Page 1

VISHAY SEMICONDUCTORS

Rectifiers

PowerTab

TM

Mounting Guidelines

Application Note

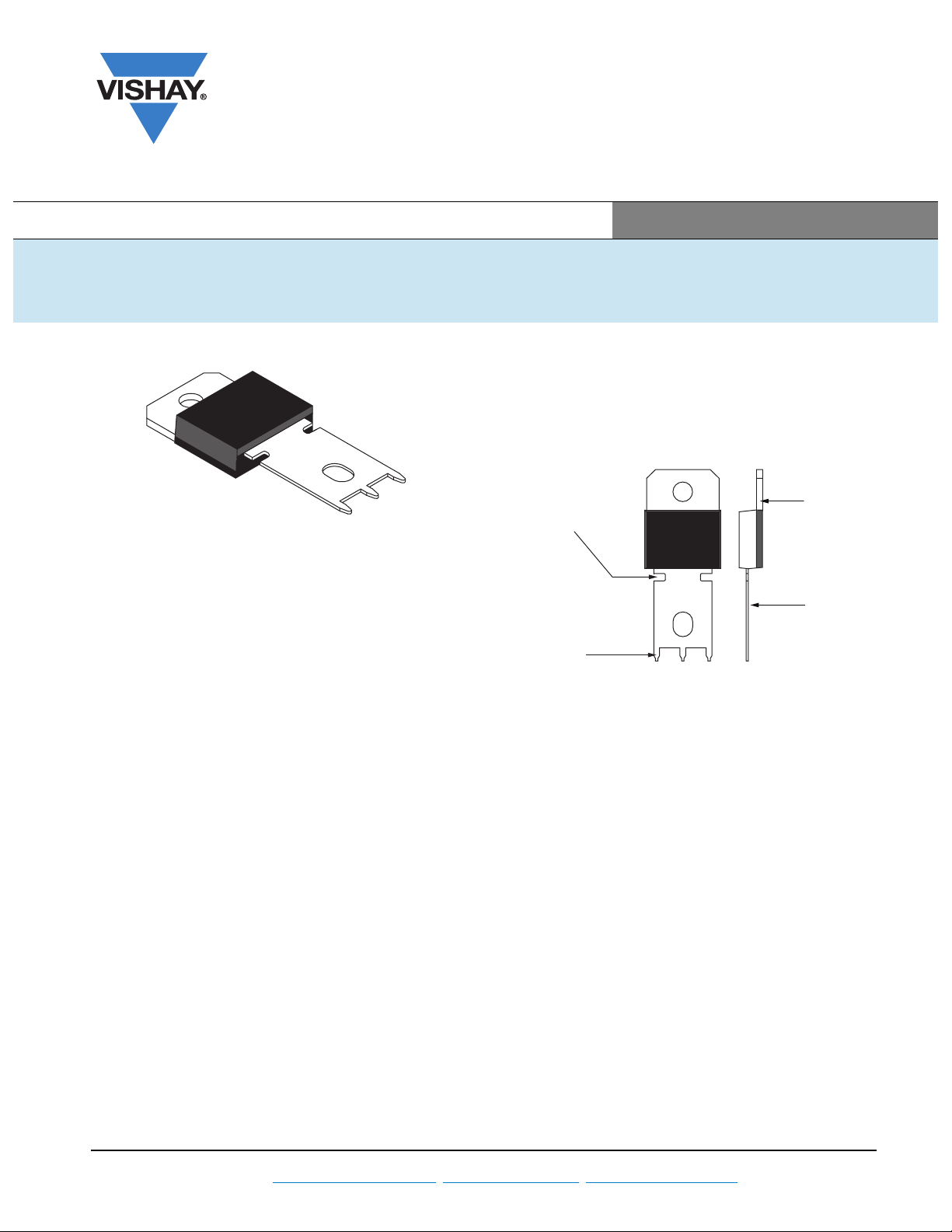

3.0 MECHANICAL CONSIDERATIONS

3.1 TYPE OF FIXINGS

The PowerTab possesses mounting holes in the tab and

lead for electrically connecting the device to heatsinks or

busbars. The lead also carries PCB insertion pins so that the

lead end may be soldered into a board.

