Page 1

Technical Documentation Rev. 04

Power Factor Regulator ESTAmat PFC-N

REFERENCE BOOK

POWER FACTOR REGULATOR

ESTAmat PFC-N

Vishay Electronic GmbH

Division ESTA

Hofmark-Aich-Strasse 36

D-84030 Landshut, Germany

Phone +49-(0)871-86 0,

Fax +49-(0)871 - 86 25 12

Page 2

Technical Documentation Rev. 04

2

Power Factor Regulator ESTAmat PFC-N

1 INSTALLATION AND CONNECTION .......................................................................... 4

1.1 Wiring diagram .......................................................................................................... 4

1.2 Connection data .......................................................................................................... 5

2 COMMISSIONING ........................................................................................................... 6

2.1 Commissioning manual: ............................................................................................. 6

2.2 Commissioning automatically: ................................................................................... 6

3 DISPLAY ........................................................................................................................... 7

4 MENU ESTAmat PFC-N ................................................................................................... 8

4.1 Measurement menu .................................................................................................... 8

4.2 Info (Step database) .................................................................................................... 9

4.3 Manual (step switching manual) .............................................................................. 10

4.4 Setup (Quick start menu) .......................................................................................... 11

5 EXPERT MENU ESTAmat PFC-N ................................................................................. 12

5.1 100 Quick start menu ................................................................................................... 13

5.2 200 Measurement settings ....................................................................................... 15

5.3 300 Setup Control System ....................................................................................... 17

5.4 400 Setup Step Database ......................................................................................... 21

5.5 500 Setup Alarm ...................................................................................................... 22

5.6 600 Resetmenu ........................................................................................................ 24

6 TECHNIAL DATA .......................................................................................................... 25

7 TROUBLESHOOTING ................................................................................................... 26

8 APPLICATIONS ............................................................................................................. 28

8.1 Fan Control ............................................................................................................... 28

8.2 Switching on COS 2 via digital input ................................................................... 29

8.3 Problems with the Step recognition. ........................................................................ 30

8.4 Transformer compensation ....................................................................................... 31

8.5 Reset defective steps respectively add aditional steps ............................................. 32

9 CUSTOMER SETTINGS ................................................................................................ 33

10 APPENDIX .................................................................................................................. 34

10.1 Settings Phase-angle ................................................................................................. 34

10.2 Connections for mixed measurement ....................................................................... 34

Page 3

Technical Documentation Rev. 04

3

Date

Name

Revision

Comment

22.07.09

Le

01

initial document release

25.01.10

Le

02

Examples added, changes to software

version 1.04

16.06.10

Le

03

Add features of software version 1.06

09.09.10

Le

04

Editorial changes

Power Factor Regulator ESTAmat PFC-N

Document history

Page 4

Technical Documentation Rev. 04

4

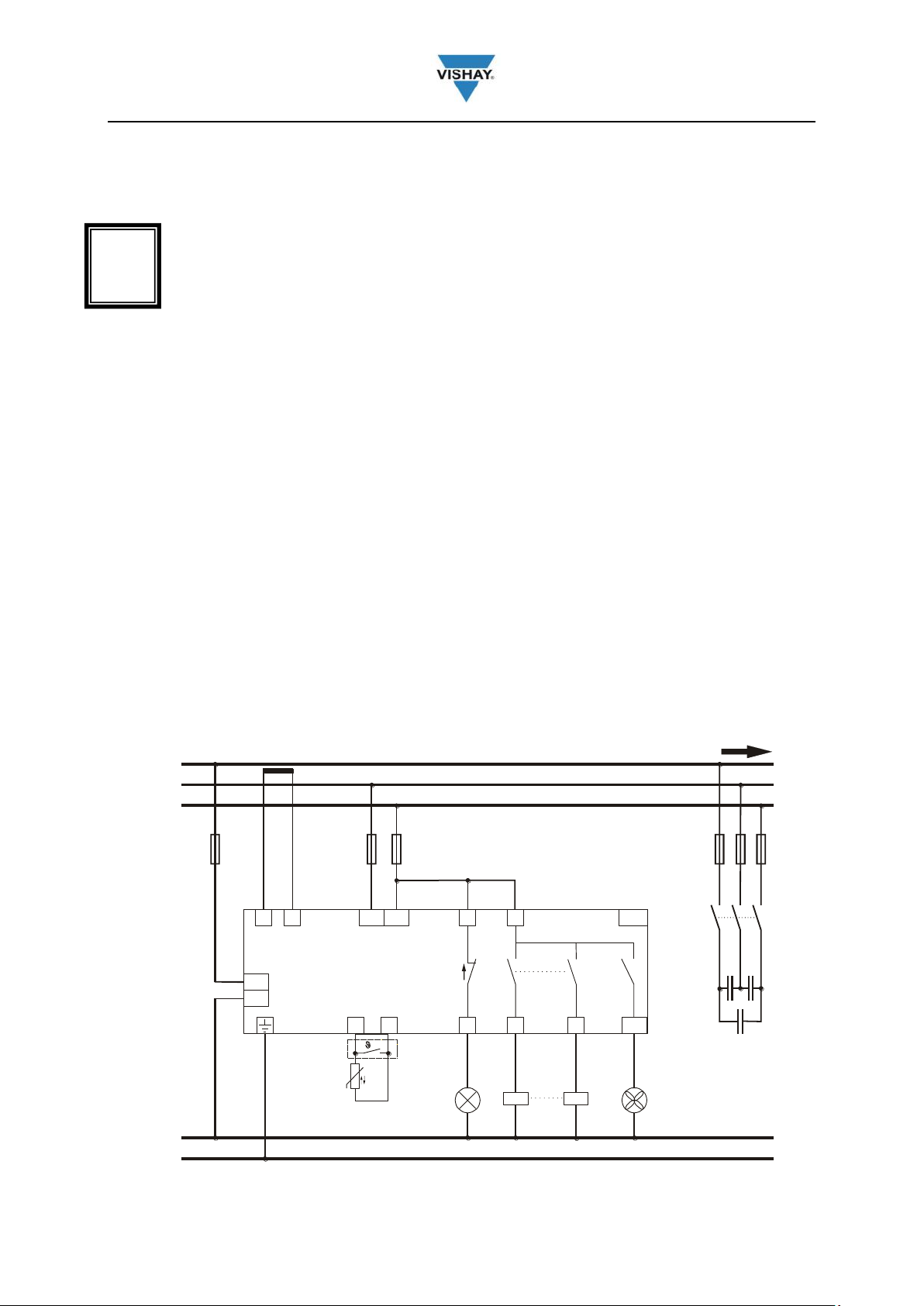

!

Load

T

K L Um1 Um2 AM

MS

1

12 1-12T1 T2

external

temperaturesensor

upto max. 12

switching output

Fan is contacted to

a switching output

Indication:

in order

(contact

closed)

K1 K12

K1-K12

L1

L2

L3

N

PE

ESTAmat PFC-N

TTL

Interface

X/1A or X/5A

15mA - 6A

Measurement Voltage

90V - 690V

Feed-in from

utility

L

N

Supply Voltage

90-300 VAC

Power Factor Regulator ESTAmat PFC-N

1 INSTALLATION AND CONNECTION

Only qualified staff is allowed to perform the installation. All legal rules have to

be observed and technical standards have to be met. Before connecting the

device check that all connecting leads are de-energized and that current

transformers are bypassed.

1) Compare auxiliary-, measurement-, control voltage, frequency and the current path of the

device (see type label) with the data of the electricity network.

2) Assemble the relay in the switch panel with the 2 mounting clips. If the device is not

fitting in the cut out the small plastic bars on the side of the case can be removed with a

knife.

3) Connect protective ground to the terminal link of the case.

4) Connect in accordance to the wiring diagram. Pay special attention to the cross section

size of the CT connections! A combined power supply and measurement ensures a safe

shutdown of capacitors at low voltage.

5) Remove short circuit links of the current transformer.

1.1 Wiring diagram

Page 5

Technical Documentation Rev. 04

5

Meas.- Supply voltage

Combined measurement and Power supply

Range 90-550V.

Terminals UM1 / UM2

With using of VT a ratio can be adjusted.

Range 1-350

Current measurement

Current measurement

Range 15mA – 6A,

Measurement transformer types x/1A or also x/5A can be used.

