Page 1

Wet Tantalum Capacitors

Sintered Anode TANTALEX

®

with True Glass-to-Tantalum Seal

PERFORMANCE CHARACTERISTICS

Operating Temperature: - 55°C to + 85°C and with

voltage derating to two-thirds the + 85°C rating at + 125°C.

Use of Type 138D capacitors for high temperature

applications is recommended.

Capacitance Tolerance: At 120Hz, + 25°C. ± 20% standard.

± 10%, ± 5% available as special.

DC Leakage Current (DCL Max.):

At + 25°C, + 85°C and + 125°C: Leakage current shall not

exceed the values listed in the Standard Ratings Tables.

Life Test: Capacitors are capable of withstanding a 2000

hour life test at a temperature of + 85°C or + 125°C at the

applicable rated DC working voltage.

138D

Vishay

Capacitors Hermetically-Sealed

FEATURES

Improved reliability through the use of a glass-to-tantalum

true hermetic anode seal is the prime feature of the Type

138D sintered anode T

ANTALEX

offers outstanding resistance to thermal shock.

Model 138D is the commercial equivalents of Tansitor Styles

WT, UWT, Mallory-NACC Styles TLX, TXX and Military Styles

CL66, CL67, CLR65, and CLR69, designed to meet the

performance requirements of Military Specification MIL-PRF39006/09/21. Capacitors in accordance with military

specifications should be ordered by their military part

numbers.

Following the life test:

1. DCL shall not exceed 125% of the original requirement.

2. The ESR shall not exceed 200% of the initial requirement.

3. Change in capacitance value shall not exceed the

percentages below.

a) 6WVDC Units: + 10% to - 25% of initial measurement.

b) 8WVDC and 10WVDC Units: + 10% to - 20% of initial

measurement.

c) 15WVDC Units: + 10% to - 15% of initial measurement.

d) 20WVDC and above: ± 10% of initial measurement.

®

capacitor. This construction

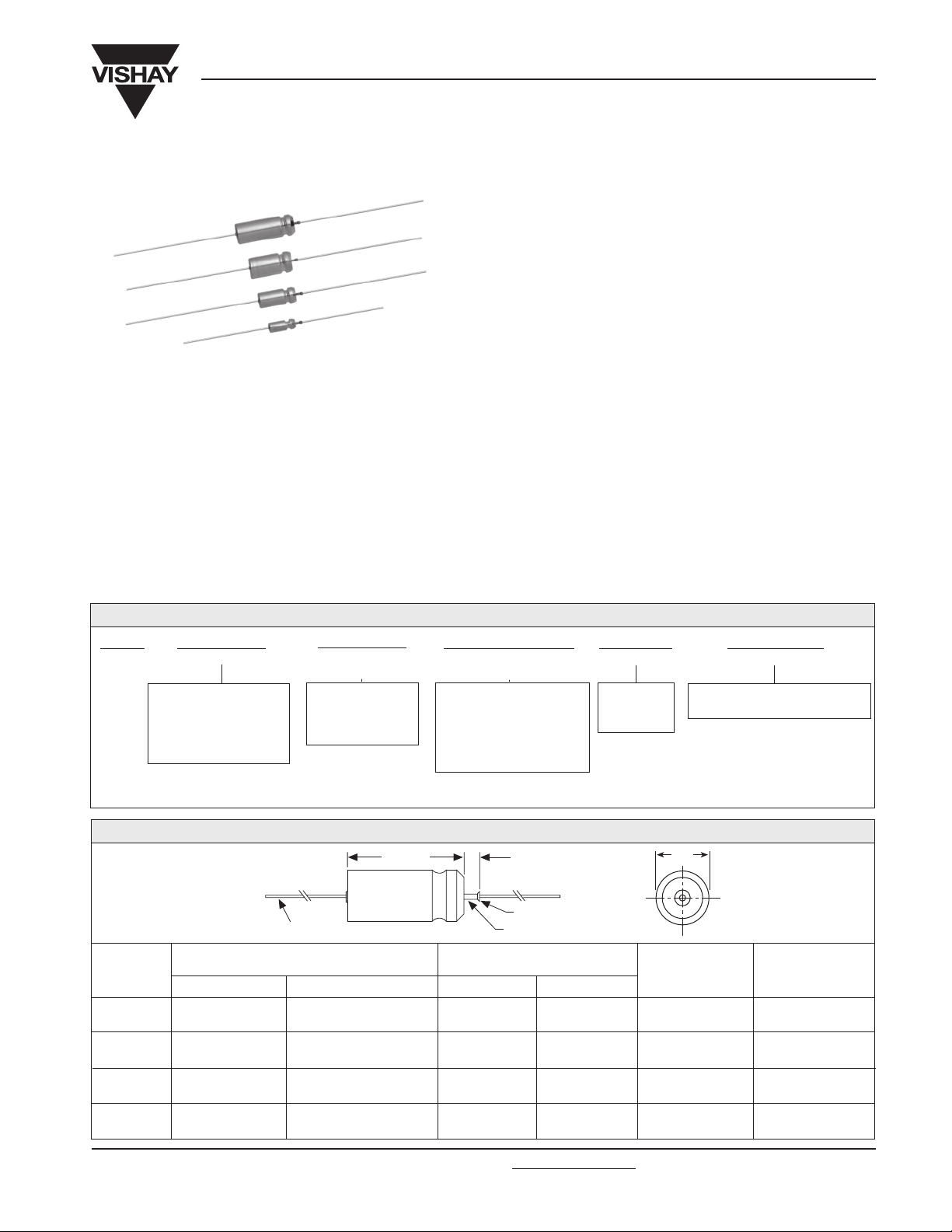

ORDERING INFORMATION

138D

MODEL

This is expressed in

picofarads. The first two

digits are the significant

figures. The third is the

Packaging: The use of formed plastic trays for packaging these axial lead components is standard. Tape and reel is not recommended

due to the unit weight.

