HFA320NJ40CPbF

Vishay High Power Products

Ultrafast Soft Recovery Diode, 320 A

TO-2 44

PRODUCT SUMMARY

I

F(AV)

V

R

at T

I

F(DC)

C

Lug

terminal

anode 1

Base common

cathode

320 A

400 V

255 A at 85 °C

HEXFRED

Lug

terminal

anode 2

®

FEATURES

• Very low Qrr and t

• Lead (Pb)-free

• Designed and qualified for industrial level

BENEFITS

• Reduced RFI and EMI

• Reduced snubbing

DESCRIPTION

HEXFRED® diodes are optimized to reduce losses and

EMI/RFI in high frequency power conditioning systems. An

extensive characterization of the recovery behavior for

different values of current, temperature and dI/dt simplifies

the calculations of losses in the operating conditions. The

softness of the recovery eliminates the need for a snubber in

most applications. These devices are ideally suited for

power converters, motors drives and other applications

where switching losses are significant portion of the total

losses.

rr

RoHS

COMPLIANT

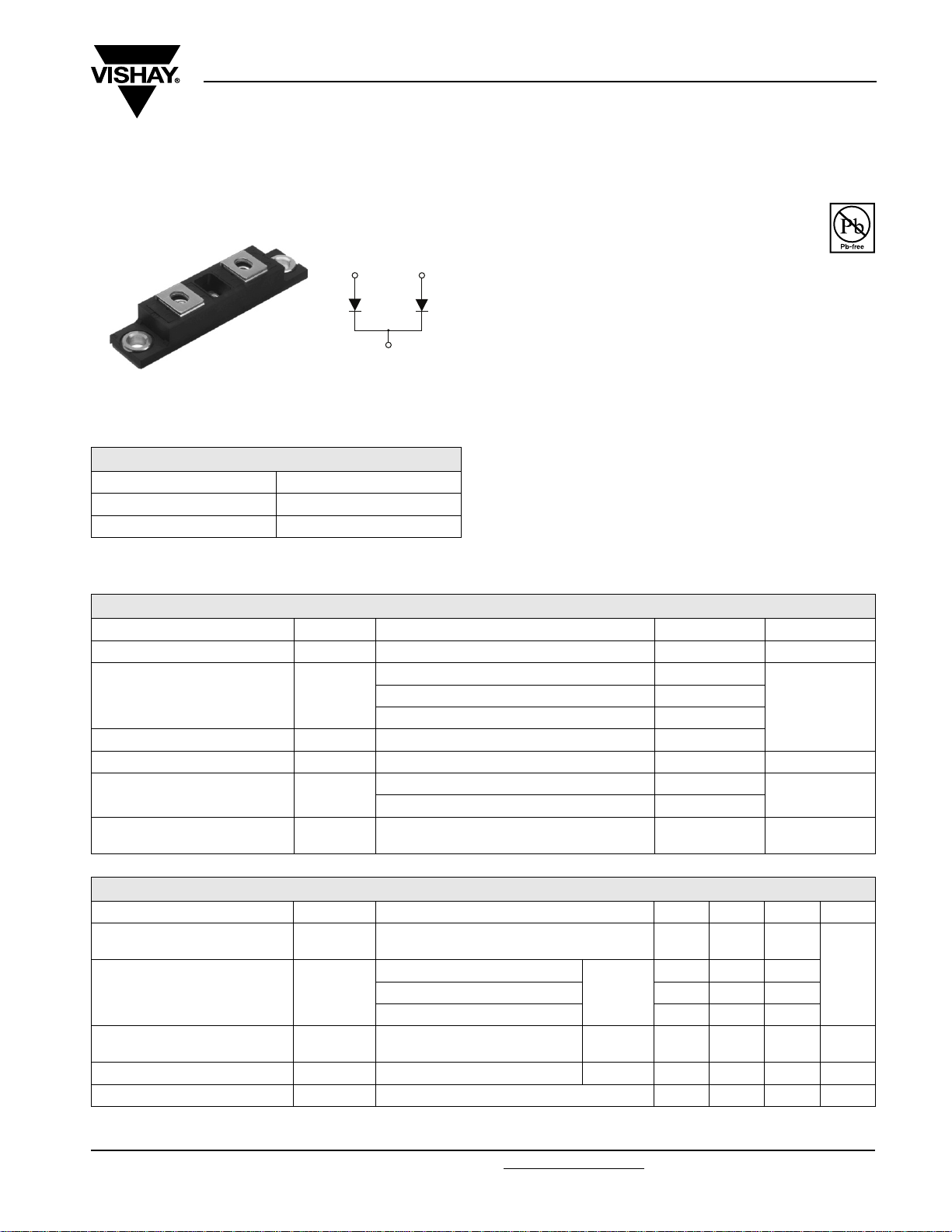

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL TEST CONDITIONS MAX. UNITS