Terminals K (S1) / L (S2)

CT ratio is 1-9600

(Devices with Firmware before 1.04 had the adjustable range

from 1-4000)

Regulation exits

Assembly with 4, 6, 8, 10, 12, 14 Regulation exits possible.

Regulation exits volt free with common root.

Terminals A 1-14.

max. breaking capacity 5A/250VAC

Alarm contact

Opens in case of alarm and grid failure (Life Contact).

Terminals M / MS

max. breaking capacity 5A/250VAC

Temperature sensor / Digital

Input

Temperature measurement or Digital Input to switch over to

second COS .

Terminals T1 / T2

Setting is explained in the Alarm menu.

Power Factor Regulator ESTAmat PFC-N

1.2 Connection data

Page 6

Technical Documentation Rev. 04

6

Power Factor Regulator ESTAmat PFC-N

2 COMMISSIONING

2.1 Commissioning manual:

After the supply voltage is applied, in ESTAmat PFC-N starts a countdown with 90 sec.

Cancel the countdown by pressing the (esc) button. Enter the “SETUP” menu and control

respectively adjust the parameters. To enter the “SETUP” menu, please follow the arrows (

) as shown at menu 4.4. All parameters of the “SETUP” menu are explained in the

corresponding chapter.

2.2 Commissioning automatically:

During the countdown, the auto-initialization can be start by pushing the ( ) button.

Automatic initialization is switching all exits. During this test it can get information, which

exits are working and it can correct the connection of the measuring channels for voltage and

current by internal settings.

Automatic initialization can be started only when the voltage and current are ok. Settings of

c/K value and the switching sequence is not required.

When mains conditions are not suitable for auto-initialization, it will be interrupted. The

controller shows the message

„Ai Abrt“. If multiple repetition do not lead to any result, the following chapters shall be

considered.

Display „Auto“: Indication „Auto“ shows that the control is working. If „Auto“ is not

displayed then control function is stopped. This can happen for the following Reasons:

manual mode is active, control function is switched off, temperature is to high, measured

current is less than 15mA, voltage or the harmonic content is outside the admissible range.

Over-and undervoltage monitoring: The ESTAmat PFC-N is equipped with an over and

undervoltage monitoring. The admissible voltage range refers to the adjusted nominal voltage.

If the measured voltage is outside of the admissible range the message U Alarm appears.

Then the setting of nominal voltage has to be adapt to local ratings. The nominal voltage is

independent of the connection always the line voltage.

Activation of the measured value display: see chapter 4.1

Page 7

Technical Documentation Rev. 04

7

AUTO, MANUAL: cosphi

SETUP, INFO: Nummer Untermenü

measured voltage is outside the set tolerance

measured current is less than 15mA (check the short

circuit bridge K and L and the entire current path

measured current is to high

The controller cannot achieve the target COS

The set limit for the THD of the voltage is exceeded

/

One or more steps are broken. The defective step is

blinking with the alarm message.

/

One or more step's have fallen below 70% of initial

power. step number and error code will flash alternately.

For devices with software version before 1.04 the alarm is

triggered at 50% of initial power.

The second temperature limit is exceeded. Stage were

switched off successively.

Set limit of operation hours has been exceeded

/

Set limit of the max. allowable operation cycles, for one

or more steps, has been exceeded.

/

Abort of auto-initialization.

INFO:

Capacitor database

AUTO:

automatic control is running

MANUAL:

manual mode

SETUP:

setup menu

ALARM:

blinking in case of alarm

NT:

COS 2 active

EXPORT:

export of active energy

1 – 14:

control exits

Power Factor Regulator ESTAmat PFC-N

3 DISPLAY

In case of an alarm will flash alternately at ESTAmat PFC-N with "ALARM" an error code in

the display. The table below gives an overview of all possible error codes.

To reset pending alarms hold the (esc) button pressed for 5 seconds.

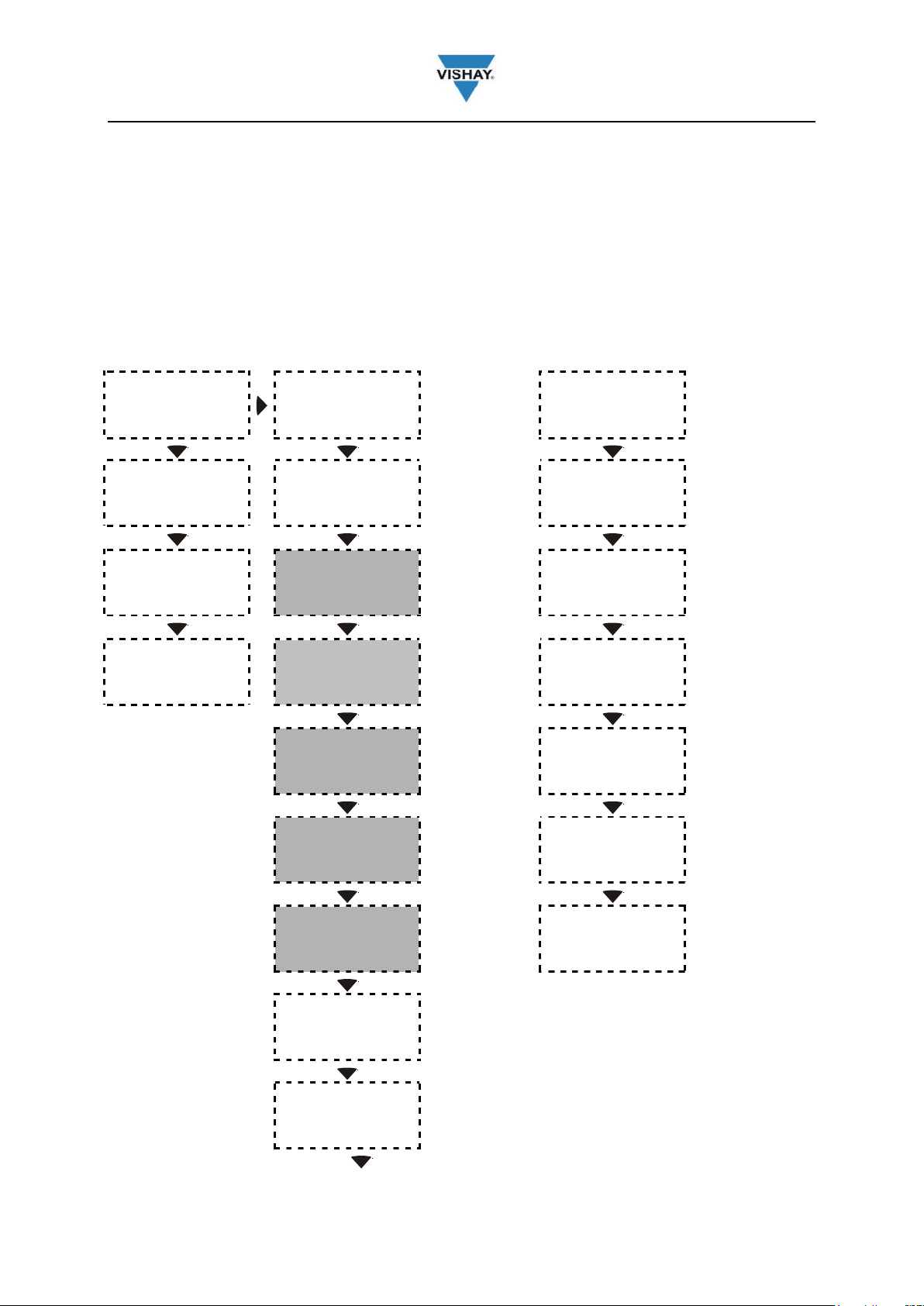

Page 8

Technical Documentation Rev. 04

8

1.00 i

1.00 i

U 400 V

Voltage

L - L

1.00 i

cos0,999

Pf

three digit

1.00 i INFO

1.00 i

U 230 V

Voltage

L - N

PF

0,888

Power factor

ratio

P/S

1.00 i MANUAL

1.00 i

I 40,45 A

current in

measured

phase

APF

1.000

Average

Power factor

1.00 i SETUP

1.00 i

P 30,37 kW

Active power

3 phase

F

50

Frequency

1.00 i

Q 82,89Var

Reactive

power

3 phase

t

58 °C

Temperature

1.00 i

▲Q 80,08

control

deviation in

kvar

thi

88 °C

Highest

measured

Temperature

1.00 i

S 30,68 kVar

Apparent

power

3 phase

OPH

188.9 h

Counter

operation

hours

1.00 i

THD U 1,41 %

Harmonic

distortion

U total

3

HarU 0,40 %

Odd single

harmonics

3 - 19

Power Factor Regulator ESTAmat PFC-N

4 MENU ESTAmat PFC-N

4.1 Measurement menu

All grey fields are hidden in the factory settings and will only appear if the CT ratio is set in

the "SETUP" menu. For devices with software version before 1.04 the complete measurement

menu is hidden and must be activated by adjusting the CT ratio.

