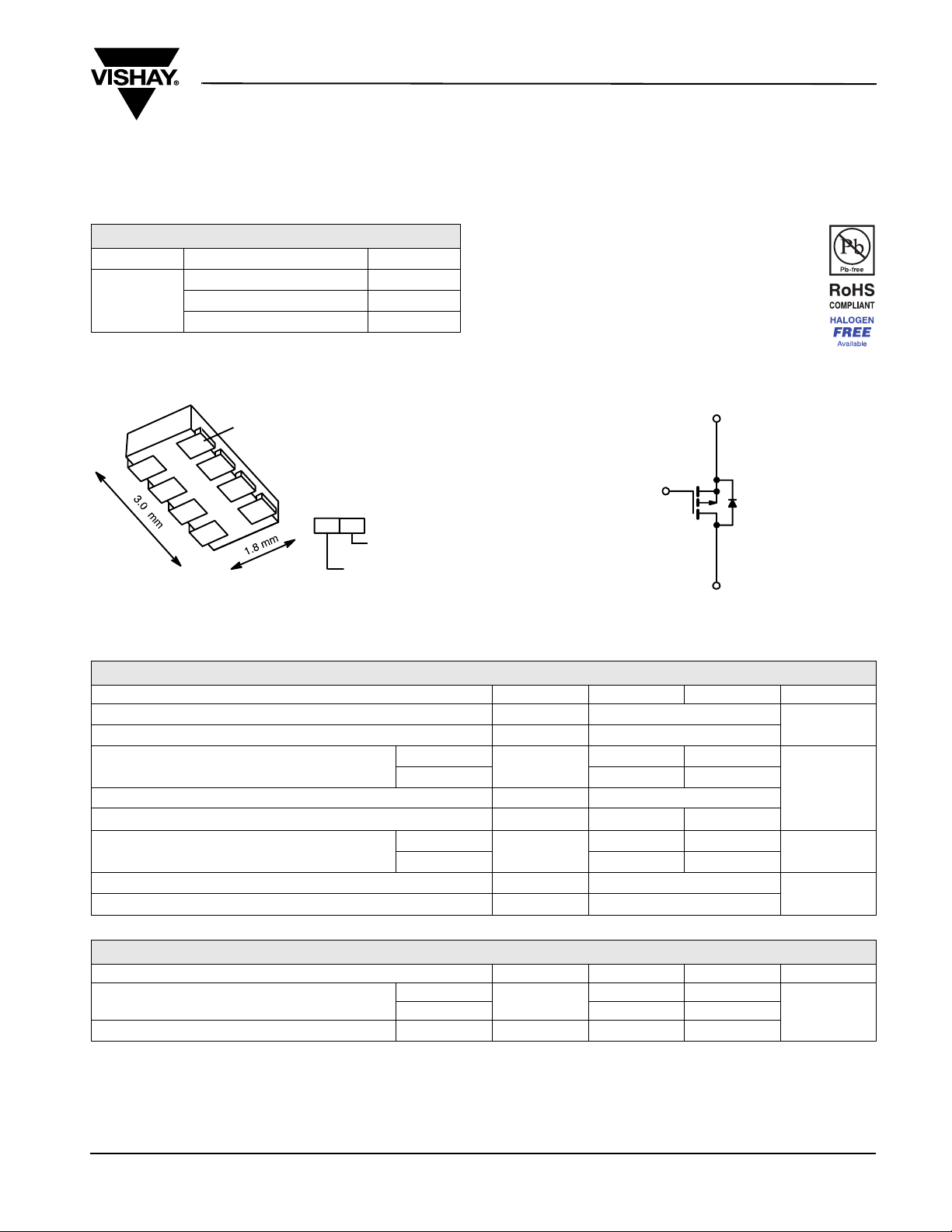

PRODUCT SUMMARY

VDS (V) R

0.076 at V

- 20

0.110 at V

0.160 at V

1206-8 ChipFET

D

D

Ordering Information: Si5447DC-T1-E3 (Lead (Pb)-free)

