System 7000 Scanner

Programmer’s Reference Manual

Version 1.01

130-000197

P. O. Box 27777, Raleigh, North Carolina, 27611, USA Phone (919) 365-3800 Fax (919) 365-3945 www.vishay.com

Vishay Micro-Measurements

TABLE OF CONTENTS

1 INTRODUCTION __________________________________________________________________________7

1.1 O

VERVIEW

1.2 P

ROGRAMMING OPTIONS

1.2.1 StrainSmart and DCOM_______________________________________________________________7

1.3 D

EFINITION OF TERMS

1.4 D

OCUMENT NOTATION AND CONVENTIONS

1.4.1 Numbering Notation __________________________________________________________________8

1.4.2 Referenced VIs, Methods, and Commands _________________________________________________8

1.5 R

EGISTERED TRADEMARK NOTICES

2 PROGRAMMING OVERVIEW _____________________________________________________________10

2.1 C

OMMUNICATING WITH THE SYSTEM

2.2 A

CCESSING MULTIPLE SCANNERS (SYNCHRONIZATION

2.3 S

YSTEM STATES

2.4 C

OMMAND OVERVIEW

2.5 D

EBUGGING TIPS

3 PROGRAM LAYOUT _____________________________________________________________________14

3.1 O

VERVIEW OF PROGRAM LAYOUT - SCANNING

3.2 O

VERVIEW OF PROGRAM LAYOUT – SINGLE CHANNEL READS

3.3 E

STABLISHING A CONNECTION TO THE SCANNER

3.4 S

YSTEM VALIDATION

3.5 C

ONFIGURATION

3.5.1 System Level Configuration ___________________________________________________________18

3.6 C

ARD-LEVEL CONFIGURATION

3.7 C

HANNEL-LEVEL CONFIGURATION

3.8 C

ONFIGURING SCAN INFORMATION

3.9 R

ECORDING

3.9.1 Setting up Simple Recording __________________________________________________________22

3.9.2 Advanced Recording Options__________________________________________________________23

3.9.2.1 Recording Groups _______________________________________________________________________ 23

3.9.2.2 Configuring Time Based Recording__________________________________________________________ 24

3.9.2.3 Configuring Manual Recording _____________________________________________________________ 26

3.9.2.4 Configuring Limits Recording ______________________________________________________________ 27

3.10 A

CQUIRING A SINGLE-POINT CHANNEL READING

3.11 A

RMING, START SCANNING, AND STOP SCANNING

3.12 S

YNCHRONIZED (NETWORKED) SCANNERS

3.13 S

TARTING AND STOPPING MANUAL RECORDING

3.14 A

CQUIRING AND DECODING RECORDED DATA

3.14.1 Identifying and Reading the Data File __________________________________________________38

3.14.2 Decoding the Data File _____________________________________________________________41

3.14.2.1 Scan ID_______________________________________________________________________________ 41

3.14.2.2 Multiple Record Rates ___________________________________________________________________ 42

3.14.2.3 Varying Data Width _____________________________________________________________________ 42

3.14.2.4 Status Information ______________________________________________________________________ 43

3.14.2.5 Status Byte ____________________________________________________________________________ 43

3.14.2.6 Examples _____________________________________________________________________________ 44

3.14.2.7 Sample Code __________________________________________________________________________ 45

3.14.3 How Data Files are Named __________________________________________________________48

3.14.4 What is a Header File? _____________________________________________________________48

3.15 A

CQUIRING REAL-TIME (ONLINE) DATA

3.15.1 Configuring the Real-time (Online) Data Transmission ____________________________________49

3.15.2 Controlling the Real-time (Online) Data Transmission _____________________________________49

3.15.3 Parsing the Real-time (Online) Data ___________________________________________________50

3.16 Z

EROING AND SHUNT CALIBRATION

3.17 S

CALING THE ANALOG-TO-DIGITAL CONVERTER COUNTS

_____________________________________________________________________________7

__________________________________________________________________7

____________________________________________________________________8

____________________________________________________8

__________________________________________________________9

7000____________________________________________________10

) _________________________________________10

________________________________________________________________________11

___________________________________________________________________11

_______________________________________________________________________13

________________________________________________15

____________________________________16

_______________________________________________17

____________________________________________________________________18

________________________________________________________________________18

_____________________________________________________________19

__________________________________________________________20

_________________________________________________________21

___________________________________________________________________________22

_____________________________________________35

_____________________________________________35

__________________________________________________35

______________________________________________37

________________________________________________38

____________________________________________________49

________________________________________________________50

_______________________________________52

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 2 of 142

4 SYSTEM STATUS AND ERROR HANDLING ________________________________________________53

4.1 E

RROR HANDLING

4.2 D

ECODING THE ERROR NUMBER

4.3 Q

UERYING SYSTEM STATUS

4.4 M

ONITORING THE EVENT/STATUS

4.4.1 Message Format____________________________________________________________________55

4.4.2 Card Status Message ________________________________________________________________55

4.4.3 Card Error Message ________________________________________________________________56

4.4.4 Control Module Error Messages _______________________________________________________56

______________________________________________________________________53

____________________________________________________________54

_______________________________________________________________54

UDP P

ORT

_________________________________________________54

5 LABVIEW INSTRUMENT DRIVER _________________________________________________________57

5.1 O

VERVIEW

5.2 S

YSTEM

5.2.1 System 7000 Instrument Driver Layout __________________________________________________57

5.2.2 System 7000 Instrument Driver Examples ________________________________________________58

5.2.3 System 7000 Instrument “Readme.html” _________________________________________________58

5.2.4 Supported LabVIEW Versions _________________________________________________________58

6 ACTIVEX INTERFACE ___________________________________________________________________59

6.1 A

CTIVE X INTERFACES

6.2 E

RROR CODES

6.3 C

ARD MASK, CHANNEL MASK, AND RECORDING GROUP MASK NOTATION

6.4 S

AMPLE PROGRAMS

6.4.1 Delphi Sample Program______________________________________________________________61

6.4.2 Visual C# Sample Program ___________________________________________________________61

6.4.3 LabWindows/CVI Sample Program _____________________________________________________61

6.5 IVMM7000C

6.5.1 Properties_________________________________________________________________________62

6.5.1.1 IPAddress Property (Read/Write) ___________________________________________________________ 62

6.5.1.2 CommandPort Property (Read/Write) ________________________________________________________ 62

6.5.1.3 DataPort Property (Read/Write) _____________________________________________________________ 62

6.5.1.4 LastErrorCode Property (Read/Write) ________________________________________________________ 63

6.5.1.5 CommandPortTimeout Property (Read/Write)__________________________________________________ 63

6.5.1.6 DataPortTimeout Property (Read/Write) ______________________________________________________ 64

6.5.2 Connection Methods_________________________________________________________________65

6.5.2.1 Open Method ___________________________________________________________________________ 65

6.5.2.2 Close Method ___________________________________________________________________________ 65

6.5.3 Action - Status Group________________________________________________________________66

6.5.3.1 Arm Method____________________________________________________________________________ 66

6.5.3.2 Disarm Method _________________________________________________________________________ 66

6.5.3.3 StartScanning Method ____________________________________________________________________ 67

6.5.3.4 StopScanning Method ____________________________________________________________________ 67

6.5.3.5 ControlManualRecording Method ___________________________________________________________ 68

6.5.3.6 ControlOnlineDataTransfer Method _________________________________________________________ 68

6.5.3.7 GetSystemState Method___________________________________________________________________ 69

6.5.3.8 GetSyncStatus Method____________________________________________________________________ 69

6.5.3.9 SynchronizeNetworkedScanners Method______________________________________________________ 70

6.5.3.10 StartSynchronizedScanning Method ________________________________________________________ 71

6.5.4 Configuration Group ________________________________________________________________72

6.5.4.1 ConfigureTimeBasedRecording Method ______________________________________________________ 72

6.5.4.2 ConfigureTimeBasedRecordingStartandStop Method ____________________________________________ 72

6.5.4.3 ConfigureManualRecording Method _________________________________________________________ 73

6.5.4.4 SetChannelRecordingGroup Method _________________________________________________________ 74

