Page 1

Sierra de incisión

Plunge-cut saw

Scie circulaire plongeante

Tauchsäge

Sega circulare a tuffo

Serra de incisão

Пила циркулярная погружная

Pilarko-zagłębiarka

SRI174T

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D’ EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D’ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

INSTRUKCJA OBSŁUGI

Page 2

2

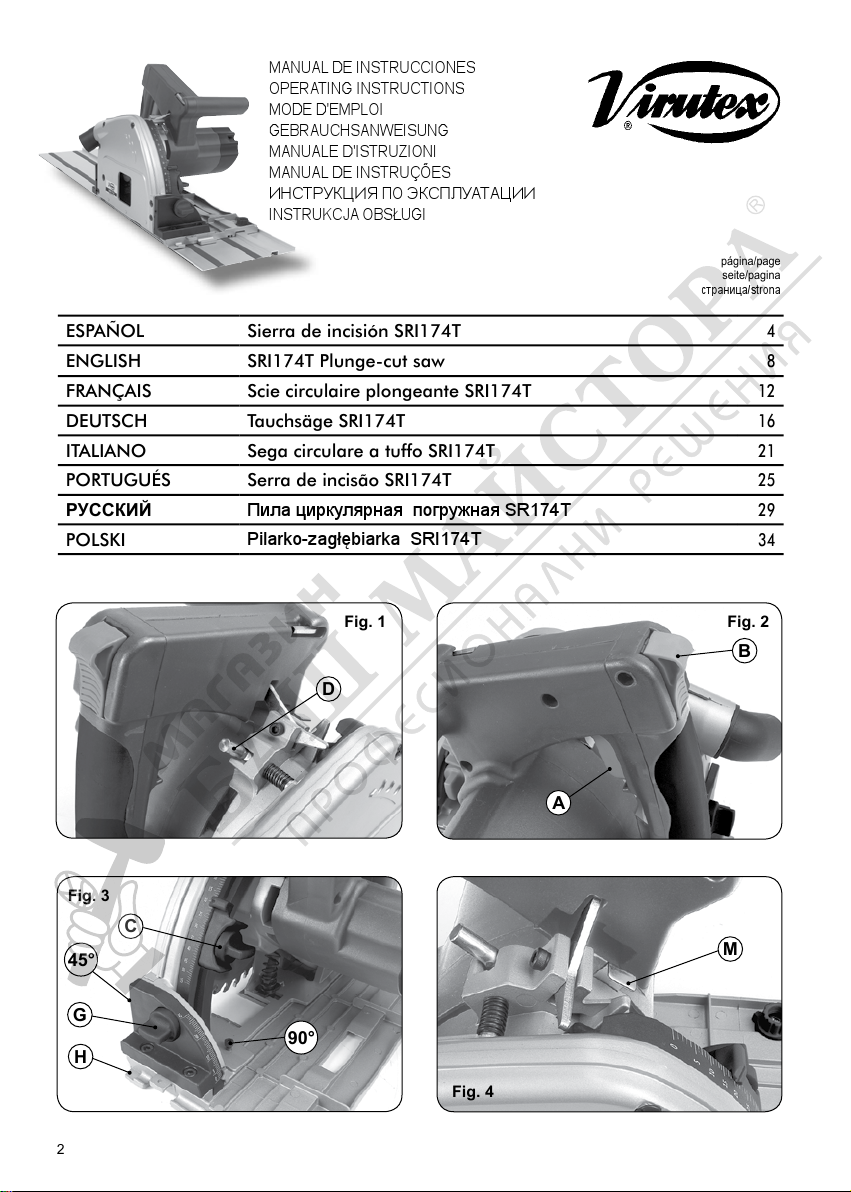

Fig. 1 Fig. 2

Fig. 4

Fig. 3

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D'EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D'ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ

