Ultrafast Rectifier

Bulletin PD-20737 rev. C 12/03

MURD620CT

Features

• Ultrafast Recovery Time

• Low Forward Voltage Drop

• Low Leakage Current

• 175°C Operating Junction Temperature

Description/ Applications

International Rectifier's MUR.. series are the state of the art Ultra

fast recovery rectifiers specifically designed with optimized

performance of forward voltage drop and ultra fast recovery time.

The planar structure and the platinum doped life time control,

guarantee the best overall performance, ruggedness and reliability

characteristics.

These devices are intended for use in the output rectification

stage of SMPS, UPS, DC-DC converters as well as free-wheeling

diode in low voltage inverters and chopper motor drives.

Their extremely optimized stored charge and low recovery

current minimize the switching losses and reduce over dissipation

in the switching element and snubbers.

Package Outline

I

D-PAK

F(AV)

t

= 25ns

rr

= 6Amp

VR = 200V

Absolute Maximum Ratings

Parameters Max Units

V

RRM

I

F(AV)

I

FSM

I

FM

TJ, T

Peak Repetitive Peak Reverse Voltage 200 V

Average Rectified Forward Current Per Device 6 A

Total Device, (Rated VR ), TC = 146°C

Non Repetitive Peak Surge Current 50

Peak Repetitive Forward Current Per Diode 6

(Rated VR , Square wave, 20 KHz), TC = 146°C

Operating Junction and Storage Temperatures - 65 to 175 °C

STG

www.irf.com

1

MURD620CT

Bulletin PD-20737 rev. C 12/03

