Page 1

MTK

PRODUCT SUMMARY

I

O

130-160MT..KPbF Series

Vishay High Power Products

Three Phase Bridge, 130/160 A

(Power Modules)

FEATURES

• Package fully compatible with the industry

standard INT-A-PAK power modules series

• High thermal conductivity package, electrically

insulated case

• Excellent power volume ratio

130/160 A

• 4000 V

• UL E78996 approved

• Totally lead (Pb)-free

• Designed and qualified for industrial level

DESCRIPTION

A range of extremely compact, encapsulated three phase

bridge rectifiers offering efficient and reliable operation.

They are intended for use in general purpose and heavy duty

applications.

isolating voltage

RMS

RoHS

COMPLIANT

MAJOR RATINGS AND CHARACTERISTICS

SYMBOL CHARACTERISTICS 130MT.K 160MT.K UNITS

I

O

I

FSM

2

I

t

2

I

√t 64 000 102 000 A2√s

V

RRM

T

Stg

T

J

T

C

50 Hz 1130 1430

60 Hz 1180 1500

50 Hz 6400 10 200

60 Hz 5800 9300

Range 800 to 1600 V

Range - 40 to 150 °C

130 (160) 160 (200) A

85 (62) 85 (60) °C

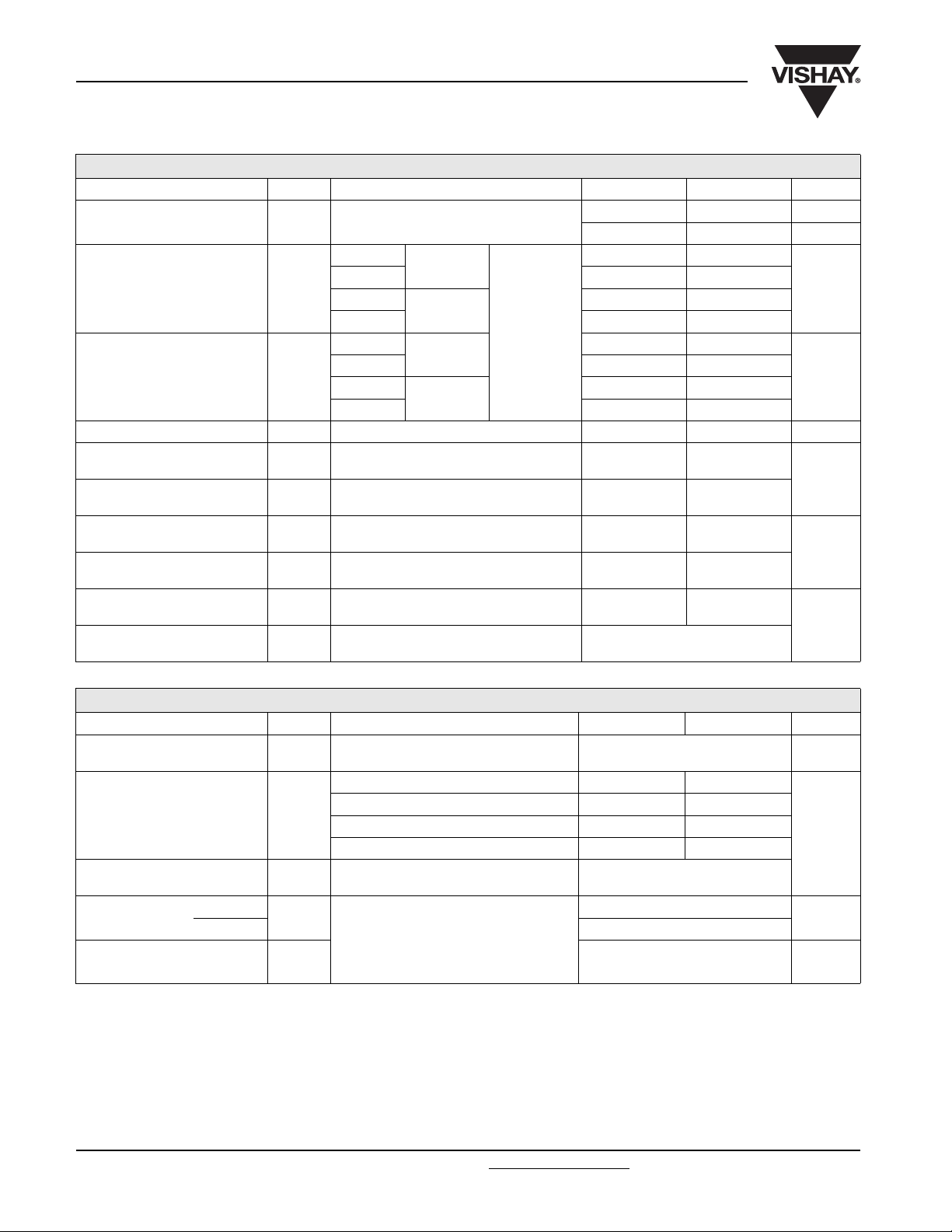

ELECTRICAL SPECIFICATIONS

VOLTAGE RATINGS

V

TYPE NUMBER

130-160MT..K

, MAXIMUM REPETITIVE

VOLTAGE

CODE

80 800 900

100 1000 1100

120 1200 1300

140 1400 1500

160 1600 1700

RRM

PEAK REVERSE VOLTAGE

V

V

, MAXIMUM NON-REPETITIVE

RSM

PEAK REVERSE VOLTAGE

V

I

RRM

AT T

A

A2s

MAXIMUM

= MAXIMUM

J

mA

10

Document Number: 94354 For technical questions, contact: ind-modules@vishay.com

Revision: 29-Apr-08 1

www.vishay.com

Page 2

130-160MT..KPbF Series

Vishay High Power Products

Three Phase Bridge, 130/160 A

(Power Modules)

FORWARD CONDUCTION

PARAMETER SYMBOL TEST CONDITIONS 130MT.K 160MT.K UNITS

Maximum DC output current

at case temperature

Maximum peak, one-cycle

forward, non-repetitive surge

current

Maximum I

Maximum I

Low level value of

threshold voltage

High level value of

threshold voltage

2

t for fusing I2t

2

√t for fusing I2√t t = 0.1 to 10 ms, no voltage reapplied 64 000 102 000 A2√s

V

V

Low level value of forward slope

resistance

High level of forward slope

resistance

Maximum forward

voltage drop

RMS isolation voltage V

I

O

I

TSM

T(TO)1

T(TO)2

r

f1

r

f2

V

FM

ISOL

120° rect. conduction angle

t = 10 ms

t = 8.3 ms 1180 1500

t = 10 ms

t = 8.3 ms 1000 1260

t = 10 ms

t = 8.3 ms 5800 9300

t = 10 ms

t = 8.3 ms 4100 6600

(16.7 % x π x I

maximum

T

J

(I > π x I

16.7 % x π x I

T

maximum

J

(I > π x I

No voltage

reapplied

RRM

Initial

T

maximum

J

= TJ

100 % V

reapplied

No voltage

reapplied

100 % V