Si5447DC-T1-GE3 (Lead (Pb)-free and Halogen-free)

D

D

Bottom View

D

D

S

(Ω)I

DS(on)

= - 4.5 V

GS

= - 2.5 V

GS

= - 1.8 V

GS

®

1

G

Marking Code

BG XX

Part #

Code

Lot Traceability

and Date Code

(A)

D

- 4.8

- 4.0

- 3.3

FEATURES

• Halogen-free According to IEC 61249-2-21

Available

• TrenchFET

®

Power MOSFETs: 1.8 V Rated

S

G

D

P-Channel MOSFE

ABSOLUTE MAXIMUM RATINGS TA = 25 °C, unless otherwise noted

Parameter Symbol 5 s Steady State Unit

Drain-Source Voltage

Gate-Source Voltage

Continuous Drain Current (T

= 150 °C)

J

a

Pulsed Drain Current

Continuous Source Current

Maximum Power Dissipation

a

a

Operating Junction and Storage Temperature Range

Soldering Recommendations (Peak Temperature)

b, c

TA = 25 °C

= 85 °C

T

A

TA = 25 °C

= 85 °C

T

A

V

DS

V

GS

I

D

I

DM

I

S

P

D

T

, T

J

stg

- 4.8 - 3.5

- 3.5 - 2.5

- 2.1 - 1.1

- 20

± 8

- 15

2.5 1.3

1.3 0.7

- 55 to 150

260

V

A

W

°C

THERMAL RESISTANCE RATINGS

Parameter Symbol Typical Maximum Unit

Maximum Junction-to-Ambient

a

Maximum Junction-to-Foot (Drain) Steady State

Notes:

a. Surface Mounted on 1" x 1" FR4 board.

t ≤ 5 s

Steady State 83 95

R

thJA

R

thJF

b. See Reliability Manual for profile. The ChipFET is a leadless package. The end of the lead terminal is exposed copper (not plated) as a result

of the singulation process in manufacturing. A solder fillet at the exposed copper tip cannot be guaranteed and is not required to ensure

adequate bottom side solder interconnection.

c. Rework Conditions: manual soldering with a soldering iron is not recommended for leadless components.

