Page 1

GB

G4 Multi Channel

Weighing Instrument

Program version 1.2.0.0

Operating instructions,

Quick installation

PM/DT/HE types

Page 2

Operating instructions, Quick installation

Page 3

G4 Multi Channel Weighing Instrument

Contents

Introduction

General ............................................................. 1

Power supply ..................................................... 1

Start-up ............................................................. 1

Maintenance ..................................................... 2

Safety information ............................................. 2

Front panel

General ..............................................................3

Display alternatives ............................................4

Operation

Zero indication and zero adjustment ..................5

Gross weight ......................................................5

Net weight ..........................................................6

Taring .................................................................6

Editing Preset Tare ............................................7

Level supervision ...............................................8

Flow display .......................................................9

Installation

Mechanical installation .....................................11

Electrical installation ........................................11

DC supply, AC supply ......................................12

CPU unit ...........................................................13

WF IN, WF IN2 and HS WF2 ...........................14

Basic set-up

General ............................................................17

Hardware configuration ....................................17

Security lock .....................................................17

Common parameters .......................................18

Clock set-up .....................................................20

Scale calibration ...............................................21

Data sheet calibration ......................................24

Deadweight calibration .....................................27

Zeroing of gross weight ....................................30

Appendix 1

Common set-up values

Appendix 2

Scale set-up values

Page 4

Operating instructions, Quick installation

PRECAUTIONS

READ this manual BEFORE operating or servicing this instrument.

FOLLOW these instructions carefully.

SAVE this manual for future reference.

WARNING

!

Only permit qualified personnel to install and service this instrument.

Exercise care when making checks, tests and adjustments

that must be made with power on.

Failing to observe these precautions can result in bodily harm.

DO NOT allow untrained personnel to operate,

clean, inspect, maintain, service, or tamper with

this instrument.

Page 5

G4 Multi Channel Weighing Instrument

Introduction

General

G4 is a high performance multi channel weighing instrument intended for industrial

systems. Its basic function is to convert the signals from strain gauge transducers to

useful weight information. Several types of communication interfaces are supported

by G4, which makes it easy to integrate the instrument into industrial processes.

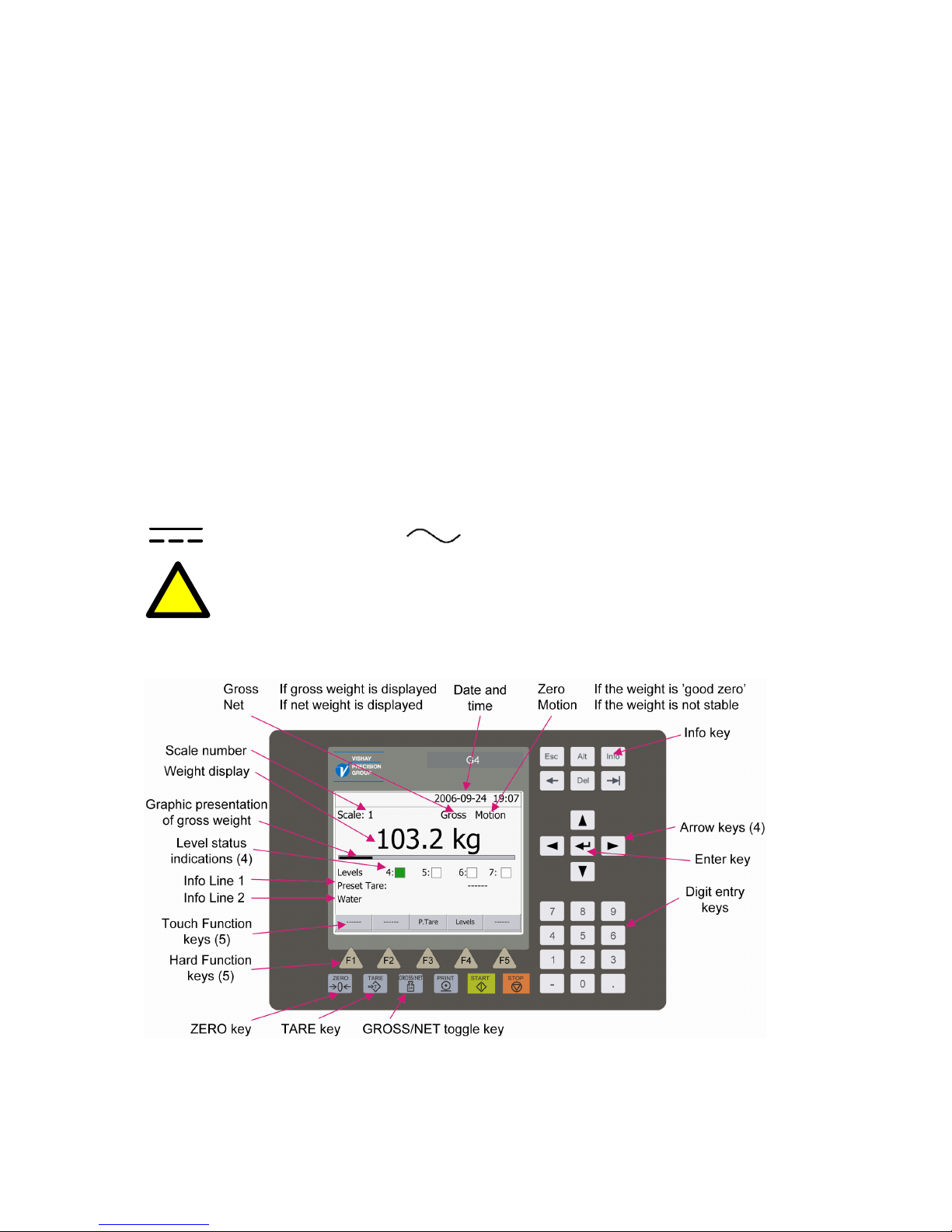

The front panel of G4, types PM/DT/HE, is flat, dustproof, and waterproof. It has

a back lighted graphical colour LCD display with touch sensitive screen for weight

information, set-up information and error messages.

It also has function keys and a numeric keypad for entry of digits.

The basic configuration of the instrument performs weighing and flow rate

calculation. All functions are controlled by set-up parameters.

‘Operating instructions, Quick installation’ for G4, types PM/DT/HE, includes basic

installation and set-up information, required for correct measuring with the instrument.

This description deals with the following points:

• Weighing with G4, types PM/DT/HE.

• Flow rate measurement.

• Quick installation.

• Data sheet calibration.

• Deadweight calibration in two points.

Additional installation and set-up of more instrument functions, not covered by this

description, can also be performed, for example:

• Complete installation.

• Complete set-up.

• Setting of communication parameters.

• Table calibration.

• Level supervision.

For a complete instrument description, refer to:

G4 Multi Channel Weighing Instrument

Technical Manual PM/DT/HE types

Power supply

Power supply to the weight indicator should not be turned off during weekends and

over-night. Continuous power supply to electronics and transducers prevents moisture

condensation in the units.

Start-up

As soon as power is connected to the instrument, a start-up period begins.

The text ‘Start up Please wait!’ and a WAIT symbol (hour-glass) will be displayed

after some seconds.

Then G4 automatically switches to normal measuring operation.

If the instrument is set for operator start-up, the text

‘Press ENTER to start operation!’ will be shown.

If a warm up time has been set, the text ‘Warming up Please wait!’ will be displayed

before the instrument switches to measuring operation.

If any error is detected, the start-up stops and an error message will be displayed.

1

Page 6

Operating instructions, Quick installation

Maintenance

The G4 instrument needs no maintenance performed by the end-user. Any service

or repair work must be performed by qualified personnel. Contact your supplier.

Cleaning

Before cleaning the G4, break the power connection to the instrument.

Use a soft cloth to clean the exterior of the instrument. For cleaning

the instrument front panel, a soft, damp, cloth may be used.

Safety information

Utilization.

Before connecting power to the instrument, check that all fixation screws at the modules

are tightened so that the instruments functional grounding by the housing is maintained.

The instrument may only be utilized for the measurement and control functions, described

in the Technical Manual for G4 Multi Channel Weighing Instrument, PM/DT/HE types.

It is especially important to adhere to the load limits of the input/output connectors.

We accept no responsibility for any damage arising from improper operation.

Any changes to the instrument, which causes any function changes, may only be

carried out by the manufacturer, or after discussion with and permission by

the manufacturer.

Meaning of symbols, used in this manual

Direct current.

Alternating current.

!

Caution, risk of danger. Documentation needs to be consulted.

Front panel of instrument G4, types PM, DT, and HE.

2

Page 7

G4 Multi Channel Weighing Instrument

Front panel

General

G4 has a flat, dustproof, and waterproof front panel with a back lighted and touch

sensitive graphic colour LCD display and all necessary keys to perform weighing,

batching, and set-up operations.

Display

G4 normally displays either gross weight or net weight digitally, and in some cases

also gives a graphic representation of the gross weight.