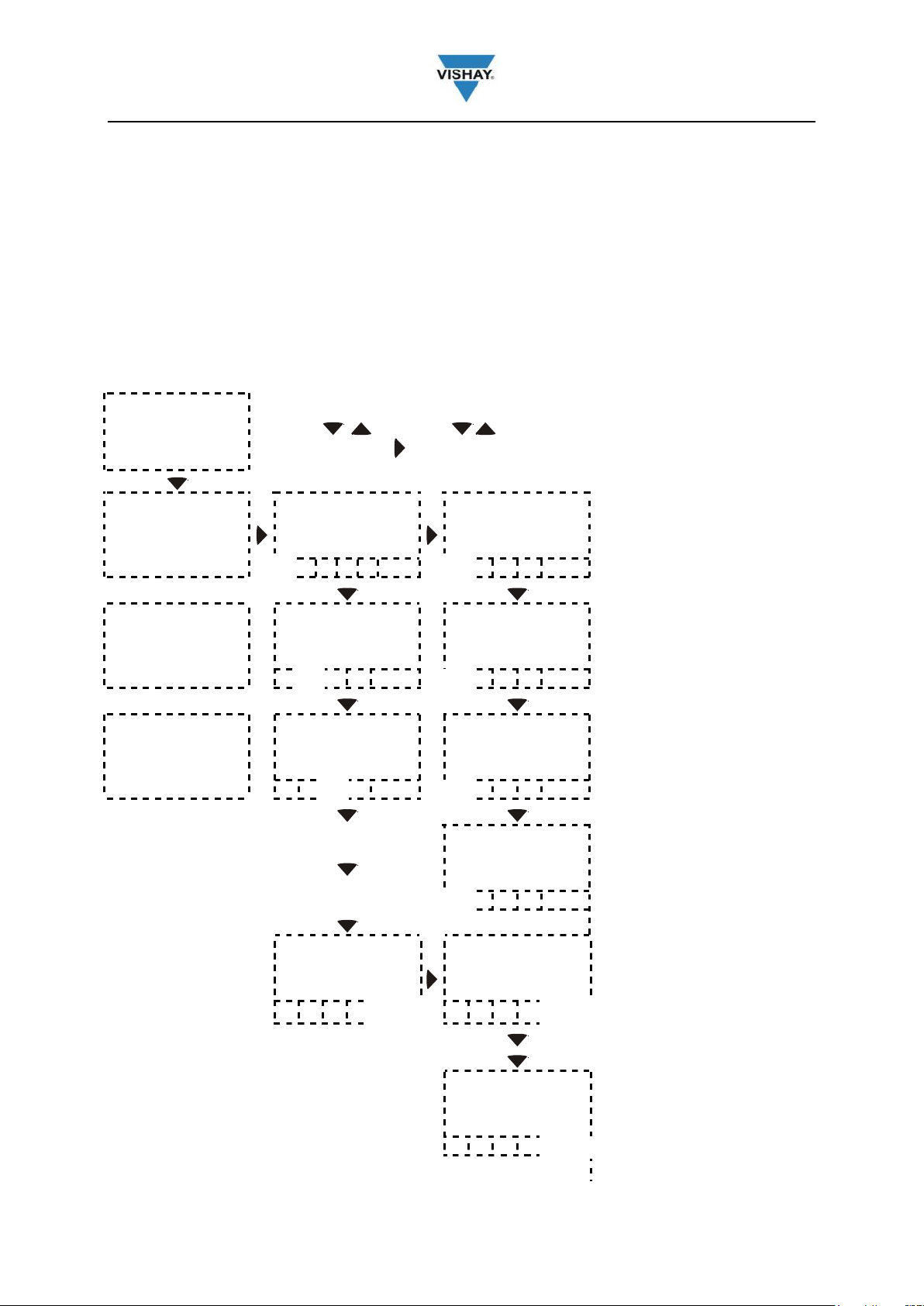

Page 9

Technical Documentation Rev. 04

9

1.00 i

Choose step with

Confirm with

View values with

1.00 i INFO

INFO

CC

25 kVar

Display of step size only if

CT ratio is set, otherwise---

1 2 3 3 4

max.

1 2 3 4 max.

1.00 i MANUAL

INFO

98 %

Current step size in %

related to initial step size

1 2 3 4 max.

1 2 3 4 max.

1.00 i SETUP

INFO

OC

808

switch cycles

1 2 3 4 max.

1 2 3 4 max.

Auto

auto: step is okay

foff: step is permanent off

fon: step is permanent on

Al: output for fan control

Flty: step detected as faulty

1 2 3 4 max.

INFO

CC

25 kVar

Display of step size only if

CT ratio is set, otherwise---

1 2 3 4 max.

1 2 3 4 max.

Auto

auto: step is okay

foff: step is permanent off

fon: step is permanent on

Al: output for fan control

Flty: step detected as faulty

1 2 3 4 max.

Power Factor Regulator ESTAmat PFC-N

4.2 Info (Step database)

In the "INFO" menu for each connected step the number of switching cycles, the current step

size and the step size in relation to the initial step size is stored.

Using these data, conclusions can be drawn on the condition of the site and the condition of

single step's. Step sizes are shown in kVar only when in the CT ratio is set in "Setup"

menu.

