Page 1

查询AN817供应商

Vishay Siliconix

A Discrete Approach to Battery Charging for Cellular Phones

Guy Moxey and Michael Speed

AN817

INTRODUCTION

All portable cordless appliances must receive power from an

external source, whether it’s a wall cube adapter , car charger,

or docking station. This external source will then charge, in a

predetermined fashion, the equipment’s internal battery.

In the case of a portable phone, the power management

system will incorporate charging control circuitry to regulate

the voltage supplied to the battery from the external charger.

External charging equipment—whether wall cubes or

chargers that utilize car cigarette lighters—will supply a

continuous but unregulated voltage to the phone, typically

4.2 V for a single Lithium-ion (Li+) cell. A typical charging

design is explored in Appendix A.

Charge control for a Li+ cell is most commonly implemented

by a discrete MOSFET in series with a Schottky diode,

controlled via the onboard power management ASIC or

system microprocessor. Integration of these two discrete

power components into a single power package, such as the

ChipFETt, reduces size and simplifies the assembly.

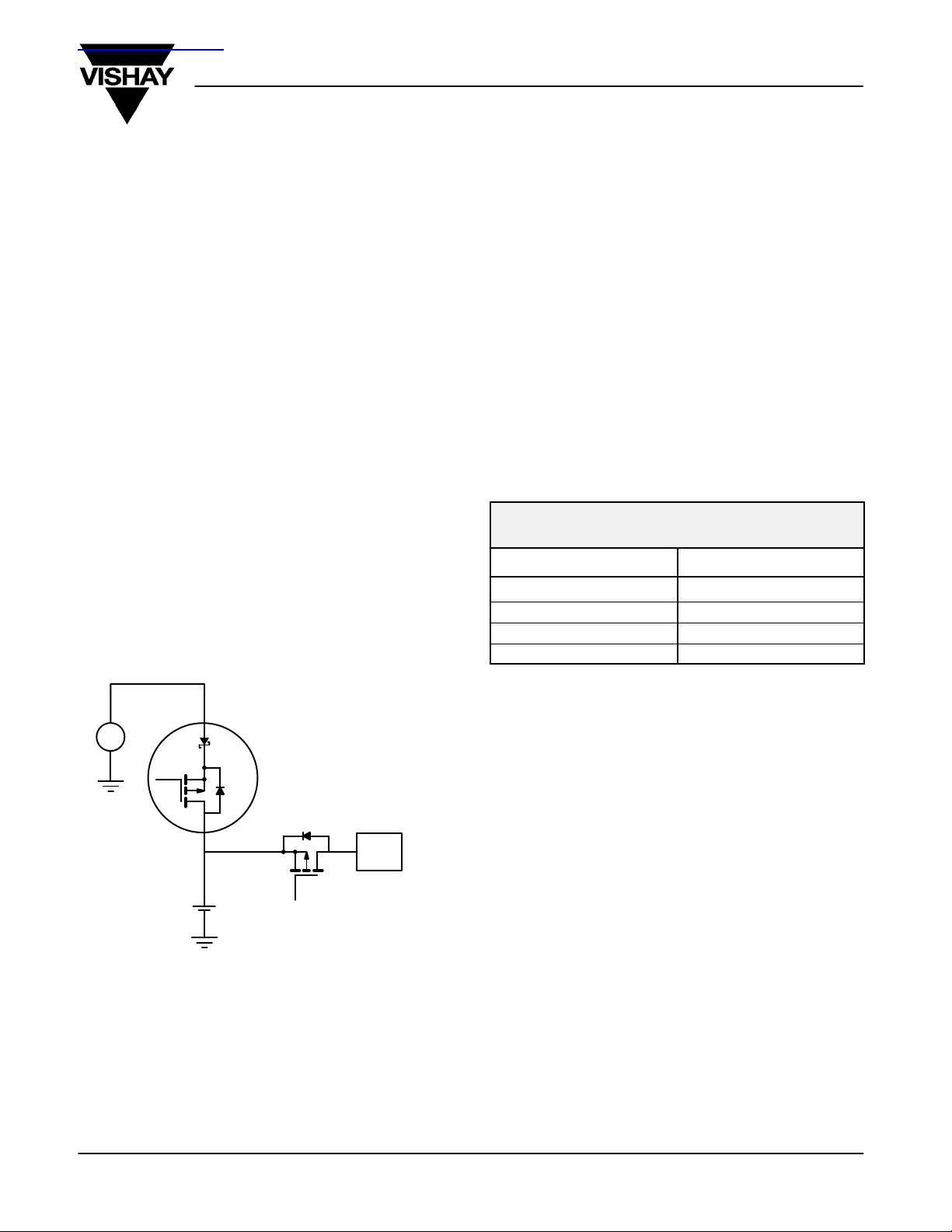

Charger

+

–

LITTLE FOOT Plust

To this end, moving away from a separate Schottky diode and

MOSFET to the single package integration of both devices, as

in the Vishay Siliconix LITTLE FOOT Plus

TM

, may have

significant advantages. However, in an integrated package

both components operate in a highly dissipative manner,

making the choice of package a critical decision.

The LITTLE FOOT Plus Schottky diodes come in a variety of

packages, with a range of r

the performance of the charger as r

values. Just as important to

DS(on)

values are the

DS(on)

thermal ratings of the packages. From the table below we can

see the choices of R

values available in today’s

thJA

industry-standard surface-mount packages.

TABLE 1.

LITTLE FOOT Plus PACKAGE OPTIONS

Device

SO-8 —Si4833DY 90

TSSOP-8 — Si6923DQ 115

TSOP-6 — Si3853DV 130

1206-8 ChipFET — Si5853DC 90

R

(_C/W) Typical

thJA

POWER DISSIPATION ISSUES

To select the correct part in the smallest package, the power

dissipated by the two power devices must be examined. In the

case of the charger switch, there are two modes of operation

to consider.

PA

Battery