Actual status information for the weight value and date and time will also be shown

at the display.

The Level status (max 4 levels) for the scale and other configurable information may

also be displayed in some cases.

If an error occurs this will be indicated by an error code at the display.

Info key

The Info key at the upper right corner of the panel is used to enter G4 menu system.

Function keys

Just below the display there are five function keys, marked F1 to F5.

Actual key functions, if any, are indicated at the lower line of the display.

To the right of the display, four arrow keys are provided. These keys control

the position of the cursor, the indicated area at the display.

The Enter key (

) is situated between the arrow keys. It is used to accept

the selection indicated by the cursor, to finish the entry of a value etc.

A set of keys for entry of digits is also provided.

Pressing function keys or the Enter key can be replaced by tapping at corresponding

areas in the display.

Symbol keys

Six keys, marked with weighing symbols, are provided at the lower border of the panel.

Three of them control the zero setting function, the tare function, and the gross/net

function. The remaining three keys have no function in these instrument versions.

Key Name Function

ZERO

0

ZERO Setting the gross weight value to zero (provided the value

is in the zeroing range: –1 % to +3 % of the capacity) and

setting the auto tare value to zero.

TARE

T

TARE Taring, i.e. entry of the gross weight as auto tare value and

display of net weight zero. Depending on actual setting

taring may be prevented if ‘Motion’ is displayed.

B/N

GROSS/NET Toggling between display of gross weight and net weight.

Net weight can be displayed only if a tare value other than

zero has been entered.

3

Page 8

Operating instructions, Quick installation

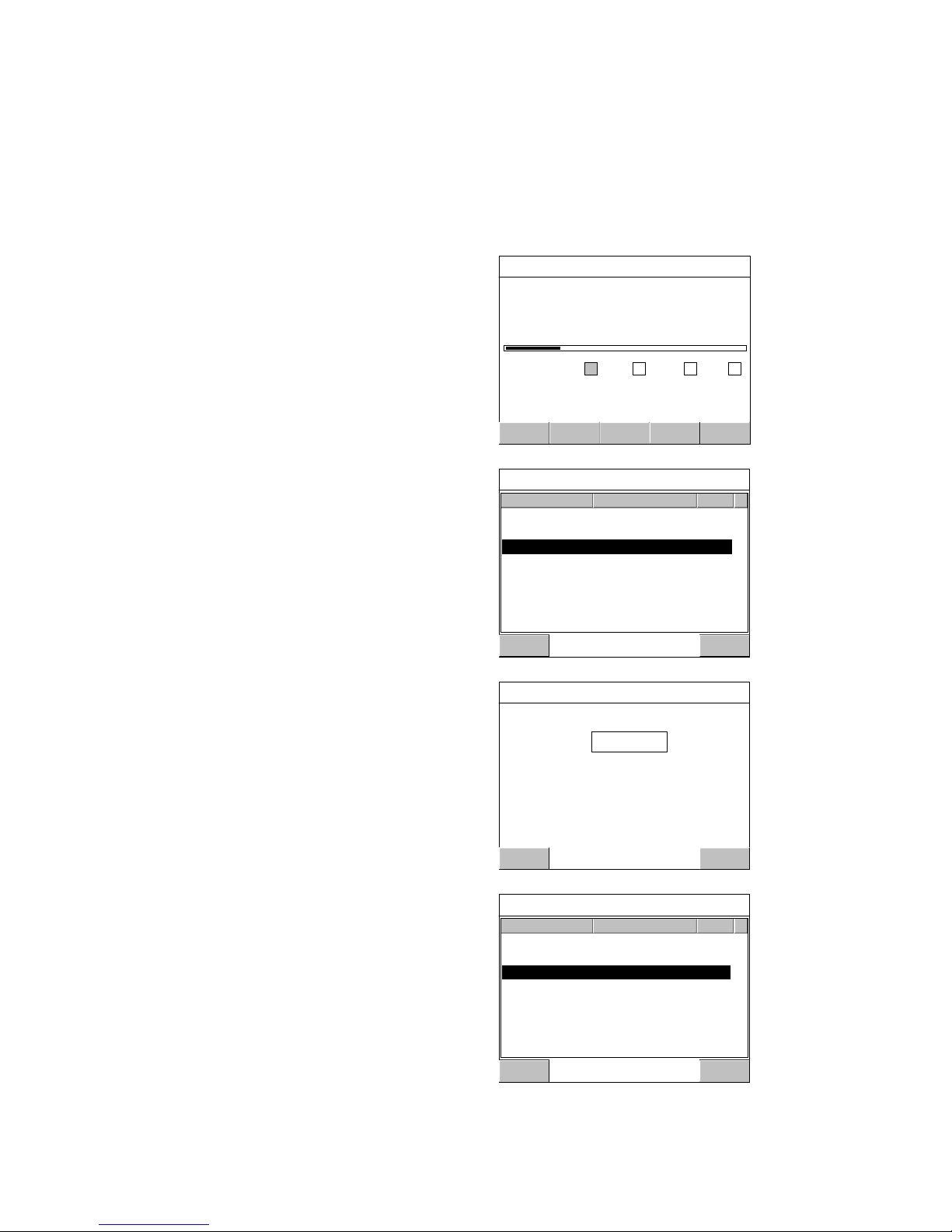

Display alternatives

It is possible to configure G4 to display one, two or four scales at a time, or a

combination of the mentioned views. If a combination of views is used, the arrow keys

'right' and 'left' are used to select a display alternative. Only configured scales will be

shown.

Arrow keys 'up' and 'down' are used to select one of the configured scales. When

several scales are displayed, the selected scale is indicated yellow. The function keys

will influence only the selected scale.

If display of only one scale is selected, detailed information of weight and other selected

information can be presented.

If display of two or four scales is selected, the weight values will be shown, but less other

information.

2006-09-24 19:07

------ ------ ------P.Tare Levels

Scale: 1 Gross

103.2 kg

Levels 4: 5: 6: 7:

Preset Tare: 33.0kg

Water

2006-09-24 19:07

------ ------ ------P.Tare Levels

Scale: 1

Gross

102.8 kg

Scale: 2

Net Zero

000.0 kg

Scale: 3

Net Zero

000.0 kg

Scale: 4

Gross

004.9 kg

2006-09-24 19:07

------ ------ ------P.Tare Levels

Scale: 2

Net Motion

3.4 kg

Scale: 1

Gross

103.2 kg

‘Level status’

Status of the level supervision is presented in four boxes below the weight value

presentation. The boxes have fixed positions. When a digit is shown at a box,

the corresponding Level is in use. For each scale the four lowest level numbers

that are in use will be shown. A Level box will be marked green when the level

of the supervised weight signal is above the set value for that Level.

‘Information lines’

By set-up parameters it is possible to configure the instrument to display selected

information on two information lines below the Level status boxes.

2006-09-24 19:07

Scale: 1 Gross

103.2 kg

Levels 4: 5: 6: 7:

Preset Tare: 33.0kg

Water

------ ------ P.Tare Levels ------

Example:

Levels 4, 5, 6, and 7 are in use; the weight signal is above Level 4.

Preset Tare (33.0 kg for Scale 1) on Info line 1.

Scale Name (Water for Scale 1) on Info line 2.

4

Page 9

G4 Multi Channel Weighing Instrument

Operation

Zero indication and zero adjustment

A basic zero setting of the gross weight for unloaded scale is performed at installation

as a part of the calibration. When a ‘good zero’ is displayed, the text ‘Zero’ is shown

to the right in the display.

Minor correction of the zero value may be needed and can rapidly be performed.

Zero adjustment

If, for unloaded scale, the text ‘Zero’ is not shown, but the gross weight is

close to zero, a rapid zero adjustment can be performed.

The gross weight must be stable (text ‘Motion’ not shown) and the key ZERO

must be enabled.

2006-09-24 19:07

Scale: 1 Gross

000.2 kg

Levels 4: 5: 6: 7:

Preset Tare: -----

Water

------ ------ P.Tare Levels ------

ZERO

0

2006-09-24 19:07

Scale: 1 Gross Zero

000.0 kg

Levels 4: 5: 6: 7:

Preset Tare: -----

Water

------ ------ P.Tare Levels ------

Zero adjustment can only be performed if the accumulated deviation from the basic zero

setting in the last calibration is within -1 % to +3 % of the ‘Capacity’.

In other cases a new basic zero setting must be performed.

Gross weight

The gross weight is the total weight loaded on the scale after zero setting.

Gross weight is displayed when the text ‘Gross’ is shown in the display.

When net weight is displayed, the GROSS/NET key can be pressed to change

to display of gross weight, provided that the GROSS/NET key is enabled.

2006-09-24 19:07

Scale: 1 Net

103.2 kg

Levels 4: 5: 6: 7:

Preset Tare: -----

Water

------ ------ P.Tare Levels ------

GROSS/NET

B/N

2006-09-24 19:07

Scale: 1 Gross

143.4 kg

Levels 4: 5: 6: 7 :

Preset Tare: ------

Water

------ ------ P.Tare Levels ------

In some cases, gross weight is shown as a graphic bar at the display.