Cathode to anode voltage V

Continuous forward current I

Single pulse forward current I

Non-repetitive avalanche energy E

Maximum power dissipation P

Operating junction and storage

temperature range

T

J

F

FSM

AS

, T

R

TC = 25 °C 420

= 85 °C 255

T

C

T

= 115 °C 160

C

Limited by junction temperature 1200

L = 100 µH, duty cycle limited by maximum T

D

TC = 25 °C 625

T

= 100 °C 250

C

Stg

J

400 V

A

1.4 mJ

W

- 55 to 150 °C

ELECTRICAL SPECIFICATIONS (TJ = 25 °C unless otherwise specified)

PARAMETER SYMBOL TEST CONDITIONS MIN. TYP. MAX. UNITS

Cathode to anode

breakdown voltage

Maximum forward voltage V

Maximum reverse

leakage current

Junction capacitance C

Series inductance L

V

BR

FM

I

RM

T

S

IR = 100 µA 400 - -

IF = 160 A

I

= 320 A - 1.30 1.54

F

I

= 160 A, TJ = 125 °C - 1.00 1.20

F

TJ = 125 °C, VR = 400 V See fig. 2 - 0.9 3 mA

VR = 200 V See fig. 3 - 370 500 pF

From top of terminal hole to mounting plane - 5.0 - nH

See fig. 1

- 1.10 1.35

V

Document Number: 94072 For technical questions, contact: ind-modules@vishay.com

Revision: 01-Aug-08 1

www.vishay.com

HFA320NJ40CPbF

Vishay High Power Products

HEXFRED

®

Ultrafast Soft Recovery

Diode, 320 A

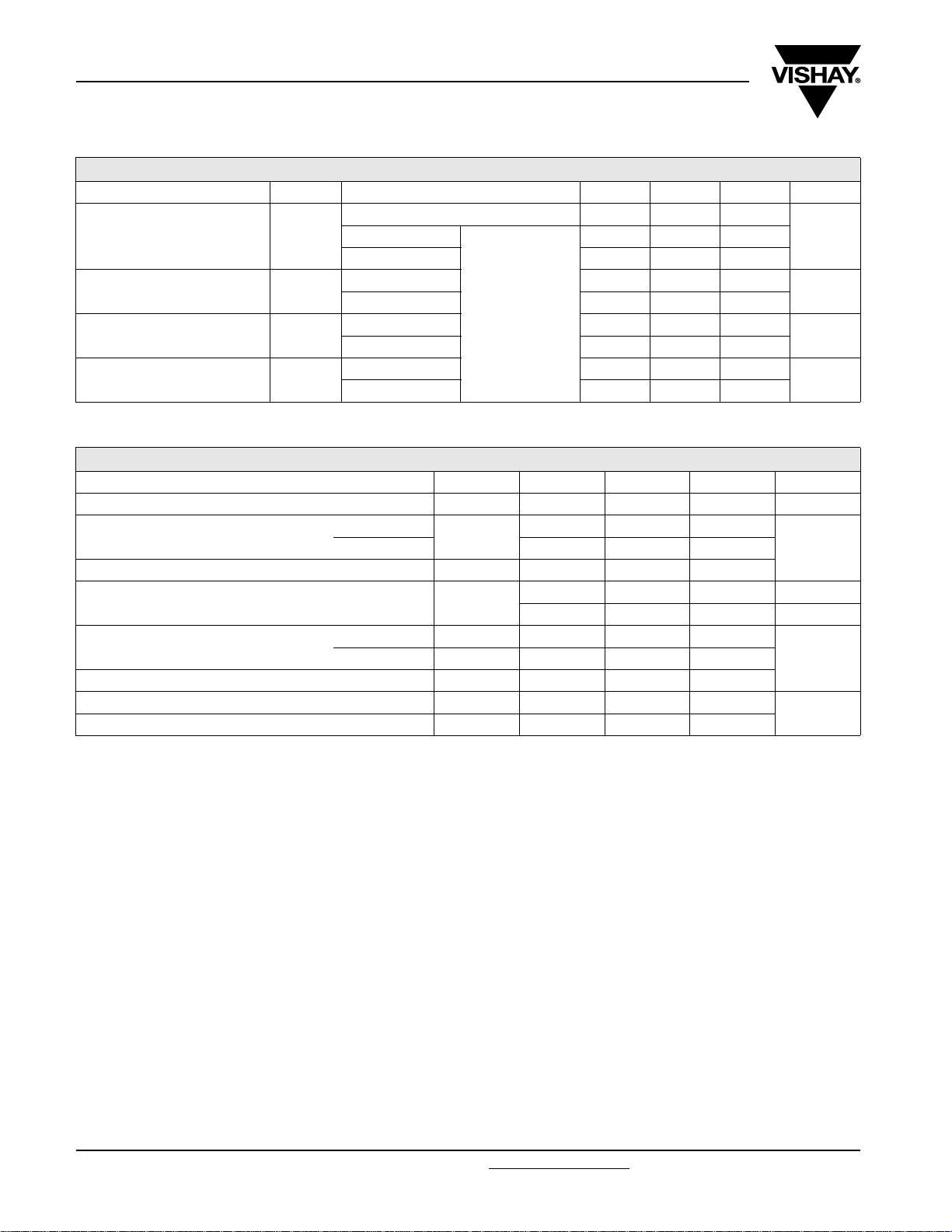

DYNAMIC RECOVERY CHARACTERISTICS (TJ = 25 °C unless otherwise specified)