Tab (header)

Stress relief slots

1.0 INTRODUCTION

The PowerTabTM package has been designed to fill the gap

in the market between the TO-247, more expensive metal

case devices and non-isolated power modules. It is the

natural replacement for metal case outlines such as

DO-203AA and DO-203AB, but it is also suitable for new

innovative solutions, thanks to a package outline that

combines low profile, excellent die to footprint ratio and

sturdy connectivity. It utilises a large lead for high current

connection, carrying both a mounting hole and PCB insertion

pins. The body is compatible with a TO-218 outline, with an

exposed heatsink and non-isolated mounting hole.

It is anticipated that the devices would find typical

applications in busbar assemblies or finned heatsinks,

reducing component count and cost of ownership.

2.0 SCOPE

This application note covers the various fixment methods

that are possible with this device, and the associated thermal

properties resulting from their use:

a. Optimum mounting torque

b. Type of fixings

c. Effect of torque on thermal resistance (“wet” and “dry”)

d. Effect of pressure on contact thermal resistance (“wet”

and “dry”)

Document Number: 95179 For technical questions within your region, please contact one of the following: www.vishay.com

Revision: 11-Jun-10 DiodesAmericas@vishay.com

, DiodesAsia@vishay.com, DiodesEurope@vishay.com 1

3.2 TAB CONNECTION

Using the mounting hole in the tab allows a designer to

attach the PowerTab to a heatsink. The tab of a PowerTab

acts as one of the terminals. There is no common additional

lead, so the mounting hole contact must be very good, with

the heatsink forming part of the circuit. For the best results

the surface of the heatsink must be as smooth and flat as

possible to maximise the contact area of the tab. A good

flatness specification would be 0.02 mm (0.0007") maximum

per 10 mm (0.393"). Ensure also that the heatsink mounting

hole has been deburred.

The mounting hole in the tab is designed to accept a M4

screw, No. 6-32 screw or 6-40 screw. A self tapping type

screw may also be used. However, only a certain type of

screw and washer may be used to attach the tab to the

heatsink because of the proximity of the mounting hole to the

plastic body.

