MKP 336 6 Y2

168x12(halfpage)

Vishay BCcomponents

Interference Suppression Film Capacitors

MKP Radial Potted Type

168x12(halfpage)

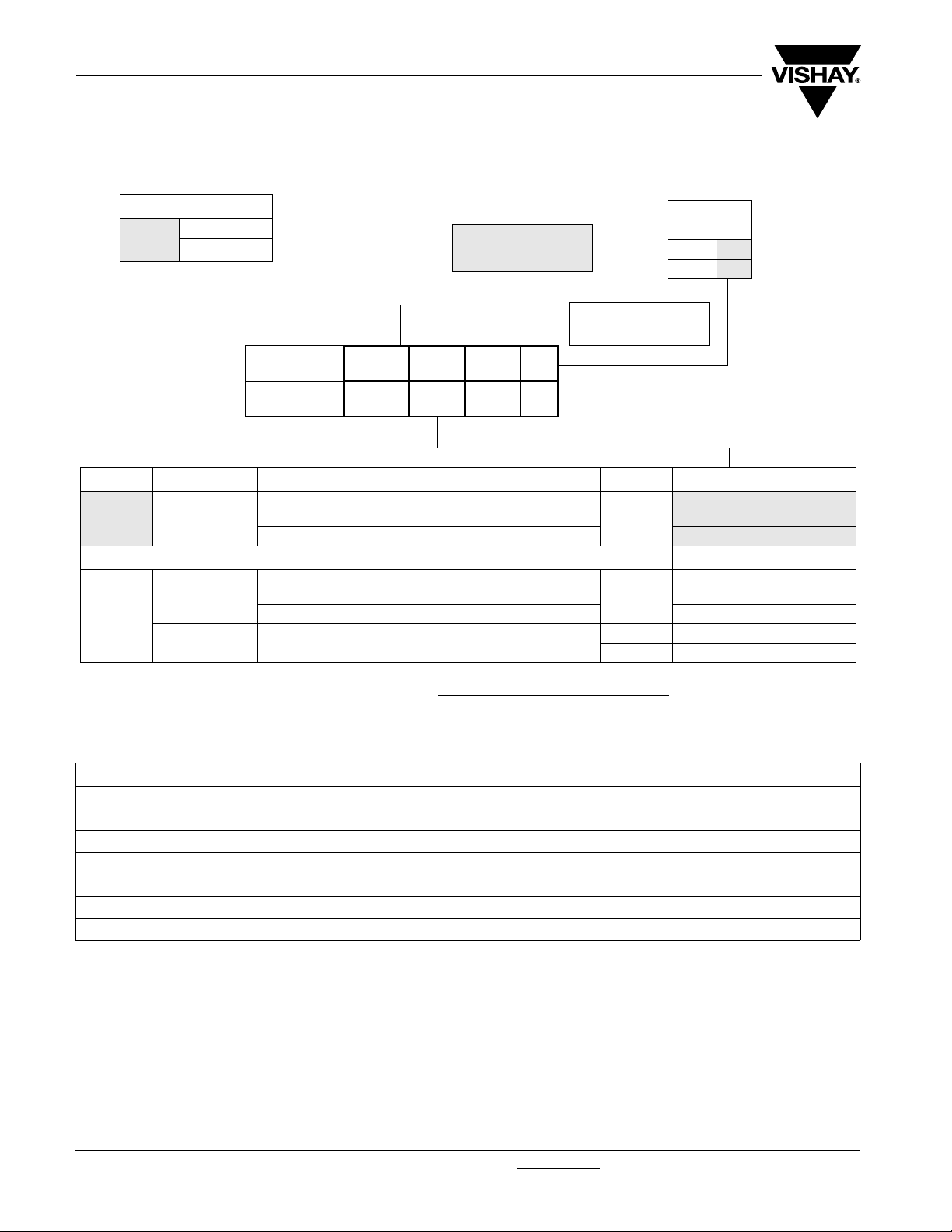

P ± 0.4

Dimensions in mm

l

h

l

t

w

Ø d

t

NO FOCUS PRODUCT: USE MKP 338 6 Y2

APPLICATIONS

Y2 class

For Y2 electromagnetic interference suppression between

line and ground applications (50/60 Hz) with a maximum

mains voltage of 300 Vac.