PARAMETER SYMBOL TEST CONDITIONS MIN. TYP. MAX. UNITS

Reverse recovery time

See fig. 5

Peak recovery current

See fig. 6

Reverse recovery charge

See fig. 7

Peak rate of recovery current

See fig. 8

dI

t

rr

I

RRM

Q

(rec)M

THERMAL - MECHANICAL SPECIFICATIONS

PARAMETER SYMBOL MIN. TYP. MAX. UNITS

Maximum junction and storage temperature range T

Thermal resistance, junction to case

Typical thermal resistance, case to heatsink R

Weight

Mounting torque

Terminal torque 30 (3.4) - 40 (4.6)

Vertical pull --80

2" lever pull --35

Note

(1)

Mounting surface must be smooth, flat, free of burrs or other protrusions. Apply a thin even film or thermal grease to mounting surface.

Gradually tighten each mounting bolt in 5 to 10 lbf ⋅ in steps until desired or maximum torque limits are reached.

IF = 1.0 A, dIF/dt = 200 A/µs, VR = 30 V - 45 -

= 25 °C

J

T

= 125 °C - 290 440

J

- 90 140

TJ = 25 °C - 8.7 20

= 160 A

I

T

= 125 °C - 18 30

J

TJ = 25 °C - 420 1100

rr

T

= 125 °C - 2600 7000

J

= 25 °C - 300 -

T

J

/dt

T

= 125 °C - 280 -

J

per leg

per module - - 0.095

F

dI

/dt = 200 A/µs

F

V

= 200 V

R

, T

J

Stg

R

thJC

thCS

- 55 - 150 °C

- - 0.19

-0.10-

-68- g

-2.4-oz.

(1)

30 (3.4) - 40 (4.6)

center hole 12 (1.4) - 18 (2.1)

°C/W

K/W

N ⋅ m

(lbf ⋅ in)