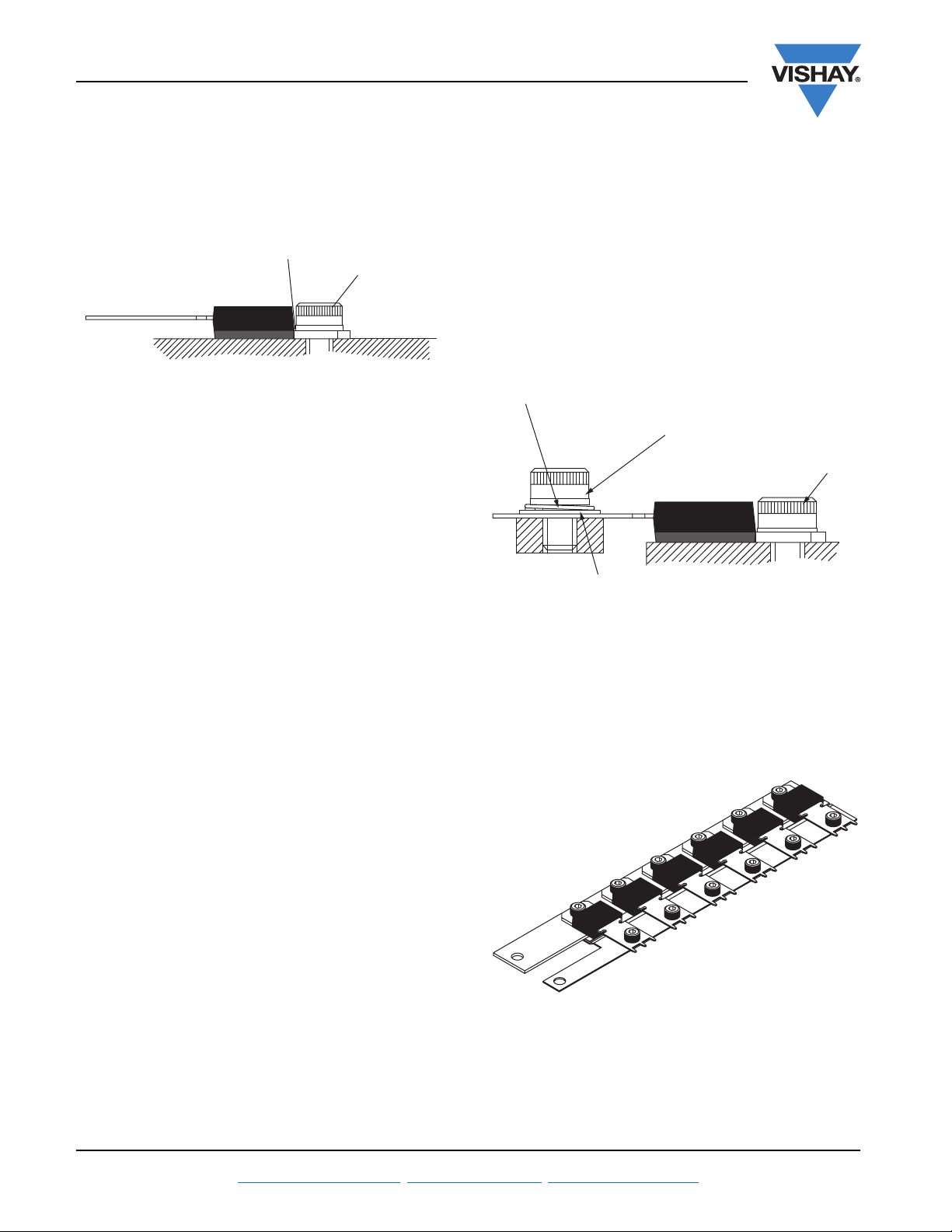

The recommended method of attachment is a socket headed

M4 screw, with a plain washer, as shown in the figure 2. The

washer used must be no larger than the diameter of the

socket head. If a larger washer is used, it can bear directly on

the edge of the plastic body, causing the body to crack when

the screw is tightened. The largest possible diameter washer

that may be used is 7.2 mm (0.283"). An alternative is a

suitably sized rectangular washer.

PCB insertion

pins

Fig. 1

Lead

APPLICATION NOTE

Page 2

Application Note

Vishay Semiconductors

PowerTabTM Mounting Guidelines

Small clearance

between washer and

plastic body

M4 socket

headed bolt

the back of the heatsink and the back of the lead is nominally

3.0 mm. This means that in busbar configurations, the lead

will either need forming down to the same level as the

heatsink, or the lead busbar will need to be raised by 3.0 mm

to the same level as the back of the lead. A typical busbar

configuration is shown in Figure 3.

Care must be taken when tightening the fixing to prevent

distortion of the lead. The lead fixing can be typically

tightened to 3.00 Nm (2.21 lbf · ft) without distortion.

Fig. 2

Similarly, M4 nuts cannot be used (on the plastic side) for the

tab connection, since there is inadequate clearance between

the hole and plastic body to rotate the nut. Using the plastic

body to prevent the nut rotating will inevitably crack the

plastic and is not recommended.

Rivets may be used but the following precautions must be

noted:

The diameter of the hole in the heatsink must be of a smaller

diameter than that of the PowerTab mounting hole, the

crimping force is controlled to give a slow pressure build-up

and the rivet used must be of a soft material. Too high a

crimping speed and pressure is likely to damage the die

inside the package and deform the header, lifting it away

from the heatsink.

Wherever possible, the use of heatsink compound is

recommended to mount the package to improve the heat

dissipation.

The recommended mounting torques, with and without

heatsink compound, may found under section 4.1 of this

application note - “Contact thermal resistance as a function

of torque on the mounting screw” and also in summary form

in Section 5.0.

