Ultrafast, Soft Recovery Diode

Bulletin PD-20617 07/00

HFA04SD60S

Features

• Ultrafast Recovery Time

• Ultrasoft Recovery

• Very Low I

• Very Low Q

• Guaranteed Avalanche

• Specified at Operating Temperature

RRM

rr

Benefits

• Reduced RFI and EMI

• Reduced Power Loss in Diode and

Switching Transistor

• Higher Frequency Operation

• Reduced Snubbing

• Reduced Parts Count

Description/ Applications

These diodes are optimized to reduce losses and EMI/RFI in

high frequency power conditioning systems. The softness of the

recovery eliminates the need for a snubber in most applications.

These devices are ideally suited for freewheeling, flyback,

power converters, motor drives, and other applications where

high speed and reduced switching losses are design

requirements.

Package Outline

I

F(AV)

D - PAK

t

= 38ns

rr

= 4Amp

VR = 600V

Absolute Maximum Ratings

Parameters Max Units

V

RRM

I

F(AV)

I

FSM

I

FRM

P

D

TJ, T

Cathode-to-Anode Voltage 600 V

Continuous Forward Current 4 A

TC = 100°C

Single Pulse Forward Current 25

Peak Repetitive Forward Current 16

TC = 116°C

Maximum Power Dissipation 10 W

TC = 100°C

Operating Junction and Storage Temperatures - 55 to 150 °C

STG

1

HFA04SD60S

Bulletin PD-20617 07/00

Electrical Characteristics @ T

Parameters

VBR, VrBreakdown Voltage, 600 - - V IR = 100µA

Blocking Voltage

V

F

I

R

C

T

L

S

Forward Voltage - 1.5 1.8 V IF = 4A

See Fig. 1 - 1.8 2.2 V IF = 8A

Max. Reverse Leakage Current - 0.17 3.0 µA VR = VR Rated

Junction Capacitance - 4 8 pF VR = 200V

Series Inductance - 8.0 - nH Measured lead to lead 5mm from package body

= 25°C (unless otherwise specified)

J

Min Typ

- 1.4 1.7 V IF = 4A, TJ = 125°C

- 44 300 µA TJ = 125°C, VR = 0.8 x VR Rated

Max Units

Test Conditions

Dynamic Recovery Characteristics @ TJ = 25°C (unless otherwise specified)

Parameters

di

t

rr

I

RRM

Q

(rec)

rr

Reverse Recovery Time -17-nsIF = 1.0A, diF/dt = 200A/µA, VR = 30V

Peak Recovery Current - 2.9 5.2 A TJ = 25°C

Reverse Recovery Charge - 40 60 nC TJ = 25°C

/dt Rate of Fall of recovery Current - 280 - TJ = 25°C

M

Min

Typ Max Units Test Conditions

- 28 426 TJ = 25°C

-3857 TJ = 125°C

- 3.7 6.7 TJ = 125°C

- 70 105 TJ = 125°C

A/µs

- 235 - TJ = 125°C

I

= 4A

F

VR = 200V

diF /dt = 200A/µs

Thermal - Mechanical Characteristics

Parameters Min Typ Max Units

T

J

T

Stg

T

S

R

thJC

R

thJA

Wt Weight - 2.0 - g

T Mounting Torque 6.0 - 12 Kg*cm

! Typical Socket Mount

2

Max. Junction Temperature Range - - - 55 to 150 °C

Max. Storage Temperature Range - - - 55 to 150

Soldering Temperature, 10 sec - - 240

Thermal Resistance, Junction to Case - - 5.0 °C/ W

!