ПО

ЭКСПЛУАТАЦИИ

INSTRUKCJA OBSŁUGI

página/page

seite/pagina

страница/strona

ESPAÑOL Sierra de incisión SRI174T

4

ENGLISH SRI174T Plunge-cut saw

8

FRANÇAIS Scie circulaire plongeante SRI174T

12

DEUTSCH Tauchsäge SRI174T

16

ITALIANO Sega circulare a tuffo SRI174T

21

PORTUGUÉS Serra de incisão SRI174T

25

РУССКИЙ Пила циркулярная погружная SR174T

29

POLSKI

Pilarko-zagłębiarka SRI174T

34

D

B

A

90°

M

C

G

H

45°

Page 3

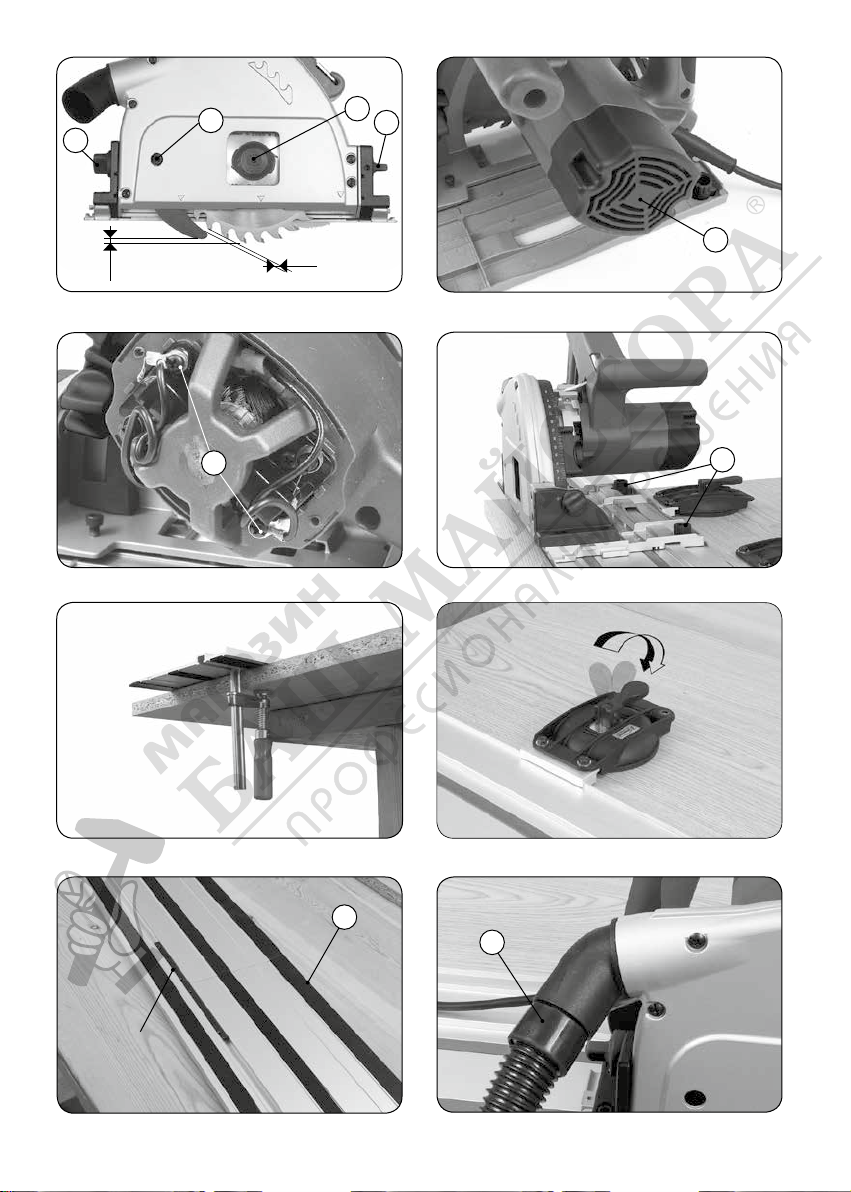

Fig. 5

G

Fig. 9

2 - 4 mm

E

F

G

L

2 - 4 mm

Fig. 7

K

Fig. 8

Fig. 6

J

Fig. 11

Fig. 10

Fig. 12

P

N

7445818

3

Page 4

8

muy diferente al valor declarado en otras condiciones

de aplicación, con otros útiles de trabajo o con un

mantenimiento insuficiente de la herramienta eléctrica

y sus útiles, pudiendo llegar a resultar un valor mucho

más elevado debido a su ciclo de trabajo y modo de uso

de la herramienta eléctrica.

