查询CWR06供应商

Solid Tantalum Chip Capacitors

MIDGET® Military, MIL-PRF-55365/4 Qualified

PERFORMANCE CHARACTERISTICS

CWR06

Vishay Sprague

FEATURES

• Weibull Failure Rates B, C; Exponential M, P, R, S.

• Tape and Reel available per EIA 481-1 and-2.

• Termination finishes available; Gold Plate, 50µ inch

minimum (standard), Solder Plated Hot Solder Dipped.

Operating Temperature: - 55°C to + 85°C. (To + 125°C

with voltage derating.)

Capacitance Range: 0.10µF-100µF

Capacitance Tolerance: ± 10%, ± 20% standard. ± 5%

available as special.

Voltage Rating: 4WVDC to 50WVDC.

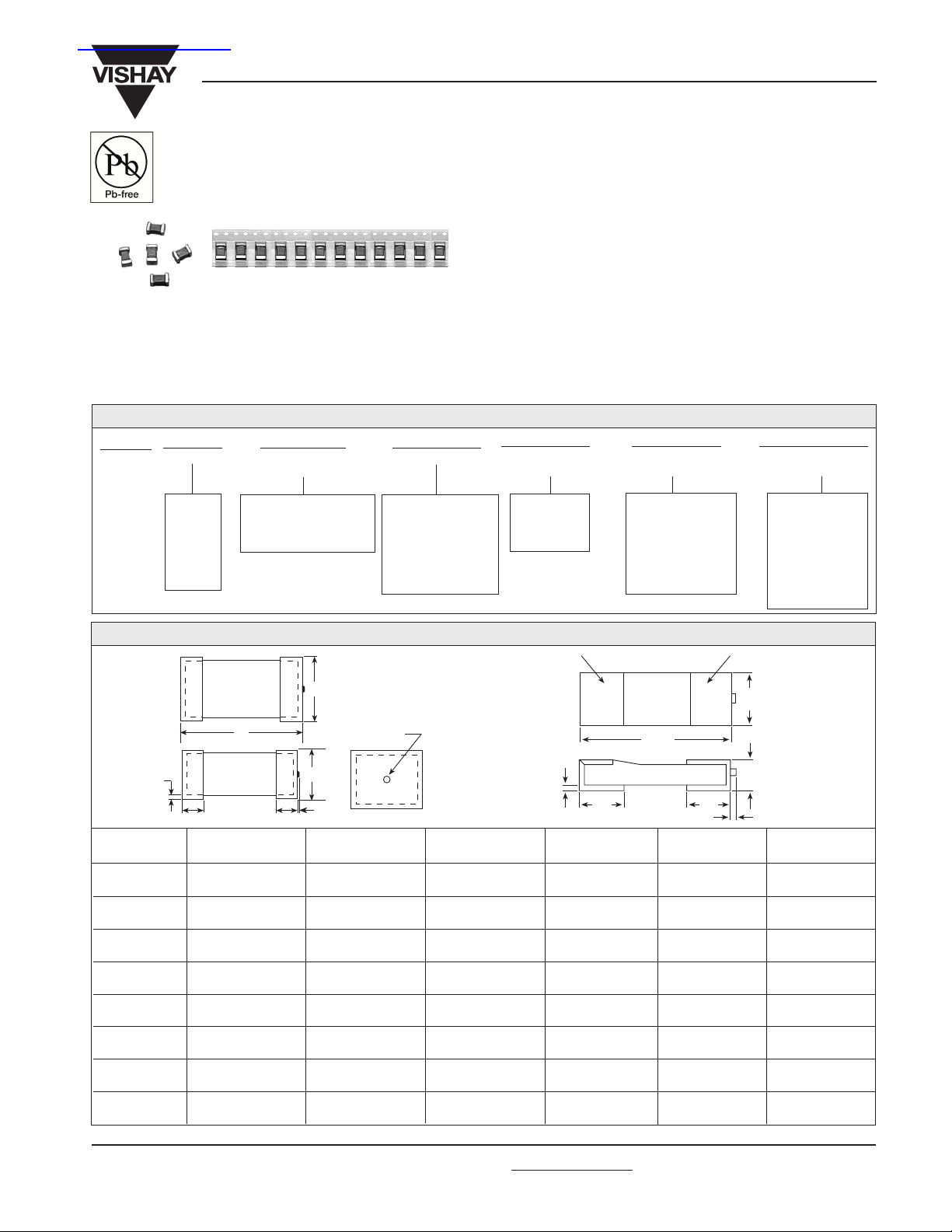

ORDERING INFORMATION

CWR06

TYPE

D

VOLTAGE

C= 4 V

D= 6 V

F = 10V

H= 15 V

J = 20 V

K = 25 V

M= 35 V

N= 50 V

B

TERMINATION

FINISH

B = Gold. Standard.