RRM

reapplied

< I < π x I

T(AV)

), TJ maximum 0.99 1.04

T(AV)

< I < π x I

T(AV)

), TJ maximum 4.17 3.13

T(AV)

T(AV)

T(AV)

),

),

Ipk = 200 A, TJ = 25 °C,

t

= 400 µs single junction

p

TJ = 25 °C, all terminal shorted

f = 50 Hz, t = 1 s

130 (160) 160 (200) A

85 (62) 85 (60) °C

1130 1430

950 1200

64 000 102 000

4500 7200

0.78 0.81

4.59 3.52

1.63 1.49

4000

A

A

V

mΩ

V

2

s

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER SYMBOL TEST CONDITIONS 130MT.K 160MT.K UNITS

Maximum junction operating

and storage temperature range

Maximum thermal resistance,

junction to case

Maximum thermal resistance,

case to heatsink

Mounting

torque ± 10 %

to heatsink

to terminal 3 to 4

Approximate weight 176 g

www.vishay.com For technical questions, contact: ind-modules@vishay.com

2 Revision: 29-Apr-08

T

, T

J

Stg

- 40 to 150 °C

DC operation per module 0.16 0.12

R

thJC

DC operation per junction 0.93 0.73

120° rect. condunction angle per module 0.18 0.15

K/W

120° rect. condunction angle per junction 1.08 0.88

R

thCS

Per module

Mounting surface smooth, flat and greased

A mounting compound is recommended

and the torque should be rechecked after

0.03

4 to 6

Nm

a period of 3 hours to allow for the

spread of the compound.

Lubricated threads.

Document Number: 94354

Page 3

130-160MT..KPbF Series

150

140

130

120

110

100

90

80

Maximum Allowable

Case Temperature (°C)

~

70

60

50

0

20 40 60 80 120100

130MT..K Series

+

-

Instantaneous Forward Voltage (V)

Fig. 1 - Current Ratings Characteristic Fig. 2 - Forward Voltage Drop Characteristics

500

130MT..K Series

450

T

= 150 °C

J

400

350

300

250

200

150

100

50

Maximum Total Power Loss (W)

0

20 40 60 80 100

0

Total Output Current (A)

Three Phase Bridge, 130/160 A

(Power Modules)

120° (Rect)

180160140

120°

(Rect)

160140120

Fig. 3 - Total Power Loss Characteristics

Vishay High Power Products

1000

100

TJ = 25 °C

R

thSA

= 0.05 K/W - ΔR

TJ = 150 °C

130MT..K Series

Per junction

10

Instantaneous Forward Current (A)

1

1.0 2.0 3.0 4.0 5.00

Instantaneous Forward Voltage (V)

500

450

400

350

300

250

200

150

100

50

Maximum Total Power Loss (W)

0.12 K/W

0.2 K/W

0.3 K/W

0.5 K/W

0.7 K/W

1.5 K/W

0

25 50 75 100 125

0

Maximum Allowable Ambient Temperature (°C)

150

1000

900

800

700

600

500

400

Forward Current (A)

Peak Half Sine Wave

300

200

1

At any rated load condition and with

130MT..K Series

Number of Equal Amplitude

rated V

applied following surge.