Por tanto, es necesario fijar medidas de seguridad de

protección al usuario contra el efecto de las vibraciones,

como pueden ser mantener la herramienta y útiles de

trabajo en perfecto estado y la organización de los

tiempos de los ciclos de trabajo (tales como tiempos

de marcha con la herramienta bajo carga, y tiempos de

marcha de la herramienta en vacío y sin ser utilizada

realmente ya que la reducción de estos últimos puede

disminuir de forma sustancial el valor total de exposición).

17. GARANTÍA

Todas las máquinas electroportátiles VIRUTEX, tienen una

garantía válida de 12 meses a partir del día de suministro,

quedando excluidas todas las manipulaciones o daños

ocasionados por manejos inadecuados o por desgaste

natural de la máquina. Para cualquier reparación, dirigirse

al servicio oficial de asistencia VIRUTEX, S.A.

VIRUTEX se reserva el derecho de modificar sus productos

sin previo aviso.

ENGLISH

SRI174T PLUNGE-CUT SAW

Important

Read these OPERATING INSTRUCTIONS

and the attached GENERAL SAFETY

INSTRUCTIONS LEAFLET carefully before

using the machine. Make sure you have

understood them before operating the

machine for the first time.

Keep both sets of instructions for any

future queries.

1. SAFETY INSTRUCTIONS FOR USING THE

PLUNGE-CUT CIRCULAR SAW

1.1 GENERAL INSTRUCTIONS

• We recommend that, while using the machine, you

keep the documents relating to it within reach, so that

you can consult them if necessary while working. We

also recommend that if possible, you keep a copy in a

safe place.

• Check the condition of the plug and cable every time

you use the machine.

• Unplug the power supply before handling the machine.

• Always keep the cable away from the moving parts

of your machine.

• Only plug into the power socket with the machine

switched off.

• If you need to use an electric extension lead, the wires

must be at least 1 mm

2

in diameter and the cable must

be completely unwound.

• Use a blocking device for the piece you are going

to work on whenever possible, so that it does not slip.

• In the event of jamming, turn the machine off imme-

diately and unplug the power supply. Do not resume work

without having removed the cause of the jamming. If this

is inside the machine, give it to an authorised technician.

• Before using an accessory, make sure that its maxi-

mum rotation speed is compatible with the machine’s

performance.

• As far as possible, always use protective equipment

such as gloves, goggles, safety shoes, etc. Off-cuts can

lead to injuries.

• Before cutting on a wall, floor or ceiling, make sure

there is no pipework behind it.

• Power tools must not be used by people under 16

years old.

• Only bring the machine in operation near to the piece

being worked on.

• Both above and below the cut path must be free of

obstacles.

• Do not put your fingers in the shavings ejection

nozzle.

• Keep your hands away from the moving saw. Avoid

contact with the saw blade that protrudes from the

lower part of the unit.

• Do not use the machine above your head.

• Do not work with materials containing asbestos.

• Do not use blades with a base disk that is thicker or

with a kerf that is smaller than the thickness of the

dividing knife.

• The cutting guide must be readjusted when changing

circular saws with different diameters.

• When the machine is turned off, wait for the blade

to stop by itself. Never stop the blade by pressing on it

from the side or in the centre.

• Always use the dividing knife.

• Never force a machine that appears to have operating

difficulties or shows some sort of weakness. There may

be a technical problem, in which case continuing to work

could damage the machine irreparably. In all cases where

the machine does not work properly, have it checked by

an authorised agent without delay.

• Use only original accessories.

1. 2 SPECIFIC INSTRUCTIONS

FOR THE MACHINE

CAUTION

Page 5

• Do not place your hands in the sawing area or near

the saw blade. Hold the machine with both hands, using

the two handles of the circular saw. This will prevent

them from being injured by the saw blade.

• Do not hold the piece to be sawn from below. The

saw protection does not cover the saw blade below the

piece to be sawn.