6.5.4.5 SetLimitType Method ____________________________________________________________________ 74

6.5.4.6 SetLimitsBasedRecordingType Method_______________________________________________________ 75

6.5.4.7 ConfigureLimitsBasedRecording ____________________________________________________________ 75

6.5.4.8 ConfigureLimitCondition method ___________________________________________________________ 76

6.5.4.9 SetLimitConditionCount Method____________________________________________________________ 77

6.5.4.10 AssignLimitToChannel Method____________________________________________________________ 78

6.5.4.11 ConfigureGlobalLimit Method_____________________________________________________________ 78

6.5.4.12 ConfigureScan Method __________________________________________________________________ 80

6.5.4.13 ConfigureStrainGageCardExcitation Method _________________________________________________ 81

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

____________________________________________________________________________57

7000 I

NSTRUMENT DRIVER

___________________________________________________________________59

__________________________________________________________________________59

_____________________________________________________________________61

ONTROL INTERFACE DESCRIPTION

_________________________________________________________57

__________________________60

_______________________________________________62

Page 3 of 142

6.5.4.14 ConfigureStrainGageChannelBridgeSettings Method ___________________________________________ 81

6.5.4.15 ConfigureHighLevelCardExcitation Method __________________________________________________ 82

6.5.4.16 ConfigureThermocoupleChannel Method ____________________________________________________ 82

6.5.4.17 ConfigureLVDTCardExcitation Method _____________________________________________________ 83

6.5.4.18 ConfigureLVDTChannelInputConnections Method ____________________________________________ 84

6.5.4.19 SetDefaultFilter Method__________________________________________________________________ 84

6.5.4.20 SetFIRFilterCoefficients Method ___________________________________________________________ 85

6.5.4.21 SetDateTimeMethod ____________________________________________________________________ 86

6.5.4.22 ConfigureOnlineDataTransfer Method_______________________________________________________ 86

6.5.4.23 SetScannerNetworkConfiguration Method ___________________________________________________ 87

6.5.4.24 SetBoxID Method ______________________________________________________________________ 88

6.5.5 Data _____________________________________________________________________________89

6.5.5.1 GetStaticADCReading Method _____________________________________________________________ 89

6.5.5.2 GetLastDataFileInformation Method _________________________________________________________ 89

6.5.6 Utilities___________________________________________________________________________91

6.5.6.1 GetControlModuleInformation Method _______________________________________________________ 91

6.5.6.2 GetFreeSpace Method ____________________________________________________________________ 92

6.5.6.3 GetCardStatusMethod ____________________________________________________________________ 92

6.5.6.4 DetectCards Method______________________________________________________________________ 93

6.5.6.5 GetCardInformation Method _______________________________________________________________ 94

6.5.6.6 Flash System LEDs Method________________________________________________________________ 95

6.5.6.7 ResetCard Method _______________________________________________________________________ 95

6.5.6.8 ShuntCalEnable Method __________________________________________________________________ 96

6.5.6.9 RemoteCalEnable Method _________________________________________________________________ 96

6.5.6.10 ClearErrors Method _____________________________________________________________________ 97

6.5.6.11 GetErrorMessage Method ________________________________________________________________ 97

6.5.6.12 RetrieveFile Method_____________________________________________________________________ 98

6.5.6.13 RetrieveLastDataFile Method _____________________________________________________________ 98

6.5.6.14 ListFiles Method _______________________________________________________________________ 99

6.5.6.15 DeleteFile Method ______________________________________________________________________ 99

6.5.6.16 DeleteLastDataFile Method ______________________________________________________________ 100

6.5.6.17 CancelFileTransferMethod_______________________________________________________________ 100

6.6 IVMM7000D

6.6.1 Properties________________________________________________________________________101

6.6.1.1 BytesTransferred Property (Read/Write) _____________________________________________________ 101

6.6.1.2 PercentComplete Property (Read/Write) _____________________________________________________ 101

6.6.1.3 TotalBytes Property (Read/Write) __________________________________________________________ 102

6.6.1.4 ErrorStatus Property (Read/Write) __________________________________________________________ 102

6.6.1.5 TransferComplete Property (Read/Write) ____________________________________________________ 102

ATATRANSFERSTATUS INTERFACE DESCRIPTION

___________________________________101

7 LOW-LEVEL COMMAND SET ____________________________________________________________103

7.1 C

ARD AND CHANNEL MASK NOTATION

7.2 C

OMMAND/QUERY SYNTAX

7.3 R

ESPONSE SYNTAX

7.3.1 Example Responses ________________________________________________________________105

7.4 C

OMMAND DESCRIPTIONS

7.4.1 Action Group _____________________________________________________________________106

7.4.1.1 Start Scanning Command_________________________________________________________________ 106

7.4.1.2 Stop Scanning Command _________________________________________________________________ 106

7.4.1.3 Start Manual Recording Command _________________________________________________________ 106

7.4.1.4 Stop Manual Recording Command _________________________________________________________ 106

7.4.1.5 Arm Command_________________________________________________________________________ 107

7.4.1.6 Disarm Command ______________________________________________________________________ 107

7.4.1.7 Start Online Data Transfer ________________________________________________________________ 107

7.4.1.8 Stop Online Data Transfer ________________________________________________________________ 107

7.4.1.9 Synchronize Networked Scanners __________________________________________________________ 108

7.4.1.10 Start Scanning on Networked Scanners _____________________________________________________ 108

7.4.2 Recording Group __________________________________________________________________109

7.4.2.1 Manual Recording Mode _________________________________________________________________ 109

7.4.2.2 Set Pre-trigger Buffer Size for Manual Recording Command _____________________________________ 109

7.4.2.3 Set Time-Based Recording Mode Command __________________________________________________ 110

7.4.2.4 Set Time-Based Recording Count Command _________________________________________________ 110

7.4.2.5 Set Time-Based Recording Delay Command__________________________________________________ 111

7.4.2.6 Set Time-Based Recording Skip Count Command _____________________________________________ 111

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

_____________________________________________________________________104

______________________________________________________________104

_______________________________________________________________106

_____________________________________________________103

Page 4 of 142

7.4.2.7 Set Time-Based Recording Burst Count Command _____________________________________________ 112

7.4.2.8 Set Time-Based Recording Burst Skip Count Command_________________________________________ 112

7.4.2.9 Set Limits-Based Recording Setting ________________________________________________________ 113

7.4.2.10 Set Limits-Based Recording Mode Command ________________________________________________ 113

7.4.2.11 Set Limits-Based Recording Skip Count Command ___________________________________________ 114

7.4.2.12 Set Limits-Based Recording Burst Count Command ___________________________________________ 114

7.4.2.13 Set Limits-Based Recording Burst Skip Count Command_______________________________________ 115

7.4.3 Scan Group ______________________________________________________________________116

7.4.3.1 Set Scan Rate Command _________________________________________________________________ 116

7.4.3.2 Create Scan List Command _______________________________________________________________ 116

7.4.3.3 AutoStop Command_____________________________________________________________________ 117

7.4.3.4 Get Last Data File Info___________________________________________________________________ 117

7.4.3.5 Set Box ID from Scan Header Command ____________________________________________________ 118

7.4.3.6 Set Project Name to Scan Header File Command ______________________________________________ 118

7.4.3.7 Set Scan Session Descriptor to Scan Header File Command ______________________________________ 118

7.4.3.8 Set Scan Session GUID to Scan Header File Command _________________________________________ 119

7.4.3.9 Set Scan Session IP Address to Scan Header File Command _____________________________________ 119

7.4.3.10 Set the Size of the Scan Buffer____________________________________________________________ 119

7.4.4 Limits Group _____________________________________________________________________120

7.4.4.1 Set Limit Type Command ________________________________________________________________ 120

7.4.4.2 Set Number of Limit Event Conditions Command _____________________________________________ 120