FIGURE 1. LITTLE FOOT Plust Schottky—The Integrated

Solution of MOSFET and Schottky in One Power

Package

+

–

Regardless of the charging device selected, the designer is

still bound by space, cost, and efficiency considerations.

There is therefore an obvious desire to increase levels of

integration and reduce the component count and board size.

Document Number: 71395

22-Jan-01

In the first phase of charging, constant current is used and the

MOSFET is operated in the linear mode. In this mode the

device is effectively a variable resistor used to regulate the

battery charging current.

Once the battery has charged to the predetermined 4.1-V

level, the system voltage loop will begin to reduce the charging

current in order to maintain the desired float voltage, hence the

constant-voltage mode. For constant-voltage operation, the

controller will terminate the MOSFET linear operation and

revert to a pulse width modulation (PWM) mode. The

MOSFET is driven as a fully-saturated (Ohmic) switch.

The Schottky diode is always required in series with the switch

to prevent reverse current flow through the MOSFET’s body

drain diode when the external power source is unplugged or

unpowered. Using separate MOSFETs and Schottkys rather

than an integrated package consumes valuable board space.

www.vishay.com

1

Page 2

AN817

Vishay Siliconix

CONSTANTĆCURRENT MODE

As the MOSFET operates in the linear mode during

constant-current charge control, the device losses can be

simply calculated from Ohm’s law:

P

LOSS

= (V

BAT(max)

– V

BAT(min)

) x I

OUT

As an effective linear regulator, the MOSFET functions in a

high-dissipation mode. In addition, the series Schottky diode

contributes to the overall power loss. Typical charging currents

range from 400 mA to 700 mA, with the Li+ battery voltage

varying from 4.1 V (fully charged) to 3.0 V (discharged)

. So at

a 500-mA charging current, the charging system for a Li+ cell

will have to dissipate:

P

MOSFET = (4.1 * 3.0)=) 0.5 = 0.55 W

LOSS

P

Schottky = VF IF = 0.48 0.5 = 0.24 W

LOSS

In total, under constant current charging the total discrete

power loss = 0.79 W

CONSTANTĆVOLTAGE MODE

For the constant-voltage portion of the charge cycle, the

MOSFET is fully saturated. Any consequent losses will be

minimal and, assuming the worst-case scenario of T

and V

of 2.5 V, can be found from:

GS

PD Conduction = (Irms)2 r

P

Switching = 1/2 VL (tr + tf) FS W

D

= (0.5)

= 0.058 W

2

0.232

DS(on)

W

of 150°C

J

with 60°C as the benchmark. Therefore, to optimize the power

dissipation to the smallest MOSFET package the following

thermal equation can be used:

PD = (T

J(max)

– T

amb

)/R

thJA

Where:

PD = 0.79 W, T

Hence re-arranging for R

= 150_C and T

J(max)

= 114_C/W.

thJA

amb

= 60_C

Good engineering practice allows a safety margin of 10% on

the T

R

thJA

value, thus decreasing the allowable package

J(max)

to approximately 104°C/W.

From both the above calculation and Table 1, we can deduce

that the best-fit package for the MOSFET plus Schottky , while

still providing suitable power dissipation, are the SO-8

package and the recently introduced ChipFETt 1206

package.

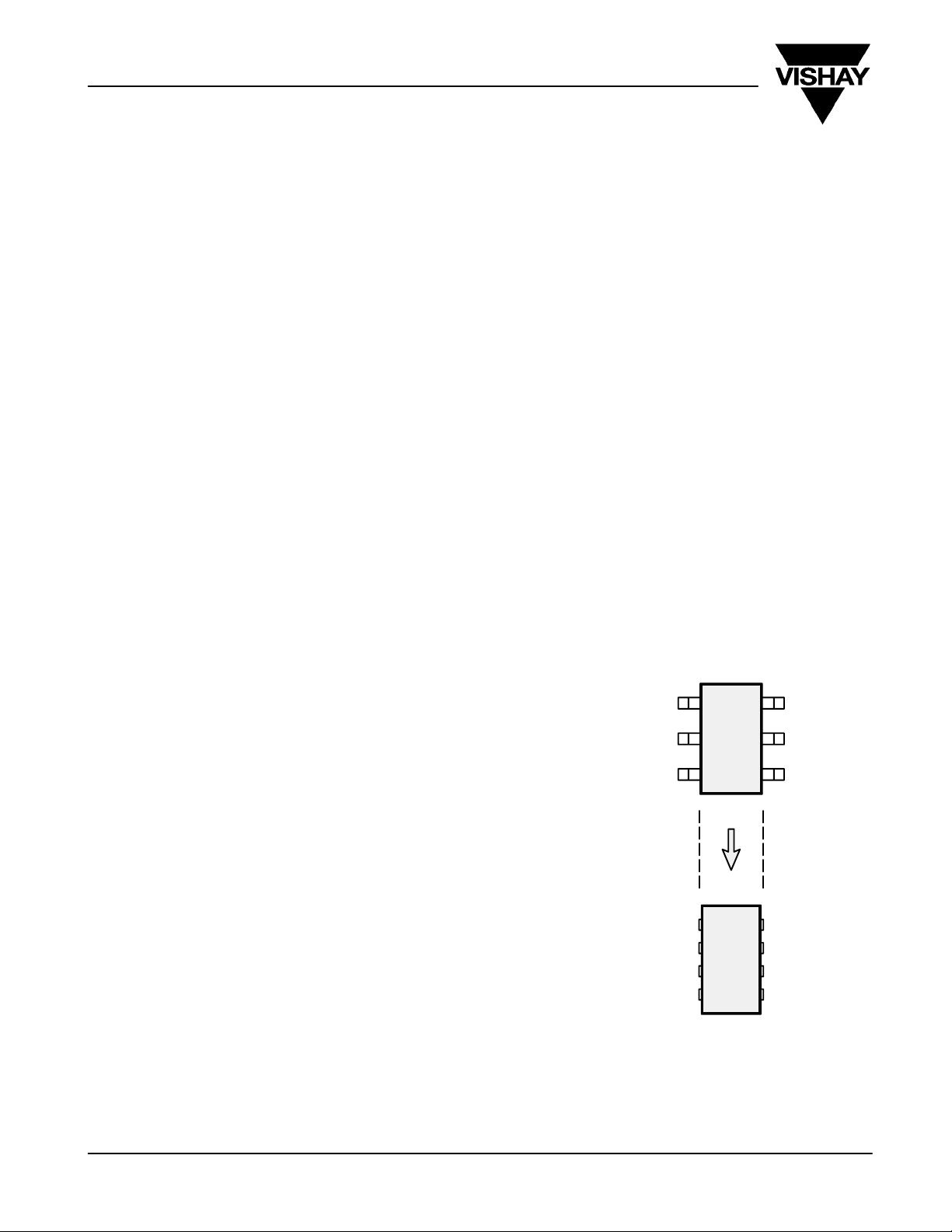

However, moving upward in package footprint may not be an

option when heavily restrained by the device size. Therefore

the new ChipFET 1206 package offers a typical R

thJA

of only

90°C/W, a footprint 40% smaller than a TSOP-6, and a thermal

performance previously possible only with the SO-8 package.

TSOP-6

Assuming switching of 100 Hz

t

and a tf value of 1 ms.

r

0.5 (4.1 0.5) (1 10 * 6 + 1 10 * 6) 100 = 2 mW

Therefore, the losses generated from the MOSFET under

constant-voltage operation are much less—approximately

7.6% —than the losses generated under constant-current

operation.

SMD PACKAGE THERMAL PERFORMANCE—

Can we dissipate the heat with LITTLE FOOT Plus?

Ambient temperatures usually quoted for component

calculation within a cell phone range between 50°C to 65°C,

www.vishay.com

2

40% Smaller Footprint

1206-8 ChipFET

FIGURE 2.

Document Number: 71395

22-Jan-01

Page 3

PACKAGE DIMENSIONS—1206Ć8 ChipFETt

AN817

Vishay Siliconix

4

D

6578

EE

4

1

3421

e