• Adapt the cutting depth to suit the thickness of the

material. No more than one complete tooth’s height

should be visible under the material.

• Never hold the piece you are going to saw with one

hand or on your leg. Place the piece somewhere it is

well supported. It is very important to fix the material

correctly in order to minimise risks of contact with the

body, jamming of the sawing blade or loss of control.

• Wear the appropriate personal protection equipment:

ear protection, protective goggles and a mask for dusty

work, and protective gloves when working with rough

materials and when changing tools.

1. 3 CAUSES OF BACKLASH

AND WAYS TO AVOID IT

• A backlash is the unexpected reaction of a saw blade

which becomes jammed, blocked or is incorrectly aligned, which may lead to the saw exiting the material in

an uncontrolled fashion and being deflected towards

the user.

• The saw blade becomes blocked when it becomes

hooked or jammed in the slot being sawn which becomes narrower, and the strength of the motor jerks it

backwards towards the user.

• If the saw blade becomes twisted or incorrectly aligned,

the teeth on the lower part of the saw can become stuck

in the surface of the material, making the blade jump

out towards the user. Backlash occurs as a consequence

of incorrect or inappropriate usage of the saw. It can

be avoided if the appropriate precautionary measures

described below are taken.

• Hold the saw with both hands and position your arms

in such a way as to be able to deal with the strength

of a backlash. Always hold the saw blade to one side.

Never place it in line with your body. In the event of a

backlash the circular saw may jerk backwards. However,

the force of the backlash can be controlled by the user

by applying the appropriate measures.

• In the event of the saw blade becoming blocked or the

sawing work stopping for any other reason, release the

on/off switch and hold the saw firmly in the material

until the saw blade has stopped completely. Do not under

any circumstances attempt to take the saw out of the

material or pull the saw backwards while the blade is

moving, as this may cause a backlash. Determine the

cause of the saw blade blockage and rectify the problem

by taking the appropriate measures.

• If you want to carry on working with a saw blade that

is in material, centre the blade on the sawing groove

and make sure that the teeth of the saw are not stuck

in the material. If the saw blade is stuck, it may come

out of the material or cause a backlash when it is

turned on again.

• Prop up large panels to prevent the risk of a backlash

when a saw blade becomes stuck. Large panels may

bend due to their own weight. The panels must be

supported on both sides, next to the sawing groove

and also on the edge.

• Do not use blunt or damaged saw blades. Saw blades

with blunt or incorrectly aligned teeth result in increased

friction, blocked saw blades and backlash, as the saw

groove is too narrow.

• Before starting to saw, set the cutting depths and angles.

If the settings change while sawing, the saw blade may

become stuck and could cause a backlash.

• Be especially careful when making plunge cuts in a

hidden area, such as a wall. The saw blade making the

plunge cut may become blocked when it comes across

hidden objects and cause a backlash.

2. SPECIFICATIONS

Motor.................................................50/60Hz

Imput power..........................................1150 W

No-load speed...................................5500/min

Saw diameter......................................160 mm

Depth of cut at 90°................................55 mm

Depth of cut at 45°...............................35 mm

Dividing knife............................................Yes

Weight....................................................4,7 Kg

Weighted equivalent continuous

acoustic pressure level A..................................................89 dBA

Acoustic power level A...................................................100 dBA

Uncertainty...................................................................K = 3 dbA

Wear ear protection!

Vibration total values.................................................ah: 3.5 m/s

Uncertainty....................................................................K: 1.5 m/s

3. STANDARD EQUIPMENT

• SRI174T plunge-cut circular saw in transport case

• One M5 Allen Key

• One dust collector connection N (Fig. 12),

ref.8204262

• Operating instructions and miscellaneous documentation.

• 800 mm guide rail (only with the SRI174T-UCP 800

mm model)

4. STARTING THE MACHINE

• Switching On - Press the safety button B then press

9

2

2

Page 6

10

button A and hold depressed. (Fig. 2)

• Switching Off - Release switch button A.

5. ADJUSTING THE CUT DEPTH

The cut depth must be approximately 5 mm greater

than the thickness of the material to be cut. Loosen

screw C (Fig. 3), set the limit of the desired cut depth

and tighten screw C again.

