Page 1

2300 SYSTEM

Signal Conditioning Amplifier

2310B

Oct 2009

Instruction Manual

Vishay Micro-Measurements

P.O. Box 27777

Raleigh, NC 27611

United States

Telephone +1-919-365-3800

FAX +1-919-365-3945

E-mail: vmm.us@vishaymg.com

www.vishaymg.com

130-000137

Page 2

INSTRUCTION MANUAL

MODEL 2310B

SIGNAL CONDITIONING AMPLIFIER

1.0 DESCRIPTION............................................................................................................................................................... 3

1.1 GENERAL........................................................................................................................................................... 3

1.2 SIGNIFICANT FEATURES .............................................................................................................................. 3

2.0 SPECIFICATIONS......................................................................................................................................................... 3

2.1 2310 SIGNAL CONDITIONING AMPLIFIER................................................................................................ 3

2.2 2350 RACK ADAPTER ...................................................................................................................................... 4

2.3 2360 PORTABLE ENCLOSURE....................................................................................................................... 4

3.0 CONTROLS .................................................................................................................................................................... 5

3.1 2310 FRONT PANEL.......................................................................................................................................... 5

3.2 2310 REAR PANEL ............................................................................................................................................ 6

4.0 OPERATING PROCEDURE ........................................................................................................................................ 7

4.1 SETUP AND AC POWER .................................................................................................................................. 7

4.2 GAGE INPUT CONNECTIONS ....................................................................................................................... 7

4.3 MILLIVOLT INPUTS........................................................................................................................................ 8

4.4 WIRING CONSIDERATIONS.......................................................................................................................... 8

4.5 OUTPUT CONNECTIONS................................................................................................................................ 9

4.7 FILTER OUTPUT SELECTOR ...................................................................................................................... 10

4.8 EXCITATION................................................................................................................................................... 10

4.9 AMPLIFIER BALANCE.................................................................................................................................. 11

4.10 BRIDGE BALANCE......................................................................................................................................... 11

4.11 BATTERY TEST .............................................................................................................................................. 11

4.12 GAIN .................................................................................................................................................................. 11

4.13 FILTER.............................................................................................................................................................. 12

4.14 DYNAMIC TESTING ...................................................................................................................................... 13

4.15 TAPE PLAYBACK........................................................................................................................................... 13

4.16 REMOTE-OPERATION RELAYS................................................................................................................. 14

4.17 QUARTER-BRIDGE NONLINEARITY........................................................................................................ 14

5.0 SHUNT CALIBRATION ............................................................................................................................................. 14

5.1 INTRODUCTION............................................................................................................................................. 14

5.2 SHUNT CALIBRATION COMPONENTS IN 2310....................................................................................... 15

5.3 SHUNT CALIBRATION — STRESS ANALYSIS......................................................................................... 15

5.4 TRANSDUCERS............................................................................................................................................... 16

5.5 STANDARD CALIBRATION RESISTORS .................................................................................................. 18

6.0 ACTIVE FILTER ......................................................................................................................................................... 19

6.1 FILTER CHARACTERISTICS ...................................................................................................................... 19

7.0 MAINTENANCE.......................................................................................................................................................... 20

7.1 ADJUSTMENTS ............................................................................................................................................... 20

7.2 BATTERY REPLACEMENT.......................................................................................................................... 22

7.3 COMPONENT REPLACEMENT................................................................................................................... 22

7.4 FUSE REPLACEMENT................................................................................................................................... 23

APPENDIX............................................................................................................................................................................ 23

WARRANTY ........................................................................................................................................................................ 24

Copyright Vishay Micro-Measurements, 1995-2009

All Rights Reserved.

Page 3

Module with Stabilizer Accessory

Complete 10-Channel 2300 System

2310 Signal Conditioning Amplifier

2350 10-Channel Rack Adapter

4-channel System in 2360 Portable Enclosure

- 2 -

Page 4

1.0 DESCRIPTON

2.0 SPECIFICATIONS

1.1 GENERAL

The 2300 Series instruments comprise a versatile multichannel system for conditioning and amplifying low-level

signals from strain gages (or strain gage based transducers)

for display or recording on external equipment. Each 2310B

Signal Conditioning Amplifier is separately powered and

electrically isolated from all others (and can be powered with

a separate line cord), although groups of amplifiers are

normally inserted into a multi-channel rack adapter or

portable enclosure.

The Model 2350 Rack Adapter accepts up to ten 2310B

Amplifiers for mounting in a standard 19-in (483-mm) rack;

the Model 2360 Portable Enclosure accepts up to four 2310B

Amplifiers for more portable use.

Each Model 2310B Amplifier incorporates precision highstability bridge completion resistors and dummy gages, and

four shunt-calibration resistors, and is complete and ready for

use as delivered — only ac power is required via the Portable

Enclosure, Rack Adapter or separate ac line cord. Input and

output connectors are supplied with each amplifier.

1.2 SIGNIFICANT FEATURES

The 2300 Series is designed to provide features essential for

accurate stress analysis data in a broad range of measurement

applications. Principal features include:

• Fully adjustable calibrated gain from 1 to 11 000.

• Accepts all strain gage inputs (foil or piezoresistive),

potentiometers, DCDT’s, etc.

• Bridge excitation from 0.7 to 15Vdc (11 steps) plus 0.2

to 7 Volts continuously variable.

• Input impedance above 100 megohms.

• Two simultaneous buffered outputs: ±10V, ±1.4V (for

tape recorders).

• Wide band operation exceeding 60 kHz, -0.5 dB at all

gains and output levels.

• Four-frequency active 6-pole filter (10 to 10 000 Hz).

• Dual-range (±5000 and ±25000µ ε) automatic bridge

balance, with keep-alive power to preserve balance for

months without external power.

• Dual-polarity two-step double-shunt calibration.

• Optional remote calibration and auto balance reset.

• Playback mode to filter and observe or re-record

previously recorded magnetic tape data.

• And many other convenience features.

All specifications are nominal or typical at +23°C unless

noted. Performance may be degraded in the presence of

high-level electromagnetic fields.

2.1 2310B SIGNAL CONDITIONING AMPLIFIER

INPUT:

Strain gages: quarter, half or full bridge (50 to

1000Ω). Built-in 120Ω and 350Ω dummy gages;

1000Ω dummy capability. See Appendix, page 23.

Transducers: foil or piezoresistive strain gage

types; DCDT displacement transducers;

potentiometers.

EXCITATION:

Eleven settings: 0.7, 1, 1.4, 2, 2.7, 3.5, 5, 7, 10, 12

and 15 Vdc ±1% max. One variable setting : 0.2 to

7 Vdc

Current: 0-100 mA, min, limited at 175 mA, max.

Regulation (0-100 mA ±10% line change): ±0.5

mV ±0.04%, max measured at remote sense points.

(Local sense: -5 mV, typical, @ 100 mA, measured

at plug.)

Remote sense error: 0.0005% per ohm of lead

resistance (350Ω load).

Noise and ripple: 0.05% p-p, max (dc to 10 kHz).

Stability: ±0.02%/°C.

Level: normally symmetrical about ground; either

side may be grounded with no effect on

performance.

BRIDGE BALANCE:

Method: counter-emf injection at pre-amp;

automatic electronic; dual range; can be disabled on

front panel.

Ranges (auto ranging):

±5000µε (±1% bridge unbalance or ±2.5 m V/V),

resolution 2.5µε (0.0012 mV/V).

±25 000µε (±5% bridge unbalance or ±12.5 mV/V),

resolution 12.5µε (0.006 mV/V).

Balance time: 2 seconds, typical.

Manual vernier balance range: 100µε (0.050

mV/V).

Interaction: essentially independent of excitation

and amplifier gain.

Storage: non-volatile digital storage without line

power for up to two years.

SHUNT CALIBRATION:

Circuit (two-level, dual polarity): Single-shunt

(for stress analysis) across any bridge arm,

including dummy gage.

Double-shunt (for transducers) across opposite

bridge arms.

Provision for four dedicated leads to shunt external

arms.

- 3 -

Page 5

CAL circuit selected by switches on p.c. board.

Standard factory-installed resistors (±0.1%)

simulate:

±200 and ±1000µε @ GF=2 across dummy

half bridge;

±1000µε @ GF=2 across dummy gage (120Ω

and 350Ω).

±1 mV/V (double shunt) for 350Ω transducer.

Remote-operation relays (Option Y): four relays

(plus remote-reset relay for bridge balance and

relay for excitation on/off). Each relay requires 10

mA @ 5 Vdc, except excitation on/off 25 mA.