S b

2X 0.10/0.13 R

A

NOTES:

1 All dimensions are in millimeters

2 Mold gate burrs shall not exceed 0.13 mm per side.

Leadframe to molded body offset in horizontal and vertical shall not

3

exceed 0.08 mm.

4 Dimensions exclusive of mode gate burrs.

5 No mold flash allowed on the top and bottom lead surface.

ECN: S-59178—Rev. A, 17-Aug-99

L

5678

4321

c

Backside View

MILLIMETERS INCHES

Dim Min Nom Max Min Nom Max

A 1.00 – 1.10 0.039 – 0.043

b 0.25 0.30 0.35 0.010 0.012 0.014

c 0.1 0.15 0.20 0.004 0.006 0.008

D 2.95 3.05 3.10 0.116 0.120 0.122

E – – 1.80 – – 0.071

E

1.55 1.65 1.70 0.061 0.065 0.067

1

e 0.65BSC 0.0256BSC

L 0.30 – 0.45 0.012 – 0.018

S 0.55BSC 0.022BSC

5_Nom 5_Nom

Focusing on the Si5853DC, this device contains a 20-V

p-channel MOSFET—with a 160-mW r

value at a 2.5-V

DS(on)

gate drive—plus a 20-V, 1-A Schottky diode. From the

previous calculations, it can be seen that the Si5853DC can be

used as a constant-current/constant-voltage charging switch,

thus eliminating the use of two separate devices and saving

significant board space. From our working example, with a

500-mA charging current the die temperature is obtained from:

TJ = (T

TJ = (60_C 0.79) + 90_C/W

T

J

PD) + R

amb

= 137.4_C

thJA

This calculation proves that the Si5835DC is a satisfactory

solution for a typical constant-current/constant-voltage

charging strategy, and can effectively replace a separate

series connected MOSFET and Schottky diode, as is

commonly used within a cellular phone.

Document Number: 71395

22-Jan-01

2

Thermal Resistance Corroboration Between a 1-in

PCB

and a Cellular-Size PCA

The R

was based on the value measured on a 1-in

value—90°C/W— that was used in the calculations

thJA

2

PCB with 1-oz

copper on both sides, as is typically used for the

characterization of power MOSFET packages.