For application limitations refer to section “Application Notes”

FEATURES

10 mm to 15 mm lead pitch.

Supplied loose in box, taped on reel

Lead (Pb)-free product

RoHS compliant product

PERMISSIBLE DC VOLTAGE

DC 1000 V

ENCAPSULATION

Plastic case, epoxy resin sealed, flame retardant UL-class

94 V-0

CLIMATIC TESTING CLASS ACC. TO EN 60068-1

55/105/56/B

CAPACITANCE RANGE (E12 SERIES)

E12 series 0.001 µF to 0.047 µF

Preferred values acc. to E6

REFERENCE STANDARDS

“IEC 60384-14 2nd edition and EN 132400”

“IEC 60065 requires, pass. flamm. class B”

250 V: UL 1414; CSA-C22.2 No 1;

300 V: UL1283; ENEC

MARKING

C-value; tolerance; rated voltage; sub-class; manufacturer’s

type designation; code for dielectric material; manufacturer

location; year and week

DIELECTRIC

Polypropylene film

ELECTRODES

Metallized film

CONSTRUCTION

Series and triple construction

RATED VOLTAGE

AC 300 V; 50 Hz to 60 Hz

CAPACITANCE TOLERANCE

± 20 %; ± 10 %

LEADS

Tinned wire

MAXIMUM APPLICATION TEMPERATURE

105 °C

DETAIL SPECIFICATION

For more detailed data and test requirements contact:

rfi@vishay.com

Document Number: 28115 For technical questions, contact: rfi@vishay.com

Revision: 23-Dec-08 171

www.vishay.com

MKP 336 6 Y2

Vishay BCcomponents

Interference Suppression Film Capacitors

MKP Radial Potted Type

COMPOSITION OF CATALOG NUMBER

TYPE AND PITCHES

336 6

Y2

10.0 mm

15.0 mm

CAPACITANCE

(numerically)

Example:

103 = 10 x 1 = 10 nF

MULTIPLIER

(nF)

0.1

2

1

3

BFC2 336 6X XX X

2222

(*) Old ordering code

TYPE PACKAGING LEAD CONFIGURATION C-TOL PREFERRED TYPES

336 6

Y2

336 6

Y2

Note:

(1) For detailed tape specification refer to Packaging information: www.vishay.com/docs/28139/packinfo.pdf

loose in box

loose in box

taped on reel

lead length 3.5 + 1/- 0.5 mm (pitch = 10 mm) or

3.5 ± 0.3 mm (pitch = 15 mm)

lead length 25.0 ± 2.0 mm

lead length 3.5 + 1/- 0.5 mm (pitch = 10 mm) or

3.5 ± 0.3 mm (pitch = 15 mm)

lead length 25.0 ± 2.0 mm BFC2 336 67...

H = 18.5 mm; P0= 12.7 mm;

(1)

reel diameter 500 mm

(*)

336 6X XX X

± 20 %

± 10 %

± 20 % BFC2 336 63...

± 10 % BFC2 336 64...

BFC2 336 60...

BFC2 336 66...

ON REQUEST

BFC2 336 61...

SPECIFIC REFERENCE DATA MKP 336 6 300 VAC

DESCRIPTION VALUE

Tangent of loss angle:

Rated voltage pulse slope (dU/dt)R at 420 Vdc

R between leads, for C ≤ 0.33 µF at 100 V; 1 minute

R between leads and case; 100 V; 1 minute

Withstanding (DC) voltage (cut off current 10 mA); rise time 100 V/s

Withstanding (AC) voltage between leads and case

www.vishay.com For technical questions, contact: rfi@vishay.com

172 Revision: 23-Dec-08

at 10 kHz

≤ 10 x 10

> 15 000 MΩ

> 30 000 MΩ

3400 V; 1 minute

2100 V; 1 minute

- 4

200 V/µs

Document Number: 28115

MKP 336 6 Y2

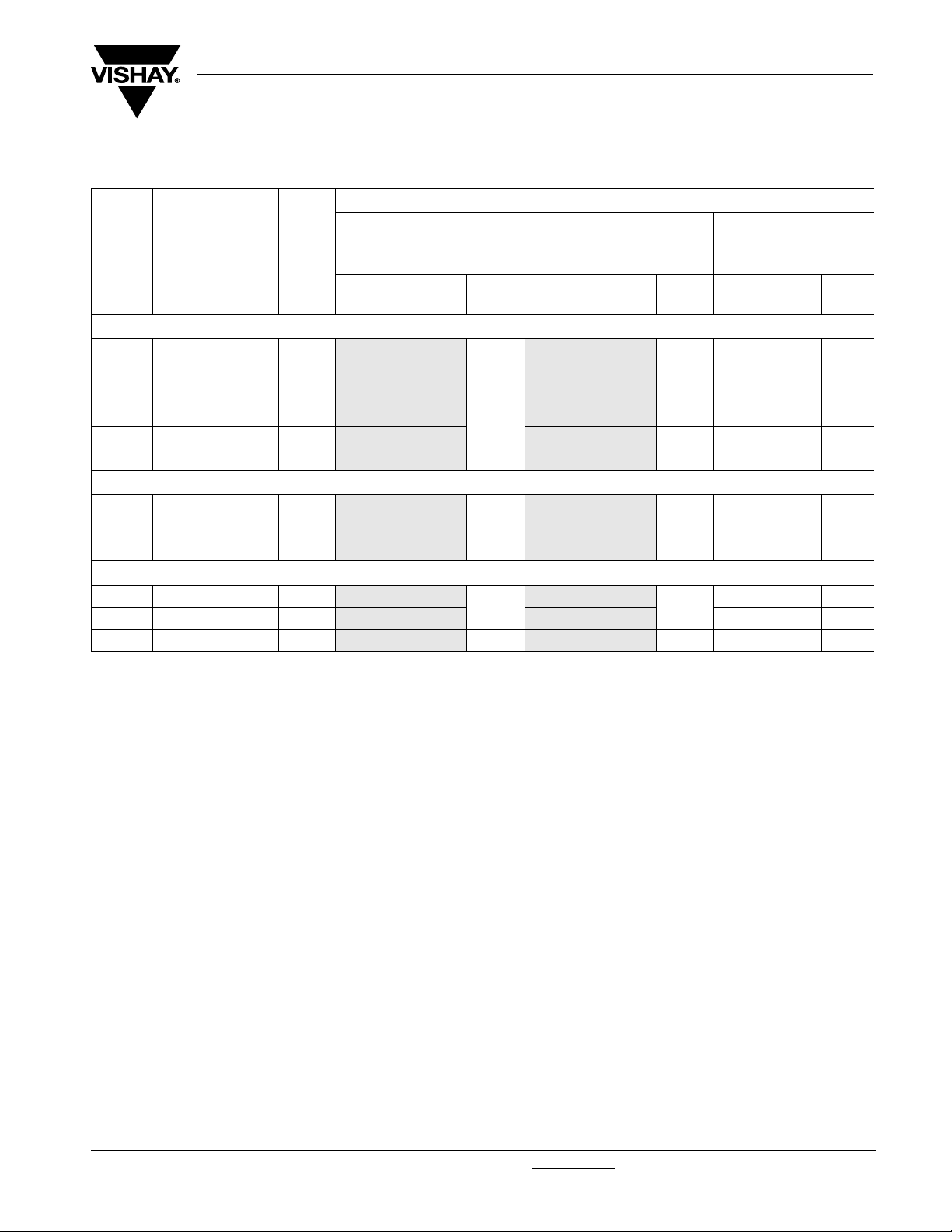

MKP 336 6 GENERAL DATA

U

= 300 V; C-tol = ± 20 %

Rac

C

(µF)

Pitch = 10.0 ± 0.4 mm; d

0.001

0.0015

0.0022

0.0033

0.0047

0.0068

Pitch = 15.0 ± 0.4 mm; d

0.0068

0.01

0.015 6.0 x 12.0 x 17.5 1.4

Pitch = 15.0 ± 0.4 mm; d

0.022 7.0 x 13.5 x 17.5 1.8

0.033 8.5 x 15.0 x 17.5 2.4

0.047 10.0 x 16.5 x 17.5 3.0

DIMENSIONS

W xHxL

(mm)

t

4.0 x 10.0 x 12.5 0.6

5.0 x 11.0 x 12.5 0.82

t

5.0 x 11.0 x 17.5 1.0

t

MASS

= 0.6 ± 0.06 mm

=0.6± 0.06 mm

=0.8± 0.08mm

Interference Suppression Film Capacitors

MKP Radial Potted Type

CATALOG NUMBER BFC2 336 6..... AND PACKAGING

LOOSE IN BOX REEL

= 3.5 + 1/- 0.5 mm (10 mm)