306

CAPACITANCE

number of zeros to

follow.

X0

CAPACITANCE

TOLERANCE

X0 = ± 20%

X9 = ± 10%

X5 = ± 5%

Special Order.

DC VOLTAGE RATING

This is expressed in volts.

To complete the three-digit

block, zeros precede the

voltage rating. A decimal

point is indicated by an "R"

006

AT + 85°C

(6R3 = 6.3 volts).

C

CASE CODE

See Ratings

and Case

Codes Table.

2

STYLE NUMBER

0 = No outer tube.

2 = Outer plastic-film insulation.

DIMENSIONS in inches [millimeters]

0.0253 ± 0.002 [0.64 ± 0.05] Dia.

(No. 22 AWG) Tinned Solderable Leads

CASE

CODE

C

F

T

K

D

0.188 ± 0.016

[4.78 ± 0.41]

0.281 ± 0.016

[7.14 ± 0.41]

0.375 ± 0.016

[9.53 ± 0.41]

0.375 ± 0.016

[9.53 ± 0.41]

BARE TUBE

0.453 + 0.031 - 0.016

[11.51 + 0.79 - 0.41]

0.641 + 0.031 - 0.016

[16.28 + 0.79 - 0.41]

0.766 + 0.031 - 0.016

[19.46 + 0.79 - 0.41]

1.062 + 0.031 - 0.023

[26.97 + 0.79 - 0.58]

L

PLASTIC - FILM INSULATION

L

D (Max.)

0.219

[5.56]

0.312

[7.92]

0.406

[10.31]

0.406

[10.31]

0.250 [6.35]

Max.

Weld

Tantalum

WITH OUTER

L (Max.)

0.608

[15.45]

0.796

[20.22]

0.921

[23.40]

1.127

[30.91]

D

LEAD

LENGTH

1.500 ± 0.250

[38.10 ± 6.35]

2.250 ± 0.250

[57.15 ± 6.35]

2.250 ± 0.250

[57.15 ± 6.35]

2.250 ± 0.250

[57.15 ± 6.35]

Max. WEIGHT

(Ounces/Grams)

0.07

[2.0]

0.18

[5.1]

0.36

[10.2]

0.49

[13.9]

Document Number: 40025

Revision 15-Oct-03

For technical questions, contact wettants@vishay.com

www.vishay.com

55

Page 2

138D

Vishay

Sintered Anode TANTALEX

STANDARD RATINGS

CAPACITANCE

(µF)

30

68

140

270

330

560

1200

25

56

220

430

850

CASE

CODE

C

C

F

F

T

T

K

C

C

F

T

K

with True Glass-to-Tantalum Seal

PART NUMBER*

138D306X0006C2

138D686X0006C2

138D147X0006F2

138D277X0006F2

138D337X0006T2

138D567X0006T2

138D128X0006K2

138D256X0008C2

138D566X0008C2

138D227X0008F2

138D437X0008T2

138D857X0008K2

Wet Tantalum Capacitors

®

Capacitors Hermetically-Sealed

Max. ESR

at + 25°C

(Ohms)

6WVDC at + 85°C . . . 4WVDC at + 125°C

4

4

2

4

2

3

1.6

8WVDC at + 85°C . . . 5WVDC at + 125°C

4

4

4

3

1

10WVDC at + 85°C . . . 7WVDC at + 125°C

Max. IMP.

at - 55°C

(Ohms)