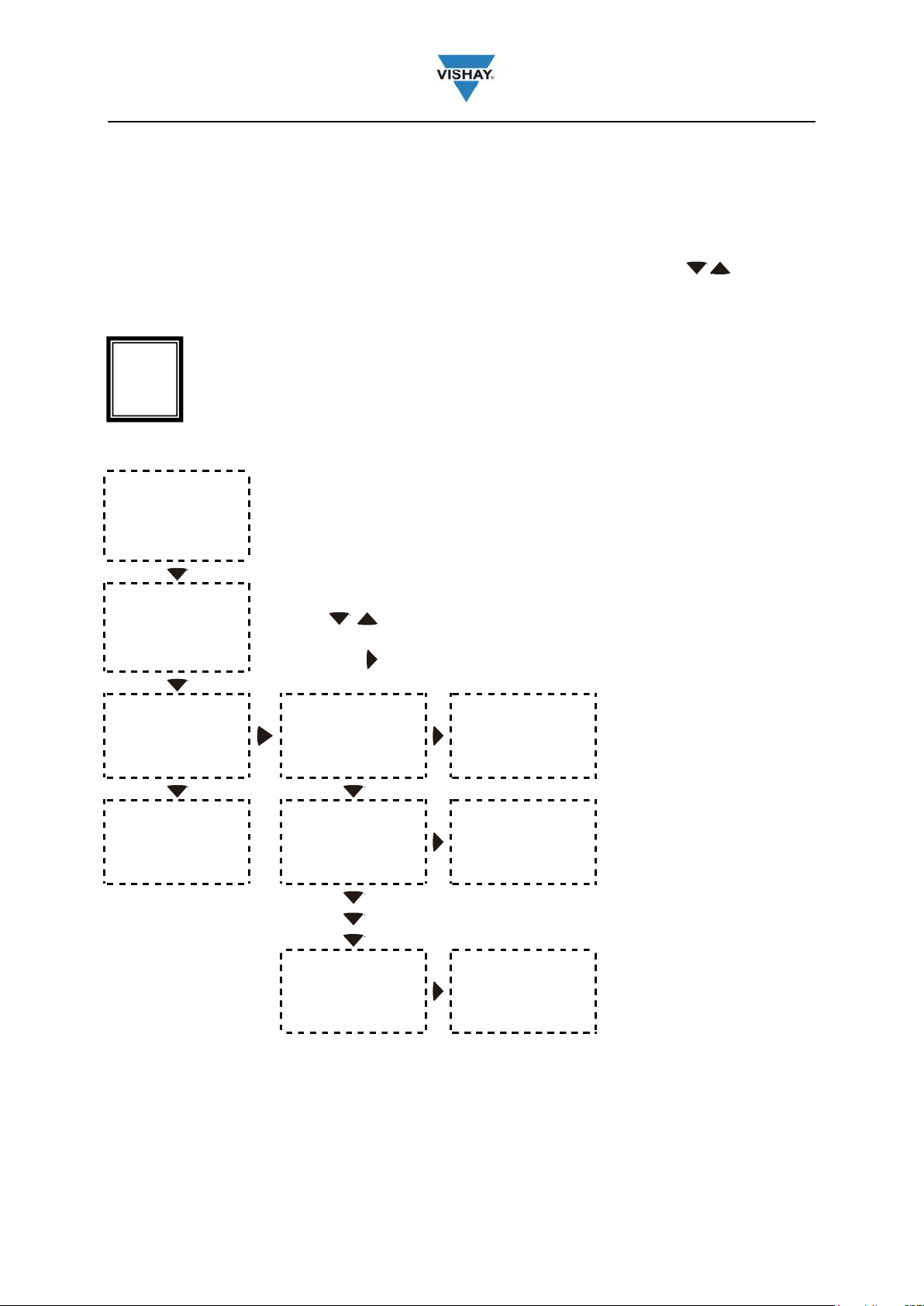

Page 10

Technical Documentation Rev. 04

10

1.00 i

1.00 i INFO

Choose step with

Switch on / off

At each switching

operation the

current Pf is

shown

1.00 i MANUAL

0,95 i MANUAL

1

1.00 i MANUAL

1

1

1.00 i SETUP

0,95 i MANUAL

2

1.00 i MANUAL

2

2

0,95 i MANUAL

14

1.00 i MANUAL

14

14

!

Power Factor Regulator ESTAmat PFC-N

4.3 Manual (step switching manual)

To enter in manual mode, please select “manual” in main menu and push ► for 3 seconds. By

entering this submenu the manual mode for the regulator is active. The automatic control is

stopped and the exits can be switched manually. By the means of the -keys the

referring step can be selected. Changing the switching state is possible by pushing the ►-key.

Manual switching is only possible when measurement voltage is in allowed

range. Otherwise over- and undervoltage protection will block this function.

After switching off an active step the discharge time is active. Only after this

time is over the step can be switched on manually again.

Page 11

Technical Documentation Rev. 04

11

1.00 i

To start the control, it’s only necessary that the nominal voltage is

correct.

All other settings are only for optimal adaptation to the conditions in the

system and display system data. To change a setting, enter the setting by

pushing the button. Change the value with and confirm with

. When you start the auto-initialization the ESTAmat PFC-N checks the

connection of the measurement and the exits. With these data, the

regulation starts automatically.

1.00 i INFO

1.00 i MANUAL

Un = nominal voltage

Setting of nominal voltage. From

this value the upper and lower limits

for voltage monitoring is calculated

1.00 i SETUP

1.00 SETUP

Un SETUP

400

ct SETUP

20

Input current transformer ratio

e.g. 250/5 = 50

pt SETUP

1

Input voltage transformer ratio

when no VT is used the value is 1

ai SETUP

no

"Yes" the controller performs the

auto-initialization again

pfc SETUP

on

"ON" automatic control

"OFF" control off

"HOLD" control freeze

cpi SETUP

1

Target COS of control

st SETUP

10

Interval between switching the

steps

Out SETUP

Possible types of output:

auto: step is used for regulation

foff: step is permanent off

fon: step is permanent on

Al: output for fan control

Valid from Version 1.06.

Power Factor Regulator ESTAmat PFC-N

4.4 Setup (Quick start menu)

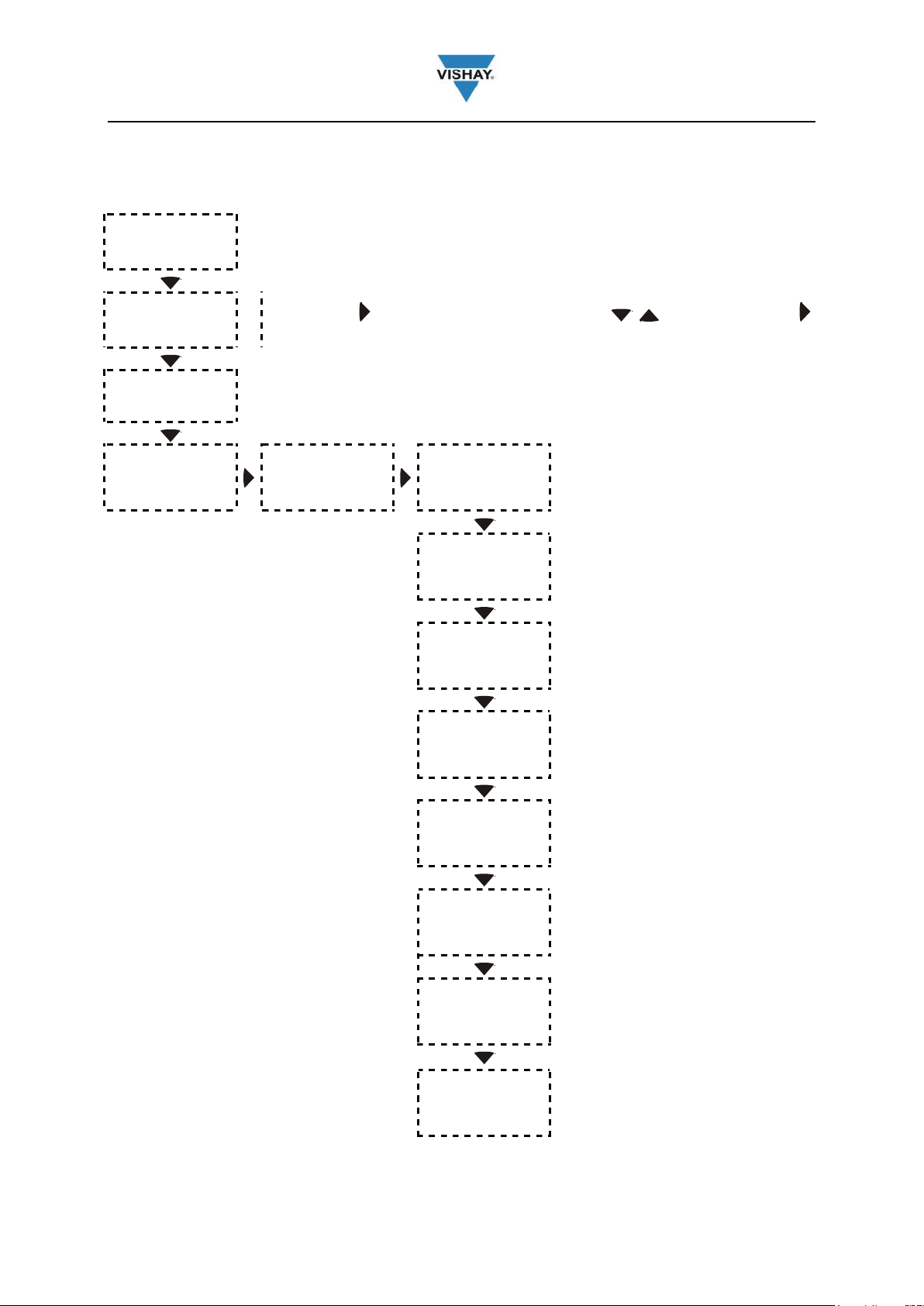

Page 12

Technical Documentation Rev. 04

12

Power Factor Regulator ESTAmat PFC-N

5 EXPERT MENU ESTAmat PFC-N

To open the expert menu of ESTAmat PFC-N, choose menu item "SETUP" and hold ( )

button until "100" appears. By using the buttons the submenus can be selected. The

expert menu of ESTAmat PFC-N is divided into six groups, where the menu items are

logically grouped together. The following groups exist:

100 Quick start menu

Contains all important points for commission.