L

(g)

(1)

t

or 3.5 ± 03 mm (= 15 mm)

Last 5 digits of

catalog number

60102

60152 66152 63152

60222 66222 63222

60332 66332 63332

60472 66472

60682 66682 63682

69005

60103 66103 63103

60153 66153 63153 900

60223

60333 66333 63333 650

60473 500 66473 450 63473 600

SPQ

1000

1000

750

l

= 25.0 ± 2.0 mm

t

Last 5 digits of

catalog number

66102

69009

66223

Vishay BCcomponents

H = 18.5 mm;

P

= 12.7 mm

0

SPQ

1250

1000

1000

500

Last 5 digits of

catalog number

63102

63472

69006

63223 800

SPQ

1400

1100

1100

Note

(1)

Weight for short lead product only

Document Number: 28115 For technical questions, contact: rfi@vishay.com

Revision: 23-Dec-08 173

www.vishay.com

MKP 336 6 Y2

Vishay BCcomponents

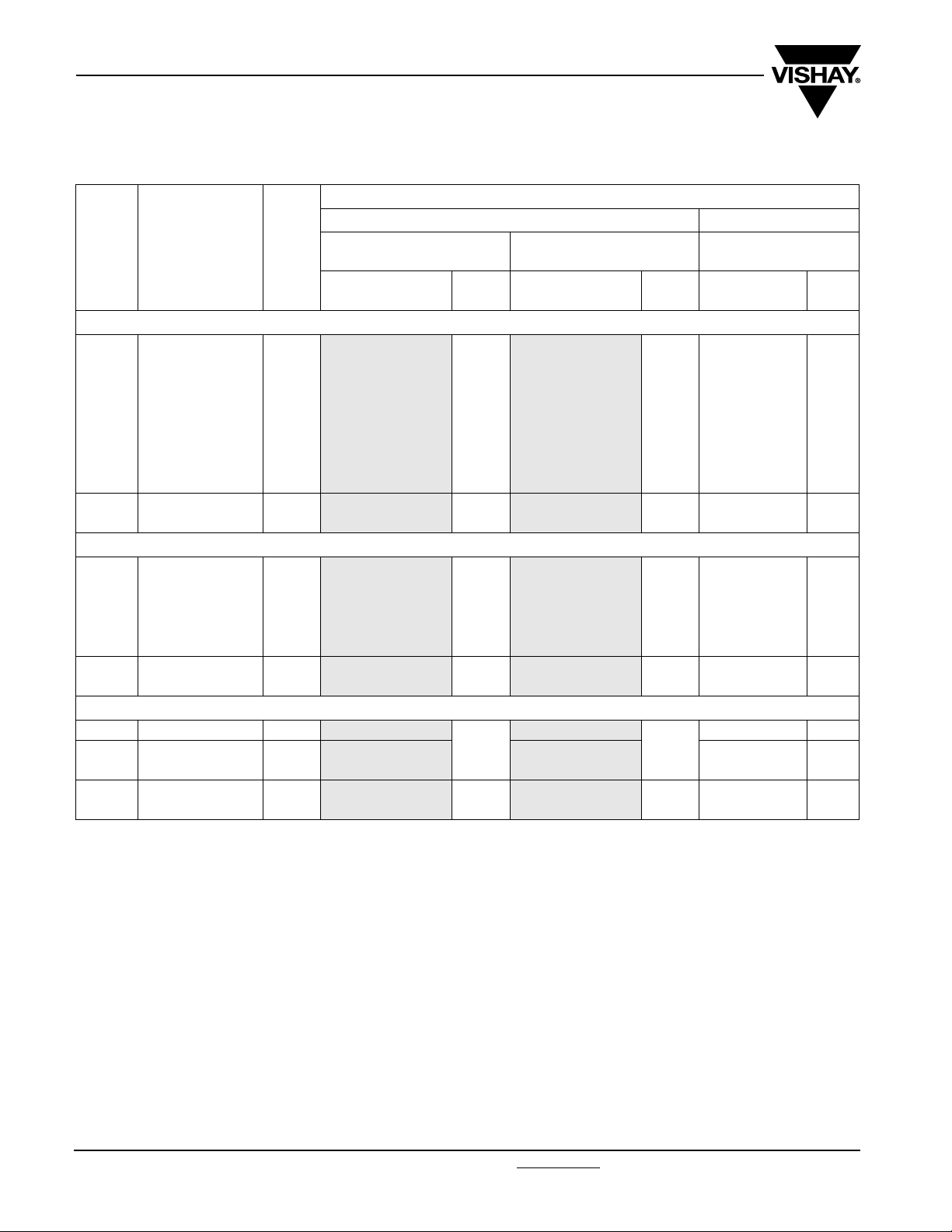

MKP 336 6 GENERAL DATA

U

= 300 V; C-tol = ± 10 %

Rac

C

(µF)

Pitch = 10.0 ± 0.4 mm; d

0.001

0.0012

0.0015

0.0018

0.0022

0.0027

0.0033

0.0039

0.0047

0.0056

Pitch = 15.0 ± 0.4 mm; d

0.0056

0.0068

0.0082

0.01

0.012

0.015

0.018

Pitch = 15.0 ± 0.4 mm; d

0.022 7.0 x 13.5 x 17.5 1.8

0.027

0.033

0.039

0.047

DIMENSIONS

WxHxL

(mm)

t

4.0 x 10.0 x 12.5 0.6

5.0 x 11.0 x 12.5 1.1

t

5.0 x 11.0 x 17.5 1.0

6.0 x 12.0 x 17.5 1.4

t

8.5 x 15.0 x 17.5 2.4

10.0 x 16.5 x 17.5 3.0

MASS

(g)

= 0.6 ± 0.06 mm

= 0.80 ± 0.08 mm

= 0.80 ± 0.08 mm

Interference Suppression Film Capacitors

MKP Radial Potted Type

CATALOG NUMBER BFC2 336 6..... AND PACKAGING

LOOSE IN BOX REEL

= 3.5 + 1/- 0.5 mm (10 mm)

L

t