Thermal Resistance, Junction to Ambient - - 80

- 0.07 - (oz)

5.0 - 10 lbf*in

(A)

0.001

0.01

0.1

1

10

100

1000

0 100 200 300 400 500

25˚C

125˚C

T = 150˚C

J

0.1

1

10

00

0123456

T = 150˚C

T = 125˚C

T = 25˚C

J

J

J

F

Instantaneous Forward Current - I

HFA04SD60S

Bulletin PD-20617 07/00

(µA)

R

Reverse Current - I

Reverse Voltage - VR (V)

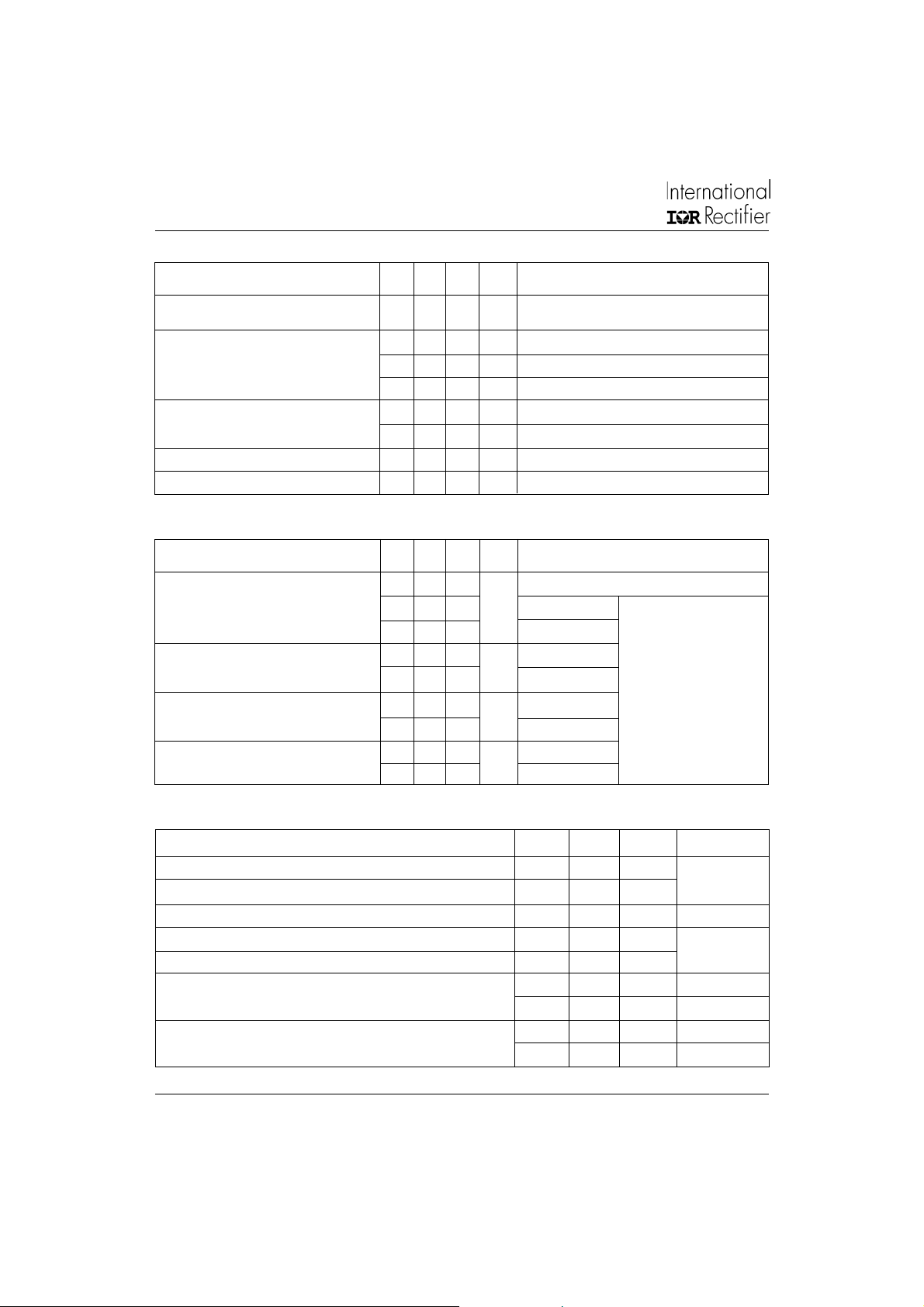

Fig. 2 - Typical Values Of Reverse Current

100

(pF)