200 Measurement settings

Contains settings to adapt the measurement of the ESTAmat PFC-N to the surrounding

network conditions.

300 Setup Control System

The items in the menu "control system" allow an optimization of the control or an adaptation

to specific site requirements.

400 Setup Step Database

In the step database, all settings and data are combined which are required to adjust and adapt

the steps.

500 Setup Alarm

The alarm menu of ESTAmat PFC-N. Here, all the alarms and monitoring functions can be

activated and the limits configured.

600 Resetmenu

Allows you to reset all settings made by the controller and stored data. Additionally, it

contains the software version of the device (displayed from 1.04).

Page 13

Technical Documentation Rev. 04

13

100 Quick start menu

MENU

FUNCTION

RANGE

Un

NOMINAL VOLTAGE = PHASE - PHASE

100...241500 V

Function of the setting of nominal voltage is to make a definition

about the nominal voltage of the system. The threshold levels for

under- and overvoltage are based on this as well as the ratings of the

capacitor sizes in step database, which are used for control and

monitoring. The capacitor sizes, which are stored in step database,

are also rated to the nominal voltage.

Ct

CT-FACTOR

1...9600

The CT FACTOR is the ratio of current transformer.

(e. g. 1000/5 = ratio 200).

At devices with software version 1.04 is the adjustment range from

1-4000.

Pt

VT-FACTOR

1...350

VT FACTOR is the ratio of the voltage transformer.

If the regulator is connected directly to the measurement voltage

without VT the value 1 has to be used.

Ai

AUTO-INITIALIZING START

Yes/No

"YES" starts auto-initializing

Automatic initialization is switching all exits. During this test it can

get information, which exits are working and it can correct the

connection of the measuring channels for voltage and current by

internal settings.

Automatic initialization can be started only when the voltage and

current are ok. Steps with step type "FON" or "AL" will be not

considered in case of new auto-initialization.

AUTOMATIC INITIALIZATION is only able to work, when

capacitors are used for compensation. If ESTAmat PFC-N has

to switch reactors for compensation of capacitive load, this

feature will cause failures. AI is working at best, when there are

stable load conditions!

At devices with software revision before 1.04, stages which are set

to "FOFF" were not retested.

PFC

START / STOP / HOLD PF-CONTROL

On/Off/Hold

Power Factor Regulator ESTAmat PFC-N

5.1 100 Quick start menu

Contains all important points for commission:

Page 14

Technical Documentation Rev. 04

14

Stopping the automatic control. The following options are available:

On: Control in automatic mode

Off: Control stops and active steps were disconnected successive

Hold: Control Stops and active step's remain switched on.

If "OFF" or "HOLD" is selected, will appear in the display "PFC"

alternating with "OFF" or "HOLD". To start the control, select

"ON".

CP1

COS 1

0.70 c ...0.70 i

This is the setting for target COS 1. It will be valid during normal

operation.

St

SWITCH INTERVAL

1...6500 s

The switch interval is the time delay between switching steps in

regulation.

The switch interval has two different functions:

1. Protecting the contactors by reducing the number of

switching cycles.

2. Building of the average of the reactive power in the time of

the switch interval.

Out

TYPE OF OUTPUT

With the exception of step type “flty” the follwing step types can be

selected:

Auto = Step is used for normal regulation algorithm.

Alarm = If the set temperature limit 1 is exceeded this step is

switched as fan output.

Fon = Step is permanently switched on (Step is still

monitored and shut down in critical situations).

Foff = Step is permanently switched off. Not used steps

should be adjusted to this type to avoid unnecessary alarm.

Flty = Step was switched three time without success and is

not longer used for automatic control.

As “flty” stored steps can be set to desired step type in this menu.

Power Factor Regulator ESTAmat PFC-N

Page 15

Technical Documentation Rev. 04

15

200 Measurement settings

MENU

FUNCTION

RANGE

201

NOMINAL VOLTAGE = PHASE – PHASE

100...241500 V

Function of the setting of nominal voltage is to make a definition

about the nominal voltage of the system. The threshold levels for

under- and overvoltage are based on this as well as the ratings of the

capacitor sizes in step database, which are used for control and

monitoring. The capacitor sizes, which are stored in step database,

are also rated to the nominal voltage.

202

CT-FACTOR

1...9600

The CT FACTOR is the ratio of current transformer.

(e. g. 1000/5 = ratio 200).

At devices with software version 1.04 is the adjustment range from

1-4000.

203

VT-FACTOR

1...350

VT FACTOR is the ratio of the voltage transformer.

If the regulator is connected directly to the measurement voltage

without VT the value 1 has to be used.

204

V-TOLERANCE

0...100 %

The setting of this value is in percent related to the nominal voltage.

By means of the set value, the upper and lower limits of the

permissible voltage range are calculated. e.g. 10% at 400V nominal

voltage is a permissible range from 360V to 440V.

205

CONNNECTION MEASUREMENT

Yes/No

"YES" voltage measurement L-L

"NO" voltage measurement L-N

CONNECTION MEASUREMENT the setting if measuring of

voltage is connected between two phases or between phase and

neutral phase. It is normally detected automatically at every start of

BLR-CM. This is done by comparing the setting NOMINAL

VOLTAGE and the real measured voltage. This cannot be changed

by hand.

If the measured voltage is outside this tolerance, the measurement

can be adjusted by hand.

206

PHASE COMPENSATION

0...345

Power Factor Regulator ESTAmat PFC-N

5.2 200 Measurement settings

Contains settings to adapt the measurement of the ESTAmat PFC-N to the surrounding

network conditions.

Page 16

Technical Documentation Rev. 04

16

The phase compensation enables the user to connect the current- and

voltage measurement channels in any way. This compensation angle

complies with the phase angle between connected active current and

voltage. This setting has to be made correct, because otherwise

correct regulation is not possible! If the current transformer is

connected inverted, additionally a phase compensation of 180°

has to be respected.

Is auto-initialization failed due to adverse network conditions, by

hand a correction angle can be set or the incorrectly recognized can

be corrected. Table 11.1 gives an overview of the connection options

with corresponding phase angles.

207

START AUTO-INITIALIZING

Yes/No

"YES" starts auto-initializing

Automatic initialization is switching all exits. During this test it can

get information, which exits are working and it can correct the

connection of the measuring channels for voltage and current by

internal settings.

Automatic initialization can be started only when the voltage and

current are ok.

AUTOMATIC INITIALIZATION is only able to work, when

capacitors are used for compensation. If ESTAmat PFC-N has

to switch reactors for compensation of capacitive load, this

feature will cause failures. AI is working at best, when there are

stable load conditions!

Steps with step type "FON" or "AL" will be not considered in case

of new auto-initialization.

At devices with software revision before 1.04, stages which are set

to "FOFF" were not retested.

208

AUTO-INITIALIZING BY REGULATOR RESTART

Yes/No

YES = after starting the ESTAmat PFC-N, a countdown is running.

During this countdown it is possible to start auto-initializing by

pushing ( ).

"NO" the countdown is not shown. To start AI, you have to choose

Quickstart SETUP.

209

SYNCHRONISATION FREQUENCY

Auto/Fix50/Fix60

Power Factor Regulator ESTAmat PFC-N

Page 17

Technical Documentation Rev. 04

17

For a high precision of the measurement, the sampling rate has to be

synchronized to the frequency of the grid. Caused by commutation

notches of mainsvoltage it is possible that the automatic

synchronizing will not work reliable. This creates failures in

measurement. To avoid these problems, the following settings can

be done:

Automatic synchronizing:

For best measurement results, when mains voltage is without

commutation notches.

FIX-50HZ: For a safe operation at 50Hz grid with bad mains

quality.

FIX-60HZ: For a safe operation at 60Hz grid with bad mains

quality.

210

TEMPERATURE OFFSET (from software revision 1.04)

-10-10°C

The temperature offset allows correction of temperature reading in a

range -10°C to +10°C.

300 Setup Control System

MENU

FUNCTION

RANGE

301

CONTROL SENSITIVITY

55...100 %

Sensitivity is the switching threshold for switching-on or switchingoff the capacitors in percent (%). The range of the sensitivity can be

between 55% and 100% (factory setting is 60%. Due to this, the in

following explanation 60% is used.).

