Virutex FR160P, FRE160P Operating Instructions Manual

FR160P / FRE160P

Fresadora tupí

Router

Défonceuse

Tischfräsmaschine

Fresatrice toupie

Fresadora tupia

Ручной фрезер

Frezarka górnowrzecionowa

MANUAL DE INSTRUCCIONES

OPERATING INSTRUCTIONS

MODE D’ EMPLOI

GEBRAUCHSANWEISUNG

MANUALE D’ISTRUZIONI

MANUAL DE INSTRUÇÕES

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

INSTRUKCJA OBSŁUGI

7

sorios y embalajes de forma respetuosa con el medio

ambiente. Respete la normativa vigente de su país.

Aplicable en la Unión Europea y en países europeos

con sistemas de recogida selectiva de residuos:

La presencia de esta marca en el producto o en el

material informativo que lo acompaña, indica que

al finalizar su vida útil no deberá eliminarse junto

con otros residuos domésticos.

Conforme a la Directiva Europea 2002/96/CE los

usuarios pueden contactar con el establecimiento

donde adquirieron el producto, o con las autoridades

locales pertinentes, para informarse sobre cómo y

dónde pueden llevarlo para que sea sometido a un

reciclaje ecológico y seguro.

VIRUTEX se reserva el derecho de modificar sus

productos sin previo aviso.

ENGLISH

FR160P-FRE160P ROUTER

(Ilustrations in page 43)

Important

Read these OPERATING INSTRUCTIONS

and the attached GENERAL SAFETY

INSTRUCTIONS LEAFLET carefully

before using the machine. Make sure

you have understood them before ope-

rating the machine for the first time.

Keep both sets of instructions for any

future queries.

1. TECHNICAL DATA

FR160P

Universal motor.........................................50/60 Hz

Input power................................................1,500 W

No-load speed.......................................25,000/min

Chuck collet Ø.............................................12 mm

Routing depth............................................0-60 mm

Revolving depth

gauge.......................6-position depth adjustment

Weight...........................................................5.4 Kg

Weighted equivalent continuous

acoustic pressure level A............................................92 dBA

Acoustic power level A.............................................103 dBA

Uncertainty...........................................................K = 3 dbA

Wear ear protection!

Vibration total values.................................a

h

: <2.5 m/s

2

Uncertainty..........................................................K: 1.5 m/s

2

FRE160P

Universal motor..........................................50 Hz

Input power................................................1,800 W

No-load speed............................11,500-23,000/min

Chuck collet Ø.............................................12 mm

Routing depth............................................0-60 mm

Revolving depth

gauge.......................6-position depth adjustment

Weight...........................................................5.4 Kg

Weighted equivalent continuous

acoustic pressure level A............................................92 dBA

Acoustic power level A............................................103 dBA

Uncertainty.............................................................K = 3 dbA

Wear ear protection!

Vibration total values........................................a

h

: <2.5 m/s

2

Uncertainty............................................................K: 1.5 m/s

2

2. OPERATION RANGE

The router is an electric appliance used for routing

wood and plastics. It is also very convenient for

trimming edges, cutting out of knots, copy cutting,

rebate cutting, making of frames and engraving.

Together with parallel guide, template followers,

compasses and profile cutters, it is an exceedingly

useful appliance.

3. SAFETY INSTRUCTIONS FOR

MACHINE OPERATION

Before using the router, carefully read

the GENERAL SAFETY INSTRUCTIONS

LEAFLET included with the machine

documentation.

- When changing tools or carrying out any other

operation near the cutting head, take your hand

from the on/off lever and unplug the machine from

8

the mains.

- Use safety goggles when working with the router.

- Always guide the router with both hands, using

the machine's two handles.

- When you have finished working, disconnect the

motor and release the base before leaving the router.

- Always place the router on its base on a flat, clean

surface.

- Always start the router by using the main on/

off lever.

- Make sure that the router cannot be accidentally

knocked over.

- Always use cutter bits with the appropriate shaft

diameter for the chuck collet and the router speed

to be used.

- The specifications of the cutter bits in the VIRUTEX

range are especially suitable for use with this router;

we recommend using cutter bits from the wide

VIRUTEX range or bits with the same specifications.

4. STANDARD EQUIPMENT

The box contains the following items:

- FR160P - FRE160P router

- A/f service key: 24

- Ø 19 mm template guide for 26-mm pitch loops.

- Lateral fence assembly

- Dust collector connection

- Operating instructions and miscellaneous docu-

mentation.

- 6022387 Cutter bit 12 to 8 adaptor

- 6022388 Cutter bit 12 to 6 adaptor

5. STARTING UP THE MACHINE

This tool has an operating switch A (Fig. 1) in the

handle, enabling the machine to be turned on and

off without releasing it.

To prevent the machine from starting up accidentally,

the switch can only be operated when the lateral

safety catch B (Fig. 3) has been released. Once the

switch is in the on position, pressure need no longer

be applied to the safety catch.