H = Solder Plate.

C = Solder Dipped

155

CAPACITANCE

This is expressed

in picofarads. The

first two digits are

the significant

figures. The third

is the number of

zeros to follow.

K

CAPACITANCE

TOLERANCE

K= ± 10%

M = ± 20%

J= ± 5%

B

FAILURE RATE

%/1000 HOURS

A = Commercial

M = 1.0

P = 0.1

R = 0.01

S = 0.001

B = 0.1

C = 0.01

DIMENSIONS in inches [millimeters]

+-

Weld and

W

L

T

1

P

CASE

CODE

A

B

C

D

E

F

G

H

Note: When solder coated terminations are required, add .015" [0.38mm] to termination dimension tolerances.

L

0.100 ± 0.015

[2.54 ± 0.38]

0.150 ± 0.015

[3.81 ± 0.38]

0.200 ± 0.015

[5.08 ± 0.38]

0.150 ± 0.015

[3.81 ± 0.38]

0.200 ± 0.015

[5.08 ± 0.38]

0.220 ± 0.015

[5.59 ± 0.38]

0.265 ± 0.015

[6.73 ± 0.38]

0.285 ± 0.015

[7.24 ± 0.38]

H

P

Dimple

Projection

Identifies

Anode (+)

Terminal

T2 Max.

W

0.050 ± 0.015

[1.27 ± 0.38]

0.050 ± 0.015

[1.27 ± 0.38]

0.050 ± 0.015

[1.27 ± 0.38]

0.100 ± 0.015

[2.54 ± 0.38]

0.100 ± 0.015

[2.54 ± 0.38]

0.135 ± 0.015

[3.43 ± 0.38]

0.110 ± 0.015

[2.79 ± 0.38]

0.150 ± 0.015

[3.81 ± 0.38]

H

0.050 ± 0.015

[1.27 ± 0.38]

0.050 ± 0.015

[1.27 ± 0.38]

0.050 ± 0.015

[1.27 ± 0.38]

0.050 ± 0.015

[1.27 ± 0.38]

0.050 ± 0.015

[1.27 ± 0.38]

0.070 ± 0.015

[1.78 ± 0.38]

0.110 ± 0.015

[2.79 ± 0.38]

0.110 ± 0.015

[2.79 ± 0.38]

-

T

1

P

P

0.030 ± 0.005

[0.76 ± 0.13]

0.030 ± 0.005

[0.76 ± 0.13]

0.030 ± 0.005

[0.76 ± 0.13]

0.030 ± 0.005

[0.76 ± 0.13]

0.030 ± 0.005

[0.76 ± 0.13]

0.030 ± 0.005

[0.76 ± 0.13]

0.050 ± 0.005

[1.27 ± 0.13]

0.050 ± 0.005

[1.27 ± 0.13]

L

P

T

1

0.005

[0.13]

0.005

[0.13]

0.005

[0.13]

0.005

[0.13]

0.005

[0.13]

0.005

[0.13]

0.005

[0.13]

0.005

[0.13]

OPTIONAL

SURGE CURRENT

OPTIONS

A = 10 Cycles at

+ 25°C

B = 10 Cycles at

-55°C and

+ 85°C.

C = 10 Cycles at

-55°C and

+ 85°C

(Before Weibull

Grading).

+

W

H

T2 Max.

T2 (Max.)

0.015

[0.38]

0.015

[0.38]

0.015

[0.38]

0.015

[0.38]

0.015

[0.38]

0.015

[0.38]

0.015

[0.38]

0.015

[0.38]