Document Number: 71256

S09-0129-Rev. C, 02-Feb-09

43 50

°C/W

14 20

www.vishay.com

1

Si5447DC

Vishay Siliconix

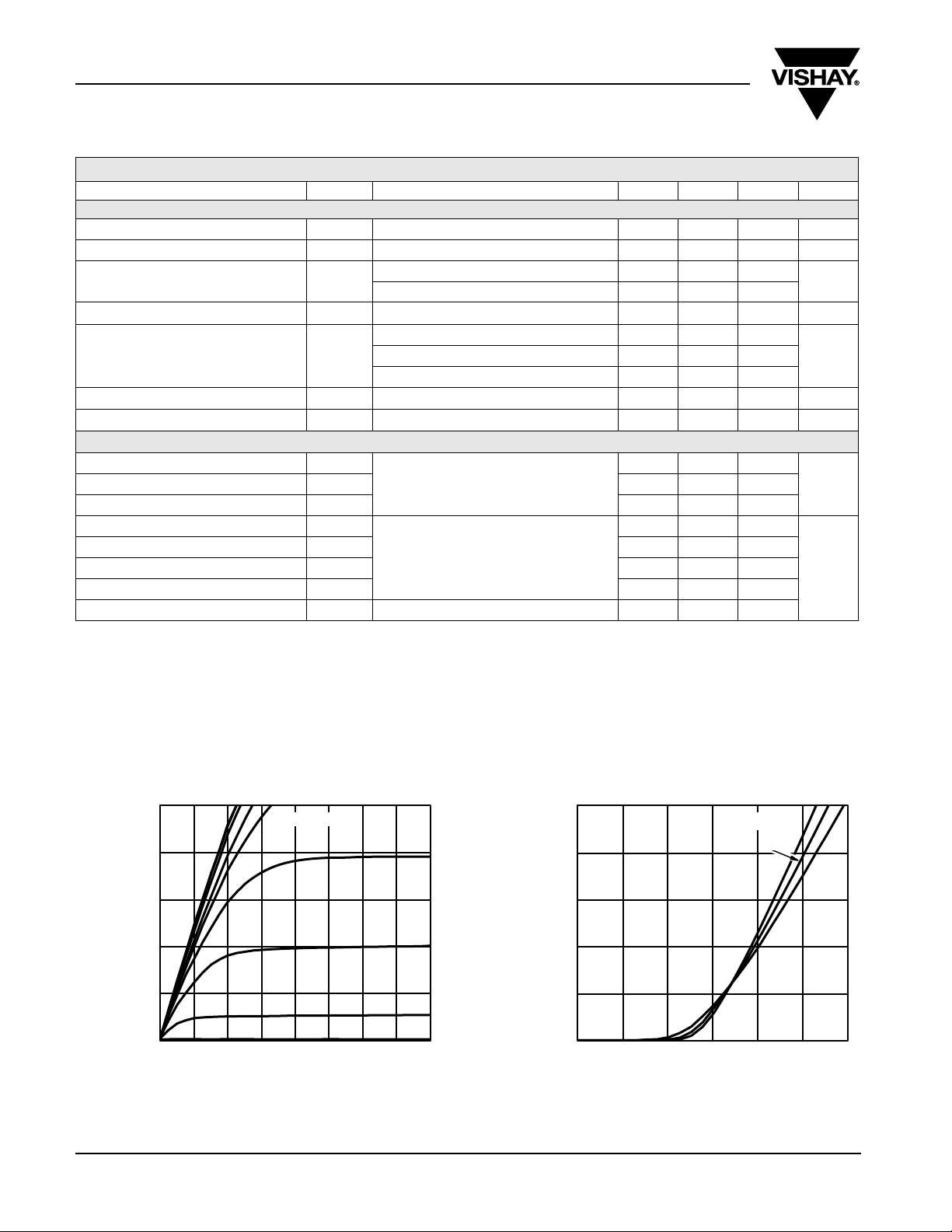

SPECIFICATIONS TJ = 25 °C, unless otherwise noted

Parameter Symbol Test Conditions Min. Typ. Max. Unit

Static

V

Gate Threshold Voltage

Gate-Body Leakage

Zero Gate Voltage Drain Current

On-State Drain Current

a

Drain-Source On-State Resistance

Forward Transconductance

Diode Forward Voltage

Dynamic

b

a

a

Total Gate Charge

Gate-Drain Charge

Tur n -O n De l ay T i m e

Rise Time

Turn-Off Delay Time

Fall Time

Source-Drain Reverse Recovery Time

V

GS(th)

I

GSS

I

DSS

I

D(on)

a

R

DS(on)

g

fs

V

SD

Q

g

Q

gs

Q

gd

t

d(on)

t

r

t

d(off)

t

f

t

rr

V

V

V

DS

I

D

Notes:

a. Pulse test; pulse width ≤ 300 µs, duty cycle ≤ 2 %.

b. Guaranteed by design, not subject to production testing.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the de vice. These are stress rating s only, and functiona l operation

