Page 1

Powerex, Inc., 200 Hillis Street, Youngwood, Pennsylvania 15697-1800 (412) 925-7272

Powerex, Europe, S.A. 428 Avenue

G.

Durand, BP107, 72003

Le

Mans, France (43) 41.14.14

Mounting Power Semiconductors

D.

I. Mounting Surface Preparation

in

the

A. Surface flatness

mounting

.001

commercial

require

rough

machining

surface

B.

Surface finish

mounting

equivalent

semiconductor

microinches

microinches

finishes

no

performance.

C.

Care

devices

as

scratches,

the

minor

one

flatness is

surface

thermal

interface

inch

per

inch.

extruded

spot

facing

plates,

etc.

to

meet

flatness

interface

to that of the

maximum

maximum

add

undue

improvement

should

be

as

well

to

minimize

and

mounting

interface

scratches,

should

realize

much

finish

in

interface.

requirements.

in

device

taken

as

voids,

other

achieving

in

etc.

more

device

area

should

Generally,

heat

sinks

and

cast

sinks;

require

additional

the

required

the

device

area

should

or

32

for

disc

and

for

stud.

cost with little or

thermal

in

handling

the

heat

sinks

nicks,

deep

imperfections

area.

While

are

not

desirable,

that

surface

critical

than

a good

be

be

Finer

so

63

in

Treated heat sink finishes

be

removed

interface

on

heat

the

mounting

chromate

removed

optimum

tin-plated

even

where

E.

Mounting

free

and films.

stored

immediately

cleaning

satisfactory

lightly

3M

Scotch

steel

Semiconductor

As

freshly

oxide

from

the

device

area.

Black

anodizing

sinks

must

be

area.

Also,

acid

dip

finishes

from

the

mounting

performance.

finishes

desirable

corrosion

interface

of

all foreign material, oxides,

and

operation

polish

wool,

in

many

could

Since

most

are

not

after

machining,

cleaning

the

mounting

Britst

pad

followed

are

areas

assembled

is

recommended.

technique

by

Cleaning

bared

aluminum

layer

in

a matter

Alcoa :# 2 electrical joint

may

be

used

to

clean

should

mounting

or paint

removed

irridite

or

must

area

Nickel

and

acceptable

applications

be a problem.

should

heat

sinks

a

is

area

with

or

No.

000

a

Solvent

forms

of

seconds,

compound

aluminum

from

be

for

and

be

are

to

fine

wipe.

an

heat

sink

mounting

Semiconductor

Surface

cleaning.

lint-free

After

cleaning,

interface

immediately

semiconductor

thereafter to

compound

metal

particles.

F.

Powerex recommends the use.

thermal Interface compound

power semiconductors.

proper

A

interface

scratches

a

device/heat

twenty-fold

case-to-sink

possible.

for

high

surfaces,

Cleaning

should

not

Parts

may

surface

an

compound

applied

device

prevent

from

application

compound

and

imperfections

sink

improvement

thermal

This

is

power

semiconductors.

followed

Solvent

be

touched

be

placed

until

final

appropriate thermal .

should

and

after

on

assembly.

be

the

attached

the

thermal

collecting dust

and

for

With

the

of a

thermal

to

fill

the

voids,

in

the

mounting

especially

area,

in

device

resistance

important

a

is

by

a

wipe.