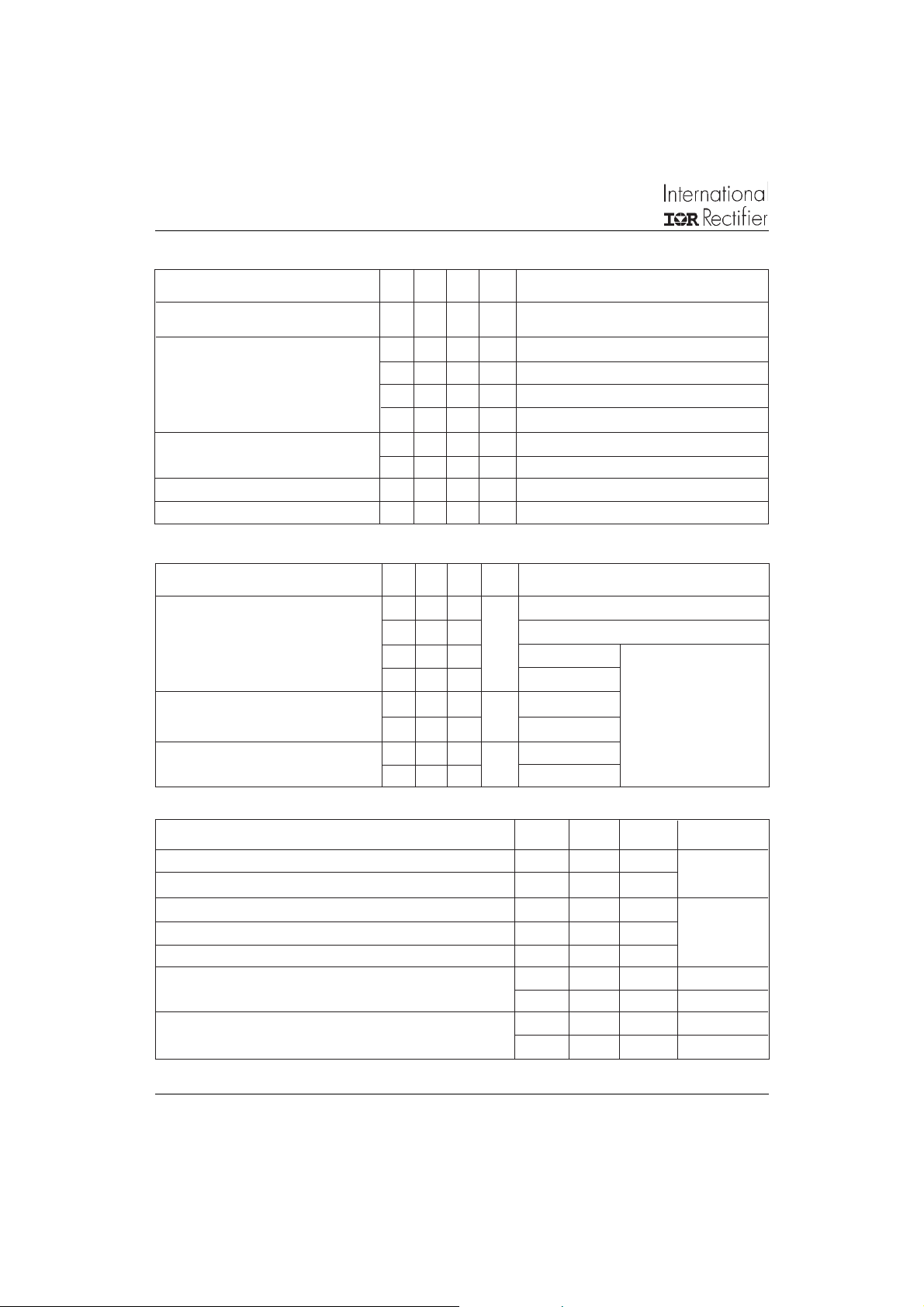

Electrical Characteristics @ T

= 25°C (unless otherwise specified)

J

Parameters Min Typ Max Units Test Conditions

VBR, VrBreakdown Voltage, 200 - - V IR = 100µA

Blocking Voltage

V

F

Forward Voltage - - 1.0 V IF = 3A

- - 0.96 V IF = 3A, TJ = 125°C

- - 1.2 V IF = 6A

- - 1.13 V IF = 6A, TJ = 125°C

I

R

Reverse Leakage Current - - 5 µA VR = VR Rated

- - 250 µA TJ = 125°C, VR = VR Rated

C

T

L

S

Junction Capacitance - 12 - pF VR = 200V

Series Inductance - 8.0 - nH .

Measured lead to lead 5mm from package body

Dynamic Recovery Characteristics @ TJ = 25°C (unless otherwise specified)

Parameters Min Typ Max Units Test Conditions

t

rr

I

RRM

Q

Reverse Recovery Time --35 ns IF = 1.0A, diF/dt = 50A/µs, VR = 30V

--25 IF = 0.5A, IR = 1.0A, I

-19- TJ = 25°C

26 TJ = 125°C

Peak Recovery Current - 3.1 - A TJ = 25°C

- 4.6 - TJ = 125°C

Reverse Recovery Charge - 30 - nC TJ = 25°C

rr

-60- TJ = 125°C

= 0.25A

REC

IF = 3A

VR = 160V

diF /dt = 200A/µs

Thermal - Mechanical Characteristics

Parameters Min Typ Max Units

T

J

T

Stg

R

thJC

R

thJA

R

thCS

Wt Weight - 0.3 - g

c Mounting Surface, Flat, Smooth and Greased

2

Max. Junction Temperature Range - - - 65 to 175 °C

Max. Storage Temperature Range - - - 65 to 175

Thermal Resistance, Junction to Case Per Leg - - 9.0 °C/ W

Thermal Resistance, Junction to Ambient Per Leg - - 80

c

Thermal Resistance, Case to Heatsink - - -

- 0.01 - (oz)

