Page 1

G4 Multi Channel

Force Instrument

Program version 101.1.0.0

Technical Manual

RM type

GB

Page 2

Page 3

G4 Multi Channel Force Instrument

1. Introduction

Manual updates ..................................... 1-1

General .................................................. 1-1

Functions ............................................... 1-2

Maintenance .......................................... 1-4

Safety information .................................. 1-4

Technical data ....................................... 1-5

Ordering information .............................. 1-12

2. Installation

Mechanical installation ........................... 2-1

Electrical installation .............................. 2-2

CPU unit ................................................. 2-3

VIEWPAN module ................................. 2-5

WF IN, WF IN2 and HS WF2 ................. 2-6

AOUT1 and AOUT4 ............................... 2-9

DIO8 ...................................................... 2-10

Profibus-DP Fieldbus Adaptor ................ 2-11

DeviceNet Fieldbus Adaptor .................. 2-13

3. Instrument Functionality

General ................................................... 3-1

Function Block ........................................ 3-1

4. Set-up

General .................................................. 4-1

Operators interface ................................ 4-2

Menu structure ....................................... 4-6

Parameters ............................................ 4-8

5. Calibration

General .................................................. 5-1

Common parameters ............................. 5-2

Calibration using datasheet ................... 5-3

Using parameters values from

a previous calibration ............................. 5-4

Calibration with known forces ................. 5-5

6. Operation

General .................................................. 6-1

Power supply ......................................... 6-1

Power-up sequence ............................... 6-1

Operating display ................................... 6-2

Security locks ........................................ 6-3

Zero setting ............................................ 6-3

Main menu ............................................. 6-4

Level supervision ................................... 6-5

Use of inputs and outputs ...................... 6-6

Filter function ......................................... 6-7

7. Communication

General .................................................. 7-1

Serial interface ........................................ 7-1

Modbus RTU Slave ................................ 7-1

Modbus TCP Slave ................................ 7-2

Modbus protocol .................................... 7-3

Fieldbus interface .................................... 7-28

8. Remote Access

General .................................................. 8-1

Browser requirements ............................. 8-1

Using the Remote Access ...................... 8-2

Security ................................................... 8-2

Remote Access Login and Logout .......... 8-3

Remote / Local Access ........................... 8-6

Remote Set-up ........................................ 8-7

Remote Access Maintenance ................. 8-10

9. Maintenance

General .................................................. 9-1

Diagnostics ............................................. 9-1

File handling ........................................... 9-4

Create Backup ....................................... 9-5

Restore Backup ..................................... 9-5

Set Default .............................................. 9-5

Program Upgrade ................................... 9-5

Instrument Restart .................................. 9-6

10. Troubleshooting

General ................................................... 10-1

Error codes ............................................ 10-1

Appendix

Declaration of Conformity ........................ App.1

Contents

Page 4

Technical Manual

PRECAUTIONS

READ this manual BEFORE operating or servicing this instrument.

FOLLOW these instructions carefully.

SAVE this manual for future reference.

DO NOT allow untrained personnel to operate,

clean, inspect, maintain, service, or tamper with

this instrument.

WARNING

Only permit qualified personnel to install and service this instrument.

Exercise care when making checks, tests and adjustments

that must be made with power on.

Failing to observe these precautions can result in bodily harm.

!

Page 5

G4 Multi Channel Force Instrument

1-1

1. Introduction

Manual updates

This manual is updated for the 101.1.0.0 program version. In this program is a web

server added which enables for the user to access the instrument using a PC running a

web browser. This manual can also be used for the previous program version

(101.0.0.0) where the only differences are the ‘Network Config.’ menu, the Instrument

restart functionality and the remote access part.

General

The G4 Instrument is a high performance multi channel force indicator intended for

industrial systems.

Its basic function is to convert the signals from strain gauge transducers to useful force

information. Transducer excitation is included as well as parameter controlled signal

processing, indication of output levels, error supervision and operation of optional

external equipment. The instrument can be equipped with up to 6 synchronized force

channels.

The instrument is modular and can be equipped with different types of I/O units to

match the demands in the specific applications. There are strain gauge transducer

interface modules, a digital input/output module, analog output modules.

Internal solid-state outputs in the instrument can be used for output functions from level

supervision or ‘In process’ indication, reporting the operating status of the G4

Instrument.

The CPU unit in the instrument has several communication interfaces. It has two serial

communication ports, an Ethernet port, an USB port and a fieldbus slot.

Several G4 Instruments can be controlled from a master computer or PLC.

Serial communication interfaces are RS-485 and RS-232 using Modbus RTU protocol.

The Ethernet interface is using Modbus TCP and the optional fieldbus interface uses

Profibus or DeviceNet.

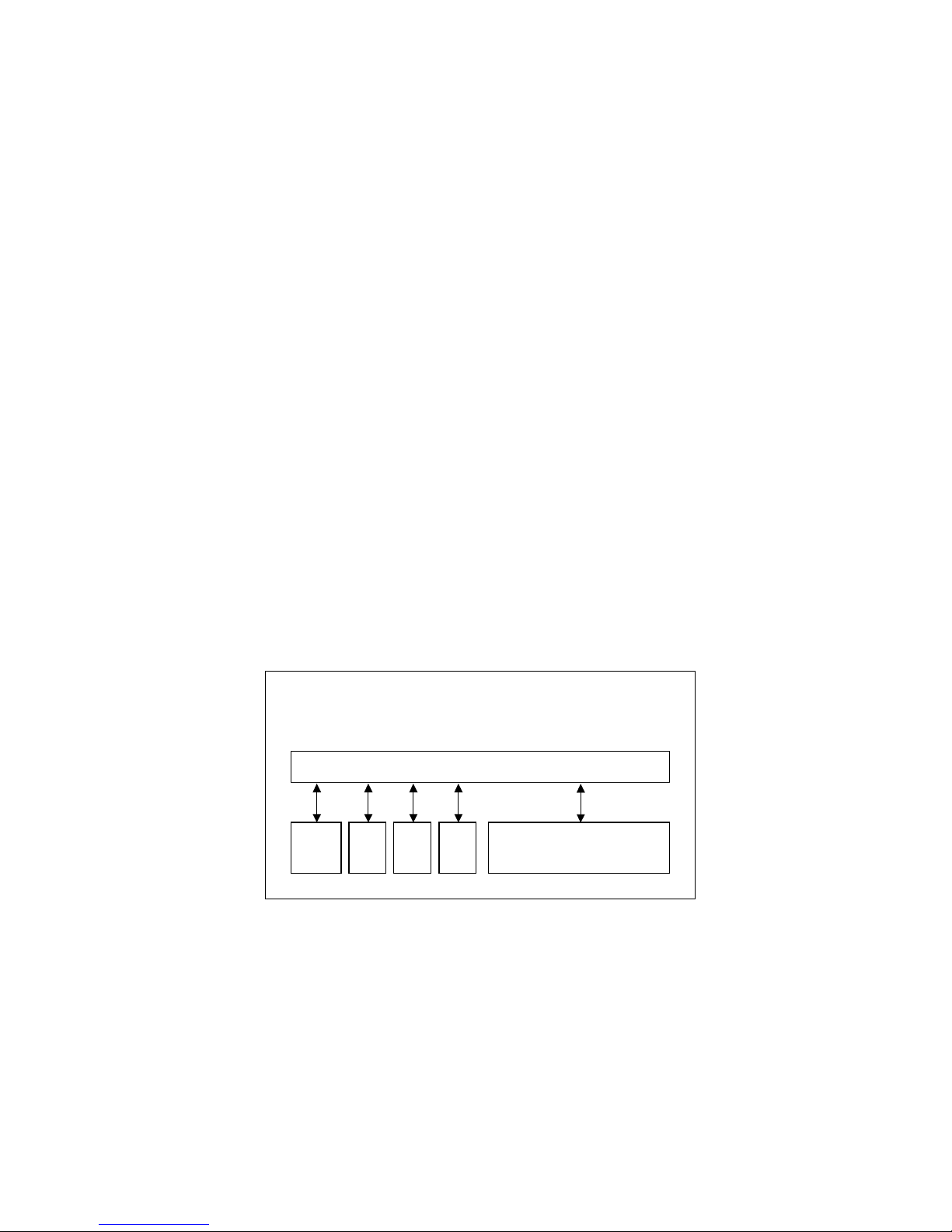

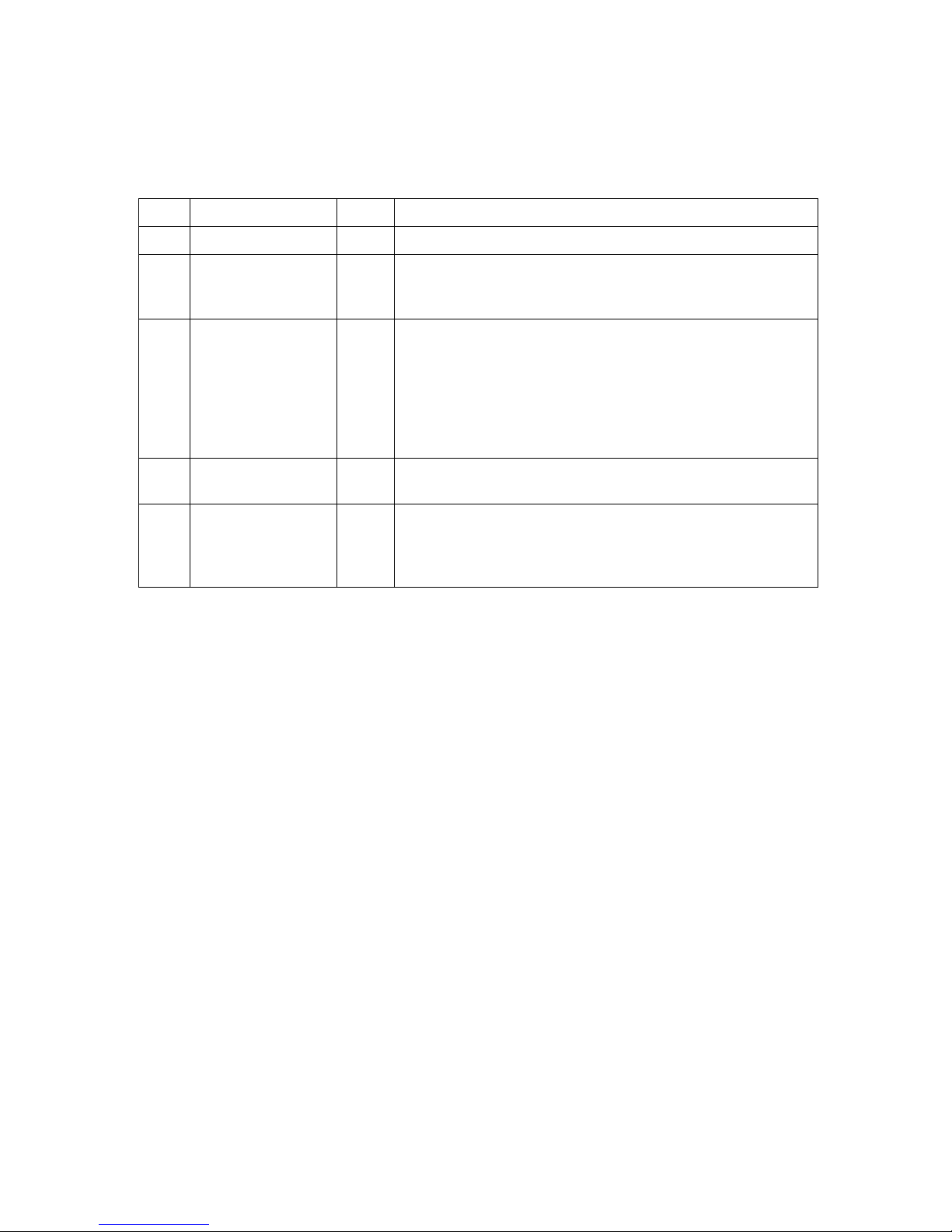

CPU

unit

I/O

unit

1

I/O

unit

2

I/O

unit

3

Service panel with

Power supply unit

Backplane

DIN rail mount version

Enclosure & mounting accessories

Block structure of a G4 Instrument

Page 6

Technical Manual

1-2

It is possible to load new software into the instrument using the USB port.

All functions in the G4 Instrument are controlled by set-up parameters. Setting of

parameter values can be performed via a service panel with display and 4 keys

(VIEWPAN module).

The Rail mount instrument type is powered with 24 V DC. All input and output signals

are galvanically isolated from the power supply by operational insulation.

Functions

Measurement with strain gauge transducers.

Both excitation voltage and output signal are measured at the transducer to avoid

influence from voltage drop in the connection cable. Excitation to the transducer, from

the G4 Instrument is provided over separate wires.

A shielded 6-wire cable must be used to connect a distant transducer to the instrument.

A/D conversion.

The analog signals from the transducer are converted to digital form and filtered

to give an internal transducer signal with high resolution.

Calculation.

The transducer excitation and signal values are combined to form an internal

transducer signal, representing the load on the transducer. Influenced by calibration

data, this signal is converted to a digital measurement value, the force value, which

can be presented at the local display window and at external equipment.

Error supervision.

As long as the error supervision detects no error, the signal ‘In process’ is present

but if an error is detected, ‘In process’ will be off and a specific error message will be

displayed. ‘In process’ can be set to control any digital output. Note that there are

force channel specific and instrument specific error detection.

Levels.

32 level comparators in the instrument can be set to switch at defined signal levels with

any selected hysteresis added, meaning that the switch level can be different for

increasing and decreasing signal. It’s possible to set level switching delays. Output

signals from these comparators are available on the serial communication. The level

comparator outputs can also be set to control digital outputs from the instrument.

Communication.

The G4 Instrument utilizes the serial interface, Ethernet and a fieldbus interface for

communication with control computer. The serial interface consists of a RS-232

(COM1) connection and a RS-485/RS-422 (COM2) connection. COM2 can be used

with 2- or 4-wire connection.

Force values, web tension values, level status, error status etc. can be collected and

commands given through the communication interfaces. Modbus RTU protocol is used

for the serial interfaces and Modbus TCP for the Ethernet connection. For the optional

fieldbus interface Profibus or DeviceNet can be used.

Page 7

G4 Multi Channel Force Instrument

1-3

Instrument modes.

In normal operation mode the G4 Instrument is presenting the measurement values on

the front panel (VIEWPAN) alphanumerical display. Values for one Function Block at a

time can be shown. During parameter set-up the instrument will continue normal

operation. However if hardware set-up parameters have been changed the instrument

will be restarted.

The operator will always be notified before the instrument is restarted.

Parameter setting.

In the instrument all operating functions are controlled by set-up parameters with

numerical values, string values, or pre-selected values from a list of alternatives.

Parameter set-up is performed by the keys at the service panel (VIEWPAN).

Presentation.

The instrument can present measured or calculated values, parameter settings etc.

at the front panel. An extensive system of menus gives the possibility to present

various information about the instrument. The VIEWPAN module can present one or

two values at a time.

Measured or calculated values, status of levels and so on, can be transferred to

external equipment via the different communication interfaces (some are optional).

Page 8

Technical Manual

1-4

Maintenance

The G4 instrument needs no maintenance, performed by the end-user. Any service

or repair work must be performed by qualified personnel.