Sensitivity is used for two checks:

1. The controller is using sensitivity to check, if a switching

operation is necessary or if it’s possible.

If the demand for compensation is bigger as 60% of the

smallest for regulation available step, BLR-CM is selecting

from step database, if there are suitable steps to switch.

2. To avoid hunting, the controller is only using steps, which

will not overshoot more than 40% (100%-60%) of its size.

302

COS 1

0.70 c ...0.70 i

This is the setting for target cos1. It will be valid during normal

operation.

303

COS 2

0.70 c ...0.70 i

Power Factor Regulator ESTAmat PFC-N

5.3 300 Setup Control System

The items in the menu "control system" allow an optimization of the control or an adaptation

to specific site requirements.

Page 18

Technical Documentation Rev. 04

18

This is the setting for target cos2. It will be valid when a switch

over is caused by the digital input or another programmable action.

304

COS 2 FOR P EXPORT

Yes/No

"YES" the controller operates in P-export with the COS 2 as

control target.

"NO" the controller operates in P-export with the COS 1.

305

SWITCH INTERVAL

1...6500 s

The switch interval is the time delay between switching steps in

regulation.

The switch interval has two different functions:

1. Protecting the contactors by reducing the number of

switching cycles.

2. Building of the average of the reactive power in the time

of the switch interval.

306

SWITCH INTERVAL STEP EXCHANGE

1...6500 s

For step exchange a separate switch interval is used. This is the

delay-time between switching-off an active step and switching-in the

next step to get a better power-factor.

307

ACTIVATE STEP EXCHANGE

Yes/No

"YES" = Step exchange is active.

"NO" = Step exchange is disabled.

Step exchange is supporting automatic control and combined filter

control algorithm to reach an optimum result. If the controller

detects that target-pf is not reached it starts searching for a step

which gives better results. If step exchange is active, the controller

can replace a switched-in step against a step which matches better,

to reach the target.

This function helps to reach target COS more exactly, when

capacitors have different sizes. If all capacitor banks have the same

size, this function makes no sense.

308

STEP RECOGNITION "OFF"

Yes/No

Power Factor Regulator ESTAmat PFC-N

Page 19

Technical Documentation Rev. 04

19

"YES": Step sizes have to be programmed by hand. The step sizes

have to be programmed by hand if:

1. When fast-oscillating load influences automatic stepsize

recognition.

2. When recognition of defective steps is not wished

3. When capacitor contactors are switching with a delay of

more than 200msec.

"NO" Stepsizes are detected and corrected automatically during

normal operation. “Step recognition ON” is the factory setting. It

allows monitoring of capacitor sizes and gives alarms when they are

faulty. Stepsizes which are programmed manually will be

overwritten by step recognition.

309

BLOCKING OF DEFECTIVE CAPACITORS

Yes/No

"YES" If a step is switched in three times without measurable

network reaction, the controller is blocking the step and doesn't use

it for the control.

Is a Step recognized to be defective, blinks in the display the

corresponding output and in the step database and menu "403" it's

displayed as step type "flty".

"NO" Steps are connected even if no network reaction is

measurable. This results unnecessary switching cycles.

Steps that are stored as defective will be tested every 24 hours or

after the controller is restarted.

310

START / STOP / HOLD PF-CONTROL

On/Off/Hold

Stopping the automatic control. The following options are available:

On: Control in automatic mode

Off: Control stops and active steps were disconnected successive

Hold: Control Stops and active step's remain switched on.

If "OFF" or "HOLD" is selected, will appear in the display "PFC"

alternating with "OFF" or "HOLD". To start the control, select

"ON".

311

CONTROL ALGORITHM

1/2/3/4

Power Factor Regulator ESTAmat PFC-N

Page 20

Technical Documentation Rev. 04

20

1. Automatic: The controller is working with the principle of

„Best Fit“. Before a switching operation, all capacitor-sizes

in step database are compared with control deviation. The

available step which gives the best results will be switched.

2. LIFO: “Last In, First Out” The controller starts with

regulation with step 1 and is switching further exits step-bystep. Switching-off is done vice versa.

3. Combined Filter: Special algorithm for combined filter

banks with two different detuned ratings. The controller is

working like in automatic mode with the principle “Best Fit”.

From odd numbered steps, there is at least or more of the

capacitance connected as from even numbered steps.

Threshold level of each step is checked separately. If steps

different sizes, this can cause inaccuracy. Step recognition is

working in this mode. If steps are detected as defective, they

are skipped in this mode. If this is not accepted, the step

recognition has to be deactivated and capacitor sizes have to

be programmed manually.

4. Progressive: The controller switches if required, several

steps in sequence with a shorter switching time. From

software 1.04, the controller uses independently of the set

switching time always 1 sec. as switching time. Furthermore,

the automatic step size detection is disabled and the step

sizes need to enter by hand. The input of the step sizes

should be as accurate as possible, because the regulator

would otherwise tend to oscillate. Leaving the "Progressive"

algorithm and use a different algorithm, the set switching

time is used the step size detection is re-enabled.

312

OFFSET REACTIVE POWER

Ct*Pt*7000

OFFSET of reactive power in kvar. This feature allows

compensating a permanent reactive load, which cannot be measured

(e.g. a transformer).

The offset of reactive power affects the readings of the following

measuring values:

current, reactive power, control deviation, apparent power,

power factor PF and cos.

313

ASYMMETRY FACTOR

-127...127

ASYMMETRY FACTOR of switch interval. The factor is the ratio

between switch interval for switching on and switching off. Switch

interval for step exchange is not affected by this setting.

X= 1 = equal

X = +2 to +127: delay switching off = switch interval multiplied by X

X = -2 to -127: delay switching on = switch interval multiplied by X

314

Q CAPACITIVE STEPS TURN OFF

Yes/No

Power Factor Regulator ESTAmat PFC-N

Page 21

Technical Documentation Rev. 04

21

"YES" As soon as a capacitive condition is recognized, the

controller switches off without keeping the switching time, the

necessary step power in order to prevent leading network conditions.

"NO" The controller works only with the set target COS .

400 Setup Step Database

MENU

FUNCTION

RANGE

401

DISCHARGE TIME

5...1200 s

The discharge time is defined once and is valid for all steps. The

discharging time is a blocking time, becoming active after switching

off a step. As long as this time is running this step is not available

for the regulation. Discharging time should be adapted to the

capacitor discharging unit.

402

STEP NOMINAL VALUE

Ct*Pt*7000

If STEP RECOGNITION is not active, it is required to do this

setting, to get proper function of the relay. The size of the capacitors

can be programmed manually in kvar. Before this programming, CT

FACTOR and NOMINAL VOLTAGE must be programmed

correctly. A change of CT FACTOR or NOMINAL VOLTAGE is

automatically changing the value of the capacitor size.

The programming can be done for each step individually in kvar. So

there is no special sequence necessary. A step can be programmed as

a capacitor (c) or as an inductor (i).

403

STEP TYPE

Auto/Al/FOn/FOff

With the exception of step type “flty” the follwing step types can be

selected:

Auto = Step is used for normal regulation algorithm.

Alarm = If the set temperature limit 1 is exceeded this step is

switched as fan output.

Fon = Step is permanently switched on (Step is still

monitored and shut down in critical situations).

Foff = Step is permanently switched off. Not used steps

should be adjusted to this type to avoid unnecessary alarm.

Flty = Step was switched three time without success and is

not longer used for automatic control.

As “flty” stored steps can be set to desired step type in this menu.If

defective steps should not be locked, you must disable this function

under the menu item "309".

Steps which are identified as defective will be tested again by the

controller every 24 hours or after a restart.

404

SWITCH CYCLES

0...262000

Power Factor Regulator ESTAmat PFC-N

5.4 400 Setup Step Database

In the step database, all settings and data are combined which are required to adjust and adapt

the steps.

Page 22

Technical Documentation Rev. 04

22

The ESTAmat PFC-N is counting and showing the switching cycles

of each step in the "Info" menu. After a contactor has been

exchanged, the switching cycles can be set to "0" in this menu.

500 Setup Alarm

MENU

FUNCTION

RANGE

501

Reset Alarm manually

Yes/No

"YES" Alarms (display and alarm relays) must be reset manually.