AMPLIFIER

Gain: 1 to 11 000 continuously variable. Direct-

reading, ±1% max. 10-turn counting knob (X1 to

X11) plus decade multiplier (X1 to X1000)

Frequency response, all gains full output:

dc coupled: dc to 125 kHz, -3 dB max.

dc to 55 kHz, -0.5 dB max.

ac coupled: 1.7Hz typ. to 125 kHz, -3 dB max.

Frequency response versus gain, full output:

GAIN

1-11 120 kHz 300 kHz

10-110 90 kHz 230 kHz

100-1100 70 kHz 150 kHz

1000-11000 55 kHz 125 kHz

Input impedance: 100 MΩ, min, differential or

common-mode, including bridge balance circuit.

Bias current: ±40 nA, typical max., each input.

Source impedance: 0 to 1000Ω each input.

Common-mode voltage: ±10V.

Common-mode rejection (gain over X100):

Shorted input: 100dB, min, at dc to 60 Hz;

90 dB, min, dc to 1 kHz;

350Ω balanced input: 90 dB, typical, dc to 1

kHz.

Stability (gain over X100): ±2 µV/°C, max, RTI

(referred to input).

Noise (gain over X100, all outputs):

0.01 to 10 Hz: 1 µV p-p RTI.

0.5 to 125 kHz: 6 µVrms, max, RTI.

FILTER:

Characteristic:

Low-pass active six-pole Butterworth standard.

Frequencies (-3 ±1 dB): 10, 100, 1000 and 10 000

Hz and wide-band.

-

0.5db

-

3 db

Outputs filtered: either one or both (switch-

selected on p.c. board).

AMPLIFIER OUTPUTS:

Standard output: ±10V @ 5 mA, min.

Tape output: ±1.414V (1 Vrms) @ 5 mA, min.

Linearity @ dc: ±0.02%.

Either output can be short-circuited with no effect

on the other.

PLAYBACK:

Input: ±1.414V full scale; input impedance 20 kΩ.

Gain: X1 to tape output; X7.07 to standard output.

Filter selection: as specified above.

Outputs: Both as specified above.

OPERATING ENVIRONMENT:

Temperature: 0° to +50°C.

Humidity: 10 to 90%, non-condensing.

POWER:

105 to 125V or 210 to 250V (switch-selected),

50/60 Hz, 10 watts, max.

Keep-alive supply (for bridge balance): Lithium

3.6V, 1/2AA or equal. Shelf life approximately

two years.

SIZE & WEIGHT:

Panel: 8.75 H x 1.706 W in (222.2 x 43.3 mm).

Case depth behind panel: 15.9 in (404 mm).

Weight: 6 lb (2.7 kg).

2.2 2350 RACK ADAPTER

APPLICATION:

Fits standard 19-in (483-mm) electronic equipment

rack.

Accepts up to ten 2310B Amplifiers. AC line

completely wired.

Wiring for remote calibration with Option Y.

POWER:

115 or 230 Vac switch selected in amplifiers, 50/60

Hz, 100 Watts max.

SIZE & WEIGHT:

8.75 H x 19 W x 19.06 D overall (222 x 483 x 484

mm).

13.5 lb (6.1 kg).

2.3 2360 PORTABLE ENCLOSURE

DESCRIPTION:

Enclosure to accept up to four 2310B Amplifiers.

- 4 -

Page 6

3.0 CONTROLS

AC wiring complete.

Wiring for remote calibration with Option Y.

POWER:

115 or 230 Vac switch selected in amplifiers, 50/60

Hz, 40 Watts max.

SIZE & WEIGHT:

9.06 H x 7.20 W x 18.90 D in

(229 x 183 x 480 mm)

6.75 lb (3.1 kg).

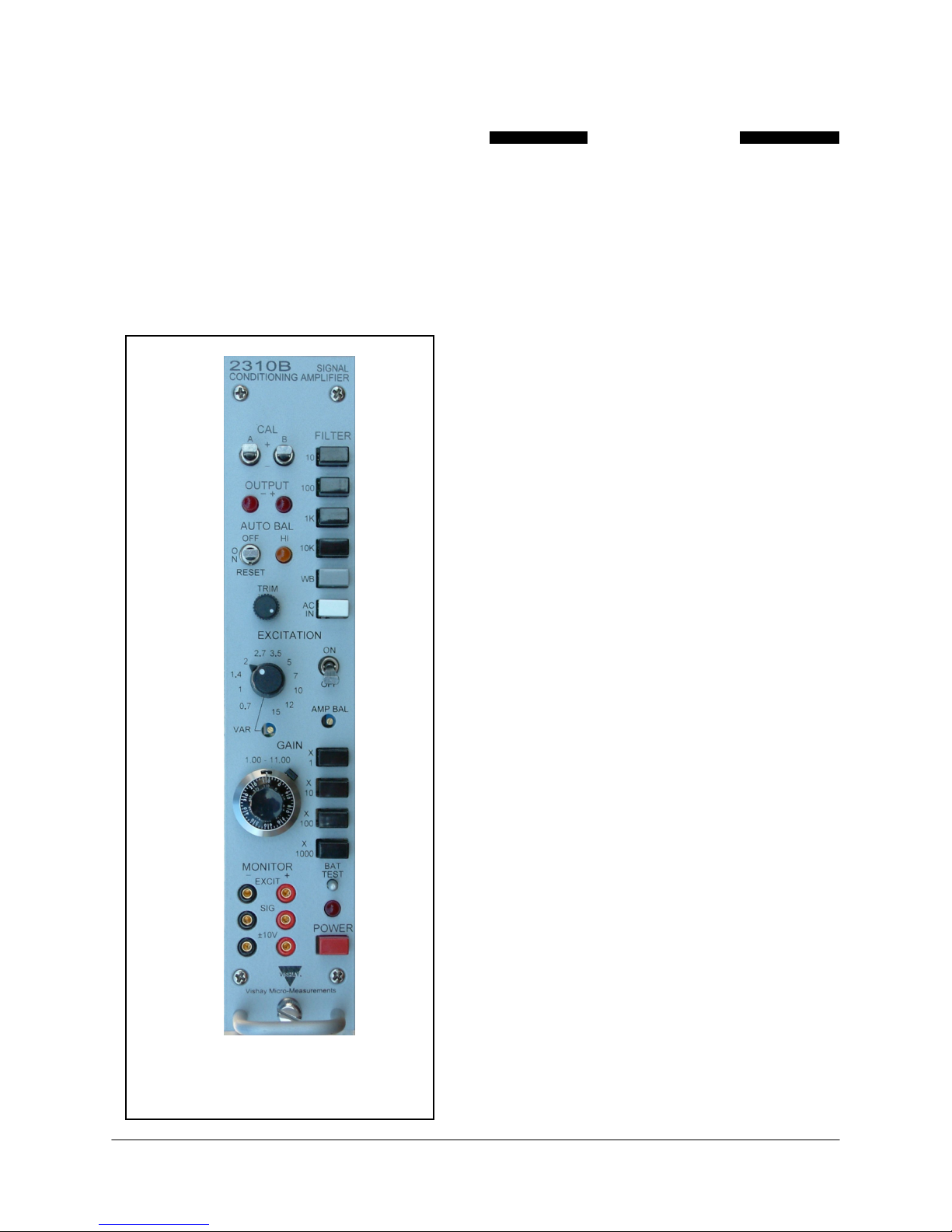

2310B Front Panel

The following functional descriptions are of a general

character for information only. The operating procedure is

covered in Section 4.0.

3.1 2310B FRONT PANEL

CAL Switches: Toggle switches to place shunt-

calibration resistors across arms of the input bridge.

“A” and “B” may simulate different input levels. (See

5.5 Standard Calibration Resistors for standard factoryinstalled resistors.)

OUTPUT Lamps: LED indicators which always

monitor the output. Primarily used to adjust AMP BAL

and check bridge balance. Fully lit with 0.04 volt at ±

10 V Output.

AUTO BAL Controls: The toggle switch has three

positions to control operation of the automatic bridge

balance circuit:

OFF (up) disables the circuit; the amplifier outputs

now represent true unbalance of the input bridge;

stored balance point is retained.

ON (center) enables the automatic bridge balance

circuit.

RESET (momentary down) triggers the automatic

bridge balance circuit to seek a new balance point.

(The prior stored balance point is replaced.)

The “HI” lamp (yellow LED) lights when the automatic

balance circuit is in its high range; it indicates a bridge

unbalance exceeding 1%. If the unbalance exceeds 5%

this lamp will cycle on and off continuously.