Contact your supplier.

Cleaning

Before cleaning the G4, break the power connection to the instrument.

Use a soft cloth to clean the exterior of the instrument.

Safety information

Utilization.

Before connecting power to the instrument, check that all fixation screws

at the modules are tightened so that the instruments functional grounding

by the housing is maintained.

The instrument may only be utilized for the measurement and control functions,

described in this Technical Manual. It is especially important to adhere to the load limits

of the input/output connectors. We accept no responsibility for any damage arising from

improper operation.

Any changes to the instrument, which causes any function changes, may only be

carried out by the manufacturer, or after discussion with and permission by the

manufacturer.

Meaning of symbols, used in this manual

Direct current.

!

Caution, risk of danger. Documentation needs to be consulted.

Page 9

G4 Multi Channel Force Instrument

1-5

Technical data

Enclosure type RM – Rail Mount enclosure

Dimensions

Enclosure design Aluminium housing with plastic frames

Rail mount DIN 46 277/3 and DIN EN 50022 (w=35 mm, h=7.5 mm)

Display, keyboard See VIEWPAN module

Environmental

Temperature range

Rated performance: -10 to +50 °C

Storage: -25 to +85 °C

Relative humidity

Max. 85% up to 40 °C, decreasing linear to 50% at 50 °C

Rated pollution Pollution degree 2

Protection IP20. For indoor use.

Altitude Up to 2000 m

EMC, RF CE (Industrial), OIML

Page 10

Technical Manual

1-6

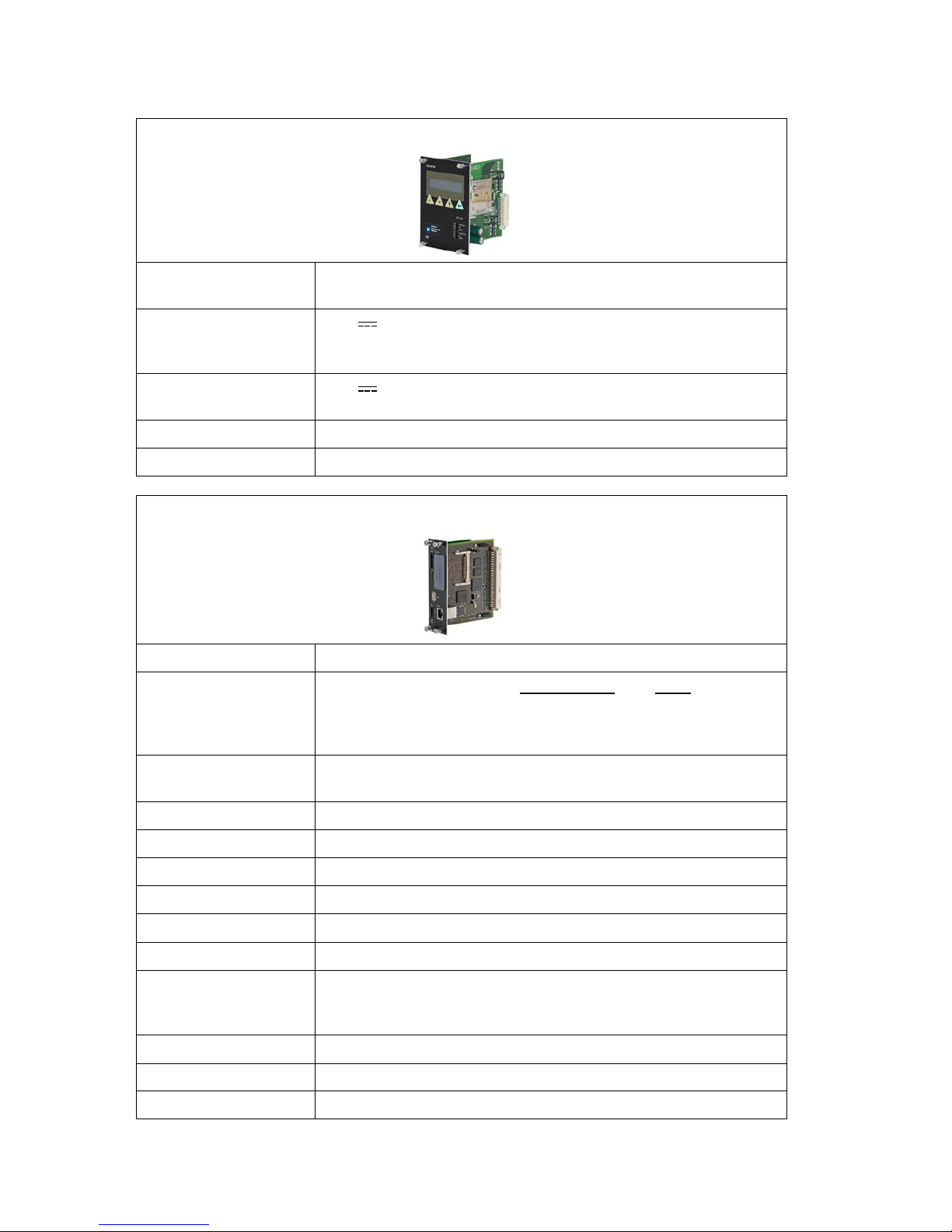

VIEWPAN

Module type Display/keypad interface with integrated power supply for the

complete instrument.

Input voltage 24 V ±15% including fluctuations, 40W

Impulse withstand (overvoltage)

category I of IEC 60364-4-443

Output voltage 24 V output 0.1 A

The same voltage as input voltage

Display

2 x 16 character LCD with backlight

Keyboard 4 keys

CPU

Module type CPU module

RTC backup battery

Manufacturer Type

Lithium battery Panasonic-BSG CR2032

CR2032 3V GP Batteries CR2032

Varta CR2032 (V)

COM1 (RS232) and

COM2 (RS485)

For process data and control

Isolated by operational insulation

Protocol Modbus RTU

Baud rate Up to 115 kbaud

Fieldbus

For process data and control (optional)

Types Profibus or DeviceNet

USB

Version 1

Keyboard USB keyboard for PC

USB Memory USB type for PC

For backup and restore of set-up parameters

For change to a new program version

Ethernet

10/100BASE-T. For process data and control

Protocols Modbus TCP, ftp, http

RJ45 Indications Green LED: Transmitting. Yellow LED: Receiving.

Page 11

G4 Multi Channel Force Instrument

1-7

WF IN / WF IN2

Module type Weight/Force input module

Max. # of transducers 8 (350 ohm) per channel

Maximum 48 transducers per instrument

Excitation voltage: 5 VDC

A/D conversion: 3.9 kHz, 16 000000 units (24 bits)

Input range +/- 7 mV/V

Update rate:

9.3 − 300 readings per second

No. of channels: WF IN has 1 Weight/Force channel

WF IN2 has 2 Weight/Force channels

Sensitivity:

0.1 µV

Zero drift: <10 nV/V/K

Span drift: <2 ppm/K

Digital I/O 4 inputs, 24 V ±15%, 5 mA from external power supply,

isolated by operational insulation

and with common return

2 outputs, 24 V ±15%, max 100 mA from external power supply,

isolated by operational insulation

and with common return

Page 12

Technical Manual

1-8

HS WF2

Module type High Speed Weight/Force input module

Max. # of transducers 4 (350 ohm) per channel

Excitation voltage: 10 VDC

A/D conversion: 20 kHz, 16 000000 units (24 bits)

Input range +/- 4.5 mV/V

Update rate:

25 − 800 readings per second

No. of channels: HS WF2 has 2 Weight/Force channels,

separately isolated by operational insulation

Sensitivity:

0.1 µV

Zero drift: <10 nV/V/K

Span drift: <2 ppm/K

Digital I/O 4 inputs, 24 V ±15%, 5 mA from external power supply,

isolated by operational insulation

and with common return

2 outputs, 24 V ±15%, max 100 mA from external power supply,

isolated by operational insulation

and with common return

Page 13

G4 Multi Channel Force Instrument

1-9

DIO8

Module type Digital input/output module

Separate I/O module 2 units can be used

Digital I/O 8 inputs, 24 V ±15%, 5 mA from external power supply,

isolated by operational insulation

and with common return

8 outputs, 24 V ±15%, max 100 mA from external power supply,

isolated by operational insulation

and with common return

AOUT1 / AOUT4

Module type Analog output module

Number of channels 1 or 4 channels,

separately isolated by operational insulation

Resolution 65000 units, 16 bits

Voltage output 0 – 10 V, -10 – 10 V, > 1 kohm load

Current output 4 – 20 mA, 0 – 20 mA, -12 – 20 mA, -20 – 20 mA,

< 500 ohm load

Update rate Function Block update rate, adjustable smoothing filter

Page 14

Technical Manual

1-10

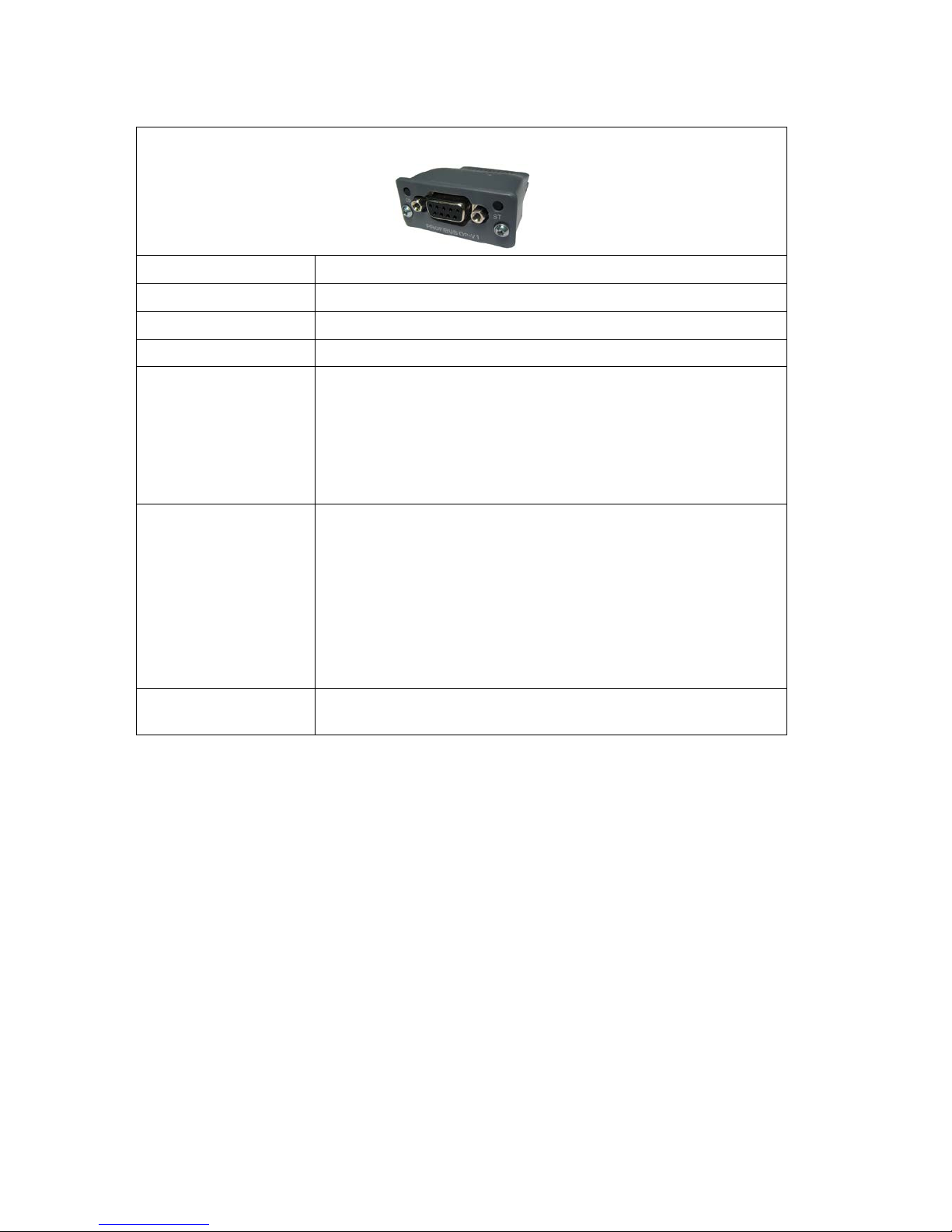

Profibus-DP

Module type Profibus-DP fieldbus adaptor

Connector Profibus 9-pin, female D-sub (DB9F)

Baudrate Auto setting 9.6 kbps – 12 Mbps

Address 1 – 125, set by parameter

Fieldbus data 16 bytes from fieldbus to instrument.

32 – 244 bytes from instrument to fieldbus (may be limited by

the master).

See chapter ‘7 Communication’ section

‘Fieldbus communication interface’ for details on fieldbus data

mapping.

Mounting The fieldbus adaptor is mounted through the front of

the CPU module with LED’s and connector accessible through

the CPU front panel.

Remove the plastic cover from the fieldbus slot in the CPU

module front panel. Insert the adaptor very carefully and make

absolutely sure that the adaptor slides correctly into the guides

in the connector on the CPU PCB. Tighten

the two fastening screws at the adaptor front and check

that the two securing hooks locks into the CPU PCB.

Settings All fieldbus settings are done with setup parameters in

the instrument. No settings are done on the module itself.

Page 15

G4 Multi Channel Force Instrument

1-11

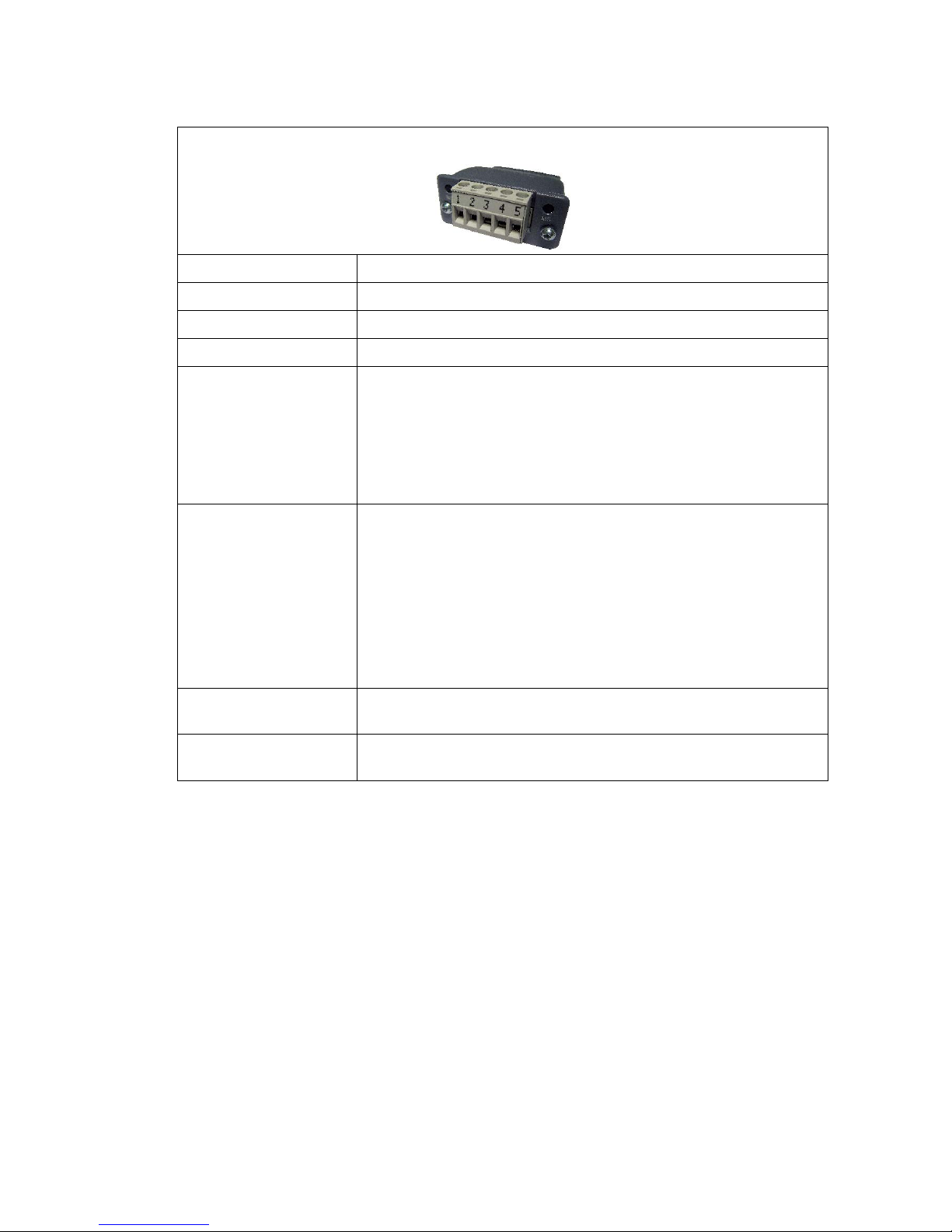

DeviceNet

Module type DeviceNet fieldbus adaptor

Connector 5 pin male connector.