100

60

40

25

20

25

20

100

59

30

25

22

Max. DCL (µA) at

+ 25°C- 55°C+ 85°C + 125°C

1

1

1

1

2

2

3

1

1

1

2

4

+ 85°C

+ 125°C

2

2

3

6.5

7.9

13

14

2

2

7

14

16

Max. CAPACITANCE

CHANGE (%) at

- 40

- 40

- 40

- 44

- 44

- 64

- 80

- 40

- 40

- 44

- 64

- 80

+ 10.5

+ 14

+ 14

+ 17.5

+ 14

+ 17.5

+ 25

+ 10.5

+ 14

+ 17.5

+ 17.5

+ 25

+ 12

+ 16

+ 16

+ 20

+ 16

+ 20

+ 25

+ 12

+ 16

+ 20

+ 20

+ 25

20

47

100

180

250

390

750

15

33

70

120

170

270

540

27

220

10

22

50

100

180

350

8.0

15

40

100

150

300

C

C

F

F

T

T

K

C

C

F

F

T

T

K

C

T

C

C

F

F

T

K

C

C

F

T

T

K

138D206X0010C2

138D476X0010C2

138D107X0010F2

138D187X0010F2

138D257X0010T2

138D397X0010T2

138D757X0010K2

138D156X0015C2

138D336X0015C2

138D706X0015F2

138D127X0015F2

138D177X0015T2

138D277X0015T2

138D547X0015K2

138D276X0020C2

138D227X0020T2

138D106X0025C2

138D226X0025C2

138D506X0025F2

138D107X0025F2

138D187X0025T2

138D357X0025K2

138D805X0030C2

138D156X0030C2

138D406X0030F2

138D107X0030T2

138D157X0030T2

138D307X0030K2

4

5

2

4

2

3

1

15WVDC at + 85°C . . . 10WVDC at + 125°C

5

5

4

4

2

3

1.0

20WVDC at + 85°C . . . 13WVDC at + 125°C

5

4

25WVDC at + 85°C . . . 15WVDC at + 125°C

6

5

4

4

4

1.3

30WVDC at + 85°C . . . 20WVDC at + 125°C

7.5

8

4

6

2.5

1.6

175

100

60

40

30

25

23

155

90

75

50

35

30

23

100

30

220

140

70

50

32

24

275

175

65

40

35

25

1

1

1

1

2

2

4

1

1

1

1

2

2

6

1

2

1

1

1

1

2

7

1

1

1

2

2

8

10

16

16

10

16

24

16

2

10

18

28

2

2

4

7

2

2

4

7

2

2

5

2

2

5

12

16

32

- 32

- 36

- 36

- 36

- 40

- 64

- 80

- 24

- 28

- 28

- 28

- 32

- 56

- 80

- 20

- 48

- 16

- 20

- 28

- 28

- 48

- 70

- 16

- 20

- 24

- 28

- 48

- 60

+ 10.5

+ 14

+ 14

+ 14

+ 14

+ 17.5

+ 25

+ 10.5

+ 14

+ 14

+ 17.5

+ 14

+ 17.5

+ 25

+ 11

+ 13

+ 8

+ 10.5

+ 13

+ 13

+ 13

+ 25

+ 8

+ 10.5

+ 10.5

+ 10.5

+ 13

+ 25

+ 12

+ 16

+ 16

+ 16

+ 16

+ 20

+ 25

+ 12

+ 16

+ 16

+ 20

+ 16

+ 20

+ 25

+ 14

+ 15

+ 9

+ 12

+ 15

+ 15

+ 15

+ 25

+ 12

+ 12

+ 12

+ 12

+ 15

+ 25

www.vishay.com

56

For technical questions, contact wettants@vishay.com

Document Number: 40025

Revision 15-Oct-03

Page 3

138D

Sintered Anode TANTALEX® Capacitors Hermetically-Sealed

STANDARD RATINGS

CAPACITANCE

(µF) PART NUMBER*

68

120

270

5.0

10

25

47

60

82

160

4.0

8.2

20

39

50

68

140

CASE

CODE

F

T

K

C

C

F

F

T

T

K

C

C

F

F

T

T

K

138D686X0035F2

138D127X0035T2

138D277X0035K2

138D505X0050C2

138D106X0050C2

138D256X0050F2

138D476X0050F2

138D606X0050T2

138D826X0050T2

138D167X0050K2

138D405X0060C2

138D825X0060C2

138D206X0060F2

138D396X0060F2

138D506X0060T2

138D686X0060T2

138D147X0060K2

Wet Tantalum Capacitors

with True Glass-to-Tantalum Seal

Max. ESR

at + 25

(Ohms)

35WVDC at + 85°C . . . 22WVDC at + 125°C

2.2

50WVDC at + 85°C . . . 30WVDC at + 125°C

2.2

60WVDC at + 85°C . . . 40WVDC at + 125°C

10

2.4

Max. IMP.

°C

at - 55

°C

(Ohms)

6

4

9

8

6

6

3

4

8

5

7

4

6

60

38

23

400

250

95

70

45

45

27

550

275

105

90

50

50

28

Max. DCL (µA) at

+ 85

°C

+ 25

+ 125°C

1

2

8

1

1

1

1

2

2

8

1

1

1

1

2

2

8

16

32

12

16

32

12

16

32

Vishay

Max. CAPACITANCE

CHANGE (%) at

°C

8

2

2

5

9

2

2

5

9

- 24

- 30

- 45

- 16

- 24

- 20

- 28

- 16

- 32

- 50

- 16

- 24

- 16

- 28

- 16

- 32

- 40

+ 12

+ 13

+ 20

+ 5

+ 8

+ 10.5

+ 10.5

+ 10.5

+ 13

+ 25

+ 10.5

+ 10.5

+ 10.5

+ 10.5

+ 20

+ 5

+ 8

+ 125°C+ 85°C- 55°C

+ 15

+ 15

+ 25

+ 6

+ 9

+ 12

+ 15

+ 12

+ 15

+ 25

+ 6

+ 9

+ 12

+ 12

+ 12

+ 12

+ 20

75WVDC at + 85°C . . . 50WVDC at + 125°C

3.5

6.8

15

33

40

56

110

2.5

4.7

11

22

30

43

86

1.7

3.6

9.0

14

18

25

56

*Part Numbers listed are for units with outer plastic-film insulation and a capacitance tolerance of ± 20%. For bare case units, substitute "0"

for "2" at the end of the Part Number. For capacitors with ± 10% tolerance, change the digit following the letter "X" to "9".