To reset upcoming alarms, hold the (esc) button pressed for 5

seconds.

"NO" As soon as the alarm condition is no longer valid, the alarms

drop out.

502

THD U Alarm

Yes/No

"YES" The set THD threshold under menu "503" is monitored.

Exceeding the set threshold will open the alarm contact and the

display will show the message " ".

"NO" THD is not monitored.

503

THD U Threshold

1...200 %

Input of the threshold for THD monitoring.

504

THD U > Threshold = disconnect steps

Yes/No

"YES" Exceeding the set threshold for THD will switch off all

active steps successive.

Warning: Steps are only switched off when it is set at point 502

to "YES".

"NO" Exceeding the set threshold follows no action.

505

Interval time before triggers THD U and Temperature threshold 2

1...255 s

Interval time after exceeding the threshold for THD U or

temperature threshold 2.

506

Freeze control if I == 0

Yes/No

"YES" The measuring current drops below 15mA freezes the

control. All active steps remains switched on.

NO" Measuring current falls below 15mA, the controller shuts down

all active steps successive.

507

Service Alarm

Yes/No

"YES" the alarm contact opens when the max set switching cycles

Power Factor Regulator ESTAmat PFC-N

5.5 500 Setup Alarm

The alarm menu of ESTAmat PFC-N. Here, all the alarms and monitoring functions can be

activated and the limits configured.

Page 23

Technical Documentation Rev. 04

23

for one or more steps have been exceeded or if the set threshold for

operation hours are reached.

"NO" no alarm when exceeding the max. switching cycles or

operation hours.

508

Max. switching cycles per step

1...262000

Threshold switching cycles for service alarm.

Display indication

509

Max. operation hours

1...65535 h

Threshold switching cycles for service alarm.

Display indication

510

Use temp. input as digital input

Yes/No

"YES" Temperature sensor is activated via a switch and causes a

switchover to COS 2 (HT / NT)

Note: This menu item is locked against menu item "512". If the

temperature alarm is set to "Yes", this point will automatically

jump to "NO" and can not be altered.

"NO" the temperature input works with plug-in temperature sensors

and monitors the in menu 513 and 514 adjustable temperature

thresholds. Parallel to the temperature sensor, a thermostat can be

connected. In this case, the controller displays "HIGH" for closed

state and "LOW" for open state.

511

DI active at HIGH signal

Yes/No

"YES" digital input is activated with closed terminals T1 & T2.

"NO" digital input is activated with open terminals T1 & T2.

512

Temperature alarm

Yes/No

"YES" the controller monitors the temperature threshold 1 and 2 and

responses accordingly.

"NO" alarm disabled.

513

Temperature threshold 1

3-74 °C

By exceeding the temperature threshold 1 switches the controller as

"AL" declared step (fan on).

514

Temperature threshold 2

4-75 °C

When the temperature exceeds temperature threshold 2, the

controller switches all active steps ("AUTO" & "FON") from

compliance with the under menu item 505 adjusted time in

succession off. In addition, in the display appears " "

and the alarm contact is opened.

515

Control alarm (target cos can not be archived)

Yes/No

"YES" alarm is triggered after 75 time switching time with ▲Q>

smallest step (Over / under compensation). Controller opens the

Power Factor Regulator ESTAmat PFC-N

Page 24

Technical Documentation Rev. 04

24

alarm contact and indicates in the Display.

"NO" no monitoring for over / under compensation.

516

Defective step alarm

Yes/No

"YES" After 3 unsuccessful switching actions alarm is triggered.

The controller opens the alarm contact and indicates

/ in the display.

Steps recognized as defective flashing in the step indication.

"NO" alarm disabled.

517

Step power loss alarm

Yes/No

"YES" If the current step size is less than 70% of the initial size, the

controller opens the alarm contact and indicates the error with output

number / . in the display.

"NO" Power loss of the capacitors is not monitored.

600 Resetmenu

MENU

FUNCTION

RANGE

601

Reset Settings

Yes/No

Sets all settings made back to factory settings.

602

Reset Step database

Yes/No

Sets all step data back to factory settings.

603

Reset operation hours

Yes/No

Sets the counter for operation hours to "0"

604

Reset average PF

Yes/No

Reset the average PF.

605

Reset max. Temperature

Yes/No

Reset the highest measured Temperature.

606

Reset alarms

Yes/No

Reset all upcoming alarm.

607

Display software version

contains the software version of the device (display from 1.04)

Power Factor Regulator ESTAmat PFC-N

5.6 600 Resetmenu

Allows you to reset all settings made by the controller and stored data. Additionally, it

contains the software version of the device (displayed from 1.04).

Page 25

Technical Documentation Rev. 04

25

Measuring- and supply

voltage:

90 – 550V AC, single phase, 45-65HZ, 5VA, max. fuse 6A VT

ratio from 1.-350.0

Current measurement

15mA – 6A, single phase, burden 20mOhm,

CT-ratio from 1-9600

Before software version 1.04 the adjustable range is 1-4000

control exits

Up to 14 relays, n/o, with common point, max. fuse 6A

breaking capacity: 250V AC / 5A

Temperature measuring:

By NTC

Alarm contact:

Relay, volt free, life contact,

max. fuse 2A, breaking capacity: 250V AC / 5A

Fan control

By using one switching exit defined as "Alarm"

Interface:

TTL, rear

Ambient temperature:

Operation: -20°C – 70°C, storage: -40°C – 85°C

Humidity:

0% - 95%, without moisture condensation

Voltage class:

II, dirt class 3 (DIN VDE 0110, part 1 / IEC60664-1)

Standards:

DIN VDE 0110 part 1 (IEC 60664-1:1992)

VDE 0411 part 1 (DIN EN 61010-1 / IEC 61010-1:2001)

VDE 0843 part 20

(DIN EN 61326 / IEC 61326: 1997 + A1:1998 +A2: 2000)

Conformity and listing:

CE

Connection:

Pluggable terminal block, screw type max. 4qmm

Case:

Front: instrument case PC/ABS (UL94-VO),

Rear: metal

Protection class:

Front: IP50, (IP54 by using a gasket),

Rear: IP20

Weight:

ca. 0,6kg

Dimension:

144x144x58mm h x w x d, cut out 138 (+0,5) x 138 (+0,5)mm

Power Factor Regulator ESTAmat PFC-N

6 TECHNIAL DATA

Page 26

Technical Documentation Rev. 04

26

Fault

possible cause

Remedy

No indication in

display

aux. voltage missing

Check the correct connection of

power supply and correct if

necessary.

Display

" "

Voltage outside

tolerance

Check measurement voltage

Check nominal voltage and

adjusted tolerance and correct if

necessary.

Display

" "

Measured current is to

small

check connection of CT,

probably there is a break in the

line

remove short circuit link of the

CT

wrong display of

current or voltage

wrong transformer

ratio

Check settings of transformer

ratios in the "SETUP" (100)

menu and correct if necessary.

The power factor is

displayed

incorrectly.

The connection

detection was not

performed.

The phase angle was

adjusted manually

false.

Offset reactive power

is adjusted.

Start "Ai" in "SETUP" menu.

Check point 206 in the

"EXPERTMENU" and correct

the phase angle if necessary.

With the compensation system, a

transformer is compensated. The

displayed Pf is in front of the

transformer. The displayed Pf is

in front of the transformer.

The power factor

does not change

after the switching

of a step.

Steps are switched

off again.

CT incorrectly

positioned.

Capacitor defect

Check installation position of the

current transformer according to

wiring diagram (current of the

load and the capacitors must be

measured!).

Check capacitor, possible fuse,

capacitor, or contactor defective.

Power Factor Regulator ESTAmat PFC-N

7 TROUBLESHOOTING

Page 27

Technical Documentation Rev. 04

27

Display

"

Current is higher than

allowed.

Check the current transformer

secondary current and possibly

replace it with matching current

transformer.

Display

"

permanent over

compensation

permanent under

compensation

Check settings (possibly step

with step type "FON")

Check contactors, contactor

contact may bonded.

Check capacitors and fuses.

Dimensioning of the system

examined.

Opposite regulation

behaviour

Current or voltage

connections swapped.

correct connection or adapt phase

compensation.