T

Vs. Reverse Voltage

T = 25˚C

J

Forward Voltage Drop - VFM (V)

Fig. 1 - Typical Forward Voltage Drop Characteristics

10

D = 0.50

1

D = 0.20

D = 0.10

D = 0.05

(°C/W)

thJC

D = 0.02

D = 0.01

Single Pulse

(Thermal Resistance)

t1, Rectangular Pulse Duration (Seconds)

Thermal Impedance Z

0.1

.01

0.00001 0.0001 0.001 0.01 0.1

Fig. 4 - Max. Thermal Impedance Z

10

Junction Capacitance - C

1

1 10 100 1000

Reverse Voltage - VR (V)

Fig. 3 - Typical Junction Capacitance

Vs. Reverse Voltage

P

DM

t

1

t

2

Notes:

1. Duty factor D = t1/ t2

2. Peak Tj = Pdm x ZthJC + Tc

Characteristics

thJC

3

HFA04SD60S

100

1000

100 1000

If = 8A

If = 4A

Vr = 200V

Tj = 125˚C

Tj = 25˚C

Bulletin PD-20617 07/00

50

If = 8A

If = 4A

40

14

12

10

If = 8A

If = 4A

8

trr (nC)

Irr (A)

6

30

4

Vr = 200V

Tj = 125˚C

Tj = 25˚C

20

100 1000

di

/dt (A/ µs)