of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

= VGS, ID = - 250 µA

DS

VDS = 0 V, VGS = ± 8 V

V

= - 16 V, V

DS

= - 16 V, V

DS

≤ - 5 V, V

DS

V

= - 4.5 V, ID = - 3.5 A

GS

V

= - 2.5 V, ID = - 2.9 A

GS

V

= - 1.8 V, ID = - 1 A

GS

GS

= 0 V

GS

= 0 V, TJ = 85 °C

= - 4.5 V

GS

VDS = - 10 V, ID = - 3.5 A

IS = - 1.1 A, V

= - 10 V, V

V

= - 10 V, RL = 10 Ω

DD

≅ - 1 A, V

GEN

GS

= 0 V

GS

= - 4.5 V, ID = - 3.5 A

= - 4.5 V, RG = 6 Ω

IF = - 1.1 A, dI/dt = 100 A/µs

- 0.45 V

± 100 nA

- 1

- 5

- 15 A

0.064 0.076

0.091 0.110

0.130 0.160

9S

- 0.8 - 1.2 V

6.5 10

1.4

1.3

14 21

29 45

42 65

35 55

30 60

µA

Ω

nCGate-Source Charge

ns

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

15

12

9

6

- Drain Current (A)I

D

3

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

www.vishay.com

2

V

DS

VGS=5thru3V

2.5 V

2V

1.5 V

1V

- Drain-to-Source Voltage (V)

Output Characteristics

15

TC= - 55 °C

12

9

6

- Drain Current (A)I

D

3

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0

VGS- Gate-to-Source Voltage (V)