C

C

F

F

T

T

K

C

C

F

F

T

T

K

C

C

F

F

T

T

K

138D355X0075C2

138D685X0075C2

138D156X0075F2

138D336X0075F2

138D406X0075T2

138D566X0075T2

138D117X0075K2

100WVDC at + 85°C . . . 65WVDC at + 125°C

138D255X0100C2

138D475X0100C2

138D116X0100F2

138D226X0100F2

138D306X0100T2

138D436X0100T2

138D866X0100K2

125WVDC at + 85°C . . . 85WVDC at + 125°C

138D175X0125C2

138D365X0125C2

138D905X0125F2

138D146X0125F2

138D186X0125T2

138D256X0125T2

138D566X0125K2

10

8

6.5

7

5

6

3.1

26.5

10

6

7

4

6

3.1

54.6

15

15

12

11

10

4.1

650

300

150

90

60

60

29

950

500

200

100

80

70

30

1250

600

240

167

129

93

32

1

1

1.0

1.0

2.0

2.0

9

1.0

1.0

1.0

1.0

2.0

2.0

9

1.0

1.0

1.0

1.0

2.0

2.0

10

2

2

5

10

12

17

36

2

2

4

9

12

17

36

2

2

5

7

9

13

40

- 16

- 20

- 16

- 24

- 16

- 28

- 35

- 16

- 16

- 16

- 16

- 16

- 20

- 25

- 16

- 16

- 16

- 16

- 16

- 16

- 25

+ 5

+ 8

+ 8

+ 10.5

+ 10.5

+ 10.5

+ 20

+ 7

+ 7

+ 7

+ 7

+ 7

+ 7

+ 15

+ 7

+ 7

+ 7

+ 7

+ 7

+ 7

+ 15

+ 6

+ 9

+ 9

+ 15

+ 12

+ 15

+ 20

+ 8

+ 8

+ 8

+ 8

+ 8

+ 8

+ 15

+ 8

+ 8

+ 8

+ 8

+ 8

+ 8

+ 15

Document Number: 40025

Revision 15-Oct-03

For technical questions, contact wettants@vishay.com

www.vishay.com

57

Page 4

138D

Vishay

Sintered Anode TANTALEX® Capacitors Hermetically-Sealed

EXTENDED RATINGS

CAPACITANCE

(µF)

560

820

1500

2200

180

470

680

1800

100

150

390

560

1200

1500

68

100

270

390

540

820

1000

56

82

220

330

47

68

180

270

350

CASE

CODE

F

F

T

K

C

F

F

K

C

C

F

F

T

K

C

C

F

F

T

T

K

C

C

F

F

C

C

F

F

T

with True Glass-to-Tantalum Seal

PART NUMBER*

138D567X0006F2

138D827X0006F2

138D158X0006T2

138D228X0006K2

138D187X0008C2

138D477X0008F2

138D687X0008F2

138D188X0008K2

138D107X0010C2

138D157X0010C2

138D397X0010F2

138D567X0010F2

138D128X0010T2

138D158X0010K2

138D686X0015C2

138D107X0015C2

138D277X0015F2

138D397X0015F2

138D547X0015T2

138D827X0015T2

138D108X0015K2

138D566X0020C2

138D826X0020C2

138D227X0020F2

138D337X0020F2

25 WVDC at + 85°C . . . 15 WVDC at + 125°C

138D476X0025C2

138D686X0025C2

138D187X0025F2

138D277X0025F2

138D357X0025T2

Wet Tantalum Capacitors

Max. ESR

at + 25°C

(Ohms)

6WVDC at + 85

2.5

2.5

1.5

1

8WVDC at + 85°C . . . 5WVDC at + 125°C

2.5

2.5

10WVDC at + 85°C . . . 7WVDC at + 125°C

15WVDC at + 85°C . . . 10WVDC at + 125°C

20WVDC at + 85°C . . . 13WVDC at + 125°C

Max. IMP.

at - 55°C

(Ohms)

°C . . . 4WVDC at + 125°C

20

18

18

13

3

1

3.0

3

2.5

2.5

1.5

1

4

4

2.5

2.5

1.8

1.8

1.2

4.3

4.3

2.7

2.7

4.3

4.3

2.7

2.7

1.8

45

25

22

14

60

54

30

27

18

15

80

72

35

31

25

22

17

90

81

35

31

100

90

37

33

27

Max. DCL (µA) at

+ 25°C

3

3

5

6

2

3

3

7

2

2

3

3

5

7

2

2

3

3

6

6

8

2

2

3

3

2

2

3

3

7

+ 85°C

+ 125°C

14

14

20

24

9

14

14

25

9

9

16

16

20

25

9

9

16

16

24

24

32

9

9

16

16

9

9

16

16

28

Max. CAPACITANCE

CHANGE (%) at

- 50

- 55

- 70

- 77

- 88

- 88

- 40

- 44

- 60

- 16

- 70

- 77

- 77

- 38

- 43

- 60

- 66

- 35

- 40

- 55

- 62

- 60

+ 85°C

+ 16

+ 16

+ 20

+ 25

+ 13

+ 16

+ 16

+ 20

+ 13

+ 13

+ 16

+ 16

+ 20

+ 25

+ 13

+ 13

+ 16

+ 16

+ 20

+ 20

+ 25

+ 13

+ 13

+ 16

+ 16

+ 12

+ 12

+ 13

+ 13

+ 20

- 55°C

- 80

- 88

- 90

- 90

- 60

- 75

- 83

- 90

+ 125°C

+ 20

+ 20

+ 25

+ 30

+ 16

+ 20

+ 20

+ 30

+ 16

+ 16

+ 20

+ 20

+ 25

+ 30

+ 16

+ 16

+ 20

+ 20

+ 25

+ 25

+ 30

+ 16

+ 16

+ 20

+ 20

+ 15

+ 15

+ 16

+ 16

+ 25

30WVDC at + 85°C . . . 20WVDC at + 125°C

39

56

150

220

330

470

560

* Part Numbers listed are for units with outer plastic-film insulation and a capacitance tolerance of ± 20%. For bare case units, substitute "0"

for "2" at the end of the Part Number. For capacitors with ± 10% tolerance, change the digit following the letter "X" to "9".