7.4.4.3 Set Limit Event Condition Command _______________________________________________________ 121

7.4.4.4 Set Lower Limit Value Command __________________________________________________________ 121

7.4.4.5 Set Upper Limit Value Command __________________________________________________________ 122

7.4.4.6 Set Pre-trigger Buffer Size Command _______________________________________________________ 122

7.4.4.7 Set Post-trigger Buffer Size Command ______________________________________________________ 122

7.4.4.8 Ignore or Accept Sync (Global) Limits ______________________________________________________ 123

7.4.4.9 Set Pre-trigger Buffer Size Command for Sync (Global) Limits ___________________________________ 123

7.4.4.10 Set Post-trigger Buffer Size Command for Sync (Global) Limits _________________________________ 123

7.4.5 Card Group ______________________________________________________________________124

7.4.5.1 Get Card Information Command (AIM/Interface Card)__________________________________________ 124

7.4.5.2 Set Excitation Command _________________________________________________________________ 125

7.4.5.3 Get Free Space Command ________________________________________________________________ 125

7.4.5.4 Card Status ____________________________________________________________________________ 126

7.4.5.5 Card Reset ____________________________________________________________________________ 126

7.4.5.6 Excitation Output Enable/Disable __________________________________________________________ 127

7.4.5.7 Aim Temperature Sensor Query____________________________________________________________ 127

7.4.5.8 Set LVDT Excitation Frequency ___________________________________________________________ 127

7.4.6 Channel Group____________________________________________________________________128

7.4.6.1 Asynchronous Read A/D Converter Command ________________________________________________ 128

7.4.6.2 Set Channel Recording Group Command ____________________________________________________ 128

7.4.6.3 Set FIR Filter Command _________________________________________________________________ 128

7.4.6.4 Shunt Calibration Resistor Enable / Disable __________________________________________________ 129

7.4.6.5 Dummy Resistor Selection________________________________________________________________ 129

7.4.6.6 Enable Half-Bridge _____________________________________________________________________ 129

7.4.6.7 Remote Calibration Resistor Enable Disable __________________________________________________ 130

7.4.6.8 Set / Query Thermocouple Type ___________________________________________________________ 130

7.4.6.9 Assign a Limit Event Condition to a Channel(s) _______________________________________________ 131

7.4.6.10 Set Default Filter Command______________________________________________________________ 131

7.4.6.11 Set LVDT Demodulator Source ___________________________________________________________ 132

7.4.7 File Group _______________________________________________________________________133

7.4.7.1 Retrieve File___________________________________________________________________________ 133

7.4.7.2 List Files______________________________________________________________________________ 134

7.4.7.3 Delete File ____________________________________________________________________________ 134

7.4.7.4 Cancel File Transfer_____________________________________________________________________ 135

7.4.7.5 List Files in Control Module ______________________________________________________________ 135

7.4.7.6 Retrieve File from Control Module _________________________________________________________ 135

7.4.7.7 Delete File from Control Module ___________________________________________________________ 136

7.4.7.8 Verify the Checksum of a Control Module File ________________________________________________ 136

7.4.8 System Group _____________________________________________________________________137

7.4.8.1 Set Date/Time _________________________________________________________________________ 137

7.4.8.2 Set IP Configuration Information___________________________________________________________ 138

7.4.8.3 Get Free Space Command ________________________________________________________________ 138

7.4.8.4 Configure Online Data ___________________________________________________________________ 139

7.4.8.5 Define Scanner’s Network Configuration ____________________________________________________ 139

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 5 of 142

7.4.8.6 Verify Sync Cable Status _________________________________________________________________ 140

7.4.8.7 Card Detect ___________________________________________________________________________ 140

7.4.8.8 Clear Errors ___________________________________________________________________________ 140

7.4.8.9 Get Control Module Information Command (Control Module) ____________________________________ 141

7.4.8.10 Display Flashing LED Sequence __________________________________________________________ 141

7.4.8.11 Clear Errors __________________________________________________________________________ 142

7.4.8.12 System Status Query ___________________________________________________________________ 142

7.4.8.13 Get Error Message from Error Code _______________________________________________________ 142

8 WARRANTY ____________________________________________________________________________143

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 6 of 142

1 INTRODUCTION

1.1 Overview

The System 7000 data acquisition instrument (scanner) may be remotely programmed via an Ethernet

(TCP/IP) interface. Any high-speed, modern personal computer supporting this interface may be used to

program the System 7000 and, as a result, the scanner can be a part of an automated instrumentation

system.

This manual assumes that you are familiar with the operation of the System 7000 scanner. Please refer to

the “System 7000 Instruction Manual” for information on specifications and operation. The instruction

manual also contains information on setting up the network connections and configuring TCP/IP and

UDP.

1.2 Programming Options

This manual describes three different methods of programming the System 7000 scanner.

National Instruments LabVIEW instrument driver

ActiveX automation interface

Low-level TCP commands

How do I choose which method is best for my application?

The LabVIEW instrument driver should be used if you are writing software using the NI

LabVIEW graphical programming language. The driver is compliant with the National

Instruments instrument driver standards.

The ActiveX automation interface is recommended for use in most applications developed in the

Microsoft Windows environment. This includes programming environments such as Microsoft

Visual Basic, Microsoft Visual C++ and C#, National Instruments LabWindows/CVI, and

Embarcadero Delphi. The ActiveX application program interface (API) simplifies your

programming by bundling related commands into a single method, managing critical timing, and

handling low-level requirements (such as building and parsing) of the TCP commands.

The low-level TCP commands should be used if your programming environment does not support

the ActiveX automation interface or if your application requires more flexibility. It is highly

recommended that you use either the LabVIEW instrument driver or the ActiveX automation

interface. Though documented here, use of the low-level commands is not supported.

1.2.1 StrainSmart and DCOM

StrainSmart is a software application, provided by Vishay Micro-Measurements, that provides a

comprehensive user interface for configuring the System 7000 and managing data collection. StrainSmart

shares fully-scaled data with other applications via DCOM. If you wish to use StrainSmart and have a

separate, custom application for monitoring data, it is recommended that you use the DCOM interface.

Please refer to the document “Overview of StrainSmart Automation Server” for more information on

using the DCOM interface. This document is found on the “Programmer’s Reference Kit” CD.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 7 of 142

1.3 Definition of Terms

Scanning

The System 7000 is said to be scanning after it has completed an “arm/start”

sequence and it is actively acquiring data.

Scan

Scan ID

Scan Rate

I/O Card or AIM

Card

StrainSmart

A scan in the System 7000 refers to a single group of data that is acquired

simultaneously. For example, if you have 2 cards in your scanner (with 8 active

channels per card), a single scan consists of all 16 readings made at the same point

in time.

Note: Many instruments refer to a single group of simultaneously acquired data as

a “sample”, whereas, a “scan” is a collection of N samples. Notice the difference

in terminology.

The scan identifier is effectively a sequence number for each scan. The first scan

read is given a Scan ID of 1, the second scan has an ID of 2, and so forth. If you

know the scan rate, you then know the elapsed time at which the scan occurred.

(e.g. with a scan rate of 1000 scans/sec, scan 1 occurs at 0 mSec, scan 2 at 1mSec,

scan 3 at 2mSec, etc…)

The rate at which scans are acquired. This can also be thought of as the sampling

rate.

This refers to a Model 7003-8-A-I Analog Input Cards coupled with either a Model

7003-8-SG Strain Gage Input Card, Model 7003-8-HL High Level Input Card,

Model 7003-8-TC Thermocouple Input Card, or a Model 7003-8-LVDT Input

Card.

StrainSmart is a software application, provided by Vishay Micro-Measurements,

that provides a comprehensive user interface for configuring the System 7000 and

managing data collection.

1.4 Document Notation and Conventions

1.4.1 Numbering Notation

Hexadecimal values are indicated by the prefix 0x, binary values by the prefix 0b, and decimal values

have no prefix.