25 °C

Transfer Characteristics

Document Number: 71256

S09-0129-Rev. C, 02-Feb-09

125 °C

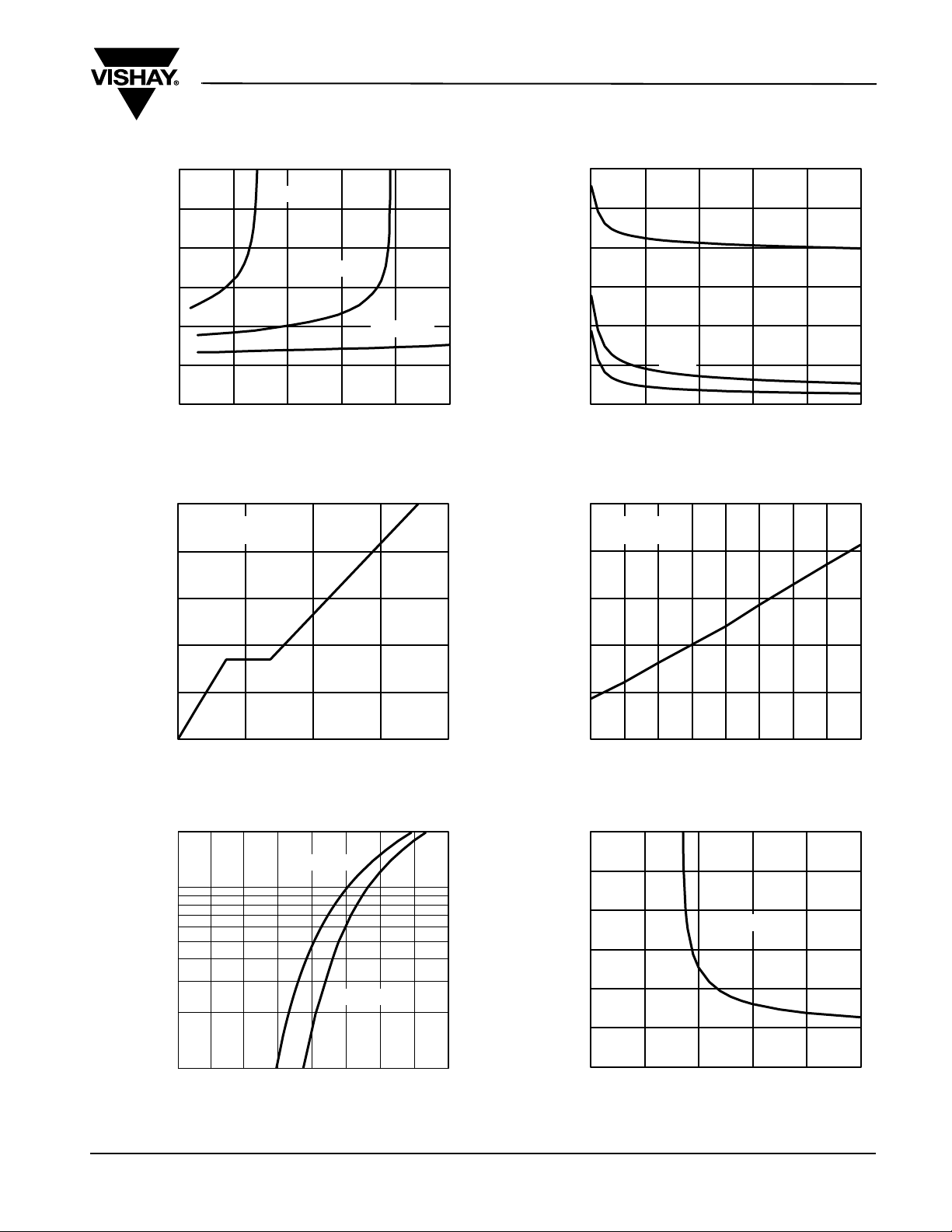

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

0.30

0.25

0.20

0.15

- On-Resistance (Ω)R

0.10

DS(on)

0.05

0.00

03691215

On-Resistance vs. Drain Current

VGS= 1.8 V

VGS= 2.5 V

- Drain Current (A)

I

D

VGS=4.5V

C - Capacitance (pF)

Si5447DC

Vishay Siliconix

1200

1000

C

iss

800

600

400

C

200

C

rss

0

0 4 8 121620

oss

- Drain-to-Source Voltage (V)

V

DS

Capacitance

5

VDS=10V

I

=3.5A

D

4

3

2

- Gate-to-Source Voltage (V)

GS

1

V

0

02468

Qg- Total Gate Charge (nC)

Gate Charge

20

TJ= 150 °C

10

- Source Current (A)I

S

TJ=25°C

1.6

VGS=4.5V

I

=3.5A

D

1.4

1.2

- On-ResistanceR

1.0

(Normalized)

DS(on)

0.8

0.6

- 50 - 25 0 25 50 75 100 125 150

- Junction Temperature (°C)

T

J

On-Resistance vs. Junction Temperature

0.30

0.25

0.20

0.15

- On-Resistance (Ω)R

0.10

DS(on)

0.05

ID=3.5A

1

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

VSD- Source-to-Drain Voltage (V)

Source-Drain Diode Forward Voltage

Document Number: 71256

S09-0129-Rev. C, 02-Feb-09

0.00

012345

VGS- Gate-to-Source Voltage (V)

On-Resistance vs. Gate-to-Source Voltage

www.vishay.com

3

Si5447DC

Vishay Siliconix

TYPICAL CHARACTERISTICS 25 °C, unless otherwise noted

0.4

50

0.3

ID= 250 µA

0.2

0.1

Variance (V)V

GS(th)

0.0

-0.1

-0.2

- 50 - 25 0 25 50 75 100 125 150

TJ- Temperature (°C)

Threshold Voltage

2

1

Duty Cycle = 0.5

0.2

0.1

0.1

Thermal Impedance

Normalized Effective Transient

0.05

0.02

Single Pulse

0.01

-4

10

-3

10

Normalized Thermal Transient Impedance, Junction-to-Ambient

2

40

30

Pow er (W)

20

10

0

0

-2

10

-1

1 100 6001010

Time (s)

Single Pulse Power

Notes:

P

DM

t

1

t

2

t

1. Duty Cycle, D =

2. Per Unit Base = R

3. T

JM-TA=PDMZthJA

4. Surface Mounted

-2

10

-1

1 10 60010

Square Wave Pulse Duration (s)

t

thJA

100

1

2

(t)

=80 °C/W

1

Duty Cycle = 0.5

0.2

0.1

0.1

Thermal Impedance

Normalized Effective Transient

0.05

0.02

Single Pulse

0.01

-4

10

-3

10

-2

10

-1

11010

Square Wave Pulse Duration (s)

Normalized Thermal Transient Impedance, Junction-to-Foot

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package/tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?71256

www.vishay.com

4

.