RRM

Initial TJ = 150°C

at 60 Hz 0.0083 s

at 50 Hz 0.0100 s

10

100

1200

1100

1000

900

800

700

600

500

Forward Current (A)

Peak Half Sine Wave

400

300

200

Maximum non-repetitive surge current

130MT..K Series

Pulse Train Duration (s)

versus pulse train duration.

Initial TJ = 150 °C

No voltage reapplied

Rated V

0.1 1.00.01

reapplied

RRM

Half Cycle Current Pulses (N)

Fig. 4 - Maximum Non-Repetitive Surge Current Fig. 5 - Maximum Non-Repetitive Surge Current

Document Number: 94354 For technical questions, contact: ind-modules@vishay.com

www.vishay.com

Revision: 29-Apr-08 3

Page 4

130-160MT..KPbF Series

Vishay High Power Products

150

140

130

120

110

100

90

80

Maximum Allowable

Case Temperature (°C)

~

70

60

50

0

80 120 20040 160

Total Output Current (A)

Fig. 6 - Current Ratings Characteristic Fig. 7 - Forward Voltage Drop Characteristics

600

160MT..K Series

T

= 150 °C

500

400

300

200

100

J

Maximum Total Power Loss (W)

0

40 80 120 160

0

Total Output Current (A)

160MT..K Series

120°

(Rect)

+

-

120°

(Rect)

Three Phase Bridge, 130/160 A

(Power Modules)

1000

100

10

Instantaneous Forward Current (A)

240

200

Fig. 8 - Total Power Loss Characteristics

1

0

600

500

0.15 K/W

400

0.2 K/W

0.3 K/W

300

0.5 K/W

200

0.7 K/W

100

1.5

Maximum Total Power Loss (W)

0

0

Maximum Allowable Ambient Temperature (°C)

TJ = 25 °C

TJ = 150 °C

160MT..K Series

Per junction

1234

Instantaneous Forward Voltage (V)

R

thSA

0.1 K/W

K/W

25

= 0.05 K/W - ΔR

50

75

100

125

5

150

1300

1200

1100

1000

900

800

700

600

Forward Current (A)

Peak Half Sine Wave

500

400

300

160MT..K Series

Number of Equal Amplitude

At any rated load condition and with

rated V

applied following surge.

RRM

Initial TJ = 150 °C

at 60 Hz 0.0083 s

at 50 Hz 0.0100 s

10 1001

1500

1400

1300

1200

1100

1000

900

800

700

600

Forward Current (A)

Peak Half Sine Wave

500

400

300

0.01

Maximum non-repetitive surge current

160MT..K Series

Pulse Train Duration (s)

versus pulse train duration.

Initial TJ = 150 °C

No voltage reapplied

Rated V

RRM

0.1

reapplied

1.0

Half Cycle Current Pulses (N)

Fig. 9 - Maximum Non-Repetitive Surge Current Fig. 10 - Maximum Non-Repetitive Surge Current

www.vishay.com For technical questions, contact: ind-modules@vishay.com

Document Number: 94354

4 Revision: 29-Apr-08

Page 5

130-160MT..KPbF Series

Three Phase Bridge, 130/160 A

10

Steady state value

= 0.93 K/W

R

thJC

R

= 0.73 K/W

thJC

(DC operation)

1

0.1

0.01

- Transient Thermal Impedance (K/W)

0.001 0.01 0.1 1

thJC

Z

ORDERING INFORMATION TABLE

Device code

16 0 MT 160 K PbF

(Power Modules)

Square Wave Pulse Duration (s)

Fig. 11 - Thermal Impedance Z

Per junction

Characteristics

thJC

Vishay High Power Products

130MT..K Series

160MT..K Series

10

- Current rating code: 13 = 130 A (average)

1

- Three phase diodes bridge

2

- Essential part number

3

- Voltage code x 10 = V

4

5

- PbF = Lead (Pb)-free

Note

• To order the optional hardware go to www.vishay.com/doc?95172

CIRCUIT CONFIGURATION

A

~

B

C

4

5132

16 = 160 A (average)

(see Voltage Ratings table)

RRM

+

D

E

-

F

LINKS TO RELATED DOCUMENTS

Dimensions http://www.vishay.com/doc?95004

Document Number: 94354 For technical questions, contact: ind-modules@vishay.com

Revision: 29-Apr-08 5

www.vishay.com

Page 6

Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000 www.vishay.com

Revision: 18-Jul-08 1

Loading...

Loading...