6. ADJUSTING THE DIVIDING KNIFE

The dividing knife helps to prevent a backlash.

For safety reasons, the dividing knife must be installed

and correctly adjusted before any sawing operation

takes place.

The dividing knife must be set so that the distance

between the saw blade circle and the dividing knife is

2 to 4 mm, and the saw blade is 2 to 4 mm lower than

the dividing knife.

Disconnect the machine from the mains

before performing any operation.

To adjust the dividing knife, the machine must be locked

in the “Saw Change” position.

To do this, pull rod D outwards (Fig. 1) and turn it 90°

clockwise until it meets the support cradle and then free

the machine using safety catch B (Fig. 2) and press this

in the cutting direction until the trigger is automatically

set in the “Saw Change” position on the machine. Use the

Allen key to loosen screw E (Fig. 5), adjust the dividing

knife as needed and retighten it.

Loosen rod D (Fig. 1) and turn it anticlockwise until its

original position and the machine will return automa-

tically to its rest position.

7. CHANGING THE SAW BLADE

Disconnect the machine from the mains

before performing any operation.

Follow the instructions in section 6, to set the machine

in the “Saw Change” position.

Once the machine is set, press lever M (Fig. 4) until the

axis is wedged in place.

Using the Allen key, loosen screw F (Fig. 5) which holds

the outer fixing plate.

Remove the outer fixing plate and the saw blade and

clean the inner saw fixing plate.

Fit the new saw blade and check that the rotation direc-

tions of the saw blade and the machine are the same.

Fit the outer fixing plate of the saw and manually attach

fastening screw F (Fig. 5) to the axis.

Press lever M (Fig. 4) until the axis is wedged in place

and tighten screw F with the Allen key.

8. ATTACHING THE DUST COLLECTOR

The dust collector connection N (Fig. 12) included in the

standard machine, can be connected to the machine by

means of the STANDARD DUST CONNECTOR FITTING, 3.5

m ref. 6446073 or 1746245 of 5 m (optional) to our dust

collectors AS182K, AS282K, or any other industrial dust

collector may be fitted (Fig. 12).

9. ADJUSTING THE CUTTING ANGLE

The machine can be adjusted to make bevelled cuts of

between 0° and 45°. To do this, loosen the front and

back knobs G (Fig. 3 and 5), adjust to the desired cutting

angle and fix them once again.

Warning: The two final positions (0° and 45°) are ad-

justed in the factory but can be readjusted by technical

service. (Fig. 3).

10. SAWING WITH THE MACHINE

Always fix the material in place so that it cannot move

when you work with it.

The machine must always be held with both hands on

the handles provided for that purpose.

Always hold the side handle with the left hand and

the front handle with the right hand to give you good

control of the saw.

Check that you have set the right cutting depth.

Place the front of the saw base on the material.

Turn the machine on and press slowly downwards until

you reach the desired cutting depth.

Always move the machine forwards,

never towards you, as this could cause a

serious accident.

Move forward gently and evenly, never sharply.

Make sure that the base of the machine is well supported

on the material.

When you saw along a previously marked line, you can

use the guide groove H (Fig. 3), located at the front of

the base, to follow the line. Groove H shows the cutting

line of the saw at any blade angle.

When you finish cutting, turn off the machine and take

it to its upper safety position.

11. SAWING BLIND SEGMENTS

BY PLUNGE CUT

When you want to cut blind segments in a panel,

proceed as follows:

Page 7

11

Always place the machine with the edge

of the base against a fixed edge, in order

to prevent backlashes.

• Turn on the machine, press slowly downwards until

you reach the adjusted cutting depth and move forward

smoothly, never sharply, in the cutting direction.

Marks I (Fig. 5) located on the protection cover show

the edges and the centre of the saw blade at its maxi-

mum cut depth.

12. GUIDE RAIL FOR PARALLEL CUTS

Guide rails, available in lengths of 800 mm and of 1400

mm, enable you to make precise and clean cuts, as

well as protecting the surface of the material against

possible damage.

The guide rails are fitted with a splinter protector P

(Fig. 11) which must be cut to size before being used

for the first time:

• Place the machine at the rear end of the guide rail.