a

of

all

a

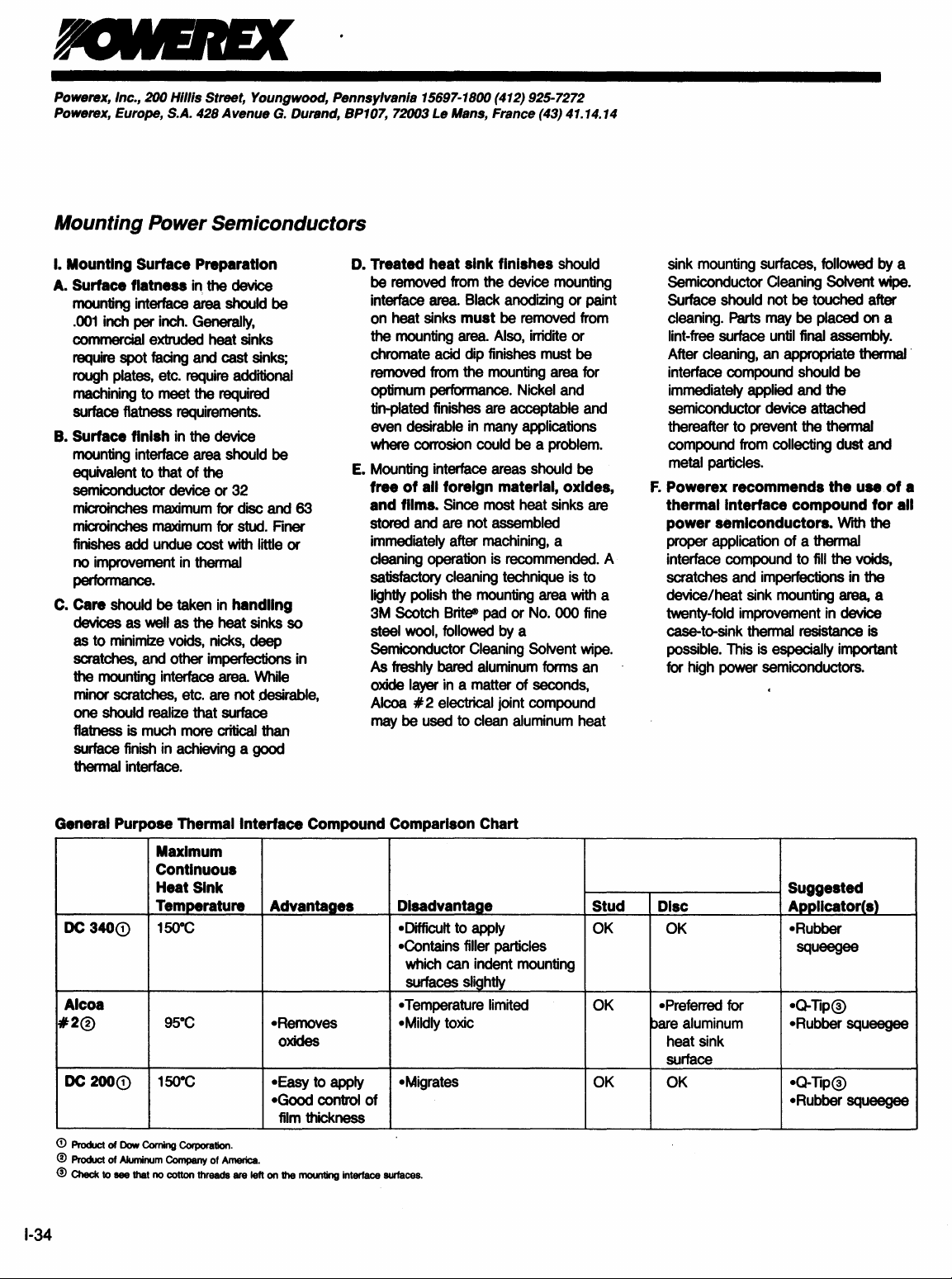

General Purpose Thermal Interface Compound Comparison Chart

Maximum

Continuous

Heat Sink

DC340Q)

Temperature

1500C

Advantages

Disadvantage

-Difficult

-Contains filler particles

which

can

surfaces

Alcoa

#2®

95°C

-Removes

-Temperature

-Mildly

toxic

oxides

DC

2OOQ)

150°C

-Easy

to

apply

-Migrates

-Good control of

film

thickness

<D

Product of

Dow

® Product of

@)

Check

Coming Corporation.

Aluminum

to

see

that

Company of America.

no

cotton threads

are

left

on

the mounting interface

surfaces.

1-34

to

apply

indent

slightly

mounting

limited

Stud

OK

OK

OK

Disc

OK

-Preferred

~ealuminum

heat

surface

for

sink

OK

Suggested

Appllcator(s)

-Rubber

squeegee

-Q-Tip@

-Rubber

squeegee

-Q-Tip@

-Rubber

squeegee

Page 2

Powerex, Inc., 200 Hillis Street, Youngwood, Pennsylvania 15697-1800 (412) 925-7272

Powerex, Europe, S.A. 428 Avenue

G.