Baudrate 125, 250, 500 kbps or Auto. Set by parameter.

Address 0 – 63, set by parameter

Fieldbus data 16 bytes from fieldbus to instrument.

32 – 244 bytes from instrument to fieldbus (may be limited by

the master).

See chapter ‘7 Communication’ section

‘Fieldbus communication interface’ for details on fieldbus data

mapping.

Mounting The fieldbus adaptor is mounted through the front of

the CPU module with LED’s and connector accessible through

the CPU front panel.

Remove the plastic cover from the fieldbus slot in the CPU

module front panel. Insert the adaptor very carefully and make

absolutely sure that the adaptor slides correctly into the guides

in the connector on the CPU PCB. Tighten

the two fastening screws at the adaptor front and check

that the two securing hooks locks into the CPU PCB.

Settings All fieldbus settings are done with setup parameters in

the instrument. No settings are done on the module itself.

Bus Supply Voltage According to the DeviceNet (Node) Specification:

nominal 24 VDC, range 11 – 25 VDC.

Page 16

Technical Manual

1-12

Ordering information

For Rail mount (RM) instruments

G4-RM-FB-S1-S2-S3-V-SW

G4 Instrument type G4

RM Enclosure type RM Rail mount

FB Fieldbus interface 0

P

D

None

Profibus

DeviceNet

Si Slot 1 to 3 type 0

2

3

4

6

7

8

Blank

HS WF2 High speed weight/force input module, 2 ch.

WF IN Weight/force input module, 1 channel.

WF IN2 Weight/force input module, 2 channels.

AOUT1 Analog Output module, 1 channel

AOUT4 Analog Output module, 4 channels

DIO8 Digital Input and output module

V User interface and

power

V VIEWPAN, 24VDC

SW Software (note 1)

W

F

S

(No code specified) Standard Weighing Program

Standard Weighing Program

Standard Force Program

Special Program (note 2)

Example: G4-RM-0-4-8-0-V-F

• G4 instrument (G4)

• Rail mount (RM)

• No field bus (0)

• Slot 1 = WF IN2 (4)

• Slot 2 = DIO8 (8)

• Slot 3 = Blank (0)

• Power =VIEWPAN unit (V)

• Software = Force program (F)

Note 1: The Software (SW) code specifies the program function that should be installed

in the instrument. If no code is specified the standard Weighing program will be

supplied.

Note 2: If a special program option is desired, the number of the special program must

be specified when ordering.

Page 17

G4 Multi Channel Force Instrument

1-13

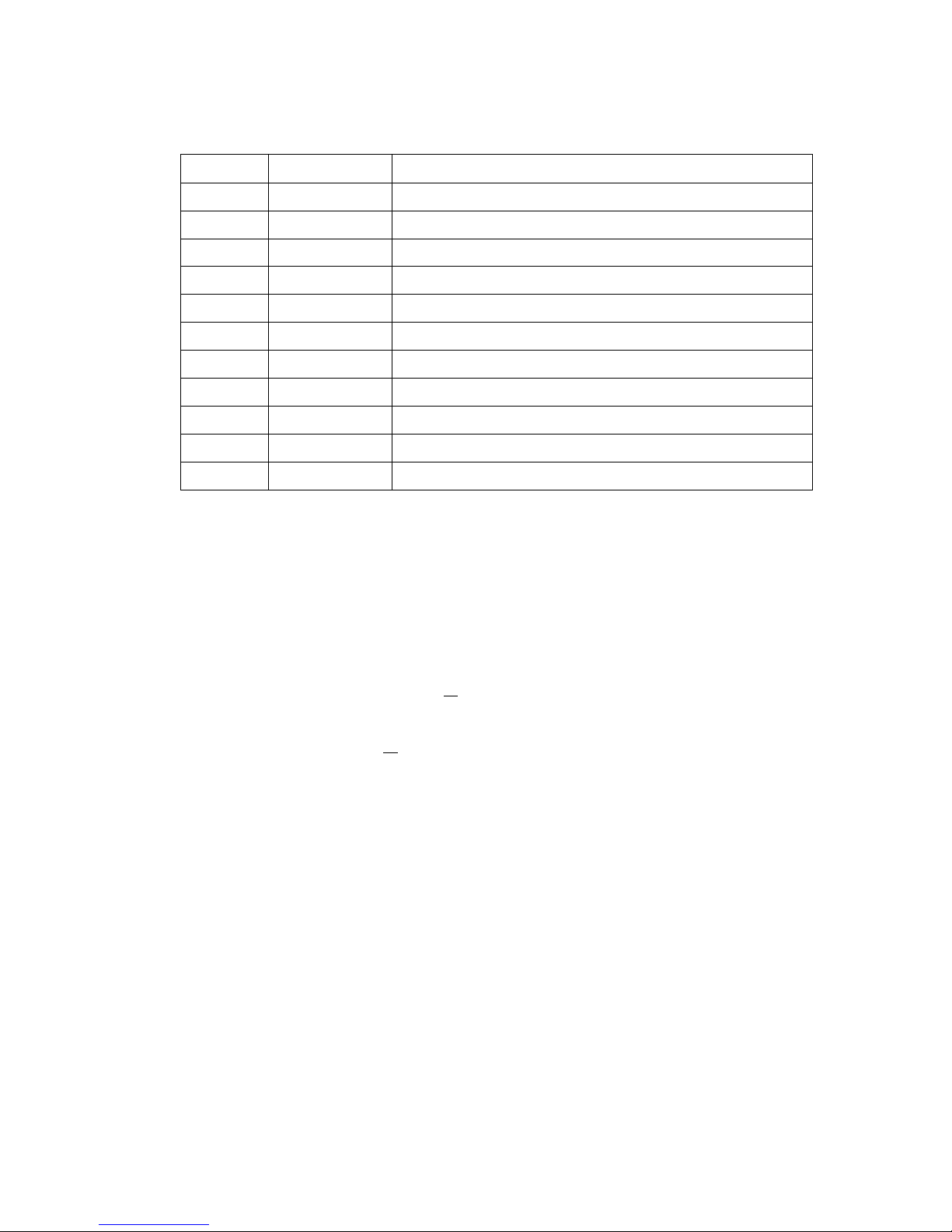

Separate modules

Spec.no

Module type Module name

110 544 CPU CPU unit

110 546 HS WF2 High speed dual Weight/Force input module

110 547 WF IN Single Weight/Force input module

110 548 WF IN2 Dual Weight/Force input module

110 549 AOUT1 Single channel analog output module

110 550 AOUT4 Four channel analog output module

110 551 DIO8 Digital input/output module

110 552 BLANK Blank panel

110 554 VIEWPAN Rail mount service panel

110 559 PROFIBUS-DP Profibus DP fieldbus adaptor

110 560 DEVICENET DeviceNet fieldbus adaptor

Module selection rules

Every system needs 1 VIEWPAN module and 1 CPU module (can be equipped with

one fieldbus adaptor).

Limitations on number of I/O modules that can be used in one instrument:

• Maximum 3 modules (not counting the VIEWPAN module).

• Maximum 3 WF IN / WF IN2 or 2 HS WF2 modules.

• HS WF2 and WF IN(2) cannot be mixed in the same system

• Maximum 1 AOUT1 or 1 AOUT4 module.

• Maximum 2 DIO8 modules.

Page 18

Technical Manual

1-14

Page 19

G4 Multi Channel Force Instrument

2-1

2. Installation

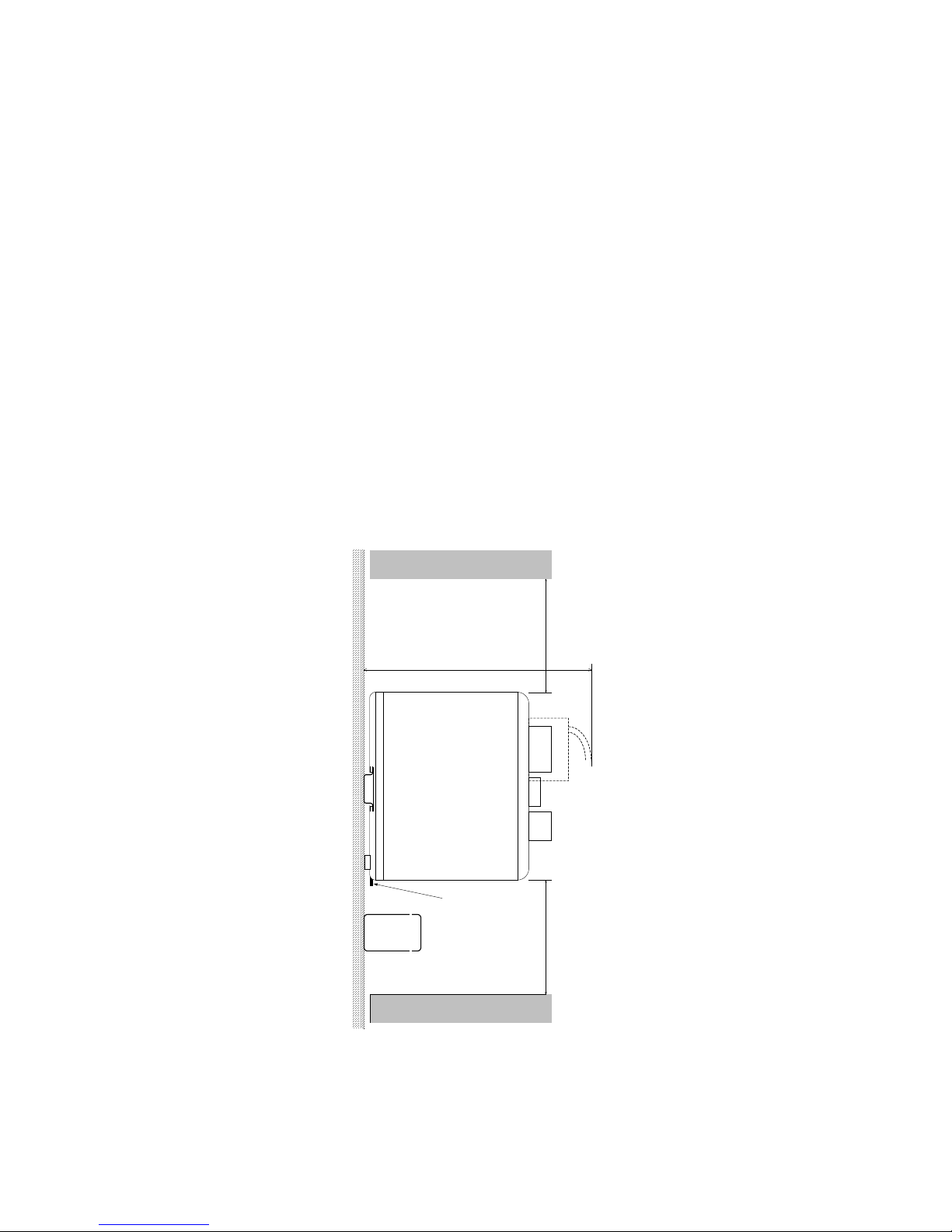

Mechanical installation

See section ‘1. Introduction – Technical data’ for references to RM mechanical

measures.

G4, RM type, should be used in a dry, clean environment or it must be mounted

in a cabinet, protecting from water, dust etc. The instrument is prepared for

mounting on a flat surface by DIN rail according to Technical data.

The instrument needs minimum 200 mm space above this surface.

To remove the instrument from the rail, the black lever at the lower bottom side of

the instrument must be engaged.

Each instrument should have a free space of minimum 30 mm to the left

and to right, 100 mm above and below the instrument.

Cable ducts may be mounted in this free space.

All electrical connections to the instrument modules are made to terminals

at the front side so enough room for these terminals should be arranged.

CABLE DUCT

LOCK LEVER

TERMINALS

100

100

200

RM instrument.

Recommended free space at the instrument.

Page 20

Technical Manual

2-2

Electrical installation

The field wiring of the instrument shall be suitable to the environment

(e.g. chemically) in the end-user application.

Field wiring installation shall comply with any national regulations, hereunder National

Electrical Code (NEC) for US and/or Canadian Electrical Code for Canada.

• A switch or circuit-breaker shall be included in the building installation.

• The switch shall be in close proximity to the equipment and

within easy reach of the operator.

• The switch shall be marked as the disconnecting device for the equipment.

• The equipment switch or circuit-breaker employed as disconnecting device shall

comply with relevant requirements of IEC 60947-1 and IEC 60947-3.

For electrical installation with an external dc supply, see page 2-5.

WARNING

Make sure that that the power to the instrument is turned off before:

- any modules are removed from or inserted in the instrument.

- any connections are connected to or disconnected from the instrument.

All modules should be regarded as ESD sensitive. Make sure that an ESD safe

environment is maintained when inserting modules, removing modules and when

handling modules separately from the instrument. Modules must be kept in

metallised ESD bag when not mounted in the instrument.

!

Page 21

G4 Multi Channel Force Instrument

2-3

!