For example,

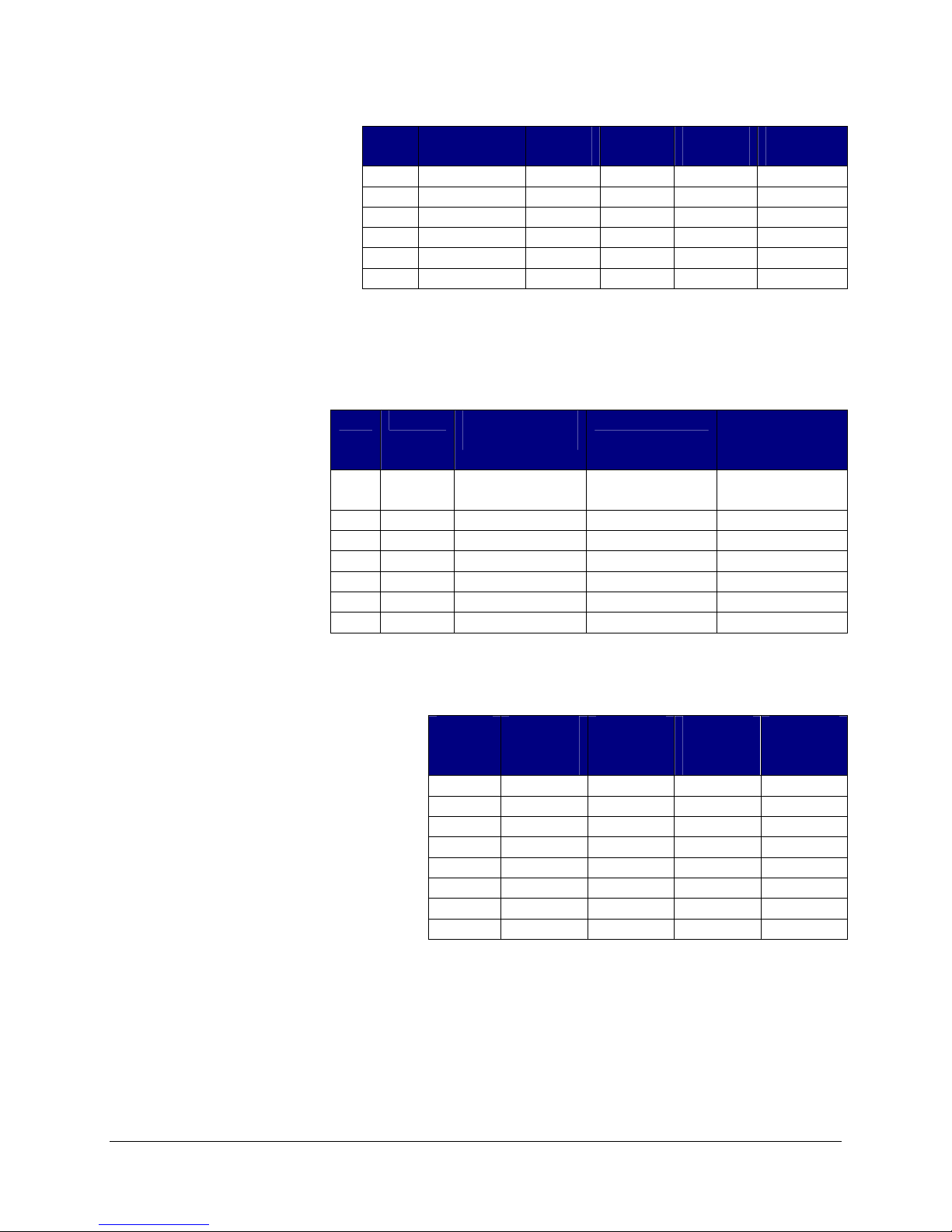

Decimal Hexadecimal Binary

10 0x0A 0b00001010

Table 1 – Numbering Notation

1.4.2 Referenced VIs, Methods, and Commands

Most sections in the Programming Overview section include a table similar to the one shown below. This

table shows the commands (or VIs or methods) that are relevant to the section.

LabVIEW Control Manual Recording VI

Active X ControlManualRecording method

Low-level Start Manual Recording command

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Stop Manual Recording command

Page 8 of 142

1.5 Registered Trademark Notices

Windows, Windows Visual Basic, Windows Visual C++, and Windows Visual C# are registered

trademarks of Microsoft Corporation in the United States and other countries. LabVIEW and

LabWindows/CVI are registered trademarks of National Instruments, Inc (NI) in the United States and

other countries. Delphi is a registered trademark of Embarcadero Technologies, Inc.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 9 of 142

2 PROGRAMMING OVERVIEW

2.1 Communicating with the System 7000

Detailed instructions on setting up the network connections and the TCP/IP and UDP settings are found in

the “System 7000 Instruction Manual”. This document describes the network communications from a

programming standpoint.

The System 7000 uses four communication ports; two for TCP communication and two for UDP

broadcasts. The host PC (via your program) must establish a connection to one or more of these ports.

Port Description

Command Port The TCP port used to transmit commands to the scanner and

receive command responses from the scanner.

File Data Port The TCP port used by the scanner to download files.

Real-time Data Port The UDP port number used to broadcast real-time data.

Event/Status Port The UDP port number used to broadcast messages containing

status or error information.

Table 2 – Communication Ports

For additional information on the TCP/IP and UDP protocols, the Internet Engineering Task Force (IETF)

is the definitive source of information. They are located at http://www.ietf.org. Some documents of

particular interest are:

IETF RFC 791: Internet Protocol (http://www.ietf.org/rfc/rfc791.txt)

IETF RFC 768: User Datagram Protocol (http://www.ietf.org/rfc/rfc768.txt)

Note: A System 7000 scanner is capable of generating a significant amount of network traffic when

broadcasting real-time data; therefore, it is important to carefully consider the network architectural

design.

2.2 Accessing Multiple Scanners (Synchronization)

It is possible to access multiple scanners with a single application. However you must establish a unique

network connection to each scanner. Individual scanners may operate independently or be synchronized

with each other (i.e. they perform simultaneous sampling because their analog-to-digital converter clock

signal is shared via synchronization cables). Synchronization is discussed in detail in the “System 7000

Instruction Manual”.

If your application does not require simultaneous sampling, it will simplify your programming (and

physical setup), if you leave your scanners unsynchronized. If you choose to synchronize your scanners,

they are referred to as being “networked” together. This should not be confused with the Ethernet

network. One scanner in the “network” must be designated as the master scanner. There is a special

command set that deals with configuring and starting data collection on synchronized scanners.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 10 of 142

2.3 System States

The System 7000 scanner has eight states.

State Description

Idle The system is waiting for commands.

Armed The system is armed and waiting for a signal to begin scanning.

Scanning The system is collecting data

Calibrating The system is calibrating.

Uploading The system is uploading data to the host.

Downloading The system is downloading data from the host PC. (internal use only)

Updating Flag The system is updating firmware. (internal use only)

Maintenance Mode The system is performing a maintenance-level command.

Table 3 – System States

2.4 Command Overview

The following chart shows the System 7000 command list broken down by functional group. It lists the

required state for each command.