Mounting Torque 6.0 - 12 Kg-cm

5.0 - 10 lbf.in

www.irf.com

MURD620CT

Bulletin PD-20737 rev. C 12/03

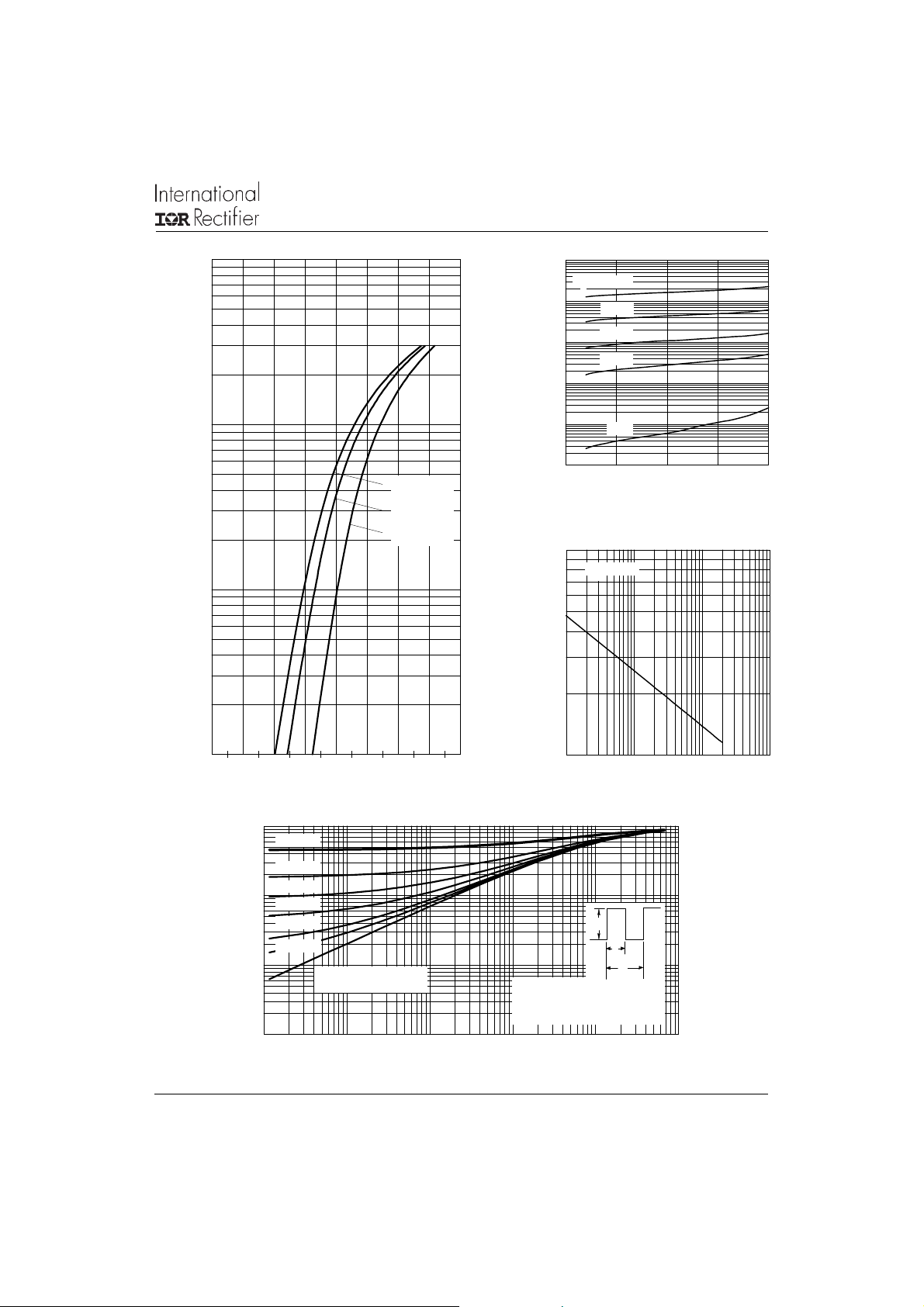

100

10

(A)