TRIM Control: A vernier control to refine bridge

balance when desired. Normally the automatic balance

circuit will achieve balance within several microstrain.

FILTER Buttons: Push buttons to reduce the upper

frequency cut-off (10 to 10 000 Hz) to reject undesired

noise during lower-frequency tests. Normally the “WB”

button would be depressed, achieving wide-band

operation (typically 125 kHz at –3dB).

The “IN” position of the “AC IN” button (alternate

action) ac-couples the amplifier thus eliminating the dc

component of the input signal. (However, modest

bridge balance is still required — see 4.14 Dynamic

Testing.)

EXCITATION Controls: The rotary switch selects the

desired bridge excitation. Most steps approximately

double the power dissipation in the bridge arms.

The toggle switch turns bridge power on or off. (Any

amplifier output in the OFF position is dc amplifier

offset, thermal emf from the bridge, or ac pickup in the

wiring.)

AMP BAL: A trimmer to adjust the amplifier balance

(EXCITATION should be OFF when this is adjusted).

- 5 -

Page 7

GAIN Controls: Amplifier gain is the reading of the

10-turn control (1000 to 11 000) multiplied by the

selected push button (X1 to X1000).

The indicated gain is the gain from the input to the ±10V

Output. At the TAPE Output the gain will be lower by a

fixed factor of 7.07.

The 10-turn counting knob is equipped with a lock that

is engaged by pulling the lever away from the front

panel and then displacing it downward.

MONITOR Jacks: Three pairs of jacks accepting

0.080-in (2-mm) diameter plugs to monitor bridge

excitation (EXCIT), bridge output (SIG) and the

amplifier output (±10V). Except for ±10V return (black

jack), 10K resistors are in series with these jacks to

provide noise isolation.

BAT TEST: A momentary push button to check the

keep-alive batteries for the automatic bridge balance

circuit. (See 4.11 Battery Test.)

POWER Button: An alternate-action push button (and

LED indicator lamp) to turn ac power “on” and “off”.

(Bridge balance is retained even with POWER off or the

amplifier unplugged.)

3.2 2310B REAR PANEL

PLAYBACK Switch: The ON (up) position connects

the adjacent Tape Recorder INPUT coaxial BNC

connector to the input of the filter circuits (if selected on

the front panel) and post amplifiers. Full-scale input is

±1.4V. Both outputs are operable.

NOTE: This recessed switch must be returned to the

NORM position to monitor incoming signals at the

INPUT connector.

±10V Connector: A coaxial BNC connector for the

±10V Output of the amplifier. The ±10V Output is

typically connected to oscilloscopes, DVM’s, analog

multiplexers, etc.

TAPE Connector: A coaxial BNC connector providing

the output normally used with tape recorders. Full scale

is ±1.414V (1 Vrms for sine waves).

INPUT Receptacle: A 15-pin quarter-turn connector to

connect the input circuit to the 2310B. Quarter, half,

and full bridges, potentiometers, or voltage inputs can be

accepted simply by using the appropriate pins; see 4.2

Gage Input Connections for details. Mating plug

supplied.

NOTE: PLAYBACK switch must be set to the NORM

position to monitor incoming signals at the INPUT

connector.

POWER Connector: A male rack-and-panel connector

which supplies ac power in the instrument. Normally, it

engages with a powered connector in the rack adapter;

an individual line cord is available for servicing by

qualified technicians only; see paragraph 4.1e.

Prewired for remote operation of shunt calibration,

bridge excitation, and automatic bridge balance. [See

4.16 Remote-Operation Relay (Option Y).]

2310B Rear Panel

- 6 -

Page 8

4.0 OPERATING PROCEDURE

Prior to taking any readings with the 2310B, each FILTER

and GAIN push-button switch should be exercised several

times for best performance and stability.

4.1 SETUP AND AC POWER: Each 2310B Signal

Conditioning Amplifier has its own power supply and

may be operated as a freestanding unit (see paragraph

4.1e), or one or more 2310B’s may be inserted into the

Model 2350 Rack Adapter or the Model 2360 Portable

Enclosure.

CAUTION: Prior to removing or installing the 2310B

Amplifier or the 2331 Digital Readout into a rack

adapter or enclosure, the ac power cord must first be

unplugged. Refer system setup and all servicing to

qualified technicians. If the 2300 System is used in a

manner that is not in accordance with instructions and its

intended use, the protection provided by the equipment

may be impaired.

4.1a Turn off all 2310B Amplifiers before inserting

them into the rack adapter or cabinet; the red

POWER button should be in the “out” position,

protruding about 1/4 in (6 mm) from the panel.

4.1b Inside of each 2310B, between the rear panel and

transformer, set the AC LINE slide switch to the

nominal ac line voltage to be used (115 or 230V).

Also on the rear panel check that the recessed

PLAYBACK switch is at the NORM (down)

position.

4.1c Install the 2310B Amplifiers into the rack adapter

or cabinet, securing the thumb-screw at the bottom

of each front panel.

4.1d Plug the detachable line cord(s) into the appropriate

2350/2360 receptacle(s).

4.1e To power a freestanding 2310B for only

troubleshooting/servicing by qualified service

personnel, an individual power cord is required.

A non-CE-approved accessory line cord is

available from Vishay Micro-Measurements as part

number 120-001196.

4.1f The line cord should be plugged into an ac

receptacle which has a good earth ground for the

third pin.

NOTE: If the plug on the power cord must be

replaced with a different type, observe the

following color code when wiring the new plug:

Black or brown: High line voltage

White or blue: Low line voltage (“neutral” or

“common”)

Green or green/yellow: Earth ground

4.2 GAGE INPUT CONNECTIONS

It is suggested that the 2310B be turned on (press the red

POWER button) and allowed to stabilize while

preparing the input connectors. To prevent powering the

input bridge circuits at this time, turn the EXCITATION

rotary switch to 0.7V and the toggle switch to OFF.

4.2a Each amplifier uses a separate input plug, which is

supplied. Additional plugs are available from

Vishay Micro-Measurements (see 7.4 Component

Replacement) or from the plug manufacturer or

distributor. Suggested types:

Amphenol/Bendix PT06A-14-15 (SR)

ITT/Cannon KPT06B14-15P

These connectors are designed to MIL-C-26482

and may be available from other manufacturers. As

an aid to the technician, the pin arrangement for the

Input plug is shown in Figure 1.

Figure 1: Input Plug Pin Arrangement

4.2b The basic input arrangements are shown in Figure

2. Note that, except when using an external full

bridge, there must be a jumper in the input plug

connecting pins H and J; this connects the

midpoint of the internal half bridge to the S+

amplifier input. Precision 120Ω and 350Ω dummy

gages are provided in each Model 2310B. If using

a quarter bridge with resistance other than 120Ω,

350Ω, or 1000Ω, use circuit A2 in Figure 2. For

1000Ω quarter bridges, see Appendix.

4.2c When using an external full bridge (especially a

precision transducer), it may be desirable to employ

the remote-sense circuitry provided in the 2310B to

maintain constant excitation at the transducer

regardless of lead resistance. To enable this circuit,

open the right side-cover of the 2310B and raise the

small red SENSE switch to REMOTE (see Figure

4). Connect the sense leads between the transducer

and pins F and G of the INPUT plug as shown in

Figure 2, C2.

4.2d If it is desired to employ shunt-calibration across

one of the external bridge arms, additional wiring

is required to achieve maximum accuracy (see 5.0

Shunt Calibration for details). However, for halfor quarter-bridge inputs, shunting the internal

dummy half bridge or dummy gage is normally

recommended; neither of these circuits requires

additional wiring from that shown in Figure 2.

- 7 -

Page 9

Figure 2: Gage Input Circuits

4.3 MILLIVOLT INPUTS

The 2310B Amplifier can accept dc inputs, such as

thermocouples, provided two requirements are observed:

a) Neither input should exceed ±10V from circuit

common in normal operation; and must never

exceed a peak voltage of ±15V; and

b) The input circuit cannot be completely floating;

there must be some external return to circuit

common for both input leads. In the case of

thermocouples welded to a nominally grounded

structure, this return is usually adequate.

The user is also cautioned regarding two sources of

possibly significant error:

a) Each input (pins A and J) requires a bias current of

approximately ±40 nA maximum typical; this

current will flow through the source impedance of

each input (to circuit common) and may cause a

measurable offset voltage.

b) Any non-symmetry in the source impedances of the

two inputs will somewhat reduce the CMR of the

amplifier.

4.4 WIRING CONSIDERATIONS

In addition to the chassis ground available at pin P of the

INPUT plug, the 2310B has an active “guard”

connection available at pin D. This guard may be a more

effective shield connection than chassis ground, but to be

effective the shield must be left disconnected (and

insulated against accidental groundings) at the gage end.

