VISHAY SEMICONDUCTORS

Power Modules

Mounting Instructions for MAGN-A-PAK,

Super MAGN-A-PAK, and MAP Block

By Kevin Liu

This application note introduces Vishay´s MAGN-A-PAK (MAP),

Super MAGN-A-PAK (SMAP), and MAGN-A-PAK Block

(MAP Block) modules. It covers their key features and gives

instructions for using heat sinks with the modules.

INTRODUCTION

Vishay’s MAP, SMAP, and MAP Block modules are

distinguished by these key features:

• High surge capability

• High voltage ratings

• Industry-standard package

• Simplified mechanical designs, rapid assembly

Important factors in the assembly process are:

• Heat sink design

• Power leads size / area

• Distance from adjacent heat-generating parts

Application Note

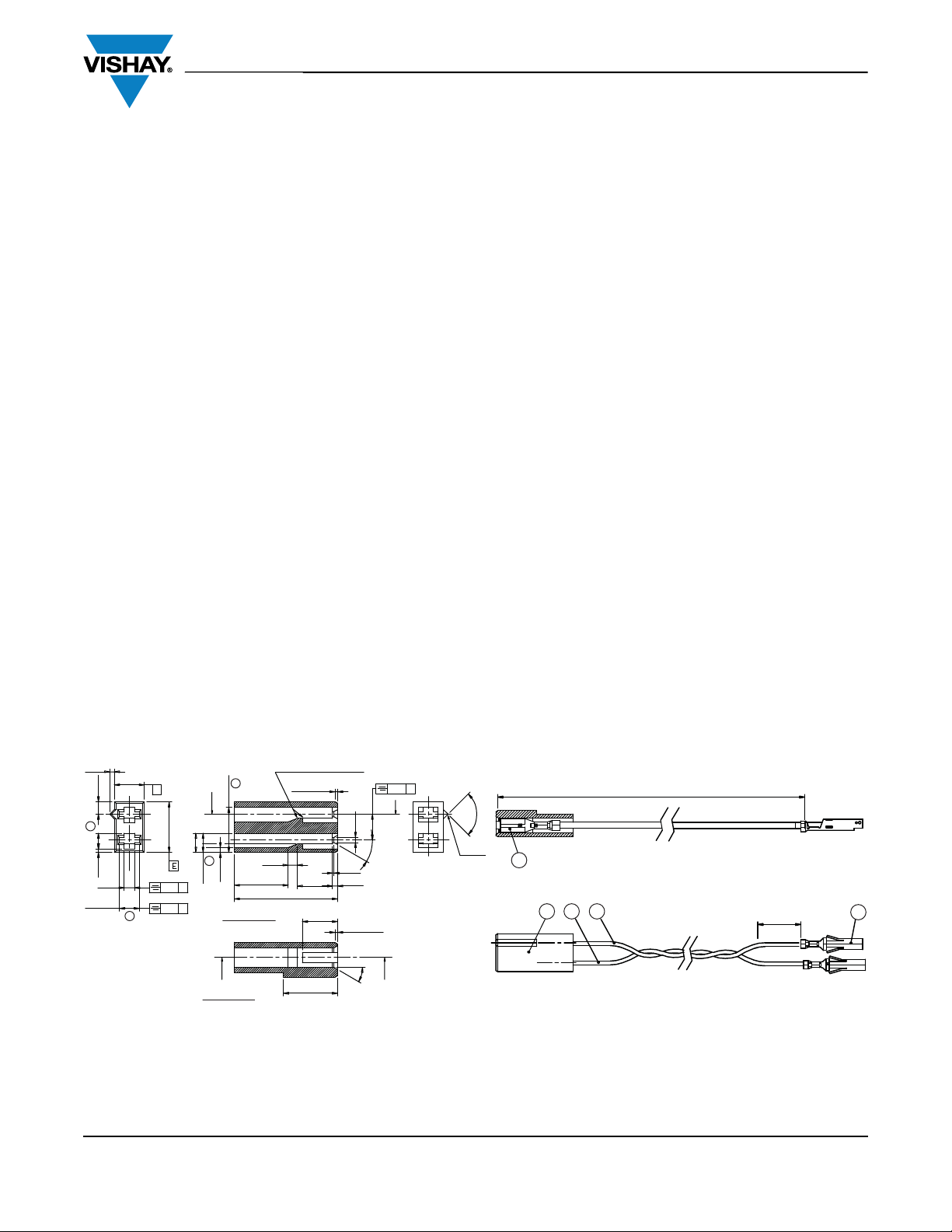

Fig. 1 - Examples of MAP

Fig. 2 - Examples of SMAP

Recommendations for each of these items and

requirements for mounting MAP, SMAP, and MAP Block

modules to the heat sink are discussed in the following

sections.