If you are using the LabVIEW instrument driver or the ActiveX interface you will find that many of these

commands have been bundled into a single “vi” or method,

Command

Group

Card

Get Card Information Idle, Armed, Scanning

Set Excitation (Strain Gage, High Level, LVDT) Idle

Excitation Output Enable/Disable (Strain Gage, High Level,

Get Free Space on Compact Flash Idle, Armed, Scanning

Get Card Status Idle, Armed, Scanning,

Card Reset Idle

Set/Query LVDT Excitation Frequency (LVDT) Idle

Query Temperature Sensor Idle

Channel

Read the A/D Converter Idle

Set Channel Recording Group Idle

Set FIR Filter Idle

Set Filter to Default Idle

Shunt Calibration Resistor Enable/Disable (Strain Gage) Idle

Remote Calibration Resistor Enable/Disable (Strain Gage) Idle

Half Bridge Enable/Disable (Strain Gage, LVDT) Idle

Select Half Bridge Dummy Resistor (Strain Gage) Idle

Set/Query Thermocouple Type Idle

Assign a Limit Event Condition to a Channel Idle

Set LVDT Demodulator Source (LVDT) Idle

Recording

Manual Recording Mode Idle

Set Pre-Trigger Buffer Size for Manual Recording Idle

Set Time-Based Recording Mode Idle

Set Time-Based Recording Count Idle

Set Time-Based Recording Delay Idle

Set Time-Based Recording Skip Count Idle

Set Time-Based Recording Burst Count Idle

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Command Valid State

Idle

LVDT)

Calibrating

Idle

Page 11 of 142

Limits-Based Recording Setting Idle

Set Limits-Based Recording Mode Idle

Set Limits-Based Recording Skip Count Idle

Set Limits-Based Recording Burst Count Idle

Set Limits-Based Recording Burst Skip Count Idle

Scan

Set Scan Rate Idle

Create Scan List Idle

Set AutoStop Idle

Get Last Data File Information Idle

Set Scanner ID in Scan Header File Idle

Set Project Name in Scan Header File Idle

Set a Descriptor in Scan Header File Idle

Set a GUID in Scan Header File Idle

Set a IP Address in Scan Header File Idle

Set the Size of the Scan Buffer Idle

Limits

(Recording)

Set Limit Type Idle

Set Number of Limit Event Conditions Idle

Set Limit Event Condition Idle

Set Lower Limit Value Idle

Set Upper Limit Value Idle

Set Pre-Limit Buffer Size Idle

Set Post-Limit Buffer Size Idle

Ignore/Accept Sync (Global) Limits Idle

Set Pre-Limit Buffer Size for Sync (Global) Limits Idle

Set Post-Limit Buffer Size for Sync (Global) Limits Idle

System

Set Date/Time Idle

Get Free Space on Compact Flash on Control Module Idle

Configure Online Data Idle, Scanning

Define Scanner’s Network Configuration Idle

Verify Sync Cable Status Idle

Card Detect Idle

Clear Errors Idle

Get Control Module Information Command Idle

Display Flashing LED Sequence Idle

System Status Query ALL

Convert System Error Code to Text Idle, Armed, Scanning

Action

Arm Idle

Disarm Armed

Start Scaning Armed

Stop Scanning Scanning

Start Manual Recording Scanning

Stop Manual Recording Scanning

Start Online Data Transfer Scanning

Stop Online Data Transfer Scanning

Synchronize Network Scanners Armed

Start Scanning on Networked Scanners Scanning

File

Retrieve File from AIM Card Idle

List Files on AIM Card Idle

Delete File on AIM Card Idle

Cancel File Transfer Uploading

List Files on Control Module Idle

Retrieve File from Control Module Idle

Delete File from Control Module Idle

Table 4 – Command List

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 12 of 142

2.5 Debugging Tips

A packet sniffer (or analyzer) program is useful for monitoring the TCP and UDP traffic to and

from your System 7000(s).

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 13 of 142

3 PROGRAM LAYOUT

This section describes common commands and techniques for programming the scanner. It does not

include all possible commands or scenarios. Refer to the documentation for your selected programming

methodology for a complete listing of capabilities.

There are two standard methods of acquiring data from channels on the scanner. You can use both

methods of data acquisition in a single application.

1 – Scanning

Scanning is the process of arming the system and starting the acquisition of multiple channels at

the same scan rate.

Why choose scanning?

You wish to sample from multiple channels simultaneously

To record the data directly onto the System 7000 scanner

Your application requires high scan rates

You wish to monitor real-time data broadcast from the scanner

2 – Single-Point Reads

Single-point reads are a direct read of the analog-to-digital converter for a single channel.

Why choose single point reads?

You have a static system (low scan rate)

There is no need to read from more than one channel simultaneously.

Simplifies programming

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 14 of 142

3.1 Overview of Program Layout - Scanning

Figure 1 shows the flow of a typical program accessing the System 7000 scanner and performing

scanning.

Idle State

Idle State

Idle State

Armed State

Connect to System and

Validate

Perform Configuration

Arm

Start Scanning

Yes

Scanning State

Idle State

(Uploading State when

No

Data is transferred)

Idle State

Scanning

(Acquiring Data)

Stop Scanning

Download Recorded Data

(optional)

Decode and Scale

Recorded Data

(optional)

Acquire More

Data?

No

UDP Data

Disconnect from

Scanner

Monitor Real-Time Data

(optional)

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Yes

Change

Configuration?

Figure 1 – Program Layout (Scanning)

Page 15 of 142

3.2 Overview of Program Layout – Single Channel Reads

Figure 2 shows the flow of a typical program accessing the System 7000 scanner and performing single

channel readings (no scanning is performed).

Idle State

Connect to System and

Validate

Idle State

Perform Configuration

Idle State

Perform a Single Reading

on One or More Channels

Yes

NO

Scale Reading (optional)

Acquire More

Data?

Yes

Change

Configuration?

Figure 2 – Program Layout (Single Channel Reads)

No

Disconnect from

Scanner

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 16 of 142

3.3 Establishing a Connection to the Scanner

The first step in programming the System 7000 scanner is connecting to one or more of its TCP and UDP

ports.

TCP Command Port

You must connect to the command port in order to send commands to and receive responses

from the scanner.

You do not need to connect to this port if you are planning on using StrainSmart to control

the scanner and you only wish to perform monitoring of the UDP data.

TCP Data Port

Connection to this port is required if you wish to download file data or directory listings from

the scanner.

If you are not recording data on the scanner (i.e. you are only monitoring real-time data) or if

you do not wish to download files you do not have to connect to this port.

UDP Real-time (Online) Data Port

You must set your program up as a listener on the multicast broadcast from the System 7000

if you wish to monitor real-time data.

If you are not monitoring real-time data, you can ignore this data port.

UDP Event Port

You must set your program up as a listener on the multicast broadcast from the System 7000

if you wish to receive event, status, and error messages from the Scanner.

If you don’t wish to receive these messages, ignore this port. It is not required to receive

status and error messages via broadcast as you may query the system for status information

via a TCP command.

Information on configuring the system network connections is contained in the “System 7000 Instruction

Manual”. You may connect to more than System 7000 scanner in a single application.

Programming tips:

1) If you cannot establish TCP connection with a scanner, verify that you can successfully “Ping”

the IP address. If you cannot communicate with the scanner with the “Ping” command, your

program will be unable to communicate as well.

2) If you still cannot establish communication, verify that no other application is currently

connected to the scanner (such as StrainSmart or the System Calibration utility).

LabVIEW Connection to the scanner is done when you pass the VISA

Active X Connection to the scanner is done by setting the, IPAddress

Low-level Varies by language and environment

resource name of the command and data ports to the

Initialize VI.

CommandPort and DataPort properties then calling the

Open() method.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 17 of 142

3.4 System Validation

After you have successfully connected with the System 7000 you may wish to confirm the connection by

validating that you are, in fact, connected to a System 7000.

LabVIEW Use the ID Query parameter to the Initialize VI to

Active X The Open() method will automatically verify the connection

Low-level Verify the identifier string in the Get Control Module

automatically perform a check. Or you may call the Query

System Information VI.

or you may call the GetSystemInformation() method.

Information command.

3.5 Configuration

3.5.1 System Level Configuration

Certain system-level commands are useful (but not required) as part of configuration.

Set the System 7000 date and time:

This should be done as part of the system startup. For closest correlation with the personal

computer clock this can also be done as part of configuration before the system is armed.

LabVIEW Use the SetDateandTime parameter to the Initialize vi to

Active X SetDateTime method

Low-level Set Date/Time command.

Clear Errors:

Clears active card and system errors. It does not delete or clear the error log files.

LabVIEW Use the ClearErrors parameter to the Initialize vi to

Active X ClearErrors method

Low-level Clear Errors command.