Maximum length of the bar corresponds to ‘Capacity’ of the scale.

5

Page 10

Operating instructions, Quick installation

Net weight

The net weight is the difference between the gross weight and a tare value.

If the tare value is zero, net weight can not be displayed.

Net weight is displayed when the text ‘Net’ is shown in the display.

When gross weight is displayed, the GROSS/NET key can be pressed to change

to display of net weight, provided that the GROSS/NET key is enabled.

2006-09-24 19:07

Scale: 1 Gross

143.4 kg

Levels 4: 5: 6: 7:

Preset Tare: ------

Water

------ ------ P.Tare Levels ------

GROSS/NET

B/N

2006-09-24 19:07

Scale: 1

Levels

Preset Tare:

Water

Net

103.2 kg

4: 5: 6: 7:

-----

------ ------ P.Tare Lev els ------

Taring

Taring means storing of a tare value for the scale. Net weight will be calculated as

the difference between the gross weight and this tare value. If the tare value is zero,

net weight will not be displayed.

At default setting, taring can always be performed, provided the key TARE is enabled.

But the scale can also be set to allow taring only at stable weight (when the text

‘Motion’ is not shown).

In G4 two tare values can be used: Auto tare and Preset tare.

Auto tare

By taring, the actual gross weight is stored as Auto tare value, and the scale will switch

to display of net weight ‘zero’.

2006-09-24 19:07

Scale: 1 Gross

014.5 kg

Levels 4: 5: 6: 7:

Preset Tare: ------

Water

------ ------ P.Tare Levels ------

TARE

T

2006-09-24 19:07

Scale: 1

Levels

Preset Tare:

Water

Net Zero

000.0 kg

4: 5: 6: 7:

-----

------ ------ P.Tare Lev els ------

6

Page 11

G4 Multi Channel Weighing Instrument

Editing Preset tare

In this example Scale 1 is set for taring with

‘Preset tare’, and for displaying the value

of the ‘Preset Tare’ at Info Line 1

(and Scale Name at Info Line 2).

The example shows editing the Preset tare

value, using the numeric keypad.

Press 'P.Tare'.

2006-09-24 19:07

Scale: 1 Gross

034.5 kg

Levels 4: 5: 6: 7:

Preset Tare: 0.00 kg

Water

------ ------ P.Tare Levels ------

Press 'Edit' to edit the value.

If Operator Lock is activated,

the Operator Code will be needed.

Preset tare, Scale 1

Preset Tare 1 0.0 kg

Edit Escape

The actual value of 'Preset tare' is displayed.

Use the numeric keypad to write the new value.

Finish by 'Enter'.

Edit: Preset tare 1

Enter Escape

Value: kg

Maximum value: 999999 kg

Minimum value: 0 kg

33.0

Menu 'Preset tare, Scale 1' will be shown

with the new value.

Press 'Escape' to return to display of

normal weighing operation.

Preset tare, Scale 1

Preset Tare 1 33.0 kg

Edit Escape

7

Page 12

Operating instructions, Quick installation

Level supervision

With G4 it is possible to supervise different weighing signals at defined levels.

The instrument contains 32 supervising units, Level 1 to Level 32, which can be

connected to the scales by the parameter set-up. For each scale up to 4 connected

Levels are indicated at the display in normal operation. All Levels connected to a scale

are shown if 'Levels' or function key F4 is pressed.

Edit Levels

The supervision levels are easily edited from

the G4 front panel during normal operation.

In this example Scale 1 has five levels of

supervision.

Level number 6 should be edited.

Press 'Levels'.

Select Level 6 by using arrow keys up and

down to position the indicator.

(Or tap at Level 6 to edit.)

Press 'Edit'.

If Operator Lock is activated, the Operator Code

will be needed.

The actual value of Level 6 is displayed.

Use the numeric keypad to write the new value.

Finish by 'Enter'.

Menu 'Levels, Scale 1' will be shown

with the new value for Level 6.

Press Escape' to return to display of

normal weighing operation.

2006-09-24 19:07

------ ------ ------P.Tare Levels

Scale: 1 Gross

034.5 kg

Levels 4: 5: 6: 7:

Preset Tare: 33.0 kg

Water

Levels, Scale 1

Edit Escape

Level 4 20.0 kg

Level 5 40.0 kg

Level 6 55.0 kg

Level 7 85.0 kg

Level 9 120.0 kg

Edit: Level 6

Enter Escape

Value: kg 60.0

Maximum value: 999999 kg

Minimum value: -999999 kg

Levels, Scale 1

Edit Escape

Level 4 20.0 kg

Level 5 40.0 kg

Level 6 60.0 kg

Level 7 85.0 kg

Level 9 120.0 kg

8

Page 13

G4 Multi Channel Weighing Instrument

Flow display

When option Flow display is activated for a scale, function key F5 will show

the text 'W/F'. Pressing function key F5, or tapping at 'W/F', will switch the scale

between display of weight value (indicated by 'Gross' or 'Net') and display of

flow value (indicated by 'Flow').

2006-09-24 19:07

Scale: 1 Gross

123.4 kg

Levels 4: 5: 6: 7:

Preset Tare: 33.0 kg

Water

------ ------ P.Tare Levels W/F

W/F

2006-09-24 19:07

Scale: 1

Levels

Preset Tare:

Water

Flow

0.00 kg/s

4: 5: 6: 7 :

33.0 kg

------ ------ P.Tare Levels W/F

9

Page 14

Operating instructions, Quick installation

10

Page 15

G4 Multi Channel Weighing Instrument

Installation

Mechanical installation

The instrument G4 has a flat plastic front panel and can be ordered with three

different housings: aluminium housing for panel mounting or stand-alone use,

or stainless steel housing for stand-alone use in harsh environment.

Instruments for panel mounting have an integrated gasket that gives sealed

attachment to mounting panels. Stand-alone instruments have sealed housings.

Electrical installation

The field wiring of the instrument shall be suitable to the environment

(e.g. chemically) in the end-user application.

Mains cables shall be separated and routed away from SELV or

!

SELV-E field wiring.

For DT and HE instruments UL Listed and KAM cord type flexible cables shall be used.

For cable diameters, see specification in the Technical Manual.

These instruments have plugged cable entry holes. Replace a suitable number of plugs

by the strain reliefs delivered with the instrument.

Field wiring installation shall comply with any national regulations, hereunder National

Electrical Code (NEC) for US and/or Canadian Electrical Code for Canada.

• A switch or circuit-breaker shall be included in the building installation.

• The switch shall be in close proximity to the equipment and

within easy reach of the operator

• The switch shall be marked as the disconnecting device for the equipment.

• The equipment switch or circuit-breaker employed as disconnecting device shall

comply with relevant requirements of IEC 60947-1 and IEC 60947-3.

The power supply for the instruments can be made via an external dc supply unit

or an internal ac/dc supply unit.

All electrical connections to G4, including connection to ground, are made via

plug-in terminal blocks. Shielded cables are needed, exept for the power input,

and the cables should be routed so that electromagnetic interference from power

cables is avoided.

WARNING

Make sure that that the power to the instrument is turned off before:

- any modules are removed from or inserted in the instrument.

- any connections are connected to or disconnected from the instrument.

All modules should be regarded as ESD sensitive. Make sure that an ESD safe

environment is maintained when inserting modules, removing modules and

when handling modules separately from the instrument. Modules must be kept

in metallised ESD bag when not mounted in the instrument.