Normally the guard shield is used inside a conventionally

grounded shield, as shown in Figure 2C. Certain

important considerations affect wiring technique,

depending on whether the purpose of the test is to

measure static or dynamic data.

4.4a Dynamic Data: It is extremely important to

minimize the extent to which the gages and lead

wires pick up electrical noise from the test

environment; this noise is usually related to the 50

or 60 Hz line power in the test area:

a) Always use twisted multi-conductor wire

(never parallel conductor wire); shielded wire

is greatly preferred, although it may prove

unnecessary in some cases using short leads.

b) Shields should be grounded at one (and only

one) end; normally the shield is grounded at

the INPUT plug and left disconnected (and

insulated against accidental grounding) at the

gage end. Do not use the shield as a conductor

(that is, do not use coaxial cable as a twoconductor wire).

c) The specimen or test structure (if metal) should

be electrically connected to a good ground.

d) Keep all wiring well clear of magnetic fields

(shields do not protect against them) such as

- 8 -

Page 10

transformers, motors, relays and heavy power

wiring.

e) With long leadwires, a completely symmetrical

circuit will yield less noise. (A half bridge on

or near the specimen will usually show less

noise than a true quarter-bridge connection; a

full bridge would be still better.)

4.4b Static Data: Precise symmetry in leadwire

resistance is highly desirable to minimize the effects

of changes in ambient temperature on these wires.

a) In the quarter-bridge circuit, always use the

three-leadwire circuit shown in Figure 2, rather

than the more obvious two-leadwire circuit.

b) Insofar as possible, group all leadwires to the

same channel in a bundle to minimize

temperature differentials between leads.

c) If long leadwires are involved, calculate the

leadwire desensitization caused by the lead

resistance. If excessive in view of the data accuracy

required, use the adjusted gage factor (see 5.3

Shunt Calibration — Stress Analysis), increase

gage resistance, or increase wire size — or all three.

4.5 OUTPUT CONNECTIONS

CAUTION: During typical use of this instrument,

shorted or open inputs as well as AUTO BAL circuit

usage will often cause the ±10V outputs to approach

±15V. (Tape output is limited to 2V.) The GALV

output could deliver over 20 mA. If such levels can

damage the output devices, it is important that proper

precautions be taken. In those situations, it is suggested

that external resistance be added to the output circuitry.

Normally the third prong on the power cord should

establish an adequate chassis to earth ground connection.

When connecting this system to the peripheral

instruments, the user should be aware that having more

than one system ground could cause noise-generating

ground loops.

The 2310B Amplifier has two simultaneous noninteracting outputs; any one or all may be used in a

particular test. Both outputs are accessible at the rear of

the 2310B utilizing coaxial (BNC) connectors.

The “±10V” Output BNC would normally be connected

to a scope, voltmeter, or multiplexer. Gain figures are

direct reading to this output.

The ±10V Output is also available at the MONITOR pin

jacks on the front panel. A 10 K resistor is used

internally to decouple any noise injection.

The TAPE Output (TAPE BNC) is normally used only

for analog magnetic tape recorders. Full-scale amplifier

output (10V at “±10V” Output) will be 1.414V at the

TAPE Output, which is the customary full-scale input for

tape recorders.

- 9 -

Page 11

15 13 14

8 7

11 10

9

12

5 4 6

3 1 2

V

Figure 4: Switch Locations on P.C. Board

4.6 FILTER OUTPUT SELECTOR

The 2310B Amplifier has a selectable low-pass filter.

This filter, controlled by front panel push buttons, can

be set for one of several frequencies or at wide-band

(“WB” button), in which case the filter is bypassed.

The filter can affect either one or both of the outputs.

To select the outputs to be filtered, open the right sidecover of the 2310B and note the two toggles on the red

FILTER switch (near the top of the p.c. board) marked

±10V, and TAPE; this switch is shown in Figure 4. Any

toggles in the IN (up) position indicate that that output

will be filtered when any FILTER button other than WB

is depressed; outputs for which the toggle is in the OUT

(down) position will still be operating at wide-band.

Filter characteristics are discussed in 4.13 Filter.

4.8 EXCITATION

Select the desired bridge excitation with the

EXCITATION selector switch.

In stress analysis, it is always desirable to use the

highest excitation that the active gage can tolerate under

the test conditions. Factors, which increase this, are

high resistance (gage resistances of 350Ω or higher),

long gage length and gage width and a good heatsinking material (such as aluminum). Clearly, small

120Ω gages on plastic materials are to be avoided if in

any way possible; even very modest excitations may be

excessive. Note that most increments on the

EXCITATION selector switch represent a voltage

increase of about 40%, or a 100% increase in power to

the gage.

When using commercial transducers, the manufacturer

usually specifies the bridge excitation. If the transducer

uses metallic (foil) gages, this is a maximum value;

while any excitation up to the “maximum” could be

used, generally 50% to 75% of this maximum will yield

improved transducer stability while retaining a good

signal-to-noise ratio. However, when using transducers

with semi-conductor (piezoresistive) gages, the specified

excitation should be used, if possible, to achieve the

advertised performance.

The bridge excitation supply in the 2310B is

semifloating. Unless some ground exists in the input

circuit, the supply automatically centers itself about

circuit common (e.g., when set at 5B, P+ will read

+2.5V above common). However, either P+ or P- may

be intentionally grounded if desired (to minimize leads

to a multi-channel system, for example) without

affecting total bridge excitation. (Accidental grounds

may cause errors, depending on where the ground

occurs. This is because up to 0.75 mA will flow through

the ground connection. Both P+ and P- are, in effect,

returned to ground through 15 kΩ resistors.)

The accuracy of the EXCITATION selector is

guaranteed to within ±1%. If for any reason the exact

setting must be known, it can be measured at the EXCIT

MONITOR pin jacks on the front panel; the

EXCITATION toggle switch must be ON to make this

measurement.

Should the user desire to change the excitation voltage

for any position on the EXCITATION selector switch,

the resistor for that setting may be changed (it is located

on the switch itself). The resistance required can be

readily calculated:

R

V

×=18000,10

(Eq. 5)

−

where: R = required resistance in ohms

V = desired excitation in volts

- 10 -

Page 12

4.9 AMPLIFIER BALANCE

With a strain gage or transducer connected to the

INPUT, the EXCITATION switch still at OFF, and the

X100 GAIN button depressed, both OUTPUT lamps at

the top of the front panel should be completely dark. If

not, turn the AMP BAL adjustment below the

EXCITATION toggle switch (using a small

screwdriver) to extinguish the lamps. (If the “-“ lamp is

lit, turn clockwise, etc.)

NOTE: If the AMP BAL adjustment does not have any

effect on the OUTPUT lamps, check that the

PLAYBACK switch (on the rear panel) is at NORM

(down).

If both lamps are lit at best null, this is an indication of

excessive noise. This noise is frequently from the 50 or

60 Hz line; check shielding and the instrument ground.

See 4.5 Output Connections. Refer to 4.4 Wiring

Considerations for further discussion on shielding.

4.10 BRIDGE BALANCE

The input must, of course, be connected to balance this

input. It is not necessary that the outputs be connected

— in fact any device that could be damaged by a fullscale output should not be connected at this time.

Having selected the desired bridge excitation, turn the

EXCITATION toggle switch to ON; one OUTPUT

lamp will probably light fully.

Just below the OUTPUT lamps, momentarily press the

AUTO BAL toggle switch all the way down to the

RESET position, and release. In 1 to 3 seconds (8

seconds under the most extreme conditions) the

OUTPUT lamps should extinguish, indicating balance.

If, after several seconds, balance is not indicated, try

again. (Occasionally a “spike” of noise from the

environment will prematurely stop the balance

operation.)

Occasionally the lamps will dim, but not go out; this

means that the output is within 0.04V of balance, which

is usually adequate, but not zero. For precise balance

turn the vernier TRIM knob to extinguish the lamps. (In

the presence of noise below 5 kHz, AUTO BAL will

normally stop short of true balance; below 500 Hz the

error is half the peak-to-peak noise amplitude.) High

levels of input noise may make it impossible to

extinguish the lamps (both lamps may remain lit).

Special input wiring, shielding, and grounding

techniques may be necessary to reduce the noise. Even

though both lamps are not extinguished (due to the noisy

environment), it may be possible to take accurate data

(depending upon the test situation).