Document Number 40009

Revision 16-Nov-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

133

CWR06

Vishay Sprague

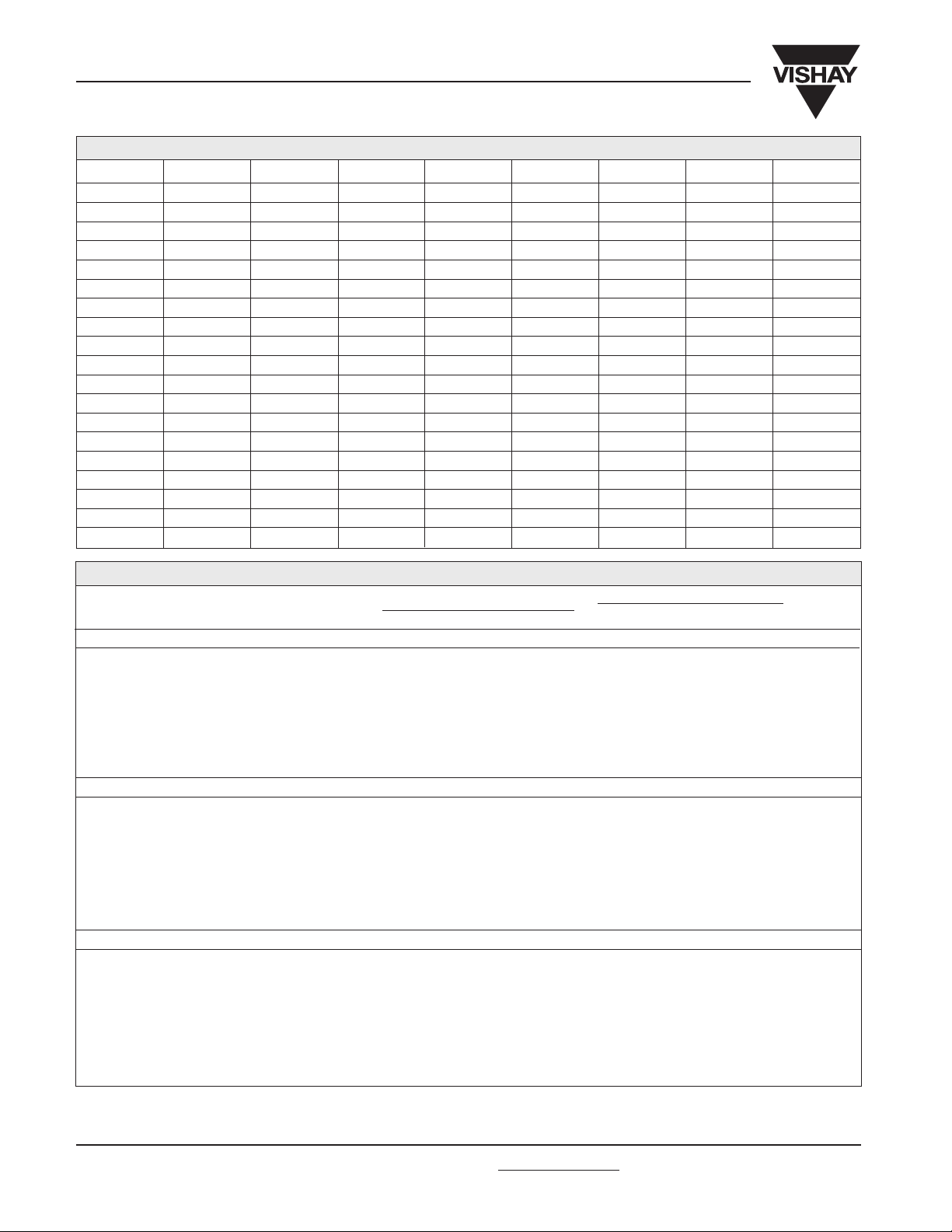

RATINGS AND CASE CODES

µF

0.10

0.15

0.22

0.33

0.47

0.68

1.0

1.5

2.2

3.3

4.7

6.8

10

15

22

33

47

68

100

4 V

A

B

C

D

E

F

G

H

6 V

A

B

C

D

E

F

G

H

10 V

A

B

C

D

E

F

G

H

15 V

A

B

C

D

E

F

G

H

20 V

A

B

B

C

D

E

F

G

H

25 V

A

B

C

D

E

F

G

G

H

35 V

A

B

C

D

E

F

G

H

50 V

A

A

B

B

C

D

E

F

F

G

H

STANDARD RATINGS

CAPACITANCE

(µF)

2.2

4.7

6.8

10

15

33

68

100

1.5

3.3

4.7

6.8

10

22

47

68

1.0

2.2

3.3

4.7

6.8

15

33

47

@ = Termination Finish: B = Gold (standard), H = solder Plated, C = Hot solder dipped