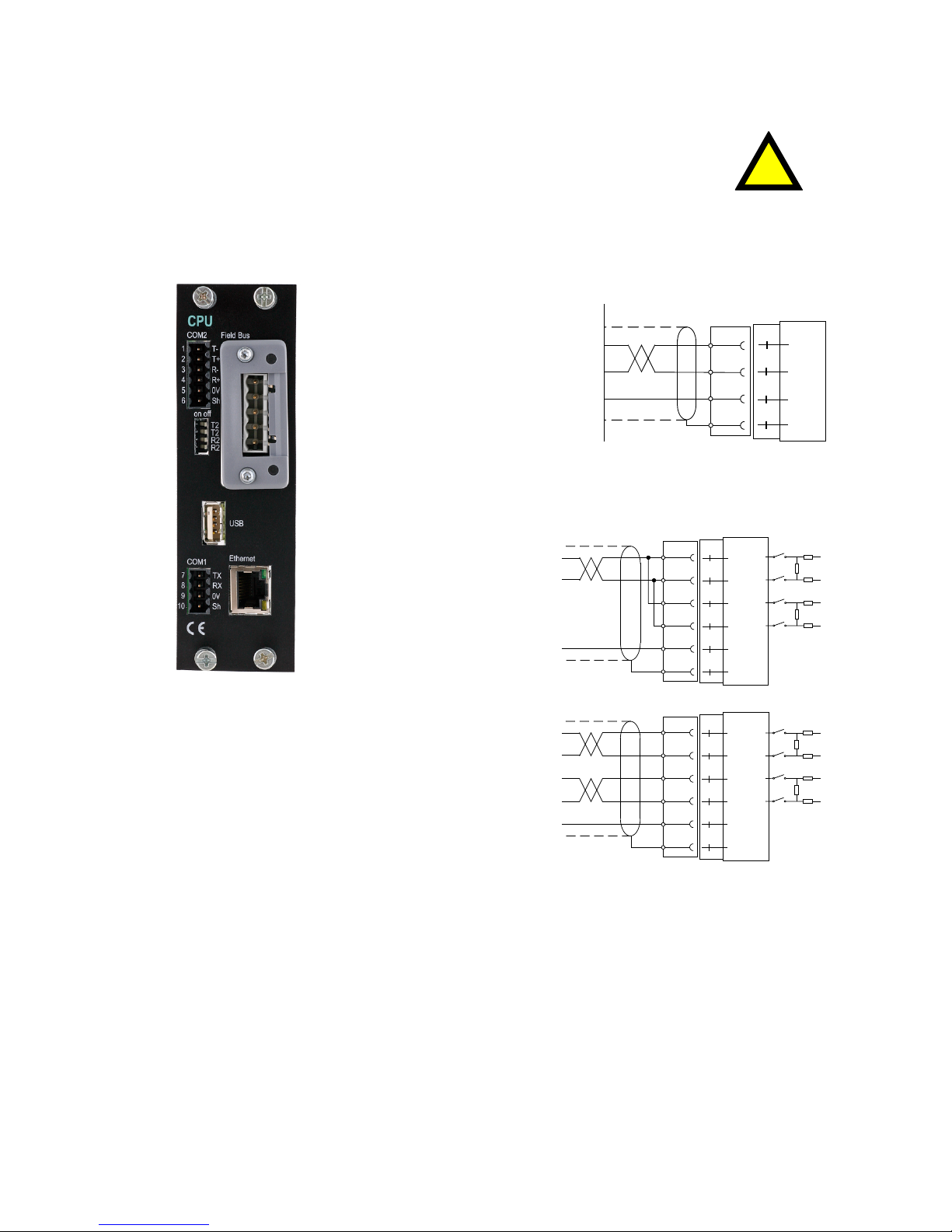

CPU unit

External computing devices connected to the CPU communication

interfaces of the instrument have to comply with the standard, UL 60950.

The internal battery in the CPU module is to be used only in the equipment

where servicing of the battery circuit and replacement of the lithium battery

will be done by a trained technician.

COM1

RS232 Serial communication.

This is a SELV/SELV-E circuit.

COM1 can be used for serial

communication with

computer/PLC (Modbus RTU).

Point to point communication,

only one G4 unit connected

to the computer/PLC.

Connections are made

to terminals 7 – 9.

Shielded cable must be used.

Connect shield to terminal 10.

COM2

RS485 Serial communication

for 2-wire or 4-wire with

common 0 V.

This is a SELV/SELV-E circuit.

COM2 can be used for serial

communication to

computer/PLC (Modbus RTU).

Connections are made

to terminals 1 – 5.

Shielded cable must be used.

Connect shield to terminal 6.

The communication lines must be terminated in

both ends. If G4 is connected at the end of the

communication line switches must be set as:

2-wire termination: Both T2 ON, both R2 OFF.

4-wire termination: Both T2 ON, both R2 ON.

TX

RX

0V

Shield

COM1 RS-232

10

9

8

7

(DTE)

RS-232

9p 25p

2 3

3 2

5 7

RS485 2-wire

1

TT+

RR+

0 V

Shield

COM2

6

2

3

4

5

+5

T2

T2

0

+5

R2

R2

0

RS485 4-wire

1

TT+

RR+

0 V

Shield

COM2

6

2

3

4

5

+5

R2

R2

0

+5

T2

T2

0

Page 22

Technical Manual

2-4

Field Bus

Slot for optional Fieldbus interface.

Profibus DP-V1 and DeviceNet are available.

See section Profibus-DP Fieldbus Adaptor or DeviceNet Fieldbus Adaptor later in this

chapter for details.

USB

Connector for USB device(s).

This port has no operational insulation and should be considered as a

SELV/SELV-E circuit.

Allows connection of following devices:

1 - USB Memory

2 - USB Keyboard

An USB hub can be used to allow connection of more than one device.

Ethernet

This is a SELV circuit. Uses crossover category 5 cable from RJ-45 Ethernet port

on the CPU front panel to PC (point to point connection) or standard cable to connect

to other equipment through a switch, hub or router which is isolating the circuit from the

public network.

Page 23

G4 Multi Channel Force Instrument

2-5

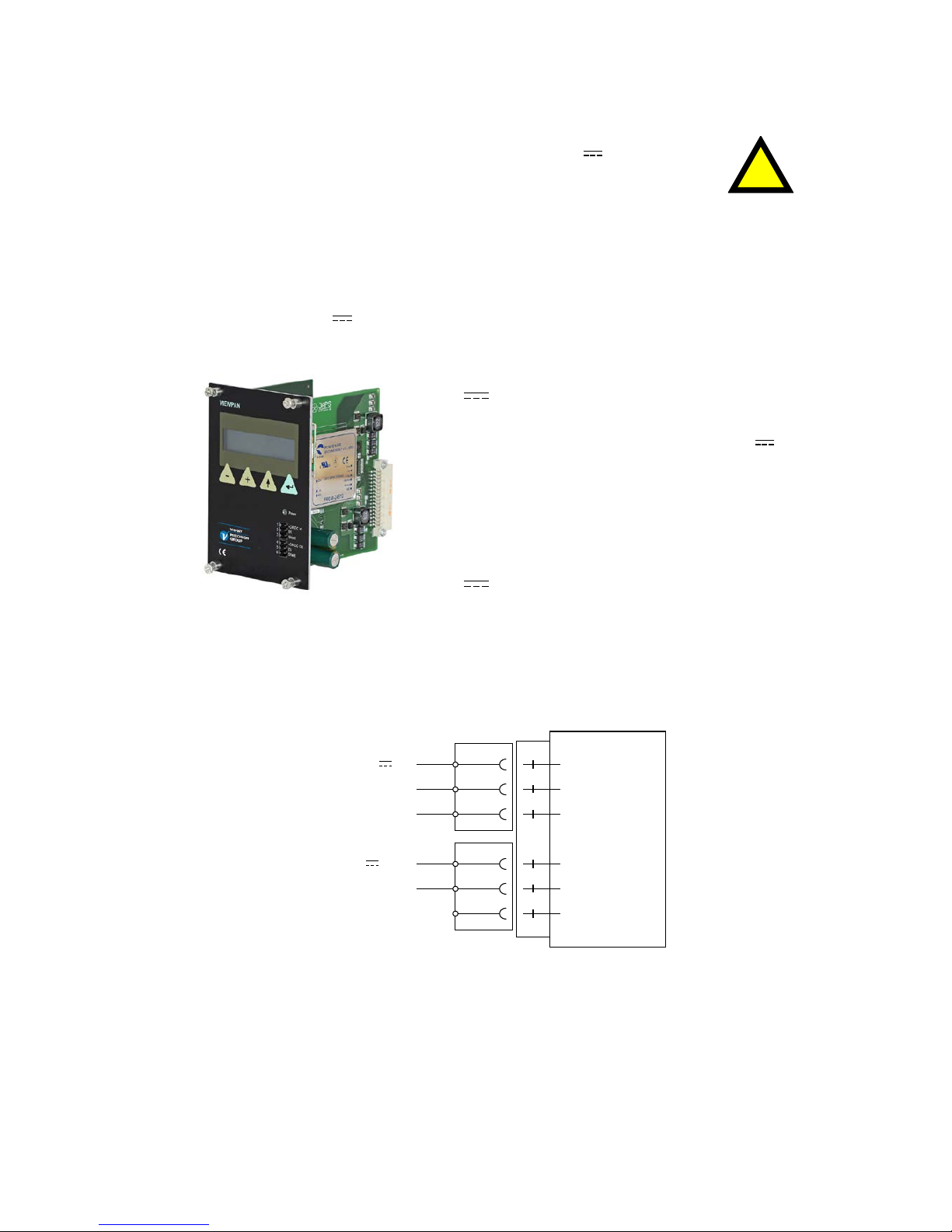

VIEWPAN module

The output of the external dc supply must be rated 24 V , ±15%

including fluctuations, min. 40 W. The supply must provide Double

Insulation between Mains parts and 24 V SELV or SELV-E Circuit, and a

limited-energy circuit (maximum available current of 8 A).

For the US market this energy limit can be achieved with an

ANSI/UL248-14 fuse rated 5A.

For other markets an IEC 60127 T type fuse rated 4A may also be used.

With integrated 24 V

power supply unit.

The integrated power supply is used to supply the complete instrument.

24 V input

Terminals 1, 2 and 3.

The G4 instrument should be powered by 24 V

,

connected according to the diagram below.

To achieve functional grounding, terminal 3

should be connected to ground.

See Technical data for input voltage ratings.

24 V output

Terminals 4 and 5 can be used to supply

max. 100 mA to digital inputs and outputs.

Connection should be according to

the diagram below.

See Technical data for ratings.

1

DC SUPPLY

2

0 V

3

Shield

4

5

0 V

6

Shield

0 V

Ground

0 V

+24 V In

+24 VDC In

+24 VDC Out+24 V Out

!

Page 24

Technical Manual

2-6

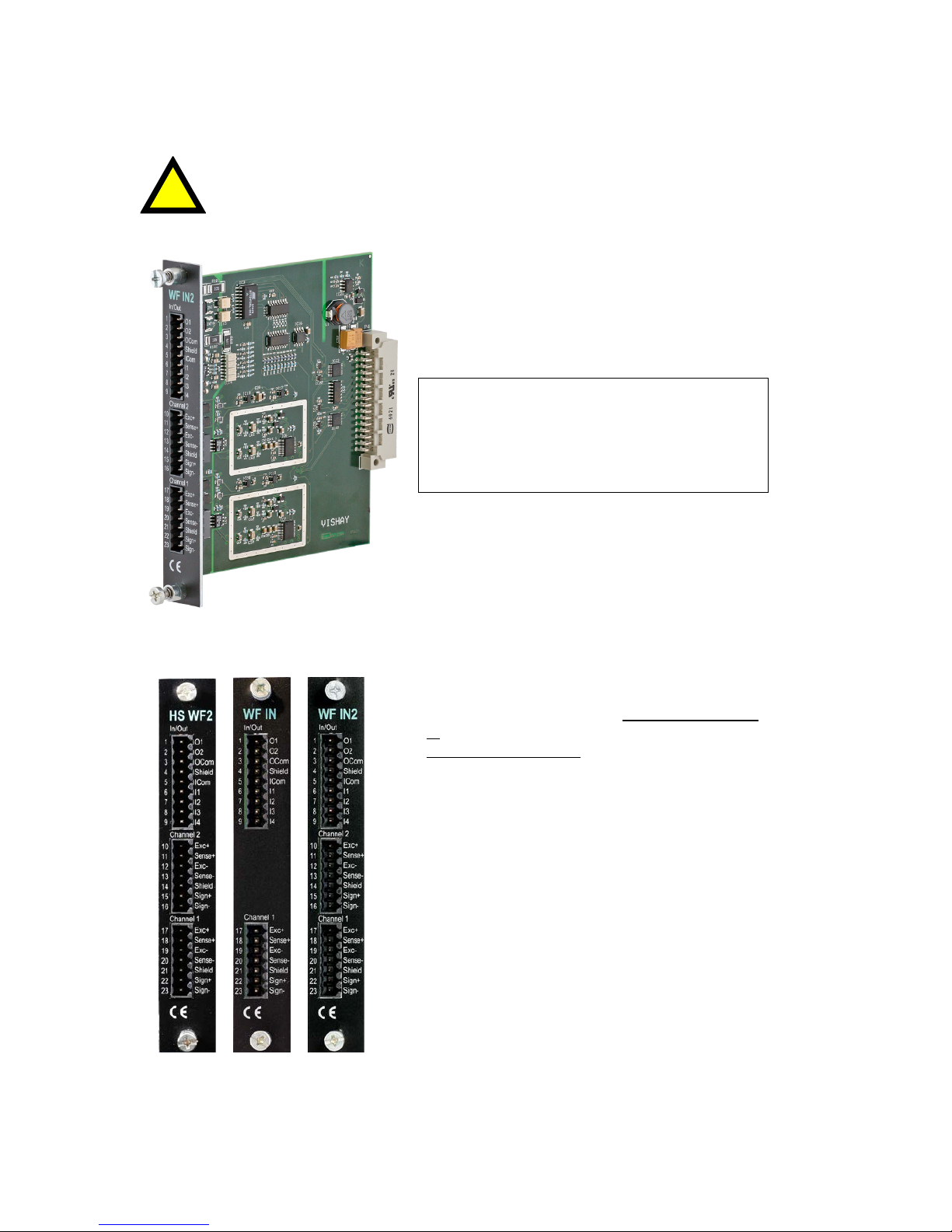

WF IN, WF IN2 and HS WF2

The voltage levels on connectors of I/O modules shall not exceed

hazardous voltage levels of 30 Vrms, 42.4 Vpeak or 60 Vdc under normal

conditions. In wet locations these voltage levels shall not exceed

16 Vrms, 22.6 Vpeak or 35 Vdc.

Transducer inputs

Terminals 17 – 23 (channel 1),

10 – 16 (channel 2).

Transducer connection should be handled with

great care to achieve good measuring data.

Transducer integrated cables may not be

shortened.

NOTE! Transducer cables must be routed at

least 200 mm away from 230/400 V, 50/60 Hz

power cables.

By cables with other frequencies or

high power, an even wider distance is

preferable.

4-wire connection can be used if the transducer

integrated cable is long enough to be

connected directly to a transducer input. At

4-wire connection, some terminals must be

interconnected as shown in figure on next

page.

6-wire connection should be used if the

integrated cable must be lengthened or if

several transducers should be connected to

one transducer input.

The channel 1 cable shield must be connected

to terminal 21 and the channel 2 cable shield

must be connected to terminal 14.

In WF IN and WF IN2 the shield terminals are

internally connected to the G4 housing, which

is internally connected to earth via the power

supply connector pin 3 (shield). The shield

shall not be connected at any other point.