If, when balance is achieved, the yellow HI lamp is lit,

this is an indication that the Automatic Bridge Balance

circuit is operating in the high range: bridge unbalance

is between 1% and 5% (5000 and 25 000 µε at GF = 2),

which would usually be considered very abnormal if

quality gages and good installation and wiring practices

were used. Before taking data it may be advisable to

explore the reason for this unbalance; possibly the gage

should be replaced.

If the HI lamp constantly cycles on and off (4 seconds

on, 4 seconds off), the unbalance at the input exceeds

5%, probably due to a gross fault or wiring error (or

EXCITATION is not ON or the PLAYBACK switch is

at ON).

Possible faults:

“+” OUTPUT lamp lit: open gage, 350Ω gage with

120Ω dummy, or P+ lead open.

“-“ OUTPUT lamp lit: shorted gage, 120Ω gage

with 350Ω dummy, or lead to D

120

(or D

350

The automatic bridge balance circuit uses a ratio

voltage-injection technique and is thus essentially

independent of both EXCITATION and GAIN.

However, if either is changed significantly and a precise

balance is desired, AUTO BAL should be RESET after

final setup. A significant change in the null when

EXCITATION is increased one position indicates that

the new excitation is probably excessive (causing selfheating in the gage) and should be returned to the lower

position; a similar change as EXCITATION is

decreased would indicate that the higher setting was

probably excessive.

4.11 BATTERY TEST

The automatic bridge balance circuit stores the balance

value digitally. The value will not be lost when

POWER is turned off (or there is a failure in the ac

mains) since the 2310B has a keep-alive supply (a small

battery) to power this circuit at all times.

To check the condition of these batteries, ac POWER

must be on. Then press the small BAT TEST button:

the “+” OUTPUT lamp should light. If the “-”

OUTPUT lamp lights, the batteries are very low and

should be replaced (see 7.3 Battery Replacement);

furthermore, instrument POWER should be left on at all

times if retention of bridge balance is desired.

Battery drain to the circuit is insignificant (less than 0.1

mA-Hr/yr) so theoretical life is several decades. But

any battery will self-discharge and should be routinely

replaced every year or two.

4.12 GAIN

The GAIN controls on the 2310B Amplifier are direct

reading. The 10-turn control may be set anywhere

between 1.000 and 11.000. This setting is then

multiplied when the push button is depressed (X1, X10,

etc.). Thus any gain between 1 and 11 000 can be

preset.

There is some overlap between ranges. For best

accuracy, a gain of 1000 should be achieved with the

dial at 10.000 and the X100 multiplier depressed, rather

than 1.000 and X1000.

The user must be aware that “system gain” is the

product of bridge excitation and amplifier gain. It is

always desirable to operate at high bridge excitation and

) open.

- 11 -

Page 13

4

thus minimize amplifier gain — and consequently

minimize the amplification of the small noise always

present. But there are constraints on the maximum

permissible excitation (see 4.8 Excitation), so amplifier

gain becomes the dependent variable.

In stress analysis, if the desired output sensitivity is

known, amplifier gain can be calculated:

K

AVV

BROUT

where: V

(at ±10V Output)

VBR = bridge excitation in volts

A = amplifier gain

K = gage factor of the strain gage

µε = strain in microstrain

(microinches/inch)

Note that this equation assumes one active gage;

additional active gages will increase the output.

Equation 6 can be rearranged as:

= amplifier output in volts

OUT

A

KV

BR

The term V

sensitivity in volts/microstrain, or V

full scale (10V) and µε the total strain to achieve fullscale output.

Using commercial transducers, where the full-scale

output sensitivity is usually known (typically 2 mV

output per volt of excitation), the output equation is very

simple:

where: V

k = transducer sensitivity in mV/V

Rearranging Equation 8:

A

/µε can be interpreted as system

OUT

BRFSOUT

= amplifier output at full-scale

OUT FS

V

FSOUT

×=kV

BR

µε

V

OUT

µε

transducer input

3

10

×

6

−

10

××××=

6

1041×××=

can be amplifier

OUT

310−

×××= kAVV

(Eq. 6)

(Eq. 7)

(Eq. 8)

(Eq. 9)

Shunt calibration is a very standard alternate technique

for establishing amplifier gain, especially for stress

analysis. It is a powerful method, when done correctly,

since it compensates for any error in bridge excitation,

amplifier gain, and the sensitivity of the external

indicator or recorder; in some arrangements it even

compensates for potential errors caused by the resistance

of the wiring to the gages, even when that resistance is

unknown.

While simple in concept, there are so many subtleties,

alternate circuits available in the 2310B, and equations,

that the user is referred to in 5.0 Shunt Calibration of

this manual, which is devoted exclusively to this topic.

When using transducers, it is often most accurate and

convenient to simply apply a known input (force, torque,

pressure, etc.) and adjust GAIN to achieve the desired

output. If this physical input is less than the full-scale

rated input to the transducer, be careful that the

amplifier (or recorder) will not limit or saturate with a

full-scale input.

4.13 FILTER

The standard 2310B is equipped with a 6-pole low-pass

active filter which, depending on which FILTER button

is depressed on the front panel, will heavily suppress

noise and signal components above the selected

frequency: 10 Hz, 100 Hz, 1 kHz or 10 kHz. The gray

button (marked WB) eliminates the filter so that the

amplifier is operating at its full bandpass (“wide-band”).

The marked frequencies are the frequencies at which the

output is suppressed 3 dB (down 30% from normal), in

accordance with standard instrumentation practice.

The filter can affect either one or both of the two

outputs. The switch to select outputs is mounted on the

internal p.c. board; it is more fully described in 4.7

Filter Output Selector.

The characteristic of the active filter is a modified

Butterworth transfer function (see Figure 8A). This

characteristic achieves a fairly sharp transition at the set

frequency and is thus generally most satisfactory where

most signal components approximate sine waves.

However, should there by an abrupt step input (as with

impact tests), the user is cautioned that the Butterworth

filter has moderate overshoot (approximately 8% with 6

poles) and it may be desirable to observe the signal in

the wide-band mode, thus avoiding the filter distortion.

See 6.0 Active Filter for further discussion of filters.

- 12 -

Page 14

Figure 5: Remote-Operation Wiring

4.14 DYNAMIC TESTING

Occasionally the only data of interest is the peak-to-peak

amplitude of dynamic signals or the frequency or shape

of the dynamic component, and it may be desirable to

suppress the static component.

To observe purely dynamic signal components, press the

white AC button (below the FILTER buttons). This is

an alternate-action push button: in the “in” position all

signals are ac-coupled (after the preamp); in the “out”

position all signals are dc-coupled. The coupling

constant suppresses 5 Hz signals approximately 5% (the

–3 dB frequency is about 1.7 Hz).

NOTE: The automatic and trim balance controls will

not affect the dc output level in the ac-coupled mode.

The preamplifier remains dc-coupled at all times to

maintain good common-mode rejection. Even when ac

coupling is selected, there is a maximum permissible

differential dc input which must not be exceeded (to

avoid saturation of the preamplifier); this limit is a

function of the GAIN push button selected:

GAIN Button Max DC Diff. Input

X1 ±10 V

X10 ±1 V

X100 or X1000 ±0.1 V

It is recommended that bridge unbalance be held within

5% (25 000 µε @ GF=2) when possible; the Automatic

Bridge Balance circuit is still operable and will

compensate entirely for this much unbalance. (With the

EXCITATION toggle switch ON, simply press AUTO

BAL to RESET momentarily.) Should the bridge

unbalance exceed 5%, AUTO BAL must be OFF (all the

way up) and the selection of GAIN button and

EXCITATION must be made very carefully so as not to

exceed the limits tabulated above.

4.15 TAPE PLAYBACK

The 2310B Amplifier can be used to re-examine data

previously recorded on magnetic tape. A suggested

practice is to originally record the data with no filter on

the TAPE output (TAPE FILTER selector toggle on the

p.c. board set at OUT); the recorded tape thus contains

all possible frequency components from the test. Even

if the data were simultaneously observed and/or

recorded on an oscillograph, with or without filtering,

the tape-recorded data would still be wide-band.

At some later date the tape-recorded data can be played

back through the 2310B and re-examined (using a scope

or recording oscillograph); since the active filter in the

2310B is operable in this playback mode, any filter

frequency (or WB) may be selected. Note that both

outputs are available.

To use the playback mode, move the PLAYBACK

switch on the rear panel of the 2310B to ON (up).

Connect the output from the tape recorder to the INPUT

BNC connector near the top of the rear panel (full-scale

input is ±1.414V or 1 Vrms for a sine wave). Outputs

(±10V and TAPE) appear at their normal connectors.