11

Page 16

Operating instructions, Quick installation

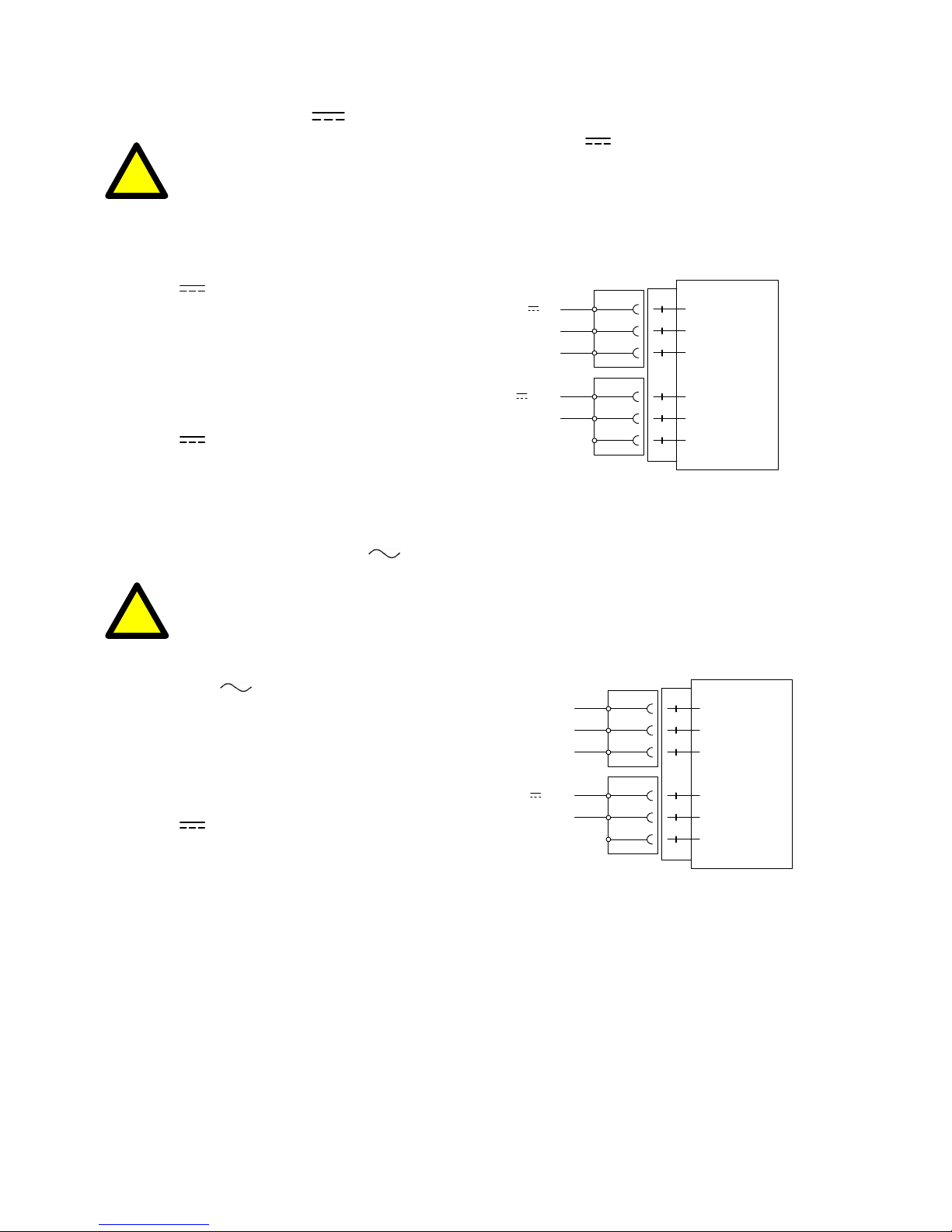

DC SUPPLY 24 V

!

The output of the external dc supply must be rated 24 V , ±15%

including fluctuations, min. 40 W. The supply must provide Double Insulation

between Mains parts and 24 V SELV or SELV-E circuit, and a limited-energy

circuit (max. available current 8 A). For the US market this energy limit

can be achieved with an ANSI/UL 248-14 fuse rated 5 A.

For other markets an IEC 60127 T type fuse rated 4 A may also be used.

24 V In

+24 V In

Terminals 1, 2, and 3.

Connect power to terminal 1 (positive) and

0 V

Ground

terminal 2 (0 V). To achieve functional

grounding, terminal 3 should be connected

to ground.

+24 V Out

0 V

24 V Out

Terminals 4 (positive) and 5 can be used

to supply max. 100 mA to logics, like

outputs and inputs.

AC SUPPLY 110-240 V

!

Mains supply cable shall be separated and routed away

from SELV or SELV-E field wiring.

Remove power before removing the module from the instrument.

Make sure the fixation screws are well tightened during operation.

110-240 V

In

Terminals 1, 2, and 3.

110-240 V~

Connect power to terminal 1 and 2.

Protective earth

To achieve functional grounding, terminal 3

should be connected to protective earth.

+24 V Out

0 V

24 V Out

Terminals 4 (positive) and 5 can be used

to supply max. 100 mA to logics, like

outputs and inputs.

1

DC SUPPLY

0 V

Shield

0 V

Shield

+24 VDC In

+24 VDC Out

2

3

4

5

6

1

AC SUPPLY

Shield

0 V

Shield

110-240 VAC

+24 VDC Out

2

3

4

5

6

12

Page 17

G4 Multi Channel Weighing Instrument

CPU unit

External computing devices connected to the CPU communication interfaces

of the instrument have to comply with the standard, UL 60950.

The internal battery in the CPU module is to be used only in the equipment

where servicing of the battery circuit and replacement of the lithium battery

will be done by a trained technician.

COM1

RS-232 Serial communication.

This is a SELV/SELV-E circuit.

COM 1 can be used for serial communication

(DTE)

RS-9p232

25p

!

with computer/PLC (Modbus RTU).

Point to point communication, only one

G4 unit connected to the computer/PLC.

Connections are made to terminals

7 to 9. Shielded cable must be used.

Connect the shield to terminal 10.

COM2

RS-485 Serial communication for

2-wire or 4-wire with common 0 V.

This is a SELV/SELV-E circuit.

Communication port COM2 can be

used for serial communication with

computer/PLC (Modbus RTU).

Connections are made to terminals

1 to 5. Shielded cable must be used.

Connect the shield to terminal 6.

The communication line must be

terminated at both ends.

If G4 is connected at the end of

the communication line, the switches

T2 and R2 must be set according to

the table below.

2-wire termination:

Both T2 switches ON,

both R2 switches OFF.

4-wire termination:

Both T2 switches ON

both R2 switches ON.

2 3

3 2

5 7

TX

RX

0V

Shield

COM1 RS-232

10

9

8

7

RS485 2-wire

COM2

+5

0

+5

0

T2

+5

T2

0

R2

+5

R2

0

1

T-

T+

R-

R+

0 V

Shield

6

2

3

4

5

T2

T2

R2

R2

RS485 4-wire

COM2

1

T-

T+

R-

R+

0 V

Shield

6

2

3

4

5

13

Page 18

Operating instructions, Quick installation

WF IN, WF IN2 and HS WF2

!

The voltage levels on connectors of I/O modules shall not exceed

hazardous voltage levels of 30 Vrms, 42.4 Vpeak or 60 Vdc under normal

conditions. In wet locations these voltage levels shall not exceed 16 Vrms,

22.6 Vpeak or 35 Vdc.

Transducer inputs

Terminals 17 – 23 (channel 1), 10 – 16 (channel 2). See next page.

Transducer connection should be handled with great care to achieve good

measuring data. Transducer integrated cables may not be shortened.

NOTE!

Transducer cables must be routed at least 200 mm away from 230/380 V, 50/60 Hz

power cables. By cables with other frequencies or high power, an even wider distance

is preferable.

4-wire connection should be used if the transducer integrated cable is long enough to

be connected directly to a transducer input. At 4-wire connection, some terminals must

be interconnected as shown in the figure on next page.

6-wire connection should be used if the integrated cable must be lengthened

or if several transducers should be connected to one transducer input.

The channel 1 cable shield must be connected to terminal 21 and

the channel 2 cable shield must be connected to terminal 14.

In WF IN and WF IN2 the shield terminals are internally connected to the G4 housing,

which is internally connected to earth via the power supply connector terminal 3 (Shield).

The shield shall not be connected at any other point.

In HS WF2 the transducer input channels are separately insulated by operational

insulation and the shields can be connected to the most convenient ground/earth point.

This can be the junction box when using multiple transducers or at the barrier ground

when using Ex zener barriers.

In the junction box SL-4 from Nobel Weighing Systems, see figure, all necessary

terminals are provided.

14

Page 19

G4 Multi Channel Weighing Instrument

10

15

13

12

11

14

16

Exc.-

Exc.+

Sign.+

Sign.-

4-wire connection

Transducer

Transducer input, ch. 2

Exc+

Sense+

Exc-

Sense-

Sign+

Sign-

Shield

Junction box 6-wire connection Transducer input, ch. 1

17

22

20

19

18

21

23

Exc.-

Exc.+

Sign.+

Sign.-

Transducer

Transducer

Exc.-

Exc.+

Sign.+

Sign.-

Exc+

Sense+

Exc-

Sense-

Sign+

Sign-

Shield

A transducer may be connected directly to terminals at the transducer input.

For several transducers or long distances,

a junction box and lengthening cable is needed.

For a HS WF2 channel, the shield can be connected to

ground/earth at any point.

15

Page 20

Operating instructions, Quick installation

16

Page 21

G4 Multi Channel Weighing Instrument

Basic set-up

General

All operating functions in G4 are controlled by parameters, stored in the instrument

memory. The actual setting of the parameter values can be edited during normal

weighing operation, using the touch display and the keys on the front panel.

WARNING. Changes done during editing of set-up parameters will affect the

behaviour of the instrument immediately. The user must take all necessary

precautions to prevent any undesired effects in process monitored or controlled

by the G4 instrument or a connected control system.

It is strongly recommended to activate the set-up lock in the instrument to prevent

any unauthorized changes of set-up parameters.