# = Cap.Tolerance: J = 5%, K = 10%, M = 20%.

* = Failure Rate B, C Weibull

CASE

CODE

M, P, R, S Exponential

4 WVDC @ + 85

A

B

C

D

E

F

G

H

CWR06D@155#*

A

CWR06D@335#*

B

CWR06D@475#*

C

CWR06D@685#*

D

CWR06D@106#*

E

CWR06D@226#*

F

CWR06D@476#*

G

CWR06D@686#*

H

A

B

C

D

E

F

G

H

PART NUMBER*

CWR06C@225#*

CWR06C@475#*

CWR06C@685#*

CWR06C@106#*

CWR06C@156#*

CWR06C@336#*

CWR06C@686#*

CWR06C@107#*

6 WVDC @ + 85°C, SURGE = 8 V . . . 4 WVDC @ + 125°C, SURGE = 5 V

10 WVDC @ + 85°C, SURGE = 13 V . . . 7 WVDC @ + 125°C, SURGE = 9 V

CWR06F@105#*

CWR06F@225#*

CWR06F@335#*

CWR06F@475#*

CWR06F@685#*

CWR06F@156#*

CWR06F@336#*

CWR06F@476#*

°C, SURGE = 5 V . . . 2.7 WVDC @ + 125°C, SURGE = 3.4 V

Max. DCL (µA) @

+ 25°C + 85°C

1.0

1.0

1.0

1.0

1.0

2.0

3.0

4.0

1.0

1.0

1.0

1.0

1.0

2.0

3.0

4.0

1.0

1.0

1.0

1.0

1.0

2.0

3.0

5.0

10

10

10

10

10

20

30

40

10

10

10

10

10

20

30

40

10

10

10

10

10

20

30

50

+ 125°C

12

12

12

12

12

24

36

48

12

12

12

12

12

24

36

48

12

12

12

12

12

24

36

60

+ 25°C

6

6

6

8

8

8

10

10

6

6

6

6

8

8

10

10

6

6

6

6

6

8

10

10

Max. DF (%) @

+ 85°C

+ 125°C

8

8

8

8

10

10

12

12

8

8

8

8

10

10

12

12

8

8

8

8

8

8

12

12

- 55°C

8

8

8

10

12

12

12

12

8

8

8

8

12

12

12

12

8

8

8

8

8

10

12

12

Max. ESR

@ + 25°C

100kHz

(Ohms)

8.0

8.0

5.5

4.0

3.5

2.2

1.1

0.9

8.0

8.0

5.5

4.5

3.5

2.2

1.1

0.9

12.0

8.0

5.5

4.5

3.5

2.5

1.1

0.9

www.vishay.com

134

For technical questions, contact tantalum@vishay.com

Document Number 40009

Revision 16-Nov-04

STANDARD RATINGS

CAPACITANCE

(

µF)

0.68

1.5

2.2

3.3

4.7

10

22

33

0.47

0.68

1.0

1.5

2.2

3.3

6.8

15

22

0.33

0.68

1.0

1.5

2.2

4.7

6.8

10

15

0.22

0.47

0.68

1.0

1.5

3.3

4.7

6.8

0.10

0.15

0.22

0.33

0.47

0.68

1.0

1.5

2.2

3.3

4.7

@ = Termination Finish: B = Gold (standard), H = solder Plated, C = Hot solder dipped