The only controls on the front panel that are operable in

the playback mode are FILTER buttons (10 to 10K and

WB).

After using the playback mode, do not forget to return

the PLAYBACK switch to NORM! Otherwise, the

normal signal presented to the INPUT connector will

have no effect on the Outputs.

- 13 -

Page 15

5.0 S

HUNT CALIBRATION

4.16 REMOTE-OPERATION RELAYS (Option Y)

Six isolated relays can be provided to operate the

following functions in the 2310B. See Figure 8.

Shunt CALibration (+A, -A, +B, and –B)

Auto Balance RESET

Bridge EXCITation on/off (to check amplifier

balance)

While the relays are not installed unless Option Y is

specified at time of order, they can be easily installed

later by a qualified technician; all wiring already exists

in the 2310B Amplifier. Each relay requires 5 Vdc (10

mA each, except 25 mA for the bridge excitation relay).

For after-sale installation, order one Relay Kit 120001191 for each 2310B Amplifier.

To control the relays in a single 2310B Amplifier the

internal +15V supply may be used, as shown in Figure

8A. When more than one 2310B is to be operated with a

single set of switches (or external relays), an external 5

Vdc power supply is required (250 mA for each 10

channels). Option Y must also be specified for the 2350

Rack Adapter or 2360 Portable Enclosure. (For aftersale installation, order one Cal Kit 120-001192 for each

2350 Rack Adapter, or Cal Kit 120-001193 for the 2360

Portable Enclosure.) The system would then be wired as

in Figure 5B.

In order to remotely initiate an automatic bridge balance,

the RESET line must first be active for a minimum of 50

milliseconds and then released. (The balance process

starts after the voltage is released.) To remotely turn off

the bridge excitation, the EXCITation off line must be

made active (5 Vdc). The other functions (CALibration)

are turned on when 5 Vdc is supplied to the appropriate

pin and turned off when the voltage is removed.

4.17 QUARTER-BRIDGE NONLINEARITY

The output of a Wheatstone bridge is somewhat

nonlinear with only one active arm. This nonlinearity is

usually insignificant in stress analysis (percent error

equals percent strain @ GF=2). Should high strains be

encountered (post-yield studies or tests on some nonmetallics), the error can be removed during data

reduction, although the user is cautioned regarding

uncertainty of the value of gage factor above 1% strain.

If it is desired to obtain an output which is linear with

∆R in one arm of a bridge, this can be achieved with the

2310B.

This technique utilizes the remote-sense leads to

maintain constant voltage across a dummy resistor, and

therefore constant current through this resistor and

through the active arm. Connections to the INPUT plug

are as follows:

Figure 6: Connections to Input Plug

Two changes to the operating procedure are required:

a) The Remote SENSE switch on the p.c. board must

be at REMOTE, and

b) The EXCITATION selector switch must be set at

half the desired bridge excitation.

The user may notice that bridge balance is somewhat

affected by this circuit (e.g., 0.5% with a 500Ω half

bridge), but this is well within the range of the

Automatic Bridge Balance circuit. (The source of this

shift is the presence of R34 — 100 kΩ — across the

active resistance.)

5.1 INTRODUCTION

Shunt calibration is a very powerful technique to

determine total system “gain” in Wheatstone bridge

systems such as the 2310B. In general, one arm of the

input bridge is shunted with a specific resistance, which

introduces a specific -∆R into this arm (simulating a

compressive strain in a strain gage). The amplifier

output will respond exactly as if that specific -∆R (i.e.,

stain) actually had occurred with the existing bridge

excitation and amplifier gain. It is only necessary to

calculate the simulated strain and read the amplifier

output to determine the system sensitivity.

IMPORTANT: It should be emphasized that the intent

of shunt calibration is to determine the performance of

the circuit and instrument into which the gage is wired;

in no way does it verify the ability of the gage itself to

measure strain nor the characteristics of its performance.

While the basic shunt calibration concept and equations

are simple and well-known, the presence of leadwire

resistance can have very significant effects on the

accuracy of the technique. Either the precise shunt

circuit used must be chosen such that the leadwire

resistance has no net effect, or a correction must be

made for this effect.

- 14 -

Page 16

The shunt calibration circuits available in the 2310B are

designed to be exceptionally versatile and easy to

change. Most circuits apply specifically to stress

analysis application; when using commercial strain gage

transducers the double-shunt method is suggested (5.4

Transducers).

5.2 SHUNT CALIBRATION COMPONENTS IN 2310B

The two CAL switches on the front panel normally

provide two independent values (A and B) of simulated

strain, each of which can be either + or -. (If both

switches are operated simultaneously the values are

algebraically additive.)

With Option Y additional relays are installed in the

2310B such that any of these four switch positions can

be operated remotely [4.16 Remote Operation Relay

(Option Y)].

Four calibration resistors, two associated with the “A”

switch and two with the “B” switch, are installed in the

miniature sockets on the right side of the p.c. board (see

Figure 4). These resistors may be changed in the field to

suit specific test requirements. See 5.5 Standard

Calibration Resistors.

A blue ten-switch Calibration Circuit Selector is

installed on the right side of the p.c. board (see Figure

4). Only two or three (or four for transducers) should

ever be closed (up) for any given circuit.

Note that the switches are divided into four groups, as

marked at the bottom: P+, P-, S+, and S-, corresponding

to the four corners of the bridge. Each group has an

“INT” switch, which connects the calibration circuit to

the indicated corner of the bridge internal to the 2310B;

and an “R” switch, which connects the circuit to a

dedicated pin in the INPUT connector — to be used

when shunting a remote active gage. The S- group has

two additional switches for shunting the internal dummy

gages (D120 and D350).

5.3 SHUNT CALIBRATION — STRESS ANALYSIS

Shunt calibration can be achieved by shunting any one

of the four arms of the input bridge — this includes the

active gage and the bridge completion arms in the

2310B. The same equation applies, but note the

definition of Ra:

µε

cal

R

=

a

+

RRK

acal

6

10

×

(Eq. 10)

)('

where: µεcal = strain simulated (microstrain)

Ra = resistance of leg shunted (ohms)

K´ = effective gage factor of active gage

R

= resistance of calibration resistor

cal

(ohms)

Ra may not be equal to the resistance of the active gage

when the shunt is across one arm of the dummy half

bridge. (But also note that no correction factor is ever

necessary for the shunting effect of the resistance

balance circuit, since the 2310B does not use the shunt

method for bridge balance.)

Gage factor (K´) in equation 10 may be the actual

package gage factor of the active strain gage (corrected

for temperature, when necessary), or it may be a value

adjusted for leadwire desensitization:

R

KK

where: K = gage factor of active gage

Rg = resistance of active gage (ohms)

Rl = resistance of leadwire(s) in series

The specific gage factor correction applicable to the

various circuits is indicated in Chart 1.

Chart 1 tabulates the recommended shunt calibration

circuits available in the 2310B, together with the switch

settings and wiring necessary to achieve them.

The calibration resistor value (calculated from Equation

10) would apply to CAL Switch A if the resistor is

installed at position A1 or A2, or it would apply to CAL

Switch B if installed at position B1 or B2; CAL A and

CAL B are totally independent. Provided that the

Calibration Selector Switches are set as specified in the

chart, resistors installed at positions not called for have

no effect on the output; it is not necessary to remove

them.

g

×='

RR

+

lg

with active gage (usually the

resistance of one leadwire) (ohms)

(Eq. 11)

- 15 -

Page 17

CKT 1: Shunt Internal Half Bridge

CKT 2: Shunt Dummy Resistor

CKT 3: Shunt Active Gage

Excitation SENSE: LOCAL

Cal Selector Switches:

#1 closed (P+ at INT)

#3 closed (P- at INT)

#5 closed (S+ at INT)

Others open (down)

Ra = 350Ω

K’ from Equation 11

Excitation SENSE: LOCAL

Cal Selector Switches:

#3 closed (P- at INT)

#9 closed for 120Ω gage

Or #10 closed for 350Ω gage

(S- at D120 or D350)

Others open (down)

Ra = nominal gage resistance

K’ = K

(Note: If cal Selector #1 is also closed,

can also simulate compression, but for

compression, K’ must be from Eq. 11).

Excitation SENSE: LOCAL

Cal Selector Switches:

#2 closed (P+ to R1)

#8 closed (S- to R4)

Others open (down)

Ra = gage resistance

K’ = K

USE: Quarter and half bridge (full bridge

with reduced accuracy).

ADVANTAGES: Same resistors for any

active gage resistance. No special wiring.

+ and – cal.

DISADVANTAGES: Must correct for

leadwire resistance.