Fig. 3 - Examples of MAP Block

HEAT SINK SPECIFICATION

The contact surface of the heat sink must be flat, with a recommended tolerance of < 0.03 mm (< 1.18 mils) and a levelling depth

(surface roughness) of < 0.02 mm (< 0.79 mils), according to DIN/ISO 1302. In general, a milled or machined surface is

satisfactory if prepared with tools in good working condition. The heat sink mounting surface must be clean, with no dirt,

corrosion, or surface oxides. It is very important to keep the mounting surface free from particles exceeding 0.05 mm (2 mils) in

thickness.

THERMAL COMPOUND

Uniformly coat the heat sink surface and the power module base plate with a good quality thermal compound.

Apply uniform pressure on the package to force the compound to spread over the entire contact area. The purpose of thermal

grease is to fill gaps at base of the plate/heat sink interface.

The use of thermal grease is recommended to ensure low case-to-sink thermal resistance. Commonly used thermal grease are

DC340 (Dow Corning) or silicone-free HTCP (Electrolube), or equivalent thermal grease. By the way, to optimize the device

performances, we suggest to select interface materials with thermal conductivity not less than 1.5 W/mK. Screen printing or

rubber rolling are the preferred methods for applying the grease.

A grease layer with a final thickness in the range of 80 μm to 100 μm is considered suitable for most applications.

Revision: 11-Sep-13

1

Document Number: 95557

APPLICATION NOTE

Application Note

Burrs not allowed

0.9

-0.1

5.8

+0.1

9.8

+0.05

2.1

+0.1

1.3

±0.05

3.8

+0.05

0.7

3.0

2.8

2.4

2.0

ref

0.9

ref

ref

1.8

ref

0.5 x 30°

0.5 x 30°

10.4

10.5

6.8

6.8

1.0

1.0

5.0

30°

90°

30°

0.3

20.0

I

I

I

I

AA

R 0.2

MAX.

B

G

G0.1

0.1

G

B

Sec. B - B

Sec. A - A

0.1

G

590

±10

3

5

4 1 2

A - DX

Not twisted both ends

38

ref

Vishay Semiconductors

Mounting Instructions for MAGN-A-PAK,

Super MAGN-A-PAK, and MAP Block

MOUNTING TO HEAT SINK

Confirm that there are no foreign particles on the surface of the screen tooling and plate. Place a suitable amount of thermal

compound on the plate and spread it evenly with a roller or spatula. The thermal grease contact and distribution will be improved

during the first hours and after heating up the system for the first time.

Bolt the module to the heat sink using the fixing holes. An even amount of torque should be applied for each individual mounting

screw. For proper mounting it is recommended to use fitted screws (refer to each individual datasheet or outline dimensions)

secured by a lock washer and flat washer. Please refer to each individual datasheet to find the torque rating that can be applied.

A torque wrench which is accurate in the specified range must be used in mounting the module to achieve optimum results.

All mounting holes should be free of burrs. The first mounting screw should be tightened to one third of the recommended

torque; the second screw should then be tightened to the same torque. We recommend mounting crosswise facing screws first

(i.e. for holes in clockwise order 1, 2, 3, 4, first mount screws in 1 and 3, then 2 and 4).

Over-tightening the mounting screw may lead to deformation of the package, which would increase the thermal resistance and

damage the semiconductors. After a period of three hours, check the torque with a final tightening in opposite sequence to allow

the thermal compound to spread.

POWER LEADS OR BUS BARS CONNECTION

Apply an even amount of torque to each individual screw. For proper connection it is recommended to use fitted screws (refer

to individual datasheet or outline dimensions) secured by a lock washer and flat washer. The maximum thread depth into the

module mounting studs should correspond to each individual package outline drawing in the datasheet. Also please refer to

each individual datasheet to find the maximum torque that can be applied. A torque wrench which is accurate in the specified

range must be used in fixing the screws of the power leads or bus bars to achieve optimum results.

SIGNAL TERMINAL AND HOUSING CONNECTION

We suggest using a receptacle fast-on terminal (with locking lance, (3) for 2.8 x 0.8 tab (series 110) ref. PN.AMP 150571-2 or

equivalent) plus tinned copper stranded cable (1)(2) UL 758, style 1587, AWG 20 (0.51 mm

ext. dia. 1.47 mm, temperature rating 125 °C).You can also use a 2-way polarized connector housing (4) as shown on

dimensional detail and female terminal (5) Mini-Fit Molex 39-00-0038 (Fig. 4).

2-way polarized connector housing, dimensional detail

Revision: 11-Sep-13

APPLICATION NOTE

Fig. 4

2

2

) ETFE insulation,

Document Number: 95557

Loading...

Loading...