lbf ⋅ in

nsT

A

nC

A/µs

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94072

2 Revision: 01-Aug-08

HFA320NJ40CPbF

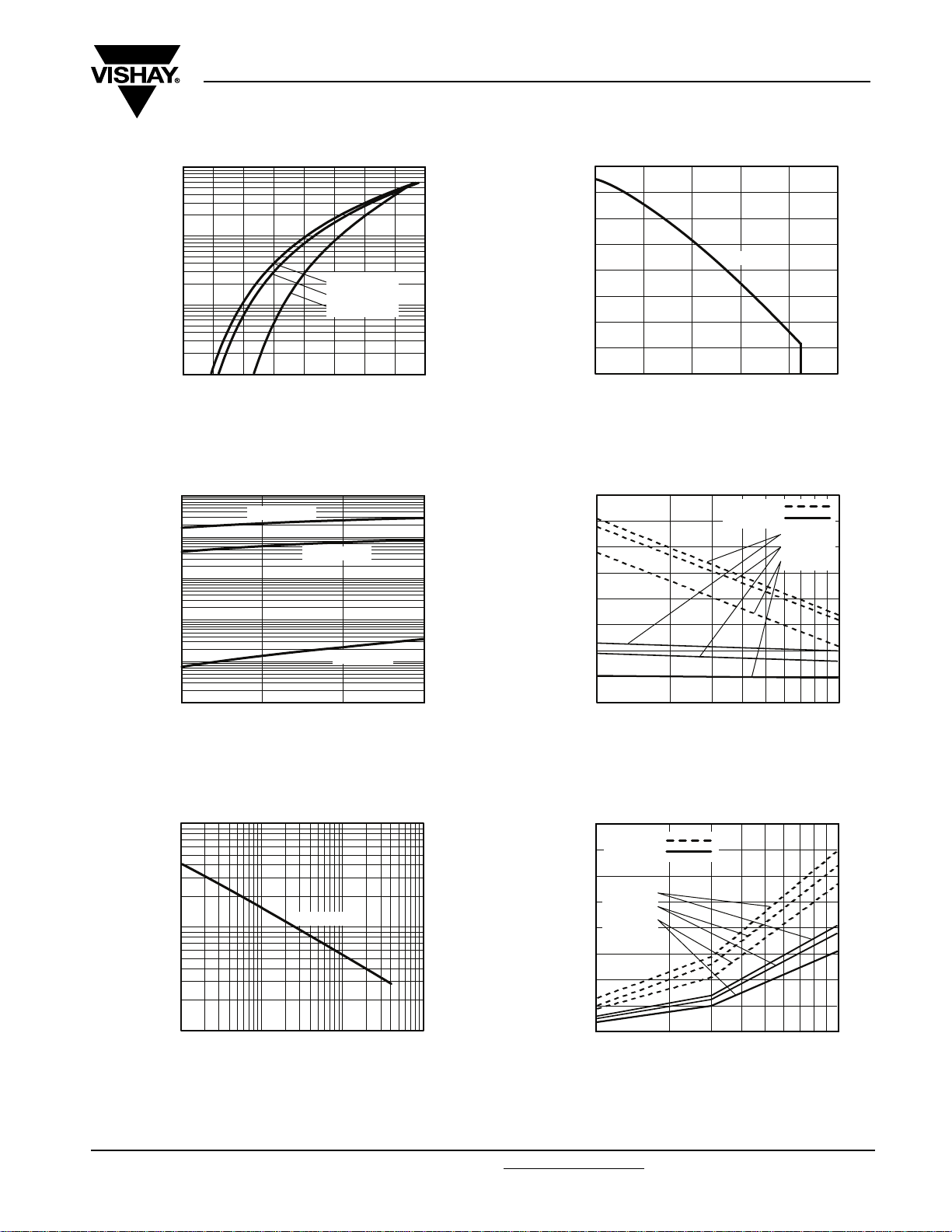

1000

100

10

1

- Instantaneous Forward Current (A)

F

I

0.2 1.80.8

0.4 1.4

Fig. 1 - Maximum Forward Voltage Drop vs.

Instantaneous Forward Current (Per Leg)

10 000

1000

100

10

- Reverse Current (µA)

1

R

I

0.1

100

Fig. 2 - Typical Reverse Current vs.

Ultrafast Soft Recovery

TJ = 150 °C

= 125 °C

T

J

= 25 °C

T

J

0.6 1.0 1.61.2

VFM - Forward Voltage Drop (V)

TJ = 150 °C

TJ = 125 °C

TJ = 25 °C

200

VR - Reverse Voltage (V)

Reverse Voltage (Per Leg)

300

HEXFRED

®

Diode, 320 A

400

Vishay High Power Products

160

140

120

100

80

60

Case Temperature (°C)

40

20

0

0 100 300 500

I

F(AV)

200 400

- DC Forward Current (A)

Maximum Allowable

Fig. 4 - Maximum Allowable Case Temperature vs. DC

Forward Current (Per Leg)

400

350

300

250

200

(ns)

rr

t

150

100

50

0

100

dIF/dt (A/µs)

Fig. 5 - Typical Reverse Recovery Time vs. dI

DC

TJ = 125 °C

TJ = 25 °C

IF = 200 A

= 160 A

I

F

= 70 A

I

F

/dt (Per Leg)

F

1000

10 000

1000

- Junction Capacitance (pF)

T

C

100

1 10 100 1000

TJ = 25 °C

VR - Reverse Voltage (V)

Fig. 3 - Typical Junction Capacitance vs. Reverse Voltage

80

TJ = 125 °C

70

TJ = 25 °C

60

IF = 200 A

50

= 160 A

I

(A)

RRM

I

F

= 70 A

I

F

40

30

20

10

0

100

dIF/dt (A/µs)

Fig. 6 - Typical Recovery Current vs. dI

1000

/dt (Per Leg)

F

(Per Leg)