(1)

or 3.5 ± 03 mm (= 15 mm)

Last 5 digits of

catalog number

61102

61122 67122 64122

61152 67152 64152

61182 67182 64182

61222 67222 64222

61272 67272 64272

61332 67332 64332

61392 67392 64392

61472

61562 67562 64562

69001

61682 67682 64682

61822 67822 64822

61103 67103 64103

61123 67123 64123

61153

61183 67183 64183

61223

61273 67273 64273

61333 67333 64333

61393

61473 67473 64473

SPQ

1000

1000

1000

1000

750

500

l

= 25.0 ± 2.0 mm

t

Last 5 digits of

catalog number

67102

67472

69007

67153

67223

67393

SPQ

1250

1000

1000

1000

500

450

H = 18.5 mm;

P

= 12.7 mm

0

Last 5 digits of

catalog number

64102

64472

69003

61153

64223 800

61393

SPQ

1400

1100

1100

900

650

600

Note

(1)

Weight for short lead product only

www.vishay.com For technical questions, contact: rfi@vishay.com Document Number: 28115

174 Revision: 23-Dec-08

MKP 336 6 Y2

6

Interference Suppression Film Capacitors

Vishay BCcomponents

MKP Radial Potted Type

SAFETY APPROVALS Y2 VOLTAGE VALUE FILE NUMBERS

EN132400 300 Vac 1 nF to 47 nF FI 2006018

UL1414 and CSA-C 22.2 No 1

antenna coupling

UL1283 300 Vac 1 nF to 47 nF E109565

The Enec-approval together with the CB-Certificate replace all national marks of the following countries (they have already signed the

ENEC-Agreement): Austria; Belgium; Czech. Republic; Denmark; Finland; France; Germany; Greece; Hungary; Ireland; Italy; Luxembourg;

Netherlands; Norway; Portugal; Slovenian; Spain; Switzerland and United Kingdom.