This section proposes a number of parameters to set, that will rapidly give

the instrument a useful presentation mode and basic measuring properties.

It contains setting of, for example, the measurement unit and resolution for

the weight value, and also some parameter settings for data sheet calibration

and deadweight calibration in two points.

If you are dealing with an already working instrument we recommend that you perform

a backup of the set-up parameters before you make any changes to the instrument.

When the set-up is finished, all parameter values should be noted (see appendix 1

and 2), or backed up in a file. Backup to an USB memory (or internal file) can be done

from menu 'Maintenance', sub menu 'Create Backup'.

Appendix 1 and 2 to this manual contains suitable forms to fill in for the instrument

hardware configuration and for the set-up parameters, covered by this manual.

Hardware configuration

The instruments G4, types PM/DT/HE, have room for one fieldbus module and six

other modules. The configuration of installed modules, used measuring channels,

and scale numbers is made in set-up parameter menu 'Hardware Config.'.

At delivery of an instrument, the hardware configuration normally corresponds to

the set-up. If any mismatch between installed modules and hardware configuration

occurs, an error message will be shown at instrument start-up.

Consult 'G4 Multi Channel Weighing Instrument Technical Manual PM/DT/HE types'

if you need to change the hardware configuration.

Security lock

With an instrument G4 it is possible to perform set-up operations during normal

operation, which may influence for example the performance of a scale. To prevent

these dangers, the instrument is equipped with security locks at two levels that can

be activated to protect from unauthorized access to editing of parameters and values.

Four-digit codes for the locks can be defined by the customer.

By default setting the code for both locks is: 1 9 3 7 .

17

Page 22

Operating instructions, Quick installation

Common parameters

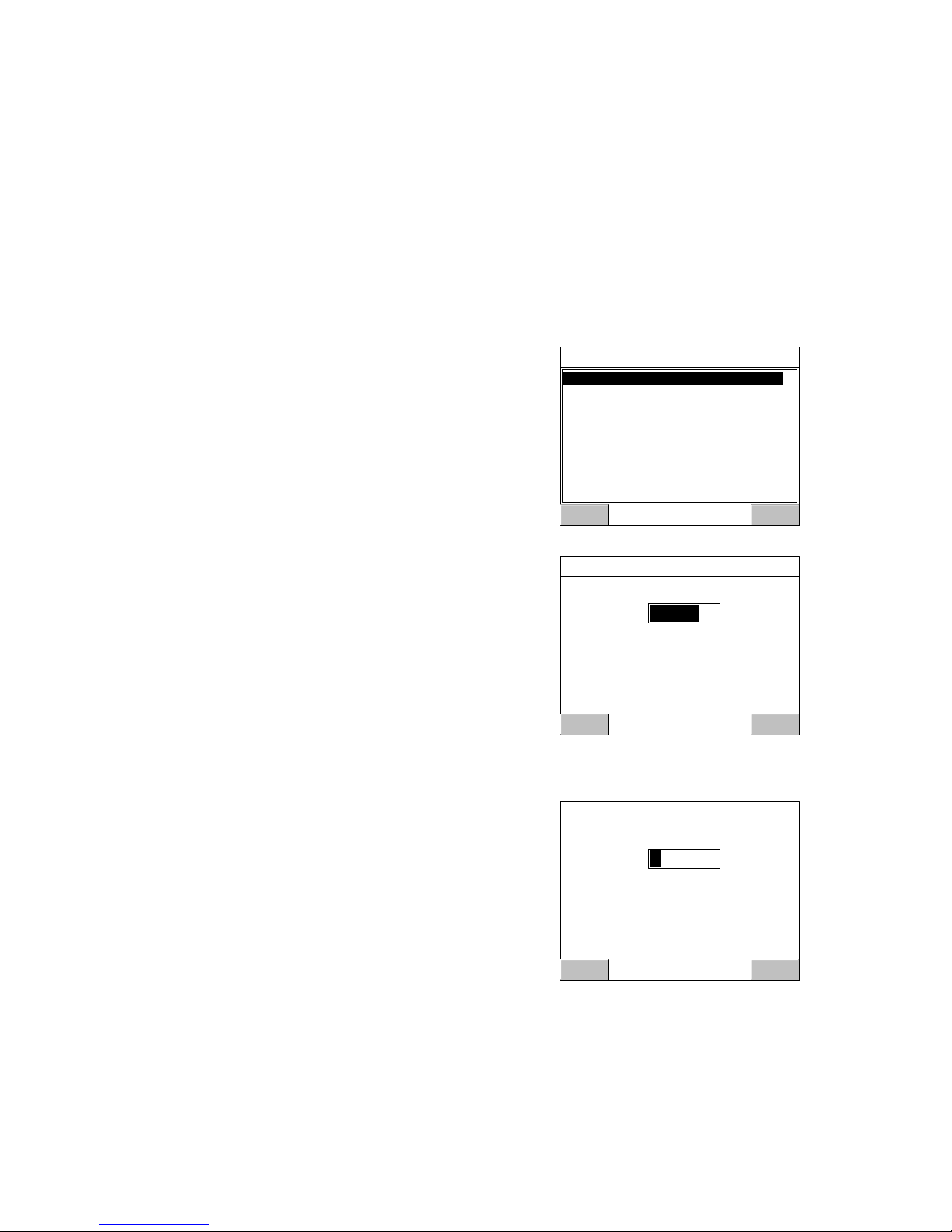

G4 has a number of parameters that are

common for the whole instrument.

They are found in menu 'General',

a sub menu to 'Set-up parameters'.

Press the key marked 'Info' at the upper right

corner of the instrument panel.

In the 'Main Menu',

use the arrow keys ‘up’ or 'down' to position

the indicator on line 'Parameter Set-up'.

Press 'Enter' to open 'Parameter Set-up'.

In menu 'Parameter set-up'

position the indicator on line 'General'.

Press 'Enter' to open 'General'.

In menu 'General', position the indicator

on the parameter to edit.

Some basic parameters are explained below.

Press 'Enter' to open the editing menu.

The Set-up Code or the Operator Code

may be needed.

Language

'Language' was selected in menu 'General'.

Use the arrow keys to position the indicator on

the desired language.

The selected language will be used for all

displayed text at the screen, and for all

parameter names.

Finish by 'Enter', and menu 'General'

will appear again.

2006-09-24 19:07

------ ------ ------P.Tare Levels

Scale: 1 Gross

034.5 kg

Levels

Main Menu

Enter Escape

Levels

Setpoints

Clock Set-up

Preset Tare

System Information

Maintenance

Network Configuration

Parameter Set-up

Parameter Set-up

Enter Escape

Hardware Config.