www.vishay.com

58

C

C

F

F

T

T

K

138D396X0030C2

138D566X0030C2

138D157X0030F2

138D227X0030F2

138D337X0030T2

138D477X0030T2

138D567X0030K2

For technical questions, contact wettants@vishay.com

5.2

5.2

2.5

2.5

1.8

1.8

1.3

110

100

40

36

28

25

20

2

2

3

3

8

8

9

16

16

32

32

36

9

9

- 32

- 38

- 50

- 60

- 50

- 65

- 65

+ 12

+ 12

+ 13

+ 13

+ 20

+ 20

+ 25

Document Number: 40025

Revision 15-Oct-03

+ 15

+ 15

+ 16

+ 16

+ 25

+ 25

+ 30

Page 5

138D

Wet Tantalum Capacitors

Sintered Anode TANTALEX

®

Capacitors Hermetically-Sealed

Vishay

with True Glass-to-Tantalum Seal

EXTENDED RATINGS

Max. CAPACITANCE

CHANGE (%) at

- 30

- 35

- 45

- 45

- 58

- 58

- 24

- 29

- 35

- 42

- 35

- 46

- 46

- 20

- 24

- 30

- 36

- 30

- 40

- 45

- 16

- 19

- 25

- 30

- 25

- 35

- 40

- 12

- 17

- 18

- 20

- 30

- 35

- 14

- 18

- 16

- 26

- 30

+ 10

+ 10

+ 13

+ 20

+ 20

+ 25

+ 10

+ 10

+ 10

+ 12

+ 20

+ 20

+ 25

+ 10

+ 10

+ 12

+ 12

+ 16

+ 16

+ 20

+ 10

+ 10

+ 12

+ 12

+ 16

+ 16

+ 20

+ 10

+ 10

+ 12

+ 12

+ 14

+ 15

+ 10

+ 12

+ 14

+ 14

+ 15

+ 125°C+ 85°C- 55°C

+ 12

+ 12

+ 16

+ 25

+ 25

+ 30

+ 12

+ 12

+ 15

+ 15

+ 25

+ 25

+ 30

+ 12

+ 12

+ 15

+ 15

+ 20

+ 20

+ 25

+ 12

+ 12

+ 15

+ 15

+ 20

+ 20

+ 25

+ 12

+ 12

+ 15

+ 15

+ 16

+ 17

+ 12

+ 15

+ 16

+ 16

+ 17

°C

55

49

32

29

22

Max. DCL (µA) at

+ 85°C

°C

+ 25

10

10

12

3

3

4

4

9

9

3

3

5

5

10

10

12

+ 125°C

2

2

3

8

8

9

2

2

4

4

6

8

9

3

3

4

4

8

8

9

3

5

16

32

32

36

9

9

24

24

32

32

36

12

12

20

20

32

32

36

12

12

24

24

36

36

40

12

12

24

24

40

48

12

24

40

40

48

9

9

Max. ESR

CAPACITANCE

(µF)

33

47

120

220

390

470

22

33

82

120

160

270

330

18

27

68

100

140

220

270

15

22

56

82

110

180

220

8.2

10

33

39

68

120

6.8

27

39

47

82

*Part Numbers listed are for units with outer plastic-film insulation and a capacitance tolerance of ± 20%. For bare case units, substitute "0"

for "2" at the end of the Part Number. For capacitors with ± 10% tolerance, change the digit following the letter "X" to "9".

CASE

CODE

C

C

F

T

T

K

C

C

F

F

T

T

K

C

C

F

F

T

T

K

C

C

F

F

T

T

K

C

C

F

F

T

K

C

F

T

T

K

138D336X0035C2

138D476X0035C2

138D127X0035F2

138D227X0035T2

138D397X0035T2

138D477X0035K2

138D226X0050C2

138D336X0050C2

138D826X0050F2

138D127X0050F2

138D167X0050T2

138D277X0050T2

138D337X0050K2

138D186X0060C2

138D276X0060C2

138D686X0060F2

138D107X0060F2

138D147X0060T2

138D227X0060T2

138D277X0060K2

138D156X0075C2

138D226X0075C2

138D566X0075F2

138D826X0075F2

138D117X0075T2

138D187X0075T2

138D227X0075K2

100WVDC at + 85°C . . . 65WVDC at + 125°C

138D825X0100C2

138D106X0100C2

138D336X0100F2

138D396X0100F2

138D686X0100T2

138D127X0100K2

138D685X0125C2

138D276X0125F2

138D396X0125T2

138D476X0125T2

138D826X0125K2

at + 25°C

(Ohms)PART NUMBER*

35WVDC at + 85°C . . . 22WVDC at + 125°C

5.2

5.2

2.5

1.8

1.8

1.3

50WVDC at + 85°C . . . 30WVDC at + 125°C

2.5

2.5

1.8

1.8

1.5

60WVDC at + 85°C . . . 40WVDC at + 125°C

2.5

1.8

1.5

75WVDC at + 85°C . . . 50WVDC at + 125°C

5

5

3

2.5

2

1.8

2.2

6

6

3.5

3.5

2.2

2.8

125WVDC at + 85°C . . . 85WVDC at + 125°C

11.7

3.5

2.2

2.2

2.8

Max. IMP.