# = Cap.Tolerance: J = 5%, K = 10%, M = 20%.

* = Failure Rate B, C Weibull

CASE

CODE

A

B

C

D

E

G

H

A

B

B

C

D

E

F

G

H

A

B

C

D

E

F

G

G

H

A

B

C

D

E

F

G

H

A

A

B

B

C

D

E

F

F

G

H

M, P, R, S Exponential

PART NUMBER*

15 WVDC @ + 85°C, SURGE = 20 V . . . 10 WVDC @ + 125°C, SURGE = 12 V

CWR06H@684#*

CWR06H@155#*

CWR06H@225#*

CWR06H@335#*

CWR06H@475#*

CWR06H@106#*

F

CWR06H@226#*

CWR06H@336#*

20 WVDC @ + 85°C, SURGE = 26 V . . . 13 WVDC @ + 125°C, SURGE = 16 V

CWR06J@474#*

CWR06J@684#*

CWR06J@105#*

CWR06J@155#*

CWR06J@225#*

CWR06J@335#*

CWR06J@685#*

CWR06J@156#*

CWR06J@226#*

25 WVDC @ + 85°C, SURGE = 32 V . . . 17 WVDC @ + 125°C, SURGE = 20 V

CWR06K@334#*

CWR06K@684#*

CWR06K@105#*

CWR06K@155#*

CWR06K@225#*

CWR06K@475#*

CWR06K@685#*

CWR06K@106#*

CWR06K@156#*

35 WVDC @ + 85°C, SURGE = 46 V . . . 23 WVDC @ + 125°C, SURGE = 28 V

CWR06M@224#*

CWR06M@474#*

CWR06M@684#*

CWR06M@105#*

CWR06M@155#*

CWR06M@335#*

CWR06M@475#*

CWR06M@685#*

50 WVDC @ + 85°C, SURGE = 65 V . . . 33 WVDC @ + 125°C, SURGE = 38 V

CWR06N@104#*

CWR06N@154#*

CWR06N@224#*

CWR06N@334#*

CWR06N@474#*

CWR06N@684#*

CWR06N@105#*

CWR06N@155#*

CWR06N@225#*

CWR06N@335#*

CWR06N@475#*

Max. DCL (µA) @

+ 25°C

1.0

1.0

1.0

1.0

1.0

2.0

4.0

5.0

1.0

1.0

1.0

1.0

1.0

1.0

2.0

3.0

4.0

1.0

1.0

1.0

1.0

1.0

2.0

2.0

3.0

4.0

1.0

1.0

1.0

1.0

1.0

1.0

2.0

3.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

2.0

2.0

3.0

+ 85°C

10

10

10

10

10

20

40

50

10

10

10

10

10

10

20

30

40

10

10

10

10

10

20

20

30

40

10

10

10

10

10

10

20

30

10

10

10

10

10

10

10

10

20

20

30

+ 125°C

12

12

12

12

12

24

48

60

12

12

12

12

12

12

24

36

48

12

12

12

12

12

24

24

36

48

12

12

12

12

12

12

24

36

12

12

12

12

12

12

12

12

24

24

36

Max. DF (%) @

+ 25°C

6

6

6

6

6

6

8

8

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

+ 85°C

+ 125°C

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

CWR06

Vishay Sprague

Max. ESR

@ + 25°C

- 55°C

8

8

8

8

8

8

10

10

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

100kHz

(Ohms)

12.0

8.0

5.5

5.0

4.0

2.5

1.1

0.9

16.0

14.0

12.0

6.0

5.0

4.0

2.4

1.1

0.9

15.0

10.0

6.5

6.5

3.5

2.5

1.2

1.4

1.0

24.0

17.0

10.0

6.5

4.5

2.5

1.5

1.3

75.0

25.0

17.0

12.0

8.0

7.0

6.0

4.0

2.5

2.0

1.5

Document Number 40009

Revision 16-Nov-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

135

CWR06

Vishay Sprague

PERFORMANCE CHARACTERISTICS

1. Operating Temperature: Capacitors are designed to

operate over the temperature range - 55°C to + 85°C.

1.1 Capacitors may be operated to + 125°C with

voltage derating to two-thirds the + 85°C rating.

+ 85°C Rating + 125°C Rating

Working

Voltage

(V)

4

6

10

15

20

25

35

50

Surge

Voltage

(V)

5

8

13

20

26

32

46

65

2. DC Working Voltage: The DC working voltage is the

maximum operating voltage for continuous duty at the

rated temperature.

3. Surge Voltage: The surge DC rating is the maximum

voltage to which the capacitors may be subjected

under any conditions, including transients and peak

ripple at the highest line voltage.

3.1 Surge Voltage Test: Capacitors shall withstand

the surge voltage applied in series with a 33 ohm

± 5% resistor at the rate of one-half minute on,

one-half minute off, at + 85°C, for 1000 successive

test cycles.

3.2 Following the surge voltage test, the dissipation

factor and the leakage current shall meet the initial

requirements; the capacitance shall not have changed

more than ± 10%.

4. Capacitance Tolerance: The capacitance of all

capacitors shall be within the specified tolerance

limits of the normal rating.

4.1 Capacitance measurements shall be made by means

of polarized capacitance bridge. The polarizing

voltage shall be of such magnitude that there shall be

no reversal of polarity due to the AC component. The

maximum voltage applied to capacitors during

measurement shall be 2 volts rms at 120 Hz at +25°C.

If the AC voltage applied is less than one-half volt rms,

no DC bias is required. Accuracy of the bridge shall

be within ± 2%.

Working

Voltage

(V)

2.7

4

7

10

13

17

23

33

Surge

Voltage

(V)

3.4

5

9

12

16

20

28

38

- 55°C

- 10%

+ 85°C

+ 10%

+ 125°C

+ 15%

6. Dissipation Factor: The dissipation factor,

determined from the expression 2πfRC, shall not

exceed values listed in the Standard Ratings Table.