F

2

0

100 1000

Average Forward Current - I

Vr = 200V

Tj = 125˚C

Tj = 25˚C

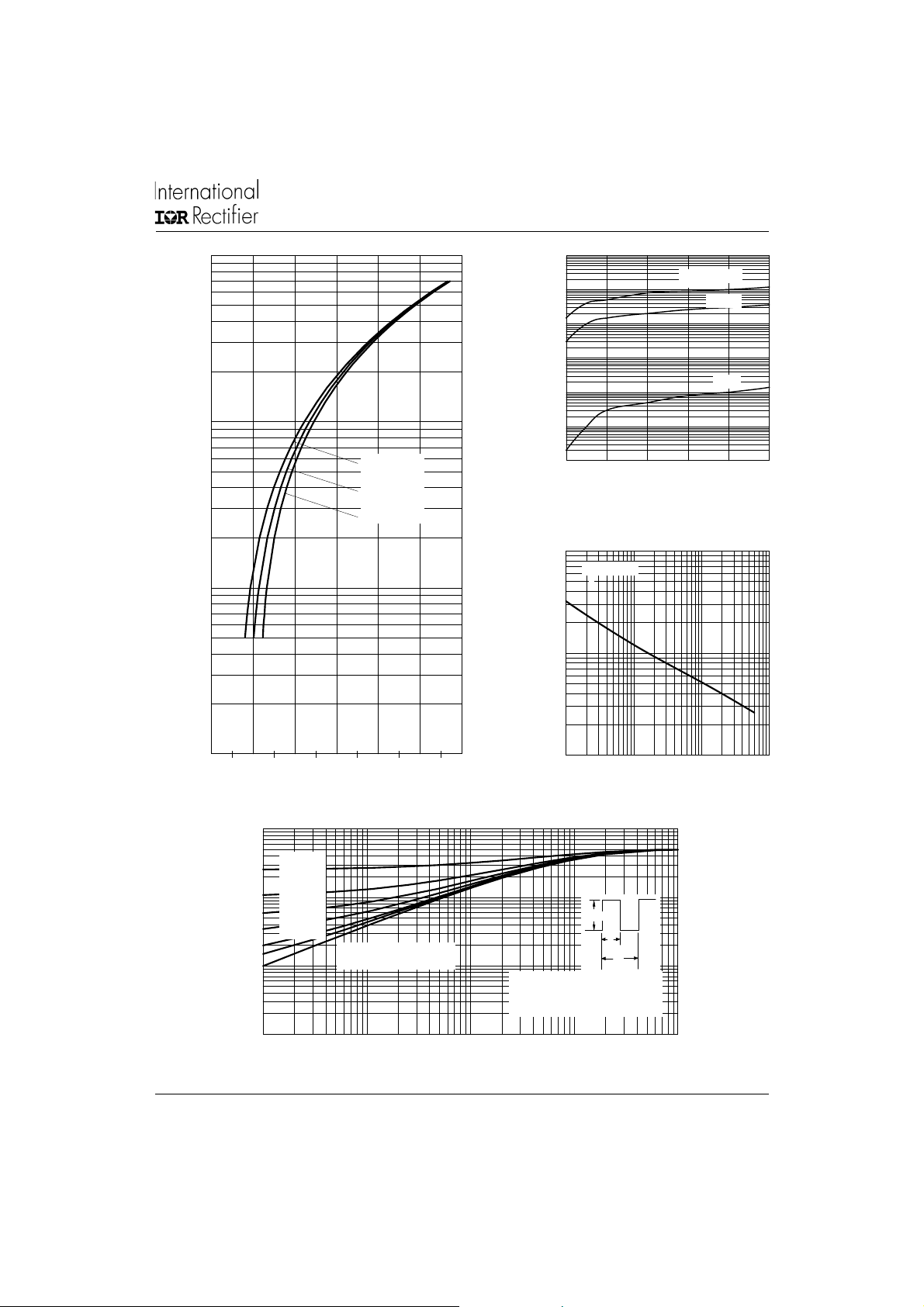

Fig. 5 - Typical Reverse Recovery vs. di F /dt Fig. 6 - Typical Recovery Current vs. di

00

Vr = 200V

Tj = 125˚C

80

Tj = 25˚C

60

F(AV)

(A)

/dt

F

4

40

20

00

Qrr ( nC )

If = 8A

If = 4A

80

60

40

20

100 1000

di

/dt (A/µs )

F

Fig. 7 - Typical Stored Charge vs. di

/ dt (A/ µs)

(rec)M

di

di F /dt (A/µs )

/dt

F

Fig. 8 - Typical di

(rec)M

/dt vs. di

/dt

F

Reverse Recovery Circuit

V = 200V

R

0.01

Ω

L = 70µH

D.U.T.

HFA04SD60S

Bulletin PD-20617 07/00

di F /dt

dif/dt

ADJUST

G

Fig. 9- Reverse Recovery Parameter Test Circuit

I

F

t

a

0

1

di F /dt

di /dt

f

1. diF/dt - Rate of change of current through zero

crossing

2. I

- Peak reverse recovery current

RRM

3. t

- Reverse recovery time measured from zero

rr

crossing point of negative going IF to point where

a line passing through 0.75 I

extrapolated to zero current

RRM

and 0.50 I

RRM

3

2

D

IRFP250

S

t

rr

t

b

Q

I

RRM

0.5

di(rec)M/dt

0.75

I

RRM

4. Qrr - Area under curve defined by t

and I

RRM

Q

rr

5. di

/dt - Peak rate of change of

(rec)M

current during tb portion of t

rr

I

=

4

RRM

t rr x I

RRM

2

5

rr

rr

Fig. 10 - Reverse Recovery Waveform and Definitions

5

HFA04SD60S

Bulletin PD-20617 07/00

Outline Table

6.73 (0.26)

6.35 (0.25)

5.46 (0.21)

5.21 (0.20)

4

1.64 (0.02)

123

1.52 (0.06)

1.15 (0.04)

1.14 (0.04)

2x

0.76 (0.03)

2.28 (0.09)

2x

Conform to JEDEC outline D-Pak

Dimensions in millimeters and (inches)

Tape & Reel Information

TRR

FEED DIRECTION

TRL

FEED DIRECTION

1.85 (0.073)

1.65 (0.065)

1.27 (0.05)

0.88 (0.03)

6.22 (0.24)

5.97 (0.23)

0.89 (0.03)

3x

0.64 (0.02)

4.57 (0.18)

4.10 (0.161)

3.90 (0.153)

10.9 0 (0.4 29)

10.7 0 (0.4 21)

2.38 (0.09)

2.19 (0.08)