In HS WF2 the transducer input channels are

separately insulated by operational insulation

and the shields can be connected to the most

convenient ground/earth point. This can be the

junction box when using multiple transducers or

at the barrier ground when using Ex zener

barriers.

In the junction box SL-4 from Nobel Weighing

Systems, see figure, all necessary terminals

and interconnections are provided.

!

Page 25

G4 Multi Channel Force Instrument

2-7

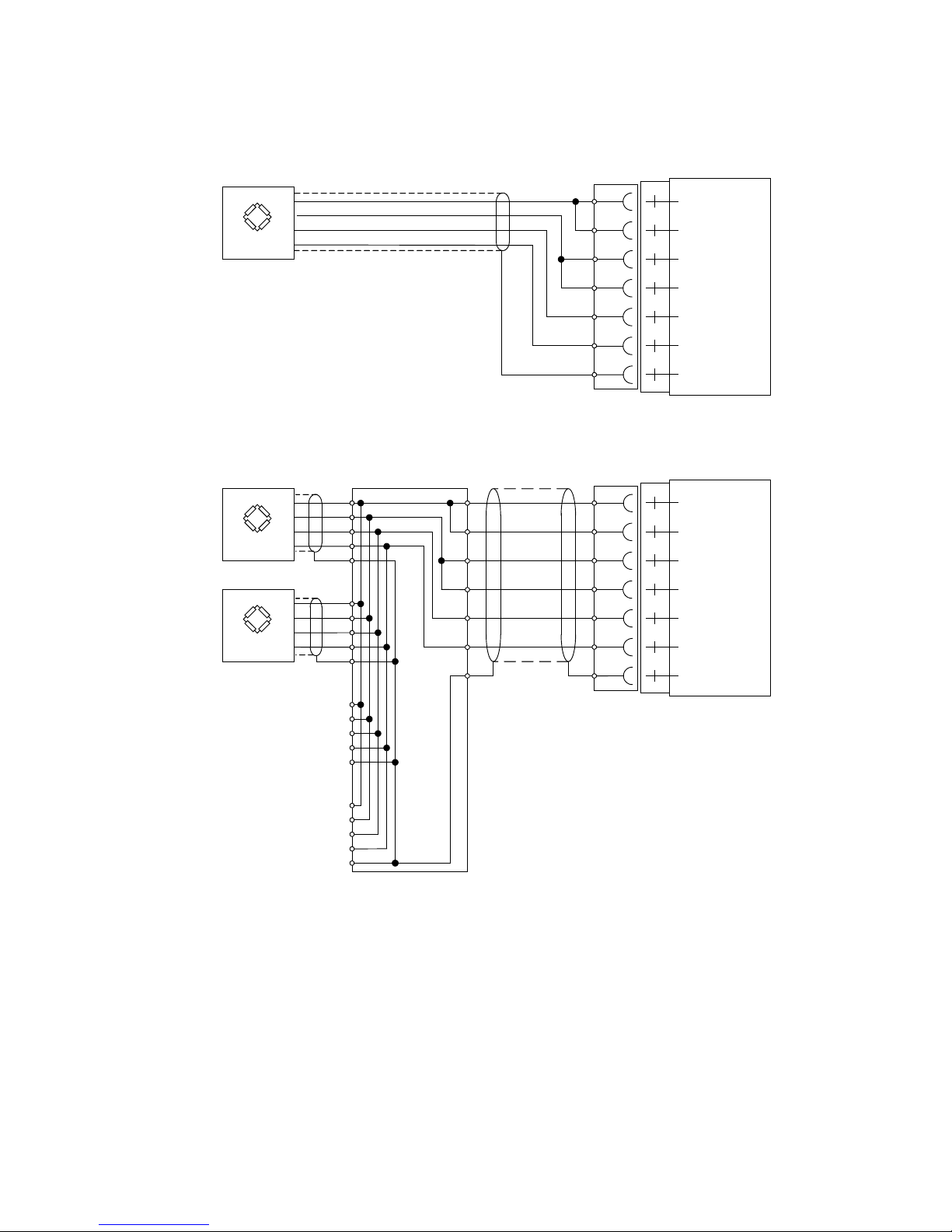

10

15

13

12

11

14

16

Exc.-

Exc.+

Sign.+

Sign.-

4-wire connection

Transducer

Transducer input, ch. 2

Exc+

Sense+

ExcSenseSign+

SignShield

Junction box

17

22

20

19

18

21

23

Transducer input, ch. 1

Exc.-

Exc.+

Sign.+

Sign.-

Transducer

Transducer

Exc.-

Exc.+

Sign.+

Sign.-

6-wire connection

Exc+

Sense+

ExcSenseSign+

SignShield

A transducer may be connected directly to terminals at the transducer input.

For several transducers or long distance, a junction box

and lengthening cable is needed.

For a HS WF2 channel, the shield can be connected to

ground/earth at any point

Page 26

Technical Manual

2-8

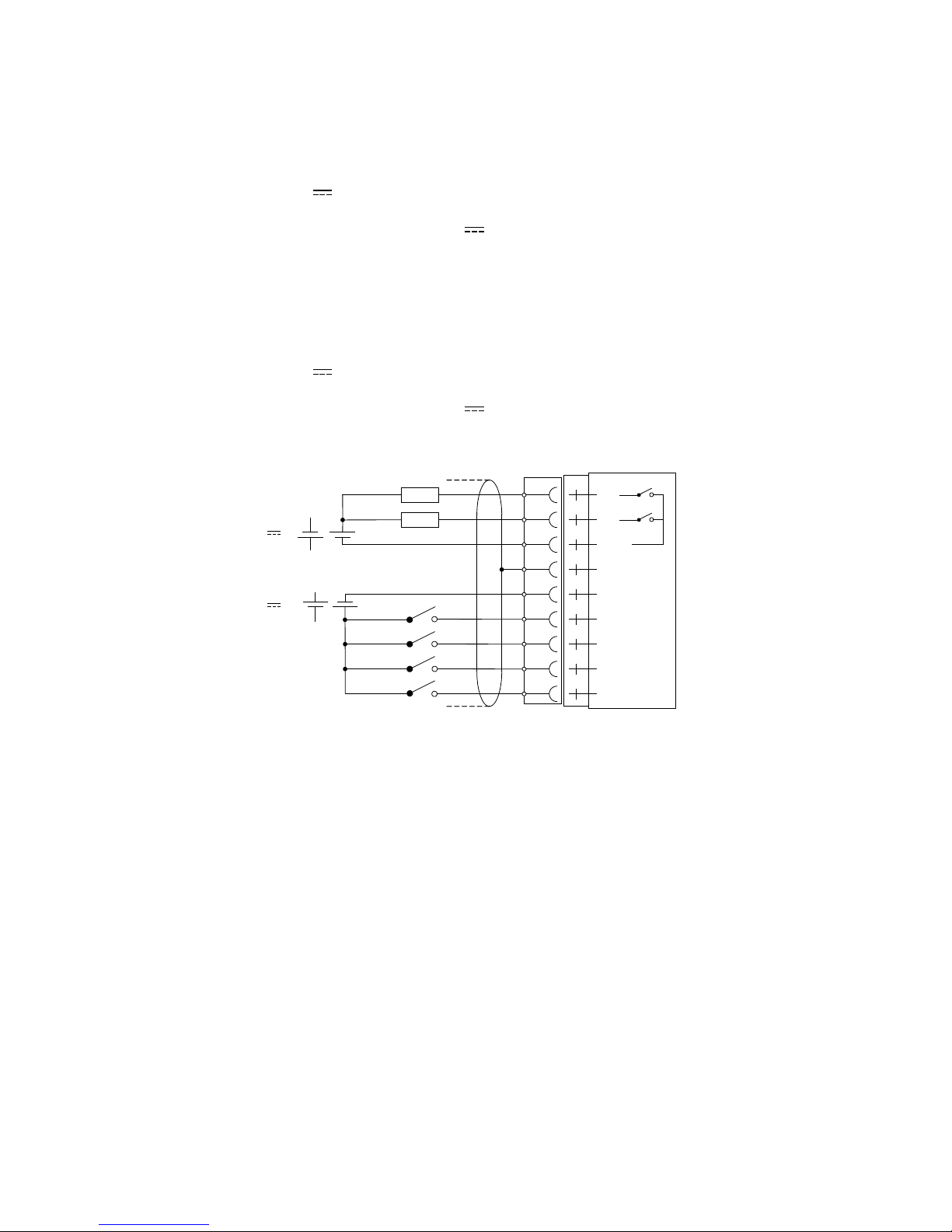

Digital inputs

Terminals 6 – 9 and terminal 5 (ICom) as a common connection.

Four digital inputs are provided, with functions that can be set in the G4 set-up.

External sourcing (24 V

) from the instrument power supply (max. 100 mA)

or from a separate DC supply must be used. Note that either the positive or

the negative pole of the voltage source (24 V

) can be connected to ICom (5).

Shielded cable/cables must be used, with the shield connected to terminal 4.

Solid state relay outputs

Terminals 1 and 2 with terminal 3 (OCom) as a common connection.

Two digital (relay) outputs are provided with contact rating given in Technical data.

External sourcing (24 V

) from the instrument power supply (max. 100 mA)

or from a separate DC supply should be used. Note that either the positive or

the negative pole of the voltage source (24 V

) can be connected to OCom (3).

Shielded cable/cables must be used, with the shield connected to terminal 4.

O1

O2

OCom

Shield

ICom

I1

I2

I3

I4

1

8

5

4

3

2

9

7

6

Load

Load

+

-

-

+

-

+

-

+

24 V

24 V

Page 27

G4 Multi Channel Force Instrument

2-9

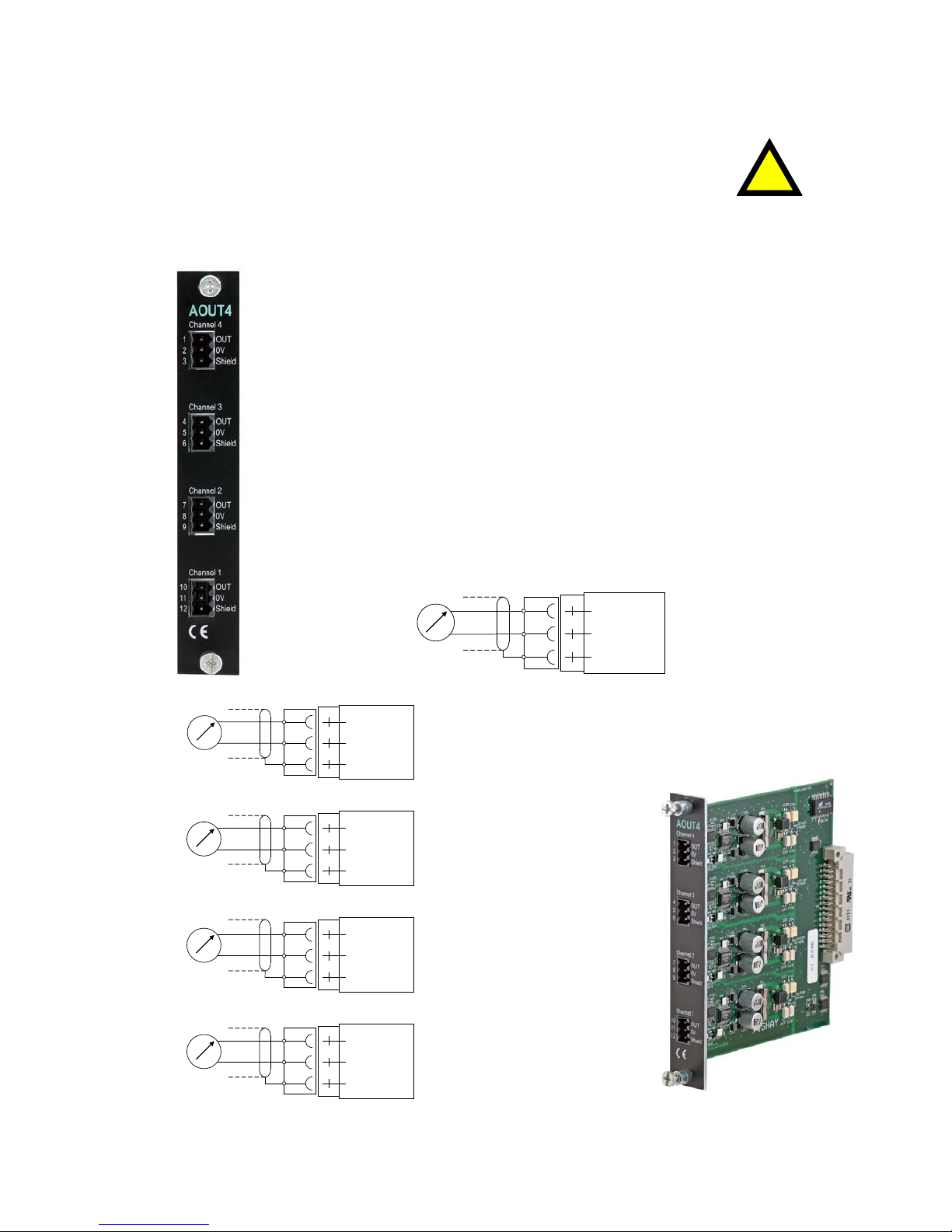

AOUT1 and AOUT4

The voltage levels on connectors of I/O modules shall not exceed

hazardous voltage levels of 30 Vrms, 42.4 Vpeak or 60 Vdc under normal

conditions. In wet locations these voltage levels shall not exceed 16 Vrms,

22.6 Vpeak or 35 Vdc.

Analog output unit

The AOUT4 unit has 4 analog output channels, independently

isolated by operational insulation.

The AOUT1 has 1 output channel, isolated by operational insulation.

The analog output signal will be connected to terminals

10, 11 (channel 1)

7, 8 (channel 2)

4, 5 (channel 3)

1, 2 (channel 4).

Shielded cable/cables must be used and the shield(s) must be connected

to the shield terminal(s) 12, 9, 6 and 3.

The shields can be connected to the most convenient ground/earth point.

OUT

0V

Shield

AOUT1 Channel 1

10

11

12

+

OUT

0V

Shield

Channel 1

10

11

12

OUT

0V

Shield

Channel 2

7

8

9

OUT

0V

Shield

Channel 3

4

5

6

OUT

0V

Shield

AOUT4 Channel 4

1

2

3

+

+

+

+

!