F

1

Instantaneous Forward Current - I

T = 175˚C

J

T = 150˚C

J

T = 25˚C

J

100

T = 175˚C

J

(µA)

R

10

1

150˚C

125˚C

100˚C

0.1

0.01

Reverse Current - I

0.001

25˚C

0 50 100 150 200

Reverse Voltage - VR (V)

Fig. 2 - Typical Values Of Reverse Current

Vs. Reverse Voltage

100

T = 25˚C

J

(pF)

T

0.1

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

Forward Voltage Drop - VFM (V)

Fig. 1 - Typical Forward Voltage Drop Characteristics

10

D = 0.50

0.1

1

D = 0.20

D = 0.10

D = 0.05

D = 0.02

D = 0.01

Single Pulse

(Thermal Resistance)

(°C/W)

thJC

Thermal Impedance Z

0.01

0.00001 0.0001 0.001 0.01 0.1 1

t1, Rectangular Pulse Duration (Seconds)

Fig. 4 - Max. Thermal Impedance Z

www.irf.com

Junction Capacitance - C

10

1 10 100 1000

Reverse Voltage - VR (V)

Fig. 3 - Typical Junction Capacitance

Vs. Reverse Voltage

P

DM

t

1

t

Notes:

1. Duty factor D = t1 / t 2

2. Peak Tj = Pdm x ZthJC + Tc

Characteristics

thJC

2

3

MURD620CT

0

0

Bulletin PD-20737 rev. C 12/03

180

170

160

DC

150

Square wave (D = 0.50)

140

Rated Vr applied

130

Allowable Case Temperature (°C)

see note (2)

120

012345

Average Forward Current - IF

(AV)

Fig. 5 - Max. Allowable Case Temperature

Vs. Average Forward Current

50

IF = 3 A

40

IF = 6 A

(A)

4.5

4

3.5

RMS Limit

3

2.5

2

1.5

1

Average Power Loss ( Watts )

0.5

0

012345

Average Forward Current - IF

D = 0.01

D = 0.02

D = 0.05

D = 0.10

D = 0.20

D = 0.50

DC

(AV)

Fig. 6 - Forward Power Loss Characteristics

140

120

100

IF = 6 A

IF = 3 A

V = 30V

R

T = 125˚C

J

T = 25˚C

J

(A)

30

trr ( nC )

20

V = 30V

R

T = 125˚C

J

T = 25˚C

J

10

100 100

di

F

/dt (A/µs )

Fig. 7 - Typical Reverse Recovery vs. di

(2) Formula used: TC = TJ - (Pd + Pd

Pd = Forward Power Loss = I

Pd

= Inverse Power Loss = VR1 x IR (1 - D); IR @ V

REV

F(AV)

4

) x R

REV

x VFM @ (I

;

thJC

/ D) (see Fig. 6);

F(AV)

/dt

F

= rated V

R1

80

60

Qrr ( nC )

40

20

0

100 100

di F /dt (A/µs )

Fig. 8 - Typical Stored Charge vs. di

R

/dt

F

www.irf.com

Reverse Recovery Circuit

V = 200V

R

0.01

Ω

L = 70µH

D.U.T.

MURD620CT

Bulletin PD-20737 rev. C 12/03

di F /dt

dif/dt

ADJUST

G

Fig. 9- Reverse Recovery Parameter Test Circuit

I

F

t

a

0

1

di F /dt

di /dt

f

1. diF/dt - Rate of change of current through zero

crossing

2. I

- Peak reverse recovery current

RRM

3. t

- Reverse recovery time measured from zero

rr

crossing point of negative going IF to point where

a line passing through 0.75 I

extrapolated to zero current

RRM

and 0.50 I

RRM

3

2

D

IRFP250

S

t

rr

t

b

Q

I

RRM

0.5

di(rec)M/dt

0.75

I

RRM

4. Qrr - Area under curve defined by t

and I

RRM

Q

rr

5. di

/dt - Peak rate of change of

(rec)M

current during tb portion of t

I

=

rr

RRM

t rr x I

4

5

rr

RRM

2

rr

www.irf.com

Fig. 10 - Reverse Recovery Waveform and Definitions

5

MURD620CT

A

Bulletin PD-20737 rev. C 12/03

Outline Table

6.73 (0.26)