Detect Cards:

Provides a listing of the slot locations where an I/O card is detected.

LabVIEW Detect Cards VI

Active X DetectCards method

Low-level Card Detect command

automatically set the date and time. You may also call the

Set Data and Time VI.

automatically clear errors. You may also call the Clear All

Errors VI.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 18 of 142

3.6 Card-level Configuration

Card-level configuration commands are performed on an individual I/O card. Any settings are applied to

all channels on the card. Instructions on how to determine the appropriate values for the settings is

beyond the scope of this manual, see the “System 7000 Instruction Manual”, the StrainSmart help system,

or contact the Vishay Micro-Measurements application engineering department for assistance.

All Cards

Query Card Type: If you have a scanner with a variety of cards, you may wish to query the

system to determine which card type (strain gage, high level, thermocouple, or LVDT) is in

each slot.

LabVIEW Query Card Information VI

Active X GetCardInformation method

Low-level Get Card Information command

Reset the Card: Resets the configuration values to the default state.

LabVIEW Use the ResetAimCards parameter to the Initialize vi to

Active X ResetCard method.

Low-level Reset Card command

Programming tip: This command should be used to set a card (and its channels) back to

the default states. This can be a useful shortcut in your program.

Strain Gage Cards

Configure the excitation settings.

LabVIEW Configure Strain Gage Card Excitation VI

Active X ConfigureStrainGageCardExcitation method

Low-level Set Excitation command

High Level Cards

Configure the excitation settings.

LabVIEW Configure High Level Card VI

Active X ConfigureHighLevelCardExcitation method

Low-level Set Excitation command

Thermocouple Cards

No card-level configuration

reset all cards. You may also call the Reset VI.

Excitation Output Enable/Disable command

(The excitation level should be set before the excitation

output is enabled.)

Excitation Output Enable/Disable command

(The excitation level should be set before the excitation

output is enabled.)

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 19 of 142

LVDT Cards

Set the frequency and enable the excitation voltage.

Note: There is interdependence between the excitation state and the demodulator source input

configuration. The System 7000 automatically sets the demodulator source to Positive Reference

when the excitation is disabled.

LabVIEW Configure LVDT Card Excitation VI

Active X ConfigureLVDTCardExcitation method

Low-level Set Excitation Frequency command

Set Excitation command

Excitation Output Enable/Disable command

(The excitation frequency and level commands should be

set before the excitation output is enabled.)

Programming tip: It is common to loop through all 16 (or 4) slots in the scanner. If the slot has a card

inserted, query the type of card, and perform the appropriate card-level configuration.

3.7 Channel-level Configuration

Channel-level commands are performed on an individual channel on the card. Remember there are

typically eight channels on a card and each must be set independently. Instructions on how to determine

the appropriate configuration settings is beyond the scope of this manual, see the “System 7000

Instruction Manual”, the StrainSmart help system, or contact the Vishay Micro-Measurements application

engineering department for assistance.

All Cards

You must assign a filter to each channel. The filter is based on the scan rate (sampling rate) of

the system. It is recommended that you use the default filter for the scan rate, though it is also

possible to enter your own 252 tap filter.

LabVIEW Configure Default Filter VI

Active X SetDefaultFilter method

Low-level Set Default Filter command

Strain Gage Cards

For strain gage cards you must configure the bridge settings.

LabVIEW Configure Strain Gage Channel Bridge Settings VI

Active X ConfigureStrainGageChannelBridgeSettings method

Low-level Enable/Disable Half Bridge command

Dummy Resistor Selection command

High Level Cards

No channel-level configuration

Thermocouple Cards

Define the thermocouple type

LabVIEW Configure Thermocouple Channel VI

Active X ConfigureThermocoupleChannel method

Low-level Set Thermocouple Type command

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 20 of 142

LVDT Cards

Select the demodulator input source.

LabVIEW Configure LVDT Channel Input Connections VI

Active X ConfigureLVDTChannelInputConnections method

Low-level Enable/Disable Half Bridge command

Set LVDT Demodulator Source command

Programming tip: As you are looping through each card in the system, you may embed a loop that

indexes through each channel on the card and perform the channel-level configuration.

3.8 Configuring Scan Information

You must also program the scan rate and the scan list for each scanner. Please refer to the definition of

scan and scan rate.

Scan Rate

Static systems (those whose inputs change slowly) generally use a much lower scan rate than

dynamic systems (those whose inputs change rapidly). You should always attempt to match your

scan rate with the highest rate of change of your inputs.

The System 7000 has a base-10 and a base-2 master clock and you are provided with a selection

of scan rates for both clocks.

The scan rate must be the same for every card and scanner in the network.

Scan List

The scan list defines which channels will be read during scanning. For example if you have 2

cards in your system, you may only wish to take readings from the first channel on each card.

Therefore your scan list will include card 1:channel 1 and card 2:channel 1.

Scan Buffer Size

The scan buffer size defines the number of scans that may be stored in the scan buffer before the

data is written to the card’s compact flash. This effects how many scans may be specified for

pre-triggering.

There is a tradeoff when considering how to size your scan buffer. A larger scan buffer size

allows you to have a larger pre-trigger buffer for use in recording. However, having a smaller

scan buffer reduces the amount of data that may potentially be lost in the event of a catastrophic

power outage (as more data has been offloaded to secure memory). It is recommended to always

use the smallest scan buffer size possible for your application

LabVIEW Configure Scan VI

Active X ConfigureScan method

Low-level Set Scan Rate command

Create Scan List command

Set the Size of the Scan Buffer command

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 21 of 142

3.9 Recording

Each card in the system has its own compact flash card and the card may be configured to store the

sampled data on the compact flash card. This data may be retrieved at the end of the scanning session.

There are three different methods for recording data. You may choose not to record data or combine one

or more of the methods.

3.9.1 Setting up Simple Recording

The most common types of recording are

1. Continuous Time-based Recording: Record all selected channels continuously at the scan rate.

Recording starts automatically when scanning starts and ends when scanning is stopped.

2. Continuous Manual Recording: Record all channels continuously at the scan rate. Recording

starts when a “Start Recording” command is received and stops when the “Stop Recording”

command is received.

Continuous Time-based Recording

To set up the System 7000 scanner for continuous time-based recording perform the following steps.

1. Assign all channels to a single recording group (group A).

2. Configure the time-based recording mode to be “Continuous”.

3. Set the time-based skip count, burst count, and burst skip count to 0.

4. Set the time-based delay and recording count to 0.

LabVIEW Configure Channel Recording Group VI

Active X SetChannelRecordingGroup method

Low-level Set Channel Recording Group command

Continuous Manual Recording

To set up the System 7000 scanner for continuous manual recording perform the following steps.

1. Assign all channels to recording group A.

2. Configure the manual recording mode to be “Continuous”.

3. Set the manual recording “pre-trigger” buffer size to 0.

LabVIEW Configure Channel Recording Group VI

Active X SetChannelRecordingGroup() method

Low-level Set Channel Recording Group command

Configure Time Based Recording VI

Configure Time Based Recording Start and Stop VI

ConfigureTimeBasedRecording method

ConfigureTimeBasedRecordingStartStop method

Set Time-Based Recording Mode command

Set Time-Based Recording Count command

Set Time-Based Recording Delay command

Set Time-Based Recording Skip Count command

Set Time-Based Recording Burst Count command

Set Time-Based Recording Burst Skip Count command

Configure Manual Recording VI

ConfigureManualRecording() method

Set Manual Recording Mode command

Set Pre-trigger Buffer Size for Manual Recording command

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 22 of 142

3.9.2 Advanced Recording Options

3.9.2.1Recording Groups

The System 7000 is capable of assigning every channel on a card to one of four recording groups (A-D).

This may be used as a means to assign different recording rates and configurations to channels. In other

words, even though all channel data is being acquired at the same rate you are capable of storing the data

with a variety of different rates and methods. The default for all channels is an assignment to group A.