USE: True quarter bridge.

ADVANTAGES: Automatically corrects

for leadwire resistance when using 3-wire

circuit. No special wiring. Accuracy

independent of precise gage resistance.

DISADVANTAGES: Useable only if

internal dummy gages are in use.

Simulates tension only.

USE: Quarter, half, full bridge.

ADVANTAGES: Classic theory using

any leadwire method for bridge wiring.

DISADVANTAGES: Two added wires

necessary. Simulates compression only.

CKT 4: Shunt Active Half Bridge

Excitation SENSE: LOCAL

Cal Selector Switches:

Chart 1: Stress Analysis Shunt Calibration Circuits

Many other arrangements are possible, but they must

be used with great care. For example, the obvious

method to shunt an active gage (quarter or half bridge)

would be simply to close the Calibration Selector

Switches for P+, P- and S- to INT, achieving a circuit

functionally similar to Circuit 4. However, the effect

of leadwire resistance is surprisingly high (some four

times greater than expected from Equation 11), so the

circuit should never be used; much more accurate

results will be achieved in these cases with Circuit 1

(or especially Circuit 2, if using a true quarter bridge).

#2 closed (P+ to R1)

#4 closed (P- to R2)

#8 closed (S- to R4)

Others open (down)

Ra = gage resistance

K’ ≅ K

USE: Half or full bridge.

ADVANTAGES: Classic theory using

any leadwire method (except resistance

between active gages but be negligible).

Simulates + and -.

DISADVANTAGES: Three added wires

necessary.

5.4 TRANSDUCERS

The term transducer in the context of a bridge

conditioner can include any full bridge composed of

strain gages with a known calibration. It may be

simply four gages properly located on a part to

measure force or torque (frequently a detail part of the

mechanism under study), or it may be a more

elaborate (and accurate) commercial transducer.

- 16 -

Page 18

Commercial transducers are much more complex

circuits since they typically have a number of

additional resistive elements to correct for the effects

of temperature to achieve the desired precise span

calibration. Nonetheless, this complexity can usually

be overlooked without greatly compromising the

accuracy of shunt calibration, if done properly.

Shunt Calibration per Calibration Certificate:

Many transducer manufacturers provide shunt

calibration information as part of the calibration

certificate. When available, this is the most reliable

method of calibration, but the specified resistance

must be connected precisely as indicated by the

manufacturer. Sometimes there are two separate pins

dedicated to shunt calibration; additional leads are

required to accomplish calibration with resistors

installed inside the 2310B. In other cases the pins

may be one normal input lead and one normal output

lead. Since the effects of leadwire resistance are very

measurable, additional leads dedicated to the shunt

calibration circuit must be used between the

transducer connector and the INPUT connector to the

2310B.

The complete schematic of the available connections

for shunt calibration of transducers is shown in Figure

7.

As an example of transducer shunt calibration, assume

that the certificate for the transducer specifies that a 10

kΩ resistor should be placed between the positive

excitation (P+) pin and the negative output (S-) pin. A

suggested method with the 2310B would be:

a) Install a 10 kΩ resistor in position “A2” on the

p.c. board.

b) In addition to the normal 4-wire connection to the

transducer (6-wire if remote excitation sense is

used), connect two additional wires; one from the

positive excitation pin on the transducer to pin M

of the 2310B INPUT plug, the other from the

transducer negative output pin to pin N of the

2310B INPUT plug.

c) Inside the 2310B, Calibration Selector Switches 2

and 8 should be ON (all others open, or down).

Figure 7: Transducer Shunt-Cal Circuitry

- 17 -

Page 19

k

Excitation SENSE would be at LOCAL, unless

the basic 6-wire system is in use, in which case it

would be at REMOTE.

d) To insert the 10 kΩ shunt, move the CAL A

toggle (on the front panel) to “-“.

If shunt calibration data is not known, the best

procedure is to calculate values to be used in doubleshunt calibration; this procedure corrects for any

normal nonsymmetry in the transducer by

simultaneously shunting two opposite legs of the

bridge. To calculate the resistor value, use the

following equation:

500

(

RR

−

shuntdouble

where: R

Common values would be as follows for a 350Ω

transducer:

MV/V Ohms (double-shunt)

1.5 116,492

The above resistors must be placed electrically at the

transducer connector (rather than the 2310B INPUT

plug) to eliminate the sizable effect of leadwire

resistance. To achieve this, four “remote-calibration”

pins (E, M, N and R) are provided in the input plug, as

shown in Figure 7.

The resistors (value as calculated in Equation 12)

would be soldered to the p.c. board turrets in positions

A1 and A2 (or B1 and B2). Now the selected

transducer output, either + or -, can be simulated

simply by operating the CAL A (or CAL B) front

panel switch.

A common arrangement may be to calculate two

resistor values (representing perhaps 100% transducer

output and 25% output), putting one pair at A1 and

A2, the other pair at B1 and B2; now either 100% or

25% of full output can be simulated by using either

CAL A or CAL B.

0

double-shunt

3 58,158

2 87,325

1 174,825

= value of each shunt

R0 = output resistance of

K = output to be simulated

)5.0

−=

resistor (ohms)

transducer (usually 350

ohms)

(mV/V)

(Eq.12)

It is important to emphasize that when using semiconductor (piezoresistive) transducers, EXCITATION

must be set at the manufacturer’s specified voltage to

achieve proper calibration. Transducers using foil

gages may be excited with any voltage below the

maximum value specified by the manufacturer,

although best overall system performance will usually

be achieved with 50% to 75% of the permissible

maximum.

5.5 STANDARD CALIBRATION RESISTORS

The 2310B is intended to be ready for use as received,

with bridge completion resistors, dummy gages and

shunt calibration resistors installed. The standard

shunt calibration resistors have been selected for

maximum flexibility for stress analysis. These

resistors are as follows:

A1 — 874.8k ±0.1%

A2 — 59.94k ±0.1%

B1 — 174.8k ±0.1%

B2 — 174.8k ±0.1%

These values provide the following shunt calibration

levels (for identification of Cal Selector Switches, see

Figure 4):

Cal

Selector

Arm

Input Circuit

¼ & ½

bridge, 350Ω

full bridge

120Ω ¼

bridge

350Ω ¼

bridge

350Ω

transducer

(double-

shunt)

*These values assume zero leadwire resistance.

Shunted

Dummy

half

bridge

Dummy

resistor

Dummy

resistor

All 1, 3, 5, 7 ±B = ±1 mV/V*

Switches

On

1, 3, 5 ±A = ±200µε

3, 9 +A = +1000µε

3, 10 +B = +1000µε

Strain Simulated

@ GF=2

±B = ±1000µε

- 18 -

Page 20

6.0 ACTIVE FILTER

6.1 FILTER CHARACTERISTICS

a) The standard 2310B is supplied with an active 6-

pole filter with Butterworth characteristics having

high-frequency cut-off at the following

frequencies: 10, 100, 1000 and 10 000 Hz.

b) While both filters (with equal poles) ultimately

reach the same slope at high frequencies, the

sharpness of the Butterworth filter at FCO results

in better attenuation at any given high frequency.

c) Should there be an instantaneous step input, the

Butterworth filter will produce 5 to 8% overshoot

(assuming precise component values), whereas

the Bessel filter has no overshoot.

This section describes filter characteristics as relates to

the 2310B.

The choice of filter characteristic (Butterworth or

Bessel) is a compromise. With reference to Figure 8,

note the following:

a) The Butterworth filter falls off much more

sharply around the –3dB frequency (FCO in the

curves).

Figure 8: Filter Characteristics

Thus the choice of characteristic is very dependent on

the type of testing performed. However, the

Butterworth, with its sharper cut-off, is generally

preferred.

When high noise rejection is required near FCO, a filter

with 6 poles is highly desirable. Although, note from

Figure 8 that there is no discernible improvement

below FCO as the number of poles is increased.

- 19 -

Page 21

7.0 MAINTENANCE

The rise time (10% to 90%) for step inputs is virtually

fixed; it is independent of both filter characteristic and

number of poles:

TimeRise

where: FCO is the cut-off frequency (-3dB) in Hz.

All multipole filters introduce a significant time delay

near and above the cut-off frequency. In multichannel dynamic studies where instantaneous outputs

from several channels are to be compared or analyzed

at a specific point in time (for example, reduction of a

3-element strain gage rosette), these three channels

must have identical filters to avoid “data skew” caused

by different time delays in the three channels.

35.0

≅

F

CO

sec

ondsin

(Eq.13)

Maintenance is to be done only by qualified technicians.