The subsequent characterization used a cellular-size PCA, so

using a point from this curve to compare thermal resistance

values—i.e., the 0.8-W point on the graph for 1206-8

ChipFET—then:

Q

= TJ – TA/P

JA

Q

= 98.5_C – 25_C/0.8

JA

Q

= 92_C/W

JA

D

The resulting QJA value is close to the 1-in2 PCB value of

90°C/W, adding credence to the earlier calculations.

www.vishay.com

3

Page 4

AN817

Vishay Siliconix

TEST RESULTS

The following graph displays the power dissipation

performance of the TSOP-6 vs. the 1206-8 on a cellular-size

PCA.

The TSOP-6 package has been used to compare performance

due to its status as the preferred footprint for power MOSFET s

in cellular designs.

Incremental steps of power were dissipated in each device

and the corresponding junction temperature was measured.

The 1206-8 ChipFET has superior P

reference points, i.e., T

= 100_C (TA of 25_C is included in

J

this value).

140

TSOP-6 = 690 mW

120

C)

_

Junction T emperature (

1206-8 ChipFET = 805 mW

100

80

60

40

20

0

0.0 0.2 0.4 0.6 0.8 1.0

TSOP-6

performance at all

D

1206-8 ChipFET

APPENDIX A

A Typical Charging Scheme

The world market for high-density rechargeable batteries as a

whole is in a transition phase between market development

and market maturation. The four most common chemistries

used to power portable equipment are Nickel Cadmium

(NiCd), Nickel Metal Hydride (NiMH), Lithium Ion (Li+) and

Lithium Polymer (LiP). NiCd is currently in market retirement,

NiMH is in full maturation, Li+ is in the market development

stage and new alternatives like LiP are in market gestation. For

today’s cellular phone, a single-cell Li+ cell is often the battery

of choice due to its small size and high energy density.

Li+ cells are generally suited to a

constant-current/constant-voltage charging strategy and

although relatively simple to implement, charging the cell

actually requires precise control of the “float voltage” region in

order to obtain the maximum capacity with long cell life. In

summary, if the voltage is too low, the cell will not be fully

charged; if the voltage is too high, the cycle life is significantly

degraded. In addition, excessive over- or under-charge of a

Li+ cell can result in catastrophic failure of the unit with

possible explosion.

As stated, the charging of a single Li+ cell will follow a CC/CV

strategy, as shown in the graph below. Region 1 is CC,

region 2 is CV.

Device Power Dissipation

FIGURE 3. Comparison of TSOP-6 vs. ChipFET

Both examples (practical and theoretical) demonstrate the

validity of using the LITTLE FOOT Plus MOSFET and

Schottky integration power package.

The Si5853DC has been shown to be a viable application for

the charger switch in single lithium-ion charging schemes.

ASSOCIATED MATERIAL

1. Design Challenges for Battery Operated Power

Management Systems: Guy Moxey, Vishay Siliconix,

PCIM2000 Europe.

2. Leadless Power Packaging Signals a New Era for Surface

Mount Semiconductor Switches: Guy Moxey,

Vishay Siliconix, Electronic Engineering, June 2000 Issue.

3. Single-Channel 1206-8 ChipFETt Power MOSFET

Recommended Pad Pattern and Thermal Performance:

Michael Speed, V ishay Siliconix: TA811, www.vishay.com

A fully discharged cell (typically 3 V) will initially be charged by

a constant current, since the cell’s voltage is well below the

4.1-V constant voltage limit. Once the cell’s voltage rises to the

float voltage of 4.1 V, the charging circuitry limits the further

rise in terminal voltage and the charging current naturally

begins to decline. Typically, manufacturers recommend that

the charging sequence be terminated roughly one hour after

the current has fallen to 10% of its peak value.

.

www.vishay.com

4

Document Number: 71395

22-Jan-01

Page 5

AN817

Vishay Siliconix

4.5

4.0

3.5

3.0

2.5

2.0

Cell Voltage (V)

1.5

1.0

0.5

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Cell Voltage

1 2

Charging Current

Charge Time (Hrs)

FIGURE 4.

4.1 V

Document Number: 71395

22-Jan-01

www.vishay.com

5

Loading...

Loading...