6.1 Measurements shall be made by the bridge method

at, or referred to, a frequency of 120 Hz and a

temperature of + 25°C.

7. Leakage Current: Measurements shall be made at

rated working voltage with an application of a

steady source of power, such as a regulated power

supply. A 1000 ohm resistor to limit the charging

current shall be connected in series with each

capacitor under test. Rated working voltage shall be

applied to capacitors for 5 minutes before making

leakage curent measurements. Units must be

stabilized at the rated temperature for 30 minutes prior

to application of voltage.

Note that the leakage current varies with temperature

and applied voltage. See graph below for the

appropriate adjustment factor.

TYPICAL LEAKAGE CURRENT FACTOR RANGE

100

+ 125°C

10

1.0

0.1

Leakage Current Factor

0.01

+ 85°C

+ 55°C

+ 25°C

0°C

- 55°C

5. Capacitance Change With Temperature: The

capacitance change with temperature shall not exceed

the following percentage of the capacitance measured

at + 25°C:

www.vishay.com

136

For technical questions, contact tantalum@vishay.com

0.001

0 10 20 30 40 50 60 70 80 90 100

Percent of Rated Voltage

Document Number 40009

Revision 16-Nov-04

PERFORMANCE CHARACTERISTICS (Continued)

7.1 At + 25°C, when measured at + 25˚C ± 5˚C, the

leakage current for any capaitor shall not exceed

the maximum value listed in the Standard Ratings

Table

7.2 At + 85

°C, when measured at + 85˚C ± 5˚C, the

leakage current for any capacitor shall not exceed the

maximum value listed in the Standard Ratings Table.

7.3 At + 125°C, when measured at + 125˚C ± 5˚C, the

leakage current for any capacitor shall not exceed the

maximum value listed in the Standard Ratings Table.

8. Life Test: Capacitors shall be capable of withstanding

a 2000 hour life test at the + 85˚C rated DC working

voltage or a 2000 hour life test at the + 125˚C derated

working voltage.

8.1 Following the life test, the capacitors shall meet the

following requirements: the capacitance at + 25˚C

shall not have changed by more than ± 10% from the

GUIDE TO APPLICATION

1. A-C Ripple Current: The maximum allowable ripple

current shall be determined from the formula:

P

I

rms

where,

P = Power Dissipation in Watts @ + 25°C as

given in the table in Paragraph Number 5

(Power Dissipation).

R

= The capacitor Equivalent Series Resistance

ESR

at the specified frequency.

2. A-C Ripple Voltage: The maximum allowable ripple

voltage shall be determined from the formula:

R

=

ESR

CWR06

Vishay Sprague

intital value; the dissipation factor shall meet the initial

requirements; the leakage current shall not be more

than the original requirements.

9. Reflow Soldering: It is recommended that these

capacitors be reflow soldered at a temperature of not

greater than + 250˚C for a period of not more than 30

seconds.

10. Marking: The small body area of these capacitors

does not permit elaborate marking schemes.

Required information will be distinctly marked on the

carton or packages in which the units are shipped.

Capacitors may be ordered with color coding at

additional cost. Color coding shall be as mutually

agreed upon by Vishay Sprague

10.1 Polarity: The anode terminal of each capacitor is

identified by the weld and dimple projection on the

anode cap (see Dimensional Configurations).

2.1 The sum of the peak AC voltage plus the DC voltage

shall not exceed the DC voltage rating of the

capacitor.

2.2 The sum of the negative peak AC voltage plus the

applied DC voltage shall not allow a voltage

reversal exceeding 10% of the DC rating at + 25°C.

3. Reverse Voltage: These capacitors are capable of

withstanding peak voltages in the reverse direction

equal to 10% of the DC rating at + 25°C, 5% of the

DC rating at + 85°C and 1% of the DC rating at

+125°C.

4. Temperature Derating: If these capacitors are to be

operated at temperatures above + 25°C, the

permissible rms ripple current or voltage shall be

calculated using the derating factors as shown:

®

and the customer.

V

= Z

rms

P

R

ESR

or, from the formula:

V

= I

where,

rms

rms

x Z

P = Power Dissipation in Watts @ + 25°C

as given in the table in Paragraph Number 5

(Power Dissipation).

R

= The capacitor Equivalent Series Resistance

ESR

at the specified frequency.

Z = The capacitor impedance at the specified

frequency.