Card Channel Group

1

1 A

2 A

3 A

4 A

5 B

6 B

7 B

8 B

2

1 A

2 B

3 C

4 D

5 A

6 B

7 C

8 D

3

1 C

2 C

3 C

4 C

5 D

6 D

7 D

8 D

Table 5

Because your scan rate is selected based upon the inputs with the highest rate of change, you may wish to

use multiple recording groups if you have some inputs that change more slowly. This reduces the amount

of data that is stored and improves system performance. A common scenario is when a system has

thermocouple inputs used to monitor the ambient temperature in addition to strain gage inputs. Because

temperatures may only change 2-3 degrees per hour the thermocouple inputs may be recorded at a slower

rate than the strain gage inputs.

In the figure below four traces are shown, each representing a unique record rate. For simplicity,

assume that only time-based recording is selected. Each point represents a recorded scan.

As an example, a scanner has three cards with the channels assigned

to groups as shown. Each channels assigned to group A is recording

at the scan rate (for example 1000 samples/sec). You may define all

the Group B channels to have a recording rate 0f 500 samples/sec,

Group C of 100 samples/sec, and Group D of 10 samples/sec.

It is recommended that you send the recording configuration for all

groups to all cards; if a card doesn’t have any channels in that group

then the configuration information isn’t used. In this way, all

channels in Group A share the same recording rate, all channels in

Group B share a rate, and so forth, regardless of card.

It is possible, but not recommended, to have the groups configured

differently on each card. This manual assumes that each recording

group is configured identically across all cards. All examples and

discussion are based on this assumption.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 23 of 142

Figure 3 – Example of Recording Groups

LabVIEW Configure Channel Recording Group VI

Active X SetChannelRecordingGroup method

Low-level Set Channel Recording Group command

3.9.2.2 Configuring Time Based Recording

Time-based recording is the type of data recording that is performed based on a time interval.

Group-level Recoding Options

The following recording options are configured based on a recording group (A-D).

Recording Mode

Time-based recording may be disabled (off) or set up to record continuously or intermittently (i.e.

in "bursts").

Off: Time-based recording is disabled

Continuous: When recording continuously, scans are recorded at a fixed rate for the

entire duration of the scan session.

Burst: In burst mode, recording may be scheduled to occur at certain intervals

throughout the scan. For example, you may specify to record a "burst" of 100 scans

every 2 minutes.

Skip Count

The skip count is used when the recording mode is “continuous” or “burst”. The skip count

allows you to specify how many scans to skip between each recorded scan. A value of 0 means

skip none (i.e. record each scan). A value of 1 means record every other scan, a value of 9 means

record every 10th scan, etc… This value is used in both continuous and burst recording modes.

If you would like to think in terms of a recording rate (i.e. record 1 scan every N secs), you can

calculate the number of scans to skip by:

Skip_Count = (Scan_Rate * Desired_Recording_Interval) - 1

For example if your scan rate is 10 scans/sec and you would like to record a scan every 5 seconds:

Skip_Count = (10 * 5) - 1 = 49 scans

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 24 of 142

And an example in different wording, if your scan rate is 2000 scans/sec (2kHz) and you would

like to record at a rate of 10 scans/sec (10Hz):

Skip_Count = (2000 /10) - 1 = 199 scans

Burst Count

The burst count is used when recording in burst mode and allows you to specify how many

recordings to store during each recording burst. It is used in conjunction with the burst skip count.

The burst count can be considered the “number of scans to record during each burst”.

For example, if your scan rate is 100 scans/sec and you would like to record 400 scans during

each burst, the burst count is simply 400.

You may also consider the burst from the perspective of “interval of time” and calculate the

number of scans to record as follows:

Burst_Count = (Recording_Rate * Record_Time)

For example if you have a scan rate of 100 scans/sec and you would like to record data for 5

seconds

Burst_Count = 100 * 5 = 500 scans

Burst Skip Count

This value is used when recording in Burst mode. It allows you to configure the interval between

each burst.

If you would like to schedule recording to occur at a recurring rate, calculate

Burst_Skip_Count = (Scan_Rate * Recording_Interval) –

Burst_Count - 1

For example if your scan rate is 10 scans/sec and you would like to have 2 scans recorded every 5

seconds

Burst_Skip_Count = (10 * 5) – 2 - 1 = 47 scans

LabVIEW Configure Time Based Recording VI

Active X ConfigureTimeBasedRecording method

Low-level Set Time-Based Recording Mode command

Set Time-Based Recording Skip Count command

Set Time-Based Recording Burst Count command

Set Time-Based Recording Burst Skip Count command

How to set up intermittent recording

You may combine the skip count, burst count, and burst skip count to set up intermittent

recording. For example, you have a scan rate of 2 kHz and wish to record at a rate of 1 kHz.

Further you wish to only perform recording for 30 seconds every 5 minutes. In other words, you

will record a 30 second “burst” of data every 5 minutes (300 seconds). That 30 second burst will

have a recording rate of 1000 samples/second. Calculate as follows:

Skip_Count = (2000 / 1000) - 1 = 1 scan

Burst_Count = 2000 * 30 = 60000 scans

Burst_Skip_Count = (2000 * 300) –60000- 1 = 539999 scans

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 25 of 142

Card-Level Recoding Options

The following time-based recording options are configured on a per card basis.

Recording Delay before Start

The number of scans to delay before recording of the data starts. A value of 0 means that the

scanner will start recording at the first scan, likewise, a value of 100 means that the scanner will

start recording at the 100th scan.

If you would like to delay a certain amount of time before recording starts you can calculate the

number of scans required to reach the time by:

Number of Scans to Delay = Scan_Rate * Time_Delay

For example if your scan rate is 10 scans/sec and you would like to delay 5 seconds before

recording starts

Number of Scans to Delay = 10scans/sec * 5 secs = 50 scans

Number of Scans to Record

Specifies the total number of scans to record. A value of 0 indicates that recording will not stop

until scanning stops! A value of 1000 means that you will stop recording after 1000 scans have

occurred. (To clarify, recording stops after the 1000th scan, not after 1000 scans have been

recorded.)

If you would like to record for a certain amount of time, you can calculate the number of scans

required to reach the time by:

Number of Scans to Record = Scan_Rate * Amount_of_Time

For example if your scan rate is 10 scans/sec and you would like to record for 30 seconds

Number of Scans to Record = 10 * 30 = 300 scans

LabVIEW Configure Time Based Recording Start and Stop VI

Active X ConfigureTimeBasedRecordingStartStop() method

Low-level Set Time-Based Recording Delay command

Set Time-Based Recording Count command

3.9.2.3 Configuring Manual Recording

Unlike time-based recording, manual recording does not start automatically. Manual recording on the

scanner starts when a “Start Manual Recording” command is received and ends when a “Stop Manual

Recording” command is received. Your program can tie these commands to a user input, a signal read

from another device, or similar.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 26 of 142

Manual Recording Mode

You have several manual recording mode options. Notice these are performed on a card level

(not a group level).

Off- Disables manual recording on the card

SingleShot- Configures the card to record one reading when a start manual recording

command is received. (There is no need to send a Stop Manual recording command.)

Continuous - Configures the card to record continuously after the manual recording is

started until manual recording is stopped

Manual Recording “Pre-Record” Buffer Size

The System 7000 buffers a defined number of scans. You may specify that when you send

the “Start Manual Recording” command to the scanner you would also like to record some

number of scans that occurred just previously. You must specify the number of “pre-record”

scans that you would like have recorded. For example, you send the “Start Recording”

command based on some external signal. The scanner receives the command when scan N is

being processed. But you want to allow for some amount of lag time between the event that

generated the signal and the “Start Recording” command being sent, so you specify that you

would also like to record the 5 most previous scans. In this case you would also be recording

scans N-5, N-4, N-3, N-2, N-1, as well as N and so on.

If you'd like to think of acquiring XX number of seconds of "pre-trigger" data, use the

following formula to convert time into scans.