Always make sure that the router is

not in contact with the part being

worked before operating the switch.

Once the machine has reached its

maximum speed, bring the machine

into contact with the material, and

stop the machine once it is completely

clear of the part. This will improve the

quality of the work.

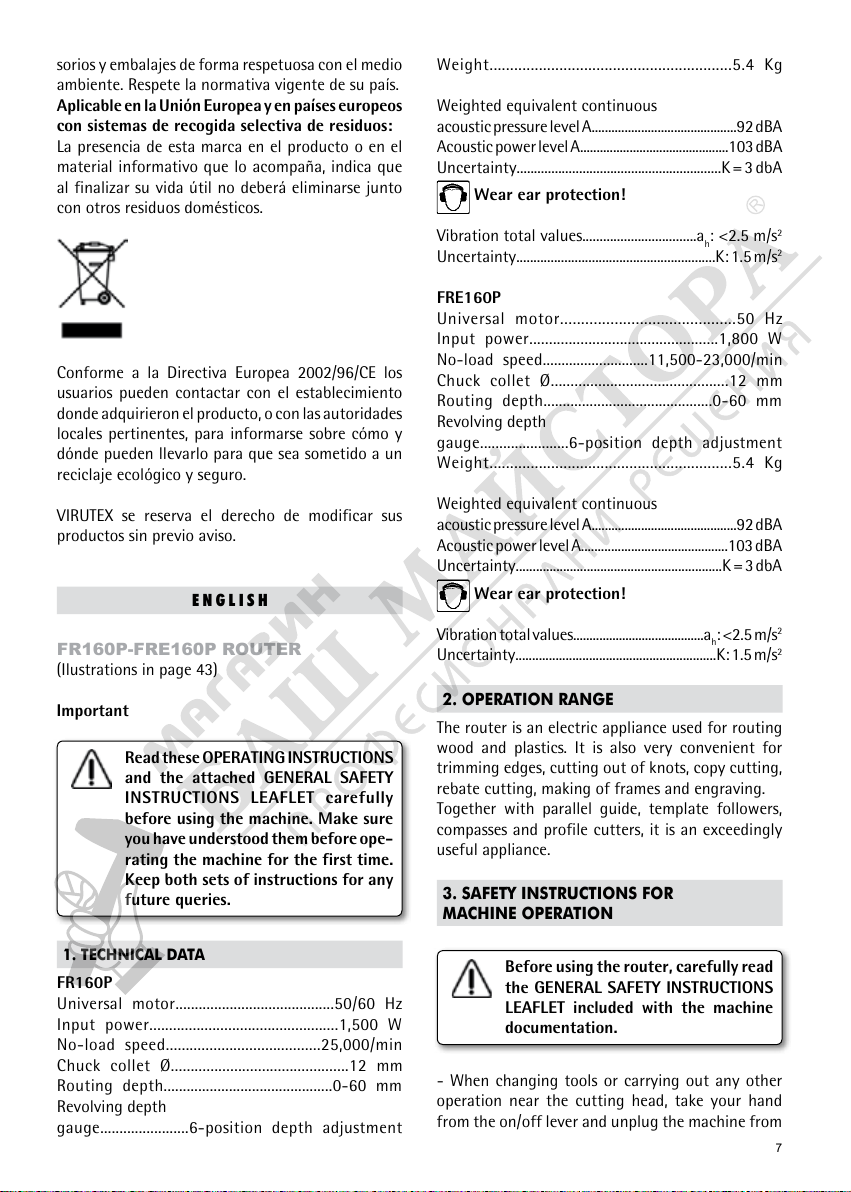

6. ADJUSTING THE SPEED 11,500 - 23,000

The surface router model FRE160P has an electronic

speed regulator C (Fig. 1) for adjusting the motor

speed, according to the size of cut and the hardness

of the material used. This ensures a better finish and

enhances the machine performance. To increase or

reduce the machine speed, turn the adjustment knob

to the right or left, depending on the task being

carried out. There are six reference numbers to assist

in setting the required speed.

The following table shows the position of the elec-

tronic speed regulator according to the diameter of

the bit and the material being worked with.

7. FITTING THE CUTTING TOOLS

Make sure that the router is disconnected

from the mains before attaching the

cutting tool.

To attach or remove the cutting tool, press the

router lock button E (Fig. 2) to prevent the shaft

from turning and loosen the chuck-holder nut F (Fig.

2) with service key G (Fig. 2) The chuck collet and

chuck-holder are attached together by pressure; you

should therefore make sure that the chuck collet is

properly positioned in the nut.

Insert the cutting tool H (Fig. 2) and, if necessary,

the corresponding bit adaptor I (Fig. 2) inside the

chuck-holder collet F (Fig. 2). Tighten the chuck

holder F (Fig. 2) tightly using the service key, while

keeping the lock button E (Fig. 2) pressed.

If you are using the 12 mm or 1/2" shaft bit, the

adaptor is not required. Always use bits with the

Loading...

Loading...