Document Number: 94072 For technical questions, contact: ind-modules@vishay.com

www.vishay.com

Revision: 01-Aug-08 3

HFA320NJ40CPbF

Vishay High Power Products

7000

TJ = 125 °C

TJ = 25 °C

6000

(nC)

rr

Q

5000

4000

3000

2000

1000

IF = 200 A

= 160 A

I

F

= 70 A

I

F

0

100

dIF/dt (A/µs)

Fig. 7 - Typical Stored Charge vs. dIF/dt (Per Leg) Fig. 8 - Typical dI

1

HEXFRED

®

Ultrafast Soft Recovery

Diode, 320 A

10 000

1000

/dt (A/µs)

(rec)M

dI

1000

100

100

200 A

160 A

70 A

TJ = 125 °C

TJ = 25 °C

dIF/dt (A/µs)

/dt vs. dIF/dt (Per Leg)

(rec)M

1000

0.1

D = 0.50

0.01

- Thermal Response

thJC

Z

0.001

0.00001 0.0001 0.001 0.01 0.1

Single pulse

(thermal response)

D = 0.33

D = 0.25

D = 0.17

D = 0.08

t1 - Rectangular Pulse Duration (s)

Fig. 9 - Maximum Thermal Impedance Z

Characteristics (Per Leg)

thJC

1

10

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94072

4 Revision: 01-Aug-08

HFA320NJ40CPbF

HEXFRED

Ultrafast Soft Recovery

Diode, 320 A

L = 70 µH

dIF/dt

adjust

Fig. 10 - Reverse Recovery Parameter Test Circuit

I

F

0

(1)

/dt - rate of change of current

(1) dI

F

through zero crossing

- peak reverse recovery current

(2) I

RRM

- reverse recovery time measured

(3) t

rr

from zero crossing point of negative

going I

through 0.75 I

extrapolated to zero current.

to point where a line passing

F

and 0.50 I

RRM

Fig. 11 - Reverse Recovery Waveform and Definitions

dIF/dt

RRM

G

V

= 200 V

R

®

Vishay High Power Products

0.01 Ω

D.U.T.

D

IRFP250

S

(3)

t

rr

t

a

(2)

I

RRM

t

b

(4)

Q

rr

0.5 I

RRM

dI

/dt

(rec)M

0.75 I

RRM

(4) Q

- area under curve defined by t

rr

and I

RRM

trr x I

(5) dI

current during t

=

Q

rr

/dt - peak rate of change of

(rec)M

portion of t

b

(5)

rr

RRM

2

rr

L = 100 µH

I

L(PK)

High-speed

D.U.T.

Current

monitor

R

g

= 25 Ω

switch

Freewheel

diode

V

d

= 50 V

+

Decay

time

V

(AVAL)

V

R(RATED)

Fig. 12 - Avalanche Test Circuit and Waveforms

Document Number: 94072 For technical questions, contact: ind-modules@vishay.com

www.vishay.com

Revision: 01-Aug-08 5

HFA320NJ40CPbF

Vishay High Power Products

HEXFRED

®

Ultrafast Soft Recovery

Diode, 320 A

ORDERING INFORMATION TABLE

Device code

Dimensions http://www.vishay.com/doc?95021

HFA 320 NJ 40 C PbF

51324

6

- HEXFRED® family, electron irradiated

1

2 - Average current rating

3 - NJ = TO-244

4

- Voltage rating (400 V)

5

- C = Common cathode

6

- Lead (Pb)-free

LINKS TO RELATED DOCUMENTS

www.vishay.com For technical questions, contact: ind-modules@vishay.com

6 Revision: 01-Aug-08

Document Number: 94072

DIMENSIONS in millimeters (inches)

3

2

3

1

Ø 5.2 (Ø 0.20)

9.6 (0.37) MIN.

93 (3.66) MAX.

¼" - 20 UNC

80 (3.15)

13 (0.51)

35 (1.37) REF.

7 (0.27)

6 (0.23)

17.5 (0.69)

16.5 (0.65)

21 (0.82)

20 (0.78)

Ø 7.2 (Ø 0.28)

(2 places)

12.6 (0.5)

Outline Dimensions

Vishay Semiconductors

TO-244

Document Number: 95021 For technical questions, contact: indmodules@vishay.com

Revision: 25-Jun-07 1

www.vishay.com

Legal Disclaimer Notice

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk and agree

to fully indemnify and hold Vishay and its distributors harmless from and against any and all claims, liabilities, expenses and

damages arising or resulting in connection with such use or sale, including attorneys fees, even if such claim alleges that Vishay

or its distributor was negligent regarding the design or manufacture of the part. Please contact authorized Vishay personnel to

obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 11-Mar-11 1

Loading...

Loading...