at - 55

(Ohms)

130

115

45

30

27

21

5

5

5

5

3

2

150

135

160

144

60

54

32

29

23

175

157

70

63

33

30

24

250

200

85

80

40

30

300

90

60

50

32

Document Number: 40025

Revision 15-Oct-03

For technical questions, contact wettants@vishay.com

www.vishay.com

59

Page 6

138D

Vishay

Sintered Anode TANTALEX

Wet Tantalum Capacitors

®

Capacitors Hermetically-Sealed

with True Glass-to-Tantalum Seal

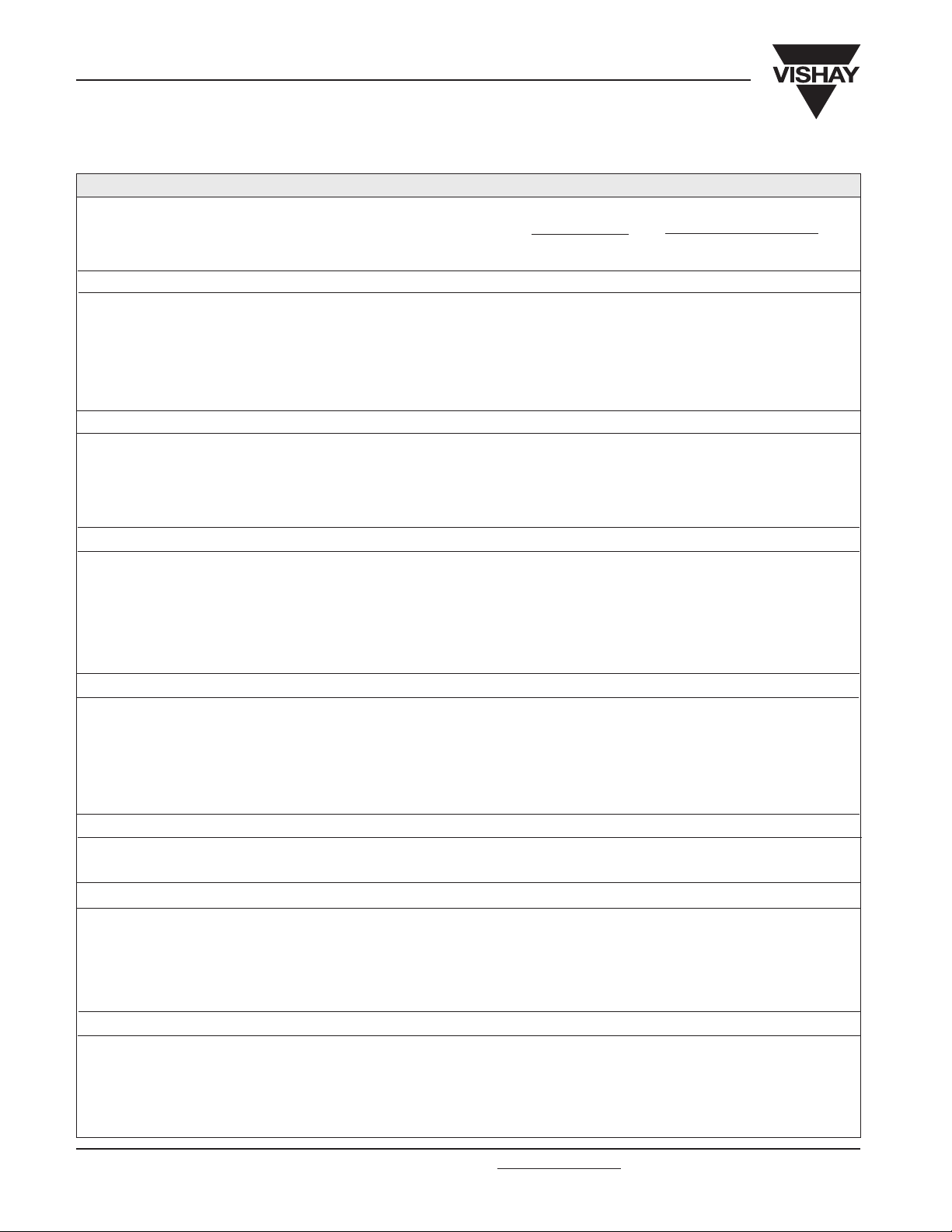

TYPICAL CURVES OF IMPEDANCE AS A FUNCTION OF FREQUENCY AT VARIOUS TEMPERATURES

“K” Case 120µF, 25V Capacitors

200

100

10

- 55°C

IMPEDANCE IN OHMS

1.0

+125°C

0.2

100 1K 10K 100K 1M 10M

+ 85°C

FREQUENCY IN HERTZ

- 40°C

- 20°C

+ 25°C

PERFORMANCE CHARACTERISTICS

1. Operating Temperature: Capacitors are designed to

operate over the temperature range of - 55°C to

+125°C.