6.35 (0.25)

5.46 (0.21)

5.21 (0.20)

4

1.64 (0.02)

123

1.52 (0.06)

1.15 (0.04)

1.14 (0.04)

2x

0.76 (0.03)

2.28 (0.09)

2x

Tape & Reel Information

TRR

FEED DIRECTION

TRL

FEED DIRECTION

1.85 (0 .073)

1.65 (0 .065)

1.27 (0.05)

0.88 (0.03)

6.22 (0.24)

5.97 (0.23)

0.89 (0.03)

3x

0.64 (0.02)

4.57 (0.18)

4.10 (0.161)

3.90 (0.153)

10.90 ( 0.429)

10.70 ( 0.421)

2.38 (0.09)

2.19 (0.08)

1.14 (0.04)

0.89 (0.03)

0.58 (0.02)

0.46 (0.02)

6.45 (0.24)

5.68 (0.22)

10.42 (0.41)

9.40 (0.37)

0.51 (0.02)

MIN.

0.58 (0.02)

0.46 (0.02)

1 - Anode

2 - Cathode

3 - Anode

4 - Cathode

Conforms to JEDEC Outline D-PAK

Dimensions in millimeters and (inches)

1.60 (0. 063)

1.50 (0. 059)

1.60 (0.063 )

1.50 (0.059 )

11.60 (0.457)

11.40 (0.449)

1.75 (0 .069)

1.25 (0 .049)

16.10 ( 0.634)

15.90 ( 0.626)

DIA.

DIA.

15.42 ( 0.609)

15.22 ( 0.601)

MINIMUM RECOMMENDED FOOTPRINT

5.97 (0.24)

6.48 (0.26)

10.67 (0.42)

2x

2.54 (0.10)

1.65 (0.06)

2.28 (0.09)

2x

2x

BASE

COMMON

CATHODE

2

123

COMMON

0.368 (0.0145)

0.342 (0.0135)

24 .30 (0.95 7)

23 .90 (0.94 1)

4.72 (0.18 6)

4.52 (0.17 8)

NODE

12

CATHODE

ANODE

360 (14.173)

DIA. MAX.

13.50 (0.532)

12.80 (0.504)

DIA.

26.40 ( 1.039)

24.40 ( 0.961)

60 (2.3 62)

DIA. MIN.

D-PAK Tape & Reel

SMD-220 Tape & Reel

When order ing, indic ate the pa rt

When ordering, indicate the

number, part orientation, and the

quantity. Quantitie s are in multipl es

part number, part orientation

of 800 piece s per reel for bo th

and the quantity. Quantities

TRL and TRR .

are in multiples of 2000

pieces per reel for TR and

multiples of 3000 pieces per

reel for both TRL and TRR.

6

www.irf.com

Ordering Information Table

MURD620CT

Bulletin PD-20737 rev. C 12/03

Device Code

MUR D 6 20 CT TRL

15243

1 - Ultrafast MUR Series

2 - D = D-Pak

3 - Current Rating (6 = 6A)

4 - Voltage Rating (20 = 200V)

5 - CT = Center Tap (Dual)

6 - Tape & Reel Suffix

6

TR = Tape & Reel

TRL = Tape & Reel (Left Oriented)

TRR = Tape & Reel (Right Oriented)

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

www.irf.com

Data and specifications subject to change without notice.

This product has been designed and qualified for Industrial Level.

Qualification Standards can be found on IR's Web site.

TAC Fax: (310) 252-7309

Visit us at www.irf.com for sales contact information. 12/03

7

Loading...

Loading...