• Turn the saw on and press downwards to the set cut

depth and cut the whole length of the splinter protector

without deviation.

• The edge of the splinter protector coincides exactly

with the edge of the cut.

ADJUSTING THE MACHINE ON THE RAIL:

The machine is equipped with adjustment knobs J (Fig.

8) which enable you to eliminate gaps between the

machine channel and the guide rail.

FASTENING THE RAIL TO THE MATERIAL:

With G-clamps, (optional accessory. 2-item set, ref.

6045710):

We recommend using G-clamps to fasten the rail to

the material.

Insert a G-clamp in the slot of the rail at each end,

move them closer to the material and fasten it at the

edges (Fig. 9).

With suction pads, (optional accessory. 2-item set, ref.

7445819):

The rail can also be fixed to the material with which

you wish to work by using the suction pads, although

only when the surface of the material is flat, smooth

and non-porous, such as melamine-coated or smooth

layered surfaces.

We recommend fitting the two suction pads on the rail,

near each edge of the material.

The suction pad works by pressing it down onto the sur-

face to which it is to be attached and moving the central

lever to the horizontal position, as shown (Fig. 10).

The suction pads are specially designed for fixing

templates during routing or sawing jobs. If the work

is carried out non-continuously, with long breaks in

between, it will be necessary to check the suction of

the pads before resuming work.

SAWING WITH A GUIDE RAIL:

Place the machine at the beginning of the guide rail,

switch on the machine, press downwards slowly until

you reach the adjusted cutting depth and move forward

smoothly, never suddenly, in the cutting direction.

13. CHANGING BRUSHES

Disconnect the machine from the mains

before performing any operation.

Brushes should be changed when they have a minimum

length of 6 mm.

To replace them:

Remove the 4 screws holding motor cover L (Fig. 6) and

remove the cover.

Take out the brushes from each brush-holder with

tweezers or pliers.

Remove the screw K (Fig. 7) fastening them, and replace

them with new ones.

Replace the motor cover L (Fig. 6) with the 4 screws.

14. OPTIONAL ACCESSORIES

7406518 UCP174T Guide rail for parallel cuts, 800 mm

(Included as standard in SRI174T-UCP model)

7406519 UCP174T Guide rail for parallel cuts, 1,400

mm

6045710 Set of 2 holding G-clamps.

7445819 Set of 2 UCP174T suction pads.

7445818 UCP rail jointing kit. Enables two rails to be

joined (see Fig. 11).

6446073 Dust collection connector 2.25 m

1746245 Dust collection connector 5 m

15. MAINTENANCE

Make sure that blade guard moves freely and that it

automatically slides over the saw blade. Check blade

guard travel before use when plug is withdrawn.

Motor housing vent slots must be kept clean. Blow out

slots from time to time.

Change carbon brushes when required. Brush length

must be at least 6 mm. Have saw serviced only at

authorized VIRUTEX service centers. Use only original

VIRUTEX spare parts.

16. NOISE AND VIBRATION LEVEL

The noise and vibration levels of this device have been

measured in accordance with European standard EN

60745-2-5 and EN 60745-1 and serve as a basis for com-

Page 8

12

parison with other machines with similar applications.

The indicated vibration level has been determined for

the device’s main applications and may be used as an

initial value for evaluating the risk presented by expo-

sure to vibrations. However, vibrations may reach levels

that are quite different from the declared value under

other application conditions, with other tools or with

insufficient maintenance of the electrical device or its

accessories, reaching a much higher value as a result

of the work cycle or the manner in which the electrical

device is used.

Therefore, it is necessary to establish safety measures

to protect the user from the effects of vibrations, such

as maintaining both the device and its tools in perfect

condition and organising the duration of work cycles

(such as operating times when the machine is subjected

to loads, and operating times when working with no-load,

in effect, not in use, as reducing the latter may have a

considerable effect upon the overall exposure value).

17. WARRANTY

All VIRUTEX power tools are guaranteed for 12 months

from the date of purchase, excluding any damage which

is a result of incorrect use or of natural wear and tear

on the machine. All repairs should be carried out by the

official VIRUTEX technical assistance service.