NumScans = ScanRate * Time

LabVIEW Configure Manual Recording VI

Active X ConfigureManualRecording method

Low-level Manual Recording Mode command

Set Pre-trigger Buffer Size for Manual Recording command

3.9.2.4 Configuring Limits Recording

Because of the flexibility of our limits recording, this section contains a lot of inter-dependent information.

There are examples at the end of the section that tie much of the material together.

How Limits Work

In the following two figures we will use two channels shown below as green and red traces on a

chart. A purple line through the middle of the chart will represent the threshold above which a

limit condition will satisfied for each channel. Anytime the channel’s trace is above the line that

channel can be said to have satisfied (or tripped) a limit condition.

Figure 4 – Limits

Figure 4 shows when limits are satisfied in yellow.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 27 of 142

Trip Scan

A trip scan is the scan that satisfies a limit when no other limit is active. When a trip scan occurs

it is recorded on all channels regardless of the recording rate. Trip scans are always recorded

because they indicate which scan initiated limits-based recording. Notice how when the channel

represented as a red line crossed the threshold, it satisfied a limit but it did not cause a trip scan.

This is because limits-based recording is already active.

Figure 5 – Limit Trip Scans

Figure 5 shows 'trip scans' as yellow dots.

Defining Limits

In the System 7000 scanner defining limits is a four-step process. First define the limit conditions, next

define how you want the card to respond to a limits condition, then assign a limit condition to a channel,

and, lastly, configure how you want recording to occur based on that limit.

Defining Limit Conditions

The first step is defining a limit conditions table that is sent to each card in the system. The table

can hold up to 50 defined conditions. (Though only incremental limits type use more than 1

condition.) The following parameters are used to define this limit condition table.

Index

Index of a limit condition in the limit condition table

Test Condition

The test condition defines the test that will activate a limit.

None - This condition does not have a limit assigned.

Greater Than - Trip when the input reading is greater than the upper limit value.

Less Than - Trip when the input reading is less than the lower limit value.

Equal - Trip when the input reading is equal to the upper limit value.

Between - Trip when the input reading is between the two limit values specified.

Outside - Trip when the input reading is outside the range specified by the two limit

values.

Range -This condition is valid only when the Limits Type is set to Range mode. The

limit will be tripped when the input reading is within the specified range as defined

by the increment/decrement values.

Lower Limit

The lower limit value is used in checking the test condition. The lower limit is used by the

Less Than, Between, Outside, and Range conditions. This value is entered in analog-todigital converter counts.

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 28 of 142

Upper Limit

The upper limit value is used in checking the test condition. The upper limit is used by the

Greater Than, Equal, Between, Outside, and Range conditions. This value is entered in

analog-to-digital converter counts.

Strain Gage 1 count = 0.5µε, or 0.25µV/V

High-Level 1 count = 100µV

Thermocouple 1 count = 1µV

LVDT 1 count = 50 µV

Table 6

rms

Number of “Pre-Limit” Scans

The System 7000 buffers a defined number of scans. You may specify that when a limit is

tripped you would also like to record some number of scans that occurred just previously.

You must specify the number of “pre-limit” scans that you would like to have recorded. If

you'd like to think of acquiring N number of seconds of "pre-limit" data, use the following

formula to convert time into scans.

NumScans = ScanRate * Time

Number of “Post-Limit” Scans

You may also specify some number of scans that should be recorded after the limit goes

inactive. If you'd like to think of acquiring N number of seconds of "post-limit" data, use the

following formula to convert time into scans.

NumScans = ScanRate * Time

Table 7 shows that

three limits are

defined.

This table should be

passed to each card

in the scanner. Note:

the indexes must be

assigned sequentially

(i.e. do not skip an index).

Index Condition Lower

Limit

Upper

Limit

Pre-Limit

Scans

Post-Limit

Scans

0 Greater Than not used 1000 100 0

1 Less Than 50 not used 0 0

2 Outside 700 800 0 0

:

:

None not used not used 0 0

None not used not used 0 0

49 None not used not used 0 0

Table 7

LabVIEW Configure Limit Condition VI

Active X ConfigureLimitCondition method

Low-level Set Limit Event Condition command

Set Lower Limit Value command

Set Upper Limit Value command

Set Pre-trigger Buffer Size command

Set Post-trigger Buffer Size command

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 29 of 142

e. This limit type

trigger buffers are valid and are

Defining the Type of Limit (how limit’s are handled by a card)

The Limit Type defines the style of limit handling performed by a card. (The limit type is the

same for all channels on a card.)

None:

Normal:

Limit conditions will not be checked.

Normal limits type allows varying methods of recording.

Examples: Record continuously when my temperature sensor indicates

greater than 100° or record while my strain gage sensor indicates a value

between 800 and 900 µStrain.

Incremental:

Allows limits to be defined with multiple sets of conditions that are

evaluated in a defined sequence. As a limit condition is met, the card

begins checking for the next limit condition in the sequenc

is often used for load or hysteresis testing. The recording type is ignored as

it is assumed to be singleshot. Pre-and postuseful in defining a fixed number of scans to be recorded at each limit.

Examples: Record 1 scan when my load cell indicates a value greater than

100 kilograms, then record 1 scan when my load cell indicates greater than

250 kgs, and finally when greater than 500 kgs.

Range:

In this mode, the card considers the first scan to trip the first limit. When

the input values shift upward or downward by the specified range, the next

limit condition is tripped. This occurs throughout the duration of scanning.

The recording type is ignored as it is assumed to be singleshot. Pre-and

post-trigger buffers are valid and are useful in defining a fixed number of

scans to be recorded at each limit.

Example: Record the first scan, then record 1 scan every time my

transducer sees another 100 kilograms added or removed.

LabVIEW Configure Limits Type VI

Active X SetLimitType method

Low-level Set Limit Type command

Assigning Limit Conditions to a Channel

Assigning the Number of Limit Conditions to a Channel

After you have defined your table of limit conditions, you should assign each limit condition to

one or more channels. The channel that is assigned the condition is the channel whose value is

monitored and compared. You may assign a single limit condition to multiple channels.

If a Normal or Range type limit is active, a channel may only have one limit condition assigned.

So the channel's limit index of 0 may be assigned to any of the 50 definable limit conditions

For Incremental limits, a channel may be associated with up to 50 limit conditions.

(i.e. channel limit indexes 0 through 49 may be assigned to any of the 50 definable limit

conditions). Note: these limits must be assigned sequentially (i.e. no channel limit indexes may

be skipped)

You must also separately define how many limit conditions are assigned to this channel ( 0

through 49).

LabVIEW Assign Limit Condition to Channel VI

Active X AssignLimitToChannel method

Low-level Assign a Limit Event Condition to a Channel command

Configure Number of Limit Conditions VI

SetLimitConditionCount method

Set Number of Limit Event Conditions command

Vishay Micro-Measurements System 7000 Programmer’s Reference Manual

Page 30 of 142

Configuring Limits-based Recording

Configuring the Limits Recording Type

The recording type determines the recording action of a card when a limit condition is

detected and the limits type is set to Normal mode

Off: No recording when limit detected

Record while limit active: Record scans while the limit condition is active.

Recording stops when the limit condition goes inactive. You may use the preand post-limit periods to extend the recording time. (Used with “normal” limit

type.)

Singleshot: Records a single scan when a limit condition goes active. You may

use the pre- and post-limit recording periods to extend the recording time. This

is a convenient way to record a fixed number of scans each time a limit

condition goes active.

Continuous: Recording starts when a limit condition is detected and continues

until scanning stops. You may define a pre-limit recording buffer size, but postlimit recording does not apply. (Used with “normal” limit type.)

LabVIEW Configure Limits Based Recording Type VI

Active X SetLimitsBasedRecordingType method

Low-level Set Limits Based Recording Settings command

Recording Groups

Recording groups are set up similarly to the time-based recording groups, please see that

section for more information.

Group-level Recoding Options

Group-level recording options are set up similarly to the time-based recording groups, please