Communication

Level Supervision

Calibration

Setpoints

Inputs

Outputs

General

General

Enter Escape

Instrument Name

Display Mode 1 & 2 & 4 Scales

Info Line 1 Mode Not in use

Start Mode Auto

Info Line 2 Mode Not in use

Date Format YYYY-MM-DD

Time Format 24 h

Language English

Gross/Net key On

Tare key On

Edit: Language

Enter Escape

English

Svenska

18

Page 23

G4 Multi Channel Weighing Instrument

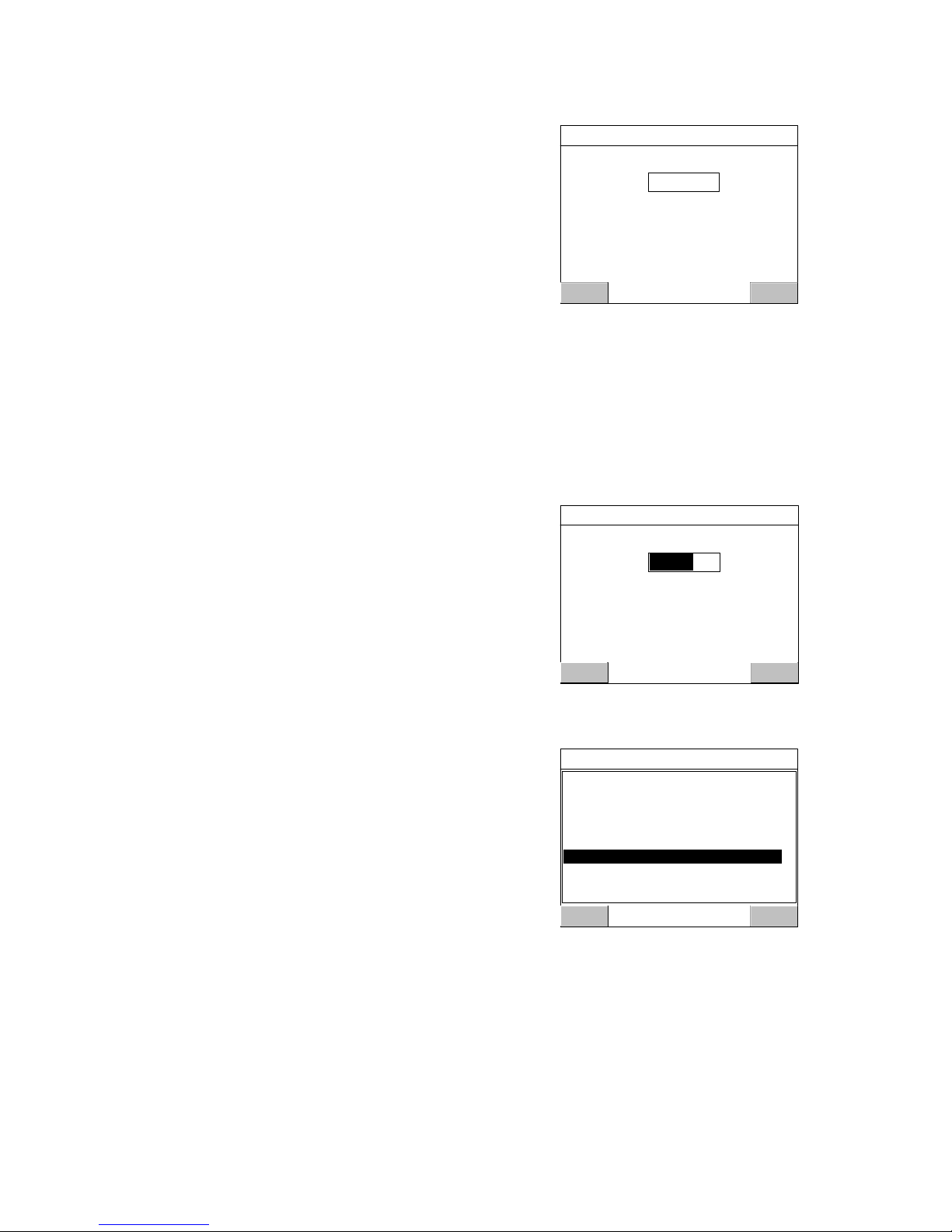

Date Format

'Date Format' was selected in menu 'General'.

Use the arrow keys to position the indicator on

the desired date format.

Y = year, M = month, D = day.

Finish by 'Enter', and menu 'General'

will appear again.

Time Format

'Time Format' was selected in menu 'General'.

Use the arrow keys to position the indicator on

the desired time format.

Finish by 'Enter', and menu 'General'

will appear again.

Set-up Lock

For security reasons, we recommend setting of

this parameter to 'On'.

'Set-up Lock' was selected in menu 'General'.

Use the arrow keys to select 'Off' or 'On' for the

Set-up Lock. If the lock is set to 'On', a 'Set-up

Code' will be needed to perform editing of

set-up parameters, and a parameter for the

'Set-up Code' will be available. See below.

Finish by 'Enter', and menu 'General' will appear

again.

Set-up Code

Edit: Date Format

Enter Escape

YYYY-MM-DD

YYYY-DD-MM

DD-MM-YYYY

DD/MM/YYYY

Edit: Time Format

Enter Escape

12 h

24 h

Edit: Set-up Lock

Enter Escape

Off

On

As the above parameter 'Set-up Lock' was set

to 'On', this parameter appeared in the list

of parameters in menu 'General'.

'Set-up Code' was selected in menu 'General'.

Use the numeric keypad to edit the default

code value '1 9 3 7' to another four-digit value.

Finish by 'Enter', and menu 'General'

will appear again.

Edit: Set-up Code

Enter Escape

Value: 1937

Maximum value: 9999

Minimum value: 1

In menu 'General', press 'Escape' twice to return to the 'Main Menu'.

See next page to perform Clock Set-up for the instrument.

19

Page 24

-

Operating instructions, Quick installation

Clock set-up

Date/time information is always presented at the G4 weight display.

Setting of correct date and time is performed in ‘Clock Set-up’,

a sub menu to the 'Main Menu'.

Setting of date and time doesn't interrupt normal weighing operation.

(To open 'Main Menu' from normal weight display, press the key marked 'Info'

at the upper right corner of the instrument front panel.)

In the 'Main Menu', use arrow keys 'up' or 'down'

to position the indicator on line 'Clock Set-up'.

Press 'Enter' to open 'Clock Set-up'.

Main Menu

Levels

Setpoints

Preset Tare

Clock Set up

Parameter Set-up

System Information

Maintenance

Network Configuration

Enter Escape

A flashing cursor line appears at 'Year'.

Use arrow keys to edit the value in the

selected field.

Use the Tab-key ( ) to move it from field

to field.

Clock Set-up

OK Cancel

Year: 2006

Month: 9

Day: 24

Time: 19 07 23

Apply

Press 'OK' to accept the new values and return to the 'Main Menu'.

Press 'Apply' to accept the new values and stay in the 'Clock Set-up' menu.

Press 'Cancel' to reject the new settings and return to the 'Main Menu'.

20

Page 25

-

G4 Multi Channel Weighing Instrument

Scale calibration

All calibration set-up parameters are set individually for each scale. The scale number

is used to distinguish similar parameters in different scales. The following example

shows a set-up sequence for Scale 1, so all parameter names will begin with 1: .

Individual parameters for the scales are found in menu 'Calibration',

a sub menu to 'Parameter Set-up'.

('Parameter Set-up' is a sub menu to the 'Main Menu'. To open 'Main Menu'

from normal weight display, press the key marked 'Info' at the upper right corner

of the instrument front panel.)

In the 'Main Menu', use the arrow keys

‘up’ or 'down' to position the indicator

on line 'Parameter Set-up'.

Press 'Enter'.

In menu 'Parameter Set-up', use the arrow keys

to position the indicator on line 'Calibration'.

Press 'Enter' to open 'Calibration'.

Main Menu

Levels

Setpoints

Clock Set-up

Preset Tare

System Information

Maintenance

Network Configuration

Parameter Set up

Enter Escape

Parameter Set-up

General

Hardware Config.

Communication

Level Supervision

Setpoints

Inputs

Outputs

Calibration

Enter Escape

Menu 'Calibration' displays the scales

that are in use.

Use arrow keys to position the indicator

on the desired Scale number,

in this example Scale 1.

Press 'Enter' to open 'Scale 1'.

Calibration

Scale 1

Scale 2

Enter Escape

21

Page 26

Operating instructions, Quick installation

In menu 'Scale 1', arrow keys can be used to scroll

the list of parameters, and to select a parameter name

by positioning the indicator on the corresponding line.

Some basic parameters are explained below.

Press 'Enter' to edit the value of a selected parameter.

The Operator Code or the Set-up Code

may be needed to continue.

Scale 1

1:Measurement Unit

1:Capacity

1:WFIN Update Rate

1:Resolution

1:Filter Window

1:Motion Detect Window

1:No Motion Delay

1:Scale Name

1:Motion Check

1:Overload Check

kg

500.0 kg

37 Hz

0.1

1.00 kg

0.10 kg

1.0 s

Off

Off

Enter Escape

1:Measurement Unit

Edit: 1:Measurement Unit

This parameter defines the measurement unit that

will be used for the measured value and for related

set-up parameters.

Use the arrow keys to position the indicator

on the desired unit.

Press 'Enter' to accept.

Menu 'Scale 1' will appear again.

NONE

g

kg

t

lb

oz

N

daN

kN

psi

Enter

Current Gross Weight:

111.36

(0.42971 mV/V)

Escape

1:Resolution

Edit: Resolution

This parameter defines the smallest change in

measured value that will be shown,

and the decimal point position for the scale.

0.1 means the scale will display 0.0 – 0.1 – 0.2 – 0.3 etc.

0.2 means the scale will display 0.0 – 0.2 – 0.4 – 0.6 etc.

0.5 means the scale will display 0.0 – 0.5 – 1.0 – 1.5 etc.

Use the arrow keys to position the indicator

on the desired resolution.

0.001

0.002

0.005

0.01

0.02

0.05

0.2

0.1

0.5

1

Enter

Current Gross Weight:

Press 'Enter' to accept.

111.36

(0.42971 mV/V)

Escape

Menu 'Scale 1' will appear again.

1:Capacity

This parameter defines the nominal range for the scale.

The value of ‘Capacity’ is shown with measurement unit

and decimal point position according to the settings

above.

Use the numerical keypad to write the desired value

of capacity for the scale.

Press 'Enter' to accept.

Menu 'Scale 1' will appear again.

Edit: 1:Capacity

Enter Escape

Value: kg500.0

Maximum value: 999999 kg

Minimum value: 0.5 kg

22

Page 27

G4 Multi Channel Weighing Instrument

The last line in menu 'Scale 1' gives access

to menu 'Scale 1 Calibration', where calibration

type can be selected.

Use the arrow keys to position the indicator on

line 'Scale 1 Calibration'.

Press 'Enter'.

Menu 'Scale 1 Calibration' shows the current

type of calibration for scale 1, and the parameter

values of that calibration.