Document Number 40009

Revision 16-Nov-04

For technical questions, contact tantalum@vishay.com

Temperature

+ 25°C

+ 55˚C

+ 85°C

+ 125°C

Derating Factor

1.0

0.9

0.8

0.4

5. Power Dissipation: Power dissipation will be

affected by the heat sinking capability of the mounting

surface. Non-sinusoidal ripple current may produce

heating effects which differ from those shown. It

is important that the equivalent

Irms

value be

established when calculating permissible operating

levels. (Power Dissipation calculated using + 25°C

temperature rise.)

www.vishay.com

137

CWR06

250

200

150

100

50

TIME (SECONDS)

TEMPERATURE DEG. CENTIGRADE

0 50 100 150 200 250 300 350

Vishay Sprague

GUIDE TO APPLICATION (Continued)

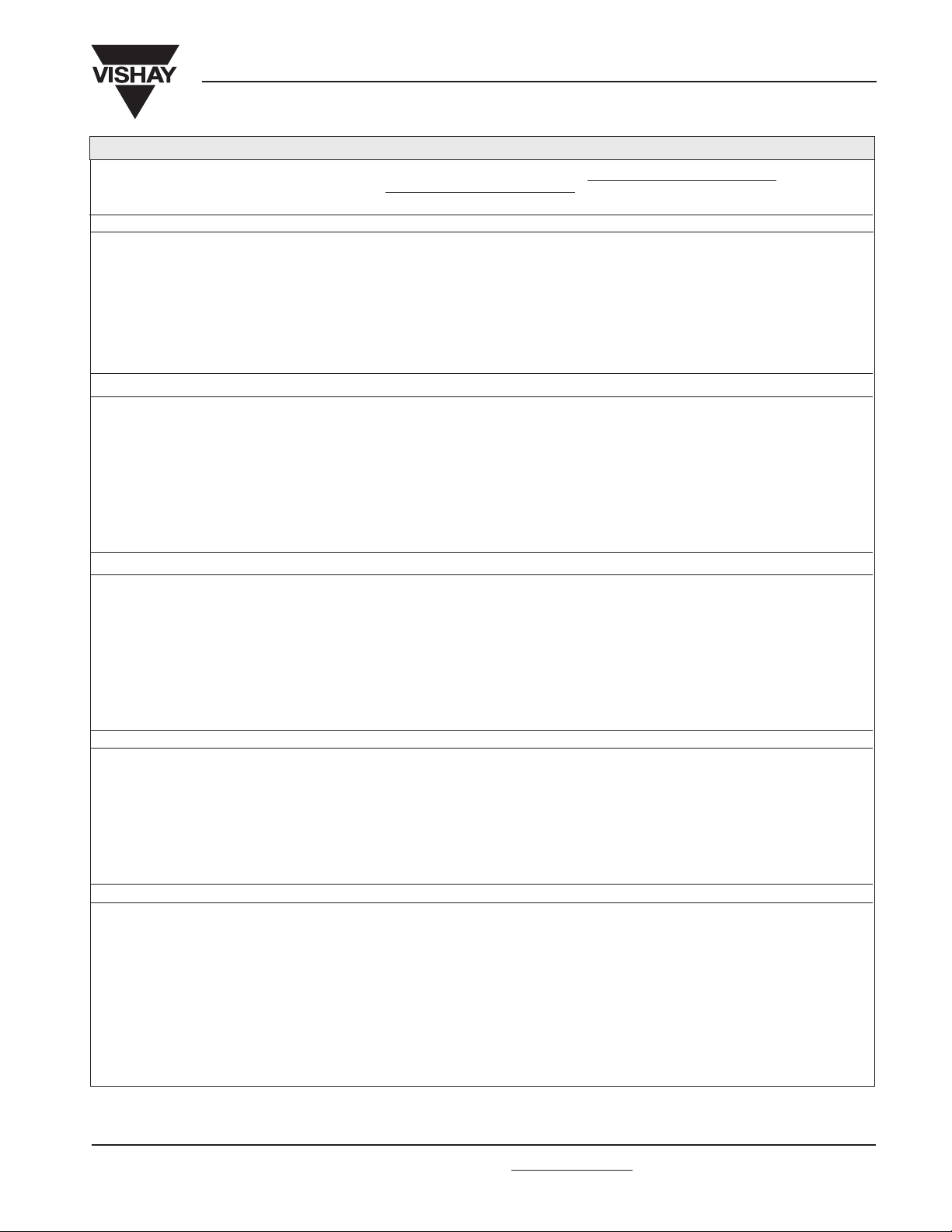

Case Code

A

B

C

D

E

F

G

H

6. Printed Circuit Board Materials: The CWR06 is

compatible with commonly used printed circuit board

materials (alumina substrates, FR4, FR5, G10, PTFEfluorocarbon and porcelainized steel). If you desire

other board materials, contact the factory for

availability.