10.42 (0.41)

9.40 (0.37)

1 - Anode

2 - Cathode

3 - Anode

4 - Cathode

1.60 (0.063)

1.50 (0.059)

1.60 (0. 063)

1.50 (0. 059)

11.6 0 (0.4 57)

11.4 0 (0.4 49)

1.75 (0.069)

1.25 (0.049)

16.1 0 (0.6 34)

15.9 0 (0.6 26)

1.14 (0.04)

0.89 (0.03)

0.58 (0.02)

0.46 (0.02)

6.45 (0.24)

5.68 (0.22)

0.51 (0.02)

MIN.

0.58 (0.02)

0.46 (0.02)

DIA.

DIA.

15.42 (0.6 09)

15.22 (0.6 01)

MINIMUM RECOMMENDED FOOTPRINT

5.97 (0.24)

6.48 (0.26)

10.67 (0.42)

2x

2.54 (0.10)

1.65 (0.06)

2.28 (0.09)

2x

2x

BASE

CATHODE

4

123

CATHODE ANODEANODE

0.368 (0.0145)

0.342 (0.0135)

24.3 0 (0.95 7)

23.9 0 (0.94 1)

4.72 (0.186)

4.52 (0.178)

360 (14.173)

DIA. M AX.

13.5 0 (0.5 32)

12.8 0 (0.5 04)

DIA.

26.4 0 (1.0 39)

24.4 0 (0.9 61)

60 (2 .362)

DIA. MIN.

SMD-220 Tape & Reel

When order ing, indicate th e part

SMD-220 Tape & Reel

number, part orientation, and th e

quantity. Quantities are in multiples

When ordering, indicate the part

of 8 00 pi eces p er reel for bo th

number, part orientation and the

TRL an d TRR.

quantity. Quantities are in

multiples of 800 pieces per reel for

both TRL and TRR.

6

Marking Information

HFA04SD60S

Bulletin PD-20617 07/00

EXAMPLE: THIS IS AN HFA04SD60S

Ordering Information Table

Device Code

HF A 04 SD 60 S

1

2

1 - Hexfred Family

2 - Electron Irradiated

3 - Current Rating (04 = 4A)

4 - D-PAK

5 - Voltage Rating (60 = 600V)

6 - Suffix

INTERNATIONAL

RECTIFIER LOGO

4

3

ASSEMBLY

LOT CODE

5

2 (K)

PART NUMBER

HFA04SD60S

9812

5K3A

DATE CODE (YYWW)

YY = YEAR

1 (K) 3 (A)

WW = WEEK

6

S= D2PAK/ Dpak

TR = Tape & Reel

TRL = Tape & Reel Left

TRR = Tape & Reel Right

WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245 U.S.A. Tel: (310) 322 3331. Fax: (310) 322 3332.

EUROPEAN HEADQUARTERS: Hurst Green, Oxted, Surrey RH8 9BB, U.K. Tel: ++ 44 1883 732020. Fax: ++ 44 1883 733408.

IR SOUTHEAST ASIA: 1 Kim Seng Promenade, Great World City West Tower,13-11, Singapore 237994. Tel: ++ 65 838 4630.

IR CANADA: 15 Lincoln Court, Brampton, Markham, Ontario L6T3Z2. Tel: (905) 453 2200. Fax: (905) 475 8801.

IR GERMANY: Saalburgstrasse 157, 61350 Bad Homburg. Tel: ++ 49 6172 96590. Fax: ++ 49 6172 965933.

IR ITALY: Via Liguria 49, 10071 Borgaro, Torino. Tel: ++ 39 11 4510111. Fax: ++ 39 11 4510220.

IR FAR EAST: K&H Bldg., 2F, 30-4 Nishi-Ikebukuro 3-Chome, Toshima-Ku, Tokyo, Japan 171. Tel: 81 3 3983 0086.

IR TAIWAN: 16 Fl. Suite D.207, Sec. 2, Tun Haw South Road, Taipei, 10673, Taiwan. Tel: 886 2 2377 9936.

7

Loading...

Loading...