To perform a new calibration, use arrow keys to

position the indicator on line '1:Calibration Type'

Press 'Enter'.

Scale 1

1:Zero Tracking Off

1:Tare Corr. Mode Auto

1:WFIN Update Rate 37 Hz

1:Flow Calculation Off

1:Filter Window 1.00 kg

1:Motion Detect Window 0.10 kg

1:No Motion Delay 1.0 s

1:Motion Check Off

1:Overload Check Off

Scale 1 Calibration

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

Scale 1 Calibration

1:Rated Output 3 2.03900 mV/V

1:Set Zero 0.00 kg

1:Zero Offset 0.00 kg

1:Conversion Factor 9.80665

1:Number of Transducers 3

1:Rated Load 2000.00

1:Rated Output 1 2.03900 mV/V

1:Rated Output 2 2.03900 mV/V

1:Calibration Type Data Sheet

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

1:Calibration Type

This parameter defines the type of calibration

to perform for the scale.

Three calibration types are available.

'Data Sheet' calibration for fast calibration

when transducer data is available and

the installation is free from mechanical

disturbances.

'Deadweight' calibration, the most accurate

calibration type, where known weights are

used to give well defined load on the scale.

'Table' calibration for entry of recorded values

from a previous calibration.

Use arrow keys to indicate the desired

type of calibration.

Press 'Enter'.

Edit: 1:Calibration Type

Data Sheet

Deadweight

Table

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

A question will be displayed.

To start the calibration, tap at 'Yes'.

Do you want to start a new calibration?

(Current calibration will be lost)

Yes No

!

Performing a data sheet calibration is described on pages 24 - 26.

Performing a deadweight calibration is described on pages 27 - 29.

23

Page 28

Operating instructions, Quick installation

Data sheet calibration

This calibration method can be used when data sheets for the transducers are

available and no external forces influence the weighing installation.

If fixed supports are included, the load must be evenly distributed on all supports.

Data sheet calibration can be performed without any transducers connected,

but the transducers must be connected as the zero setting is performed.

A data sheet calibration for a scale should start with the scale parameters,

described on page 22.

This example shows a Data Sheet calibration for Scale 1.

When data sheet calibration has been selected

and you have accepted to start a new calibration,

menu 'Scale 1 Calibration' will be displayed again.

Use arrow keys 'up' and 'down' to select a parameter

to edit, then press 'Enter' to accept.

All parameters are explained below.

Scale 1 Calibration

1:Rated Output 3 2.03900 mV/V

1:Set Zero 0.00 kg

1:Zero Offset 0.00 kg

1:Conversion Factor 9.80665

1:Number of Transducers 3

1:Rated Load 2000.00

1:Rated Output 1 2.03900 mV/V

1:Rated Output 2 2.03900 mV/V

1:Calibration Type Data Sheet

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

1:Conversion Factor

This parameter defines the relationship between a

weight value expressed in transducer data sheet unit

and the same weight value expressed in measurement

unit. The default value, 9.80665, can be used when

transducers in N (Newton) are used for weighing in kg.

Use the numeric keypad to write a new value for

'1:Conversion Factor'.

Press 'Enter' to accept.

Edit: 1:Conversion Factor

Enter Escape

Value: 9.80665

Maximum value: 100

Minimum value: 0.01

Current Gross Weight:

(0.42971 mV/V)

111.36

Menu 'Scale 1 Calibration' will appear again.

1:Number of Transducers

This parameter value should be set to the number of

support points for the load, including all transducers

and fixed support points. The number will affect

the number of lines '1:Rated Output'.

Use the numeric keypad to write a new value for

'1:Number of Transducers’.

Press 'Enter' to accept.

Menu 'Scale 1 Calibration' will appear again.

Edit: 1:Number of Transducers

Enter Escape

Value: 3

Maximum value: 4

Minimum value: 1

Current Gross Weight:

(0.42971 mV/V)

111.36

24

Page 29

G4 Multi Channel Weighing Instrument

1:Rated Load

Rated load for the transducer is a value, given in

the data sheet. All the transducers in the scale

must have the same impedance and rated load.

The rated load value, expressed in the unit of the

data sheet, should be entered for this parameter.

Use the numeric keypad to write

a new value for '1:Rated Load’.

Press 'Enter' to accept.

Menu 'Scale 1 Calibration' will appear again.

1:Rated Output 1, 2, etc

The number of lines '1:Rated Output …'

corresponds to '1:Number of Transducers' above.

These parameter values should be set to

the output signal values for the transducers,

given in the data sheets.

For a fixed support point the value of the rated

output should be set to 0.00000 mV/V.

Use the numeric keypad to write

a new value for '1:Rated Output 1’.

Edit: 1:Rated Load

Enter Escape

Value: 2000.00

Maximum value: 999999

Minimum value: 1

Current Gross Weight:

(0.42971 mV/V)

111.36

Edit: 1:Rated Output 1

Enter Escape

Value: mV/V 2.03900

Maximum value: 9.99999 mV/V

Minimum value: 0 mV/V

Current Gross Weight:

(0.42971 mV/V)

111.36

Press 'Enter' to accept.

Menu 'Scale 1 Calibration' will appear again and the rated output value for all

transducers and fixed support points can be entered in the same way.

1:Set Zero

This parameter is used to make the scale display

gross weight zero when it is unloaded. Make sure

the scale is completely unloaded before this setting

is performed.

The current gross weight is indicated in the display.

The value '0.00 kg' is proposed for '1:Set Zero'.

Press 'Enter' to accept 0.00 kg.

Edit: 1:Set Zero

Enter Escape

Value: kg0.00

Maximum value: 999999 kg

Minimum value: -999999 kg

Current Gross Weight:

(0.42971 mV/V)

111.36

Menu 'Scale 1 Calibration' will be displayed with

the 'Current gross weight' changed to the new

value of '1:Set Zero' ('zero' in this example).

The value of '1:Zero Offset' has changed

correspondingly.

1:Zero Offset

This parameter shows the offset value needed

to make the scale display the gross weight 'zero'

for unloaded scale.

The value of '1:Zero Offset' should not be edited.

Scale 1 Calibration

1:Rated Output 3 2.03900 mV/V

1:Calibration Type Data Sheet

1:Zero Offset 111.36 kg

1:Conversion Factor 9.80665

1:Number of Transducers 3

1:Rated Load 2000.00

1:Rated Output 1 2.03900 mV/V

1:Rated Output 2 2.03900 mV/V

1:Set Zero 0.00 kg

Enter

Current Gross Weight:

(0.42971 mV/V)

000.00

Escape

25

Page 30

Operating instructions, Quick installation

Exit calibration

To exit from calibration, press 'Escape' twice.

A question will be displayed.

Answer Yes to keep the new settings in

the instrument memory,

answer No to exit calibration without saving

(all changes will be rejected).

In both cases the instrument switches

to sub menu 'Calibration'.

Answer Cancel to continue the calibration for Scale 1.

Now it is possible to perform calibration of any remaining scales,

or to return to normal weight display by pressing 'Escape' several times.

Exit calibration

X

Calibration parameter(s) changed!

Do you want to keep the new settings?

No Cancel Yes

?

26

Page 31

G4 Multi Channel Weighing Instrument

Deadweight calibration

This is the most accurate calibration method. It requires that known weights

to at least two-thirds of the scale capacity are available.

A deadweight calibration of a scale should start with the scale parameters,

described on page 22.

An asterisk ( * ) will be shown at the calibration parameters that have not yet

been stored.

This example shows a two-point Deadweight calibration for Scale 1.

When deadweight calibration has been selected

and you have accepted to start a new calibration,

menu 'Scale 1 Calibration' will be displayed again.

Use arrow keys 'up' or 'down' to select a parameter

to edit, then press 'Enter' to accept.

All parameters are explained below.

Scale 1 Calibration

1:Set Zero 0.00 kg

1:Zero Offset 0.00 kg

1:No of Calibration points 2

1:Value Cal. P1* 0.0 kg

1:Value Cal. P2* 500.0 kg

1:Transd. Signal P1 0.00000 mV/V

1:Transd. Signal P2 1.66631 mV/V

1:Calibration Type Deadweight

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

1:No of Calibration Points

This parameter defines the number of calibration

points. Up to six points can be selected, parameters

for load value and transducer signal will be

displayed for the selected number of points.

In this example a two-point calibration is described.

Use the numeric keypad to write '2'

for '1:No of Calibration Points’.

Press 'Enter' to accept.

Edit: 1:No of Calibration points

Enter Escape

Value: 2

Maximum value: 6

Minimum value: 2

Current Gross Weight:

(0.42971 mV/V)

111.36

Menu 'Scale 1 Calibration' will appear again.

1:Value Cal. P1

This parameter defines the load for the lowest

calibration point. Normally the scale should be

unloaded and the parameter value set to 0 (zero).

This weight value and the corresponding transducer

signal value are automatically stored for the scale.

The current gross weight is indicated at the bottom

line in the display.