UP TO + 85°C AT + 125°C UP TO + 85°C AT + 125°C

WORKING WORKING WORKING WORKING

VOLTAGE VOLTAGE VOLTAGE VOLTAGE

(V) (V) (V) (V)

6 4 35 22

8 5 50 30

10 7 60 40

15 10 75 50

20 13 100 70

25 15 125 85

30 20 150 100

2. DC Working Voltage: The DC working voltage is the

maximum operating voltage for continuous duty at the

rated temperature.

3. Surge Voltage: The surge DC rating is the maximum

voltage to which the capacitors should be subjected

under any conditions. This includes transients and

peak ripple at the highest line voltage. The surge

voltage of capacitors rated below 150 volts is 115% of

the rated DC working voltage. The surge voltage of

capacitors rated at 150 volts DC is 165 volts.

3.1 Surge Voltage Test: Capacitors shall withstand the

surge voltage test applied through a 1000 ohm ± 10%

resistor in series with the capacitor and voltage source

at the rate of one-half minute on, four and one-half

minutes off, for 1000 successive test cycles at + 85°C

or + 125°C.

4. Capacitance Tolerance: The capacitance of all

capacitors shall be within the specified tolerance limits

of the nominal rating.

200

100

10

IMPEDANCE IN OHMS

1.0

0.2

100 1K 10K 100K 1M 10M

4.1 Capacitance measurements shall be made by the

bridge method at or referred to, a frequency of 120Hz

at a temperature of + 25°C. A polarizing voltage shall

be used of such magnitude that there shall be no

reversal of polarity due to the AC component. The

maximum AC voltage will be 1 volt rms applied during

measurement.

5. Capacitance Change With Temperature: The

capacitance change with temperature shall not exceed

the limits given in the Standard and Extended Ratings

Table for each capacitor.

6. Equivalent Series Resistance: Measurements shall

be made by the bridge method at or referred to, a

frequency of 120Hz at a temperature of + 25°C. A

polarizing voltage shall be used of such magnitude that

there shall be no reversal of polarity due to the AC

component. The maximum AC voltage will be 1 volt

rms applied during measurement.

6.1. The equivalent series resistance shall not exceed the

maximum value in ohms listed in the Standard and

Extended Ratings Table for each capacitor.

6.2. The dissipation factor may be calculated from the

equivalent series resistance and capacitance values

as shown:

where:

“C” Case 10µF. 100V Capacitors

+125°C

FREQUENCY IN HERTZ

+ 85°C

DF = 2πfRC

4

10

DF = Dissipation Factor in %

R = ESR in ohms

C = Capacitance in µF

f = frequency in Hz

- 55°C

- 40°C

- 20°C

+ 25°C

www.vishay.com

60

For technical questions, contact wettants@vishay.com

Document Number: 40025

Revision 15-Oct-03

Page 7

138D

Wet Tantalum Capacitors

Sintered Anode TANTALEX

with True Glass-to-Tantalum Seal

PERFORMANCE CHARACTERISTICS (Cont’d)

At 120Hz, the above equation becomes:

DF = R x C

13.26

For example, percent dissipation factor of a 30µF, 6

volt capacitor, which has a maximum ESR of 3.4 ohms

at + 25°C and 120Hz, would be calculated as shown:

DF = 2π x 120 x 3.4 x 30

7. Leakage Current: Measurements shall be made at

the applicable rated working voltage at + 25°C ± 5°C

through application of a steady source of power, such

as a regulated power supply. The total resistance in

series with each capacitor shall be between 1000 ohms

and 10,000 ohms. The voltage shall be applied to the

capacitor for 5 minutes before making the leakage

current measurement.

7.1. The maximum leakage current for any capacitor shall

not exceed the value in microamperes listed in the

Standard and Extended Ratings Table for each

capacitor.