7. Attachment:

7.1 Solder Paste: The recommended thickness of the

solder paste after application is .007" ± .001"

[.178mm ± .025mm]. Care should be exercised in

selecting the solder paste. The metal purity should

be as high as practical. The flux (in the paste) must

be active enough to remove the oxides formed on the

metallization prior to the exposure to soldering heat. In

practice this can be aided by extending the solder

preheat time at temperatures below the liquidous state

of the solder.

7.2 Soldering: Capacitors can be attached by

conventional soldering techniques - vapor phase,

infrared reflow, wave soldering and hot plate methods.

The Soldering Profile chart shows maximum

recomended time/temperature conditions for soldering. Attachment with a soldering iron is not recommended due to the difficulty of controlling temperature

and time at temperature.

8. Cleaning (Flux Removal) After Soldering: The

CWR06 is compatible with all commonly used solvents

such as TES, TMS, Prelete, Chlorethane, Terpene

and aqueous cleaning media. However, CFC/ODS

products are not used in the production of these

devices and are not recommended. Solvents

containing methylene chloride or other epoxy solvents

should be avoided since these attack the epoxy

encapsulation material.

9 Recommended Mounting Pad Geometries: The

area under the tantalum wire nib should not be

metallized on the PC board. The width dimension

indicated is the same as the maximum width of the

capacitor. This is to minimize lateral movement.

www.vishay.com

138

Maximum Permissible

Power Dissipation

°C (Watts) in free air

@ + 25

0.060

0.075

0.075

0.085

0.095

0.110

0.120

0.150

For technical questions, contact tantalum@vishay.com

REFLOW SOLDER PADS*

in inches [millimetres]

A

B C B

PAD

CASE WIDTH METALIZATION SEPARATION

CODE (A) (B) (C)

A 0.65 0.050 0.040

(1.6) (1.3) (1.0)

B 0.065 0.070 0.055

(1.6) (1.8) (1.4)

C 0.065 0.070 0.120

(1.6) (1.8) (0.3)

D 0.115 0.070 0.070

(2.9) (1.8) (1.8)

E 0.115 0.070 0.120

(2.9) (1.8) (3.0)

F 0.150 0.070 0.140

(3.8) (1.8) (3.6)

G 0.125 0.070 0.170

(3.2) (1.8) (4.3)

H 0.165 0.090 0.170

(4.2) (2.3) (4.3)

RECOMMENDED REFLOW SOLDERING PROFILE

Document Number 40009

Revision 16-Nov-04

TAPE AND REEL PACKAGING

Standard orientation is with the cathode

(-) nearest to the sprocket holes

per EIA-481-1 and IEC 286-3.

Top Cover

Thickness

CWR06

Vishay Sprague

Tape and Reel Specifications: All case codes are available on

plastic embossed tape per EIA-481-1 and EIA-481-2. Tape reeling

per IEC 286-3 is also available. Standard reel diameter is 7"

[178mm]. 13" [330mm] reels are available and recommended as

the most cost effective packaging method. The most efficient

packaging quantities are full reel increments on a given reel

diameter. The quantities shown allow for the sealed empty pockets

required to be in conformance with EIA-481-1 and EIA-481-2. Reel

size and packaging orientation must be specified in the Vishay

Sprague part number.

Tape

Carrier

Embossment

Notes:

1. 12mm and 16mm embossed tape with

components shall pass around radius "R"

without damage. The minimum trailer length

may require additional length to provide R

minimum for reels with hub diameters

approaching N minimum.

Case

Code

A

B

C

D

E

F

G

H

Tape

Width

8mm

12mm

12mm

12mm

12mm

12mm

16mm

16mm

R

Min.

Bending Radius

(Note 1)

R Minimum:

8mm 1/2 Pitch and 8mm = .984" [25mm]

12mm, 12mm Double Pitch and 16mm =1.181" [30mm].

Component

Pitch

Quantity per Full

7" [178 mm] Reel

4mm

4mm

4mm

4mm

4mm

8mm

8mm

8mm

2500

2500

2500

2500

2500

1000

600

600

Units Per Reel

Quantity per Half

7" [178 mm] Reel

1250

1250

1250

1250

1250

500

300

300

Document Number 40009

Revision 16-Nov-04

For technical questions, contact tantalum@vishay.com

www.vishay.com

139

Loading...

Loading...