Durand, BP107, 72003 Le Mans, France (43) 41.14.14

II. Mounting TIps

A.

Mount studs

for

Stud Devices

to

a heat sink

through a clearance hole

of

(1)

hex

nut

and

a lockwasher or

nut or

(2)

hex

nut-belleville washer

hex

tenz

combination or

B.

Diameter

of

the mounting

clearance hole

the diameter of

1/64"

and

perpendicular to the

C.

Remove proJections from

the

should

nut.

should

not exceed

stud

by

be

accurately drilled

mounting

mounting clearance hole.

and drilled holes

deburred.

be

deburred

exceeding

D.

Avoid

drilling

stud

devices.

tends to

hole

degree perpendicularity tolerance

necessary

mounting

E.

Apply appropriate thermal

unscrew

can

Interface compound

film

to the

as

device

surface

stud

compound

threads of the

be

alter

torque

stud device.

F.

Always use a torque wrench

mounting

individual

correct

quality torque

specified

used.

applied

the semiconductor

of the heat

device

lubricated as

the

recommended

and

torque to

range,

The

on

should

The

edge

with

a chamfer not

.01

"

radius.

and

tapping holes for

Thermal

the

occur,

and

between

surface

mounting

well

on

and

cause

stud

device

torque

the

the hole

is

as

to the mounting

sink.

the heat sink to

to seat the device.

stud

and

this

undue

devices.

data

be

wrench,

should

should

hex

nut while holding

stationary.

be

of the hole

ratcheting

stud

the 1/10 of a

difficult to

in

a very thin

area

only of the

Rotate the

nut

will

drastically

mounting

stress on the

Refer

sheet for the

used.

accurate

always

always

by

more

surface.

Punched

carefully

from

and

achieve.

must

to the

A

good

in

be

means

pal

than

may

which

the

spread

The

not

when

the

be

G.

Do

not

exceed maximum

recommended torque limits.

Application of excessive torque

major

cause

of

stud

device

problems.

mechanically

torque or thermally

little.

III. Mounting Tips

A.

Machine

Semiconductors

damaged

or

spot face the heat

by

damaged

for

Disc Devices

can

too

sink mounting surface areas

diameter larger than that

to

disc pole face

Keep

spot

face

interference

disc

package.

B.

Use locating pins (or alternative

method)

optimum

Preassemble

hammer

each

useful

Improperly

using

wrong

device

of

causes

problems.

C.

Apply appropriate thermal

to

load

into center

heat

sink. A gauge

to prevent excessive

mounting

a locating

diameter,

seating

the silicon

of disc device mounting

Interface compound

film

to

the

mounting

device,

surfaces of the heat

disc to

seat the

D.

Check the polarity

prior to assembly to

is

Also

prior to

E.

Follow Clamping TIps

1.

2.

as

well

spread

devices.

installed

Use

clamp

even

Select the proper

aware

temperature limitation (less than

130°C for most

in

position

assembly.

a self-leveling type mounting

to

assure

distribution of

of

clamp

be mounted.

shallow to prevent

with

other parts of the

center the disc for

distribution.

roll

pins

with

a light

dowel

hole

block

disc off center or

pin

too

long

resulting

and

element,

as

the compound and to

the

desired

SCR

in

possible fracturing

are

major

in

a very thin

surfaces of the

to the

mounting

sinks.

Rotate the

of

the deVIce

insure

the device

direction.

gate

leads,

parallelism

pressure.

size

clamp;

insulation

clamps).

is

a

mounting

be

much

by

too

to

of

the

in

is

pin

length.

andlor

improper

/

etc.

and

be

3.

Coat

clamp

threads for

discs

with

Never-Seez®

equivalent

to prevent nut

binding

are

4.

Take

to prevent bodily

forces

resulting

a

becoming a flying

5.

Prestressing

force prior to actual

application

springs

clamps.

6.

Preset

assembly

deflection type indicators.

7.

Apply

evenly,

disc.

8.

Advance

equal

tightening

9.