Page 28

Technical Manual

2-10

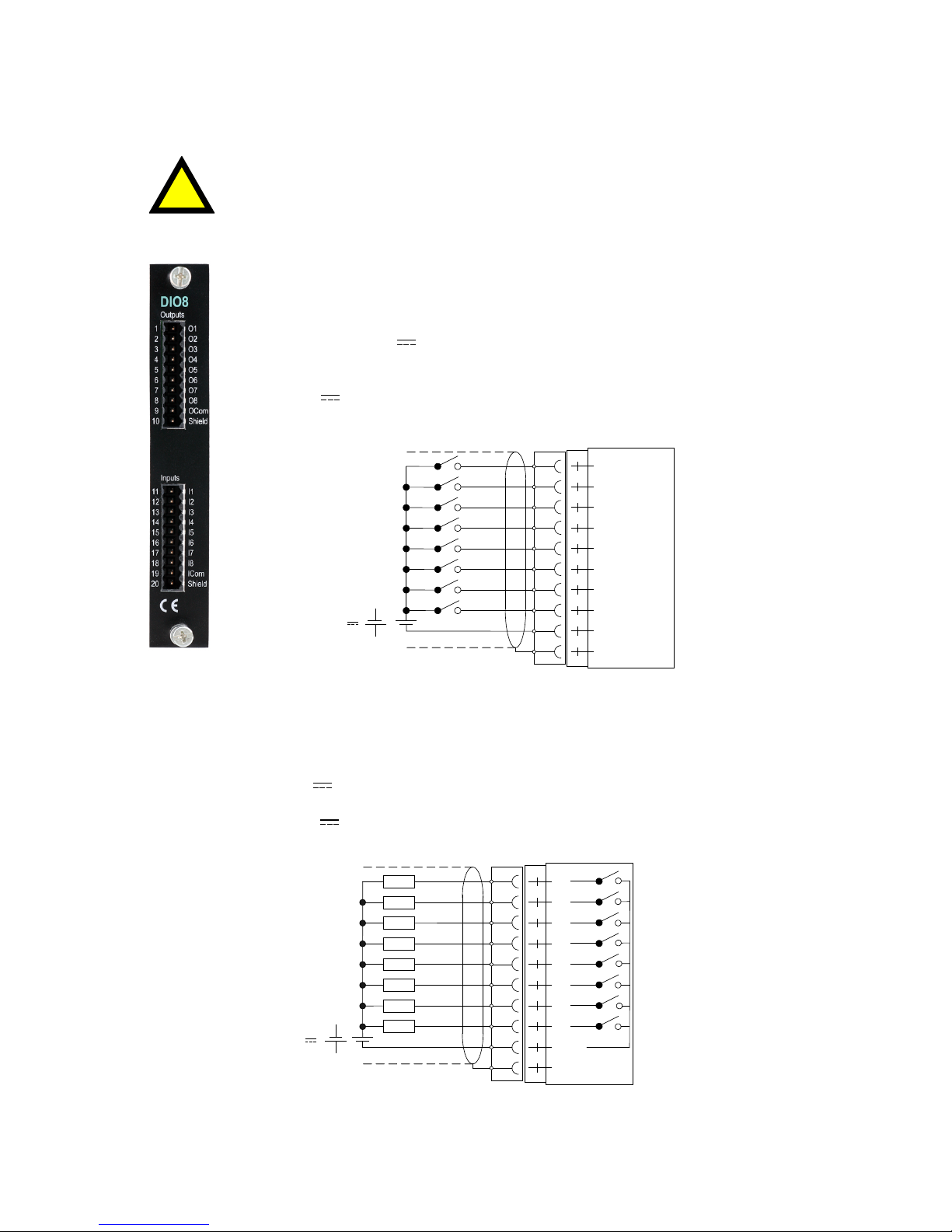

DIO8

The voltage levels on connectors of I/O modules shall not exceed

hazardous voltage levels of 30 Vrms, 42.4 Vpeak or 60 Vdc under

normal conditions. In wet locations these voltage levels shall not exceed

16 Vrms, 22.6 Vpeak or 35 Vdc.

Digital inputs

Terminals 11 – 18 and terminal 19 (ICom) as a common connection.

Eight digital inputs are provided, with functions that can be set

in the G4 set-up.

External sourcing (24 V

) from the instrument power supply

(max. 100 mA) or from a separate DC supply must be used.

Note that either the positive or the negative pole of the voltage

source (24 V

) can be connected to ICom (19).

Shielded cable/cables must be used, with the shield connected

to terminal 20.

I1

I2

I3

I4

I5

I6

I7

I8

ICom

Shield

-

+

+

11

12

13

14

15

16

17

18

19

20

24 V

Solid state relay outputs

Terminals 1 - 8 with terminal 9 (OCom) as a common connection.

Eight digital (relay) outputs are provided with contact rating given in Technical data.

External sourcing (24 V

) from the instrument power supply (max. 100 mA) or from a

separate DC supply must be used. Note that either the positive or the negative pole of

the voltage source (24 V

) can be connected to OCom (9).

Shielded cable/cables must be used, with the shield connected to terminal 10.

O1

O2

O3

O4

O5

O6

O7

O8

OCom

Shield

Load

Load

Load

Load

Load

Load

Load

Load

+

-

+

-

1

2

4

3

5

6

7

8

9

10

24 V

!

Page 29

G4 Multi Channel Force Instrument

2-11

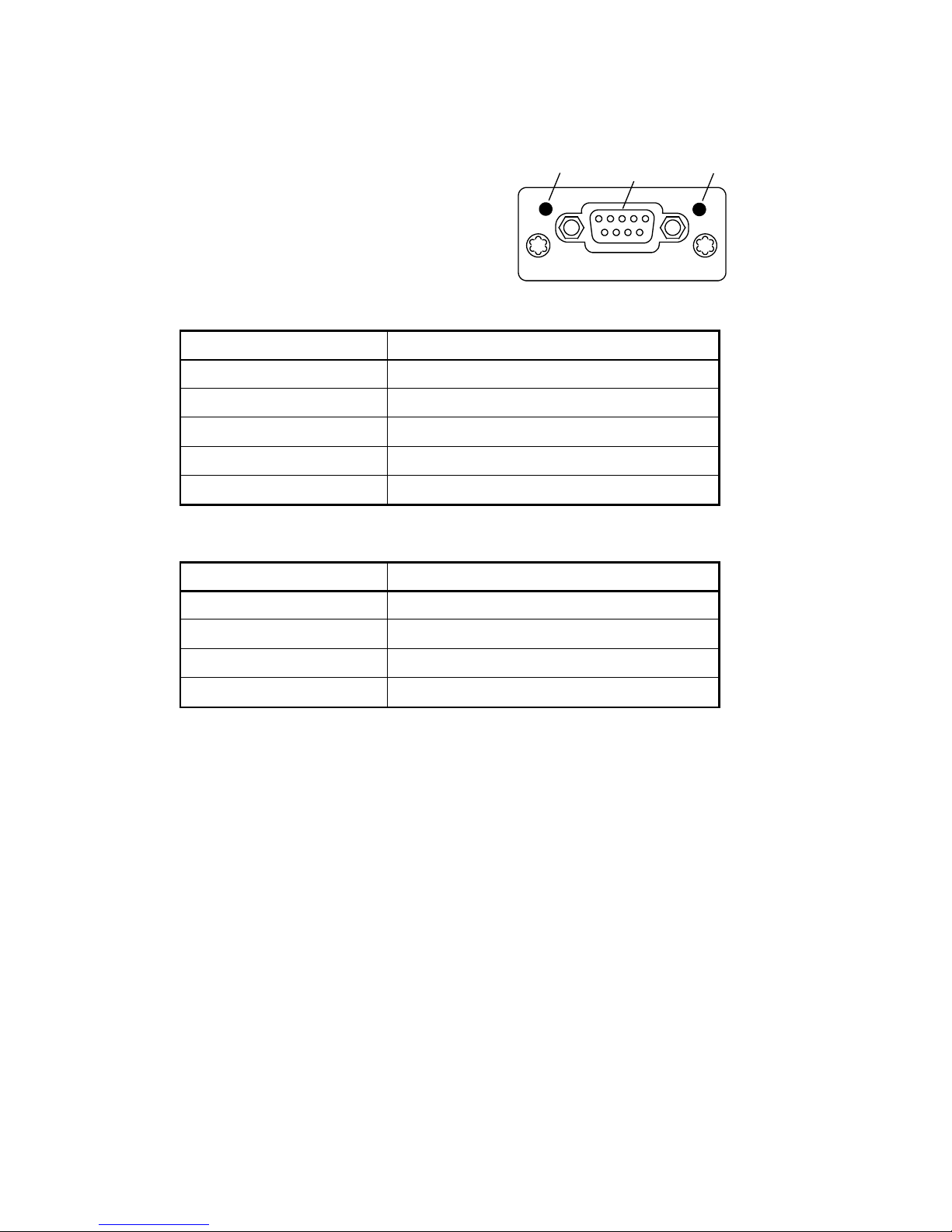

Profibus-DP Fieldbus Adaptor

Profibus module front view

(1) Operation mode LED.

(2) Status LED.

(3) Profibus connector.

Operation mode LED

State Indication

Off Not online / No power

Green On-line, data exchange

Flashing Green On-line, clear

Flashing Red (1 flash) Parameterization error

Flashing Red (2 flashes) Profibus configuration error

Status LED

State Indication

Off No power or not initialised

Green Initialised

Flashing Green Initialised, diagnostic event(s) present

Red Exception error

OP ST

PROFIBUS DP-V1

(1)

(2)

(3)

Page 30

Technical Manual

2-12

Profibus connector (DB9F)

Pin Signal Description

1 - -

2 - 3 B line Positive RxD/TxD, RS485 level

4 RTS Request to send

5 GND Bus Ground (isolated)

6 + 5V Bus Output +5V termination power (isolated)

7 - 8 A line Negative RxD/TxD, RS485 level

9 - Housing Cable shield Internally connected to the Anybus protective

earth via cable shield filters according to the

Profibus standard.

For connection of the adaptor to the Profibus master, use a Profibus standard cable

and connector according to the diagram below.

For reliable fieldbus function, line termination must be arranged in both ends of the

transmission line. For a G4 instrument, at the end of the cable, a connector with line

termination should be used. For all other G4 Instruments connection without line

termination should be used.

For configuration of the adaptor, a GSD file (VISH0AB3.GSD) is available and should

be installed in the master.

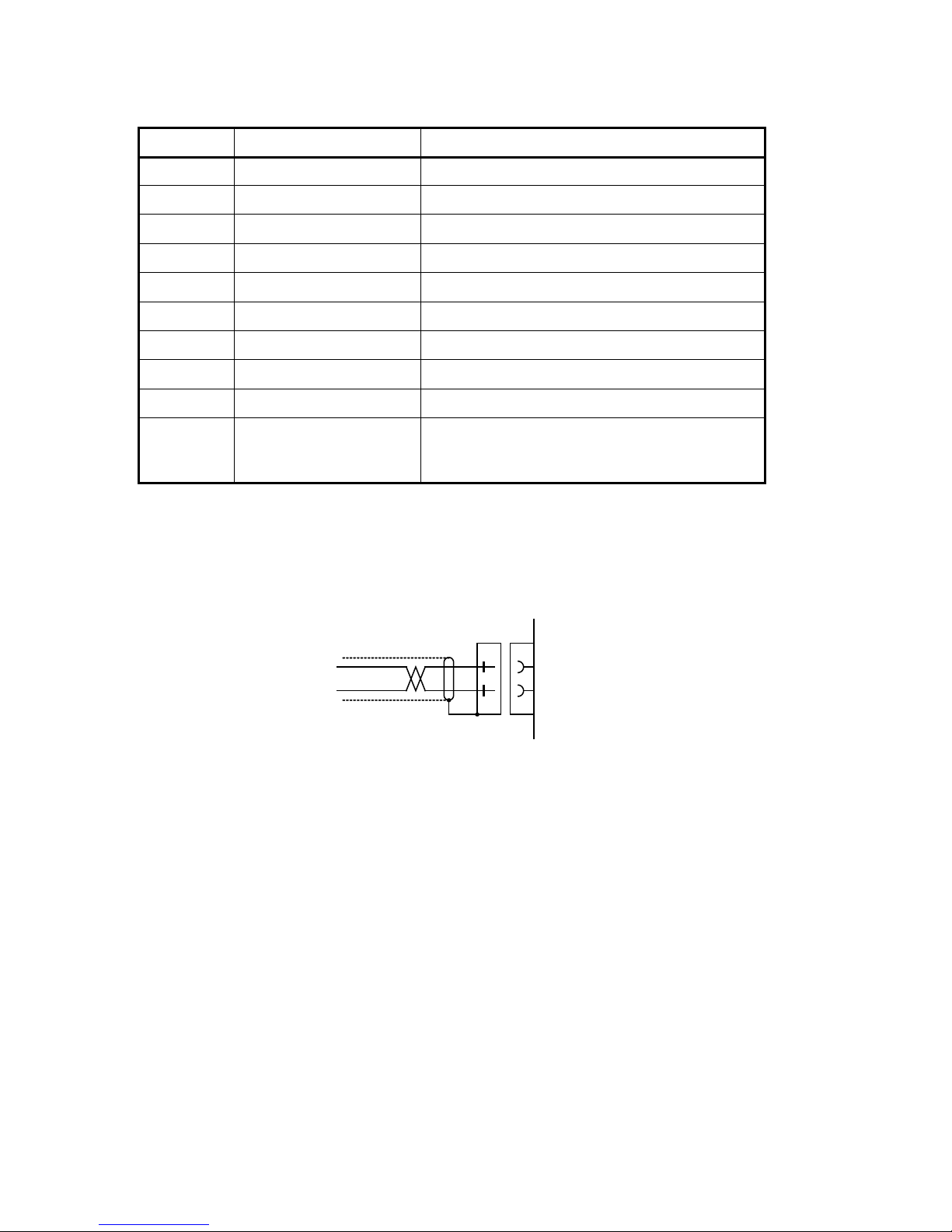

G4 Modular

Instrument

D-sub

A-line

B-line

8

3

shield

Page 31

G4 Multi Channel Force Instrument

2-13

DeviceNet Fieldbus Adaptor

DeviceNet module front view

(1) Network Status LED.

(2) Module Status LED.

(3) DeviceNet connector.

Network Status LED

State Indication

Off Not online / No power

Green On-line, one or more connections are established

Flashing Green (1 Hz) On-line, no connections established

Red Critical link failure

Flashing Red (1 Hz) One or more connections time out

Alternating Red/Green Self test

Module Status LED

State Indication

Off No power

Green Operating in normal condition

Flashing Green (1 Hz) Missing or incomplete configuration

Red Unrecoverable fault(s)

Flashing Red (1 Hz) Recoverable fault(s)

Alternating Red/Green Self test

NS MS

DeviceNet

(1)

(2)

(3)

(Pin 1)

Page 32

Technical Manual

2-14

DeviceNet connector

Pin Signal Description

1 V- Negative bus supply voltage

2 CAN L CAN low bus line

3 Shield Cable shield

4 CAN H CAN high bus line

5 V+ Positive bus supply voltage

For connection of the adaptor to the DeviceNet master, use a standard cable for

DeviceNet, or similar shielded cable with twisted pairs and a connector according to

the diagram below.

G4 Modular

Instrument

CAN L

2

4

shield

1

5

3

CAN H

V-

V+

For reliable fieldbus function, line termination must be arranged in both ends of the

transmission line. For a G4 instrument placed at the end of the line, terminate line by

placing a 121-ohm resistor between CAN L (pin 2) and CAN H (pin 4).

For configuration of the adaptor an EDS file is supplied with the instrument that should

be installed in the master. Note that the EDS file is a generic type supplied by the

module manufacturer. The file doesn’t contain any reference to the G4 Instrument or to

Nobel Weighing Systems.

Page 33

G4 Multi Channel Force Instrument

3-1

3. Instrument Functionality

General

This chapter describes the functionality of the different parts of the force instrument.

Function Block

All measuring functions in the instrument are based on configurable function blocks.

A Function Block is used to calculate the force or web tension of one to four inputs and

the sums and differences if more than one input is used. With a four channel Function

Block there are intermediate sum of force/web tension values calculated (A + B and

C + D).