Individual steps are

not switched on or

off.

wrong setting

Verify whether the steps were

defined as Step type "FON" or

"FOFF" (permanently on or off).

Steps are detected

as defective.

Steps are switched

off again.

Step defective

Check capacitor, possibly fuse,

capacitor or contactor defective.

Steps are not

switched.

The steps are to large.

The required reactive power is

below the switching threshold.

Switching threshold is 60% of

the smallest available step.

Power Factor Regulator ESTAmat PFC-N

Page 28

Technical Documentation Rev. 04

28

Power Factor Regulator ESTAmat PFC-N

8 APPLICATIONS

8.1 Fan Control

The fan control is to be regulated through the ESTAmat PFC-N.

Solution:

If the ESTAmat PFC-N is equipped with a temperature sensor (option –L), can be via one of

the switching exits, a fan to be controlled.

Procedure:

Enable temperature alarm

In the expert menu item 512 set to "YES" (temperature alarm on).

Set temperature thresholds

Set the following items 513 (temperature threshold 1) and 514 (temperature threshold

2the temperature thresholds. By exceeding the temperature threshold 1 is witched the fan

output. When you exceed the temperature threshold 2, all steps are switched off to prevent

overheating.

Select fan output

Select item 403 in expert menu and adjust for the step which shall work as the fan output

step type "AL".

Features:

In order to prevent hunting of the fan relay, the fan is turned off only at a temperature below

the set limit by at least 3°C. If the ESTAmat PFC-N is equipped with a temperature sensor,

the current cabinet temperature is displayed and the highest measured temperature is stored in

thi. Parallel to the temperature sensor can be connected a thermostat. By close of the

thermostat , the temperature limit 2 is activated.

Page 29

Technical Documentation Rev. 04

29

Power Factor Regulator ESTAmat PFC-N

8.2 Switching on COS 2 via digital input

By using a switch, the ESTAmat PFC-N will be switched to COS 2.

Solution:

Using the temperature input as digital input.

Procedure:

Enable digital input

Set item 510 in expert menu to "YES".

Using digital input as n/o or n/c

"YES" digital input is activated with closed terminals T1 & T2.

"NO" digital input is activated with open terminals T1 & T2.

Features:

The temperature input is used as a digital input, shows the controller at active input "high"

and with not active input "low" instead of the temperature. The controller uses with active

digital input the COS 2 and will show "NT" in the display.

Page 30

Technical Documentation Rev. 04

30

Power Factor Regulator ESTAmat PFC-N

8.3 Problems with the Step recognition.

The controller is used in a system with rapid changes in load conditions and has problems

with the automatic step recognition

Solution:

To solve this problem, the step sizes must be entered by hand, and the step recognition must

be turned off.

Procedure:

Stop control.

Set item PFC to "OFF" in menu 100 (quick start menu).

switch off Step detection.

Set item 308 to "Yes" (step recognition off) in the expert menu.

enter step sizes.

Setting the nominal value of the capacitors connected at point 402 in the expert menu.

Check step type

For problems with the step detection, it may happen that the connected steps will be stored

by the controller incorrectly as "FIX-OFF". Therefore, the step type of each step should be

controlled under the menu item "403". All steps of the automatic control used, must be

use the step type "AUTO".

Features:

By switching off the automatic step recognition, a step failure or power loss is not reported.

To monitor the system anyway, it is appropriate to enable the control alarm to be alerted in

case of failure timely. (See alarm menu)

Page 31

Technical Documentation Rev. 04

31

20kV / 50Hz

400V / 50Hz

BLR-CX

Last

Transformator

Transformer

Load

ESTAmat

Power Factor Regulator ESTAmat PFC-N

8.4 Transformer compensation

The compensation of a transformer can be solved with the ESTAmat PFC-N in two ways:

8.4.1 Setting a reactive power offset

Setting reactive power offset. This is added to the required compensation power within the

system.

Procedure:

Determine the required capacitive reactive power to compensate the transformer. Enter the

calculated value in the menu item "312". Control will start immediately with the additional

required reactive power.

Features:

The set here reactive power offset is always added to the measured reactive power. Therefore,

it's always the Pf appears before the transformer. This means that the system can capacitive,

but the measurement of the utility the required Pf recoded.

By the current measurement on medium voltage side, is the from the transformer caused

reactive power measured and regulated by the connected compensation system.

8.4.2 Mixed measurement:

Procedure:

Connect the measurement of the controller

as shown in the diagram adjacent. Then

start the automatic initialization. The

vector group ot the transformer is

automatically considered.

Connection:

When auto-initialization will be aborted,

under item 11.2, the most common

transformer vector groups are listed.

Page 32

Technical Documentation Rev. 04

32

Power Factor Regulator ESTAmat PFC-N

8.5 Reset defective steps respectively add aditional steps

If the controller has a step recognized as defective (3 switching operations without result), it

will be excluded for 24 hours from the regulation. After this period, the step is tested again

from the controller. If the controller can detect the step it will again be included in the control.

If not the step is blocked again for 24hours after 3 unsuccessful switching cycles. Defect steps

are in the "INFO" menu with the step type "flty" marked and flashing in the step indication.

When a compensation system need additional capacitors to be added, proceed as described

below:

Procedure:

Select item "403" in expert menu and use the buttons to select the corresponding step.

Confirm with ( ) button and use the buttons to adjust step type "AUTO".

Feature:

If a step because of power loss greater than 30% is exchanged, it's appropriate for the step, to

program the nominal step size by hand. Select the affected step in menu "402" and program

the nominal step size.

If the alarm was triggered by a defective contactor should, upon the exchange took place, the

accumulated switching operation under item "404" set to "0".

Page 33

Technical Documentation Rev. 04

33

Menu

Factory setting

Customer setting

Menu

Factory setting

Customer setting

100

400

Un

400 V

401

75 s

Ct

1

402

5 var (1-max.)

Pt

1

403

AUTO (1-max.)

Ai

NO

404

0 (1-max.)

PFC

ON

500

CP1

1

501

NO

St

10 s

502

NO

200

503

20 %

201

400 V

504

NO

202

1

505

60 s

203

1

506

NO

204

10%

507

NO

205

NO

508

262 k

206

0

509

65.5 k h

207

NO

510

NO

208

YES

511

NO

209

AUTO

512

NO

300

513

30 °C

301

60%

514

55 °C

302

1

515

0 °C

303

0,95 i

516

NO

304

NO

517

NO

305

10 s

518

NO

306

2 s

600

307

YES

601

NO

308

NO

602

NO

309

YES

603

NO

310

ON

604

NO

311

1

605

NO

312

0

606

NO

313

1

607

1.xx

314

NO

Power Factor Regulator ESTAmat PFC-N

9 CUSTOMER SETTINGS

Page 34

Technical Documentation Rev. 04

34

Voltage

L1-N

L2-N

L3-N

L1-N

L2-N

L3-N

L1-N

L2-N

L3-N

CT

L1

L2

L3

L2

L3

L1

L3

L1

L2

Phase-angle

0°

0°

0°

240°

240°

240°

120°

120°

120°

Voltage

L2-L3

L3-L1

L1-L2

L2-L3

L3-L1

L1-L2

L2-L3

L3-L1

L1-L2

CT

L1

L2

L3

L2

L3

L1

L3

L1

L2

Phase-angle

90°

90°

90°

330°

330°

330°

210°

210°

210°

Transformer vector group

CT

Voltage

Dy5

L1

L2-N

Dy5

L2

N-L3

Dy5

L3

N-L1

Yz5

L1

L2-N

Yz5

L2

N-L3

Yz5

L3

N-L1

Dx6

L1

L3-L2

Dx6

L2

L2-L1

Dx6

L3

L1-L3

Yy6

L1

L3-L2

Yy6

L2

L2-L1

Yy6

L3

L1-L3

Dy11

L1

N-L2

Dy11

L2

L3-N

Dy11

L3

L1-N

Yz11

L1

N-L2

Yz11

L2

L3-N

Yz11

L3

L1-N

Power Factor Regulator ESTAmat PFC-N

10 APPENDIX

10.1 Settings Phase-angle

10.2 Connections for mixed measurement

Page 35

Technical Documentation Rev. 04

35

Power Factor Regulator ESTAmat PFC-N

Notes

Loading...

Loading...