If necessary, use the numeric keypad to write

a new value for '1:Value Cal. P1'.

Press 'Enter' to accept.

Menu 'Scale 1 Calibration' will appear again.

Edit: 1:Value Cal. P1*

Enter Escape

Value: kg 0.0

Maximum value: 999999 kg

Minimum value: -999999 kg

Current Gross Weight:

(0.42971 mV/V)

111.36

27

Page 32

Operating instructions, Quick installation

1:Value Cal. P2

This parameter, in a two point calibration, defines

the load for the highest calibration point. Normally

the scale should be loaded to at least two-thirds

of the scale capacity.

This weight value and the corresponding transducer

signal value are automatically stored for the scale.

The current gross weight is indicated at the bottom

line in the display.

Use the numeric keypad to write the actual

load on the scale for '1:Value Cal. P2'.

Press 'Enter' to accept.

Menu 'Scale 1 Calibration' will appear again.

1:Transd. Signal P1 and 1:Transd. Signal P2

These parameters are only shown and cannot be

edited.

1:Set Zero

This parameter is used to make the scale display

gross weight zero when it is unloaded. Make sure

the scale is completely unloaded before this setting

is performed.

The current gross weight is indicated in the display.

The value '0.00 kg' is proposed for '1:Set Zero'.

Press 'Enter' to accept 0.00 kg.

Menu 'Scale 1 Calibration' will be displayed with

the 'Current gross weight' changed to the new

value of '1:Set Zero'.

The value of '1:Zero Offset' has changed

correspondingly.

1:Zero Offset

This parameter shows the offset value needed

to make the scale display the gross weight 'zero'

for unloaded scale.

The value of '1:Zero Offset' should not be edited.

Edit: 1:Value Cal. P2*

Enter Escape

Value: kg 100.0

Maximum value: 999999 kg

Minimum value: -999999 kg

Current Gross Weight:

(0.67298 mV/V)

098.29

Edit: 1:Set Zero

Enter Escape

Value: kg0.00

Maximum value: 999999 kg

Minimum value: -999999 kg

Current Gross Weight:

(0.42965 mV/V)

-000.38

Scale 1 Calibration

1:Zero Offset -0.38 kg

1:No of Calibration points 2

1:Value Cal. P1 0.0 kg

1:Value Cal. P2 500.0 kg

1:Transd. Signal P1 0.42971 mV/V

1:Transd. Signal P2 0.67298 mV/V

1:Calibration Type Deadweight

1:Set Zero 0.00 kg

Enter

Current Gross Weight:

(0.42965 mV/V)

000.00

Escape

28

Page 33

G4 Multi Channel Weighing Instrument

Exit calibration

To exit from calibration, press 'Escape' twice.

A question will be displayed.

Answer Yes to keep the new settings

in the instrument memory,

answer No to exit calibration without saving

(all changes will be rejected).

In both cases the instrument switches

to sub menu 'Calibration'.

Answer Cancel to continue the calibration for Scale 1.

Now it is possible to perform calibration of any remaining scales,

or to return to normal weight display by pressing 'Escape' several times.

Exit calibration

X

Calibration parameter(s) changed!

Do you want to keep the new settings?

No Cancel Yes

?

29

Page 34

Operating instructions, Quick installation

Zeroing of gross weight

When the scale installation is calibrated, a zeroing is performed in order to get

the gross weight zero when the scale is unloaded. If mechanical equipment is added

later, this will affect the weight display for the scale, and a new zeroing of the gross

weight becomes necessary.

NOTE! The scale must be unloaded when zeroing is performed.

Access ‘Set Zero' for any calibration type.

Navigate to menu 'Calibration' and select

the desired scale, in this example 'Scale 1'.

The sequence is described on page 21.

In menu 'Scale 1', use arrow key 'down'

to position the indicator at the bottom line:

'Scale 1 Calibration'.

Press 'Enter'.

Scale 1

1:Zero Tracking Off

1:Tare Corr. Mode Auto

1:WFIN Update Rate 37 Hz

1:Flow Calculation Off

1:Filter Window 1.00 kg

1:Motion Detect Window 0.10 kg

1:No Motion Delay 1.0 s

1:Motion Check Off

1:Overload Check Off

Scale 1 Calibration

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

In menu 'Scale 1 Calibration', use arrow key 'down'

to position the indicator at line '1:Set Zero'.

Press 'Enter'.

The Set-up Code or the Operator Code

may be needed.

Scale 1 Calibration

1:Zero Offset 0.00 kg

1:Calibration Type Deadweight

1:No of Calibration points 2

1:Value Cal. P1 0.0 kg

1:Value Cal. P2 500.0 kg

1:Transd. Signal P1 0.38793 mV/V

1:Transd. Signal P2 1.66631 mV/V

1:Set Zero 0.00 kg

Enter

Current Gross Weight:

(0.42971 mV/V)

111.36

Escape

Menu 'Edit: 1:Set Zero' is displayed,

and the current gross weight is indicated

on the bottom line in the screen.

The value '0.00 kg' is proposed for '1:Set Zero'.

Press 'Enter' to accept 0.00 kg.

Edit: 1:Set Zero

Enter Escape

Value: kg0.00

Maximum value: 999999 kg

Minimum value: -999999 kg

Current Gross Weight:

(0.42971 mV/V)

111.36

Menu 'Scale 1 Calibration' will be displayed with

the 'Current gross weight' changed to the new

value of '1:Set Zero'.

The value of '1:Zero Offset' has changed

correspondingly.

Press 'Escape' to exit from calibration, like described

for 'Deadweight' calibration on page 29.

Scale 1 Calibration

1:Zero Offset 111.36 kg

1:Calibration Type Deadweight

1:No of Calibration points 2

1:Value Cal. P1 0.0 kg

1:Value Cal. P2 500.0 kg

1:Transd. Signal P1 0.38793 mV/V

1:Transd. Signal P2 1.66631 mV/V

1:Set Zero 0.00 kg

Enter

Current Gross Weight:

(0.42971 mV/V)

000.00

Escape

30

Page 35

G4 Multi Channel Weighing Instrument

Common set-up values

Note: Only the set-up parameters covered in this manual are listed.

Location/Notes: .........................................................................................................

Software version: ............................................ Serial number: ...............................

Date: ...................................................

Hardware position Module Serial no. Notes

Slot 1 ......................... ........................... ...........................

Slot 2 ......................... ........................... ...........................

Slot 3 ......................... ........................... ...........................

Slot 4 ......................... ........................... ...........................

Slot 5 ......................... ........................... ...........................

Slot 6 ......................... ........................... ...........................

Fieldbus module ......................... ........................... ...........................

(at the CPU-unit)

Parameter name Default value Set-up value

Language English ...........................

Date Format YYYY-MM-DD ...........................

Time Format 24 h ...........................

Set-up Lock Off ...........................

Set-up Code 1 9 3 7 ...........................

Appendix 1

Common set-up values

Page 36

Operating instructions, Quick installation

Page 37

G4 Multi Channel Weighing Instrument

Scale set-up values

Note: Only the set-up parameters covered in this manual are listed.

Locations/Notes: ............................................................................................................

........................................................................................................................................

Module: .................................... Ser. no.: ......................... Slot no.: ...........................

Channel number: .......................... ...........................

Scale number: .......................... ...........................

Parameter name: Default values

X:Measurement Unit kg ........................... ...........................

X:Resolution 0.1 ........................... ...........................

X:Capacity 500.0 ........................... ...........................

X:Calibration Type Data sheet ........................... ...........................

X:Conversion Factor 9.80665 ........................... ...........................

X:Number of Transd. 3 ........................... ...........................

X:Rated Load 2000.0 ........................... ...........................

X:Rated Output 1 2.03900 ........................... ...........................

X:Rated Output 2 2.03900 ........................... ...........................

X:Rated Output 3 2.03900 ........................... ...........................

X:Rated Output 4 2.03900 ........................... ...........................

X:No of Calibration Points 2 ........................... ...........................

X:Value Cal. P1 0.0 ........................... ...........................

X:Value Cal. P2 500.0 ........................... ...........................

X:Transd. Signal P1 0.00000 ........................... ...........................

X:Transd. Signal P2 1.66631 ........................... ...........................

X:Zero Offset 0.00 ........................... ...........................

Appendix 2

Scale set-up values

Page 38

Operating instructions, Quick installation

Page 39

Page 40

Document no. 35196

Article no. 600 856 R1c

© Vishay Nobel AB, 2011-06-15

Subject to changes without notice.

Vishay Nobel AB BLH

Box 423, SE-691 27 Karlskoga, Sweden 3 Edgewater Drive, Norwood, MA 02726, USA

Phone +46 586 63000 · Fax +46 586 63099 Phone

: 781-298-2200 Fax: 781-762-3988

pw.se@vishaypg.com pw.us@vishaypg.com

www. weighingsolutions.com www.weighingsolutions.com

Loading...

Loading...