The Function Block type is selected with parameter ‘Func.BlockX Type’ (Hardware

Configuration menu) and the value of the parameter can be set to ‘Not In Use’,

‘1 Channel’, ‘2 Channel’ or ‘4 Channel’. The type is selected individually for each used

Function Block.

A measuring channel, i.e. a connection on a WF IN / WF IN2 or HS WF2 module,

should be assigned to each Function Block input. The inputs of a Function Block are

named Input A to input D. Note that each measuring channel can only be assigned to

one Function Block input. Inputs cannot be shared between Function Blocks. The

maximum number of measuring channels in an instrument is 8 if WF IN2 modules are

used and 4 if HS WF2 modules are used.

A Function Block input can also be set to ‘Not In Use’ which means that the actual

input value used is always 0. This can be useful when using three transducers in a

4 channel Function Block or for testing purposes.

In the menu Param. Set-up – Calibration –

Function Block 1 (- 8) are parameters for configuration and

calibration located. Only used Function Blocks are displayed in

the menu.

The calibration parameters shown in the figure is for Function

Block 1.

There are sets of calibration parameters for each force input.

Parameters named ‘1:A …..’ belongs to input A, parameters

named ‘1:B …..’ belongs to input B and so on.

Calibration must be done for separately for each input.

All other parameters (‘1: …..’) are common for the whole

Function Block.

In the instrument and throughout this manual are outputs from

Function Blocks used for Display, Analog Outputs, Levels,

Communication, etc. These Output Signals are explained in the

tables below. The actual value for each “Output” is depending

on the Function Block type. E.g. if the sum of inputs C and D, on

a 4 channel Function Block, should be monitored on an analog

output, Output 2 should be chosen as the source for the analog

1:HSWF Update R.

800 Hz

1:Calibr. Type

Table

1:A ValueCal.P1

0 N

1:A T.Signal P1

0.00000 mV/V

1:A ValueCal.P2

1000 N

1:A T.Signal P2

2.00000 mV/V

1:A Set Zero

0.0 N

1:A Zero Offset

0.0 mV/V

1:B ValueCal.P1

0 N

1:B T.Signal P1

0.00000 mV/V

Page 34

Technical Manual

3-2

output. Also the input forces are available for monitoring etc, see ‘Common values’

later in this chapter.

Force Mode

The following table and figures explains the function and the values from a Function

Block in force mode (set-up parameter ‘X:Web T. Mode’ = Off).

A ‘(F)’ in the table below indicates a force value.

Value

1 Channel

Func. Block

2 Channel

Func. Block

4 Channel

Func. Block

Sum

Input A (F)

Input A+B (F)

Input A+B+C+D (F)

Difference

-

Input A-B (F)

Input (A+B) – (C+D) (F)

Output 1

Input A (F)

Input A (F)

Input A+B (F)

Output 2

-

Input B (F)

Input C+D (F)

Output 3

- - Input A (F)

Output 4

- - Input B (F)

Output 5

- - Input C (F)

Output 6

- - Input D (F)

Input A

Output 1

Sum

One Channel Function block, Force mode

Sum

Input A

Output 1

Input B Output 2

Difference

+

+

+

-

Two Channel Function block, Force mode

Input A

Sum

Output 3

Input B

Output 4

Output 1

Input C

Output 5

Input D Output 6

Output 2

Difference

+

+

+

+

+

+

+

-

Four Channel Function block, Force mode

Page 35

G4 Multi Channel Force Instrument

3-3

Web Tension Mode

A Function Block can be configured for web tension measuring by setting set-up

parameter ‘X:Web T. Mode’ to On. In this case some of the force values will be

recalculated to a web tension value using the ‘X:Web T. Factor’ as shown below.

Web Tension Value = Force Value / Web Tension Factor

If the Force Values are correctly calibrated in the desired measuring direction then the

‘Web T. Factor’ shall be set to the length of the roller (machine width) to get correct

Web Tension values, e.g. N/m. In other cases the ‘Web T. Factor’ must be calculated

based on calibration direction, web tension measuring direction, roller length, etc.

The following table and figures explains the function and the values from a Function

Block in web tension mode.

A ‘(F)’ in the table below indicates a force value and a ‘(WT)’ a web tension value.

Value

1 Channel

Func. Block

2 Channel

Func. Block

4 Channel

Func. Block

Sum

Input A (WT)

Input (A+B) / 2 (WT)

Input (A+B+C+D) / 2 (WT)

Difference

-

Input A-B (WT)

Input (A+B) – (C+D) (WT)

Output 1

Input A (WT)

Input A (WT)

Input A+B (WT)

Output 2

Input A (F)

Input B (WT)

Input C+D (WT)

Output 3

-

Input A (F)

Input A (F)

Output 4

-

Input B (F)

Input B (F)

Output 5

- - Input C (F)

Output 6

- - Input D (F)

Output 7

- - Input A+B (F)

Output 8

- - Input C+D (F)

Sum

Input A

1 / WTF

Output 2

Output 1

WTF = Web Tension Factor

One Channel Function block, Web Tension mode

Sum

Input A

1 / WTF

Output 3

Output 1

Input B

1 / WTF

Output 2

Output 4

Difference

1/2

+

+

+

-

WTF = Web Tension Factor

Two Channel Function block, Web Tension mode

Page 36

Technical Manual

3-4

Input A

Sum

Output 3

Input B

Output 4

1 / WTF

Output 7

Output 1

Input C

Output 5

Input D

Output 6

1 / WTF

Output 2

Output 8

Difference

1/2

+

+

+

+

+

+

+

-

WTF = Web Tension Factor

Four Channel Function block, Web Tension mode

Common values

The following table explains the available input values to a Function Block. These

values are the same for a Function Block both in force mode and tension mode.

Value

1 Channel

Func. Block

2 Channel

Func. Block

4 Channel

Func. Block

Input A Force

Inp. A Force

Inp. A Force

Inp. A Force

Input B Force

-

Inp. B Force

Inp. B Force

Input C Force

- - Inp. C Force

Input D Force

- - Inp. D Force

Input A Signal (mV/V)

Inp. A Signal

Inp. A Signal

Inp. A Signal

Input B Signal (mV/V)

-

Inp. B Signal

Inp. B Signal

Input C Signal (mV/V)

- - Inp. C Signal

Input D Signal (mV/V)

- - Inp. D Signal

Page 37

G4 Multi Channel Force Instrument

4-1

4. Set-up

General

All operating functions in the G4 Instrument are controlled by parameters. The

parameter values are permanently stored in the instrument and will not be lost when

the unit is switched off. At delivery the parameters are factory-set to default values,

giving the instrument an initial standard function.

The actual setting of the parameter values can be read and edited during normal

measuring operation in sub menu ‘Parameter Set-up’.

Editing of parameter values can be performed using the alphanumeric display and keys

on the front panel of the VIEWPAN module. After editing hardware parameters the

instrument will be restarted.

In the instrument there are two levels of security locks provided to protect from

unauthorized access to instrument functions and editing of parameters and values. The

locks are opened by four-digit codes.

Warning: Changes done during editing of set-up parameters will affect the behavior of

the instrument immediately. The user must take all necessary precautions to prevent

any undesired effects in the process monitored or controlled by the G4 instrument or a

connected control system.

It is strongly recommended to activate the set-up lock in the instrument to prevent any

unauthorized changes of set-up parameters.

It’s a good practice to make a backup of the set-up after changes have been done. See

chapter ‘8 Maintenance’ for more information on backup and restore.

The ‘Parameter Set-up’ menu contain the following sub menus:

General: This parameter group controls the general functionality of the instrument.

Such as display language, display contrast, security, key functions and so on.

Hardware Configuration: Parameters used for configuring the instrument hardware.

Here parameters that are used for basic configuration, of the Function blocks, found.

Note that when the instrument is starting up it will check that the installed hardware is

compatible with the settings. If not an alarm will be issued.

Calibration: Parameters that affect the behavior of the eight possible Function Blocks

in the instrument. There are parameters for calibration type, calibration values, filter

settings etc. All Function Blocks are individually settable.

Communication: Sub menus are Serial Com, Ethernet and Fieldbus.

Serial Com sub menu content is parameters used to set-up COM1 (RS232) and COM2

(RS485) on the CPU module. Parameters are among others: com. port mode, baud

rate and data format. Ethernet sub menu content is parameters for Modbus TCP

configuration. Fieldbus sub menu content is configuration parameters related to

fieldbus communication such as address, baud rate and transmitted data setup.

Level Supervision: The instrument has 32 level supervisors that are configured from

this sub menu. Settings for each level are which Function Block that the individual level

is to monitor and which signal that shall be monitored from the selected Function Block.

Signals that can be monitored are Sum value, Difference value, Output 1 and so on.

The output function e.g. if the output shall be active above or below the set level is

Page 38

Technical Manual

4-2

configured here. There are parameters for hystereses setting and level switching

delays.

Inputs: The use of the instruments digital inputs is set in this menu. Note that the

inputs are numbered 11 to 38. Inputs 11 to 18 corresponds to inputs on slot 1 I/O

module, 21 to 28 correspond to inputs on slot 2 I/O and so on. The actual number of

inputs depends on what type of I/O-module that is installed in the respective slots. A

DIO8 module has 8 inputs a WF IN2 module has 4 inputs while an AOUT1 or AOUT4

has no inputs. Inputs can be used for zeroing of Function Blocks.

Outputs: The outputs menu contains the settings controlling the function of each

output. Numbering is 11 to 38 for the I/O module outputs. See section ‘Inputs’ above on

how individual output numbers correspond to each I/O slot. Each output can be

assigned an output function: Level output status or ‘In Process’ status.

Analog Outputs: This menu controls the behavior of an AOUT4 or an AOUT1 Analog

output module. The output signal source (Function Block No and signal type) can be

selected. Also output type and range high/low is settable.

Operators interface

The DIN-rail type of instrument uses the service

panel (VIEWPAN) located in the I/O slot system of

the instrument as operator interface. It also

includes a 24 VDC power supply that supports the

complete instrument with power. The VIEWPAN

module occupies slots 4 to 6.

It is also possible to connect a standard USB

keyboard for PC to the USB connector

at the CPU module. The keyboard will work in

parallel with the keys on VIEWPAN and will make

it easier to handle the configuration of the

instrument, as it can be used as an input for digits

and characters.

The keyboard keys ' + ', ' - ', ' ↑ ' or 'Esc', and

'Enter' will correspond the VIEWPAN keys ' + ',

' - ', ' ↑ ' , and ' ↵ '.

Function key 'F11' on the keyboard can be used

to access the 'Main Menu'.

ViewPan module

Page 39

G4 Multi Channel Force Instrument

4-3

From any of the operating display views, displaying the main menu is done by pressing

‘+’ and ‘↑’ keys simultaneously for 1 second.

The ViewPan ‘+’ and ‘−’ keys are used to scroll the available menu items and the ‘↵’

key is used to enter the selected sub menu. Pressing the ‘↑’ key when in the main

menu will make the instrument display the operating menu.

To move one step back in the menu structure press the ‘↑’ key. The ‘↑’ key is also used

to cancel any parameter editing.

1: 385 N

20

Main Menu

Levels

Main Menu

Clock Set-up

+

-

+

+ 1 second

+

Levels Menu

Clock Set-up

Menu

Main Menu

Param. Set-up

-

+

Parameter Set-

up Menu

Main Menu

System Info.

-

+

System Info

Menu

Main Menu

Maintenance

-

Maintenance Menu

+

Main Menu

Network Config

-

Network Config

Menu

ViewPan main menu

Page 40

Technical Manual

4-4

Parameter Set-up menu

To enter a Parameter Set-up sub menu the

desired one is selected by scrolling with ‘+’ or ‘−’

keys until it’s shown. Then the sub menu is

entered by pressing ‘↵’. Returning to ‘Main

Menu’ from ‘Parameter Set-up’ menu is done by

pressing the ‘↑’ key.

Main Menu

Param. Set-up

Param. Set-up

General

Param. Set-up

Hardware Config.

+

-

Param. Set-up

Calibration

+

-

+

Param. Set-up

Communication

-

+

Param. Set-up

Level Superv.

-

+

Param. Set-up

Inputs

-

+

Param. Set-up

Outputs

-

+

Param. Set-up

Analog Outputs

-

Parameter set-up menu

Page 41

G4 Multi Channel Force Instrument

4-5

Parameter editing procedure

This example shows the ‘General’

parameter menu but editing is done similar

throughout the menu system.

The desired menu is selected by scrolling

with ‘+’ or ‘−’ keys until it is shown. Then the

sub menu is entered by pressing ‘↵’.

Returning to previous menu from a sub

menu is done by pressing the ‘↑’ key.

The desired parameter is selected by

scrolling with ‘+’ or ‘−’ keys until it is shown.

As the wanted set-up parameter is

displayed, press ‘↵’ to start the editing

procedure. This will place a flashing cursor

to the left on the lower line, and a numerical

parameter value will get leading zeros. The

cursor indicates that editing can be

performed and that the panel key functions

are different.

+ Key function:

Increment the cursor digit, or go to next

alternative in case of a choice parameter.

−

Key function:

Decrement the cursor digit, or go to

previous alternative in case of a choice

parameter.

↵ Key function (short press):

Accept the value of the cursor digit and go

to next digit.

↵ Key function (1 sec press):

Accept the actual parameter value and

finish editing. If a value outside the range for

a numeric parameter is entered, an error

message is displayed. Then press any key

to remove the message and make

continued editing possible.

↑

Key function:

Cancel the edited value, and interrupt the

editing.

Parameter set-up

General

Language

English

Instrument Name

+

-

Start Mode

Auto

+

-

+

Display Contrast

6

-

+

Date Format

YYYY-MM-DD

-

+

Time Format

24 h

-

+

Zero key

Off

-

+

Operator Lock

On

-

+

Operator Code

****

-

+

Set-up Lock

On

-

+

Set-up Code

****

-

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

Edit

parameter

’General’ parameters menu

Page 42

Technical Manual

4-6

Menu structure

(Cont. on next

page)

Main Menu

*Levels

*Clock Set-up

*Param. Set-up

*System Info.

*Maintenance

*Network Config

Param. Set-up

*General

*Hardware Config.

*Calibration

*Communication

*Level Superv.

*Inputs

*Outputs

*Analog Outputs

General

Language

Instrument Name

Start Mode

Display Contrast

Date Format

Time Format

Zero Key

Operator Lock

Operator Code

Set-up Lock

Set-up Code

Hardware Config.