VIRUTEX reserves the right to modify its products wi-

thout prior notice.

FRANÇAIS

SCIE CIRCULAIRE PLONGEANTE

SRI174T

Important

Avant d'utiliser la machine, lisez attenti-

vement ce MANUEL D'INSTRUCTIONS et la

BROCHURE D'INSTRUCTIONS GÉNÉRALES

DE SÉCURITÉ qui vous sont fournis avec

cette machine. Assurez-vous de bien

avoir tout compris avant de commencer

à travailler avec la machine.

Gardez toujours ces deux manuels

d'instructions à portée de la main pour

pouvoir les consulter, en cas de besoin

1. INSTRUCTIONS DE SÉCURITÉ POUR LE MANIE-

MENT DE LA SCIE CIRCULAIRE PLONGEANTE

1.1 INSTRUCTIONS GÉNÉRALES

• Il est recommandé de toujours avoir sous la main tous

les documents relatifs à la machine lors de son utilisation,

pour pouvoir les consulter en cas de besoin quand on

travaille; de même, il est conseillé d’en conserver, si

possible, une copie dans un endroit sûr.

• À chaque nouvelle utilisation de la machine, il faut

contrôler l’état de la prise et du câble.

• Avant toute manipulation de la machine, débrancher

la prise de courant.

• Toujours maintenir le câble éloigné des parties mobiles

de la machine.

• Vérifier que l’interrupteur de la machine est sur arrêt

avant de brancher la prise sur le secteur.

• En cas d’utilisation d’une rallonge électrique, les fils

doivent avoir une section minimum de 1 mm

2

et le câble

doit être complètement déroulé.

• Prévoir aussi fréquemment que possible un dispositif

de blocage de la pièce à travailler, pour éviter que

celle-ci ne glisse.

• En cas de blocage, arrêter immédiatement la machine

et débrancher la prise de courant. Ne pas reprendre le

travail sans avoir éliminé la cause du blocage ; si celle-ci

provient de la machine, il faut la faire réparer par un

service technique agréé.

• Avant l’utilisation d’un accessoire, il faut vérifier si

sa vitesse de rotation maximale est compatible avec les

rendements de la machine.

• Dans la mesure du possible, toujours utiliser des

équipements de protection tels que gants, lunettes,

chaussures de sécurité, etc. Les déchets de coupe peuvent

causer des blessures.

• Avant de couper une cloison, un plafond ou un

plancher, il faut vérifier qu’il n’y a pas de canalisation

à l’intérieur.

• Les outils électriques ne doivent pas être utilisés par

des personnes de moins de 16 ans.

• Quand l’appareil est en marche, il ne faut le diriger

que vers la pièce à travailler.

• La trajectoire de coupe ne doit pas comporter

d’obstacles sur sa partie supérieure et inférieure.

• Ne pas mettre les doigts dans la buse d’expulsion

des copeaux.

• Toujours maintenir les mains à distance de la lame de

scie en mouvement. Éviter le contact avec la lame de scie

qui dépasse de la partie inférieure de la pièce.

• Ne pas guider l’appareil en le tenant au-dessus de

la tête.

• Il est interdit de travailler avec des matériaux conte-

nant de l’amiante.

• Ne pas employer de lames de scie ayant un disque base

plus épais ou un avoyage plus petit que l’épaisseur du

couteau diviseur.

• Le guide de coupe doit être de nouveau réglé quand

on remplace des lames de scies circulaires ayant des

diamètres différents.

• Au moment de l’arrêt de la machine, attendre que la

lame s’arrête de tourner toute seule. Ne jamais freiner

Page 9

Virutex, S.A.

Antoni Capmany, 1

08028 Barcelona (Spain)

www.virutex.es

7496587 122015

http://www.virutex.es/registre

Acceda a toda la información técnica.

Access to all technical information.

Accès à toute l’information technique.

Zugang zu allen technischen Daten.

Accedere a tutte le informazioni tecniche.

Aceso a todas as informações técnicas.

Dostęp do wszystkich informacji technicznych.

Доступ ко всей технической информации.

Loading...

Loading...