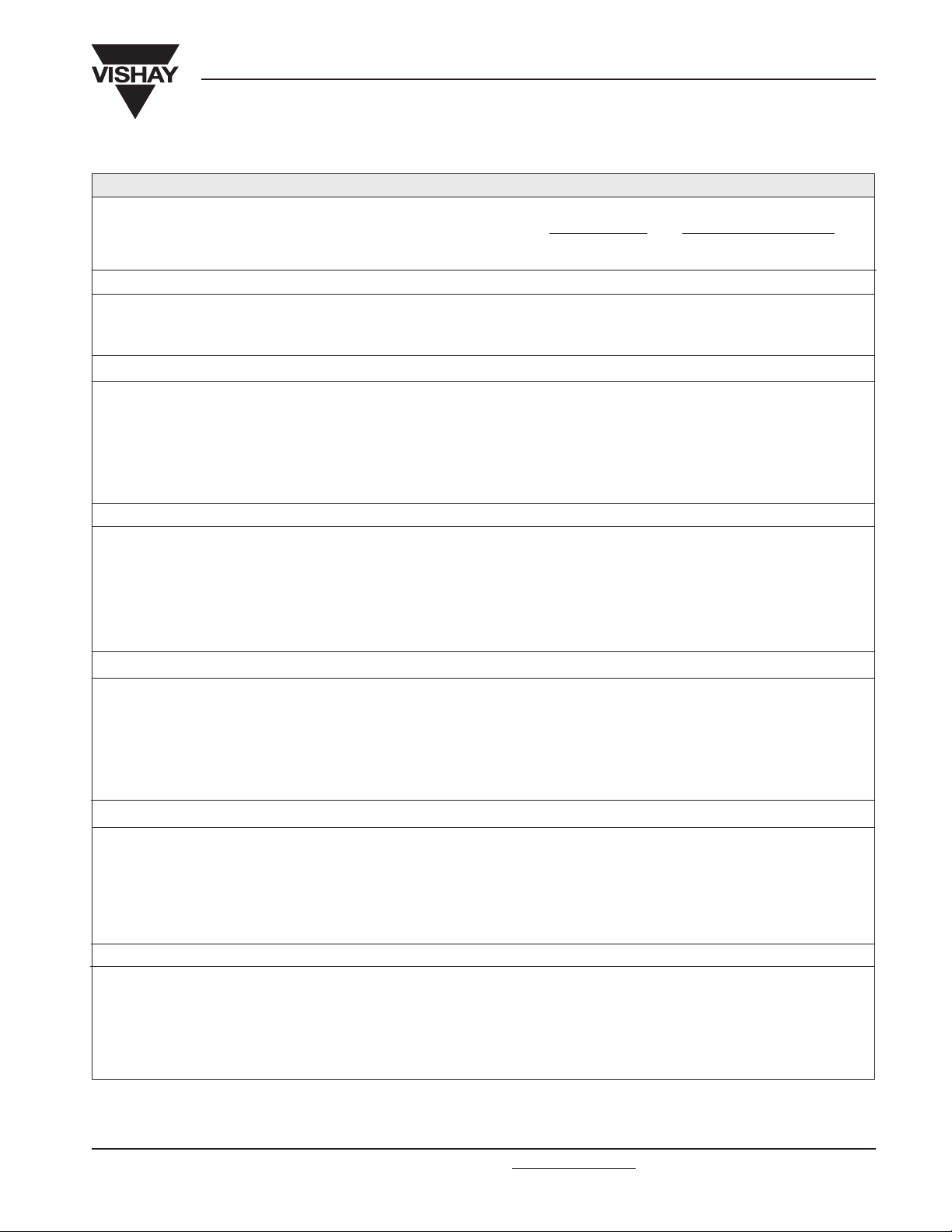

Note: leakage current varies with applied voltage. See graph below

for the appropriate adjustment factor.

10

4

LEAKAGE AS A FUNCTION OF VOLTAGE &

TEMPERATURE

Leakage Current Factor

Percent of Rated Voltage

8. Low Temperature Impedance: The impedance of any

capacitor at - 55°C at 120Hz, shall not exceed the

values given in the Standard and Extended Ratings

Tables.

=

3.4 x 30

13.26

= 7.7%

®

Capacitors Hermetically-Sealed

9. Life Test: Capacitors are capable of withstanding a

2000 hour life test at a temperature of + 85°C or

+ 125°C at the applicable rated DC working voltage.

10. High Frequency Vibration: Capacitors shall with

stand vibration from 10Hz to 2000Hz at 20g when

tested.

11. Lead Pull Test: Capacitors shall withstand a lead

tensile stress of 3 pounds (13.2N) for 30 seconds,

applied axially.

12. Marking: Capacitors shall be marked with Sprague

and/or the Sprague® trademark 2, the Sprague® type

(138D); rated capacitance and tolerance (the tolerance

shall be coded, using the list shown in How to Order);

rated DC working voltage at + 85°C; the standard EIA

date code of manufacture.

GUIDE TO APPLICATION

1. Ripple Current: All capacitors will withstand rms ripple

currents as listed for each capacitor.

1.1. The rms ripple current rating is independent of

temperature or frequency within the following

limitations:

1.1.1.At frequencies of less than 120Hz, the rated rms ripple

current must be multiplied by the factors shown:

FREQUENCY IN HERTZ

25 50 60 100

0.36 0.59 0.65 0.88

1.1.2 The sum of the peak AC voltage plus the DC voltage

shall not exceed the DC working voltage of the

capacitor.

1.1.3 The sum of the negative peak AC voltage, plus the

applied DC voltage shall not allow a voltage reversal.

2. Cleaning wiring boards with Type 138D capacitors:

Customary cleaning solvents used in the electronics

industry at present will not affect Type 138D capacitors.

However, the use of ultrasonic cleaning techniques is

not recommended under any circumstances.

3. Apparent Capacitance: Note that in timing circuit

applications, the circuit designer must take into account

two important variables which affect any electrolytic

capacitor. These are the internal leakage resistance

of the capacitor and its dielectric absorption, which will

depend on the elapsed time since the capacitor was

last energized.

In applications where electrolytic capacitors are

subjected to DC energy, or in effect, extremely low

frequencies, the value of the apparent capacitance will

be somewhat higher than that which is measured at

120HZ.

4. No Reverse Voltage: The application of reverse

voltage to these capacitors will cause internal damage.

The resulting damage will lead to immediate or delayed

failure of the unit. This will take the form of a

catastrophic short circuit with possible expulsion of the

electrolyte.

Vishay

®

Document Number: 40025

Revision 15-Oct-03

For technical questions, contact wettants@vishay.com

www.vishay.com

61

Loading...

Loading...