MOUNTING

Normal Use

The capacitors are designed for mounting on printed-circuit

boards. The capacitors packed in bandoliers are designed

for mounting in printed-circuit boards by means of automatic

insertion machines.

Specific Method of Mounting to Withstand Vibration and

Shock

In order to withstand vibration and shock tests, it must be

ensured that the stand-off pips are in good contact with the

printed-circuit board:

• The capacitors shall be mechanically fixed by the leads

250 Vac 1 nF to 47 nF E112471

Eccentricity

l

= I + 0.3 mm

max.

Storage Temperature

• Storage temperature: T

= - 25 °C to + 40 °C with RH

stg

maximum 80 % without condensation

b

= b + 0.3 mm

max.

CBA11

Space Requirements on printed Circuit Board

The maximum length and width of film capacitors is shown in

Figure:

• Eccentricity as in figure. The maximum eccentricity is

smaller than or equal to the lead diameter of the product

concerned

• Product height with seating plane as given by “IEC 60717”

as reference: h

≤ h + 0.3 mm

max.

Ratings and Characteristics Reference Conditions

Unless otherwise specified, all electrical values apply to an

ambient temperature of 23 °C ± 1 °C, an atmospheric

pressure of 86 kPa to 106 kPa and a relative humidity of

50 % ± 2 %.

For reference testing, a conditioning period shall be applied

over 96 hours ± 4 hours by heating the products in a

circulating air oven at the rated temperature and a relative

humidity not exceeding 20 %.

Document Number: 28115 For technical questions, contact: rfi@vishay.com

Revision: 23-Dec-08 175

www.vishay.com

MKP 336 6 Y2

Vishay BCcomponents

CHARACTERISTICS

Capacitance

4

ΔC/C

(%)

2

typical

0

- 2

- 4

- 6

- 50

Impedance

3

10

Impedance

(Ω)

101

100

0 50 100Ta mb (°C)

1 nF

4.7 nF

10 nF

47 nF

Interference Suppression Film Capacitors

MKP Radial Potted Type

Tangent of loss angle

3

10

)

- 4

Dissipation

Factor (x 10

2

10

1

10

min.

0

10

1

Resonant frequency

2

10

f (MHz)

1

10

2 3 4

10 nF < C ≤ 47 nF

10 nF

≤

C

5

10 10 101010

f (Hz)

10-1

-

2

10

4

10

5

10

6

10

10

Max RMS voltage and AC current (sinewave)

3

10

AC voltage

(V)

2

10

T

≤ 105 °C

amb

1

10

1

10

2

10

3

10

10

0

7

4

f (Hz)

f (Hz)

8

10

5

10

10

10

AC current

10

10

10

1

3

(mA)

1

0

-1

10

≤ 105 °C

4

47 nF

10 nF

4.7 nF

1nF

f (Hz)

C (nF)

10

5

10 47

T

amb

1

2

10

3

10

10

www.vishay.com For technical questions, contact: rfi@vishay.com Document Number: 28115

176 Revision: 23-Dec-08

MKP 336 6 Y2

Interference Suppression Film Capacitors

Vishay BCcomponents

MKP Radial Potted Type

Insulation resistance

6

10

RC (s)

5

10

4

10

0

20 40 60

APPLICATION NOTES

• For Y2 electromagnetic interference suppression between line and ground (50/60 Hz) with a maximum mains voltage of

300 Vac ± 10 % instability.

• These capacitors are not intended for continuous pulse applications. For these situations, capacitors of the AC and pulse

program must be used.

• The maximum ambient temperature must not exceed 105 °C.

• Rated voltage pulse slope:

If the pulse voltage is lower than the rated voltage, the values of the specific reference data can be multiplied by 420 Vdc and

divided by the applied voltage.

80

100

(°C)

T

amb

Document Number: 28115 For technical questions, contact: rfi@vishay.com

Revision: 23-Dec-08 177

www.vishay.com

MKP 336 6 Y2

Vishay BCcomponents

Interference Suppression Film Capacitors

MKP Radial Potted Type

INSPECTION REQUIREMENTS

General Notes:

1. Sub-clause numbers of tests and performance requirements refer to the “ Sectional Specification, IEC-puplication EN 132400

(IEC 60384-14) and section One of this specification”.