3.3 CLIP MOUNTING

If desired, use may be made of a clip to attach the package

to a heatsink. The recommended point for the placement of

the clip is directly over the die, ie in the middle of the plastic

body. This will give the best contact thermal resistance. Also

refer to section 4.2 and 5.0 of this application note for the

optimum clip force.

Sprung washer

Busbar connection to lead

Heatsink connection

washer

Plain

Fig. 3

Another solution is a laminated busbar, as supplied by the

Rogers Mektron Busbar Division. Here a single busbar is

stamped to the step height of the package and an isolating

laminate and second busbar added. The PowerTab

TM

packages can then be bolted (or rivetted) down to this strip

to form a single assembly, with two large single outputs. A

typical example is shown below in Figure 4.

3.4 LEAD CONNECTION

The mounting hole in the lead of the PowerTab is oval in

shape. This slotted hole allows for some movement between

the two mounting holes in an assembly, and for any

assembly tolerances. Any M4 screw, No. 6-32 or 6-40 screw

Fig. 4

or nut combination may be used to secure the lead. The use

of a plane and spring washer is recommended to allow for

movement of the lead due to thermal expansion or vibration.

This will also, along with the stress relief slots, minimize

the possibility of the plastic body cracking under

tension/compression stresses. The step difference between

APPLICATION NOTE

www.vishay.com For technical questions within your region, please contact one of the following: Document Number: 95179

2 DiodesAmericas@vishay.com

, DiodesAsia@vishay.com, DiodesEurope@vishay.com Revision: 11-Jun-10

Page 3

Vishay Semiconductors

PowerTabTM Mounting Guidelines

Application Note

3.5 LEADFORMING

In some applications, forming or bending the lead to an angle

of 90° is desirable (Figure 5). This could facilitate connection

to a PCB situated above the package. The minimum

recommended distance of the bend point from the plastic

body is 2.50 mm (0.098"). This will produce a leadform as

shown in Figure 5.

The form occurs at the lower edge of the stress relief slots in

the lead. The vertical height of the lead, measured from the

underside of the unformed section of lead is typically

16.6 mm (0.653"). The stress relief slots, as well as making

the leadforming operation simpler, help to reduce the

stresses imposed on the plastic body caused by differential

expansion at higher operating temperatures. During the

leadforming operation, it is very important that the area of

lead between the plastic and the bend is securely clamped,

to ensure that the plastic is not cracked by this operation.

The physical source of the contact resistance is a result of

the fact that surfaces are never perfectly flat. Even for two

well prepared surfaces contact only actually occurs at

several points separated by large air gaps. As air is a very

good thermal insulator this is undesirable and increases the

thermal resistance. There are two ways of reducing the

volume of air trapped between the surfaces. One is to

increase the force holding the two surfaces together and the

other is to improve the quality of the contact area by filling in

the gaps. In the case of the former this can be done by either

applying a force above the die with a clip or by increasing the

torque on the screw which mounts the tab to the heatsink.

The second technique requires the use of a heatsinking

compound. This is usually a silicone grease loaded with

electrically insulating, thermally conductive material such as

alumina. The purpose of the grease is to fill the gaps without

increasing the distance between the two surfaces. If the layer

of grease is too thick then the thermal resistance will be

increased. When using heatsinking compound in conjunction

with a PowerTab it is important to remember that electrical

contact to the drain can only be made through the mounting

tab. In addition to this, care must be taken to avoid getting

any compound in the screw threads or mounting holes as this

will affect the accuracy of the torque measurement.