Document Number: 71256

S09-0129-Rev. C, 02-Feb-09

1206-8 ChipFETR

Package Information

Vishay Siliconix

4

D

6578

4

3421

S b

NOTES:

1. All dimensions are in millimeaters.

2. Mold gate burrs shall not exceed 0.13 mm per side.

3. Leadframe to molded body offset is horizontal and vertical shall not exceed

4. Dimensions exclusive of mold gate burrs.

5. No mold flash allowed on the top and bottom lead surface.

e

0.08 mm.

EE

1

2X 0.10/0.13 R

A

L

5678

4321

c

x

C1

Backside View

DETAIL X

Document Number: 71151

15-Jan-04

MILLIMETERS INCHES

Dim Min Nom Max Min Nom Max

1.00 − 1.10 0.039 − 0.043

A

0.25 0.30 0.35 0.010 0.012 0.014

b

0.1 0.15 0.20 0.004 0.006 0.008

c

c1

D

E

E

e

L

S

ECN: C-03528—Rev. F, 19-Jan-04

DWG: 5547

0 − 0.038 0 − 0.0015

2.95 3.05 3.10 0.116 0.120 0.122

1.825 1.90 1.975 0.072 0.075 0.078

1.55 1.65 1.70 0.061 0.065 0.067

1

0.65 BSC 0.0256 BSC

0.28 − 0.42 0.011 − 0.017

0.55 BSC 0.022 BSC

5_Nom 5_Nom

www.vishay.com

1

AN811

Vishay Siliconix

Single-Channel 1206-8 ChipFETr Power MOSFET Recommended

Pad Pattern and Thermal Performance

INTRODUCTION

New Vishay Siliconix ChipFETs in the leadless 1206-8

package feature the same outline as popular 1206-8 resistors

and capacitors but provide all the performance of true power

semiconductor devices. The 1206-8 ChipFET has the same

footprint as the body of the LITTLE FOOTR TSOP-6, and can

be thought of as a leadless TSOP-6 for purposes of visualizing

board area, but its thermal performance bears comparison

with the much larger SO-8.

This technical note discusses the single-channel ChipFET

1206-8 pin-out, package outline, pad patterns, evaluation

board layout, and thermal performance.

PIN-OUT

Figure 1 shows the pin-out description and Pin 1 identification

for the single-channel 1206-8 ChipFET device. The pin-out is

similar to the TSOP-6 configuration, with two additional drain

pins to enhance power dissipation and thermal performance.

The legs of the device are very short, again helping to reduce

the thermal path to the external heatsink/pcb and allowing a

larger die to be fitted in the device if necessary.

Single 1206-8 ChipFET

1

D

D

D

D

D

D

G

S

26 mil

FIGURE 2. Footprint With Copper Spreading

The pad pattern with copper spreading shown in Figure 2

improves the thermal area of the drain connections (pins

1,2,3,6.7,8) while remaining within the confines of the basic

footprint. The drain copper area is 0.0054 sq. in. or

3.51 sq. mm). This will assist the power dissipation path away

from the device (through the copper leadframe) and into the

board and exterior chassis (if applicable) for the single device.

The addition of a further copper area and/or the addition of vias

to other board layers will enhance the performance still further.

An example of this method is implemented on the

Vishay Siliconix Evaluation Board described in the next

section (Figure 3).

THE VISHAY SILICONIX EVALUATION

BOARD FOR THE SINGLE 1206-8

80 mil

68 mil

28 mil

Bottom View

FIGURE 1.

For package dimensions see the 1206-8 ChipFET package

outline drawing (http://www.vishay.com/doc?71151).

BASIC PAD PATTERNS

The basic pad layout with dimensions is shown in Application

Note 826, Recommended Minimum Pad Patterns With Outline

Drawing Access for Vishay Siliconix MOSFETs,

(http://www.vishay.com/doc?72286). This is sufficient for low

power dissipation MOSFET applications, but power

semiconductor performance requires a greater copper pad

area, particularly for the drain leads.