Fieldbus

Slot 1 Module

Slot 2 Module

Slot 3 Module

Func.Block1 Type

F.Block 1 Inp.A

F.Block 1 Inp.B

F.Block 1 Inp.C

F.Block 1 Inp.D

Func.Block2 Type

F.Block 2 Inp.A

F.Block 2 Inp.B

F.Block 2 Inp.C

F.Block 2 Inp.D

Func.Block3 Type

F.Block 3 Inp.A

F.Block 3 Inp.B

F.Block 3 Inp.C

F.Block 3 Inp.D

Func.Block4 Type

F.Block 4 Inp.A

F.Block 4 Inp.B

F.Block 4 Inp.C

F.Block 4 Inp.D

Func.Block5 Type

F.Block 5 Inp.A

F.Block 5 Inp.B

F.Block 5 Inp.C

F.Block 5 Inp.D

Func.Block6 Type

F.Block 6 Inp.A

F.Block 6 Inp.B

F.Block 6 Inp.C

F.Block 6 Inp.D

Func.Block7 Type

F.Block 7 Inp.A

F.Block 7 Inp.B

F.Block 7 Inp.C

F.Block 7 Inp.D

Func.Block8 Type

F.Block 8 Inp.A

F.Block 8 Inp.B

F.Block 8 Inp.C

F.Block 8 Inp.D

Calibration

*Function Block 1

*Function Block 2

*Function Block 3

*Function Block 4

*Function Block 5

*Function Block 6

*Function Block 7

*Function Block 8

Function Block 1..8

1:Func.BlockName

1:Web T. Mode

1:Measurem. Unit

1:Resolution

1:Web T.Unit

1:Web T.Resol.

1:Web T.Factor

1:HSWF Update R.

1:WFIN Update R.

1:Calibr. Type

1:A ValueCal.P1

1:A T. Signal P1

1:A ValueCal.P2

1:A T. Signal P2

1:A Set Zero

1:A Zero Offset

1:B ValueCal.P1

1:B T. Signal P1

1:B ValueCal.P2

1:B T. Signal P2

1:B Set Zero

1:B Zero Offset

1:C ValueCal.P1

1:C T. Signal P1

1:C ValueCal.P2

1:C T. Signal P2

1:C Set Zero

1:C Zero Offset

1:D ValueCal.P1

1:D T. Signal P1

1:D ValueCal.P2

1:D T. Signal P2

1:D Set Zero

1:D Zero Offset

*sub menu

Levels

Level values for

configured levels

Clock Set-up

Date and time set-up

(Cont. on next page)

Menu structure (continued)

Page 43

G4 Multi Channel Force Instrument

4-7

Inputs

*Inputs Slot 1

*Inputs Slot 2

*Inputs Slot 3

Outputs

*Outputs Slot 1

*Outputs Slot 2

*Outputs Slot 3

Analog Outputs

AOUT1 Source

AOUT1 F.Block

AOUT1 Outp.Type

AOUT1 Range Low

AOUT1 Range High

AOUT1 Bandwidth

AOUT1 Low Adj.

AOUT1 High Adj.

AOUT2 Source

AOUT2 F.Block

AOUT2 Outp.Type

AOUT2 Range Low

AOUT2 Range High

AOUT2 Bandwidth

AOUT2 Low Adj.

AOUT2 High Adj

AOUT3 Source

AOUT3 F.Block

AOUT3 Outp.Type

AOUT3 Range Low

AOUT3 Range High

AOUT3 Bandwidth

AOUT3 Low Adj.

AOUT3 High Adj.

AOUT4 Source

AOUT4 F.Block

AOUT4 Outp.Type

AOUT4 Range Low

AOUT4 Range High

AOUT4 Bandwidth

AOUT4 Low Adj.

AOUT4 High Adj.

(from previous page)

Inputs Slot 1..3

Input 11 Use

Input 11 F.Block

Input 12 Use

Input 12 F.Block

…….

Input 18 Use

Input 18 F.Block

Outputs Slot 1..3

Outp. 11 Source

Output 11 Level

Outp. 12 Source

Output 12 Level

…….

Outp. 18 Source

Output 18 Level

(from previous page)

System Info.

Information on serial

numbers, program

versions, network

status and installed

I/O modules.

Maintenance

*Diagnostics

*File Handling

*Create Backup

*Restore Backup

*Set Default

*Program Upgrade

Network Config

*IP Config.

*Server Config.

Level Superv.

*Level 1

*Level 2

*Level 3

…….

*Level 31

*Level 32

Level 1..32

Level 1 Source

Level 1 Mode

Level 1 F.Block

Level 1 Output

Level 1 Hyst.

Level 1 Up Del.

Level 1 Dn.Del.

Communication

Modbus Address

COM1:Mode

COM1:Baudrate

COM1:Data Format

COM1:Min Reply T

COM1:Float Form.

COM2:Mode

COM2:Baudrate

COM2:Data Format

COM2:Min Reply T

COM2:Float Form.

Modbus TCP Slave

Float Format

Serial Com.

Ethernet

*Serial Com.

*Ethernet

*Fieldbus

Address

Baudrate

No of Data Block

Block 1 Type

Block 1 Format

Block 1 FB

Block 2 Type

Block 2 Format

Block 2 FB

Block 3 Type

Block 3 Format

Block 3 FB

…….

Block 11 Type

Block 11 Format

Block 11 FB

Block 12 Type

Block 12 Format

Block 12 FB

Fieldbus

(continued) Menu structure

Page 44

Technical Manual

4-8

Parameters

On the following pages a survey of all parameters is presented. The parameters are

divided in groups following the menu they belong to. For choice parameters the

available choices are given. For numerical parameters, a value range is given.

At the end of the table, the default value is given in < >.

To the right there is a short parameter explanation and, in italic, the results for

the different alternatives.

Range/Alternatives Explanation and

<default value> result of alternatives.

Menu ‘General’

Language

English

Svenska

<English>

Defines the language to be used in menus and messages.

Instrument Name

<> A 16-character string that is used at printing in reports and so

on.

Start Mode

Command

Auto

<Auto>

Defines the start mode after power-on or reset.

Command: A ‘start operation’ command from

control computer or panel key is required for start up.

Auto: Automatic start up.

Display Contrast

0

1

2

3

4

5

6

7

<5>

Defines the text contrast for the alphanumerical display.

Low values giving lower contrast.

High values giving sharper characters but reduced readability

at slanted display.

Date Format

YYYY-MM-DD

YYYY-DD-MM

DD-MM-YYYY

MM/DD/YYYY

<YYYY-MM-DD>

Defines the date format.

YYYY: = year. MM: = month. DD: = day.

Page 45

G4 Multi Channel Force Instrument

4-9

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

Time Format

12 h

24 h

<24h>

Defines the time format.

12 h: 12 hour time format.

24 h: 24 hour time format.

Zero Key

Off

On

<Off>

Disables/enables the Zero function from the front panel.

Off: The Zero function is disabled.

On: The Zero function is enabled.

Operator Lock

Off

On

<Off>

Off: Operator lock is not activated.

On: Operator lock is activated, preventing unauthorized access

to the instrument.

See chapter 6 ‘Operation − Security locks’

Operator Code

Range:

1 - 9999

<1937>

Defines the valid code for Operator lock.

If ‘Set-up lock’ (see below) is ‘On’ this code will not give access

to functions that requires the ‘Set-up Code’.

Note: this parameter is only shown if ‘Operator Lock’ is set to

‘On’

Set-up Lock

Off

On

<Off>

Off: Set-up lock is not activated.

On: Operator lock is activated, preventing unauthorized access

to the instrument.

See chapter 6 ‘Operation − Security locks’

Set-up Code

Range:

1 - 9999

<1937>

Defines the valid code for Set-up lock.

If ‘Operator lock’ (see above) is ‘On’ this code will still give

access to all menus in the Main menu.

Note: this parameter is only shown if ‘Set-up Lock‘ is set to ‘On’

Page 46

Technical Manual

4-10

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

Menu ‘Hardware Config.’

Fieldbus

Not In Use

Profibus

DeviceNet

<Not In Use>

This parameter defines what type of fieldbus that will be used in

the CPU.

Not In Use: The fieldbus is not used regardless of any installed

module.

Profibus: A Profibus type of fieldbus module is used.

DeviceNet: A DeviceNet type of fieldbus module is used.

Slot 1 Module

No module

HSWF2

WFIN

WFIN2

AOUT1

AOUT4

DIO8

<WFIN2>

This parameter defines what type of I/O-module is installed in

slot 1.

No module: No module is used in this slot.

HSWF2: A 2 channel high speed weight/force module.

WFIN: A 1 channel, weight/force measuring module.

WFIN2: A 2 channel, weight/force measuring module.

AOUT1: A 1 channel analog output module.

AOUT4: A 4 channel analog output module.

DIO8: A 8/8 digital input/output module.

Slot 2 Module

< No module > This parameter defines what type of I/O- module is installed in

slot 2. See ‘Slot 1 Module type’ for details on parameter values.

Slot 3 Module

< No module > This parameter defines what type of I/O- module is installed in

slot 3. See ‘Slot 1 Module type’ for details on parameter values.

Func.Block1 Type

Not In Use

1 Channel

2 Channel

4 Channel

< 1 Channel >

This parameter defines if Function Block 1 is used and, if used,

the no of inputs it should use.

Not In Use: The Function Block is not used.

1 Channel: 1 channel type.

2 Channel: 2 channel type.

4 Channel: 4 channel type.

Page 47

G4 Multi Channel Force Instrument

4-11

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

F.Block 1 Inp.A

Not In Use

Slot 1, Ch 1

Slot 1, Ch 2

Slot 2, Ch 1

Slot 2, Ch 2

Slot 3, Ch 1

Slot 3, Ch 2

(Slot 4, Ch 1)

(Slot 4, Ch 2)

(Slot 5, Ch 1)

(Slot 5, Ch 2)

(Slot 6, Ch 1)

(Slot 6, Ch 2)

< Slot 1, Ch 1 >

This parameter defines which measuring channel (slot and

channel) that should be use as input A to Function Block 1.

Not In Use: The input is not used

Slot 1, Ch 1: Use measuring channel 1 of slot 1

Slot 1, Ch 2: Use measuring channel 2 of slot 1

Slot 2, Ch 1: Use measuring channel 1 of slot 2

Slot 2, Ch 2: Use measuring channel 2 of slot 2

Slot 3, Ch 1: Use measuring channel 1 of slot 3

Slot 3, Ch 2: Use measuring channel 2 of slot 3

Note: selection of ‘Slot 4, Ch 1’ to ‘Slot 6, Ch 2’ not allowed in

the RM type of instrument.

Note: this parameter is not shown if ‘Function Block 1 Type’ is

‘Not In Use’.

F.Block 1 Inp.B

Not In Use

Slot 1, Ch 1

Slot 1, Ch 2

Slot 2, Ch 1

Slot 2, Ch 2

Slot 3, Ch 1

Slot 3, Ch 2

(Slot 4, Ch 1)

(Slot 4, Ch 2)

(Slot 5, Ch 1)

(Slot 5, Ch 2)

(Slot 6, Ch 1)

(Slot 6, Ch 2)

< Not In Use >

This parameter defines which measuring channel (slot and

channel) that should be use as input B to Function Block 1.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 1 Type’ is

‘2 Channel’ or ‘4 Channel’.

F.Block 1 Inp.C

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be use as input C to Function Block 1.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 1 Type’ is

‘4 Channel’.

F.Block 1 Inp.D

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be use as input D to Function Block 1.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 1 Type’ is

‘4 Channel’.

Page 48

Technical Manual

4-12

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

Func.Block2 Type

Not In Use

1 Channel

2 Channel

4 Channel

< 1 Channel >

This parameter defines if Function Block 2 is used and, if used,

the no of inputs it should use.

Not In Use: The Function Block is not used.

1 Channel: 1 channel type.

2 Channel: 2 channel type.

4 Channel: 4 channel type.

F.Block 2 Inp.A

< Slot 1, Ch 2 > This parameter defines which measuring channel (slot and

channel) that should be used as input A to Function Block 2.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is not shown if ‘Function Block 2 Type’ is

‘Not In Use’.

F.Block 2 Inp.B

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input B to Function Block 2.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 2 Type’ is

‘2 Channel’ or ‘4 Channel’.

F.Block 2 Inp.C

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input C to Function Block 2.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 2 Type’ is

‘4 Channel’.

F.Block 2 Inp.D

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input D to Function Block 2.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 2 Type’ is

‘4 Channel’.

Page 49

G4 Multi Channel Force Instrument

4-13

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

Func.Block3 Type

Not In Use

1 Channel

2 Channel

4 Channel

< Not In Use >

This parameter defines if Function Block 3 is used and, if used,

the no of inputs it should use.

Not In Use: The Function Block is not used.

1 Channel: 1 channel type.

2 Channel: 2 channel type.

4 Channel: 4 channel type.

F.Block 3 Inp.A

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input A to Function Block 3.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is not shown if ‘Function Block 3 Type’ is

‘Not In Use’.

F.Block 3 Inp.B

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input B to Function Block 3.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 3 Type’ is

‘2 Channel’ or ‘4 Channel’.

F.Block 3 Inp.C

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input C to Function Block 3.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 3 Type’ is

‘4 Channel’.

F.Block 3 Inp.D

< Not In Use > This parameter defines which measuring channel (slot and

channel) that should be used as input D to Function Block 3.

See ‘F.Block 1 Inp. A.’ for a description of parameter values.

Note: this parameter is only shown if ‘Function Block 3 Type’ is

‘4 Channel’.

For an explanation of parameters for Function Blocks 4 to 8 see:

‘Func.Block3 Type’

‘F.Block 3 Inp.A.’

‘F.Block 3 Inp.B.’

‘F.Block 3 Inp.C.’

‘F.Block 3 Inp.D.’

Note that the parameters for a Function Block are shown or not shown depending on

the setting of parameter ‘Func. Block X Type’, for that specific Function Block.

Page 50

Technical Manual

4-14

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

Menus ‘Function Block 1’ – ‘Function Block 8’

The Calibration menu contains up to 6 sub menus, one for each used Function Block.

The parameters are the same for all 6 menus. Here only Function Block 1 parameters

are shown. Note that the Function Block number is shown as a prefix to the parameter

name, here ‘1:’ Also note that the menu is only shown if the parameter

‘Func. Block X Type’, for the actual Function Block, is not set to ‘Not In Use’.

1:Func.BlockName

<> A 16-character string that is used at printing, in reports etc.

1:Web T. Mode

Off

On

<Off>

Selects Force or Web Tension mode for the Function Block.

Off: Force mode.

On: Web Tension Mode.

1:Measurem. Unit

NONE

N

daN

kN

MN

lbf

kgf

Nm

N/m

kN/m

PLI

g

kg

t

lb

oz

psi

kPa

MPa

bar

l

mm

m

inch

feet

st

pcs

%

mV/V

<N>

Defines the unit that should be used for measured force value(s)

and for related set-up parameters.

Page 51

G4 Multi Channel Force Instrument

4-15

Range/Alternatives Explanation and

<default value> resul t of al ternatives.

1:Resolution

0.001

0.002

0.005

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10

20

50

<1>

Defines the decimal point position and resolution format for the

displayed force value. All set-up parameters using the

measurement unit will be written with the decimal point position

selected in this menu.

If the last digits of the displayed value are not stable, a more

coarse resolution can be selected to get a stable reading.

1:Web T.Unit

NONE

N/m

kN/m

PLI

%

<N/m>

Defines the unit that should be used for measured web tension

value(s) and for related set-up parameters.

Note: this parameter is only shown if ‘1:Web Tension Mode‘ is

set to ‘On’

1:Web T. Resol.

0.001

0.002

0.005

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10

20

50

<1>

Defines the decimal point position and resolution format for the

displayed web tension value. All set-up parameters using the

web tension unit will be written with the decimal point position

selected in this menu.

If the last digits of the displayed value are not stable, a more

coarse resolution can be selected to get a stable reading.

Note: this parameter is only shown if ‘1:Web Tension Mode‘ is

set to ‘On’

1:Web T.Factor