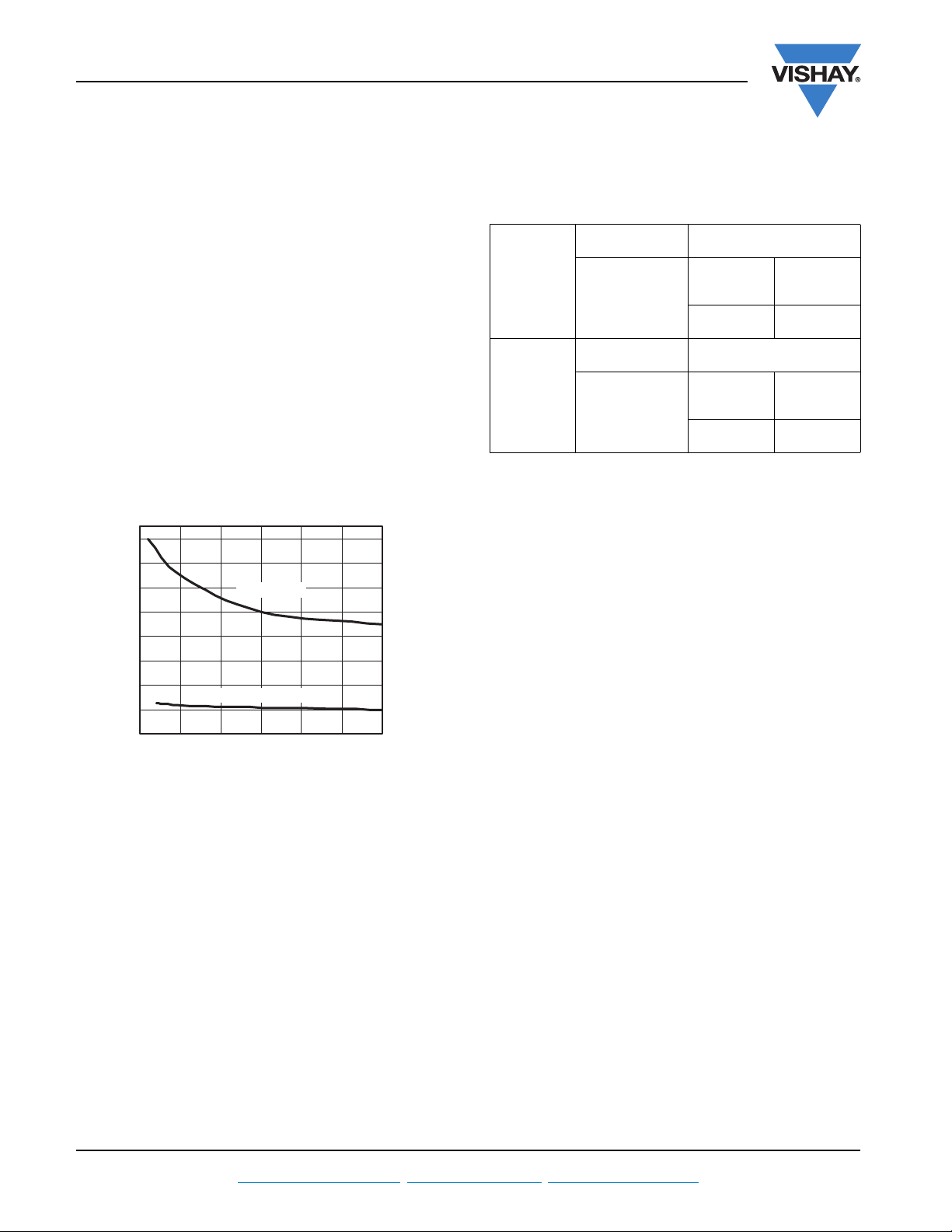

For the purpose of this application note the contact thermal

resistance has been measured as a function of both the

torque on the mounting screw and the force above the die. In

PowerTabTM with 90° leadform

Fig. 5

Care must also be taken not flex or bend the lead over sharp

angles repeatedly. If the lead is bent through 30° and back

both cases measurements have been performed with and

without heatsinking compound.

4.1 CONTACT THERMAL RESISTANCE AS A FUNCTION

OF TORQUE ON THE MOUNTING SCREW

again more than twice, it will be considerably weakened and

liable to breakage.