7.1 ADJUSTMENTS

To assist in maintenance, the following the diagram is

provided to indicate the position of the IC and adjustments

that are used to calibrate the 2310B. Also shown are the

relays used for shunt cal and zero functions. Schematic

diagrams are available to those who wish to gain a more

detailed understanding of circuit operations and for

organizations that choose to do their own repairs and

adjustments. Our Applications Engineering Department

can provide these diagrams, upon request, in paper and/or

electronic formats.

Figure 9: P.C. Board Layout — Trim Adjustments

- 20 -

Page 22

There are a number of trim adjustments on the p.c.

board; no adjustment of these controls should be

necessary unless a component is changed, principally

one of the integrated circuits. Each trim control is

marked on the p.c. board with a letter of the alphabet

to assist the technician. Additionally, many test points

are marked on the component side of the board.

Figure 9 shows the location of the various

adjustments.

The 2310B must have ac power during servicing (see

4.1 Setup and AC Power); accessory power cord 120001196 is suggested.

The trim adjustments fall into three general categories:

power supply checks and set points, common-mode

adjustment, and balance adjustments for most

operational amplifiers.

The bridge power supply reference can be set with or

without an input to the 2310B, using a digital

voltmeter. It is should be set 0.1% (if possible) after

15 minutes warmup.

METER LEADS READING ADJUST

- +

TP16* TP 5 +15.00V±0.5V NA

TP16* TP 17 -15.00V±0.5V NA

P- TP18 +18.00V±0.5V NA

P- TP19 +15.00V±0.01V C

*TP16 is the same as chassis or common.

The amplifier balance controls should be set in the

sequence listed at right, after the instrument has been

warmed up for at least 15 minutes. The inputs must be

shorted together and grounded by connecting INPUT

plug pins A, J and P together. All readings should be

made with a digital voltmeter or stable dc scope with a

resolution of at least 1 mV; when possible set balances

to within 0.2 mV of zero. All readings are relative to

circuit common (OUTPUT pin 1). The front panel

AMP BAL trimmer must be approximately centered

(11 turns from one end), EXCITATION at OFF, and

AC coupling button “out” (for dc coupling). Also, the

front panel settings listed at right must be made prior

to adjustment and not changed unless subsequently

directed to do so.

Auto Balance adjustments should be made with a

350Ω bridge connected to the input; it should be

possible to unbalance this bridge randomly up to about

3% unbalance.

METER

LEAD FRONT PANEL

TP1 GAIN button X100 G

TP1 GAIN button X1 J U19

TP1 GAIN button X1000 G

TP2 — N U20

TP2 AC button “IN” * U20

TP3 GAIN button X1 and

dial 11.000

TP4 GAIN dial 11.000

FILTER 100

TP6 FILTER WB V U25

TP7 — W U8

TP8 — X U26

ADJUST

MENT

R U17

T U12, U13,

BALANCED

U16, U18,

U16, U18,

*Press AC button IN, reading shift <5mV

Adjustments D and E are set to make the 2310B

output (after “balancing” the bridge) independent of

bridge excitation:

a) Set GAIN at approximately X100; bridge outputs

(amplifier inputs) shorted together.

b) With EXCITATION at OFF, null LED’s with

AMP BAL.

c) EXCITATION ON, set at 15 V. Press RESET;

use TRIM to extinguish LED’s.

d) EXCITATION at 2 V; LED’s should stay out. If

+ LED lights, turn adjustment E clockwise to

slightly light – LED, and vise versa.

e) If an adjustment was required, repeat (c) and (d).

f) Unbalance the input bridge approximately 3%

(10K shunt across one 350Ω arm suggested) and

remove short across bridge output.

g) Follow steps (b) through (e), but trim adjustment

D.

Adjustment F is set for best null (on average) using

Auto Balance. The following procedure is suggested:

a) Set GAIN at 500 and EXCITATION at 5 V.

b) With EXCITATION at OFF, null LED’s with

AMP BAL.

c) With any random bridge unbalance, turn

EXCITATION to ON and press RESET. If, at

“balance”, the + LED is lit somewhat, turn

adjustment F counter-clockwise (and vice versa)

until both LED’s are extinguished at “balance”.

IC

U21

U21

U14

- 21 -

Page 23

d) Repeat above procedure with several random

bridge unbalances to achieve best average

performance. (If reading the ±10V output with a

DVM, readings at “balance” ideally should be

between 0 and –3 mV, which is the theoretical

resolution of the circuit at these settings.)

Adjustments H, L, M and Y (C31) all affect commonmode rejection in the preamplifier. They are most

conveniently set using an audio oscillator (10 Hz to 5

kHz):

a) Connect the oscillator between circuit ground and

the two amplifier inputs (INPUT pins A and J)

shorted together. Set the oscillator for about 10

Vp-p (3.5 Vrms).

b) Connect oscilloscope to ±10V (TP7) output, ac-

coupled.

c) Set GAIN dial at 1.000 and press X1 button.

d) Set oscillator at 10 Hz; adjust M for best null on

scope.

e) Set oscillator at 1 kHz; adjust L for best null.

f) Repeat (d) and (e) if adjustments were required.

g) Press X100 GAIN button.

h) Set oscillator at 10 Hz; adjust H for best null.

i) Set oscillator at 1 kHz; adjust capacitor Y (C31)

for best null.

j) Repeat (h) and (i) if adjustments were required.

k) If (h) and (i) required significant adjustment,

repeat from (c) on.

7.2 BATTERY REPLACEMENT

The current drain from the keep-alive batteries in the

automatic bridge balance circuit is continuous with

POWER off, whether the instrument is plugged in or

not, but this current is so small 5 to 10 nA) that selfdischarge (i.e., shelf-life) is far more significant.

The batteries should be replaced when the test circuit

indicates low voltage (see 4.11 Battery Test), or

routinely two years after installation.

The batteries used in the 2310B are widely used and

are available at most electronic supply stores. Eagle

Picher PT-2150 (Lithium 3.6Volt, 1/2AA) or equal is

recommended for a replacement. Any of the

following silver oxide batteries may be used (two

required):

To replace the battery:

a) Disconnect power and remove cover on left side

of the 2310B.

b) Locate the battery holder near the rear of the

2310B.

c) Note the orientation of the existing battery.

d) Remove and properly dispose of the old battery

in accordance with local codes.

e) Install the new battery with the positive end (case

of cell) toward the rear of the instrument, and the

negative end toward the front.

f) Replace 2310B side cover.

g) Apply ac power to the 2310B and press BAT

TEST; the + OUTPUT lamp should light.

7.3 COMPONENT REPLACEMENT

It is recommended that a defective 2310B be returned

to Vishay Micro-Measurements for factory service,

especially during the warranty period (to preserve the

warranty); however, a qualified technician can often

repair the unit in the field. Most electronic

components used are standard commercially available

items. Any component can be purchased from Vishay

Micro-Measurements (if the Vishay MicroMeasurements part number is not listed below, please

provide us with the component symbol and value —

or an adequate description of the part — and the

instrument serial number).

The following information may be of value for field

service.

7.3a Resistors:

The 1% resistors are generally 100 ppm/°C, and

0.1% values are generally 25 ppm/°C).

All 0.05% and tighter tolerances are Vishay

SMR1DR (2 ppm/°C) and must be ordered from

Vishay Micro-Measurements.

Resistors R71 through R74 are part of the bridge

completion assembly and must be ordered as part

200-131240.

7.3b Connectors Symbol P/N

Input plug, 15-pin

[Bendix PT06A-14-15P(SR)]

Mating power plug (not supplied)

(ITT/Cannon DA15S or equal)

Remote cal plug (for 2350/2360)

(Cinch-Jones S-308-CCT)

Line cord (for 2350 and 2360)

(Belden 17742)

P5 12X300531

— 12X300151

— 12X300533

— 21X300126

7.3c Battery

Keep-alive supply

(Eagle Picher PT-2150)

B1

23X500004

(1 required)

7.3d Toggle Switches

Filter selector (on p.c.b.)

(Grayhill 76TC03)

Excitation sense selector

(on p.c.b.) (Grayhill 76TD01)

SW1 10X900046

SW5 10X900047

- 22 -

Page 24

Calibration selector (on p.c.b.)

(CTS 206-10)

Cal A and Cal B

(C&K 7103P3D9V30QE)

Auto Balance

(C&K 7213PD9V38)

Excitation on/off

(C&K 7201P3D9V30QE)

SW7 10X900048

S8,

10X600136

S9

S10 10X600160

S12 10X600137

7.4 FUSE REPLACEMENT

Fuse replacement is to be done only by qualified