Apply the

on

too

clamp,

down to correct force - start

clamping

a.

b.

type

and

when

high

being

applied.

necessary

can

result

in

the

broken

the

can

and

to

screen

indicators to

on

clamps that

clamping

and

perpendicularly to the

nuts onto clamp bolts

length

and

with

a

correct

the device data

much

force be

do

not

attempt to

procedure allover

Manual

appropriate

advance

until

gauge

or the

turns

on

HydrauliC

apply

the assembly

a

torque each nut

alternately to

Release

method -

nuts

either the

reads

required

are

applied,

type of

press method -

the calibrated force to

good

quality torque

press.

large

area

or

compound,

clamp

clamping

safety

harm

in

clamp breakage

projectile.

clamp

help

force

finger tight before

wrench.

force as described

sheet.

applied

wrench,

1/4

the

clamp

with

10ft.

in

order

thread

forces

precautions

as

high

bolt

to its

rated

use

in

the

to seat clamp

out defective

zero

before

have

smoothly,

Should

to the

back

again.

using

an

alternately

tum each

clamp

indicator

desired

force

number of

depending

used.

press.

Using

wrench,

1/4

tum

Ibs.

torque.

load

1-35

Page 3

Powerex, Inc., 200 Hillis Street, Youngwood, Pennsylvania 15697-1800 (412) 925-7272

Powerex, Europe, S.A.

F.

Install

disc

assemblies

way

that

the

always

semiconductor

affected by electrical connections or

supports. Only one of the

may

mounting bracket; cable and bus

connections that

sinks must

relief built

G.

IV.

Powerex recommends the use of a thermal

interface compound for all power

semiconductors. With the proper

application of a thermal interface

compound to fill the air voids, scratches,

and imperfections

mounting interface area, one can achieve

up to a twenty-fold improvement in device

case-to-sink thermal resistance as well as

retard oxidation or corrosion. The General

Purpose Thermal Interface Compound

Comparison Chart included in this

application information presents a

comparison of three different types of

thermal interface compounds. These

compounds are typical of those that are

commercially available; they have been

evaluated and tested by Powerex and have

been found to exhibit good field

performance. When property applied and

mounted per the recommendations

included herein, the use of these

compounds will allow the user to meet the

case-to-sink thermal resistance values

published on the Powerex device data

sheet

be

centered

be rigidly attached to a bus bar

be flexible or have stress

in.

Develop a thorough

procedure

every detail in mounting a disc is much

more critical than

device. Successful and reliable device

operation depends on itl

Application

428

Avenue

clamping

on

so as not to be

In

such

force

the

G.

Durand, BP107, 72003 Le Mans, France (43) 41.14.14

a

will

two heat sinks

bar

tie

to the other heat

disc

mounting

as attention to each and

in

mounting a stud

of

Thermal

in

the device/heat sink

Compounds

or

V.

Tips

For

Applying

Interface

A.

Always

mounting

to application of the thermal interface

a

compound.

Select

B.

Interface

application.

limitations, advantages, disadvantages,

etc. to see that they are compatible

with your needs.

Apply

C.

Interface

film

(s)

mounting surface(s). Rotate the device

on the heat sink(s) to spread

compound and to seat the device.

Thermal interface compound may

applied to the device mounting

interface(s)

sink flatness, finish, and surface

cleaning have been property

performed. Compound should still

applied in a very thin film and then

device rotated on heat sink per

previous directions.

Wipe

D.

from

with a Semiconductor Cleaning

Solvent and a lint-free towel after

mounting the device. Otherwise,

thermal compound on the insulator

(glass or ceramic) housing could

collect dust and metal particles and

cause arc-over.

E.

Use

sparingly.

compound is a major cause of device

mounting problems. The thermal

interface compound should appear

only as a thin, moist film when

properly applied

Compounds

perform

surface

the

appropriate

compound

appropriate

compound

to the device mounting interface

as well as to the heat sink

only

away

edges

thermal

Applying too much

Thermal

the

necessary

preparation

thermal

for

your

Note the temperature

thermal

In a

very

provided device/heat

excess

compound

of

the

contact

interface

to

compound

a mounting surface.

area

prior

thin

be

be

1-36

Loading...

Loading...