4.0 THERMAL CONSIDERATIONS

One of the major considerations when mounting all power

semiconductor packages is the dissipation of heat. This is

because the performance of the device is limited by the

junction temperature of the die and the glass transition

temperature of the plastic. Indeed there are maximum

allowable temperatures above which the device is not

functional. The way in which a device is mounted can have a

large effect on the thermal contact between the header and

the heatsink and hence on the ability of the package to

dissipate heat. This is often referred to as the contact thermal

resistance and is quoted in datasheets. In the present note

we shall concentrate on the thermal resistance between the

case and the heatsink as this is the most dependent on the

mounting technique.

1.6

1.4

1.2

1.0

0.8

0.6

0.4

Thermal Resistance (°C/W)

0.2

0

0 0.5 1.0 1.5

Dry mounting

With heatsink compound

Torque (Nm)

Fig. 6

Figure 6 shows the contact thermal resistance as a function

of torque with and without heatsink compound. The package

was mounted using a M4 screw in accordance with the

mounting instructions described in this application note. It

can be seen from the graph that in the case of a dry mounted

Document Number: 95179 For technical questions within your region, please contact one of the following: www.vishay.com

Revision: 11-Jun-10 DiodesAmericas@vishay.com

, DiodesAsia@vishay.com, DiodesEurope@vishay.com 3

APPLICATION NOTE

Page 4

Application Note

Vishay Semiconductors

PowerTabTM Mounting Guidelines

device the contact thermal resistance can be reduced to a

minimum of 1 °C/W by increasing the torque up to an

optimum value of 1.1 Nm. Further increasing the torque is not

beneficial since the header/mounting tab becomes

deformed, lifting the package away from the heatsink and

hence increasing the thermal resistance. The use of heatsink

compound reduces the thermal resistance by a factor of

78 % to 0.22 °C/W. The dependence on torque is also

reduced. This measurement was acheived using a device

with 60 W power applied for 100 s, on an “infinite” heatsink.

Recommended torque:

Without heatsink compound: 1.1 Nm (0.81 lbf · ft) to give a

thermal resistance, case to sink, of 1 °C/W.

With heatsink compound: 0.8 Nm (0.59 lbf · ft) to give a

thermal resistance, case to sink, of 0.22 °C/W.

4.2 CONTACT THERMAL RESISTANCE AS A FUNCTION

OF FORCE ABOVE THE DIE (CLIP MOUNTING)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

Thermal Resistance (°C/W)

0.2

0

0 100 20050 150 250 300

With heatsink compound

Dry mounting

Force (N)

Fig. 7

Figure 7 shows the contact thermal resistance as a function

of force above the die with and without heatsink. It can be

seen from the graph that when heatsink compound is not

used the contact resistance decreases with increasing force.

However there is a point beyond which the advantage gained

by increasing the force is offset by the additional cost

required to do so. The use of heatsink compound reduces

the thermal resistance by a factor of 85 % and also makes

the thermal resistance less dependent on the applied force.

This measurement was acheived using a device with 60 W

power applied for 100 s, on an “infinite” heatsink.

Recommended force:

Without heatsink compound: 20 N (4.5 lbf) minimum to give

a thermal resistance, case to sink, of 1.5 °C/W.

With heatsink compound: 20 N (4.5 lbf) minimum to give a

thermal resistance, case to sink, of 0.23 °C/W.

5.0 SUMMARY TABLE

Maximum

allowable torque

Screw

Mounting

Clip

Mounting

2.4 Nm

(21.24 lbf · in)

Maximum

allowable force

250 N

(56.21 lbf)

Thermal mounting

Without

heatsink

compound

1 °C/W

at 1.1 Nm

Thermal mounting

Without

heatsink

compound

1.5 °C/W

at 20 N

With heatsink

With heatsink

compound

0.22 °C/W

at 0.8 Nm

compound

0.23 °C/W

at 20 N

APPLICATION NOTE

www.vishay.com For technical questions within your region, please contact one of the following: Document Number: 95179

4 DiodesAmericas@vishay.com

, DiodesAsia@vishay.com, DiodesEurope@vishay.com Revision: 11-Jun-10

Loading...

Loading...