2. In this table: D = destructive

ND = non destructive

Group C inspection requirements

SUB - CLAUSE NUMBER

AND TEST

Group C inspection (periodic) see section “General notes“ item 3

SUB-GROUP C1A PART OF SAMPLE

OF SUB-GROUP C1

4.1 Dimensions (detail) As specified in Chapters “General data”

Initial measurements Capacitance

4.3 Robustness of

terminations

4.4 Resistance to soldering heat No pre-drying

4.19 Component solvent

resistance

4.4.2 Final measurements Visual examination No visible damage

SUB - GROUP C1B PART OF SAMPLE

OF SUB - GROUP C1

Initial measurements Capacitance

4.20 Solvent resistance of the marking:

see Section “General notes”; item 5

4.6 Rapid change of temperature θA = - 55 °C

4.6.1 Inspection Duration t = 30 minutes

D

OR

ND

D

Tangent of loss angle at 10 kHz

Tensile: load 10 N; 10 secondsBending:

load 5 N; 4 x 90°

Method: 1A

Solder bath: 260 °C

Duration: 10 seconds

Isopropylalcohol at room temperature

Method: 2

Immersion time: 5 ± 0.5 minutes

Recovery time:

Min. 1 hour, max. 2 hours

Capacitance |ΔC/C| ≤ 5 % of the value measured

Tangent of loss angle Increase of tan δ:

Insulation resistance As specified in Section “Insulation

D

Tangent of loss angle at 10 kHz

Isopropylalcohol at room temperature

Method: 1

Rubbing material: cotton wool

Immersion time: 5 ± 0.5 minutes

θB = + 105 °C

5 cycles

CONDITIONS PERFORMANCE REQUIREMENTS

of this specification

No visible damage

Legible marking

initially

≤ 0.008

Compared to values measured initially

Resistance” of this specification

No visible damage

Legible marking

www.vishay.com For technical questions, contact: rfi@vishay.com Document Number: 28115

178 Revision: 23-Dec-08

MKP 336 6 Y2

Interference Suppression Film Capacitors

Vishay BCcomponents

MKP Radial Potted Type

SUB - CLAUSE NUMBER

AND TEST

4.7 Vibration (see note 3) Visual examination

4.7.2 Final inspection Visual examination No visible damage

4.9 Shock (see note 3) Mounting: see Section “Mounting” for

4.9.2 Final measurements Visual examination No visible damage

SUB - GROUP C1 COMBINED

SAMPLE OF SPECIMENS OF

SUB - GROUPS C1A AND C1B

4.11 Climatic sequence

4.11.1 Initial measurements Capacitance

4.11.2 Dry heat Temperature: 105 °C

4.11.3 Damp heat cyclic

Tes t Db

First cycle

4.11.4 Cold Temperature: - 55 °C

4.11.5 Damp heat cyclic

Test Db

remaining cycles

4.11.6 Final measurements Visual examination No visible damage

D

OR

ND

Mounting: see Section “Mounting” of this

specification

Procedure B4

Frequency range: 10 Hz to 55 Hz.

Amplitude: 0.75 mm or

Acceleration 98 m/s²

(whichever is less severe)

Total duration 6 hours.

more information

Pulse shape: half sine

Acceleration: 490 m/s²

Duration of pulse: 11 ms.

Capacitance |ΔC/C| ≤ 5 % of the value measured

Tangent of loss angle Increase of tan δ:

Insulation resistance As specified in Section “Insulation

D

Measured in 4.4.2 and 4.9.2

Tangent of loss angle:

Measured initially in C1A and C1B

Duration: 16 hours

Duration: 2 hours

CONDITIONS PERFORMANCE REQUIREMENTS

No visible damage

initially

≤ 0.008

Compared to values measured

initially

Resistance” of this specification

Legible marking

Capacitance |ΔC/C| ≤ 5 % of the value measured in

Tangent of loss angle Increase of tan δ:

Voltage proof

2250 Vdc; 1 minute between term.

Insulation resistance ≥ 50 % of values specified in Section

Document Number: 28115 For technical questions, contact: rfi@vishay.com

Revision: 23-Dec-08 179

4.11.1.

≤ 0.008

Compared to values measured in

4.11.1.