Document Number: 71126

12-Dec-03

The ChipFET 1206-08 evaluation board measures 0.6 in by

0.5 in. Its copper pad pattern consists of an increased pad area

around the six drain leads on the top-side—approximately

0.0482 sq. in. 31.1 sq. mm—and vias added through to the

underside of the board, again with a maximized copper pad

area of approximately the board-size dimensions. The outer

package outline is for the 8-pin DIP, which will allow test

sockets to be used to assist in testing.

The thermal performance of the 1206-8 on this board has been

measured with the results following on the next page. The

testing included comparison with the minimum recommended

footprint on the evaluation board-size pcb and the industry

standard one-inch square FR4 pcb with copper on both sides

of the board.

www.vishay.com

1

AN811

Vishay Siliconix

Front of Board

ChipFETr

FIGURE 3.

THERMAL PERFORMANCE

Junction-to-Foot Thermal Resistance

(the Package Performance)

Thermal performance for the 1206-8 ChipFET measured as

junction-to-foot thermal resistance is 15_C/W typical, 20_C/W

maximum for the single device. The “foot” is the drain lead of

the device as it connects with the body. This is identical to the

SO-8 package R

shortening the leads to the point where they become only a

small part of the total footprint area.

Junction-to-Ambient Thermal Resistance

(dependent on pcb size)

The typical R

80_C/W steady state, compared with 68_C/W for the SO-8.

Maximum ratings are 95_C/W for the 1206-8 versus 80_C/W

for the SO-8.

performance, a feat made possible by

Q

jf

for the single-channel 1206-8 ChipFET is

Q

ja

Back of Board

vishay.com

The results show that a major reduction can be made in the

thermal resistance by increasing the copper drain area. In this

example, a 45_C/W reduction was achieved without having to

increase the size of the board. If increasing board size is an

option, a further 33_C/W reduction was obtained by

maximizing the copper from the drain on the larger 1” square

pcb.

160

120

80

40

Thermal Resistance (C/W)

Min. Footprint

Single EVB

1” Square PCB

Testing

To aid comparison further, Figure 4 illustrates ChipFET 1206-8

thermal performance on two different board sizes and three

different pad patterns. The results display the thermal

performance out to steady state and produce a graphic

account of how an increased copper pad area for the drain

connections can enhance thermal performance. The

measured steady state values of R

for the single 1206-8

Q

ja

ChipFET are :

1) Minimum recommended pad pattern (see

156_C/W

Figure 2) on the evaluation board size of

0.5 in x 0.6 in.

2) The evaluation board with the pad pattern

111_C/W

described on Figure 3.

3) Industry standard 1” square pcb with

78_C/W

maximum copper both sides.

www.vishay.com

2

0

-5

10

10

-3

-4

10

FIGURE 4. Single 1206−8 ChipFET

-2

10

Time (Secs)

-1

1

1010

100 1000

SUMMARY

The thermal results for the single-channel 1206-8 ChipFET

package display similar power dissipation performance to the

SO-8 with a footprint reduction of 80%. Careful design of the

package has allowed for this performance to be achieved. The

short leads allow the die size to be maximized and thermal

resistance to be reduced within the confines of the TSOP-6

body size.

ASSOCIATED DOCUMENT

1206-8 ChipFET Dual Thermal performance, AN812

(http://www.vishay.com/doc?71127).

Document Number: 71126

12-Dec-03

Application Note 826

Vishay Siliconix

RECOMMENDED MINIMUM PADS FOR 1206-8 ChipFET

0.093

(2.357)

0.080

(2.032)

®

0.036

(0.914)

0.022

(0.559)

Return to Index

Return to Index

0.026

(0.650)

0.016

(0.406)

Recommended Minimum Pads

Dimensions in Inches/(mm)

0.010

(0.244)

APPLICATION NOTE

www.vishay.com Document Number: 72593

2 Revision: 21-Jan-08

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12

1

Document Number: 91000

Loading...

Loading...