No permanent breakdown or flash-over

“Insulation resistance” of this

specification

www.vishay.com

MKP 336 6 Y2

Vishay BCcomponents

Interference Suppression Film Capacitors

MKP Radial Potted Type

SUB - CLAUSE NUMBER

AND TEST

SUB - GROUP C2 D

4.12 Damp heat steady state 56 days, 40 °C, 90 to 95 % RH no load

4.12.1 Initial measurements Capacitance

4.12.3 Final measurements Visual examination No visible damage

D

OR

ND

capacitance

Tangent of loss angle at 10 kHz

Capacitance |ΔC/C| ≤ 5 % of the value measured in

Tangent of loss angle Increase of tan δ:

Voltage proof

2250 Vdc; 1 minute between term.

CONDITIONS PERFORMANCE REQUIREMENTS

Legible marking

4.12.1.

≤ 0.007

Compared to values measured in

4.12.1.

No permanent breakdown or flash-over

Insulation resistance ≥ 50 % of values specified in Section

SUB- GROUP C3 D

4.13.1 Initial measurements Capacitance

4.13 Impulse voltage 3 successive impulses, full wave, peak

4.14 Endurance Duration: 1000 hours

4.14.7 Final measurements Visual examination No visible damage

Tangent of loss angle at 10 kHz

voltage:

5 kV

Max. 24 pulses

1.7 U

at 105 °C

Rac

Once in every hour the voltage is

increased to 1000 V (RMS) for 0.1 s via

resistor of 47 Ω ± 5 %

Capacitance |ΔC/C| ≤ 10 % compared to values

Tangent of loss angle Increase of tan δ:

Voltage proof

2250 Vdc;

1 minute between terminations

“Insulation resistance” of this

specification

No selfhealing breakdowns or flashover

Legible marking

measured in 4.13.1.

≤ 0.007

Compared to values measured in

No permanent breakdown or flash-over

Insulation resistance ≥ 50 % of values specified in Section

www.vishay.com For technical questions, contact: rfi@vishay.com Document Number: 28115

180 Revision: 23-Dec-08

“Insulation resistance” of this

specification

MKP 336 6 Y2

Interference Suppression Film Capacitors

MKP Radial Potted Type

SUB - CLAUSE NUMBER

AND TEST

SUB - GROUP C 4 D

4.15 Charge and discharge 10 000 cycles

4.15.1 Initial measurements Capacitance

4.15.3 Final measurements Capacitance |ΔC/C| ≤ 10 % compared to values

SUB - GROUP C5 D

4.16 Radio frequency characteristic Resonance frequency As specified in Section “Resonant

SUB - GROUP C6 D

4.17 Passive flammability

Class B

D

OR

ND

(50 c/s) charge to U

Duration: 5 ms

Discharge resistance:

R

=

R

min.

Tangent of loss angle at 10 kHz

Tangent of loss angle Increase of tan δ:

Insulation resistance ≥ 50 % of values specified in Section

Bore of gas jet: Ø 0.5 mm

Fuel: butane

Test duration for actual volume V in mm³:

V ≤ 250: 10 seconds

250 < V ≤ 500: 20 seconds

500 < V ≤ 1750: 30 seconds

V > 1750: 60 seconds

One flame application

CONDITIONS PERFORMANCE REQUIREMENTS

half sinewave

R

420 Vdc

---------------------------------------------------

1.5 C dU()dt()⁄()×

= 2.2 Ω

measured in 4.15.1.

≤ 0.008

Compared to values measured in

4.15.1.

“Insulation resistance” of this

specification

frequency” of this specification. ± 10 %

After removing test flame from capacitor,

the capacitor must not continue to burn

for more than 10 seconds. No burning

particle must drop from the sample.

BCcomponents

Vishay

12 mm

~ 8 mm

45.0°

SUB - GROUP C7 D

4.18 Active flammability 20 x 5 kV discharges on the test

Document Number: 28115 For technical questions, contact: rfi@vishay.com

Revision: 23-Dec-08 181

capacitor connected to U

R

The cheese cloth around the capacitors

shall not burn with a flame.

No electrical measurements are

required.

www.vishay.com

Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 18-Jul-08 1

Loading...

Loading...